Assembled wedge forming mold for acute-angle U-shaped stamping part

A technology for forming molds and stamping parts, which is applied in the field of wedge forming molds that can be assembled and assembled, can solve the problems of increasing the number of molds, rising manufacturing costs, and increasing difficulties in mold management and maintenance, and achieves the effects of reducing manufacturing costs and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

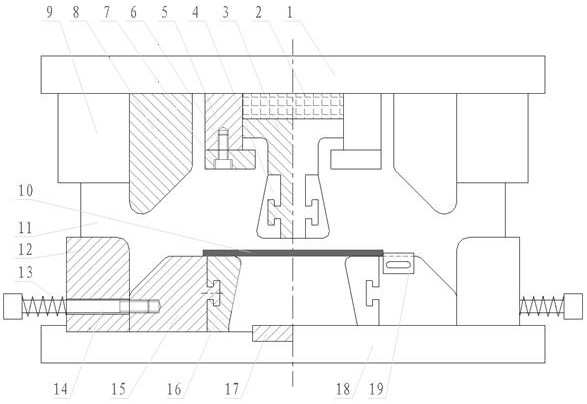

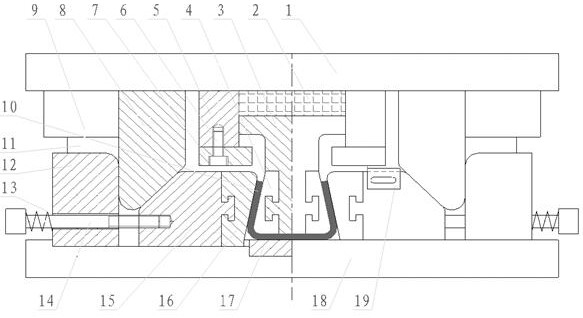

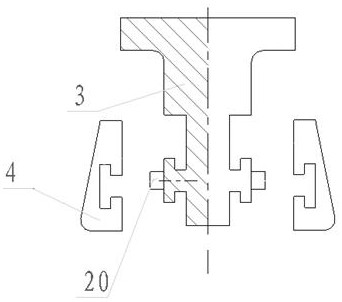

[0019] Such as Figure 1-7 As shown in the figure, a wedge-forming mold that can be assembled for acute-angle U-shaped stamping parts, the upper and lower templates are arranged in parallel up and down, and a pair of cylindrical countersunk holes are provided on the left and right sides behind the upper template 1, and guide sleeves 9 are installed in the holes. A pair of cylindrical countersunk holes are provided on the left and right sides of the rear of the lower formwork 18, and guide posts 11 are installed in the holes. The punch guide seat 5 is provided with a module punch between the punch guide seats 5, and a pair of symmetrical fixed bodies 12 are arranged on the left and right sides of the lower template 18, and the inner side of the fixed body 12 is provided with a module die, and the two module dies The part 10 located directly below the module punch is placed on the top, the press lifts the upper template 1 to a specified height, and the part 10 is placed on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com