Magnetic pulse bending device for controlling U-shaped piece springback and forming method

A bending device and bending forming technology, applied in the field of sheet metal forming, can solve the problems of high production cost, complex structure, and long production cycle, and achieve the effects of improving quality, improving process applicability, and increasing forming limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

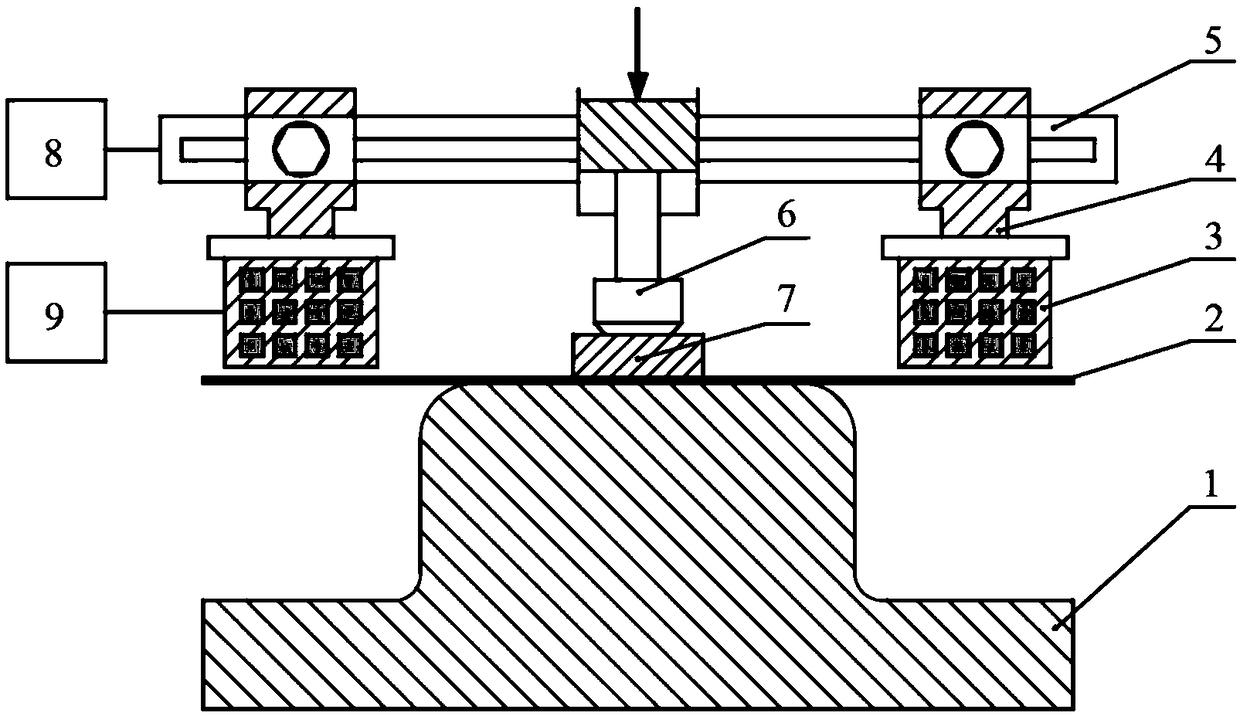

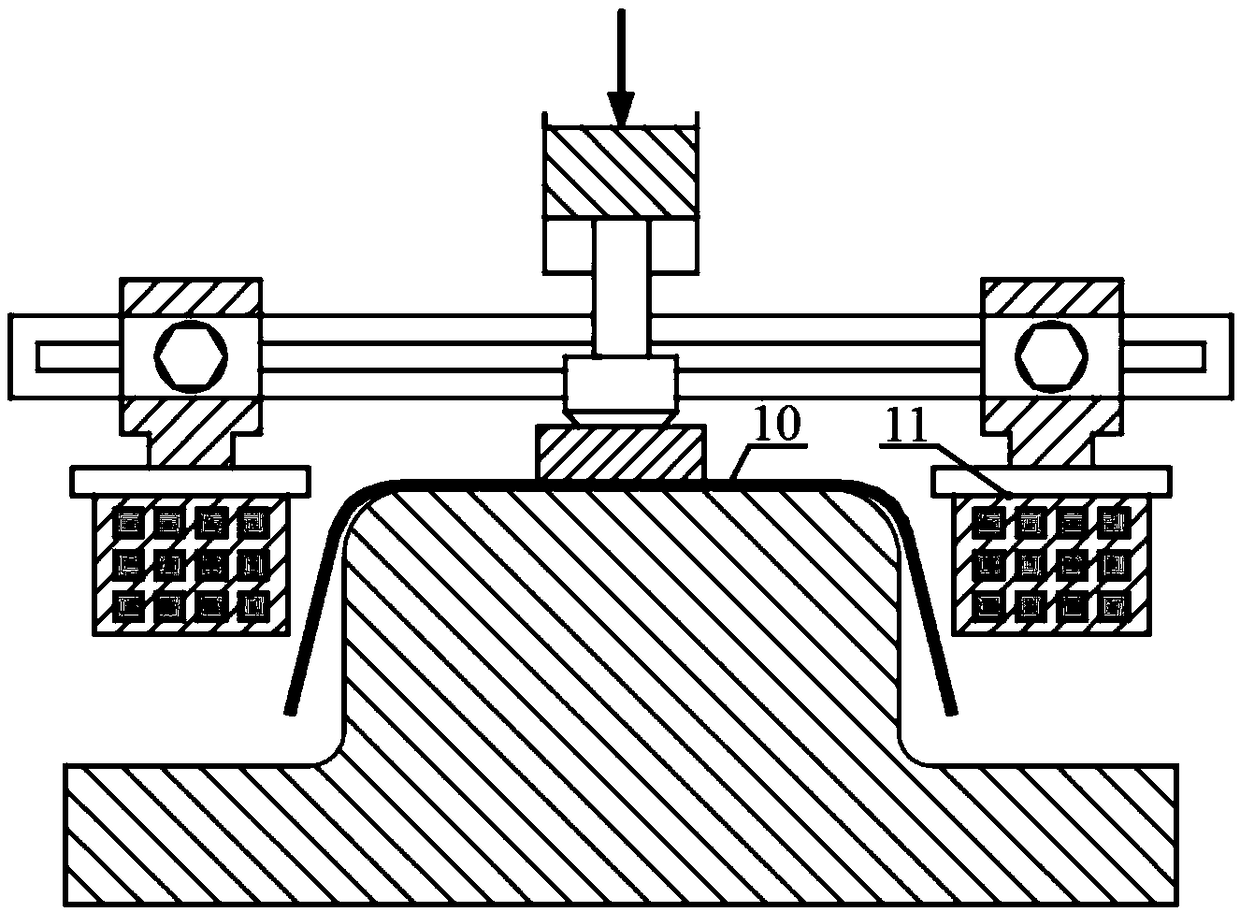

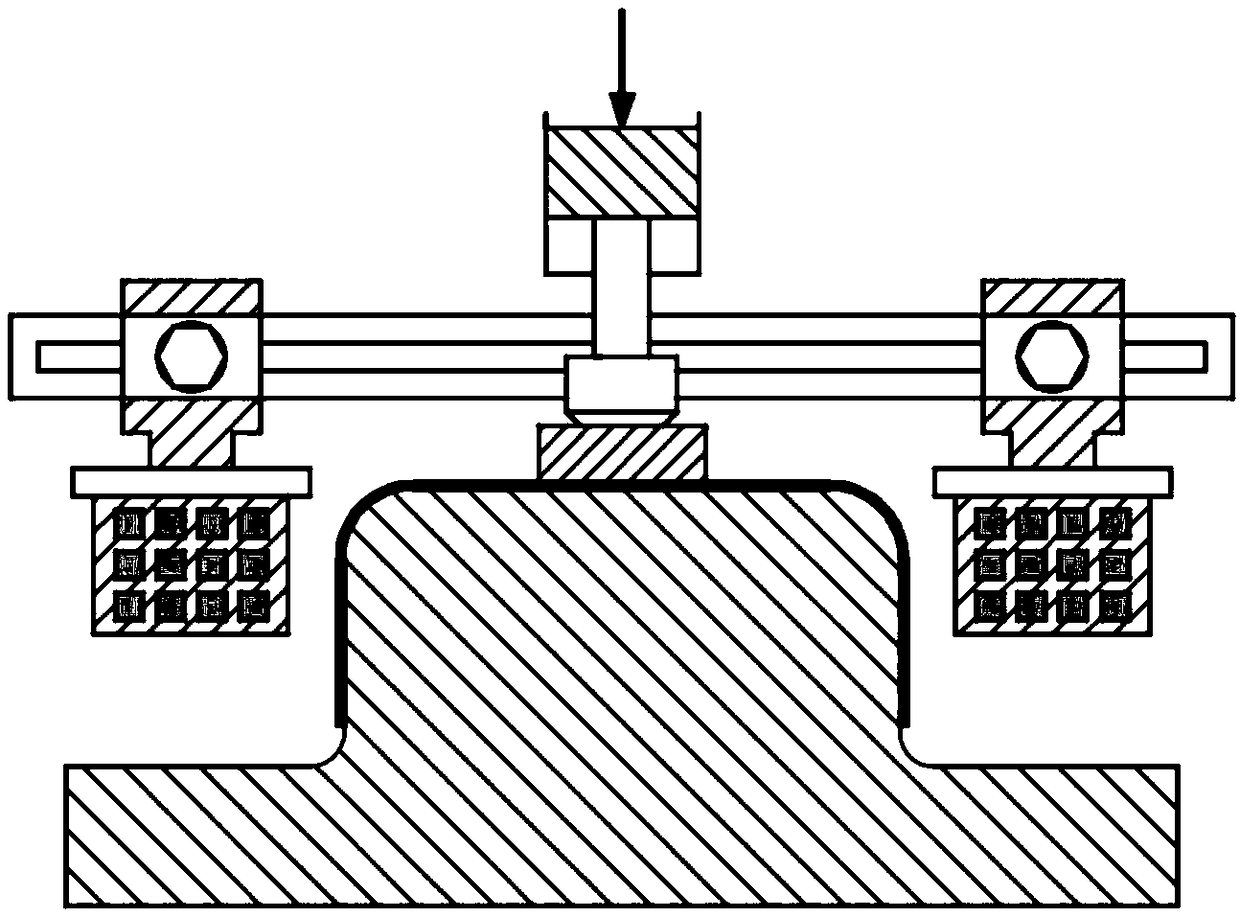

[0054] In this embodiment, the length of the sheet to be bent is 400 mm, the width is 150 mm, and the thickness is 1.5 mm. The punch radius is 10 mm. The bottom side of the target U-shaped piece is 190 mm long and the straight side is 90 mm long. In this embodiment, the process method of controlling the springback of the U-shaped part based on the magnetic pulse bending of the punch forming mainly includes the following steps:

[0055] 1) Place the sheet material 2 on the punch 1, place the compression block 7 on the sheet material, ensure that the centers of the punch, sheet material, and compression block coincide, and control the hydraulic device 6 to provide the compression block 20KN pressing force to fix the sheet;

[0056] 2) Adjust the three-dimensional mobile platform so that the forming coil moves vertically to a distance of 3 mm from the upper surface of the sheet to ensure that the forming coil is in a better discharge position. Adjust the left and right sliders so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com