Patents

Literature

44results about How to "Improve processing suitability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

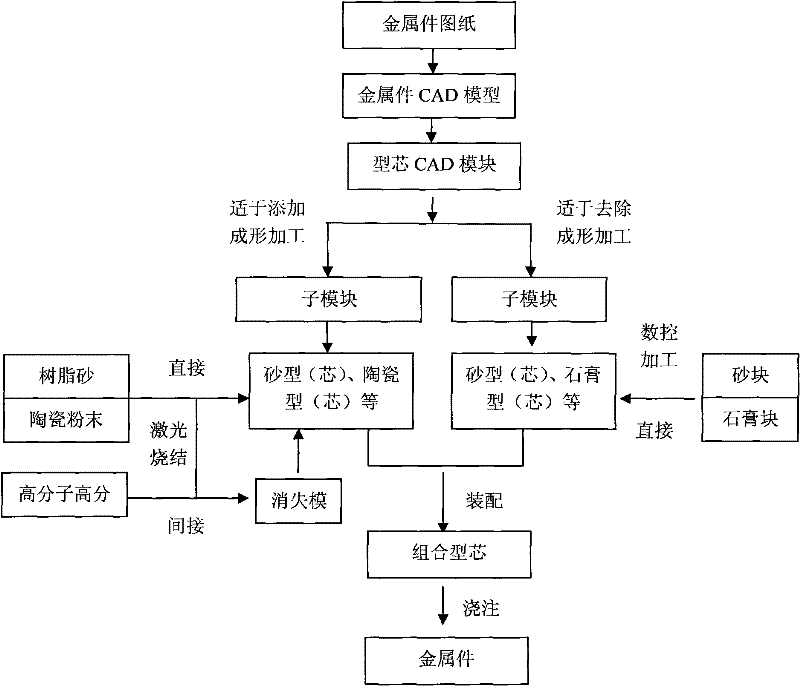

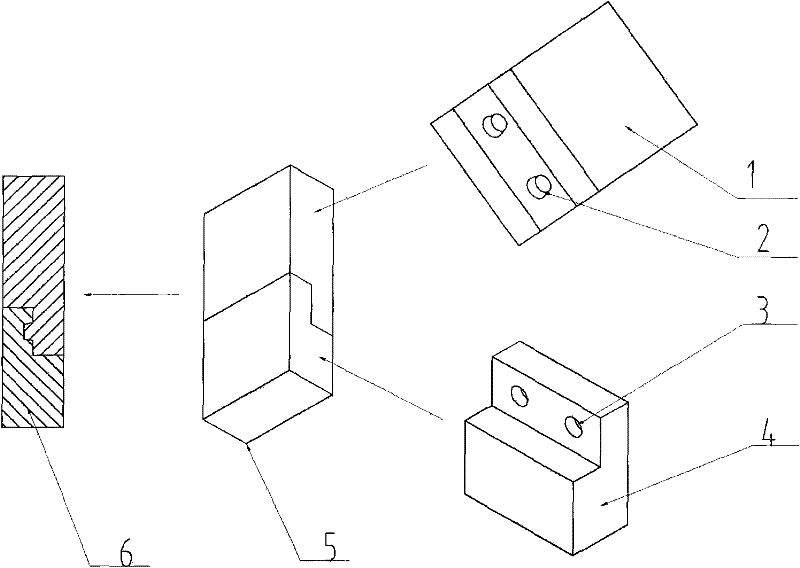

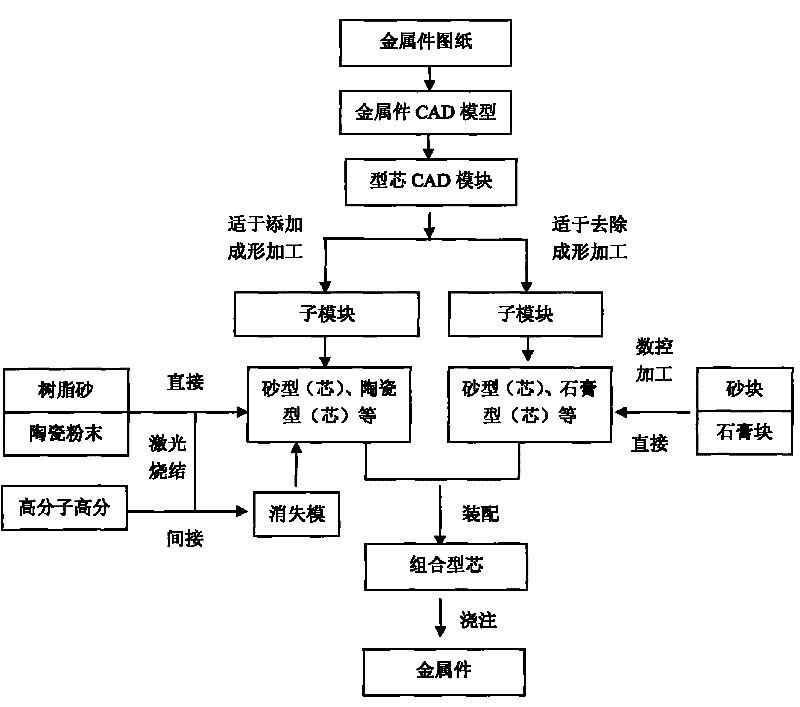

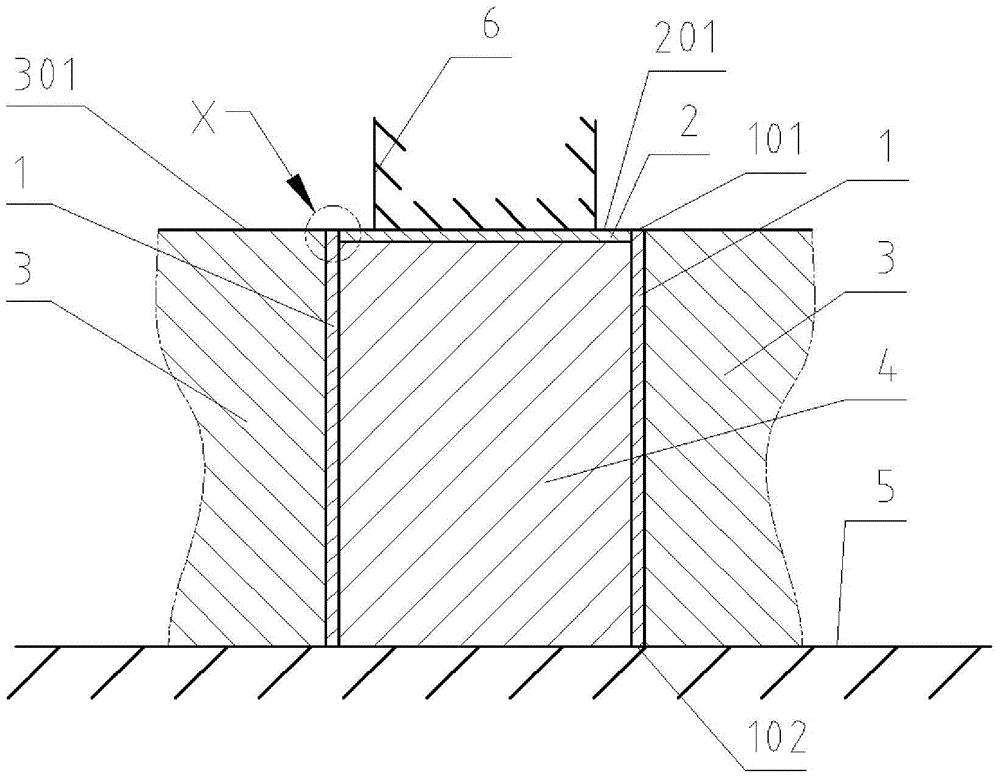

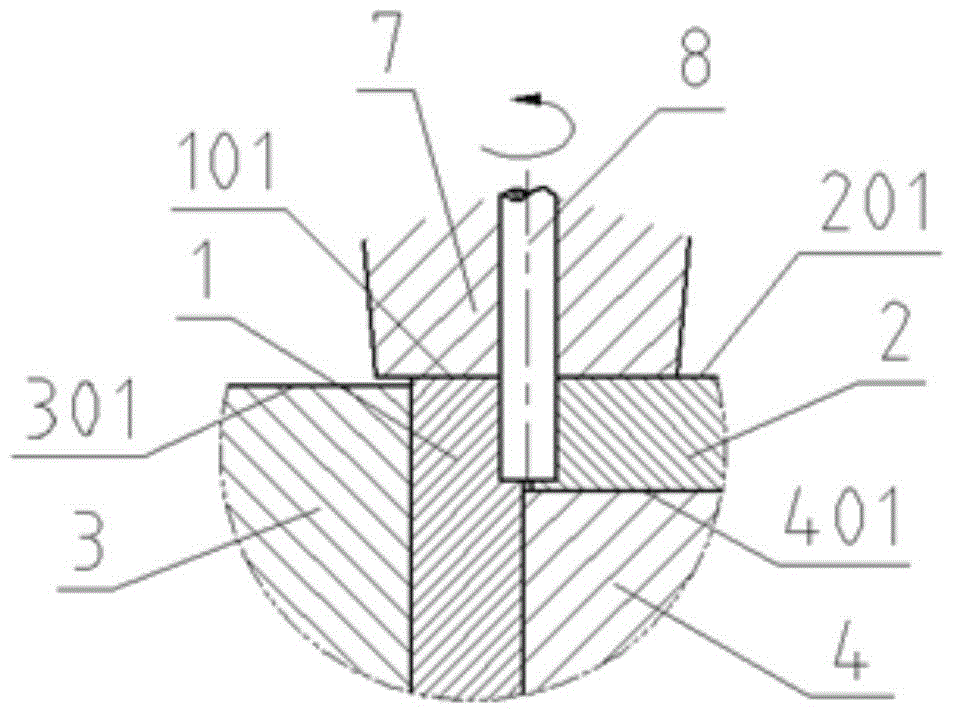

Rapid composite precision manufacturing method for a metal part

ActiveCN102451882AFast preparationManufacturing process flexibilityFoundry mouldsFoundry coresNumerical controlComputer Aided Design

The invention relates to a rapid composite precision manufacturing method for a metal part. The method comprises the following steps: 1, segmenting a three-dimensional CAD (computer aided design) model according to the structure, the dimension and performances of a part on the basis of characteristics of the structure of the part, and applying a laser sintering technology to a complex structure submodule to obtain a (core) shell; 2, obtaining a large dimension and simple structure submodule through a modeling-free numerical control machine tool processing technology; and 3, combining the submodules obtained through the two technologies, and casting them to form an entity. The method which combines the high precision of the laser sintering and the rapidness of the modeling-free numerical control processing allows high precision products according with requirements to be rapidly processed, and the method is especially suitable for the individual small batch manufacturing

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

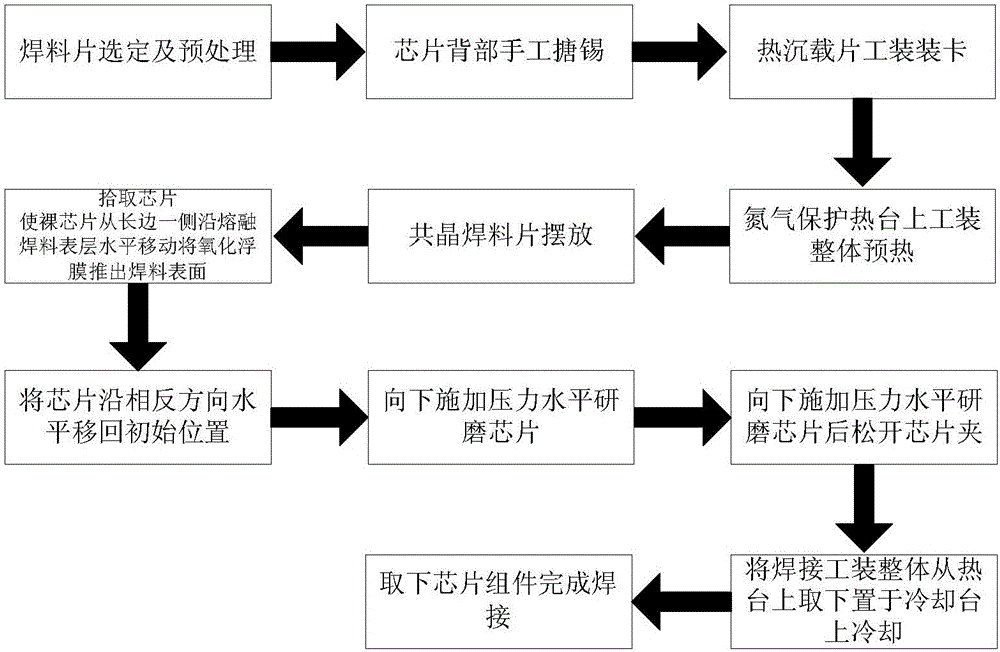

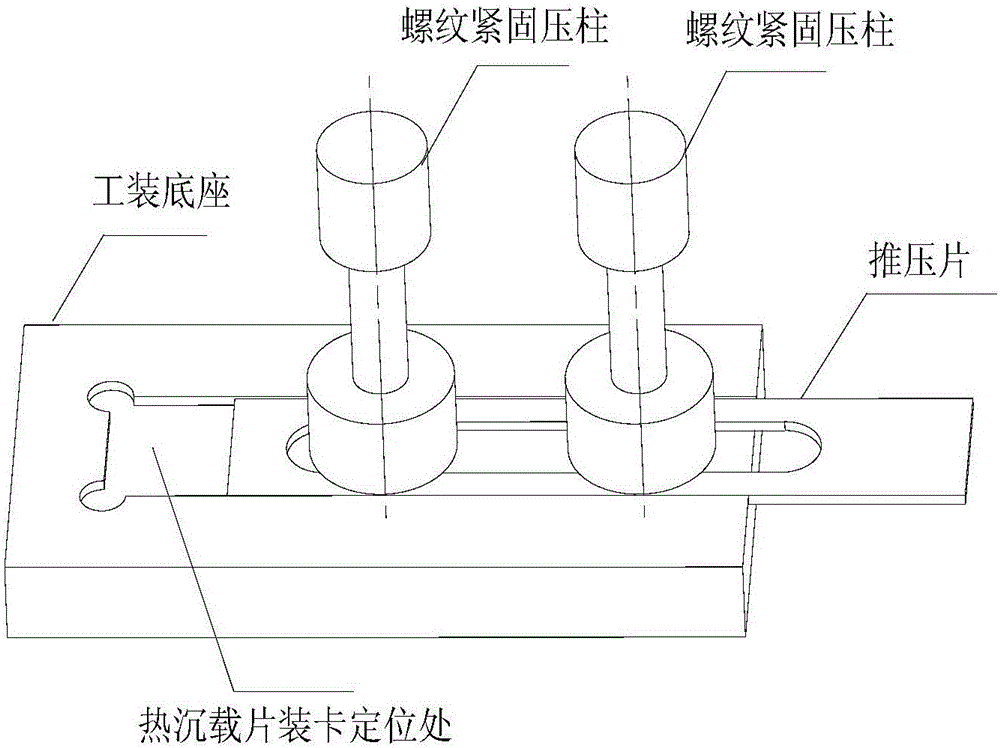

High-penetration-rate semiconductor bare chip manual eutectic welding method

ActiveCN105977173AStrong penetrating powerIncrease productivitySolid-state devicesSoldering apparatusEngineeringSemiconductor

The invention relates to a high-penetration-rate semiconductor bare chip eutectic welding method based on manual operation. According to the method, the penetration rate of semiconductor bare chip manual eutectic welding is greatly improved and the production efficiency and technology applicability can be effectively improved by arranging a reasonable and effective manual eutectic welding processes, and designing and using a general positioning clamping tool. The method is applicable to smalllot and diversified development-type products, and can effectively reduce the production cost and improve the production efficiency while ensuring the high welding quality.

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

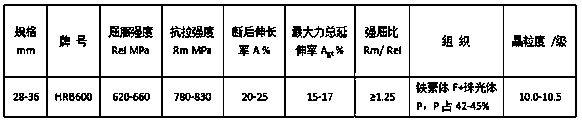

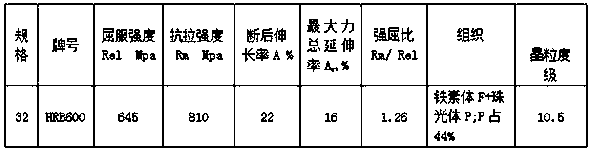

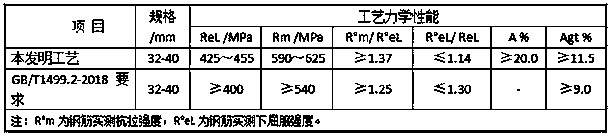

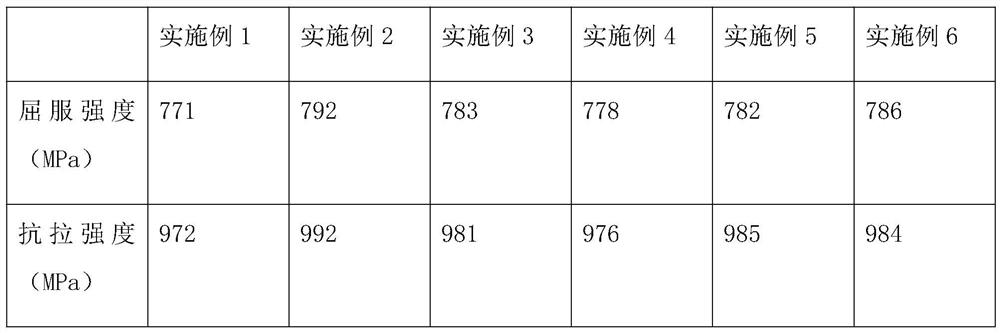

Large-specification fine-grain high-strength anti-seismic reinforcement steel bars and preparation method thereof

ActiveCN111101079AImprove plastic toughnessHigh strengthProcess efficiency improvementBridge engineeringRebar

The invention discloses theta 28-36mm HRB600 high-strength anti-seismic reinforcement steel bars for a hydropower project. The reinforcement steel bars are characterized in that steel comprises the following chemical components by weight: C 0.23-0.26wt%, Si 0.50-0.65wt%, Mn 1.45-1.55wt%, S 0.025-0.035wt%, P 0.030-0.040wt%, Cr 0.12-0.18wt%, Mo 0.020-0.035wt%, V 0.125-0.140wt%, and the balance beingFe and inevitable impurities. The invention also discloses a preparation method of the large-specification HRB600 high-strength anti-seismic reinforcement steel bars. A vanadium, chromium and molybdenum composite microalloying process is adopted, microalloying strengthening elements such as vanadium-nitrogen alloy, ferrochromium and ferromolybdenum are added into the steel, and the low final rolling temperature is controlled by a pre-penetrating water-controlled cooling device (4.9m in length) in the steel rolling process, the formation and precipitation of fine and dispersed microalloy carbon (nitrogen) secondary phase are promoted, and the toughness is obviously improved during improvement of steel strength. The reinforcement steel bars can be used for sdam and flood control tunnel construction engineering and road and bridge engineering of the Jinshajiang hydropower station, and has the advantages of low production cost, strong process applicability, reliable operation, stable product and the like.

Owner:WUKUN STEEL

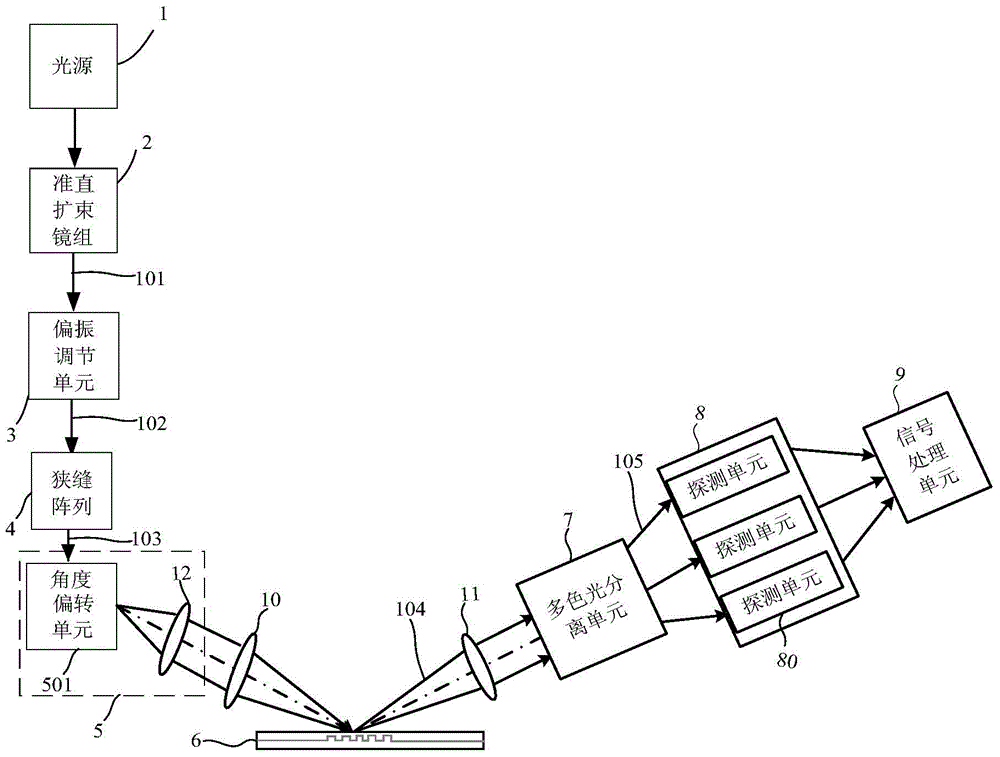

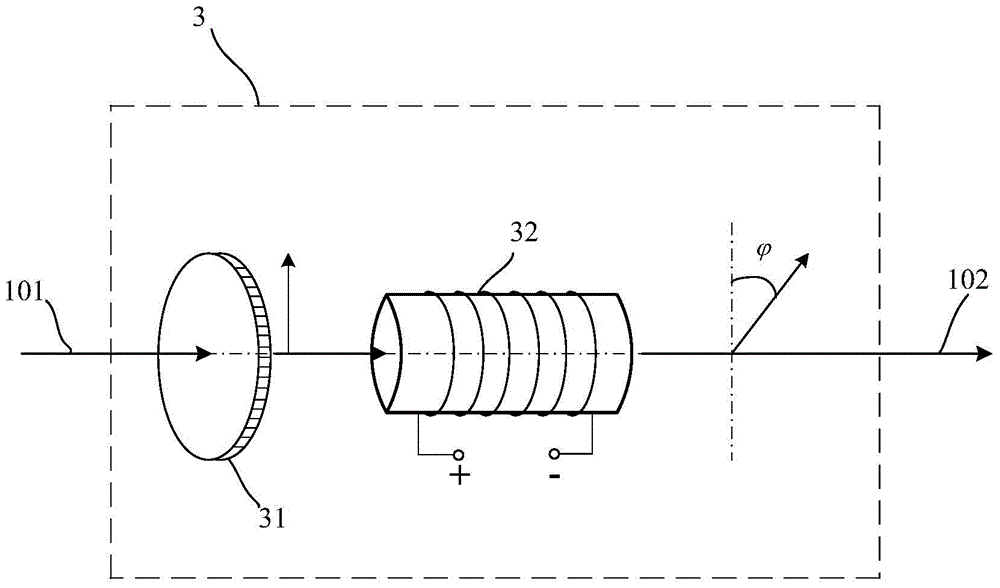

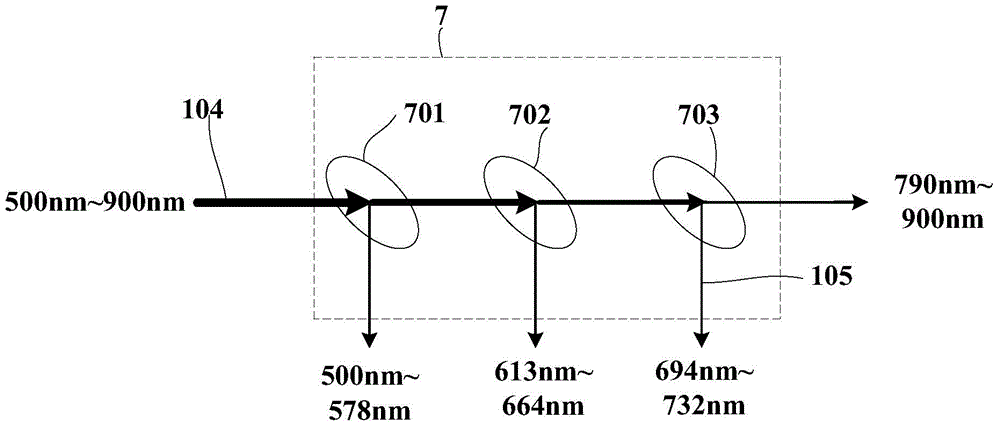

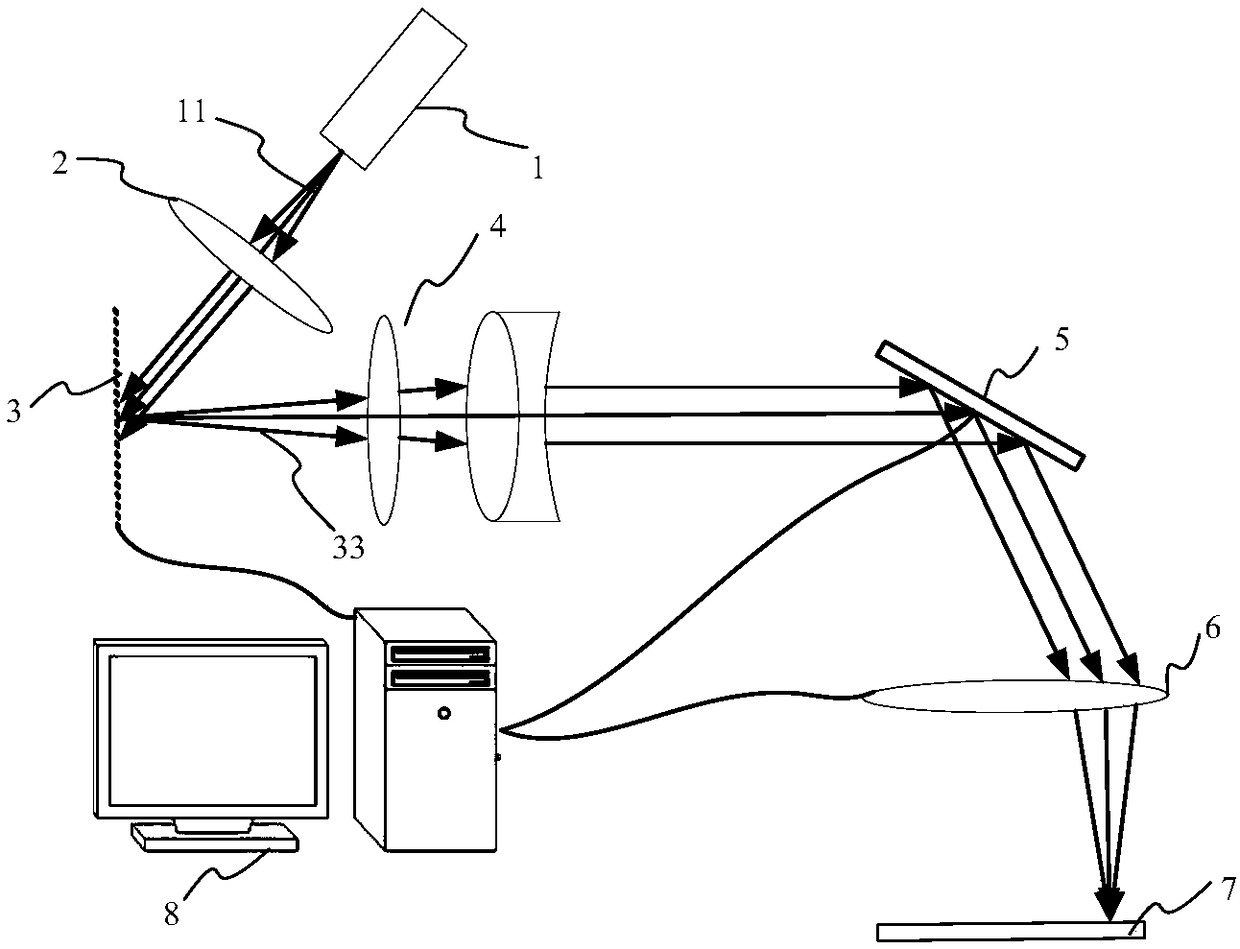

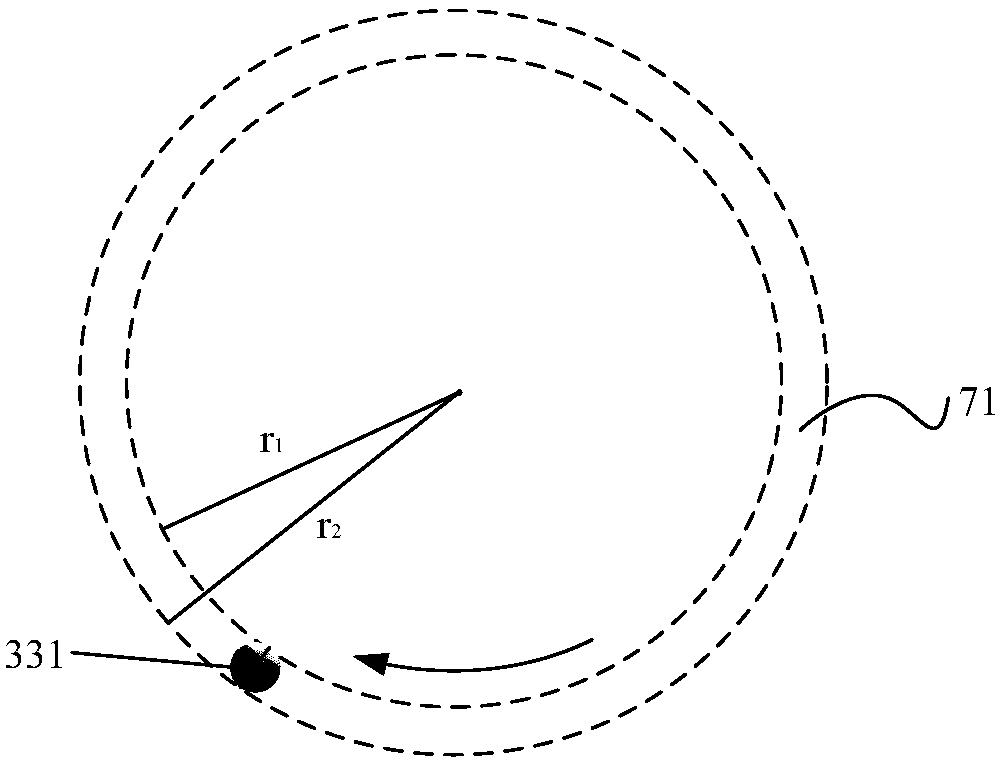

Silicon chip surface height and gradient detection apparatus and method thereof

ActiveCN105700296AAccurate Surface Position InformationImprove processing suitabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusBeam expanderBroadband light source

The invention discloses a silicon chip surface height and gradient detection apparatus and a method thereof. The detection apparatus comprises a light source, a collimating beam expander, a slit array, an angle adjusting unit, a first lens, a silicon chip to be detected, a second lens, a detector and a signal processing unit which are sequentially arranged from a detection light path, and also comprises a polarization modulation unit positioned between the collimating beam expander and the slit array, and a polychromatic light separating unit positioned between the second lens and the detector, and the detector is composed of a plurality of detection units. The polychromatic light separating unit arranged in the invention separates broadband reflected lights into independent wavebands, all the wavebands are individually detected through the corresponding detection units, and detection information of all the wavebands is comprehensively processed to well eliminate the influences of the bottom layer pattern of the silicon chip in order to obtain accurate silicon chip surface position information; and the broadband light source is used, so the light source energy utilization rate is improved, and the processing suitability of the detection apparatus to different silicon chips is improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

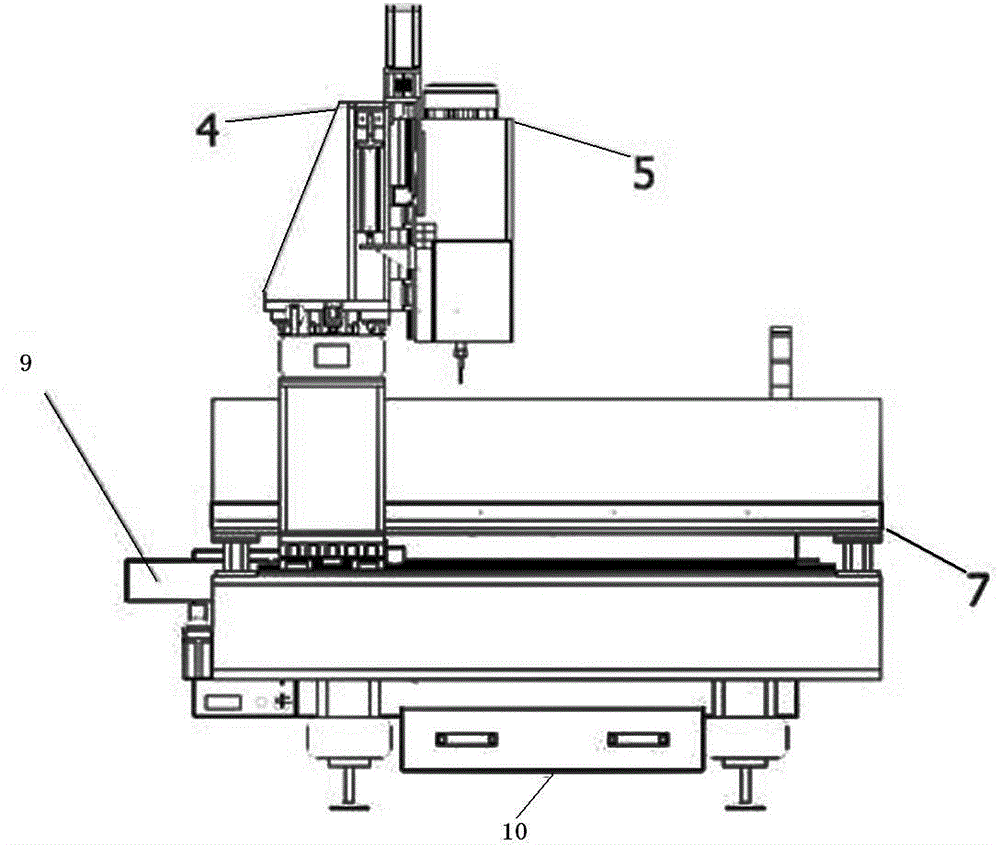

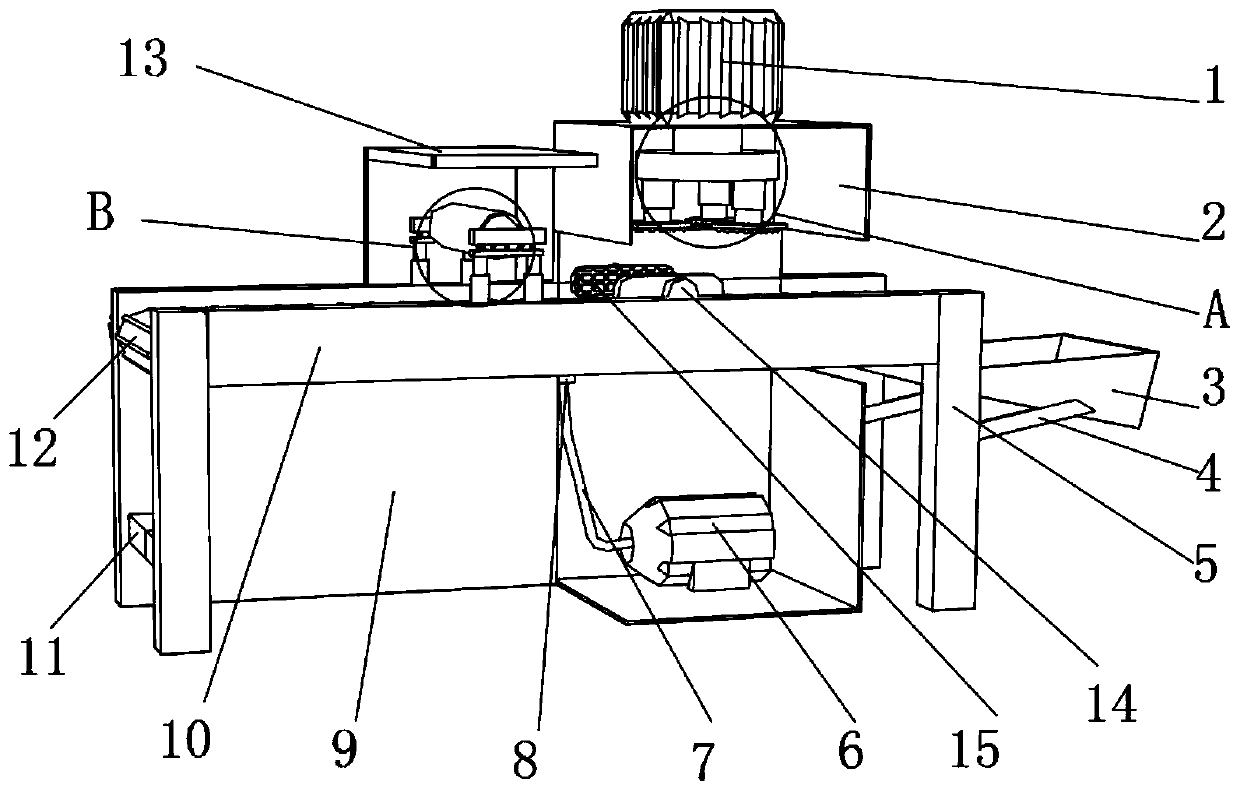

Three-axis multi-head gantry machining equipment

ActiveCN103817370AImprove machining accuracyHigh speedLarge fixed membersMilling equipment detailsEngineeringOmni directional

Owner:TAICANG WEGOMA MACHINERY

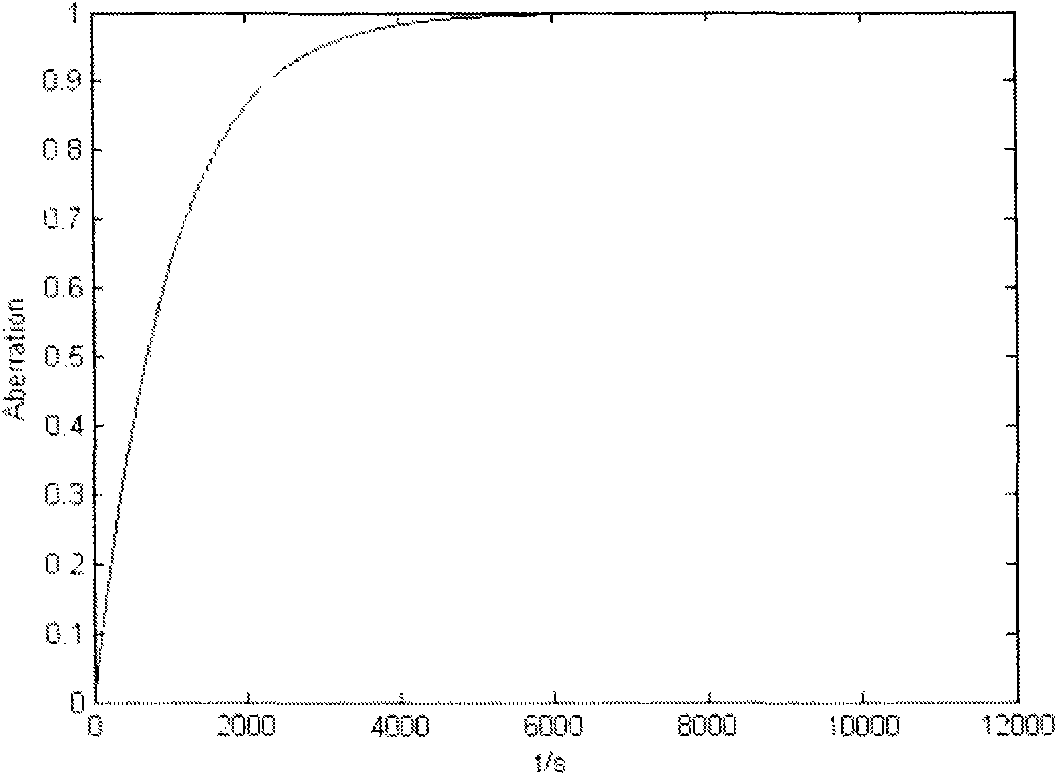

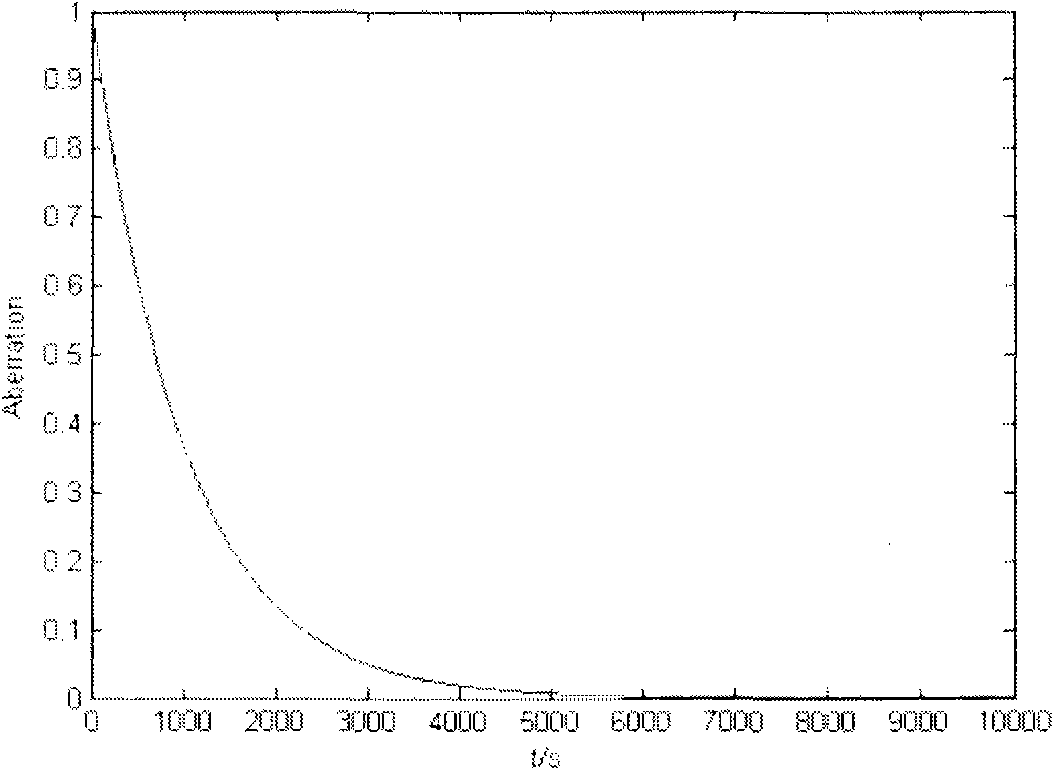

Latent epoxy resin system for wind-driven generator blades and preparation method for latent epoxy resin system

The invention discloses a latent epoxy resin system for wind-driven generator blades. The latent epoxy resin system is formed by combining a resin part and a curing agent part, wherein the resin part comprises bisphenol A epoxy resin and a diluent; and the curing agent part comprises a polyether amine compound, an alicyclic amine compound and an organic guanidine compound. The preparation method comprises the following steps of: (1) preparing materials in a ratio of the resin part to the curing agent part respectively and preparing mixing equipment; (2) preparing the resin part and the curing agent part respectively; and (3) preparing the latent epoxy resin system and mixing the prepared resin part and the prepared curing agent part in the ratio uniformly. The latent epoxy resin system has the characteristics of flexible gelation time, low requirement of the operating environment on the temperature, high operability and the like, the operability of the epoxy resin system is greatly improved when the epoxy resin system is applied to a blade vacuum perfusion process, the production efficiency and qualification rate of the blades are improved, and the production cost of enterprises is reduced.

Owner:DONGFANG TURBINE CO LTD

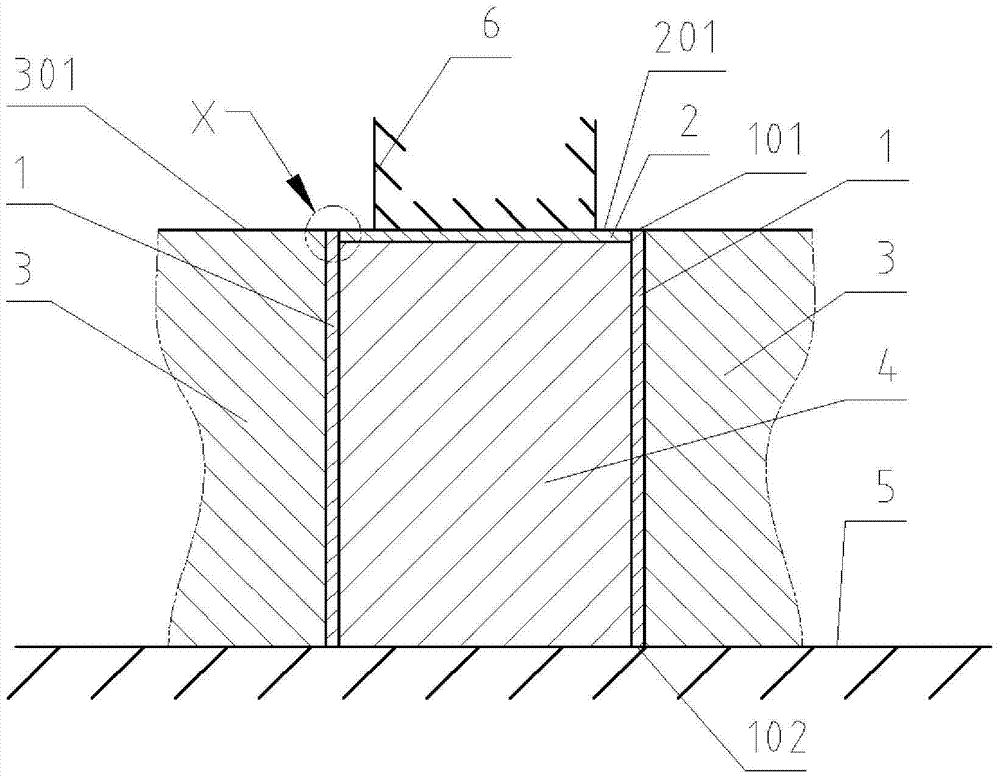

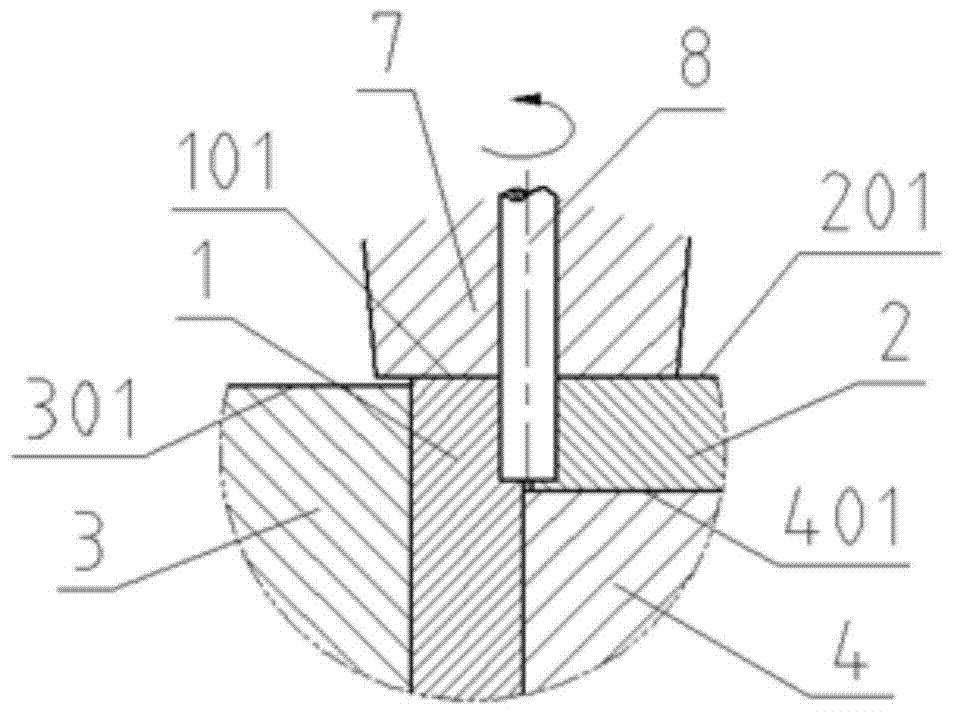

Laminated lithium battery aluminum shell structure and manufacturing method thereof

ActiveCN105140429AImprove sealingImprove connection reliabilitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringSpot welding

The invention discloses a laminated lithium battery aluminum shell structure and a manufacturing method thereof. The structure comprises a shell bottom and a shell wall, wherein the shell bottom is completely located in the shell wall, the peripheral outline of the shell bottom is attached to the shell wall with a 0-0.2 mm gap reserved on each side, and the shell bottom and the shell wall are connected through friction stir spot welding. The laminated lithium battery aluminum shell structure manufactured with the method is high in strength reliability and sealing performance, neat and attractive in appearance, and capable of improving the shape consistency of batteries.

Owner:昆山斯格威电子科技有限公司

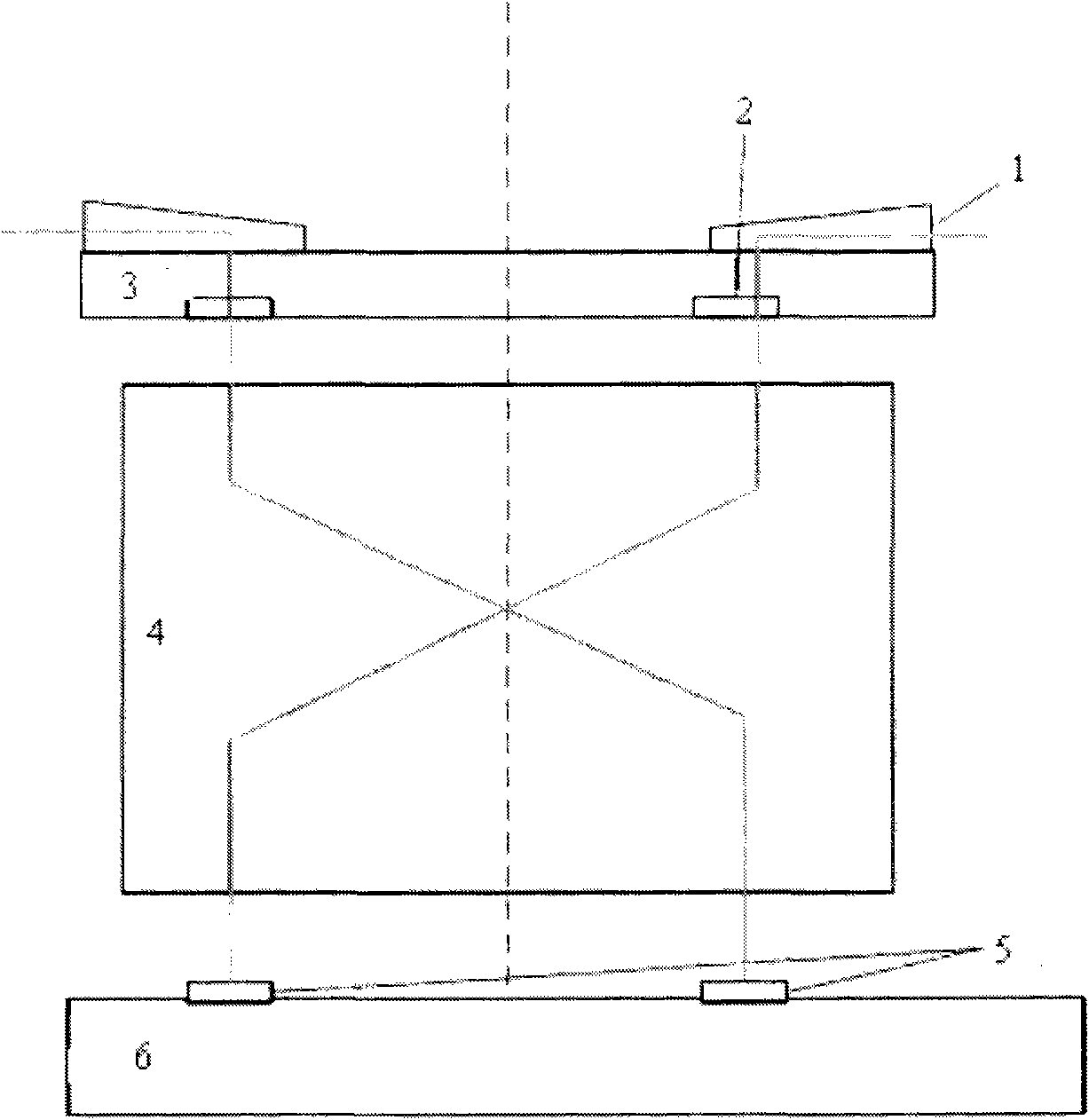

Lens heat effect measuring system and measuring method

InactiveCN102735425ALow costImprove processing suitabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusHeat effectLight transmission

The invention discloses a lens heat effect measuring system which comprises a mask, an object marker, a lens to be measured, and a workpiece table sequentially along the direction of light transmission, and further comprises at least one machine vision system. The at least one machine vision system is located on the workpiece table. Light emitted from the object marker is imaged on the at least one machine vision system through the lens to be measured. The invention further discloses a lens heat effect measuring method.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

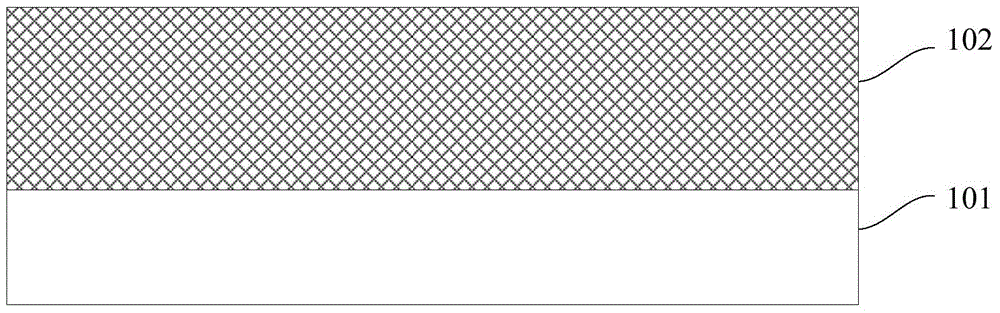

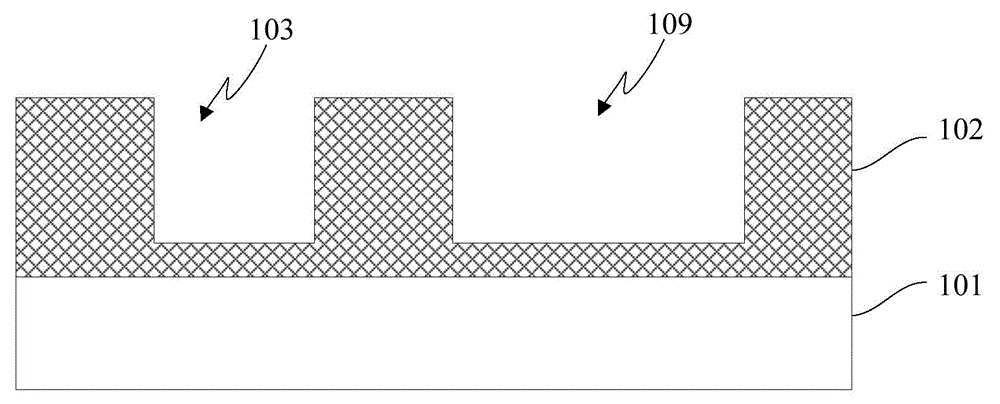

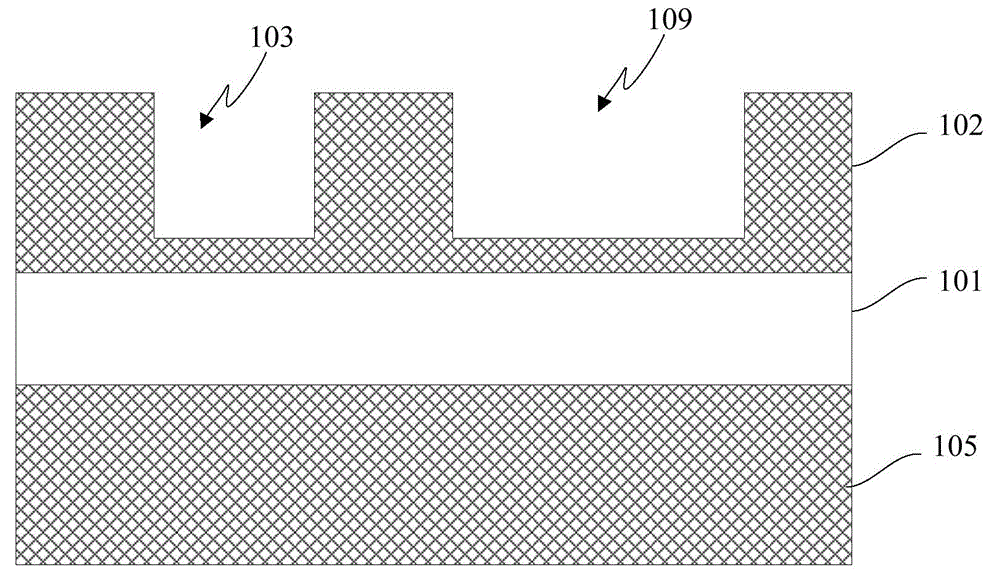

Preparation method for micro circuit flexible circuit board based on micro-nano imprinting technology

ActiveCN105338742AReduce areaReduce line widthPrinted element electric connection formationMicro nanoFlexible circuits

The invention provides a preparation method for a micro circuit flexible circuit board based on a micro-nano imprinting technology. The preparation method comprises the steps of forming a first flexible material layer and a second flexible material layer on the two surfaces of a substrate separately, forming a first groove structure and a first hole site structure, and forming a second groove structure and a second hole site structure separately; forming first conductive structures in each first groove structure and the first hole site structure; forming through holes in the substrate; and forming second conductive circuits in each second groove structure, the second hole site structure and the through holes to form a two-side interconnecting circuit. According to the preparation method for the micro circuit flexible circuit board based on the micro-nano imprinting technology, the combination between the conventional circuit board and the IC technology is realized, so that the application of micro electronic products on the flexible circuit boards is possible; the conductive circuits are embedded, so that the reliability of the circuits is greatly improved; the circuits prepared by a printing process or an electroplating process can form metal layers of different thicknesses in the internal and on the surface of the grooves; and in addition, a roll-to-roll technology is adopted, and pore formation is realized in the metal layer depositing process, so that the technology can be simplified and the cost can be reduced.

Owner:SHANGHAI LIANGZI HUIJING ELECTRONICS CO LTD

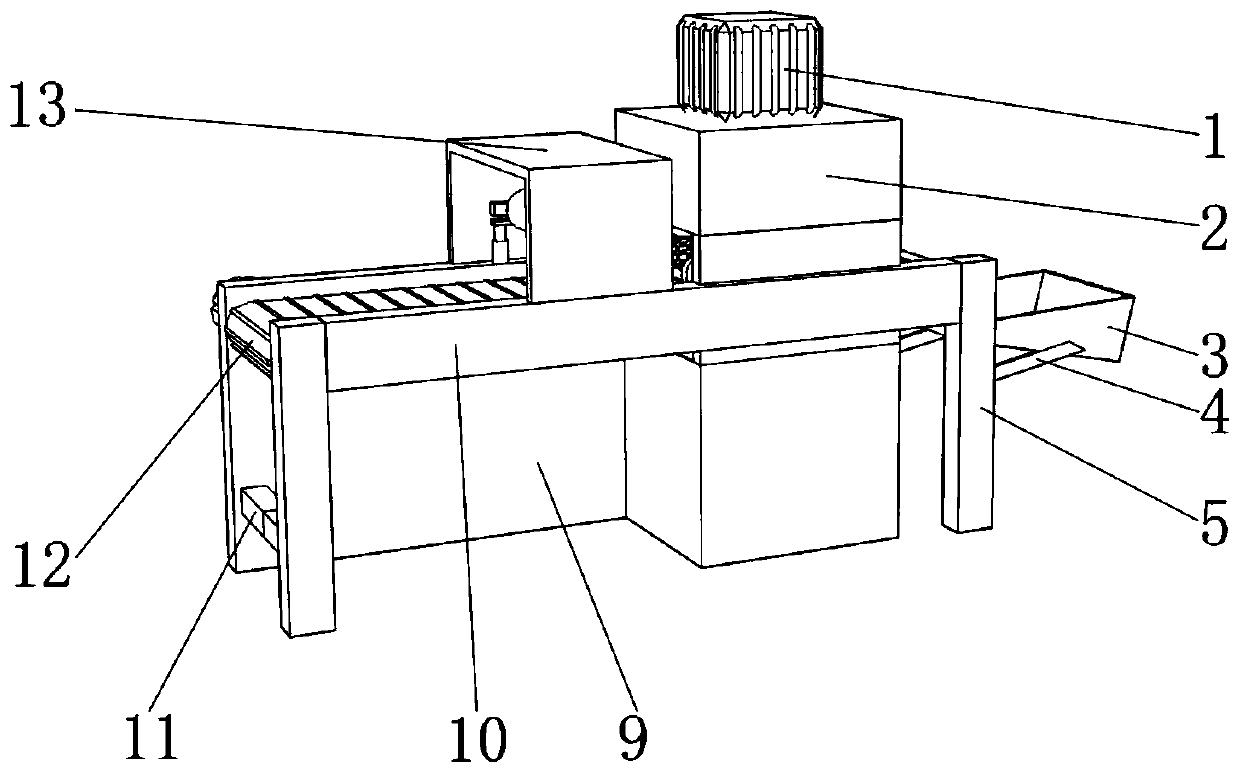

Shell embossing device for electronic product production

InactiveCN110813825AImprove cleaning effectImprove processing suitabilityCleaning using toolsEmbossing decorationsElectric machineryProduct processing

The invention relates to the technical field of electronic product processing, and discloses a shell embossing device for electronic product production. The shell embossing device comprises a bearingplate, supporting legs, a baffle, a first box body and a second box body, wherein the bearing plate, the supporting legs and the baffle are fixedly mounted each another to form a mounting frame, the first box body and the second box body are fixedly mounted on the mounting frame, the top end of the outer wall of the first box body is fixedly connected with a stepping motor, the output end of the stepping motor is fixedly connected with a printing assembly, the printing assembly comprises a rotating shaft, and the top end of the rotating shaft is connected with the bottom end of the output shaft of the stepping motor through a coupler. According to the shell embossing device, a product shell is cleaned by a dust removing rubber roller before embossing, and springs enable the dust removing rubber roller to automatically and finely adjust the position, so that the dust removing rubber roller makes contact with the upper surface of raw materials more closely, and the cleaning effect of thedevice is improved; and multiple embossing heads are arranged, and the multiple embossing heads can work at the same time, so that produced shell flower types are increased, and the machining applicability is improved.

Owner:南京市旗心电子科技有限公司

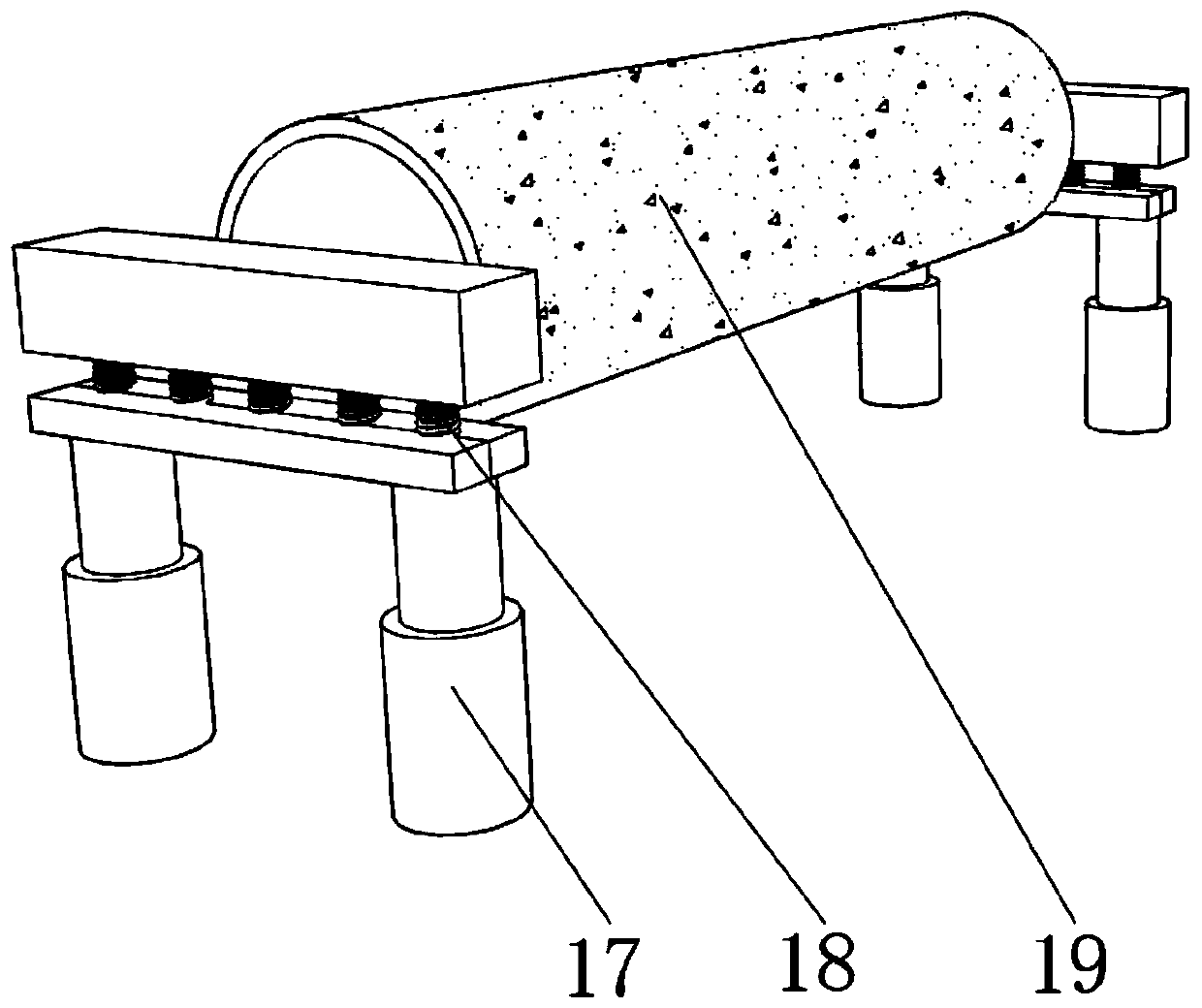

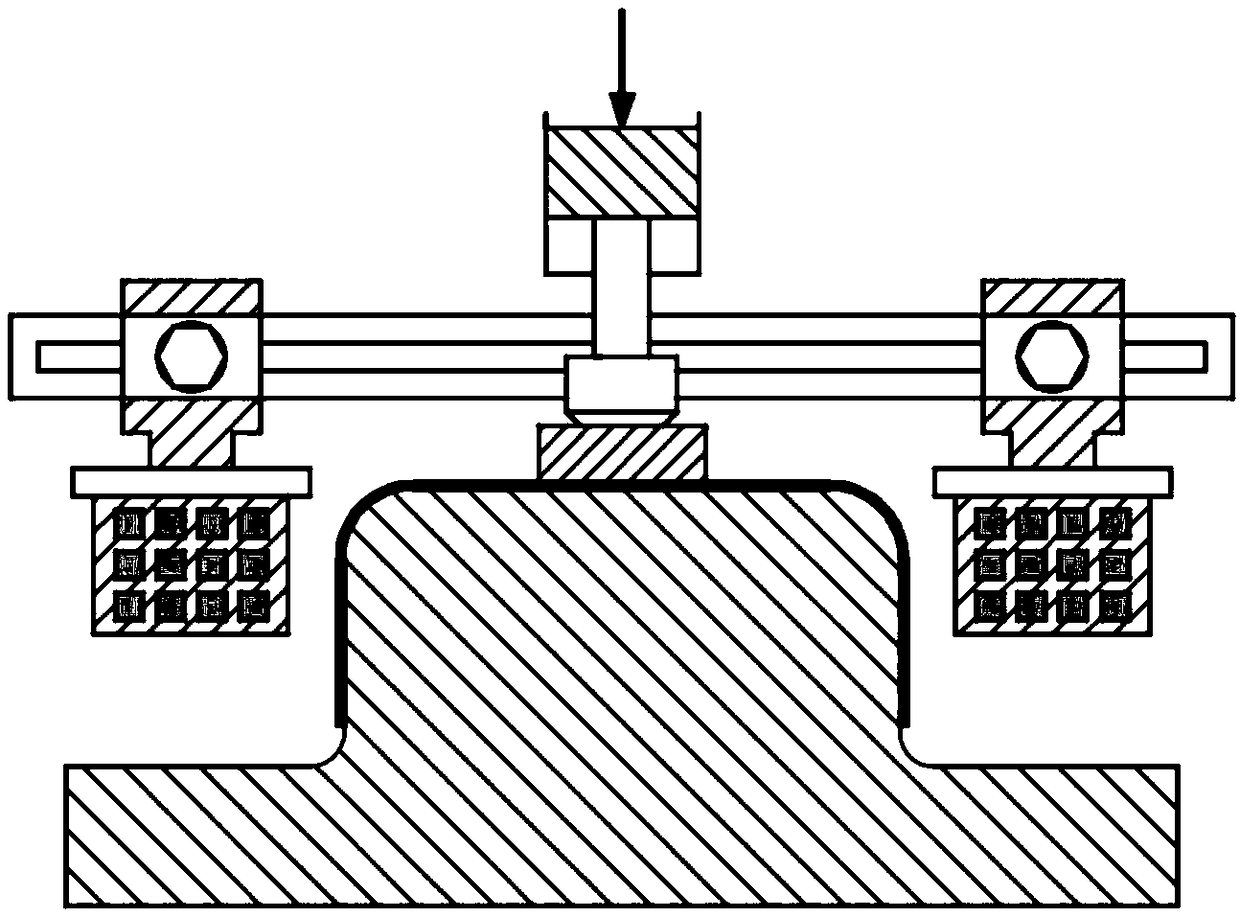

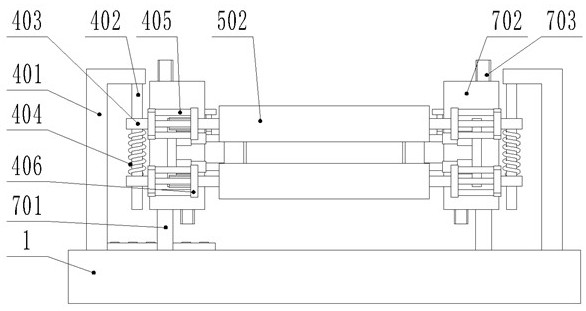

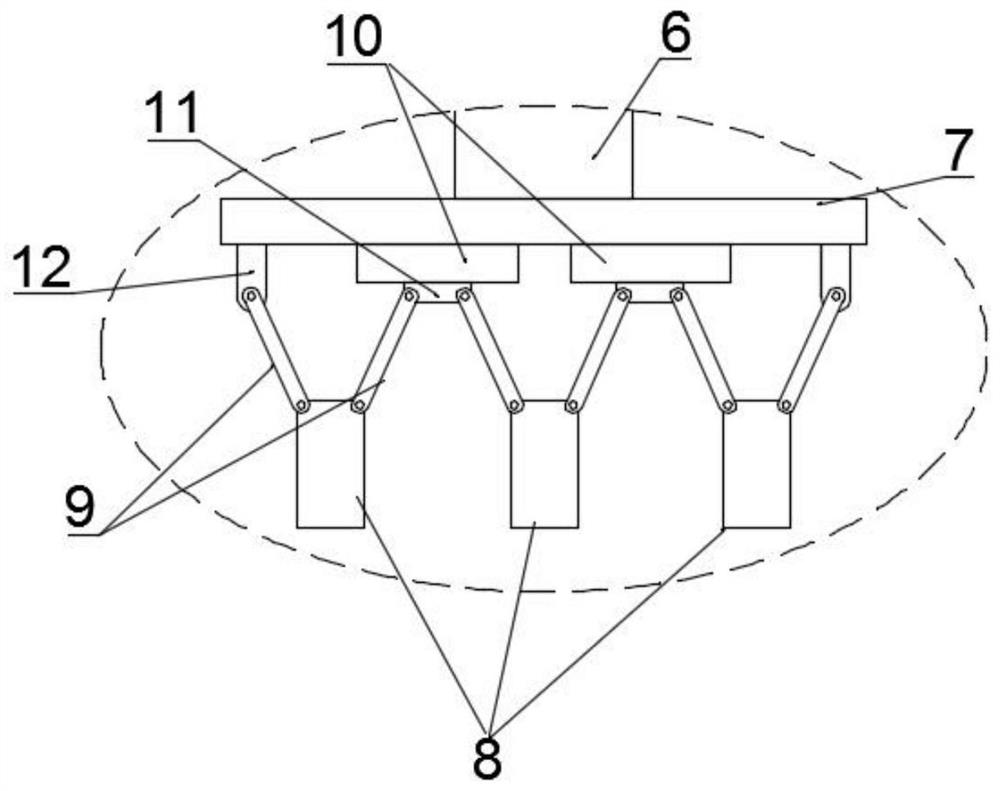

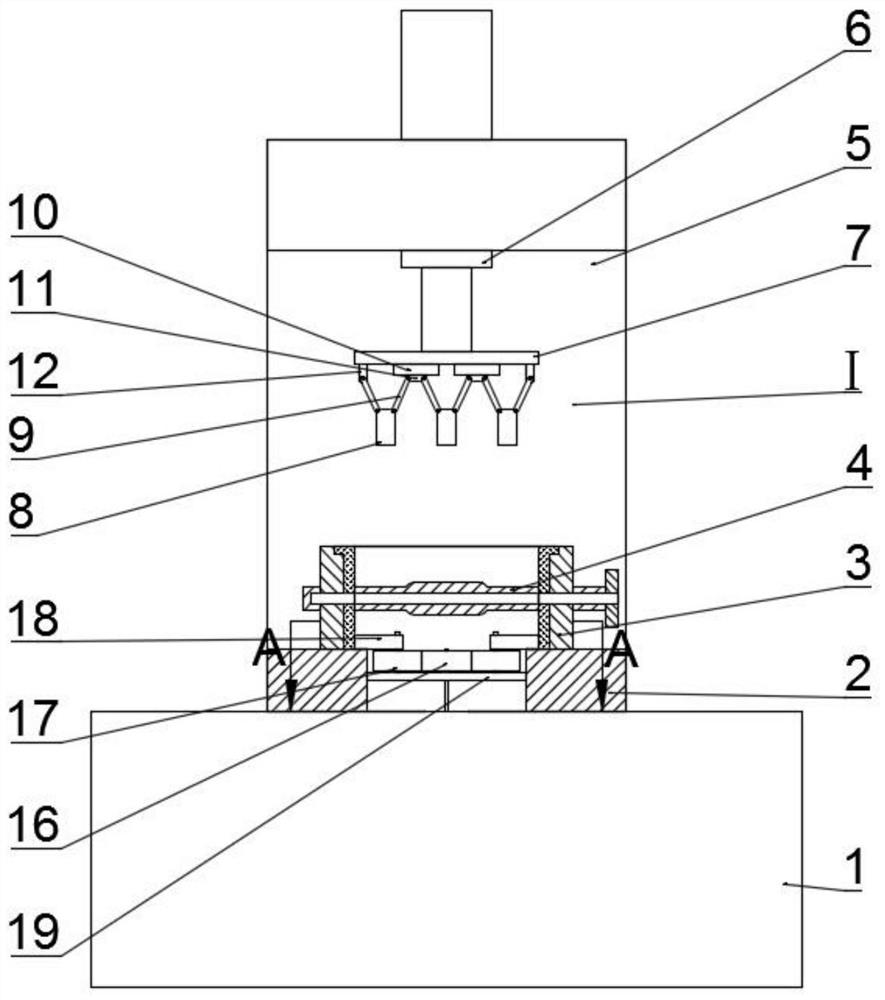

Magnetic pulse bending device for controlling U-shaped piece springback and forming method

The invention belongs to the field of metal plate forming, and particularly discloses a magnetic pulse bending device for controlling U-shaped piece springback and a forming method. The bending devicecomprises a forming unit, a compression unit and an adjusting unit, the forming unit comprises a male die and an electromagnetic forming assembly, the male die is used for controlling the bending shape of a to-be-formed plate material, and the electromagnetic forming assembly is used for conducting magnetic pulse bending forming on the plate material; the compression unit is used for applying compression force to a center zone of the bottom of a U-shaped piece; and the adjusting unit is used for adjusting the position of the electromagnetic forming assembly relative to the to-be-formed platematerial. According to the forming method, the magnetic pulse bending device is used for conducting two-step magnetic pulse bending forming, and bending forming of the U-shaped piece is completed. Bymeans of the device and method, the springback phenomenon generated after bending forming of the U-shaped piece can be effectively controlled, and the die structure and the technological flow are greatly simplified.

Owner:HUAZHONG UNIV OF SCI & TECH

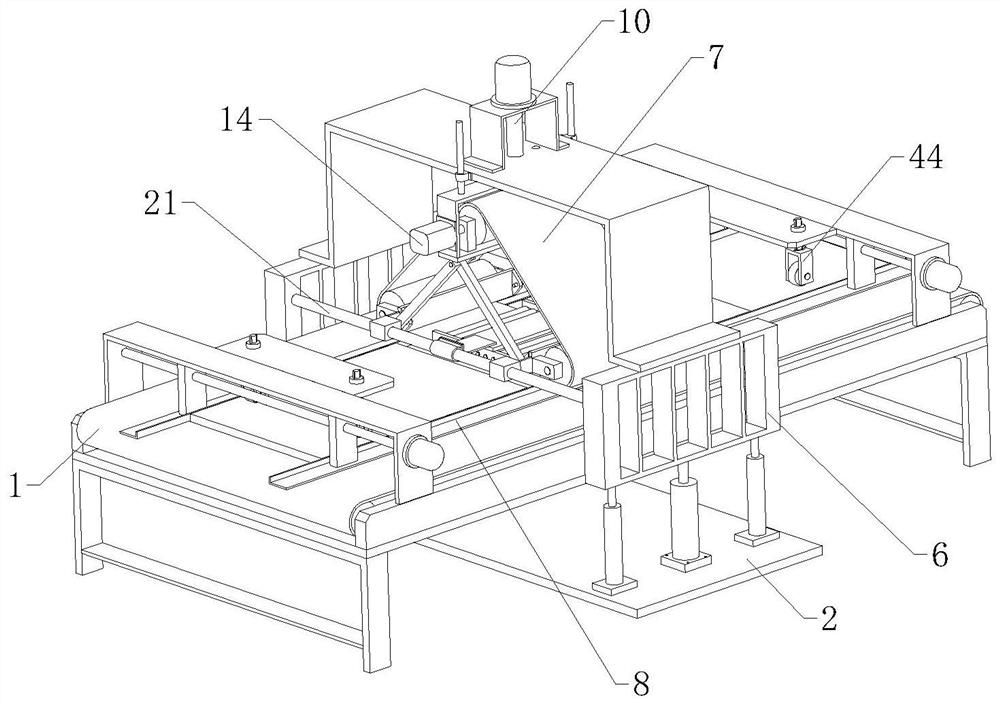

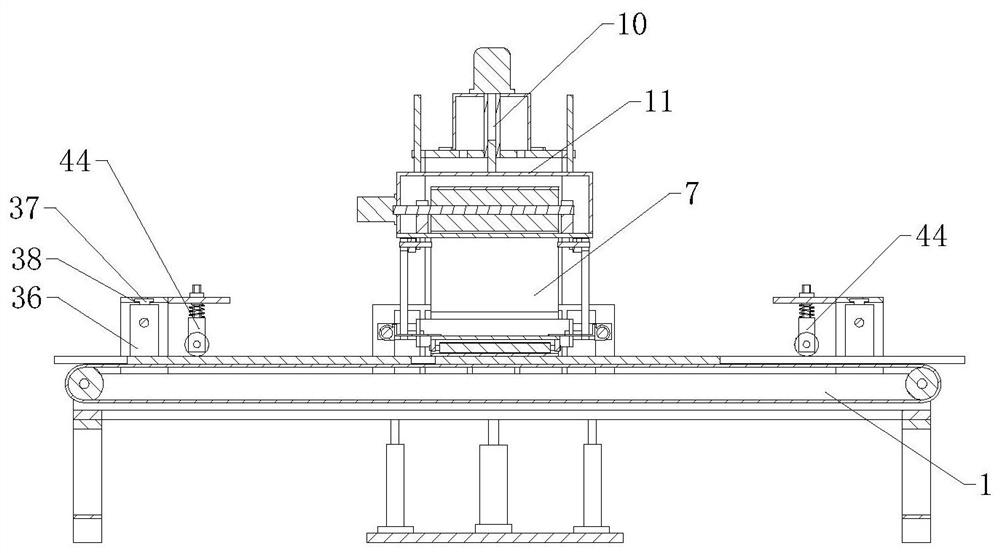

Width-adjustable belt sander

InactiveCN112388465APrevent rotationPlay a buffer roleBelt grinding machinesGrinding feedersStructural engineeringSander

The invention relates to the technical field of sanders, in particular to a width-adjustable belt sander. The width-adjustable belt sander comprises a feeding conveyor, a bottom plate erected below the feeding conveyor, a width adjusting sanding assembly, two positioning driving assemblies and two lifting assemblies, wherein the two lifting assemblies are symmetrically located on the two sides ofthe feeding conveyor, the two lifting assemblies are installed at the two ends of the bottom plate, each lifting assembly comprises a lifting vertical support, the width adjusting sanding assembly isarranged between the two lifting vertical supports, the width adjusting sanding assembly comprises a polishing abrasive belt distributed in the width direction of the feeding conveyor, positioning guide plates are arranged on the two sides of the upper portion of the feeding conveyor, the two positioning driving assemblies are symmetrically arranged at the two ends of the feeding conveyor, and theworking ends of the two positioning driving assemblies are connected with the two ends of each positioning guide plate. The equipment is provided with two plate positioning structures used for positioning and guiding plates, the length of the polishing abrasive belt can be automatically adjusted according to the width of the plates, and the machining applicability is improved.

Owner:嘉善康达自动化机械股份有限公司

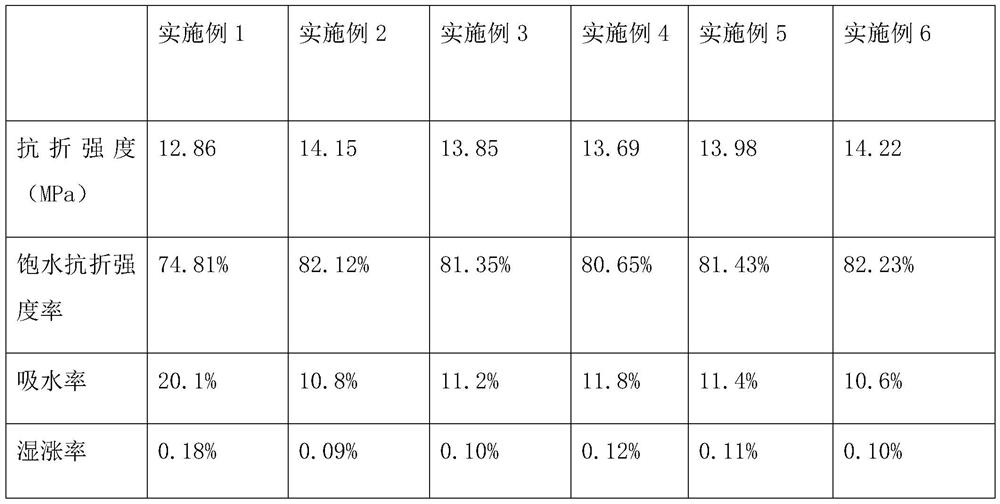

Manufacturing method of artificial inorganic imitated stone texture decorative plate

The invention provides a manufacturing method of an artificial inorganic imitated stone texture decorative plate, the modified cellulose is prepared from the wheat straw and the corn straw, and the mechanical property of the decorative plate is improved through the synergistic effect of the modified cellulose, the coal ash and the white carbon black; foamed glass is prepared by uniformly coating the surfaces of hollow glass beads with a layer of graphite-like phase carbon nitride, and the foamed glass is pressed on the main body mixture to form a thermal insulation layer, so that the high temperature resistance and flame retardance of the decorative plate are improved; by adding and rographolide and radix isatidis, the mildew-proof and antibacterial properties of the decorative plate are improved; the insulating layer is coated with an imitated stone coating. The decorative plate produced by the method realizes reasonable matching of high strength, obdurability, high temperature resistance and water resistance, and has the advantages of lower production cost, higher process applicability, higher operability, controllable product quality and the like.

Owner:江苏仙野建材有限公司

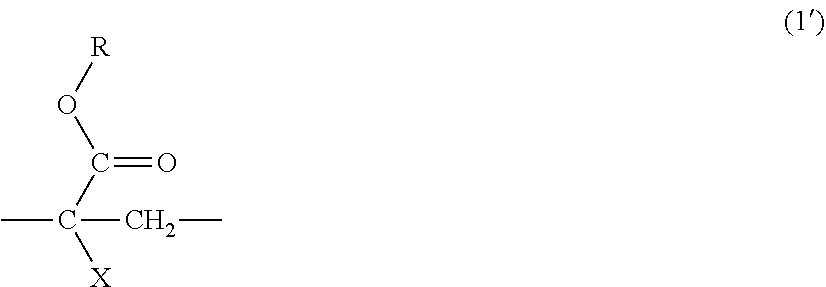

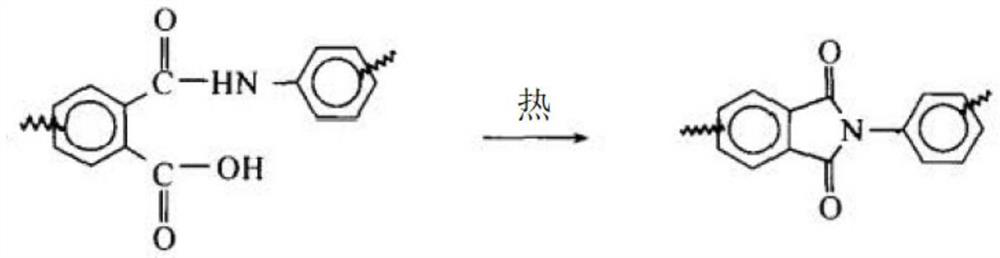

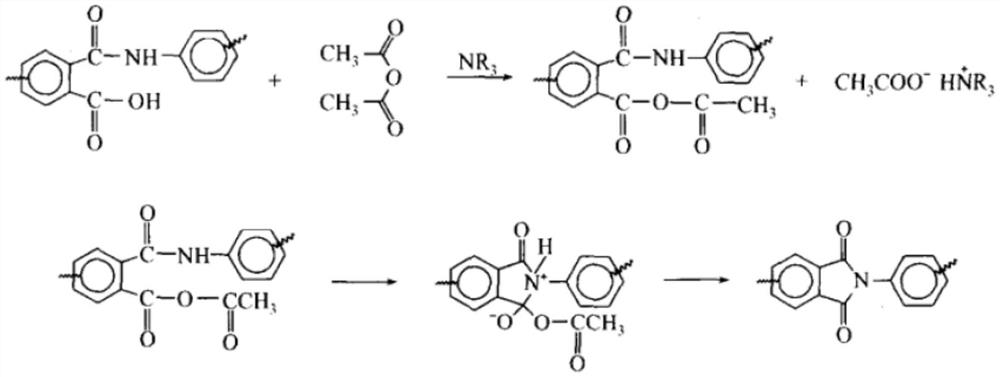

Macromonomer copolymer, epoxy resin composition, adhesive, molding material, and cured product

PendingUS20200199352A1Increase flexibilityImprove processing suitabilityEpoxy resin adhesivesPolymer scienceMeth-

There is provided an epoxy resin composition comprising a (meth)acrylic copolymer (A), an epoxy resin (B), and a curing agent (C), wherein the (meth)acrylic copolymer (A) has a constituent unit derived from a macromonomer (a) and a constituent unit derived from a vinyl monomer (b), and wherein a glass transition temperature (TgB) of a polymer obtained by polymerizing only the vinyl monomer (b) is 25° C. or less.

Owner:MITSUBISHI CHEM CORP

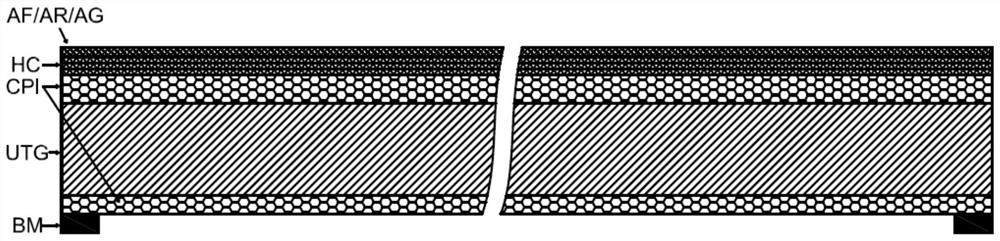

Flexible composite cover plate and manufacturing method thereof

The invention discloses a flexible composite cover plate and a manufacturing method thereof. The flexible composite cover plate at least comprises ultra-thin glass and a transparent polyimide layer formed on the ultra-thin glass, and the transparent polyimide layer is formed by conducting composite imidization treatment on a transparent polyamide acid layer smeared on the ultra-thin glass, whereinthe composite imidization treatment comprises low-temperature thermal imidization treatment and chemical imidization treatment which are carried out in sequence. The technological process is free ofa high-temperature manufacturing procedure, energy consumption is effectively reduced, the technological applicability is high, part of the imidization process is carried out in a solution, and particle pollution can be effectively avoided; the cross-cut tester adhesive force of each film layer is as high as 5B, the surface hardness is greater than 5H, and the bending resistance and the impact resistance are relatively strong; and besides, the invention further discloses a structure of the flexible composite cover plate with a black ink pattern layer and a preparation method of the flexible composite cover plate, that is, the black ink pattern is printed on the surface of the transparent polyimide layer, so that the risk that the printing screen plate is in direct contact with the ultrathin glass to scratch the ultrathin glass is eliminated.

Owner:CHENGDU TOMI SHUANG DU OPTOELECTRONICS CO LTD

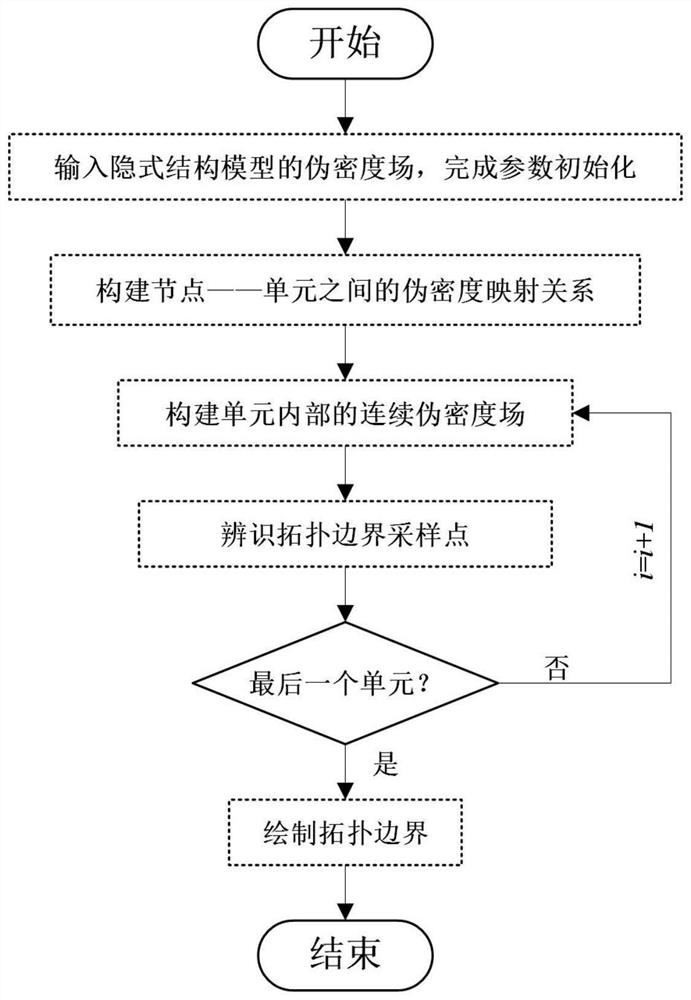

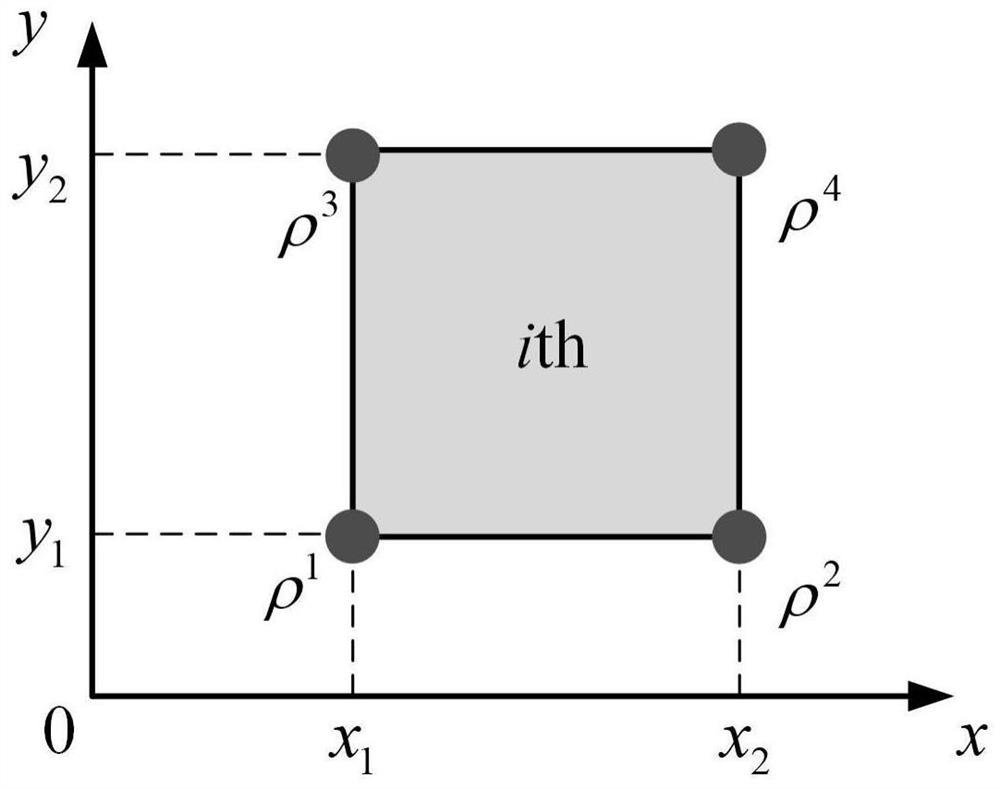

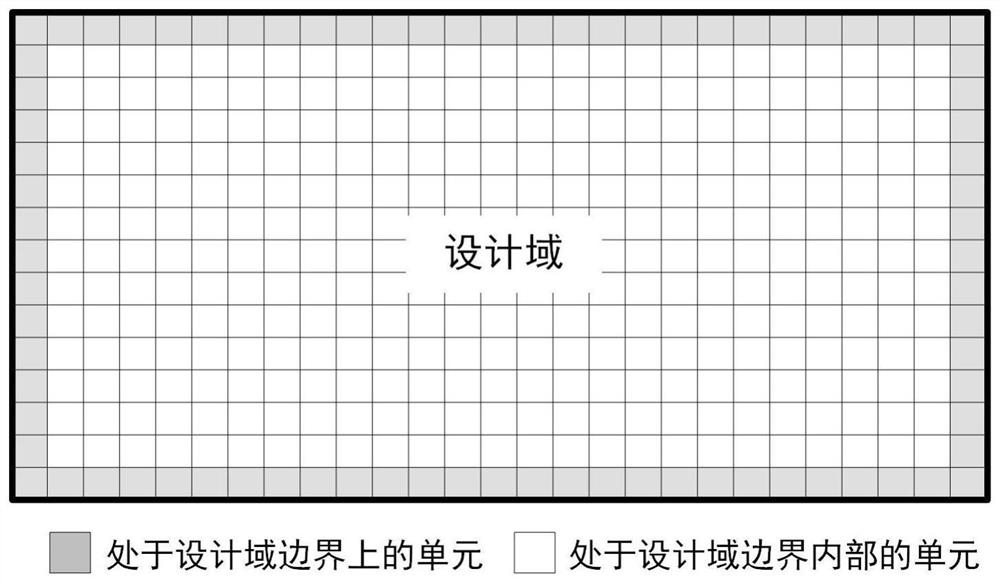

High-fidelity vector diagram conversion method for pixel type topological optimization result

PendingCN113268842AAchieve smooth transitionImprove processing suitabilityGeometric CADGeometric image transformationAlgorithmTopological optimization

The invention discloses a high-fidelity vector diagram conversion method for a pixel type topological optimization result, and the method comprises the steps: constructing an intra-unit continuous pseudo-density field on the basis of the grid description of an implicit structure model, and identifying the coordinates of a topological boundary sampling point; carrying out cubic spline curve fitting on the basis of the sampling points so as to form a boundary explicit expression of the implicit topological structure; the explicit geometric description obtained through the method can be seamlessly connected with a CAD system, unification of a design result and a machining structure is achieved, and later-stage further design optimization of engineering designers is facilitated.

Owner:XI AN JIAOTONG UNIV

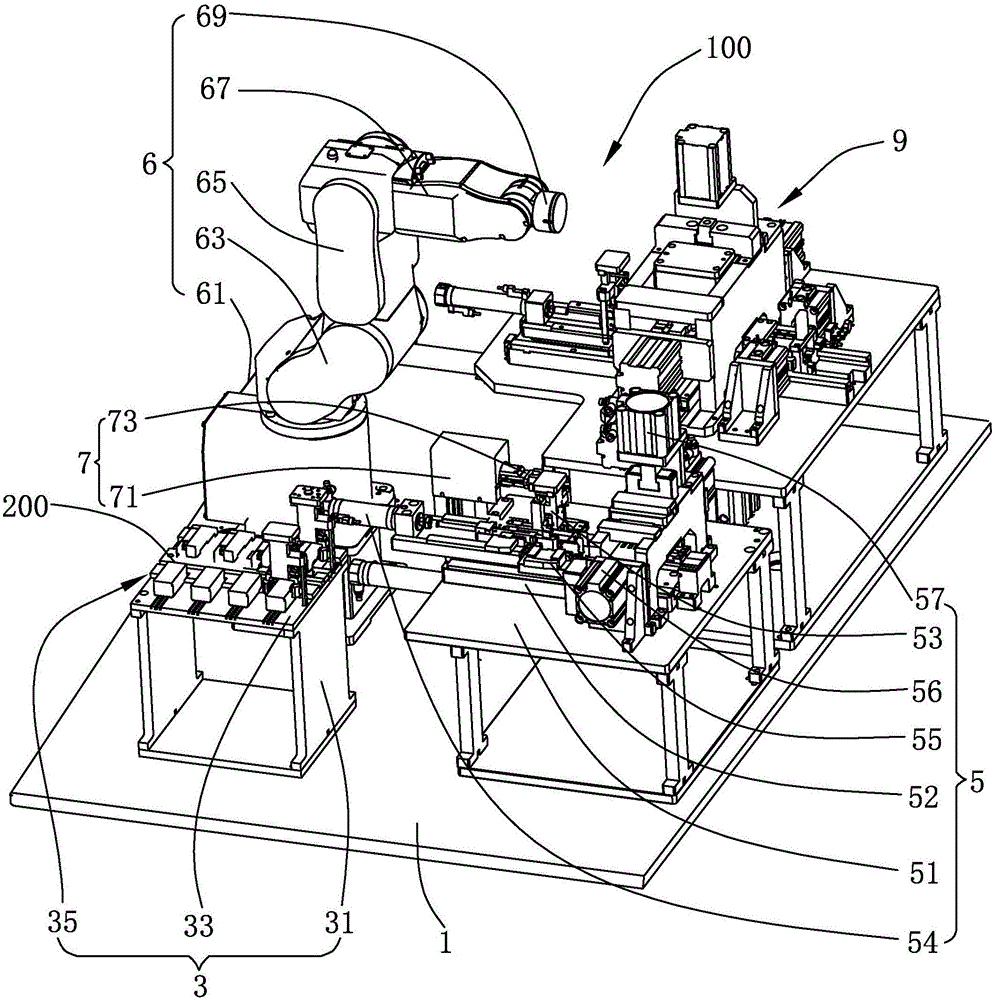

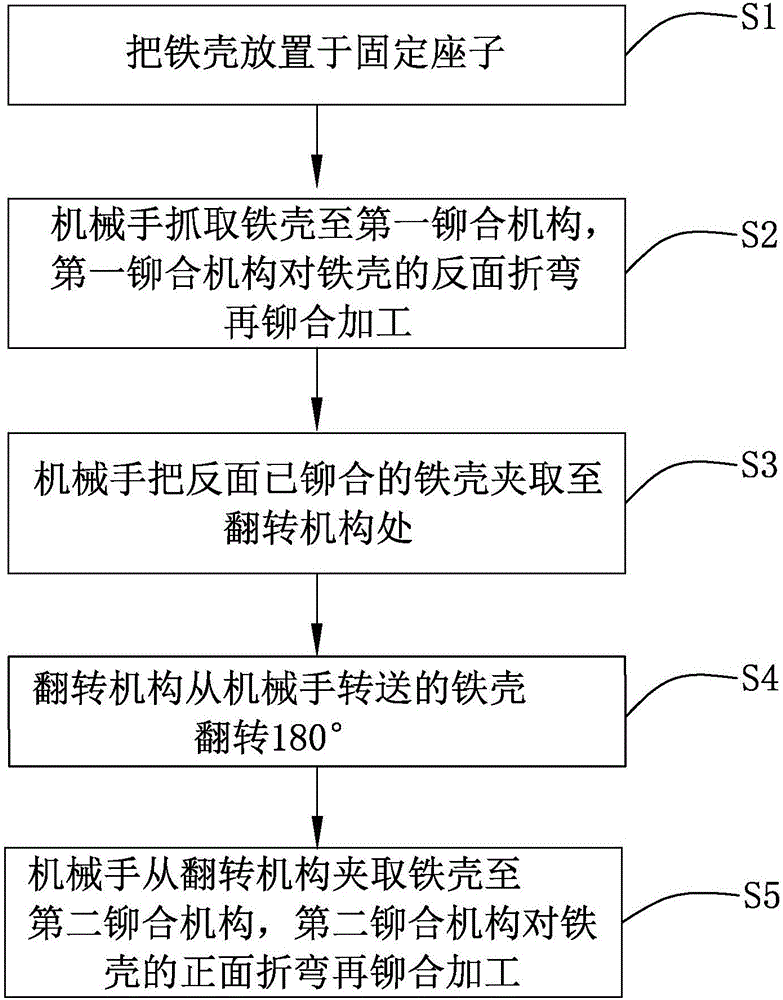

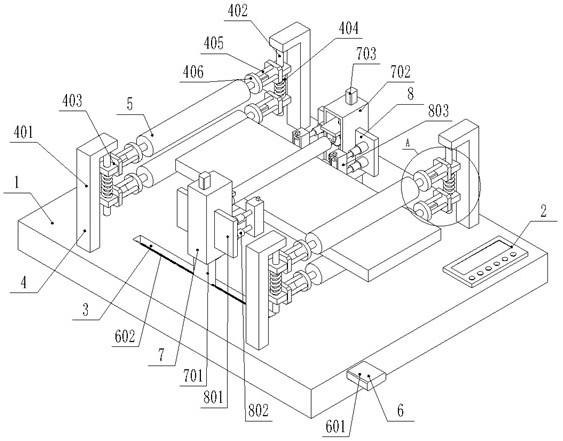

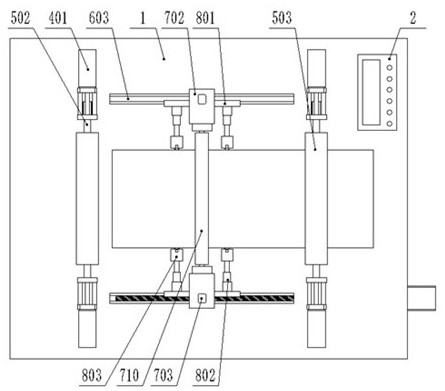

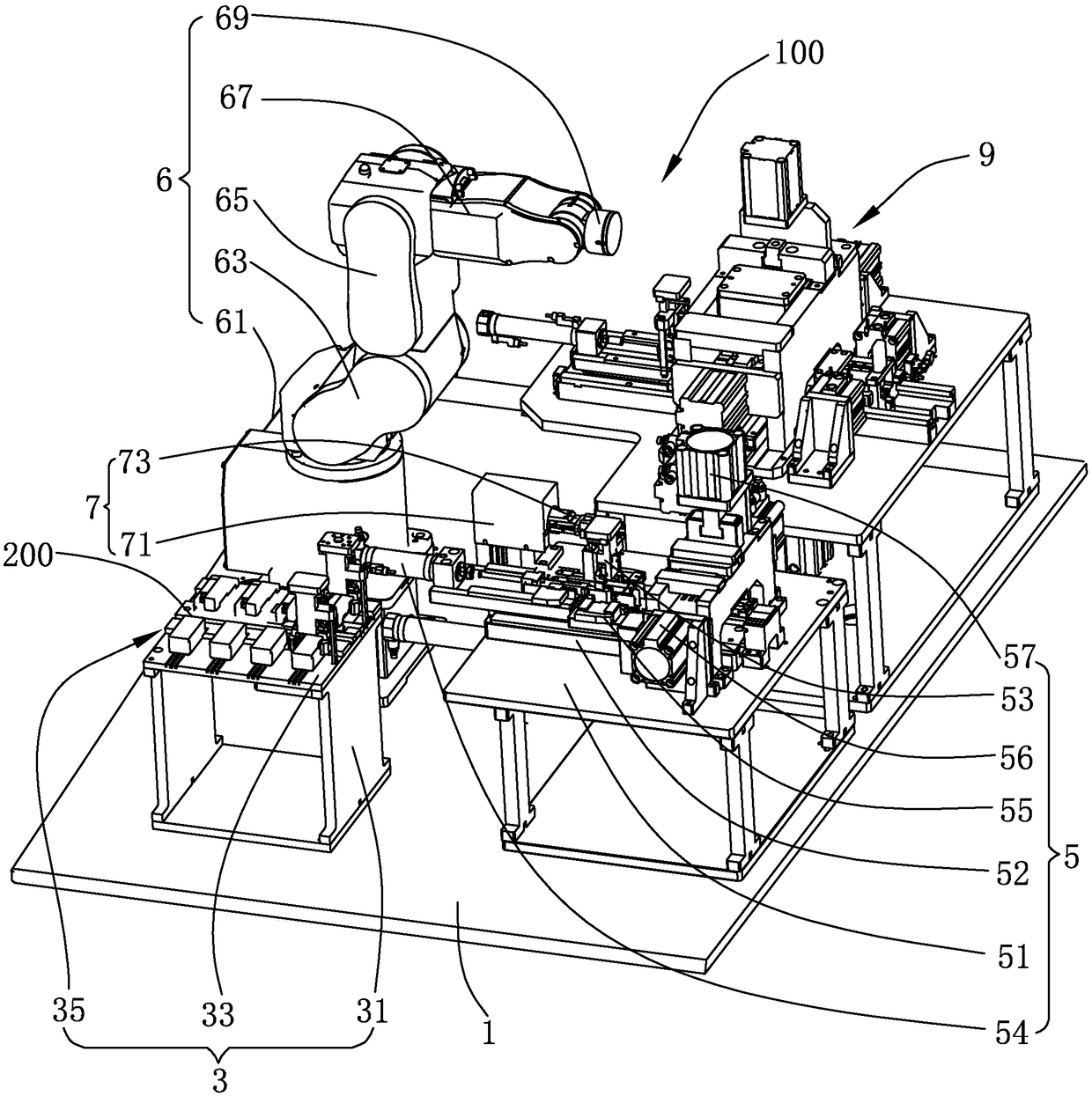

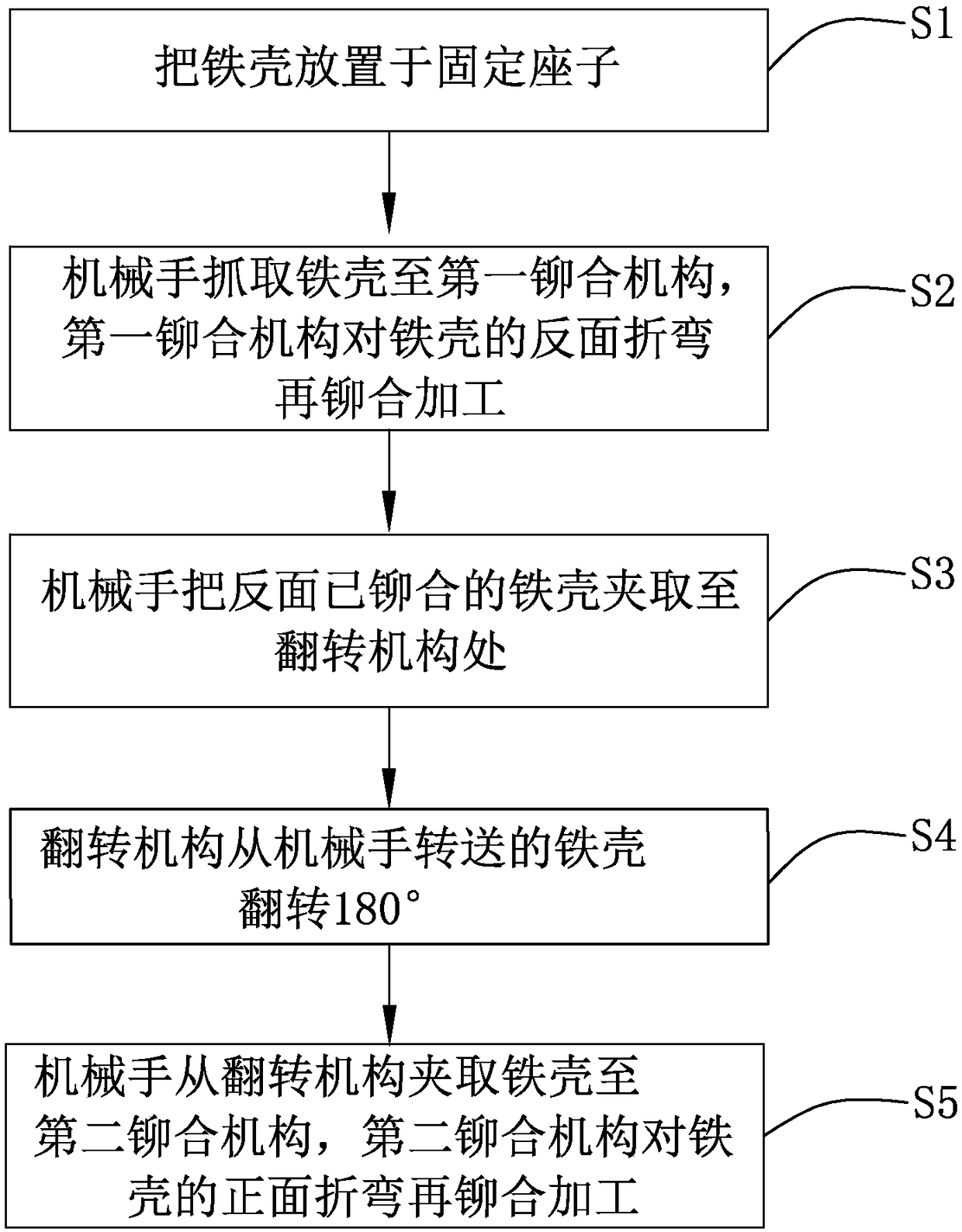

Iron shell riveting method

ActiveCN106475476AIncrease productivityImprove machining accuracyMetal-working feeding devicesPositioning devicesManipulatorMachining

The invention discloses an iron shell riveting method. The iron shell riveting method is used for riveting machining of an iron shell and comprises the following steps that the iron shell is placed on a fixed seat, the iron shell is grabbed to a first riveting mechanism by a manipulator, and the back face of the iron shell is bended and riveted by the first riveting mechanism; the iron shell with a riveted back face is grabbed to a turnover mechanism by the manipulator, and the turnover mechanism grabs the iron shell transferred by the manipulator and turns over 180 degrees; and the iron shell is grabbed to a second riveting mechanism by the manipulator from the turnover mechanism, and the front face of the iron shell is bended and riveted. According to the iron shell riveting method, the back face and the front face of the iron shell are bended and riveted by the first riveting mechanism and the second riveting mechanism in sequence, so that the upgrade of iron machining from manual work to automatic production is achieved, and production efficiency and machining precision are improved.

Owner:GUANGDONG SHUOTAI INTELLIGENT EQUIP

Plate processing device for building engineering construction

ActiveCN114770347AImprove polishing efficiencyImprove processing suitabilityGrinding carriagesPolishing machinesStructural engineeringManufacturing engineering

The invention discloses a plate processing device for constructional engineering construction, and relates to the technical field of constructional engineering construction machinery, the plate processing device comprises a base, a control device is arranged on the surface of the base, and a sliding groove is formed in the surface of the base; the conveying mechanism is arranged on the surface of the base provided with the sliding groove; the polishing mechanism is arranged on the surface of the side, provided with the conveying mechanism, of the base. The auxiliary mechanism is arranged on the surface of the polishing mechanism. By arranging the polishing assembly, the device can polish the upper surface and the lower surface of a plate at the same time, the procedure that the plate needs to be turned over and then polished is avoided, the polishing efficiency of the plate is greatly improved, the polishing roller close to the adjusting screw rod is arranged to be movable, the device can polish plates of different models, and the polishing efficiency is greatly improved. The processing applicability of the device is improved; and by arranging the auxiliary assembly, the device not only can polish the upper surface and the lower surface of the plate simultaneously, but also can polish the side face of the plate, and the plate polishing efficiency of the device is improved.

Owner:徐州大成环境科技有限公司

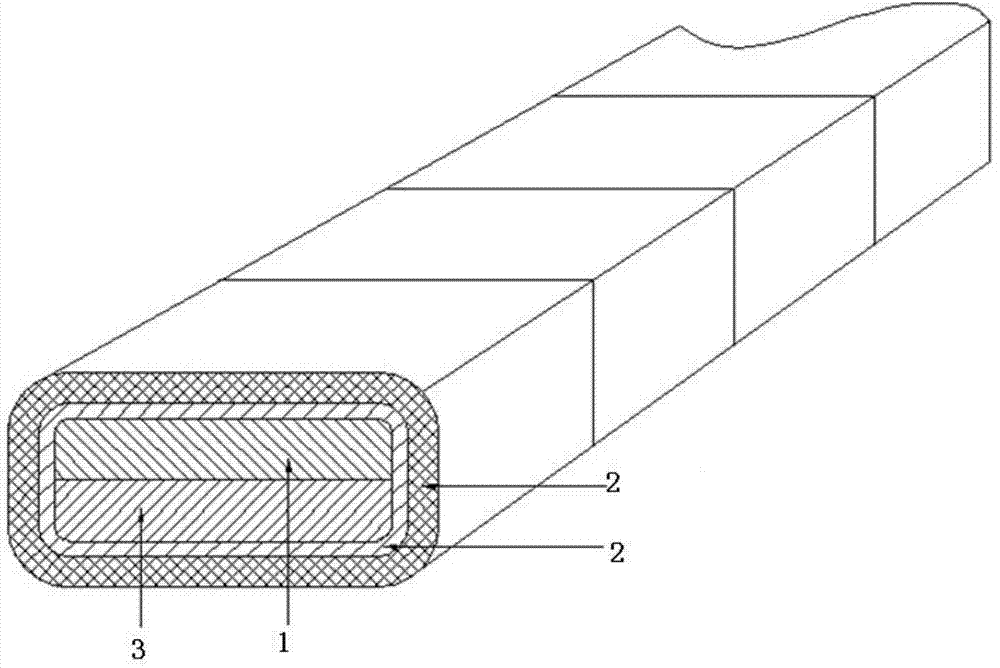

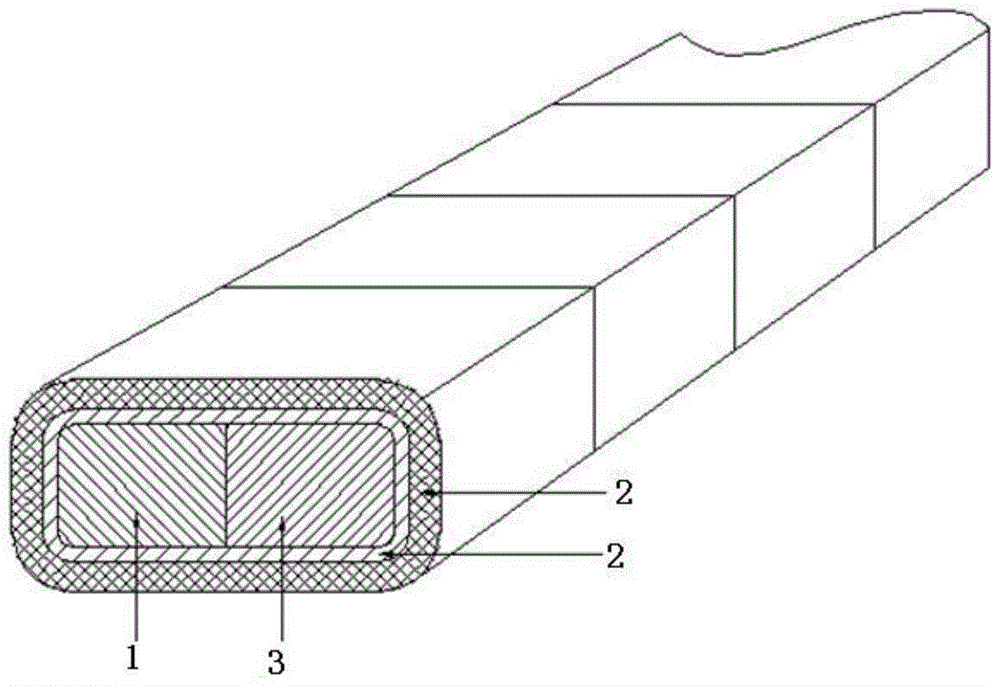

Electromagnetic wire for motor coil winding

ActiveCN103490542AIncrease profitPromote lowerNon-insulated conductorsWindings insulation shape/form/constructionElectrical conductorElectric machine

The invention relates to an electromagnetic wire for a motor coil winding. The electromagnetic wire comprises a conductor and an insulating layer, the conductor is composed of a first flat conductor body and a second flat conductor body, the first flat conductor body and the second flat conductor body are respectively provided with an upper lateral face, a lower lateral face, a left lateral face and a right later face, wherein the widths of the upper lateral faces and the widths of the lower lateral faces are 3-8 times larger than the widths of the left lateral faces and the widths of the right lateral faces, the lower lateral face of the first flat conductor body is in right-angle transition with the left lateral face and the right lateral face of the first flat conductor body, the upper lateral face of the second flat conductor body is in right-angle transition with the left lateral face and the right lateral face of the second flat conductor body, the lower lateral face of the first flat conductor body is in close fit with the upper lateral face of the second flat conductor body, the upper lateral face of the first flat conductor body is in arc-shaped transition with the left lateral face and the right lateral face of the first flat conductor body, and the lower lateral face of the second flat conductor body is in arc-shaped transition with the left lateral face and the right lateral face of the second flat conductor body. The electromagnetic wire is beneficial to thinning motor insulation and improving the using rate of a motor groove, improves the motor thermal conductivity, reduces the motor size under the condition that the temperature rise is same, saves the cost, reduces using materials, improves the technology applicability and keeps insulating performance unchanged.

Owner:SUZHOU GUANLONG MAGNET WIRE

Rust-proof heat-resistant deformed steel and processing technology thereof

InactiveCN113583541AImprove high temperature oxidation resistanceHigh strengthFireproof paintsAnti-corrosive paintsManganeseHigh pressure water

The invention provides anti-rust heat-resistant deformed steel and a processing technology thereof. The deformed steel comprises a base material, a heat-resistant layer and an anti-rust layer; the base material comprises the following chemical components in percentage by mass: 0.2 to 1 percent of carbon, 2 to 3 percent of silicon, 8.2 to 10 percent of tungsten, 2 to 6 percent of molybdenum, 20 to 45 percent of chromium, 0.1 to 0.2 percent of cobalt, 0.5 to 1 percent of manganese, 0.2 to 0.6 percent of vanadium and the balance of iron; the processing technology of the base material comprises the steps of cleaning, dephosphorization, rolling, controlled cooling and straightening; specifically, a steel billet is placed in a cleaning solution, subjected to ultrasonic cleaning and drying and then heated to 1000-1200 DEG C in a furnace, the steel billet is discharged out of the furnace, cooled and then descaled through high-pressure water of 15-25 MPa, the steel billet is sent to a two-roller reversible rolling mill to be roughly rolled, then a universal continuous rolling unit is adopted for continuous rolling, controlled cooling and straightening, and the base material is obtained; the base material is subjected to sand blasting treatment, the surface of the base material is coated with the epoxy micaceous iron oxide intermediate paint, and then the epoxy micaceous iron oxide intermediate paint is coated with the anti-rust coating to serve as an anti-rust layer; and the antirust layer is coated with a heat-resistant coating as a heat-resistant layer.

Owner:常州市方正型钢有限公司

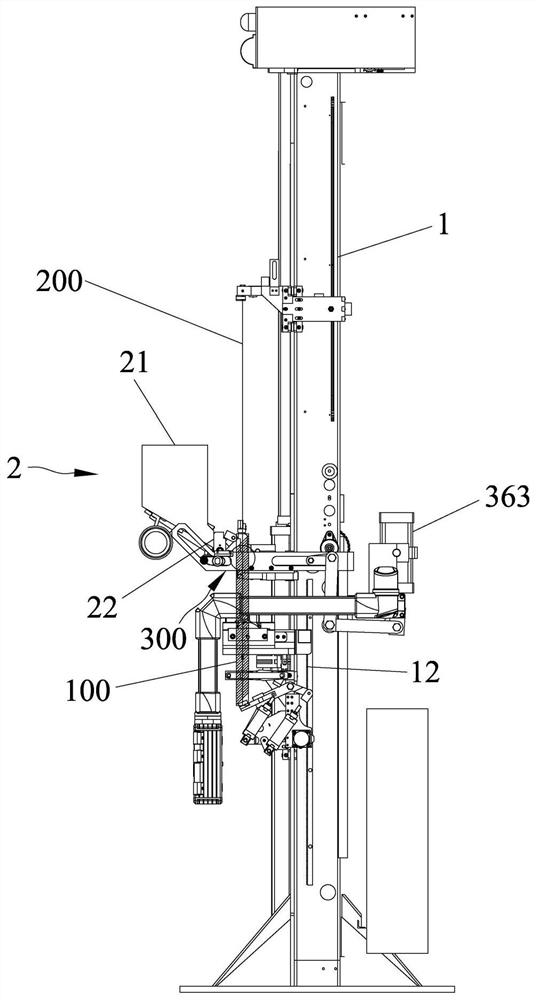

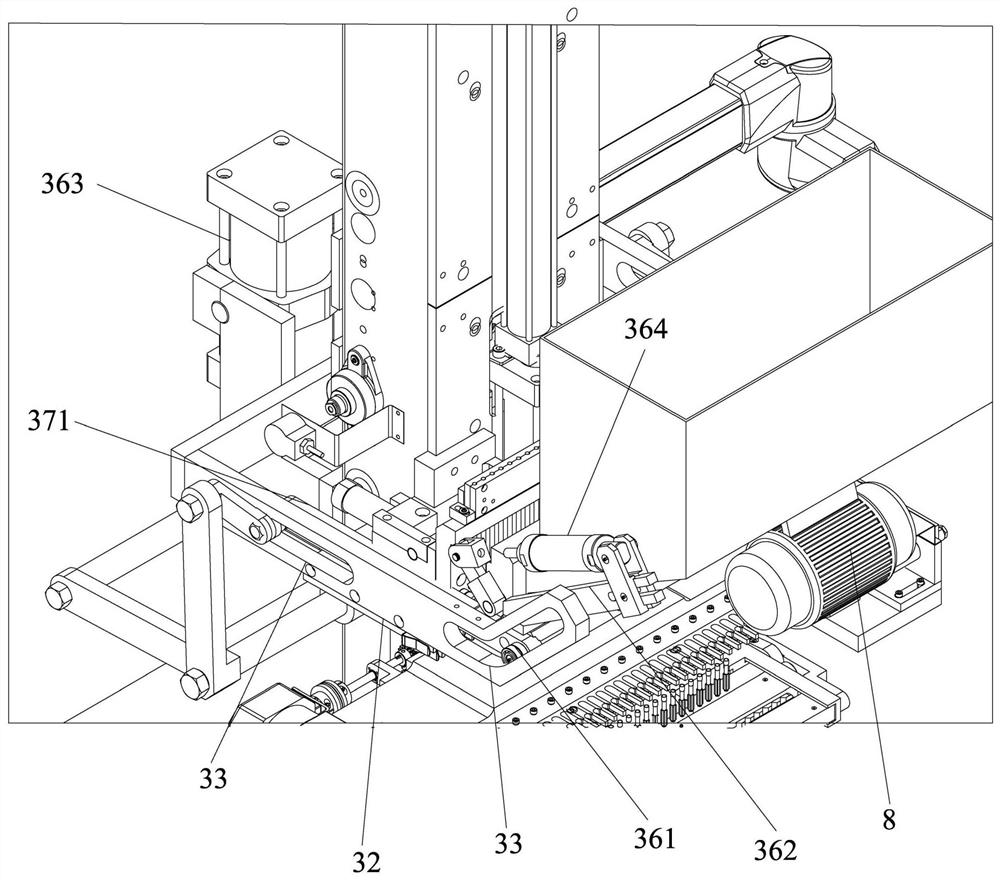

A butterfly plate assembly device of a butterfly valve assembly machine

ActiveCN112453865BGuarantee the accuracy of combination installationGuaranteed production efficiencyMetal working apparatusStorage managementButterfly valve

Owner:深圳市汇鑫通源科技有限公司

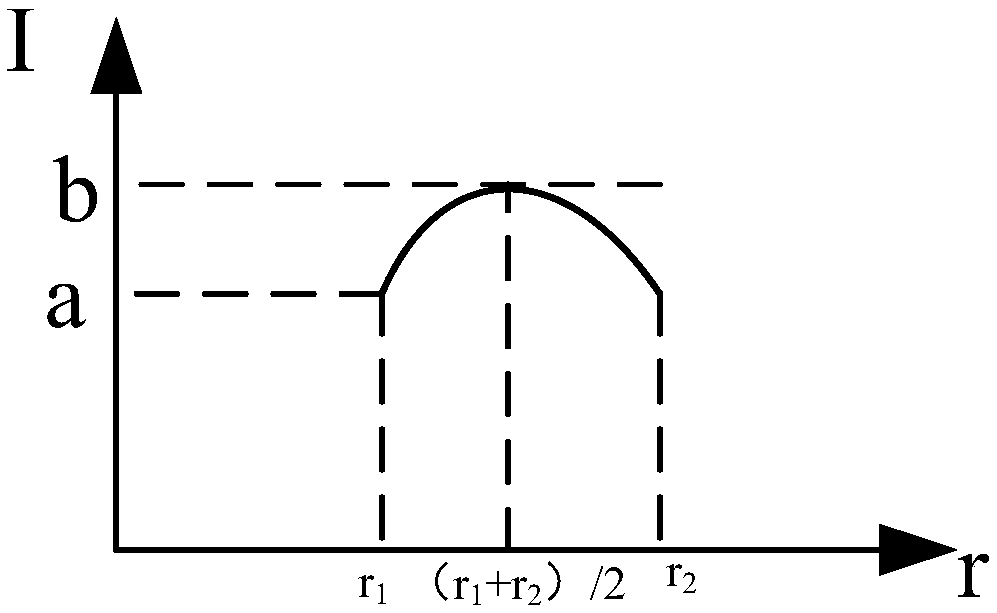

Laser scanning packaging system and method

ActiveCN109422449AImprove matchImprove processing suitabilitySolid-state devicesSemiconductor/solid-state device manufacturingLight spotComputer module

The invention provides a laser scanning packaging system and a method. The system comprises a light source module for providing incidence laser, a micro-reflecting mirror array and a control module, wherein the control module is used for carrying out light spot modulation on the incidence laser through adjusting the micro-reflecting mirror array, and the light spot modulation comprises the step ofcarrying out light spot morphology modulation and light spot energy distribution modulation on the incidence laser. Therefore, light spot morphology modulation and light spot energy distribution modulation can be carried out in real time according to the morphology and size of an area required to be packaged, thus, the aim that the morphology of a light spot is matched with the packaged area andthe energy of the packaged area is uniformly distributed is achieved, and the adaptability of a laser-scanning glass packaging process is improved; and a reflecting direction of a modulated light spotis adjusted through arranging a reflecting mirror group, and then, the aim of scanning the packaged area by the laser is achieved, so that mechanical vibrations are reduced, and the gas tightness oflaser-scanning glass packaging is improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Iron shell riveting method

ActiveCN106475476BIncrease productivityImprove machining accuracyMetal-working feeding devicesPositioning devicesManipulatorMachining

The invention discloses an iron shell riveting method. The iron shell riveting method is used for riveting machining of an iron shell and comprises the following steps that the iron shell is placed on a fixed seat, the iron shell is grabbed to a first riveting mechanism by a manipulator, and the back face of the iron shell is bended and riveted by the first riveting mechanism; the iron shell with a riveted back face is grabbed to a turnover mechanism by the manipulator, and the turnover mechanism grabs the iron shell transferred by the manipulator and turns over 180 degrees; and the iron shell is grabbed to a second riveting mechanism by the manipulator from the turnover mechanism, and the front face of the iron shell is bended and riveted. According to the iron shell riveting method, the back face and the front face of the iron shell are bended and riveted by the first riveting mechanism and the second riveting mechanism in sequence, so that the upgrade of iron machining from manual work to automatic production is achieved, and production efficiency and machining precision are improved.

Owner:GUANGDONG SHUOTAI INTELLIGENT EQUIP

Special adhesive for hollow composite insulator and preparation method thereof

PendingCN113025250AFast curingImprove impact toughnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesInterference fitAdhesive

The invention relates to the technical field of adhesives, and discloses a special adhesive for a hollow composite insulator and a preparation method of the special adhesive, and the special adhesive comprises the following components in parts by mass: a component A: 90-110 parts of epoxy resin, 1-2 parts of nano aluminum oxide, 0.5-1 part of a silane coupling agent, 8-12 parts of an organic solvent and 120-160 parts of a filler a; The component B comprises the following components in parts by weight: 60-70 parts of a curing agent, 20-30 parts of a toughening agent, 1 part of an accelerant, 60-80 parts of filler b and 0.5-1 part of a flatting agent; The mass ratio of the component A to the component B is 1: 1. The curing time of the current common adhesive is about 2 hours, and the curing time of the adhesive disclosed by the invention is 30-45 minutes; According to the method, the damage test is carried out on a hollow composite insulator sample, and the final damage value is increased by about 13% compared with the prior art. Therefore, the adhesive has the characteristics of good bonding performance, high impact toughness, moderate viscosity, rapid curing and the like, is particularly suitable for an end connection structure in interference fit, and is high in process applicability.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID

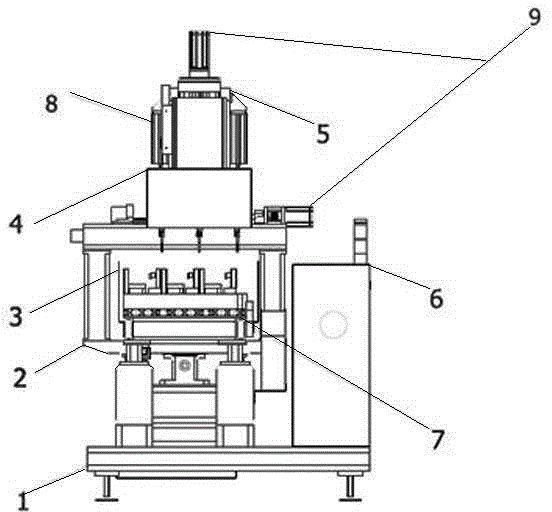

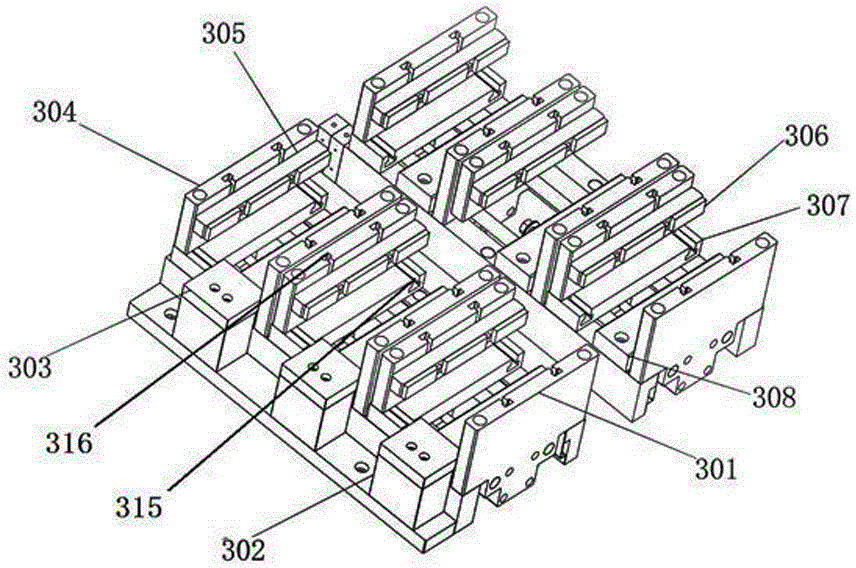

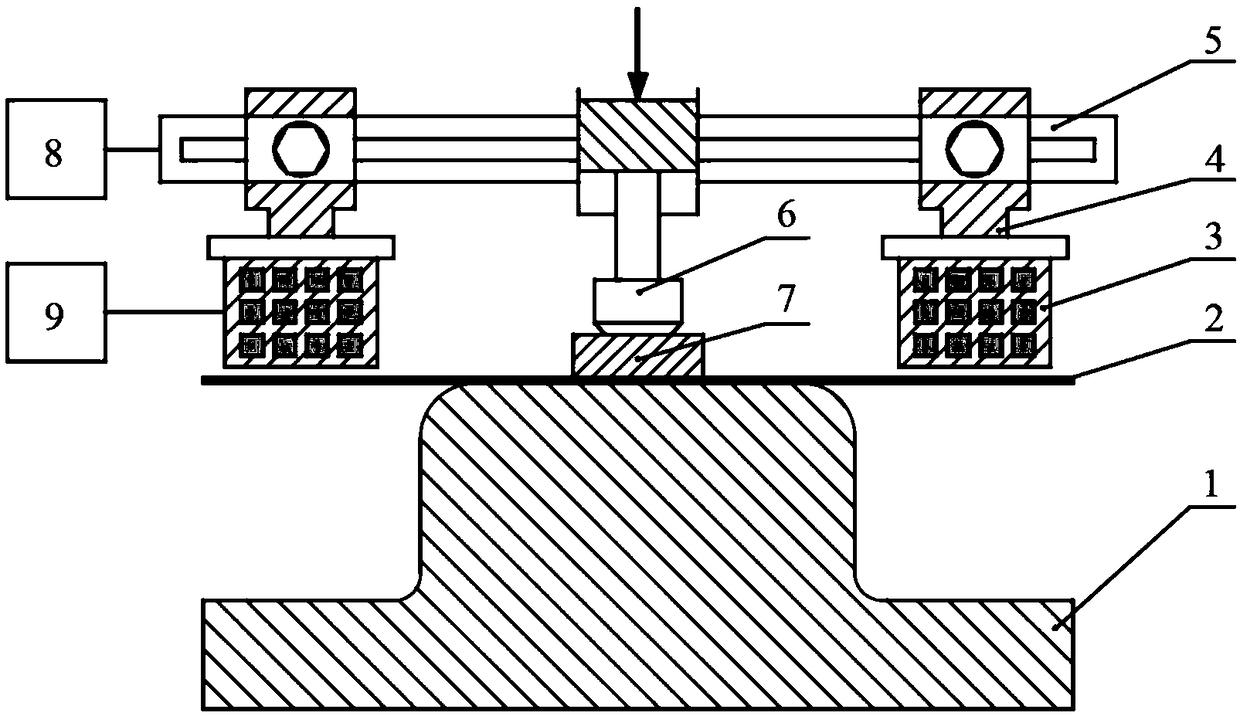

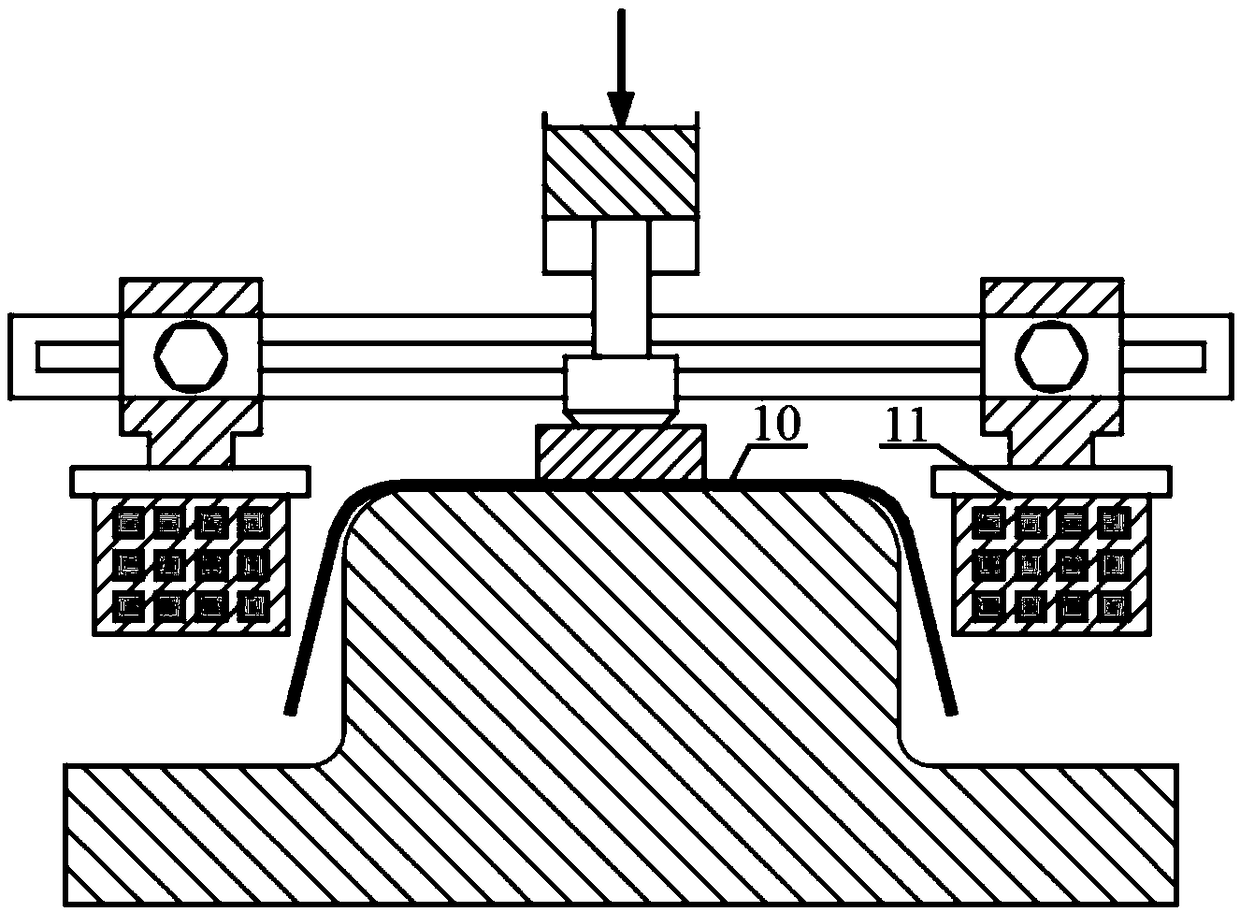

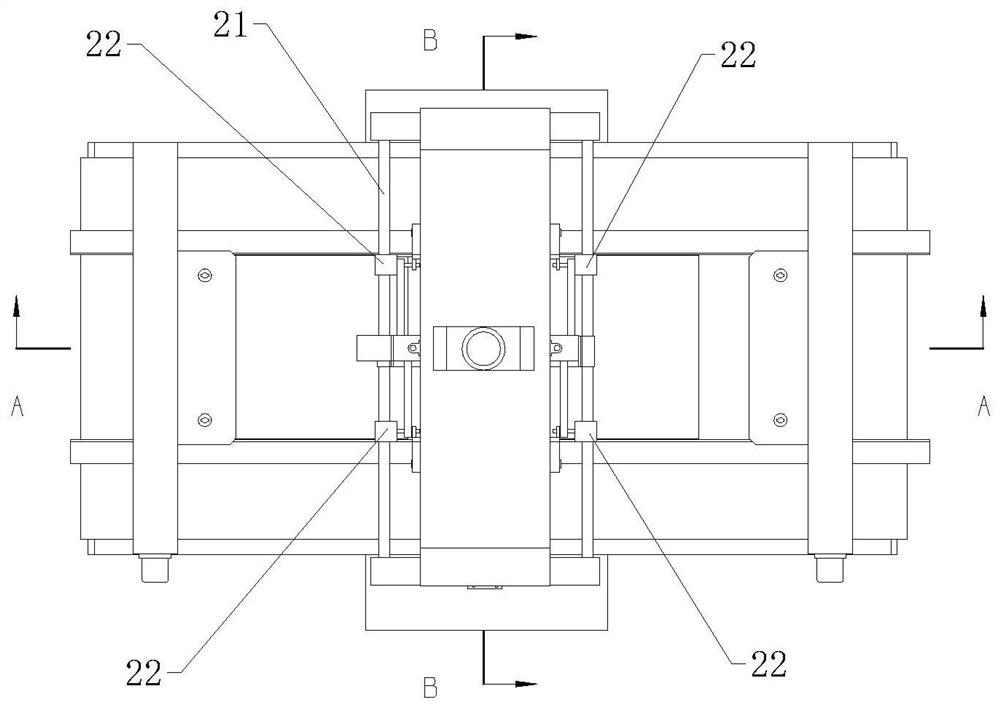

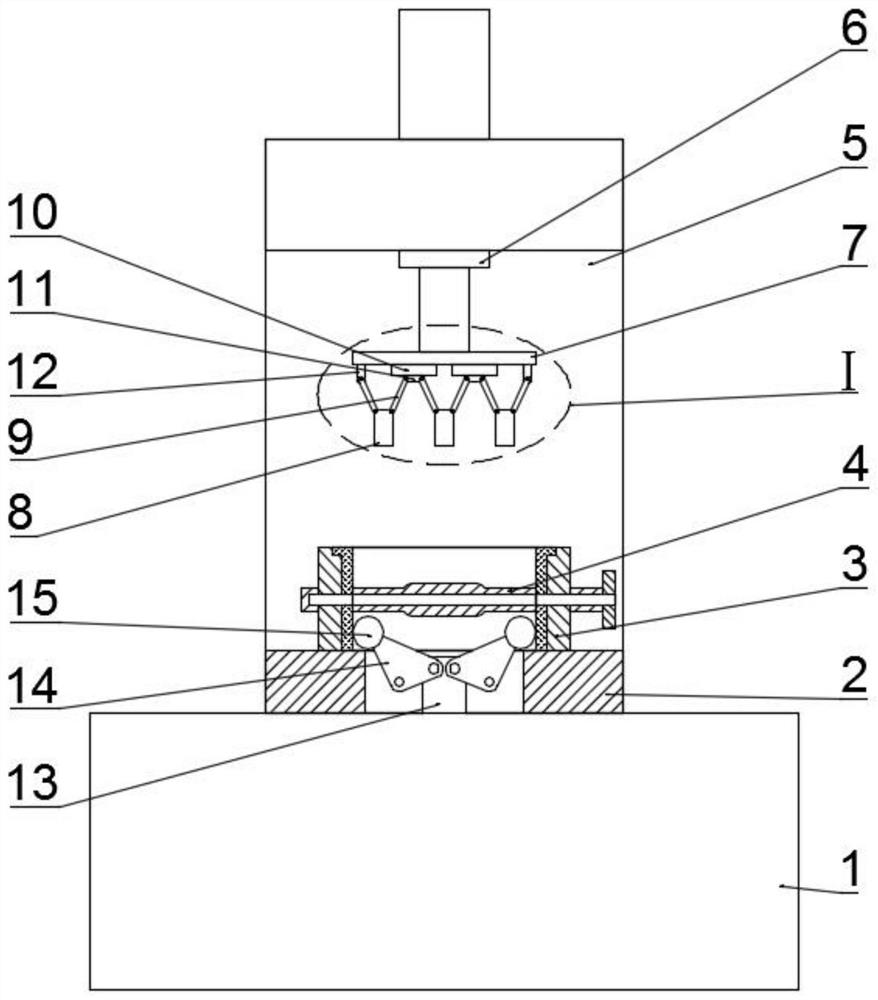

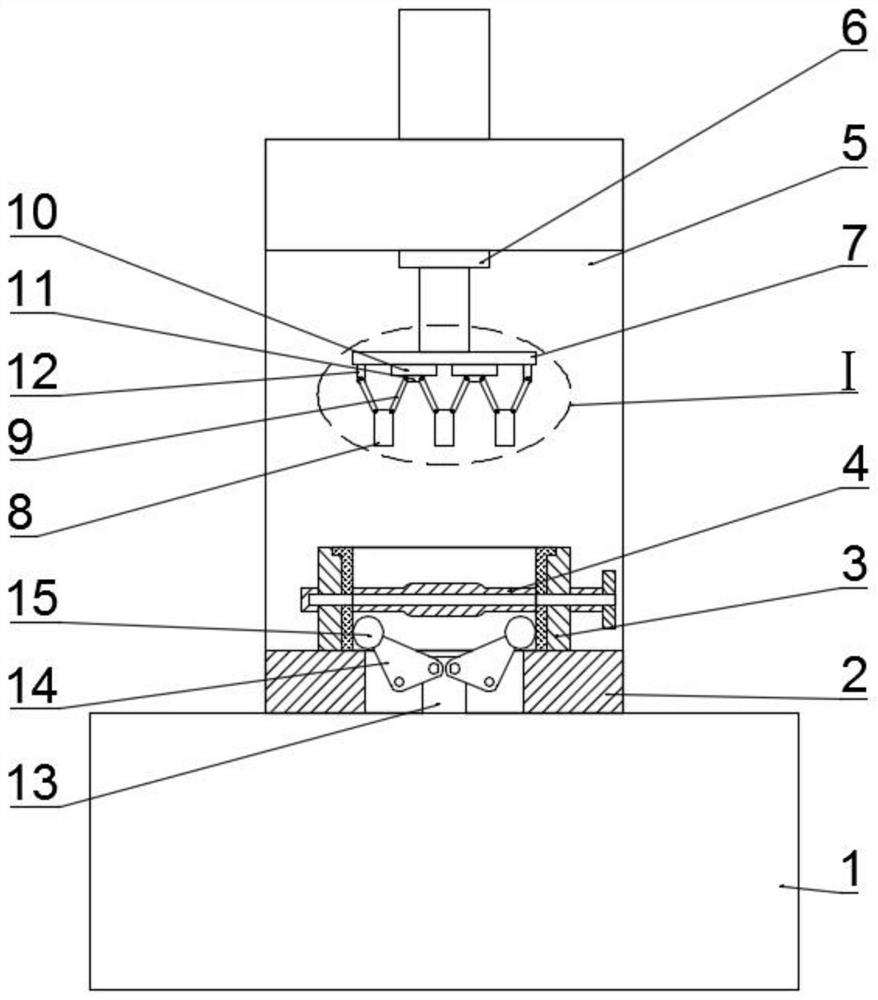

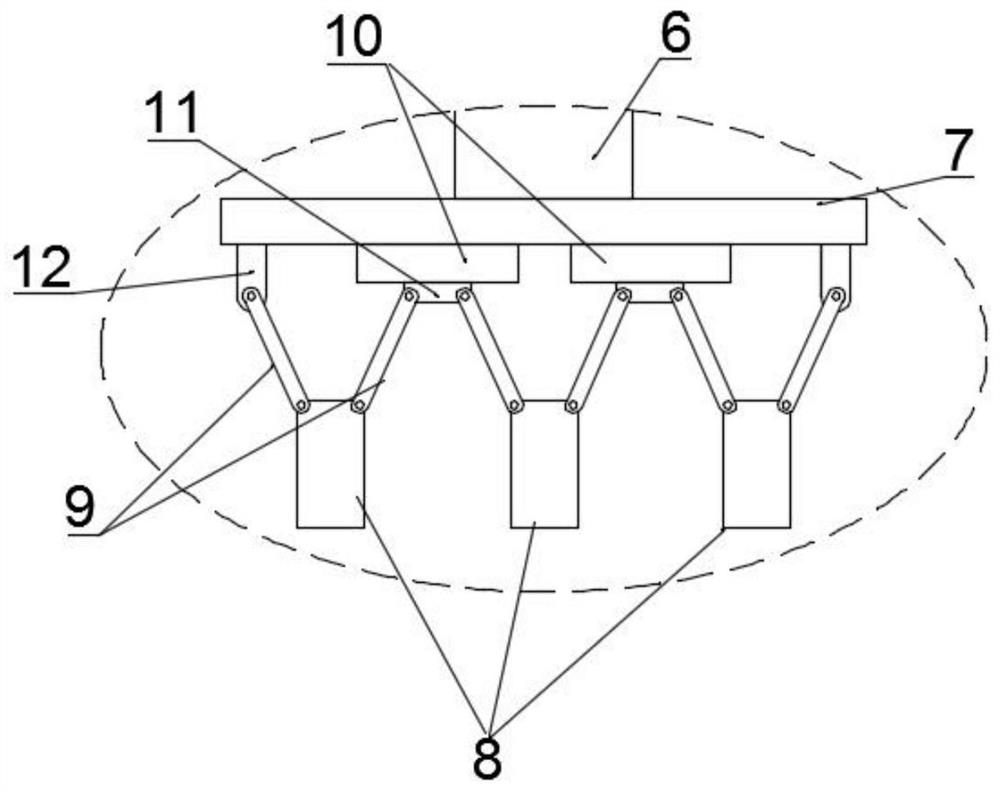

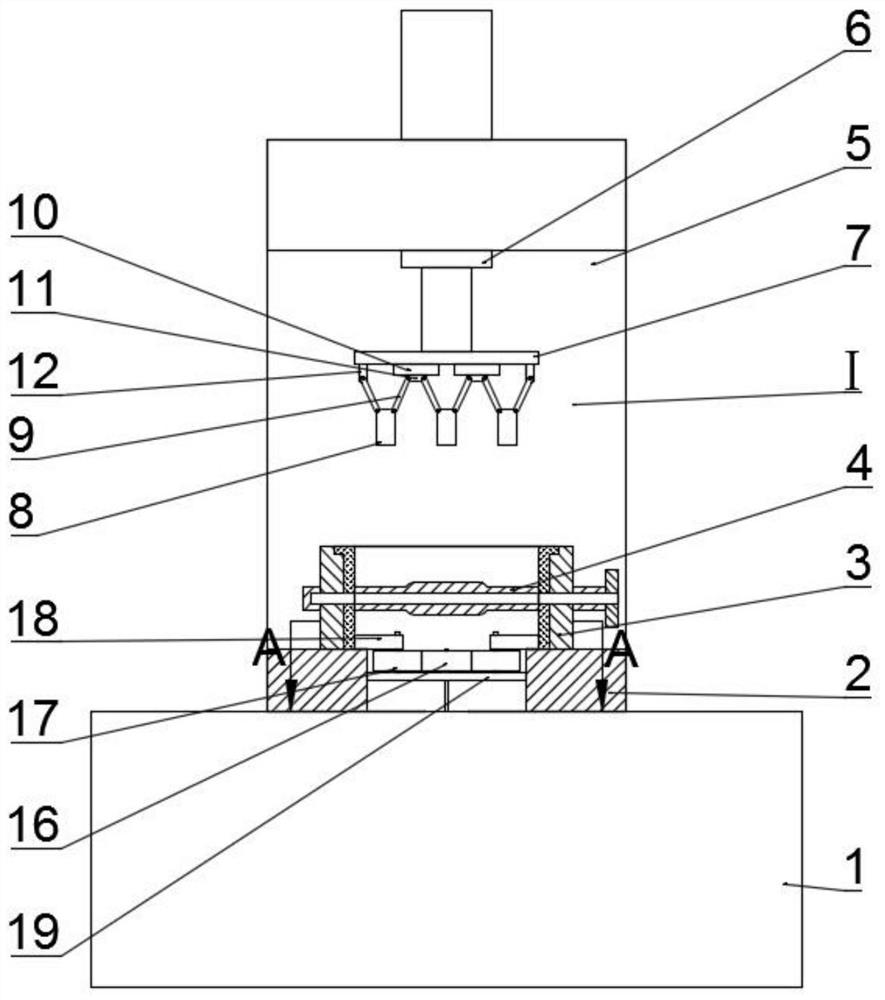

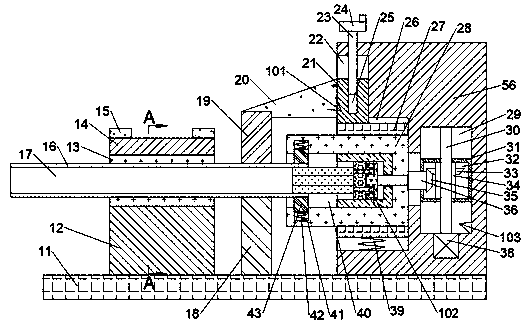

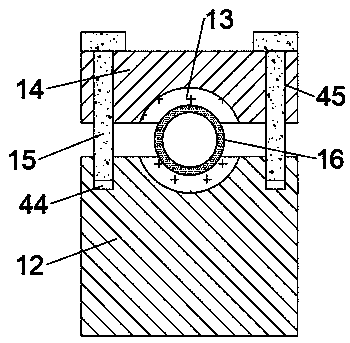

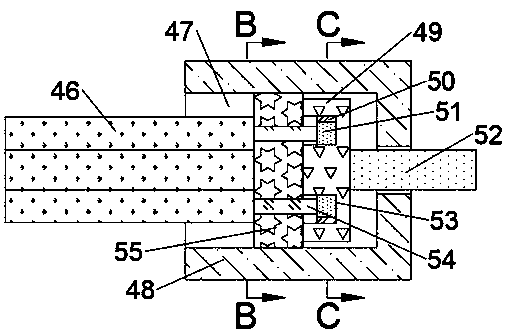

Butterfly plate combination device of butterfly valve assembling machine

ActiveCN112453865AGuarantee the accuracy of combination installationGuaranteed production efficiencyMetal working apparatusMachineButterfly valve

The invention provides a butterfly plate combination device of a butterfly valve assembling machine, and relates to the technical field of valve production. The butterfly plate combination device of the butterfly valve assembling machine comprises a machine table, a machining table installed on the machine table and used for containing valve bodies and a vertical plate fixedly arranged on the machine table, and a lifting plate is arranged at the upper part of the machining table. According to the butterfly plate combination device, balanced downward pressure can also be applied to non-planar butterfly plates, so that the accuracy of combined installation of the different types of butterfly plates and the valve bodies is guaranteed, for different types of butterfly valves, a pressure head does not need to be replaced frequently, the production efficiency is guaranteed, and the production cost and the storage and management cost are also reduced; according to the butterfly plate combination device, the butterfly plates of the different types of butterfly valves can be pressed down to proper positions, and therefore the machining applicability of the butterfly plate combination deviceis improved; and by arranging a valve body limiting mechanism, the valve bodies to be machined can be quickly and firmly limited by the butterfly plate combination device, and the machining quality is guaranteed.

Owner:深圳市汇鑫通源科技有限公司

Anti-deformation polishing machining device based on thin-walled steel pipe

InactiveCN111266987AImprove processing suitabilityStrong transmissionGrinding carriagesPolishing machinesSteel tubeThin walled

The invention discloses an anti-deformation polishing machining device based on a thin-walled steel pipe. The anti-deformation polishing machining device comprises a base and a machine body, the machine body is fixedly arranged on the top surface of the base, a supporting platform is fixedly arranged on the top surface of the base, the thin-walled steel pipe can be placed on the top surface of thesupporting platform, the supporting platform is located on the left side of the machine body, a lifting cavity with a leftward opening is formed in the machine body, and a moving cavity with a leftward opening is formed in the lower side of the lifting cavity in a communicating mode. According to the anti-deformation polishing machining device, a method of manual positioning is adopted to make amachining part in the device always at the same level with the steel pipe, the machining applicability of the steel pipes with different diameters is effectively improved, a method of rotating an arc-shaped supporting plate outward to expand and cling to the inner wall of the steel pipe is adopted, and the deformation of the thin-walled steel pipe caused by the excessive polishing pressure when the thin-walled steel pipe is polished on the outer side can be effectively avoided.

Owner:浦江县旭星机械科技有限公司

Aluminum shell structure of laminated lithium battery and manufacturing method thereof

ActiveCN105140429BImprove sealingImprove connection reliabilitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsStructural engineeringSpot welding

Owner:昆山斯格威电子科技有限公司

Magnet wire used in motor coil windings

ActiveCN103489509BIncrease profitPromote lowerNon-insulated conductorsWindings insulation shape/form/constructionElectrical conductorEngineering

The invention relates to an electromagnetic wire used for a motor coil winding. The electromagnetic wire comprises a conductor and an insulating layer. The conductor is composed of a first flat conductor body and a second flat conductor body, and the first flat conductor body and the second flat conductor body respectively comprise an upper side face, a lower side face, a left side face and a right side face, wherein the width of each upper side face and each lower side face is twice or more than twice of the width of each lower side face and each right side face. The right side face of the first flat conductor body is in right angle transition with the upper side face of the first flat conductor body and the lower side face of the first flat conductor body, the left side face of the second flat conductor body is in right angle transition with the upper side face of the second flat conductor body and the lower side face of the second flat conductor body, the right side face of the first flat conductor body is tightly attached to the left side face of the second flat conductor body, the left side face of the first flat conductor body is in arc transition with the upper side face of the first flat conductor body and the lower side face of the first flat conductor body, and the right side face of the second flat conductor body is in arc transition with the upper side face of the second flat conductor body and the lower side face of the second flat conductor body. The electromagnetic wire used for the motor coil winding has the advantages of being beneficial to thinning the insulating layer of a motor, improving the utilization rate of a groove of the motor, improving the heat conductivity of the motor, reducing the size of the motor under the same temperature rise, saving cost, reducing the use level of materials, improving the technology adaptability, and keeping the insulating performance unchanged.

Owner:SUZHOU GUANLONG MAGNET WIRE

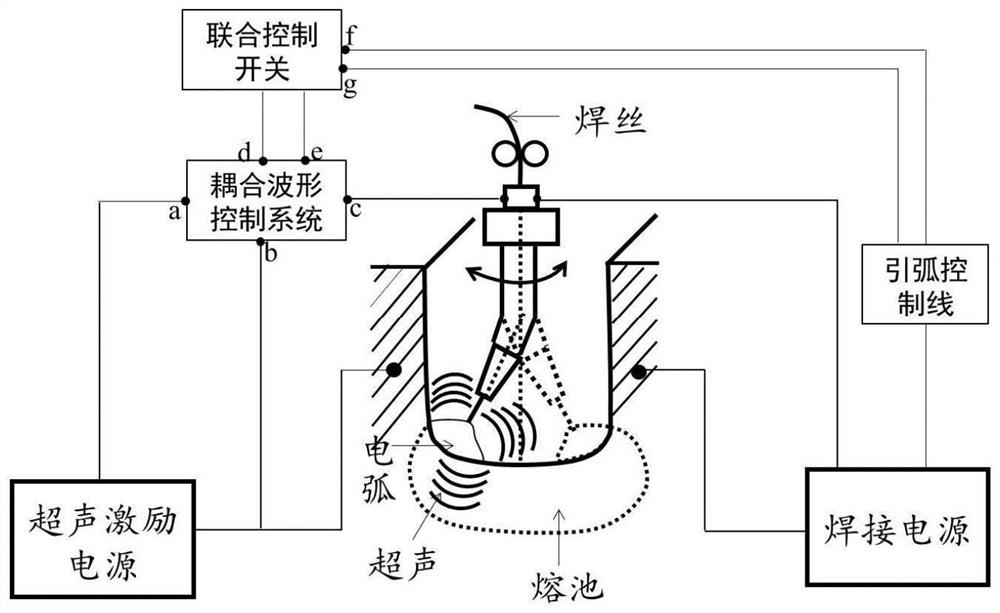

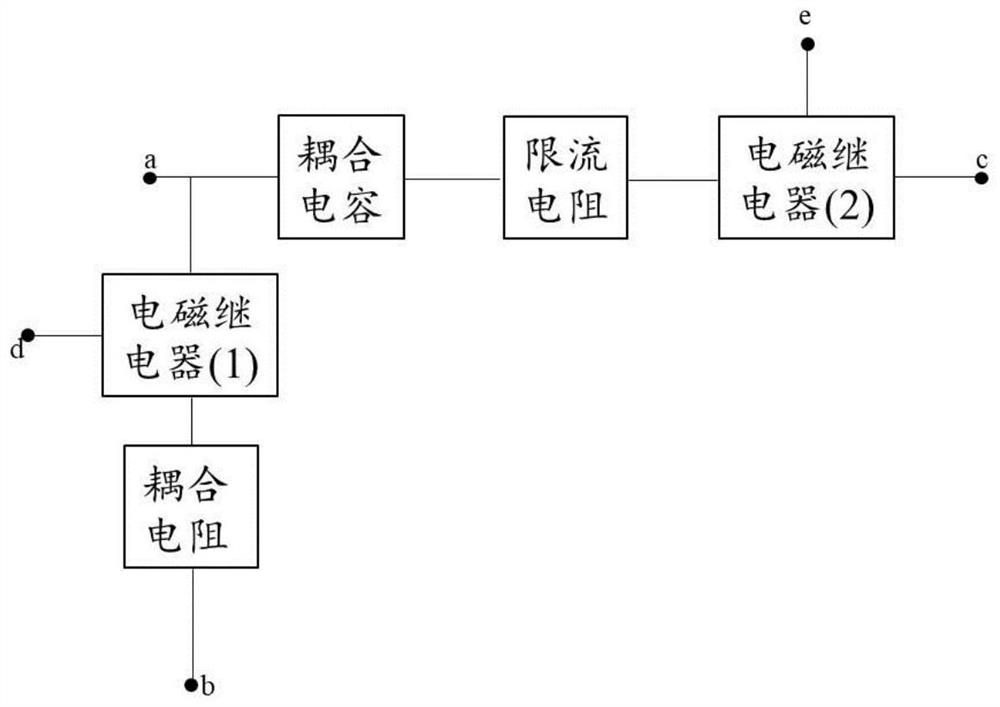

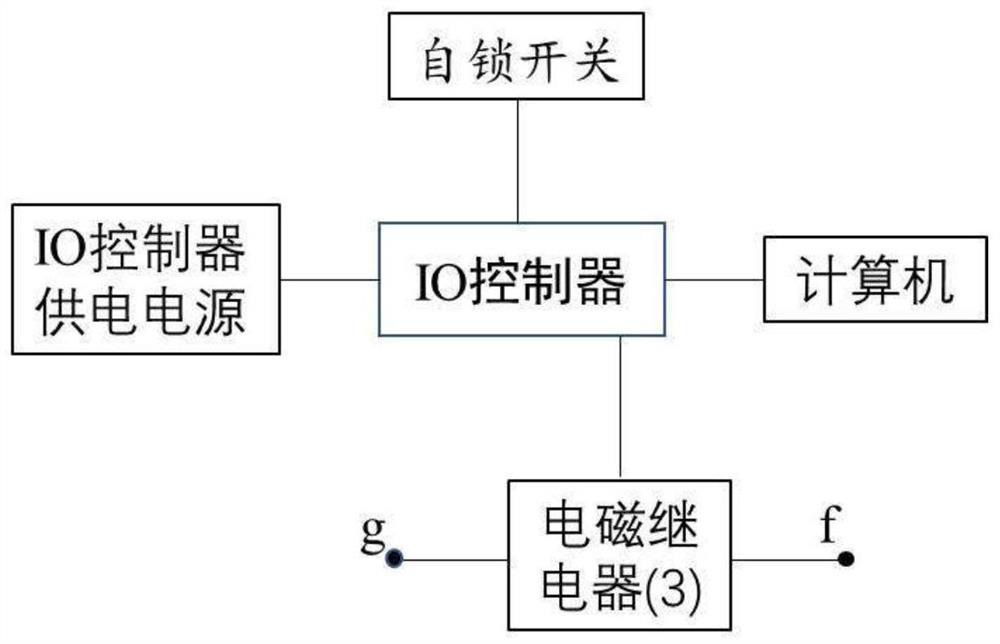

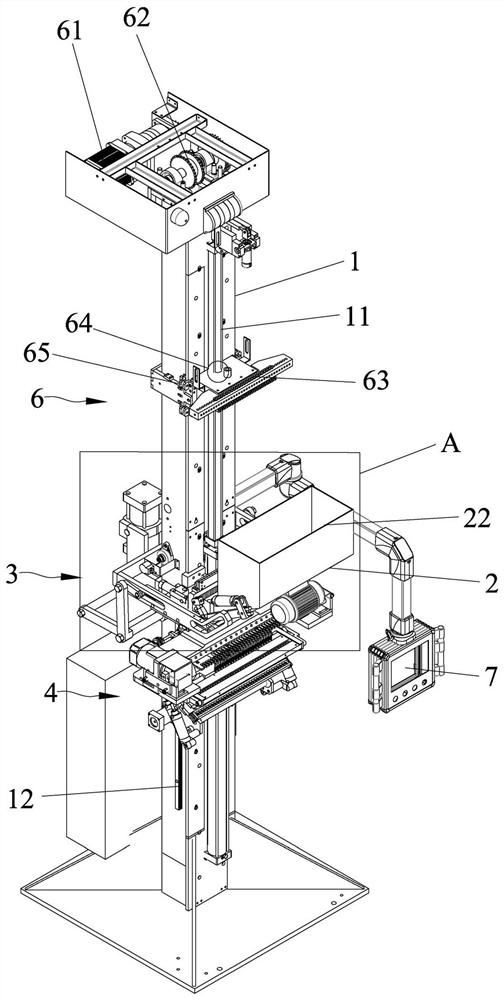

Ultrasonic narrow gap welding system and method for aluminum alloys

ActiveCN112404662BAvoid the adverse effects of thinningIncrease heat input changeElectrode supporting devicesGrinding machinesCapacitanceEngineering

The invention discloses an ultrasonic narrow gap welding system and method for aluminum alloys. The welding system is composed of an ultrasonic frequency excitation power source, a coupled waveform control system, a welding power source, a narrow gap welding torch and a joint control switch. The welding method is as follows: The joint control switch performs asynchronous and precise control of the welding circuit and the ultrasonic circuit according to the set program; the coupling waveform control system uses the current limiting resistor to control the charging and discharging of the coupling capacitor to realize an ultrasonic frequency coupling electric signal with low thermal influence, thereby avoiding the additional heat of the electric coupling. The adverse effect of input on the grain refinement of the weld; by controlling the ultrasonic excitation frequency to ensure that the molten pool is in resonance during welding of each layer, changing the ultrasonic input energy during welding of different layers, realizing the homogenization of the structure of the narrow gap welding joint, and removing the weld Air holes solve the problem of uneven joint performance. At the same time, the swing angle and sidewall dwell time of the traditional swing arc narrow gap welding are reduced, and the welding efficiency is improved.

Owner:JIANGSU UNIV OF SCI & TECH

Dust-free powder filling equipment for tubular object in single protection

ActiveCN112469152AConvenient secondary positioningReduce pollutionIncreasing energy efficiencyHeating element shapesStructural engineeringPosition sensor

The invention discloses dust-free powder filling equipment for a tubular object in single protection. The equipment comprises a cylindrical rack, a powder box, an upper mold, a fixing device, a transition table, a vibration device and a control device, the powder box is used for placing powder for filling the tubular object, the upper mold is provided with a powder guide channel communicated witha discharge port; the fixing device supports the bottom of the tubular object, the transition table is used for limiting the middle of the tubular object, and the powder guide channel is provided witha switch valve. The bottom of a tubular object is placed on the fixing device, then the upper end of the tubular object is positioned through the upper mold, the upper end of the tubular object is connected with the powder guide channel, and the transition table is arranged between the upper mold and the fixing device, so that secondary positioning of the tubular object is facilitated; the amountof powder in the tubular object is controlled by controlling opening and closing of the switch valve through the control device, the volume of the powder in the tubular object can be obtained in timethrough the position sensor, the situation that the powder in the tubular object exceeds the preset filling amount is avoided, and dust pollution is reduced.

Owner:东莞市沃尔隆智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com