High-penetration-rate semiconductor bare chip manual eutectic welding method

A technology of eutectic welding and penetration rate, applied in semiconductor devices, semiconductor/solid-state device manufacturing, welding equipment, etc. Improve production efficiency and process applicability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

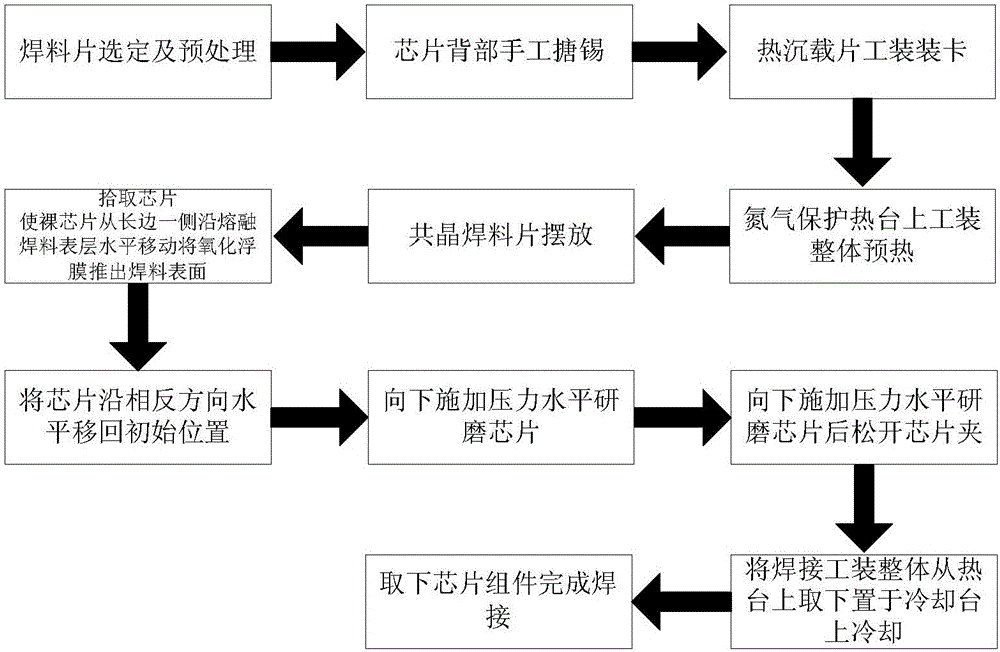

[0025] The technical process of the present invention based on pure manual high penetration rate eutectic welding method is as attached figure 1 shown.

[0026] Analyze the characteristics and application occasions of the bare chip to be soldered, select an alloy solder sheet with a suitable composition, and determine the size and thickness of the solder sheet according to the actual size of the chip.

[0027] According to the different uses of tinning and eutectic soldering on the back of the chip, the alloy solder sheet is reduced and cut according to the approximate shape of the chip (the size of the soldering sheet for tinning is 70% to 80% of the chip area, and the size of the eutectic soldering sheet is the chip area 85% to 90% of that).

[0028] The oxide film produced by long-term placement of chips and sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com