Preparation method for micro circuit flexible circuit board based on micro-nano imprinting technology

A flexible circuit board, micro-nano technology, applied in the direction of printed circuit manufacturing, printed circuit, and the formation of electrical connection of printed components, can solve the problems of complex circuit board manufacturing process and high cost, reduce line width, not easy to scratch, The effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Such as Figure 1 to Figure 7 As shown, this embodiment provides a method for preparing a flexible circuit board with fine circuits based on micro-nano imprinting technology, which at least includes the following steps:

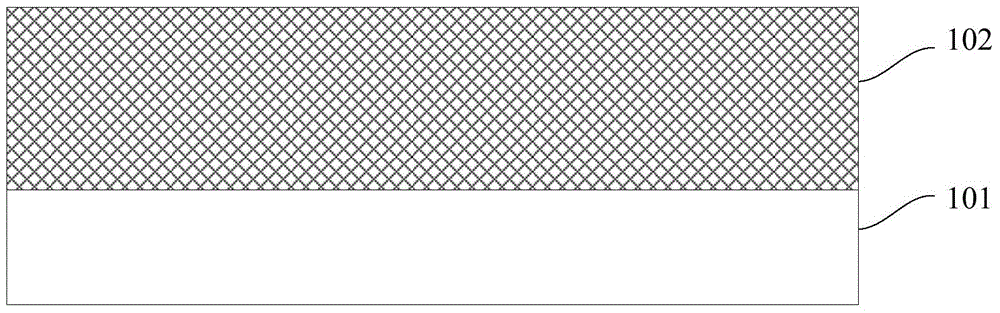

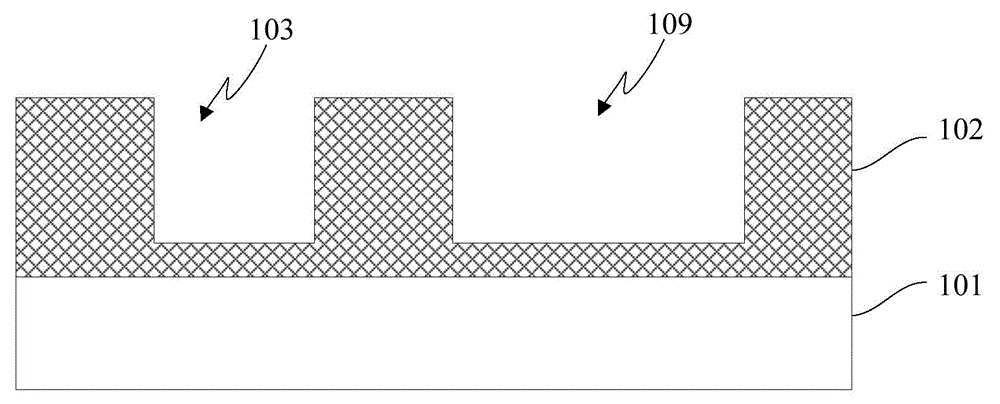

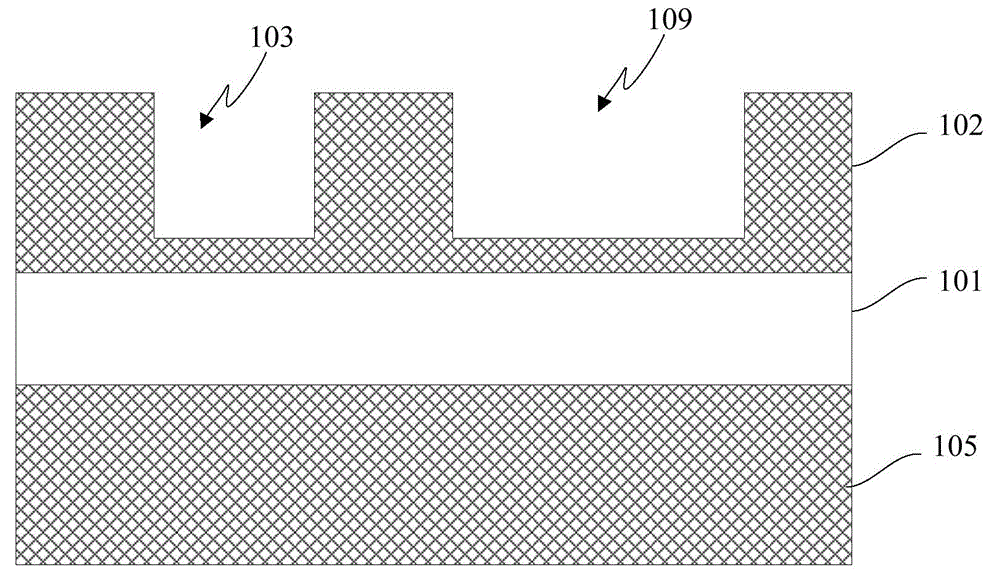

[0058] Such as Figure 1 ~ Figure 2 As shown, step 1) is performed first, providing a substrate 101, forming a first flexible material layer 102 on the first surface of the substrate 101, and forming a plurality of first groove structures 103 on the surface of the first flexible material layer 102 and several first hole structures 109;

[0059] As an example, the substrate 101 includes a PET flexible substrate and a PI flexible substrate. In this embodiment, the substrate is a PET flexible substrate.

[0060] As an example, the first flexible material layer 102 is a UV adhesive layer. In addition, it should be noted that UV glue is also called photosensitive glue and ultraviolet curing glue, which can be used as glue for paints, coatings, inks, etc. ...

Embodiment 2

[0076] Such as Figure 8 ~ Figure 10 As shown, this embodiment provides a method for preparing a flexible circuit board with fine circuits based on micro-nano imprinting technology, which at least includes the following steps:

[0077] Such as Figure 8 ~ Figure 9 As shown, step 1) is first performed, providing a substrate 201, forming a flexible material layer 202 on the surface of the substrate 201, and forming a plurality of groove structures 203 on the surface of the flexible material layer 202;

[0078] Such as Figure 10 As shown, then step 2) is performed to form conductive lines 204 in each groove structure 203 .

[0079] As an example, the groove structure has a depth of 30 microns to 50 microns, a width of 2 microns to 40 microns, and a cross-sectional shape of a trapezoidal structure with side walls having a draft angle of 1 to 3 degrees.

[0080] As an example, the groove structure is prepared by mold embossing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com