Shell embossing device for electronic product production

An electronic product and embossing technology, which is applied in the fields of decorative arts, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of low production efficiency and inability to produce multiple embossed shells at the same time, so as to improve efficiency and improve Processing suitability, effect of improving embossing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

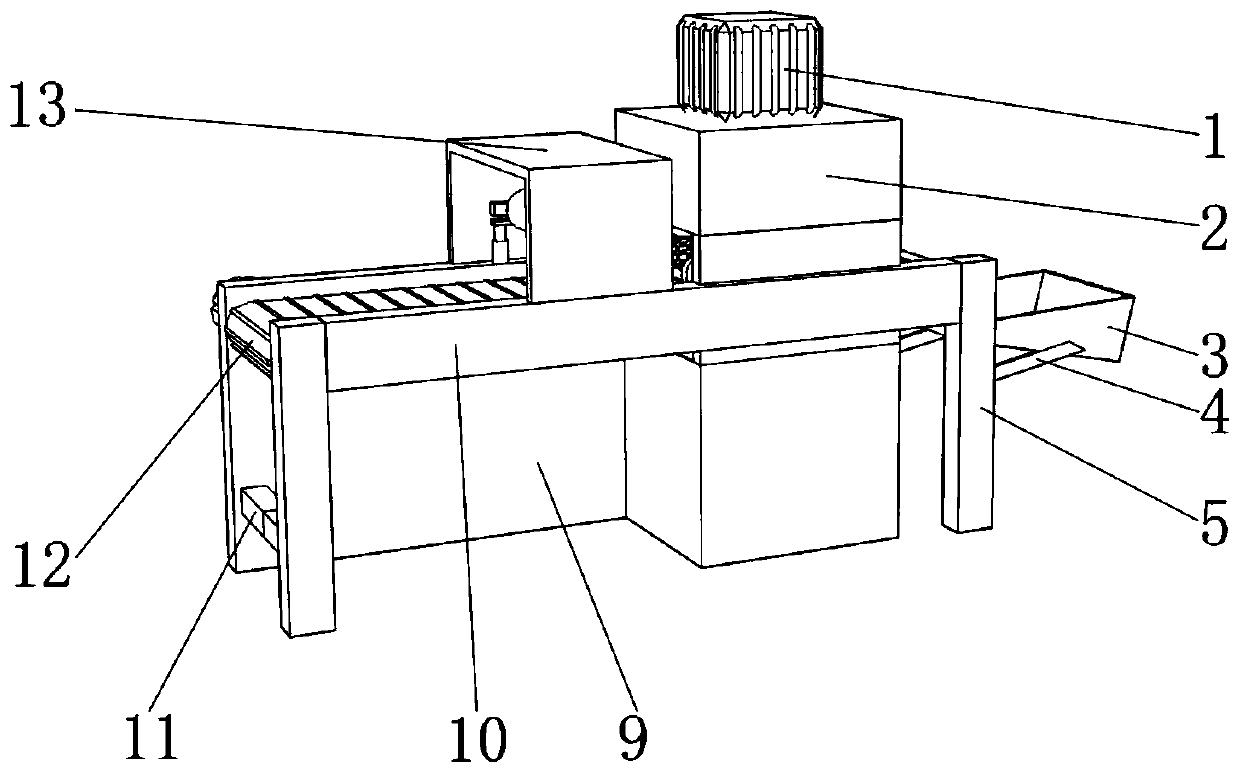

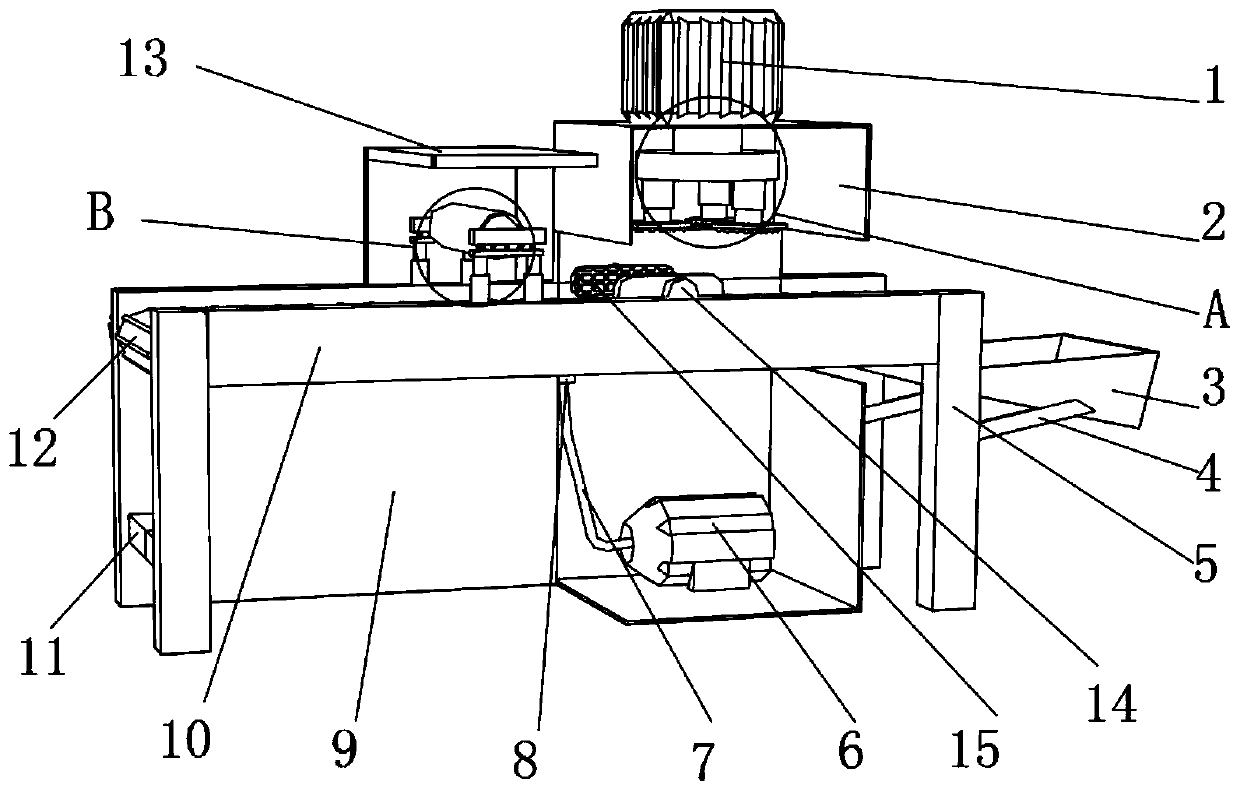

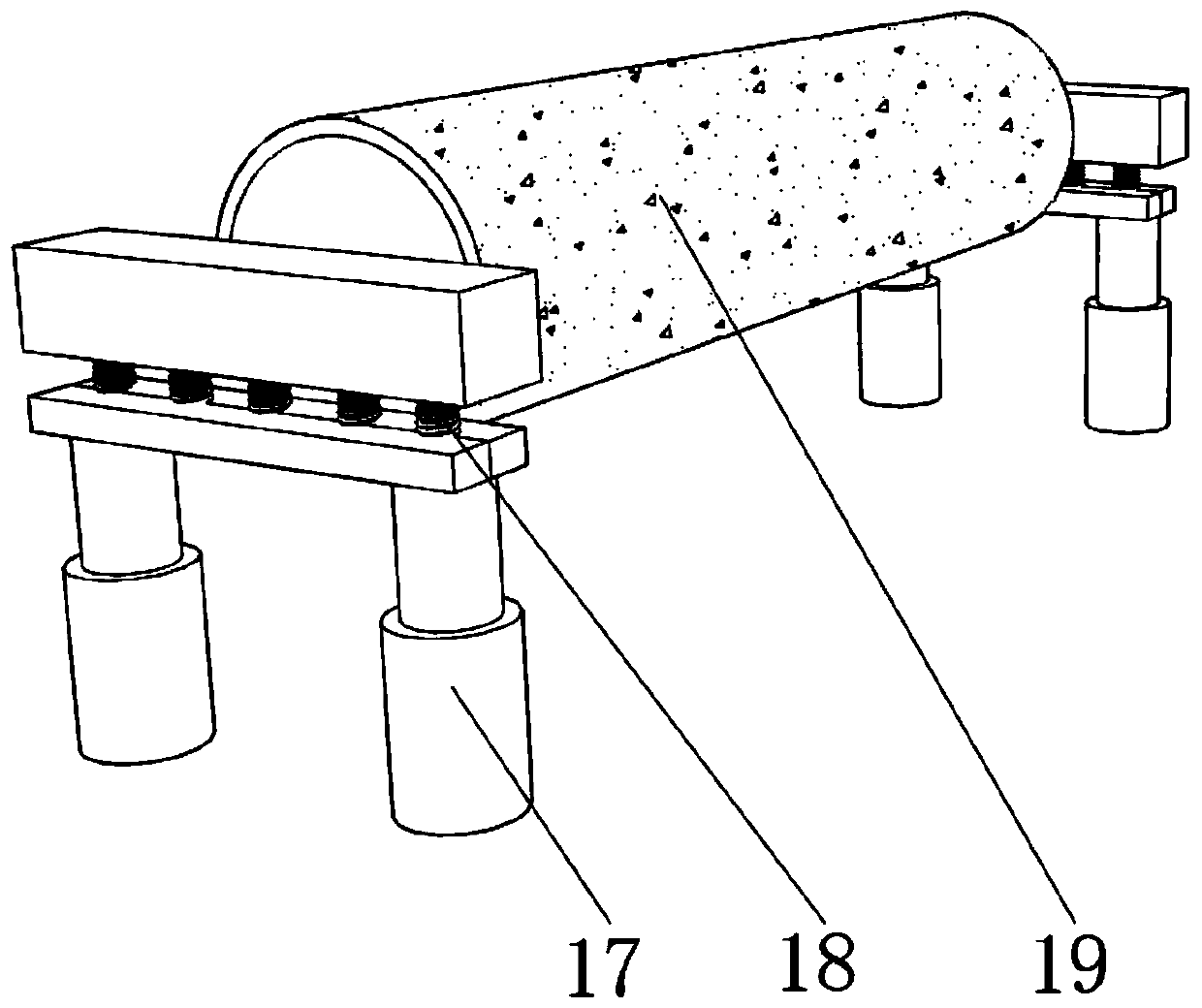

[0032] Reference Figure 1-5 , A shell embossing device for the production of electronic products, comprising a bearing plate 9, a supporting leg 5, a baffle 10, a first box body 2 and a second box body 13, and the bearing plate 9 and the supporting leg 5 are fixedly connected with each other. The rod 11, the load-bearing plate 9, the supporting leg 5 and the baffle 10 are fixedly installed to form a mounting frame. The first box body 2 and the second box body 13 are fixedly installed on the mounting frame, and the top of the outer wall of the first box body 2 is fixedly connected with Stepping motor 1, and the output end of the stepping motor 1 is fixedly connected with a printing assembly. The printing assembly includes a rotating shaft 21. The top end of the rotating shaft 21 and the bottom end of the output shaft of the stepping motor 1 are connected by a coupling. The bottom of the rotating shaft 21 is open There is a groove, and a plurality of pressure rods 22 are fixedly...

Embodiment 2

[0036] Reference Image 6 , A shell embossing device for the production of electronic products. Compared with the embodiment 1, the main difference of this embodiment is that in this embodiment, an observation port 23 is opened on one side of the first box body 2 so that the first box body 2 can be observed. The internal conditions not only improve the quality of embossing, but also avoid safety accidents.

[0037] The working principle of this embodiment: When it is necessary to check the embossing condition of the product shell in the first box 2, it can be observed through the observation port 23.

[0038] The electrical components appearing in this article are all connected to the external main controller and 220V mains power, and the main controller can be a computer and other conventional known equipment that controls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com