Bearing cleaning machine using bubble enhancement reaction

A technology for enhancing reaction and bearing cleaning, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc. Promotes irregular rotation, improves cleaning, and promotes shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

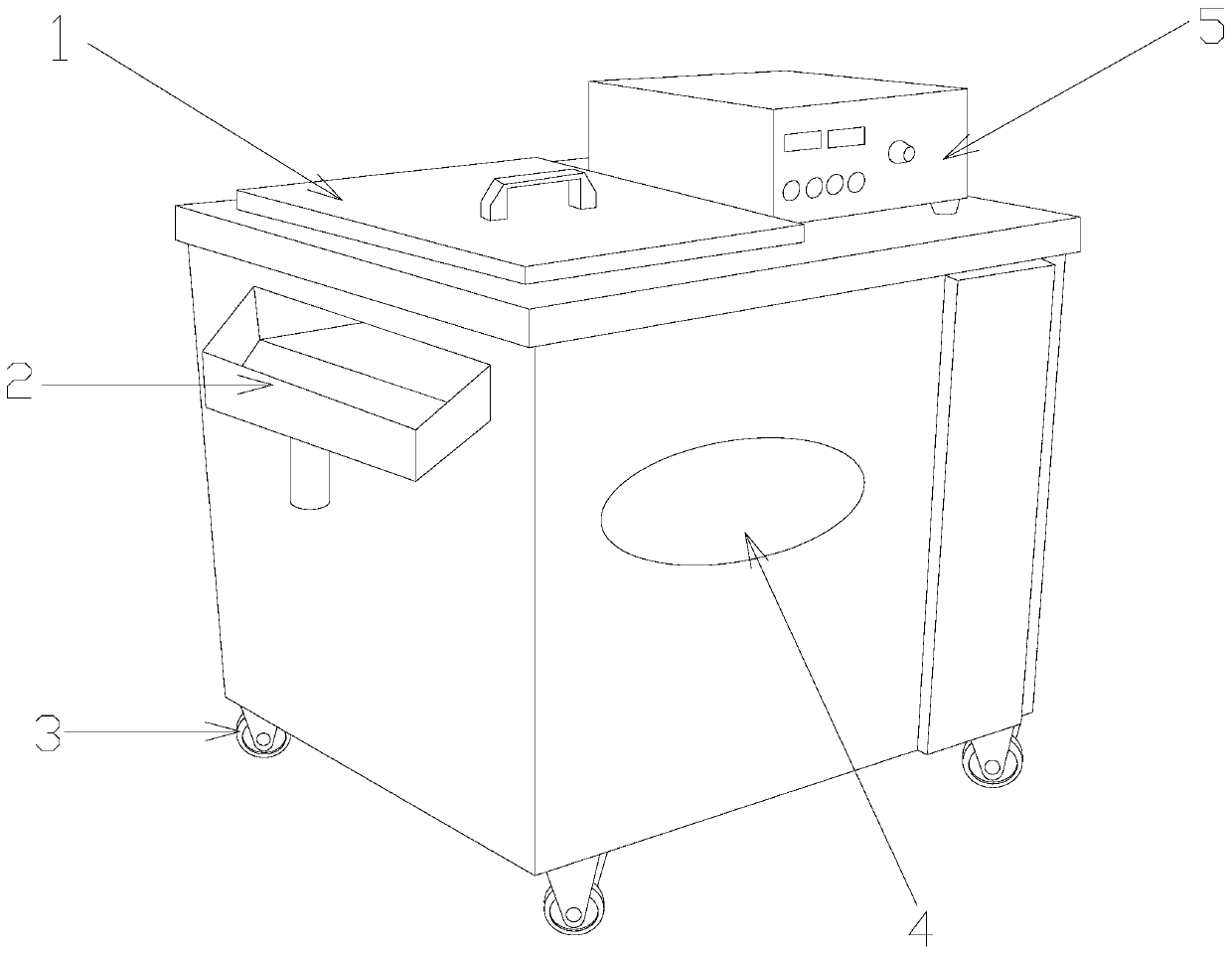

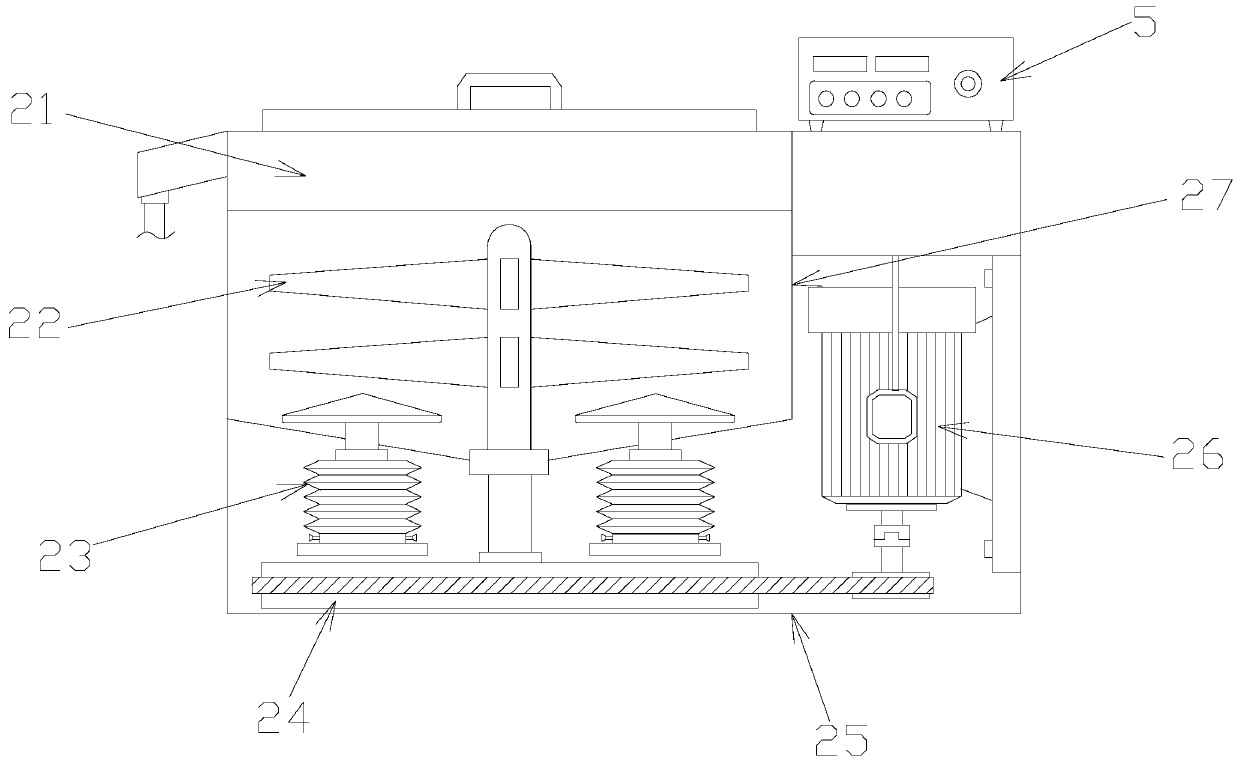

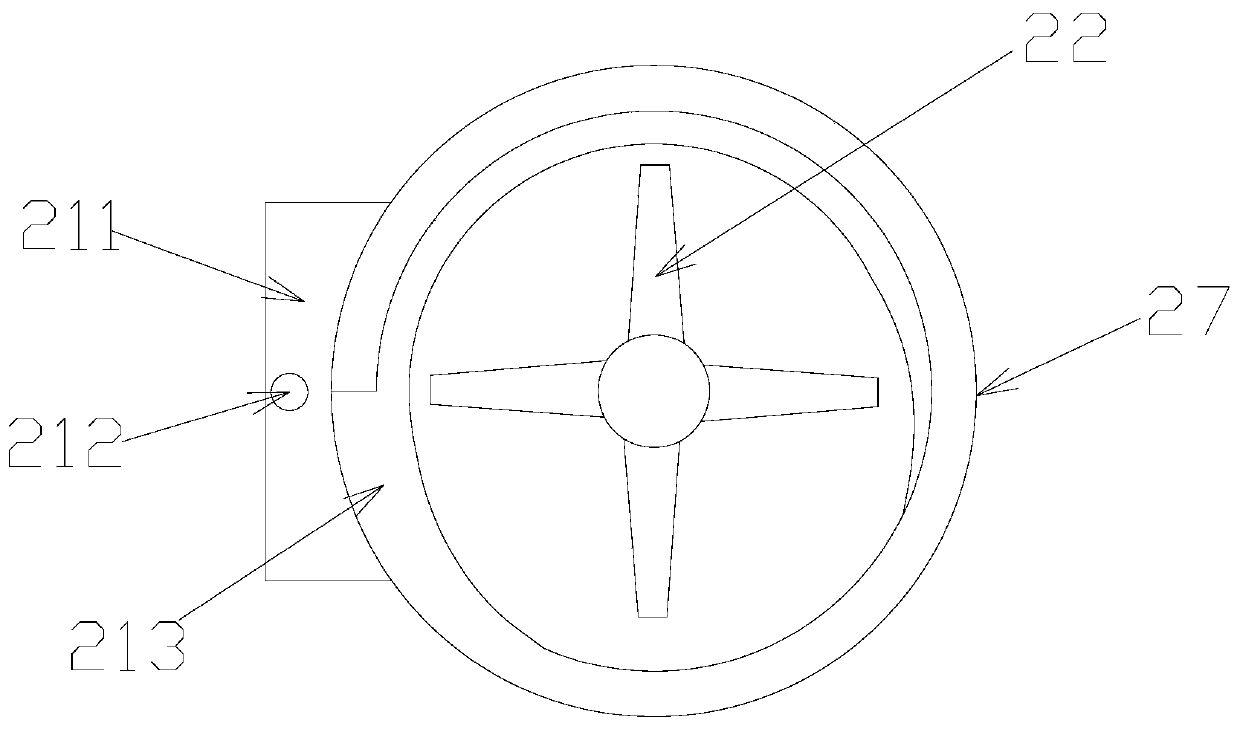

[0025] see Figure 1-Figure 2 , the present invention provides a bearing cleaning machine utilizing air bubbles to enhance the reaction, the structure of which includes a splash-proof sealing cover 1, a cleaning machine main body 2, a universal moving wheel 3, a product nameplate 4, and a cleaning machine controller 5. The cleaning machine The main body 2 is a hollow rectangular structure, the top of the universal moving wheel 3 and the four corners of the bottom surface of the washing machine main body 2 are fixed together by bolts, and the back of the splash-proof sealing cover 1 is buckled together with the upper surface of the washing machine main body 2 , the back of the product nameplate 4 is connected to the front of the washing machine main body 2 through glue, and the washing machine controller 5 is installed on the right side of the upper surface of the washing machine main body 2 and is electrically connected with the washing machine main body 2; the washing machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com