Patents

Literature

54results about How to "Improve embossing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

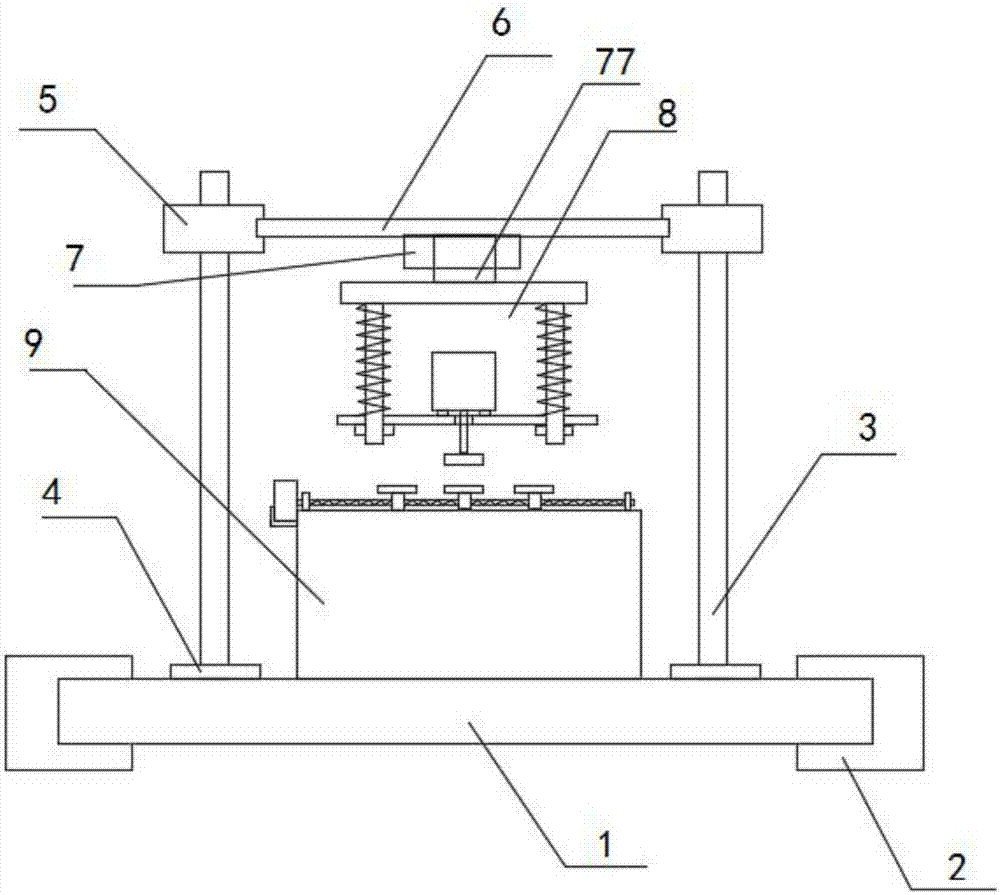

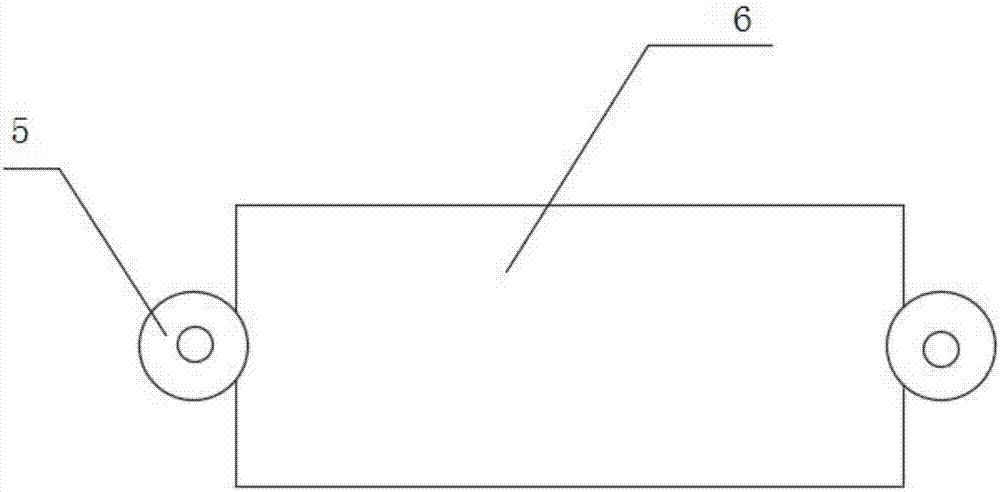

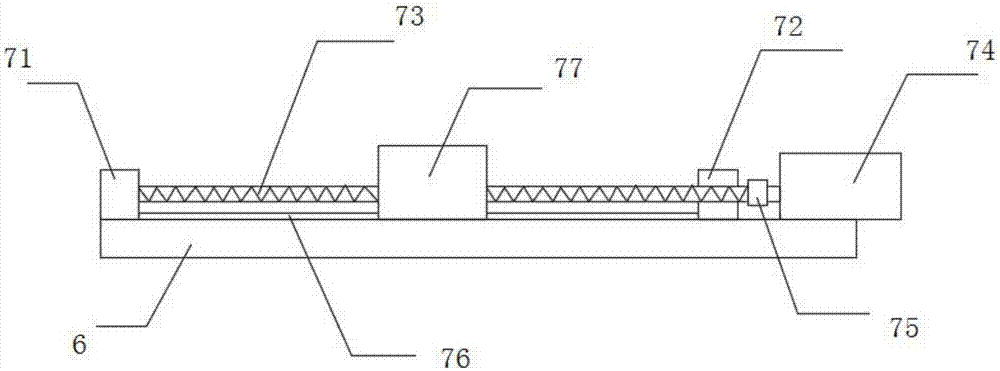

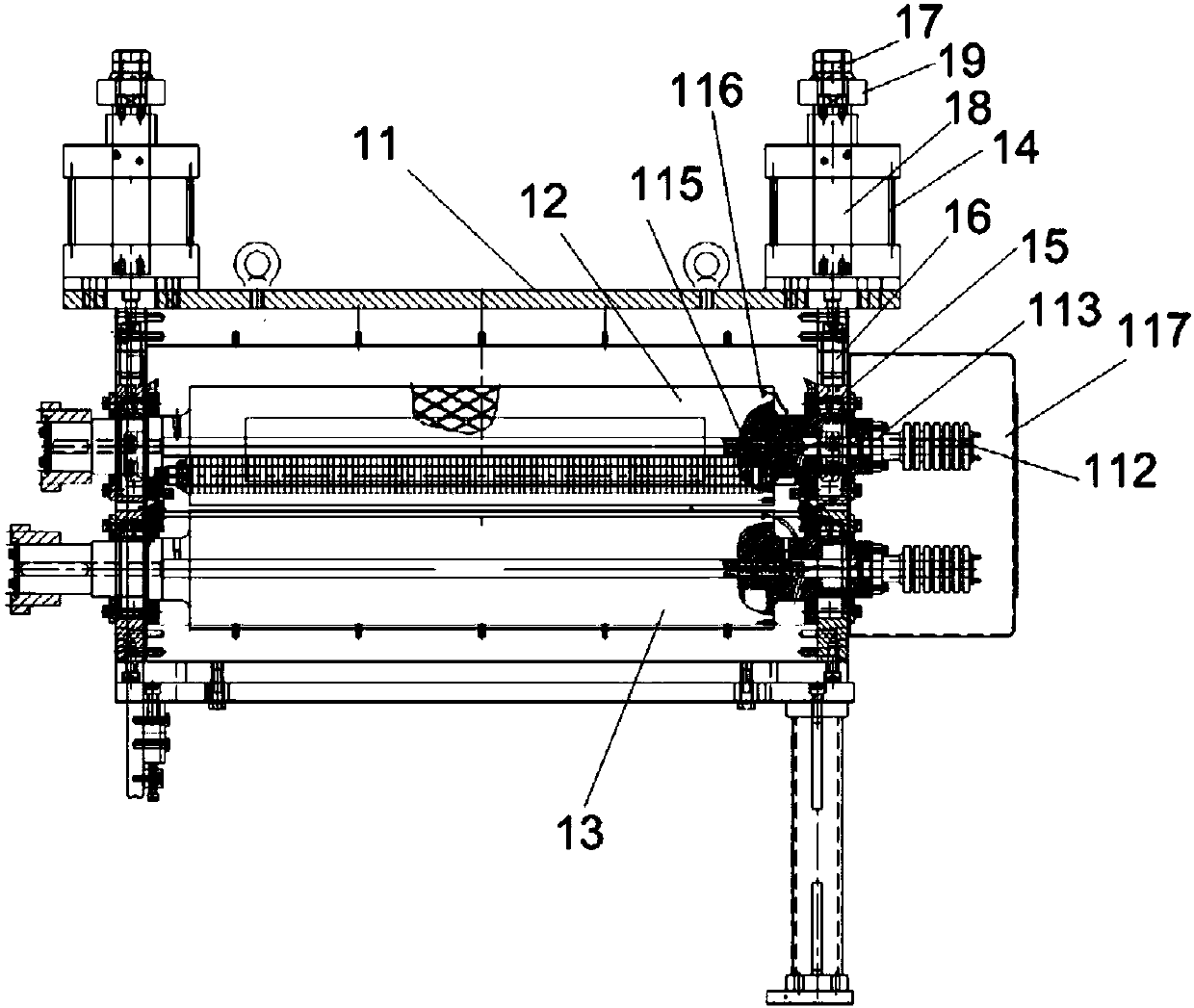

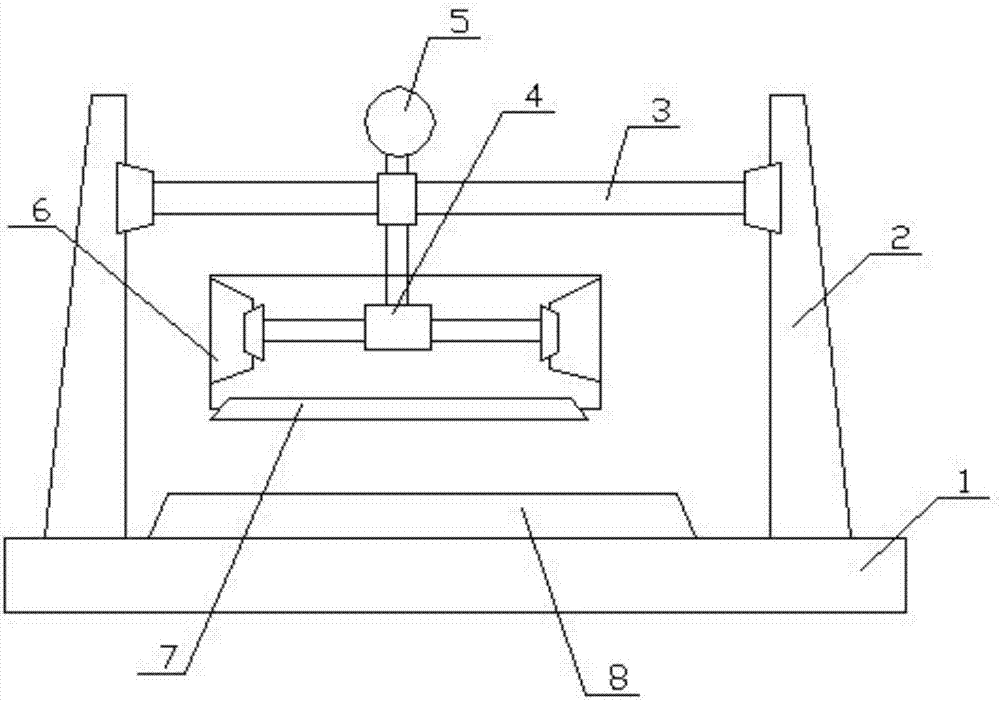

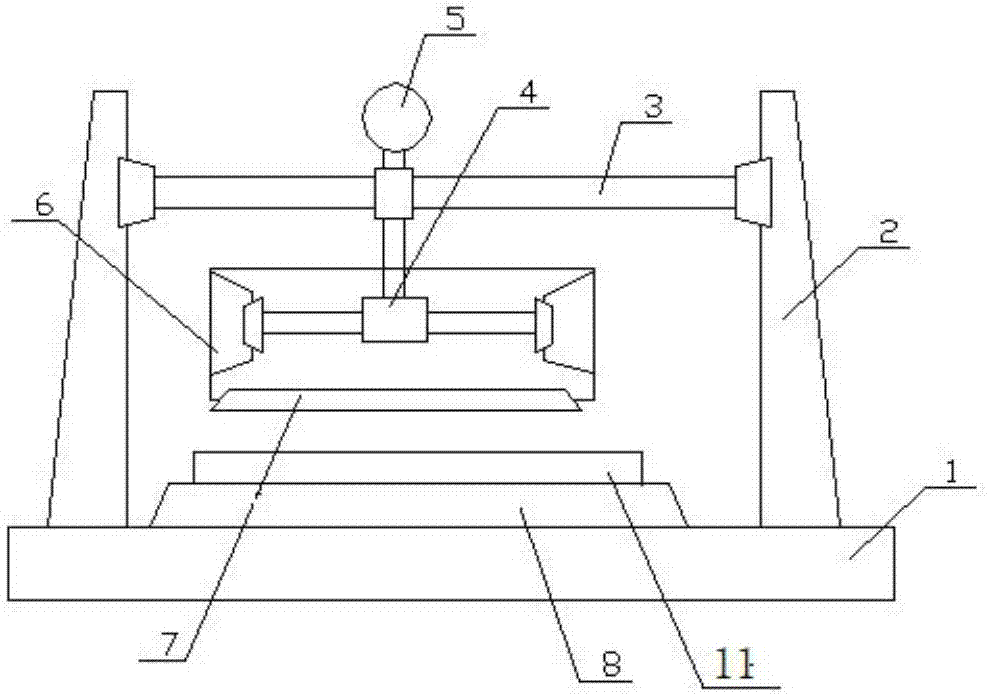

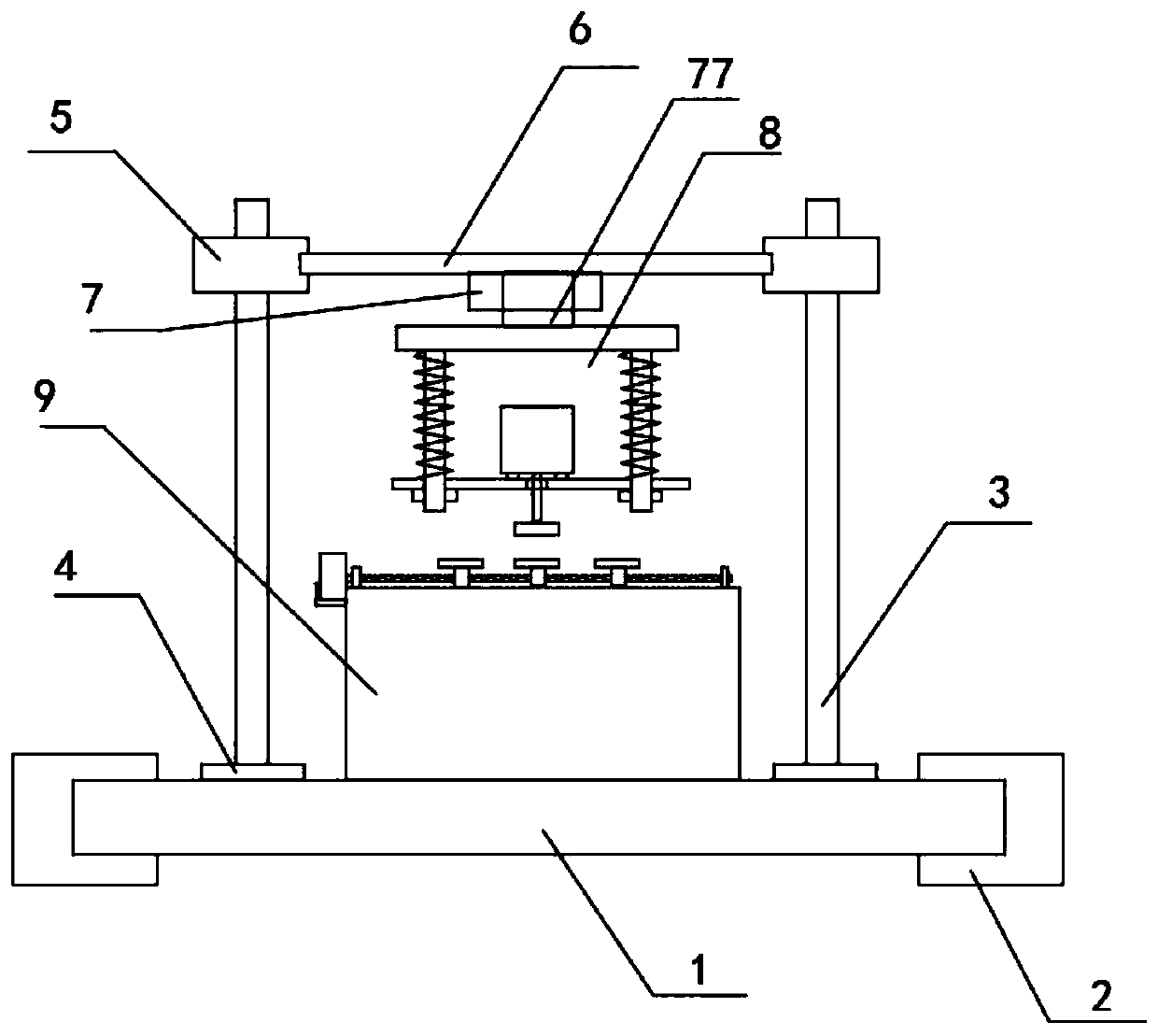

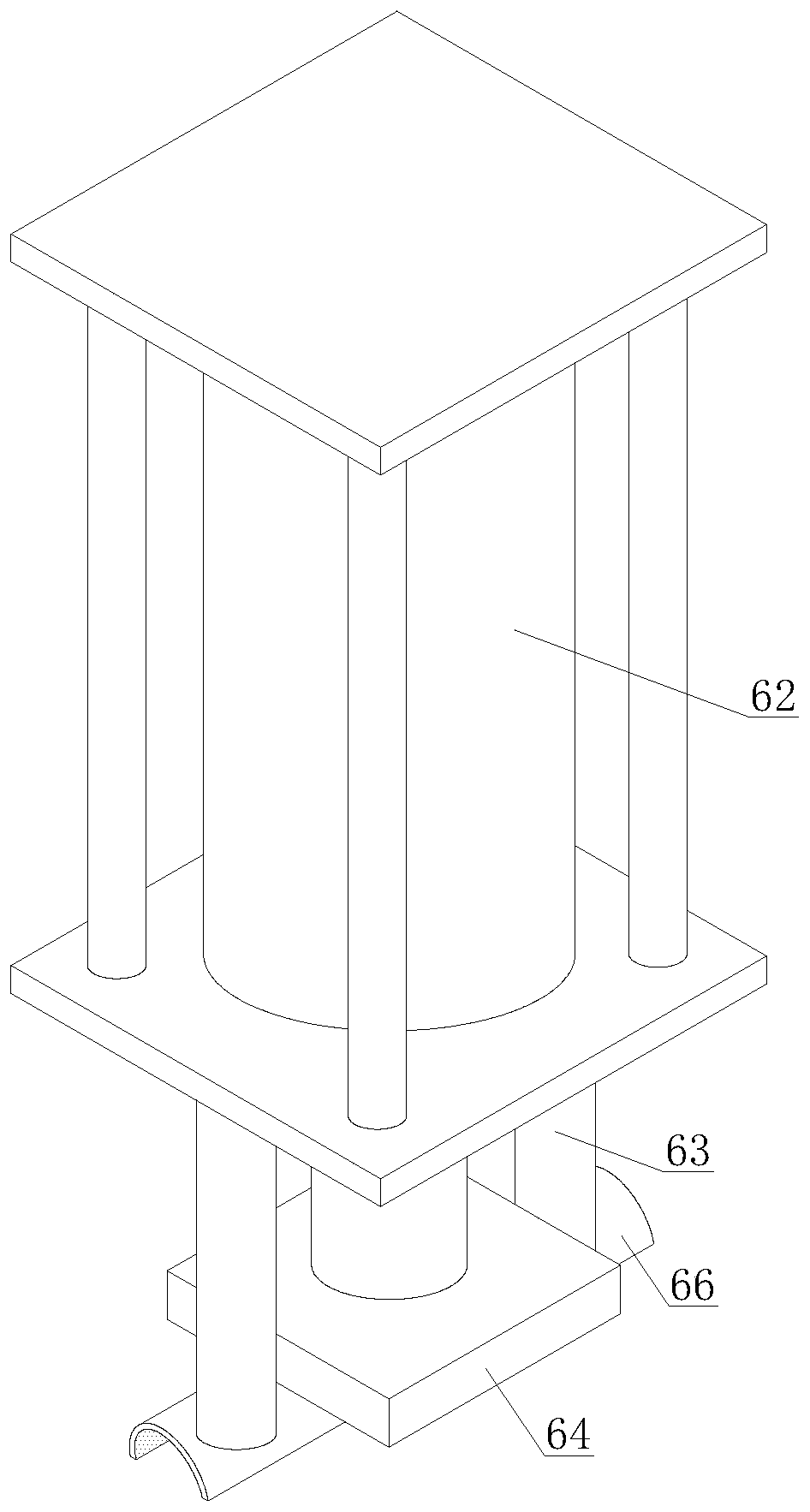

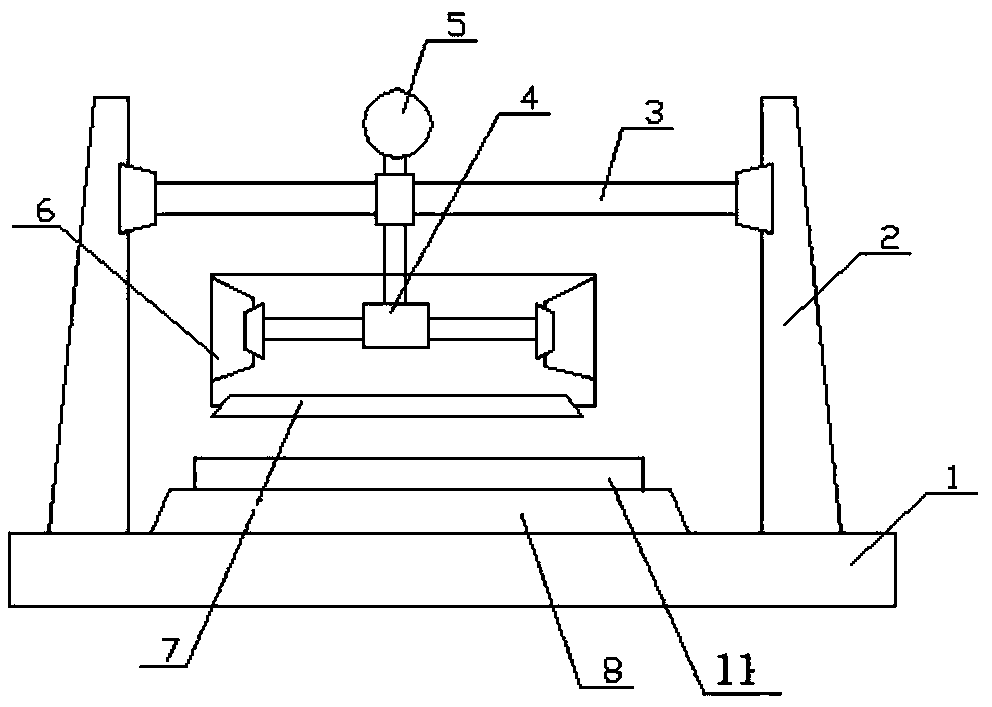

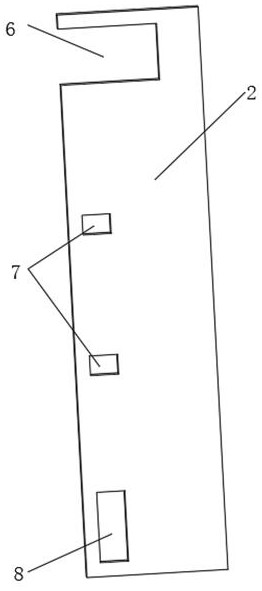

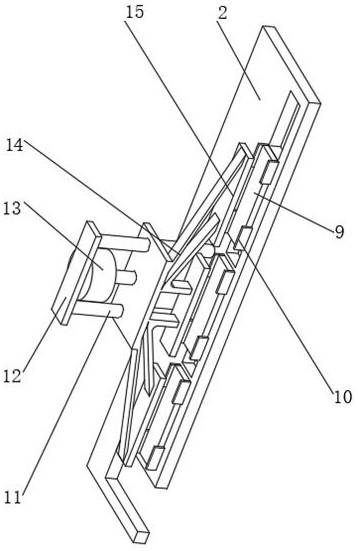

Multi-station button embossing device

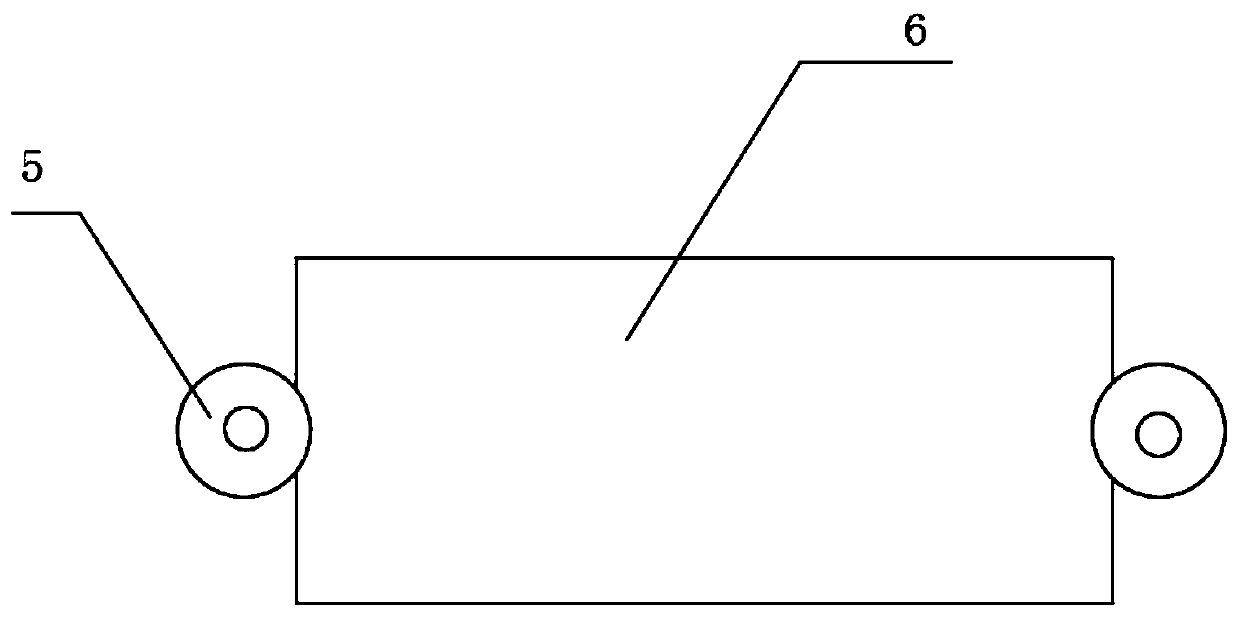

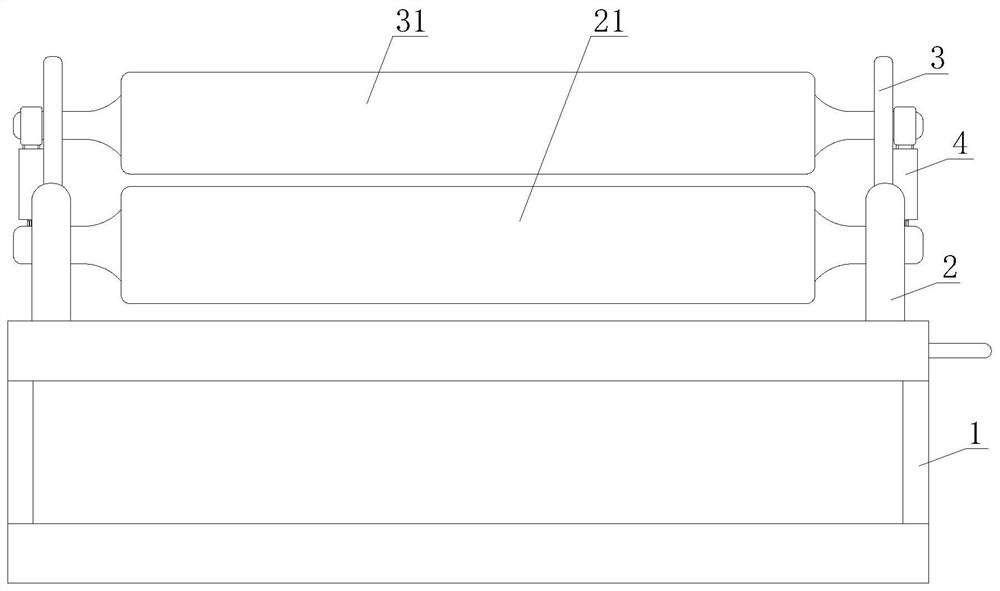

The invention provides a multi-station button embossing device. The device comprises a base plate, supporting parts are fixed to the left side and the right side of the base plate correspondingly, supporting shafts are rotatably connected to the left side and the right side of the surface of the base plate, the bottoms and the tops of the supporting shafts are each of a thread structure, the supporting shafts are located on the inner sides of the supporting parts, shaft sleeves are rotatably connected to the contact face ends of the supporting shafts and the base plate, cylinders are rotatably connected to the upper ends of the supporting shafts, each cylinder is provided with a vertically through round through hole, the inner walls of the round through holes are of thread structures, annular grooves are formed in the side faces of the cylinders, inserting parts are arranged on the left side and the right side of a fixed table plate in a protruding manner, make contact with the annular grooves and enable the fixed table plate to be fixed to the cylinders, a moving assembly is arranged at the lower end of the fixed table plate, an embossing assembly is connected to the lower end of the moving assembly, and an adjustable button fixing assembly is fixed to the upper end of the middle of the base plate.

Owner:嘉善梦溪服饰辅料厂(普通合伙)

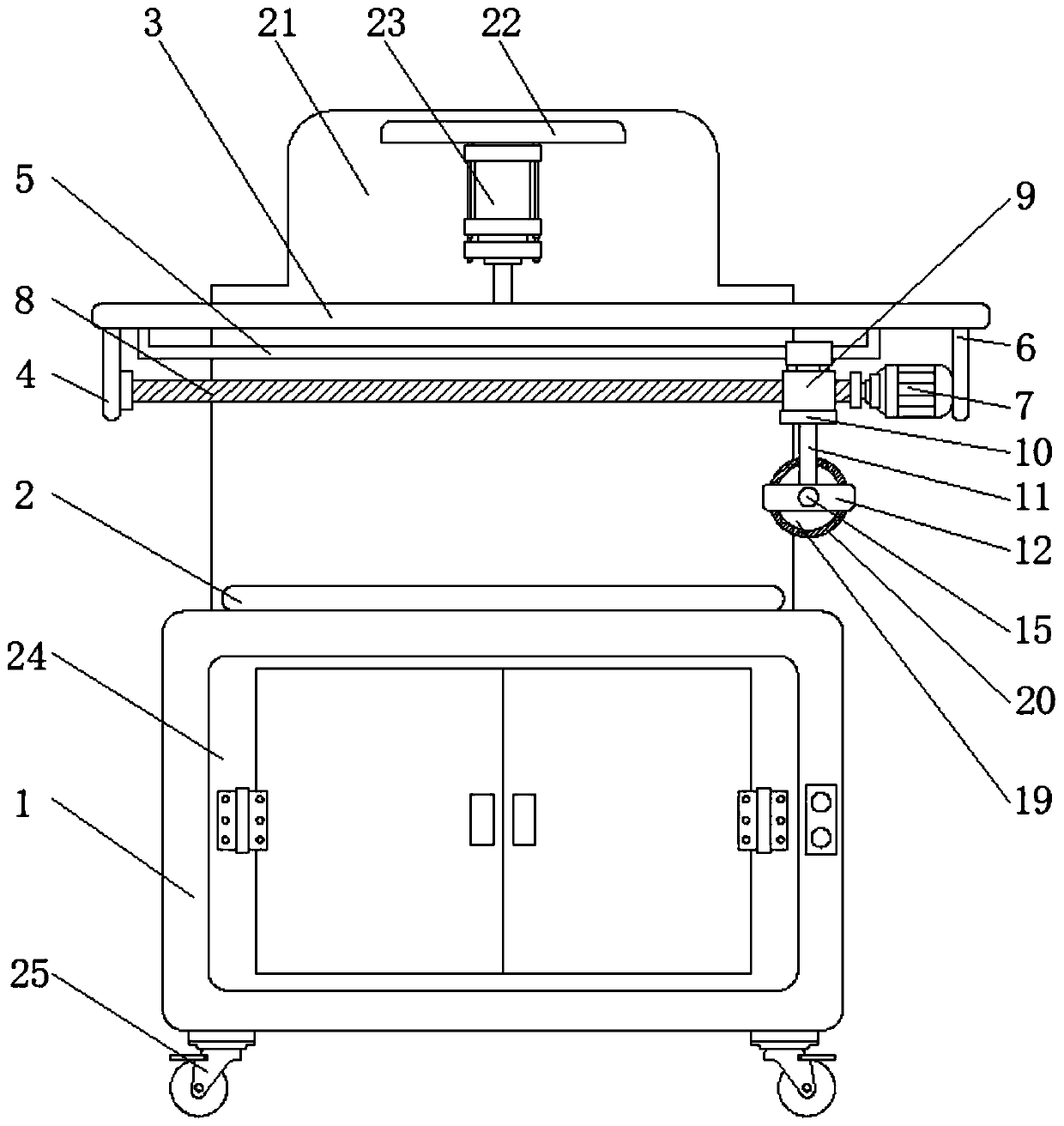

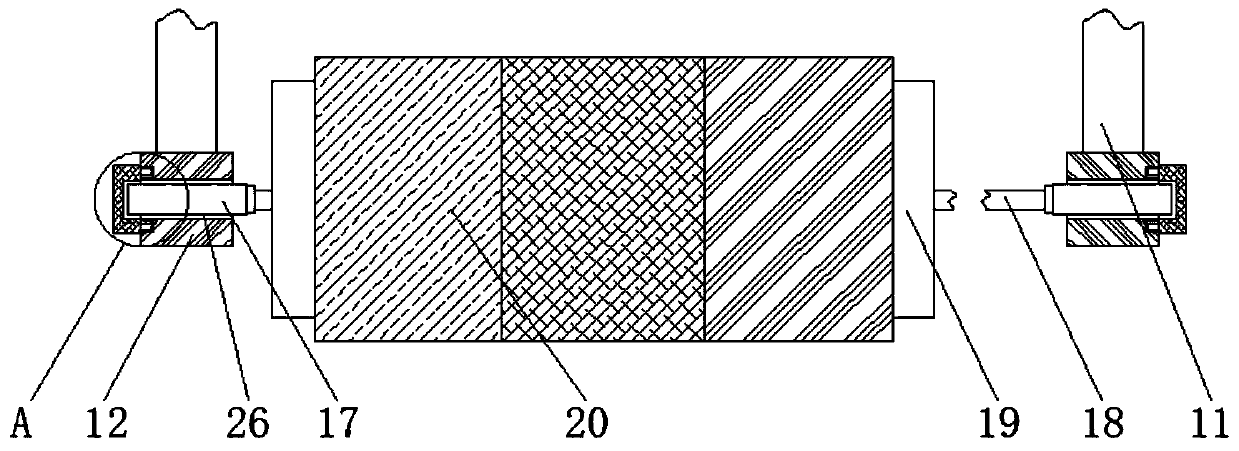

Shell embossing device for electronic product production

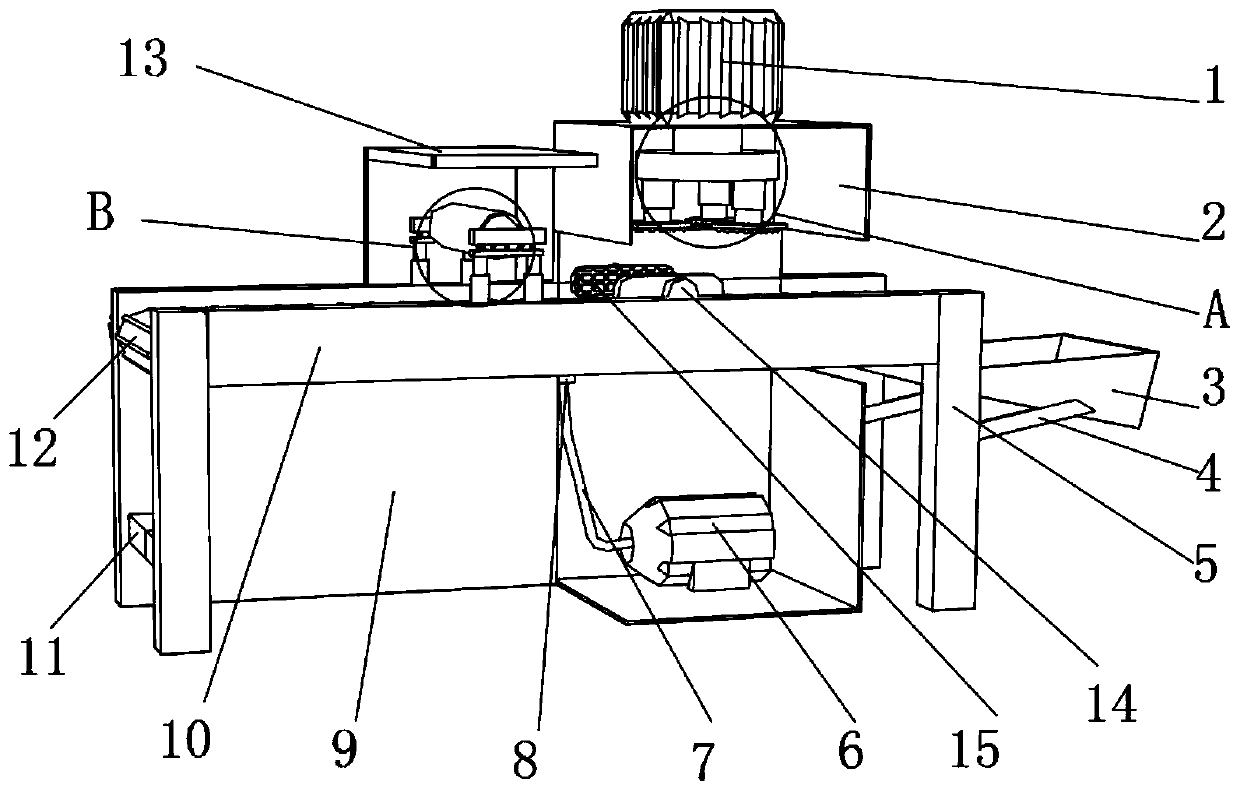

InactiveCN110813825AImprove cleaning effectImprove processing suitabilityCleaning using toolsEmbossing decorationsElectric machineryProduct processing

The invention relates to the technical field of electronic product processing, and discloses a shell embossing device for electronic product production. The shell embossing device comprises a bearingplate, supporting legs, a baffle, a first box body and a second box body, wherein the bearing plate, the supporting legs and the baffle are fixedly mounted each another to form a mounting frame, the first box body and the second box body are fixedly mounted on the mounting frame, the top end of the outer wall of the first box body is fixedly connected with a stepping motor, the output end of the stepping motor is fixedly connected with a printing assembly, the printing assembly comprises a rotating shaft, and the top end of the rotating shaft is connected with the bottom end of the output shaft of the stepping motor through a coupler. According to the shell embossing device, a product shell is cleaned by a dust removing rubber roller before embossing, and springs enable the dust removing rubber roller to automatically and finely adjust the position, so that the dust removing rubber roller makes contact with the upper surface of raw materials more closely, and the cleaning effect of thedevice is improved; and multiple embossing heads are arranged, and the multiple embossing heads can work at the same time, so that produced shell flower types are increased, and the machining applicability is improved.

Owner:南京市旗心电子科技有限公司

Shell embossing device for electronic product production

The invention relates to the technical field of electronic product production equipment, and discloses a shell embossing device for electronic product production. The device comprises a workbench andan embossing device body, wherein the output end of the embossing device body is fixedly connected with an embossing head through a bolt; the upper surface of the workbench is fixedly connected with afixing frame; the inner wall of the bottom end of the fixing frame is slidably connected with symmetrically distributed clamping plates; the outer walls of the two clamping plates are sleeved with astorage plate together; openings matched with the clamping plates are formed in the two side walls of the storage plate; a plurality of telescopic rods are fixedly connected to the lower surface of the storage plate; and the bottom ends of the multiple telescopic rods are fixedly connected with the inner wall of the bottom end of the fixing frame. According to the shell embossing device, a shell can be automatically fixed with less time and labor, so that the labor intensity of workers is relieved, the embossing efficiency of the shell of an electronic product is improved, the moving efficiency of the embossing device for electronic product production can be effectively improved, less time and labor are needed in the moving process, and accordingly the waste of labor is avoided.

Owner:马鞍山小古精密机电科技有限公司

Stainless steel plate surface embossing treatment process

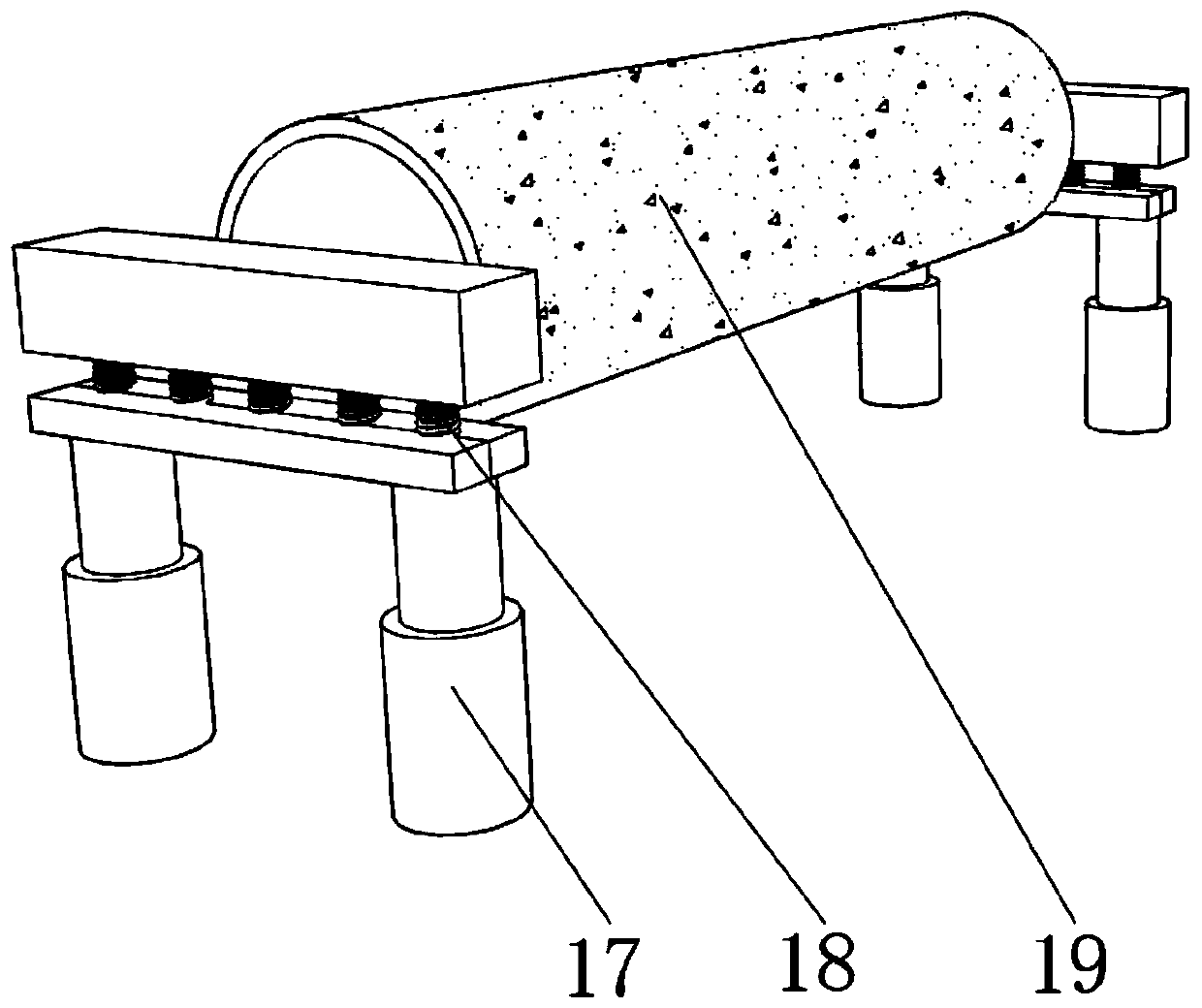

InactiveCN112026419ASolve the problem of uneven patternSolve the effect of wasting energyEmbossing decorationsSS - Stainless steelMaterials science

The invention discloses a stainless steel plate surface embossing treatment process, and belongs to the technical field of stainless steel plate surface embossing. The stainless steel plate surface embossing treatment process comprises a frame, an embossing mechanism, a limiting mechanism and a driving mechanism, a sliding rail is fixedly installed at the upper end of the frame, the embossing mechanism is slidably connected to the upper end of the frame through the sliding rail, and the limiting mechanism is slidably connected to the outer wall of the frame; the driving mechanism is slidably connected to the inner wall of the frame, one embossing roller is adopted to cooperate with the two auxiliary rollers, a hydraulic system is used for cooperating with a locking mechanism to adjust embossing depths, thus, the problem that due to adjustment of hand wheels, the feeding amounts of the two hand wheels are not uniform, and consequently the embossing depths are different is solved, and astainless steel plate is embossed through two-way symmetry; and the auxiliary rollers are the same as the embossing roller in linear speed and opposite to the embossing roller in direction through a transmission mechanism, and the problems that the stainless steel embossing plate and the embossing roller slide, the embossing edge is fuzzy, and even the wire drawing phenomenon occurs on the surfaceof the stainless steel plate are solved.

Owner:黄涛

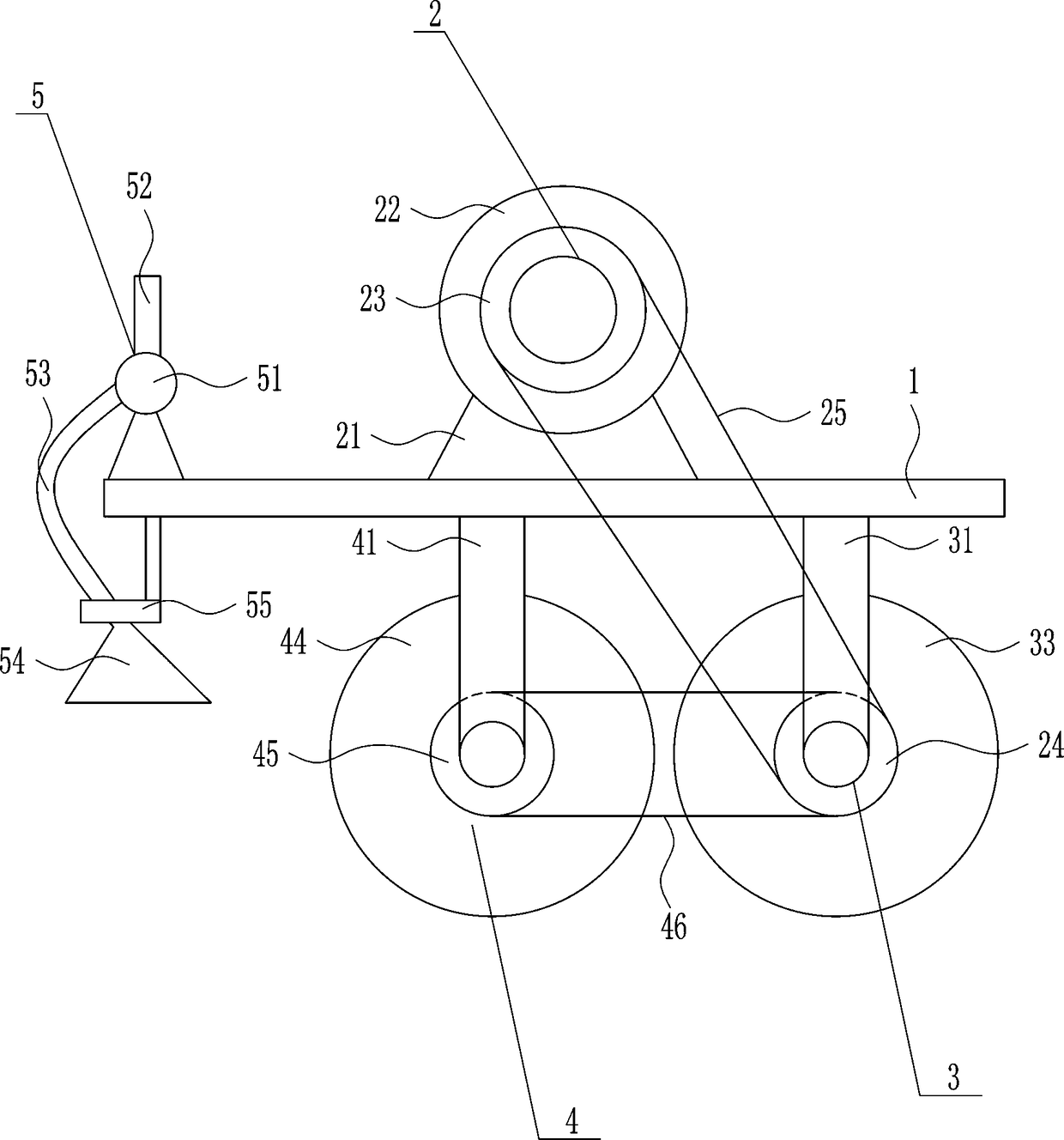

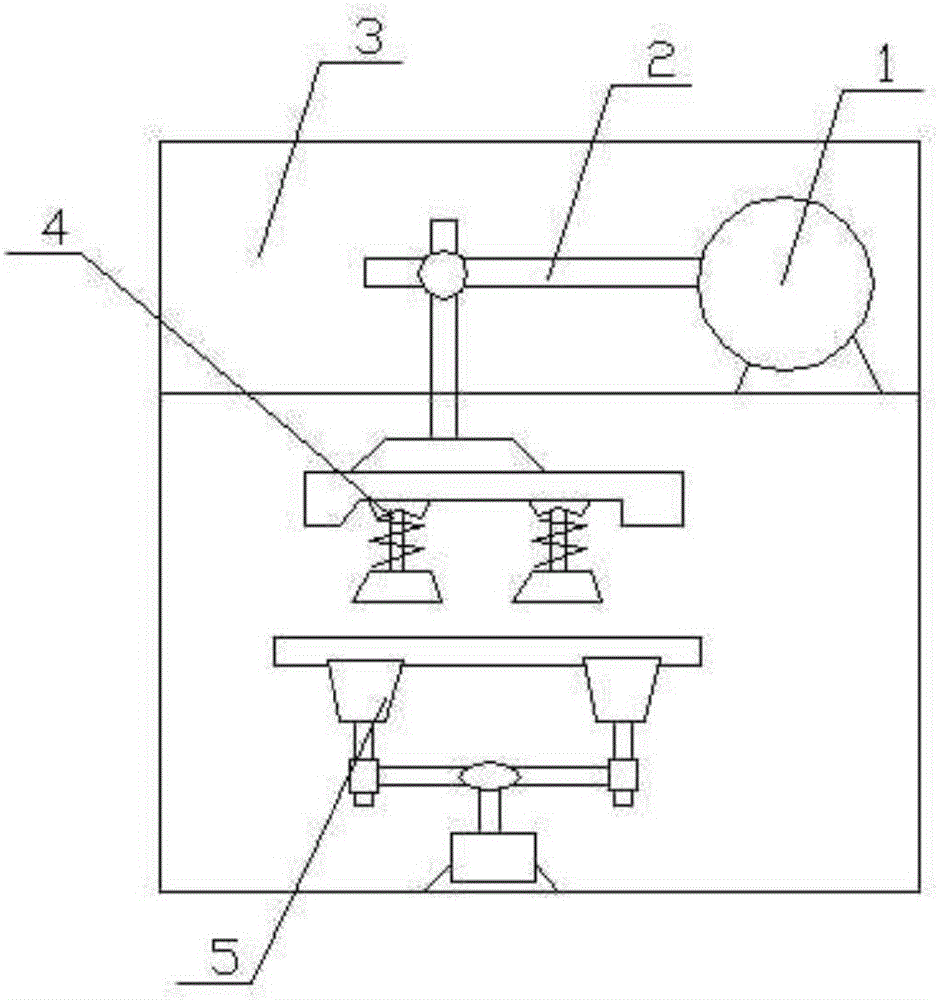

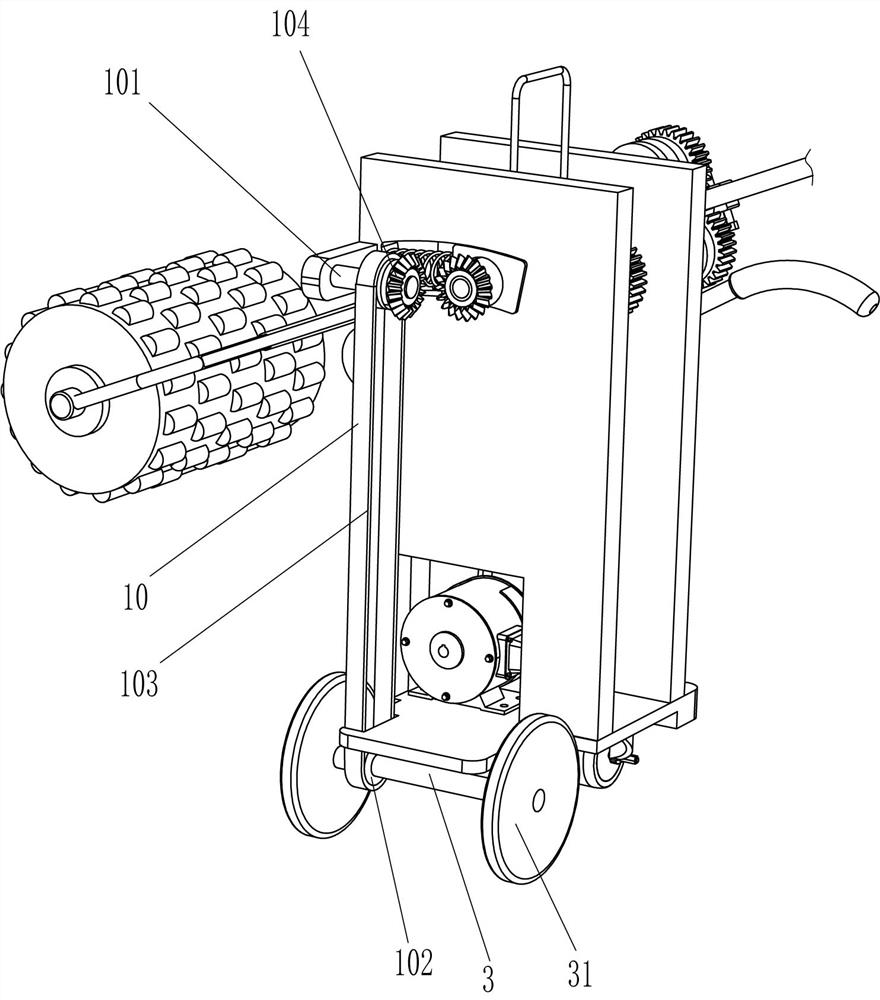

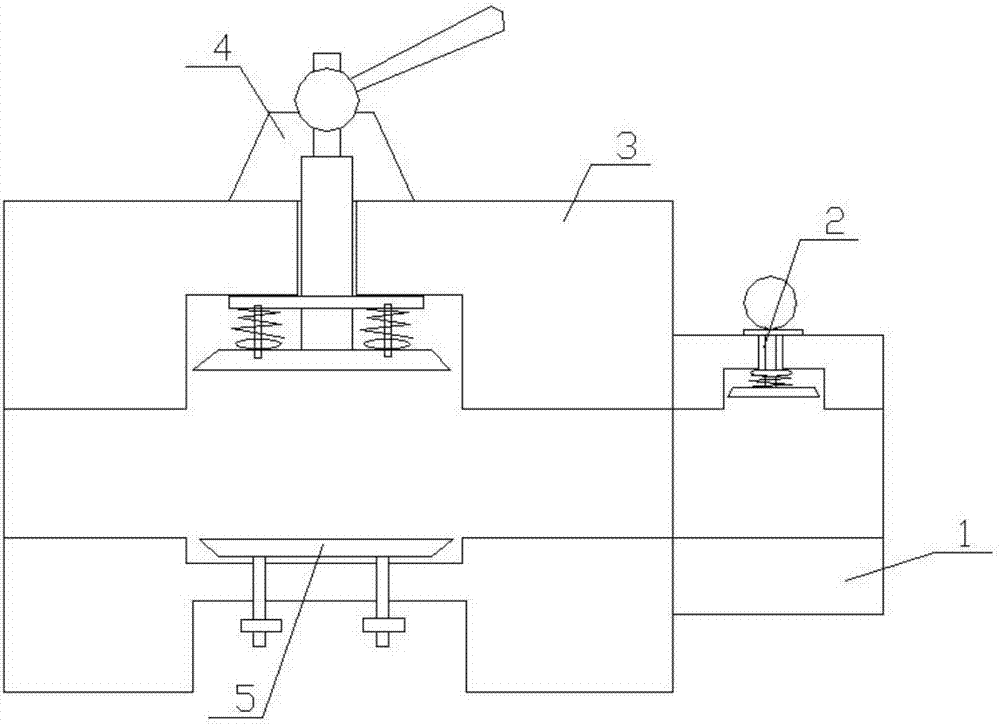

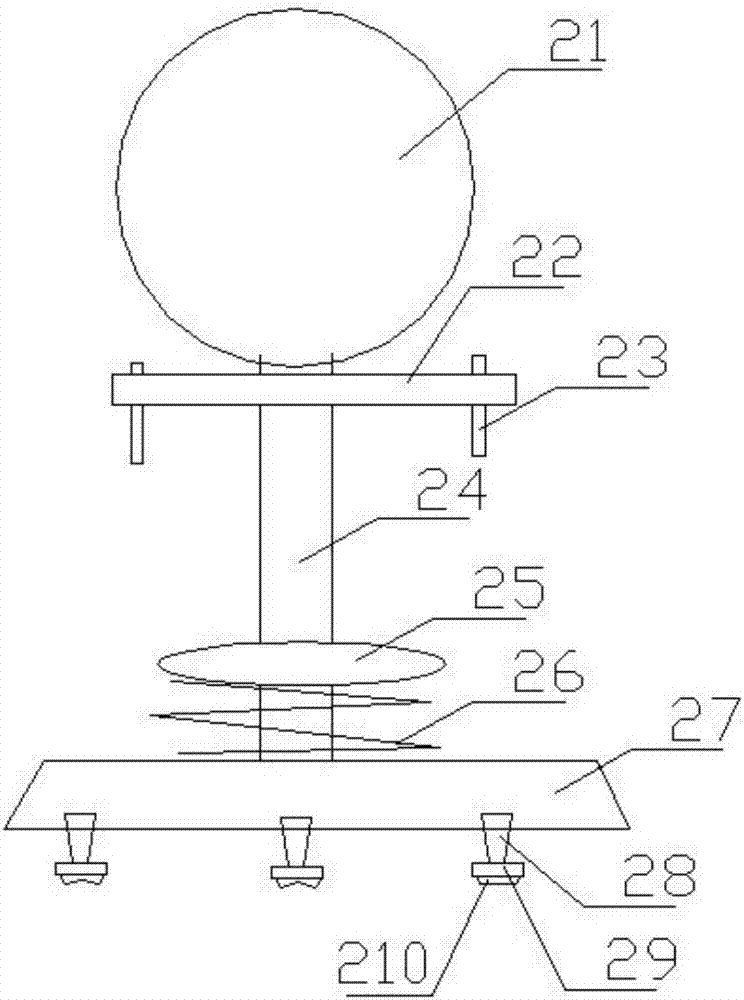

Cement pavement embossing equipment for road construction

InactiveCN108221606AIncrease frictionNot easy to slipRoads maintainenceRoad surfaceRoad construction

The invention relates to cement pavement embossing equipment, in particular to cement pavement embossing equipment for road construction. The invention provides cement pavement embossing equipment forthe road construction, which is high in embossing efficiency and simple in operation and is capable of carrying out certain drying treatment on a pavement. In order to solve the technical problem, the cement pavement embossing equipment for the road construction comprises a bottom plate and the like, wherein a driving mechanism is arranged in the middle position of the top part of the bottom plate; a leveling mechanism is arranged at the right side of the bottom part of the bottom plate; an embossing mechanism is arranged in the middle position of the bottom part of the bottom plate. The cement pavement embossing equipment provided by the invention achieves the effects of high embossing efficiency, simple operation and capacity of carrying out certain drying treatment on the pavement after embossing; the leveling mechanism and the embossing mechanism are driven to work through the driving mechanism, the pavement is leveled at the first and is subjected to embossing treatment after leveling, the working efficiency is high, and meanwhile, certain drying treatment can be carried out on the pavement after embossing.

Owner:谢春丽

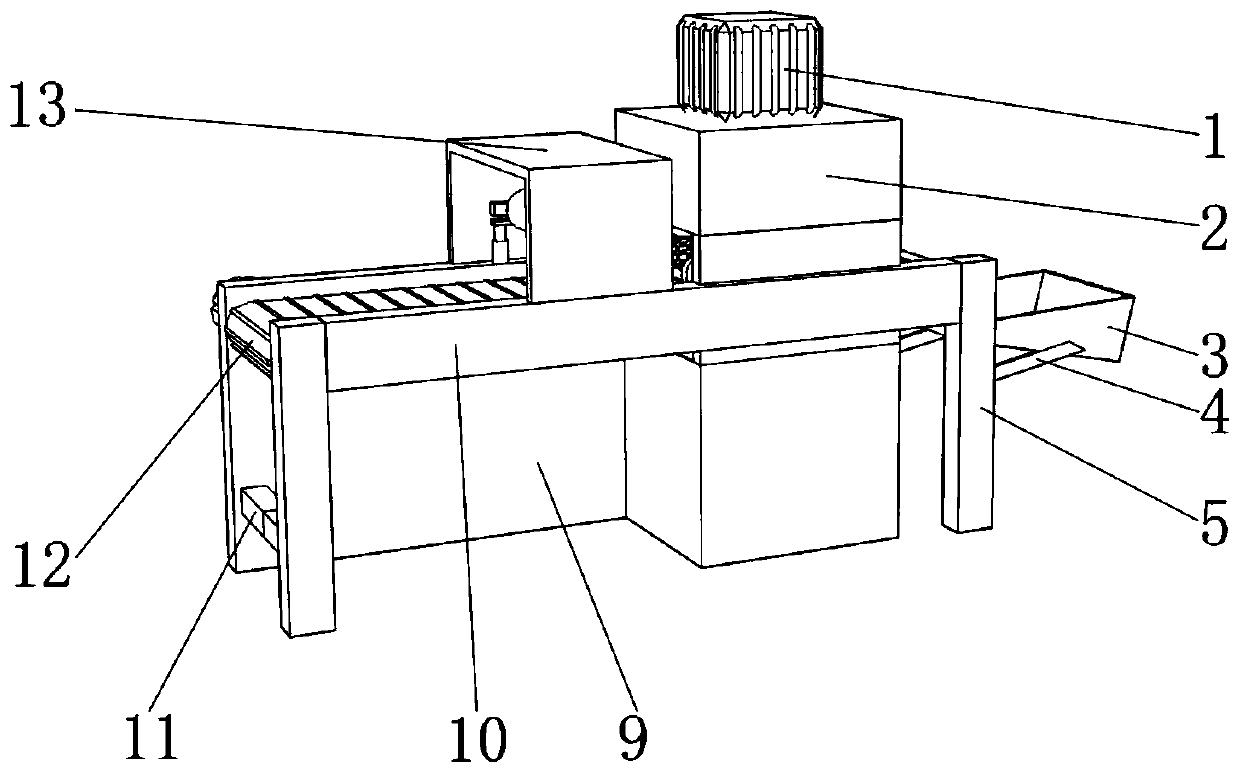

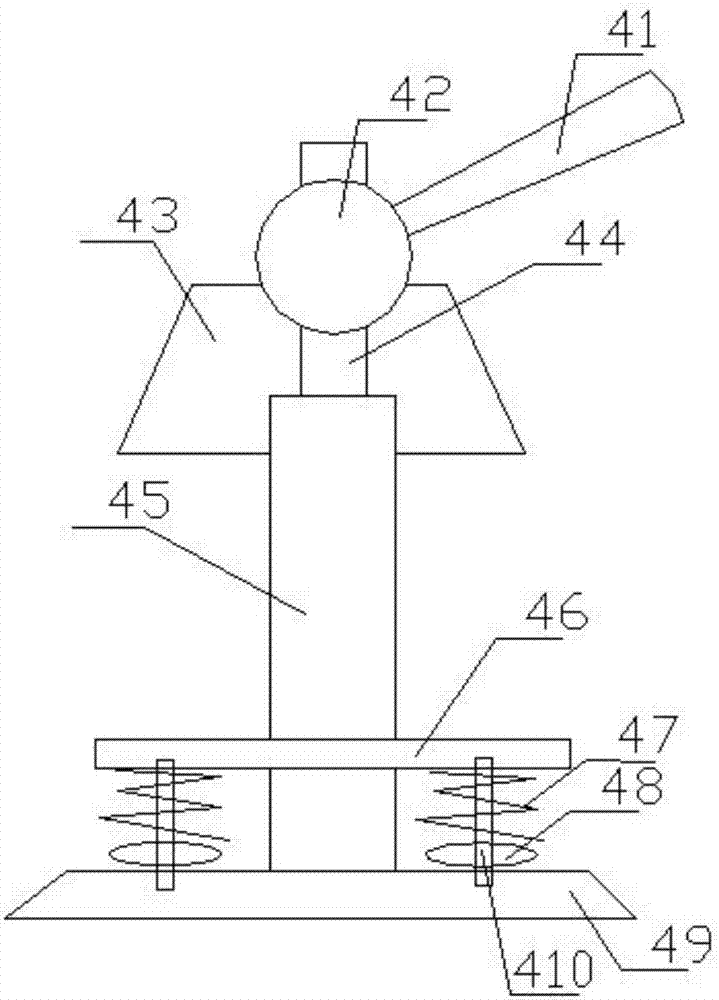

High-efficient continuous embossing device

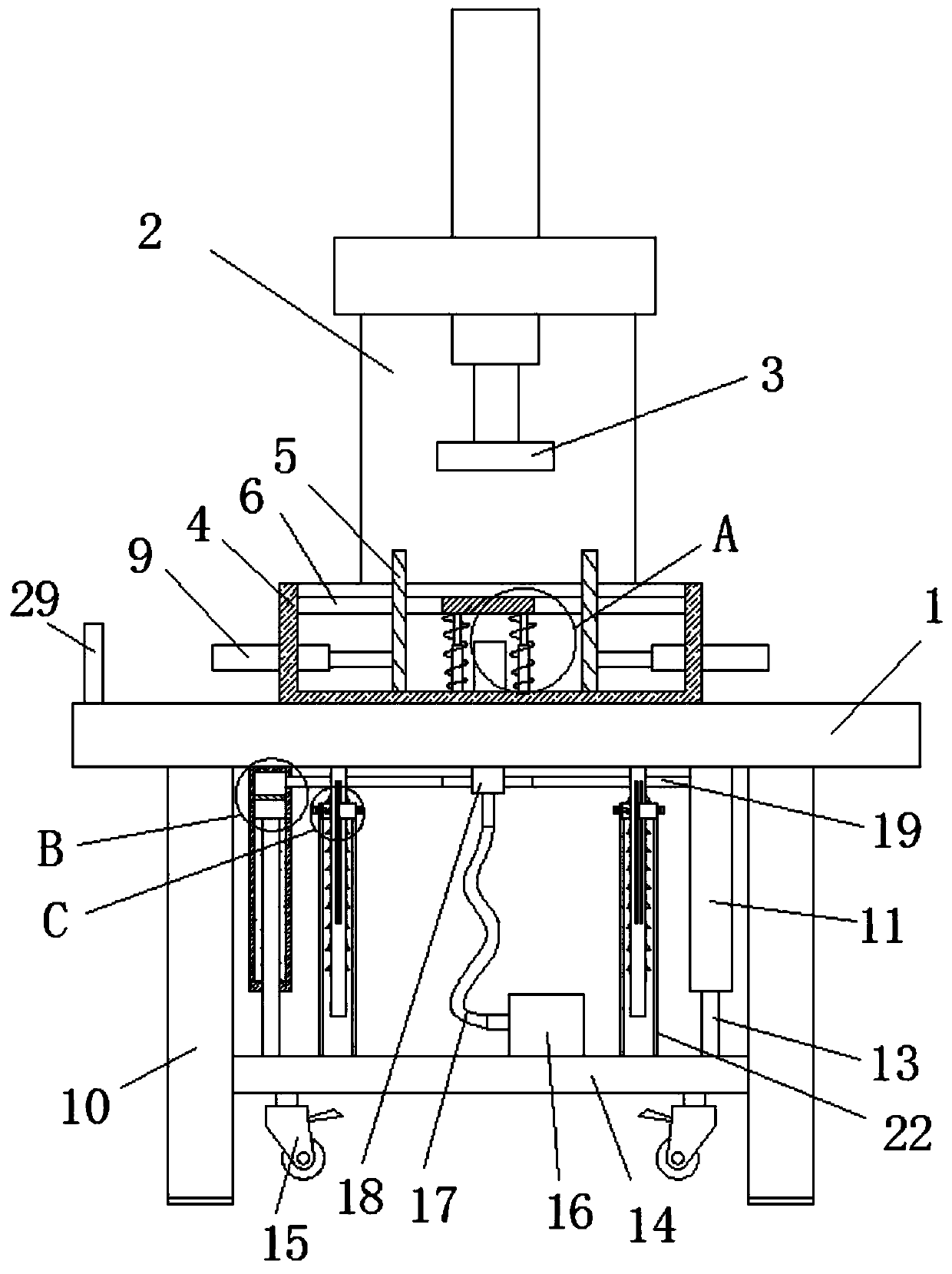

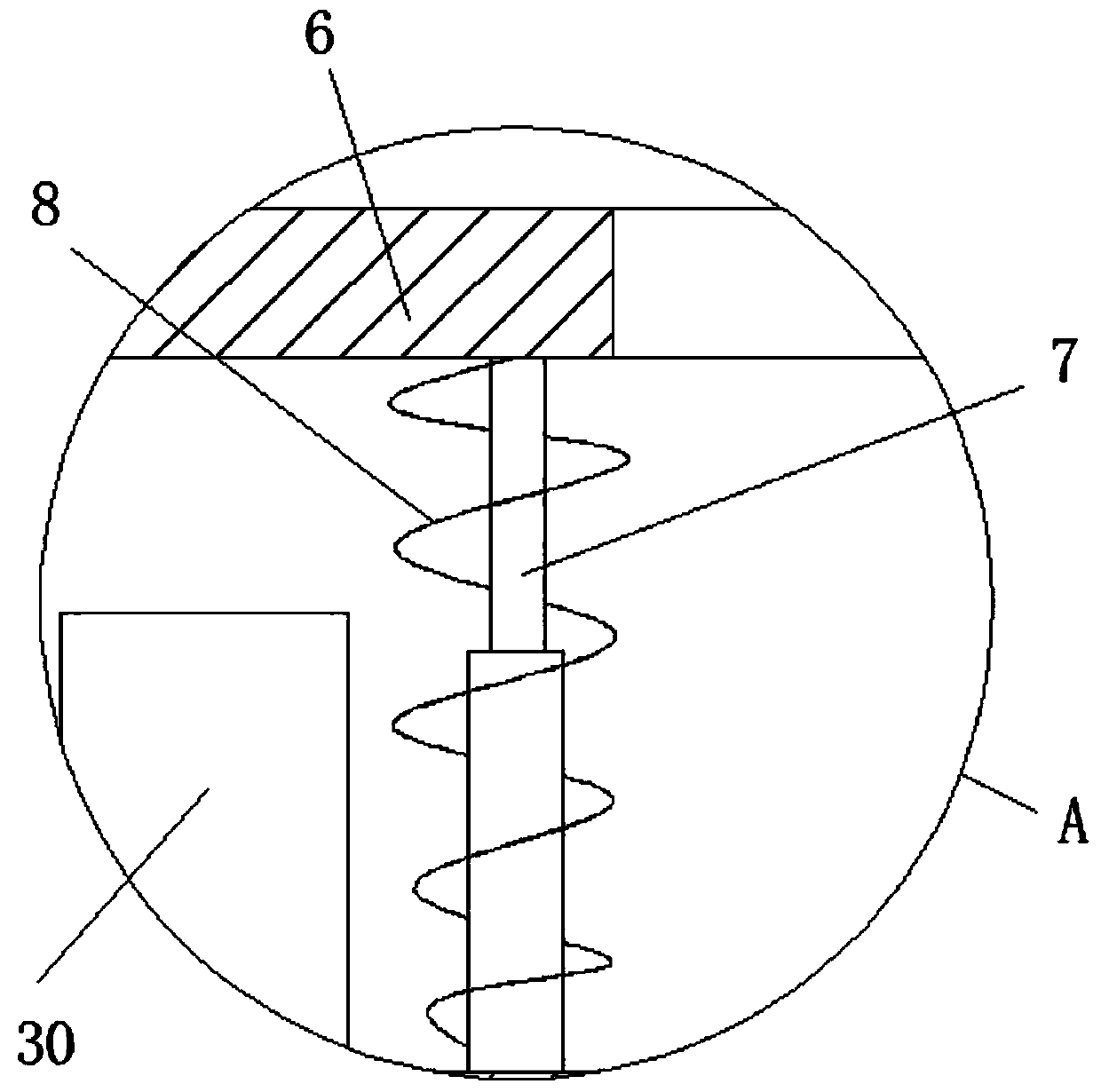

InactiveCN108690885AHigh degree of automationImprove embossing efficiencyLeather surface mechanical treatmentEngineeringSlider crank

The invention discloses a high-efficient continuous embossing device which comprises a base and a guide pillar. A first guide rail is arranged on the left side of the guide pillar; a motor is arrangedabove the guide pillar and is connected with a crank; a connecting rod is connected to the lower end of the crank; a first sliding block is connected to the lower part of the connecting rod and is arranged on the first guide rail; a second guide rail is arranged on the left side of the upper part of the base; a second sliding block is arranged on the second guide rail; a connecting shaft is arranged between the first sliding block and the second sliding block; an embossing mechanism is arranged on the connecting shaft; a conveying mechanism is arranged in the middle of the upper part of the base; clamping mechanisms are arranged on two sides of the base; and materials are put on the conveying mechanism. According to the high-efficient continuous embossing device provided by the invention,through the slider-crank mechanism, the embossing mechanism can be used for continuously embossing, the gaps of patterns embossed by the embossing mechanism can be controlled through controlling therotating speed of the motor, and patterns with different embossings can be embossed through replacing different upper molds, so that the high-efficient continuous embossing device is high in automation degree, convenient to use, stable to work, good in embossing quality, and high in embossing efficiency.

Owner:王秀荣

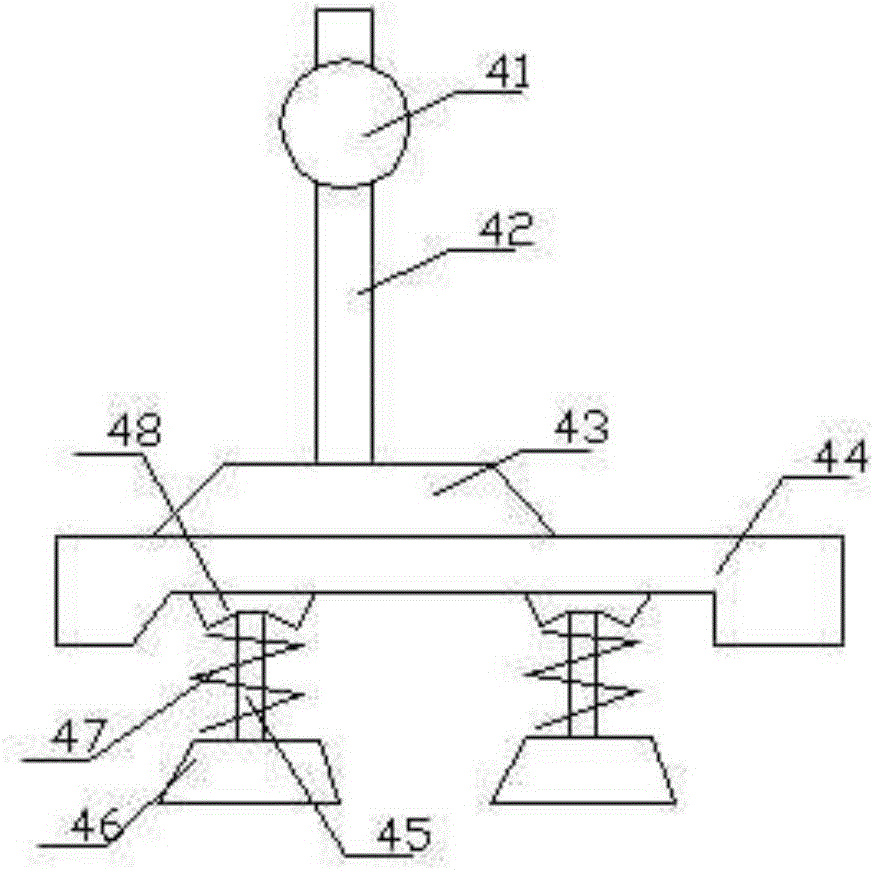

Fully-automatic embosser used for clothing

The invention relates to the technical field of clothing processing, and especially relates to a fully-automatic embosser used for clothing. The fully-automatic embosser used for clothing comprises a machine box, and also comprises a motor arranged at the upper portion of the machine box, an output shaft arranged on the motor in a rotary manner, an object carrier arranged at the lower portion of the machine box, and embossing parts; and every embossing part comprises an installation frame, a first fixed piece arranged at the upper end of the installation frame, a driven shaft arranged at the upper end of the first fixed piece in a rotary manner, a first rotary connecting piece arranged at the upper portion of the driven shaft in a rotary manner, a lower portion compacting piece, an inner guiding rod arranged at the lower side of the lower portion compacting piece, an embossing block and a first spring sleeving on the inner guiding rod and compacted to the upper side of the embossing block. The fully-automatic embosser used for clothing has the advantages of convenience in operation, convenience in adjustment, and high embossing efficiency.

Owner:姚雅珍

Knurling technique for non-woven paper

InactiveCN104044303ANot easy to lose shapeRealize instant embossingMechanical working/deformationKnurlingProcess engineering

The invention discloses a knurling technique for non-woven paper, which comprises the following steps: 1, drying the non-woven paper at 140-180 DEG C till the non-woven paper is dry; 2, atomizing the surface of the non-woven paper; 3, performing hot-pressing treatment, wherein the hot-pressing temperature is at 150-200 DEG C, the speed is at 10-15m / min and the required pressure is between 5 and 8 kilograms; 4, drying and rolling. According to the knurling technique for the non-woven paper, the knurling efficiency can be greatly increased during a production process while the knurling quality of the acquired non-woven paper is high.

Owner:ZHEJIANG WALLIFE DECORATION MATERIAL

Special compounding device used for medical pad production line

InactiveCN107776173AReduce usageEasy to destroyLamination ancillary operationsLaminationProduction lineFluff pulp

The invention discloses a composite device specially used for a medical pad production line, which comprises an embossing mechanism for compounding multi-layer materials as a whole, a double-end embossing mechanism for compounding both ends of the multi-layer material, and a double-side embossing mechanism for compounding both sides of the multi-layer material Mechanism, the embossing mechanism and the embossing mechanism at both ends are hot-pressing composite mechanism, and the embossing mechanism on both sides is an ultrasonic composite mechanism; the embossing mechanism includes the first bracket, the first smooth roller and the first embossing roller and the first Pressure control structure; the embossing mechanism at both ends includes a second support, a second smooth roller, a second embossing roller, and a second pressure control structure; the embossing mechanism at both sides includes a third support, two ultrasonic pattern rollers and an ultrasonic generator; The entire roll surface of the first embossing roll is provided with anilox patterns, and the roll surface of the second embossing roll is provided with a pattern. The invention omits the use of fluff pulp and glue as raw materials, reduces product production costs, improves economic benefits, facilitates the destruction and recycling of disposable medical pads, and prevents glue from polluting the environment.

Owner:杭州军锋机械有限公司

An automatic embossing device

Owner:嘉善申乐五金塑料有限公司

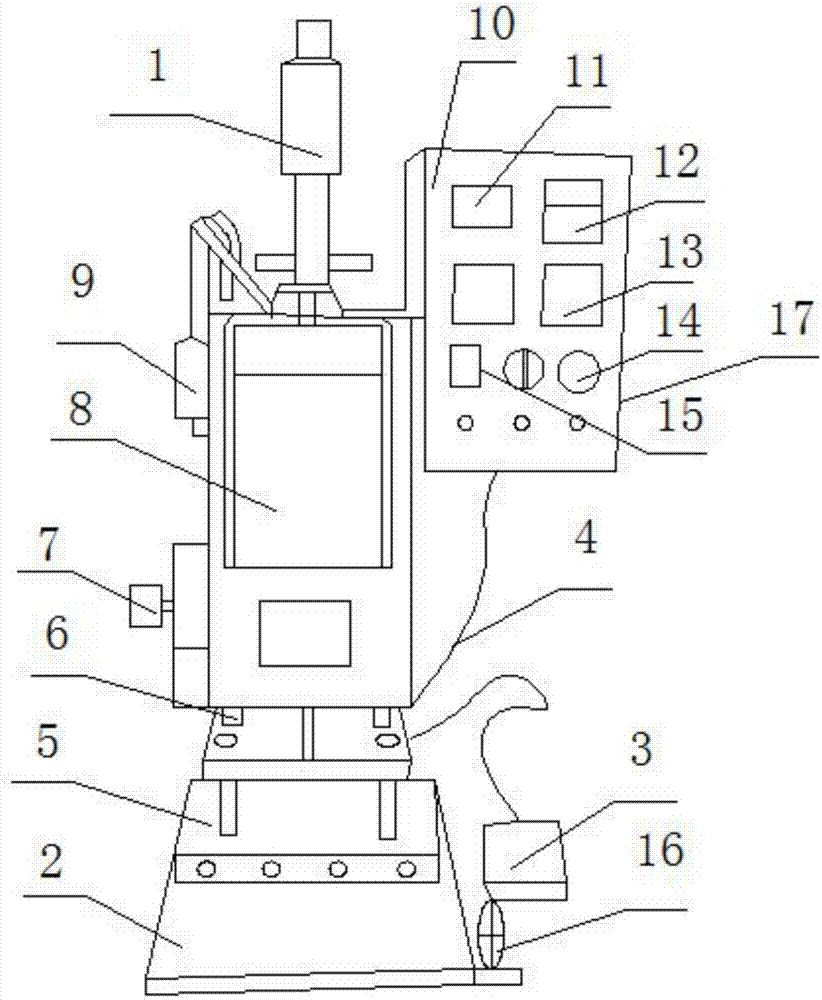

Embossing machine

InactiveCN107385122AImprove embossing efficiencySimple structureSkins/hides/leather/fur manufacturing apparatusLeather surface mechanical treatmentEngineeringTimer

The invention discloses an embossing machine, which includes a depth adjusting screw, a fixed base, a foot switch, a heating plate, a lifting device, a pressure regulating valve, a cylinder, a solenoid valve, a high temperature resistant dust collector, and an anti-interference device. There is a depth adjustment screw on the top of the leather embossing machine, a heating plate on the fixed base, a high temperature resistant dust collector on the right end of the fixed base, the heating plate is connected with the foot switch, and the upper part of the heating plate is connected with the lifting device to adjust the pressure. The valve is connected to the cylinder, and the cylinder is connected to the solenoid valve. There is a control device on the side of the cylinder. The control device is equipped with a counter and a press-down timer, as well as an emergency stop button and a power switch. The side of the control device is equipped with anti-interference equipment. , the control device is connected with the lifting device through the power line. The embossing machine of the present invention has a fully automated embossing process, a high-temperature resistant dust collector device, and anti-interference equipment, high embossing efficiency, simple structure, and high safety factor in the embossing process.

Owner:天津惟迅恒科技有限公司

Method of constructure for stereo colour road surface mfg. with pressed lines and colour sprayed on asphalt road surface

InactiveCN1598152AContinuityLess likely to cause damageIn situ pavingsRoads maintainenceRoad surfaceFixed position

The invention relates to a bituminous pavement construction method with solid chromatic effect. The paving method has entirety and continuity. It can press into various solid grid and dope various color to change the original ponderous black rode surface into colorful. The construction method is softening treatment: the original or newly aid bituminous pavement is softened by infrared heater to 80-100 deg.C; fixing position: the coining grid is paved on the softened road surface and fixed position exactly; graining: the fixed grid is pressed into bituminous pavement by vibrating rammer device, rammer force is from 2.5-5ton, three dimensional moulage on the road surface painting sealing the stamped road surface is doped coating material after the road surface is cooling; coating water sealing layer.

Owner:戴锋 +2

Method of constructure for stereo colour road surface mfg. with pressed lines and colour sprayed on asphalt road surface

InactiveCN100339537CContinuityLess likely to cause damageIn situ pavingsRoads maintainenceRoad surfaceFixed position

The invention relates to a bituminous pavement construction method with solid chromatic effect. The paving method has entirety and continuity. It can press into various solid grid and dope various color to change the original ponderous black rode surface into colorful. The construction method is softening treatment: the original or newly aid bituminous pavement is softened by infrared heater to 80-100 deg.C; fixing position: the coining grid is paved on the softened road surface and fixed position exactly; graining: the fixed grid is pressed into bituminous pavement by vibrating rammer device, rammer force is from 2.5-5ton, three dimensional moulage on the road surface painting sealing the stamped road surface is doped coating material after the road surface is cooling; coating water sealing layer.

Owner:戴锋 +2

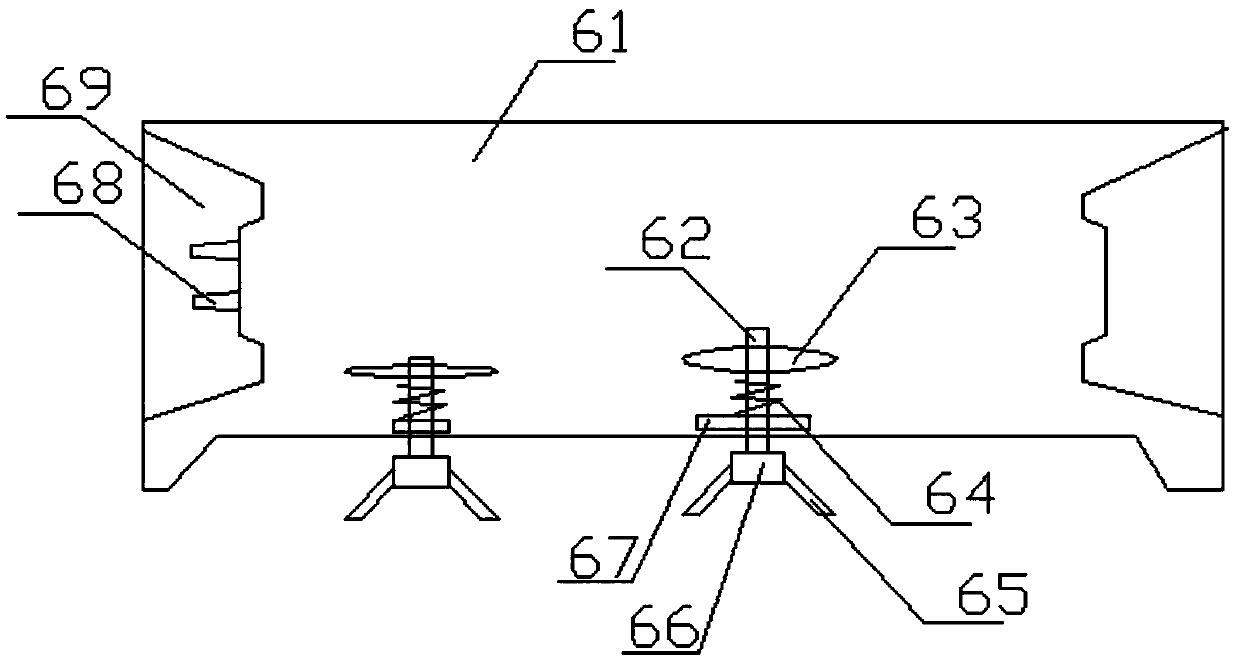

Leather embossing device for fur production

The invention relates to the technical field of leather embossing, in particular to a leather embossing device for fur production. The leather embossing device for fur production comprises a base and further comprises a supporting frame arranged on the edge of the upper end of the base, a cross beam arranged on the upper portion of the supporting frame, an operating platform arranged on the base, a transmission component arranged on the lower side of the cross beam, a motor rotationally arranged at the upper end of the transmission component, an installation cylinder arranged on the outer side of the transmission component and an embossing plate arranged on the outer side of the installation cylinder.

Owner:JIASHAN SHENGLAISI CASHMERE

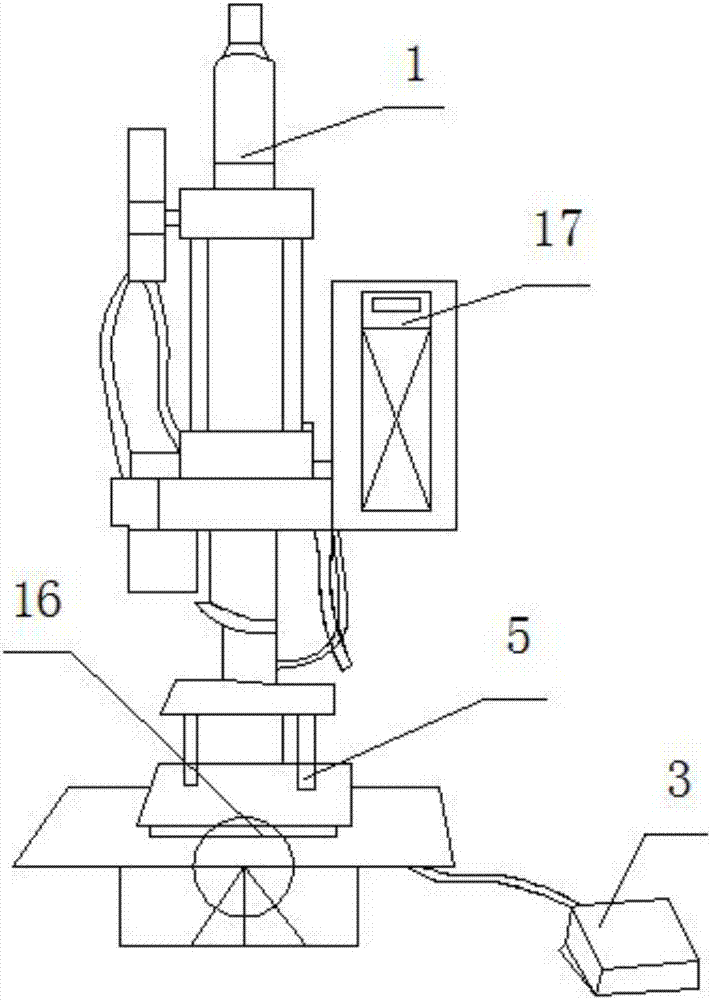

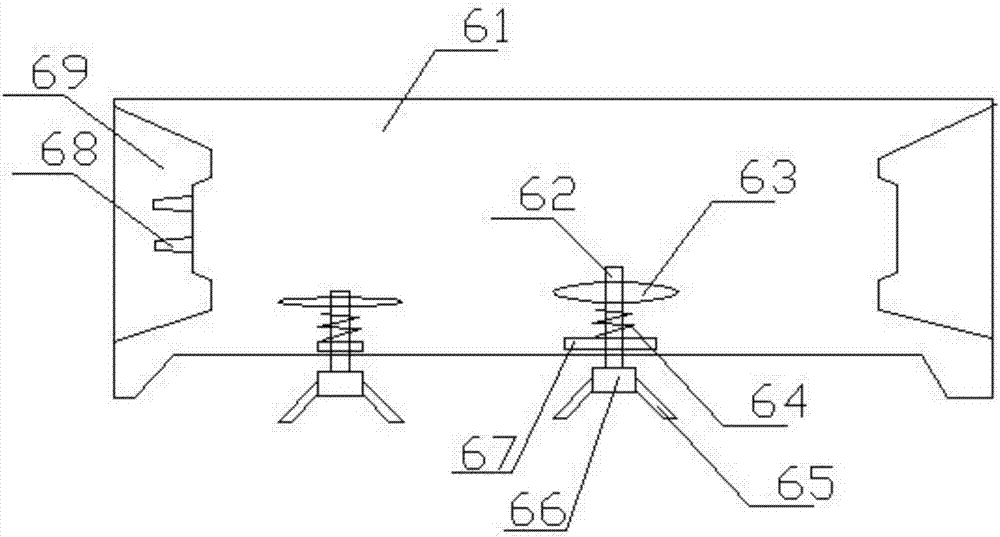

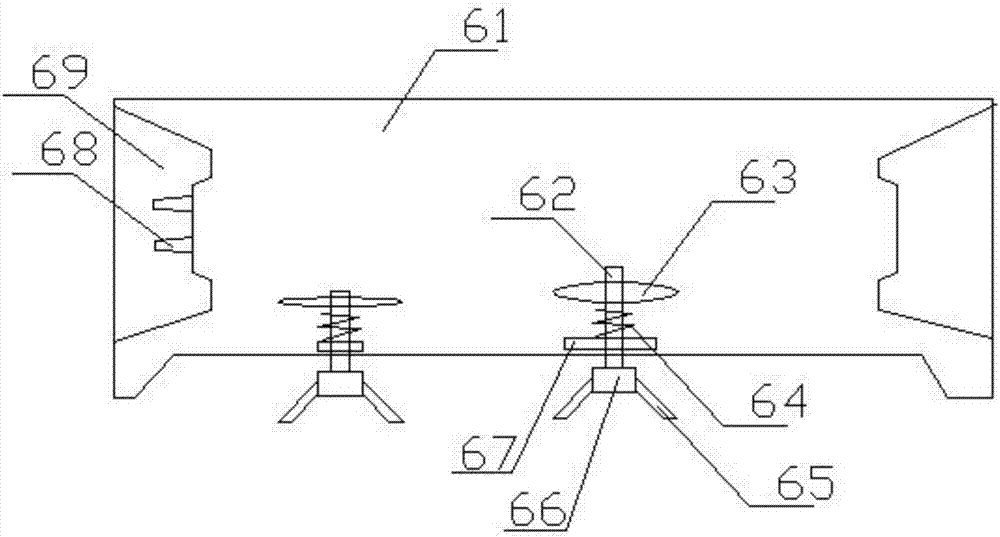

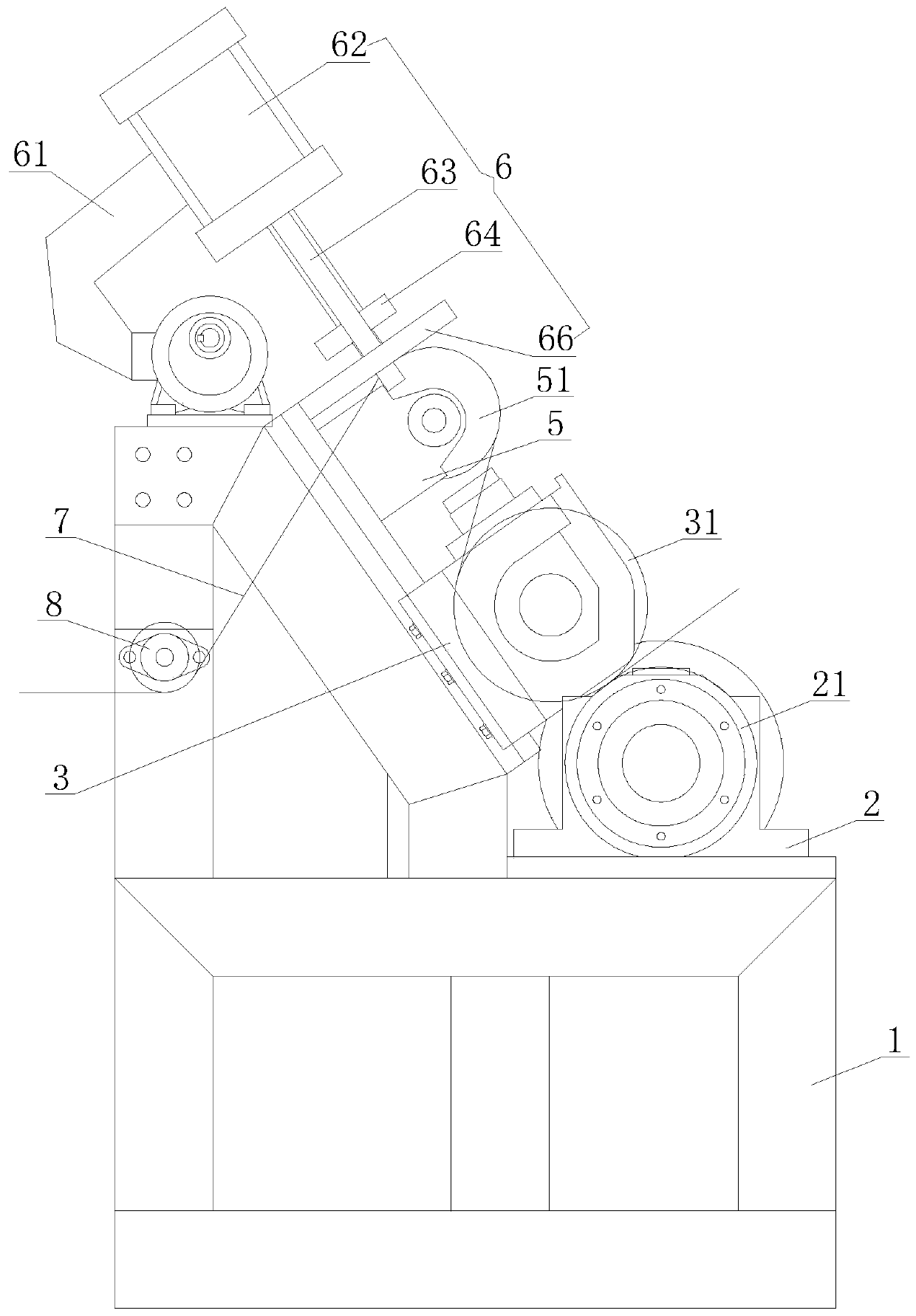

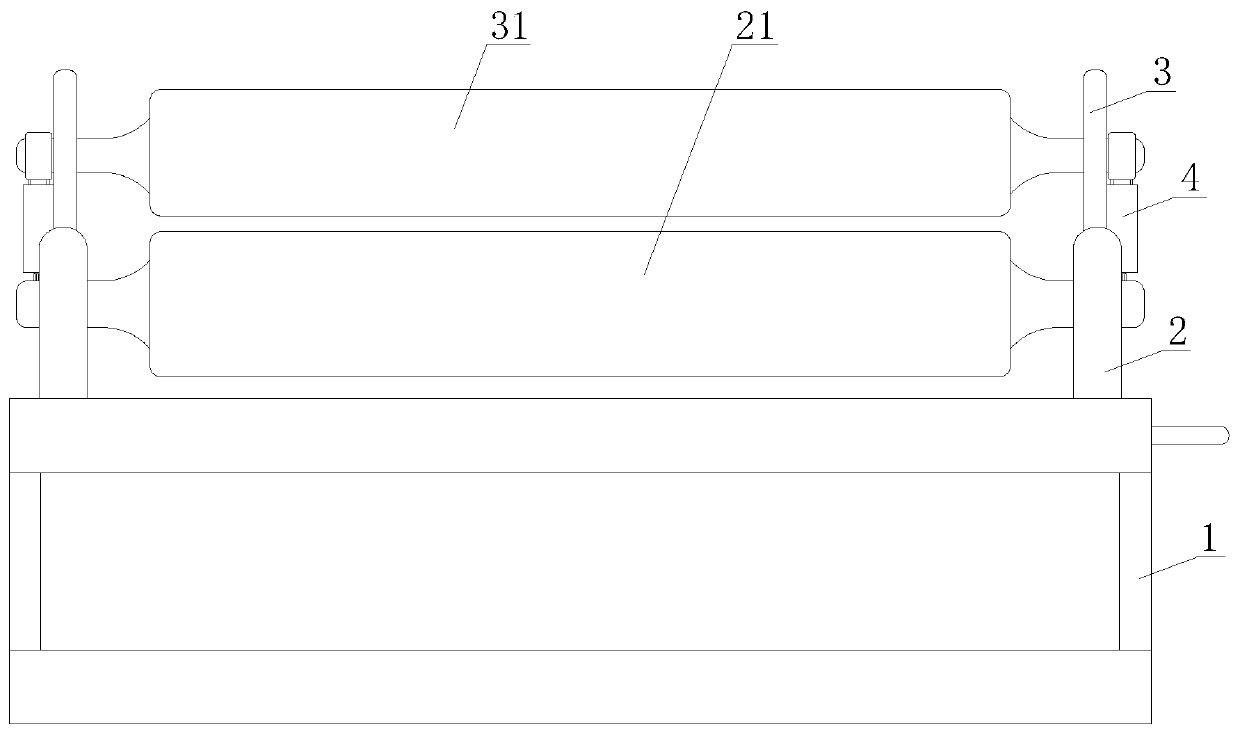

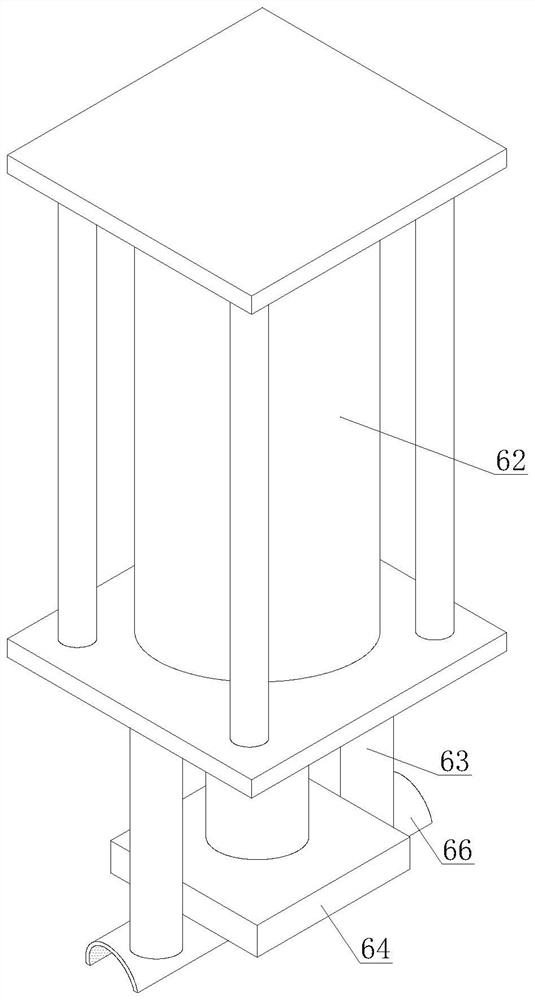

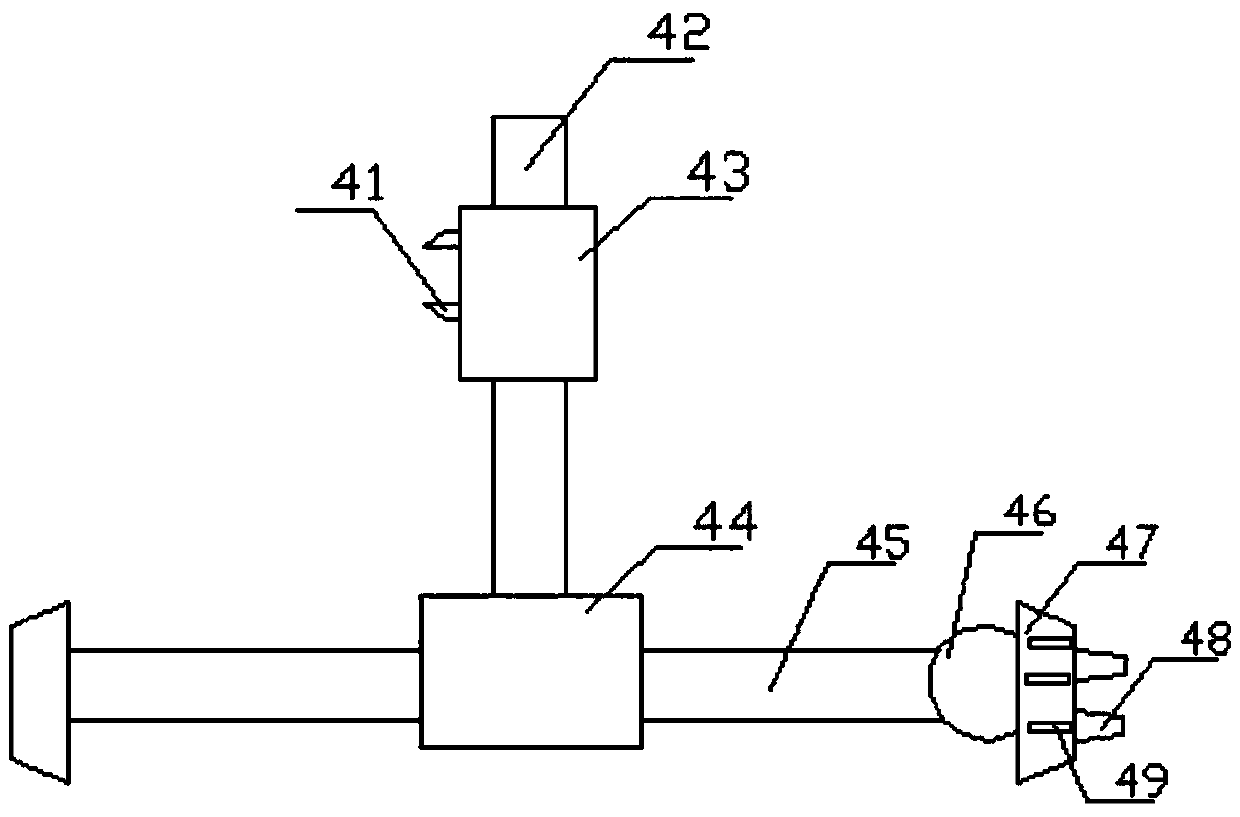

Fur embossing device capable of achieving automatic discharging

ActiveCN106987659AEasy to adjustImprove embossing efficiencyLeather surface mechanical treatmentEngineeringTransverse beam

The invention relates to the technical field of fur embossing, in particular to a fur embossing device capable of achieving automatic discharging. The fur embossing device capable of achieving automatic discharging comprises a base, and further comprises a supporting frame arranged at the edge of the upper end of the base, a transverse beam arranged at the upper portion of the rising supporting frame, an operation table arranged on the upper side of the base, a transmission component arranged on the lower side of the transverse beam, a motor arranged at the upper end of the transmission component in a rotary manner, an installation barrel arranged on the outer side of the transmission component and an embossing plate arranged on the outer side of the installation barrel.

Owner:JIASHAN SHENGLAISI CASHMERE

Production process of embossed solar coated photovoltaic glass

PendingCN114262153AImprove light transmissionEvenly heatedGlass furnace apparatusGlass drawing apparatusAluminium oxideSodium oxide

The invention relates to a production process of embossed solar coated photovoltaic glass, which comprises the following steps: (1) weighing the following components in parts by weight: 60-70 parts of quartz sand, 5-8 parts of aluminum oxide, 0.5-1 part of barium oxide, 2-3 parts of sodium oxide, 3-8 parts of calcium oxide, 0.4-1.5 parts of yttrium oxide, 0.05-0.15 part of cerium oxide, 0.3-3 parts of sodium sulfate, 0.1-3 parts of sodium nitrate and 0.5-1.5 parts of kaolin; (2) mixing and ball-milling the raw materials, and heating, melting and clarifying; (3) discharging bubbles from the molten glass liquid, thinning the molten glass liquid in a forming area, and cooling and forming the molten glass liquid to obtain a glass plate; (4) immediately conveying the glass plate to an embossing area, carrying out heat preservation after embossing, and conveying the glass plate to an annealing area to obtain an embossed glass plate; (5) cleaning the embossed glass plate, drying, removing dust, and preheating the embossed glass plate in a preheating area; (6) enabling the preheated embossed glass plate to enter a coating area for coating, and then curing to form the embossed solar photovoltaic glass plate; the invention has the advantages of high transmittance, high glass melting rate and high production efficiency.

Owner:NANJING SOLGLASS SCI & TECH

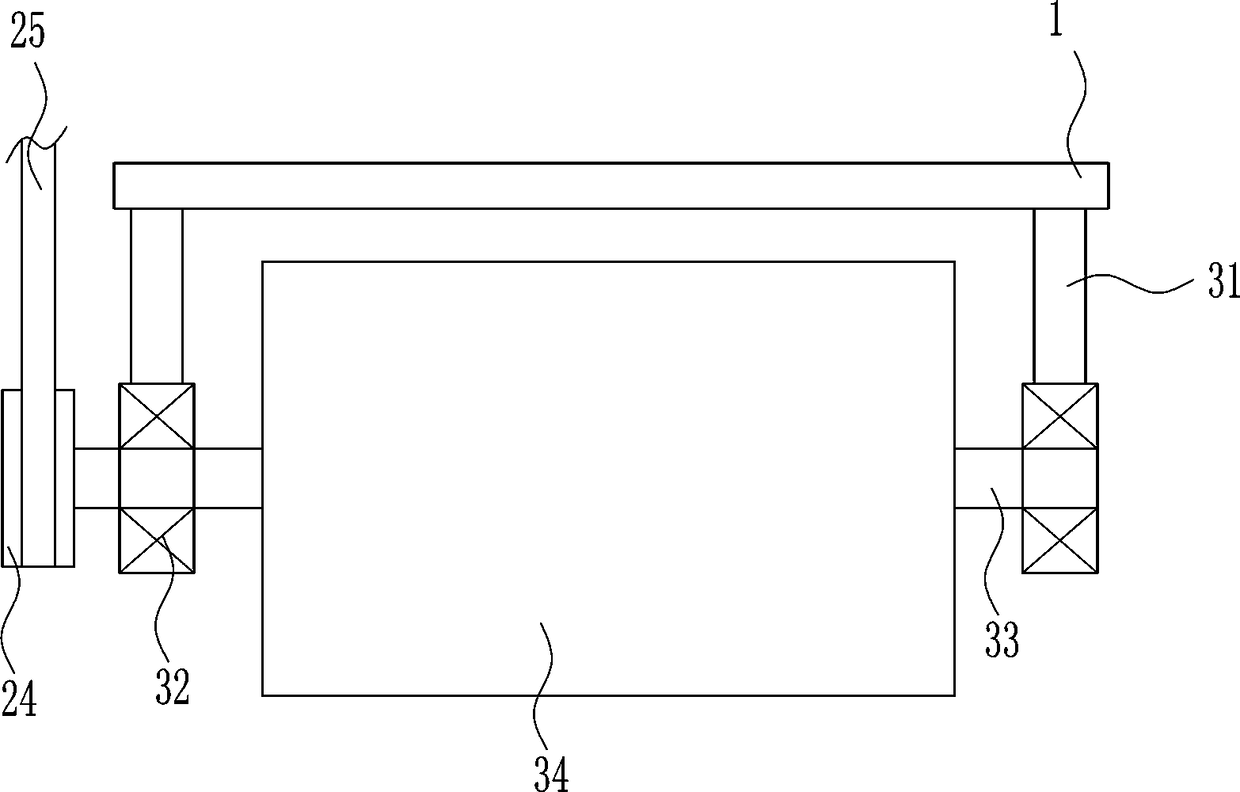

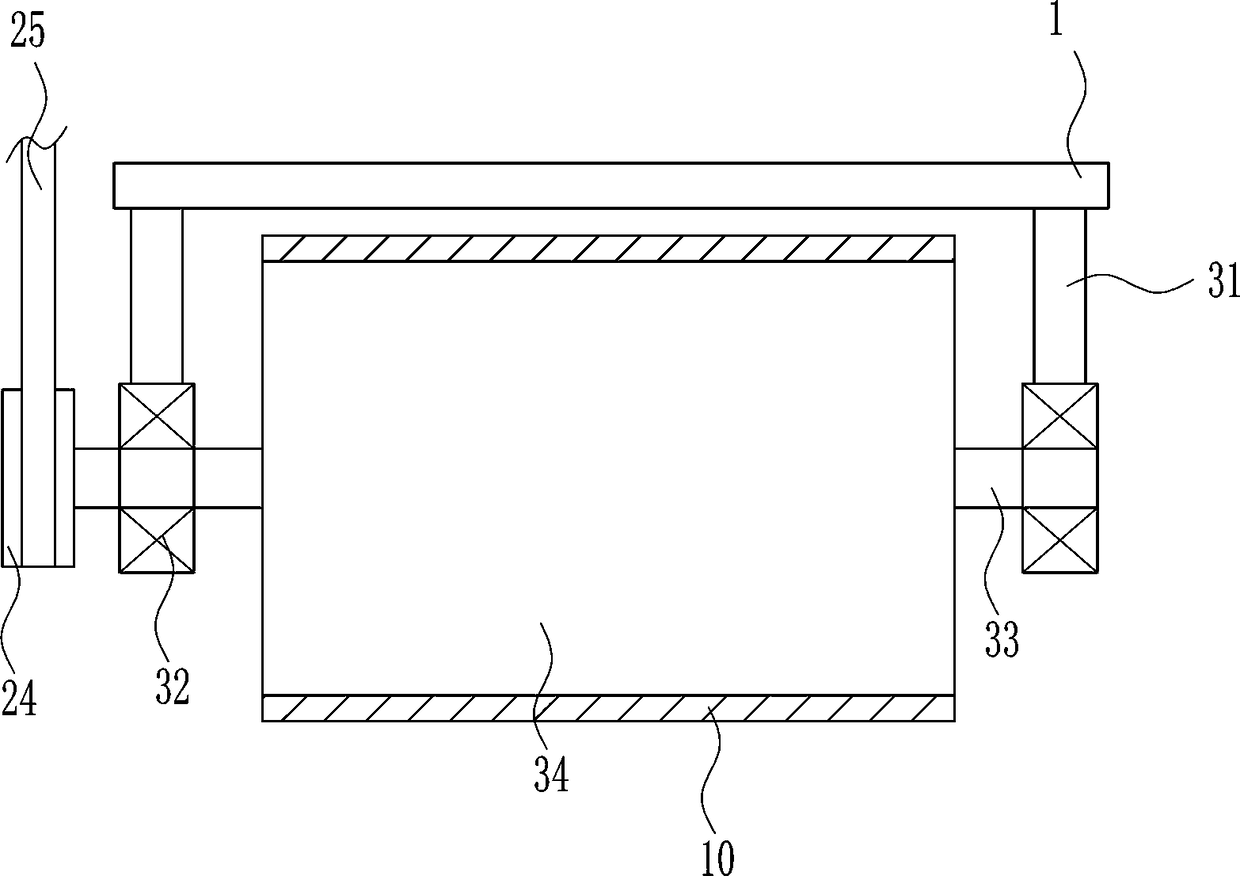

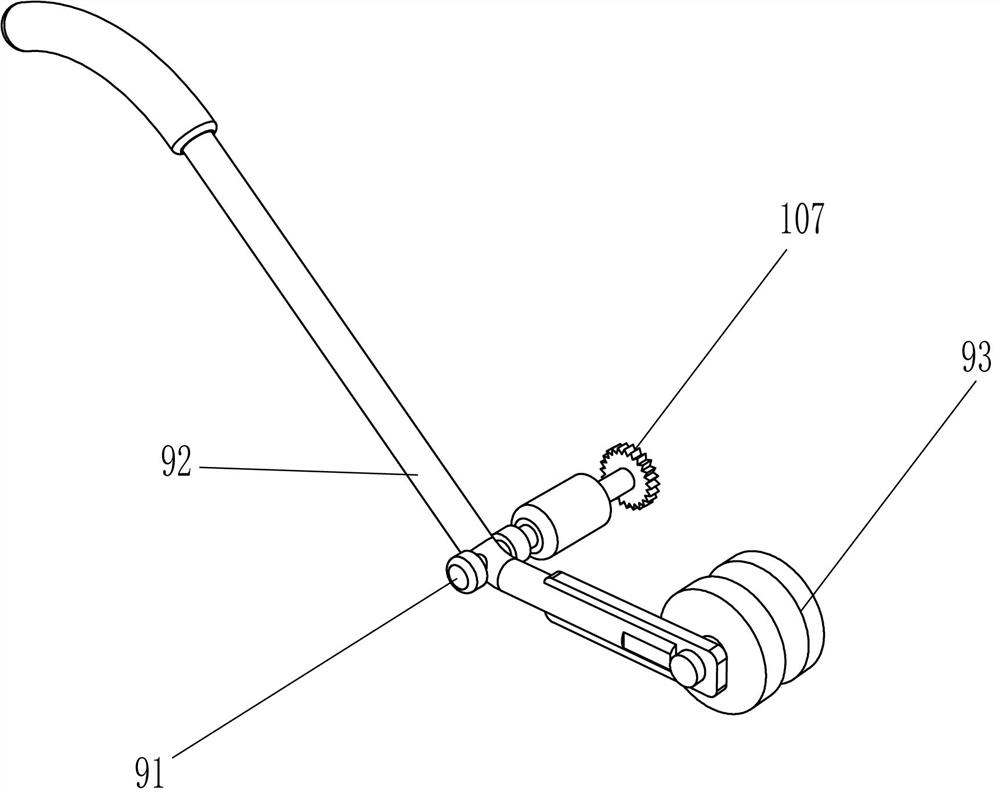

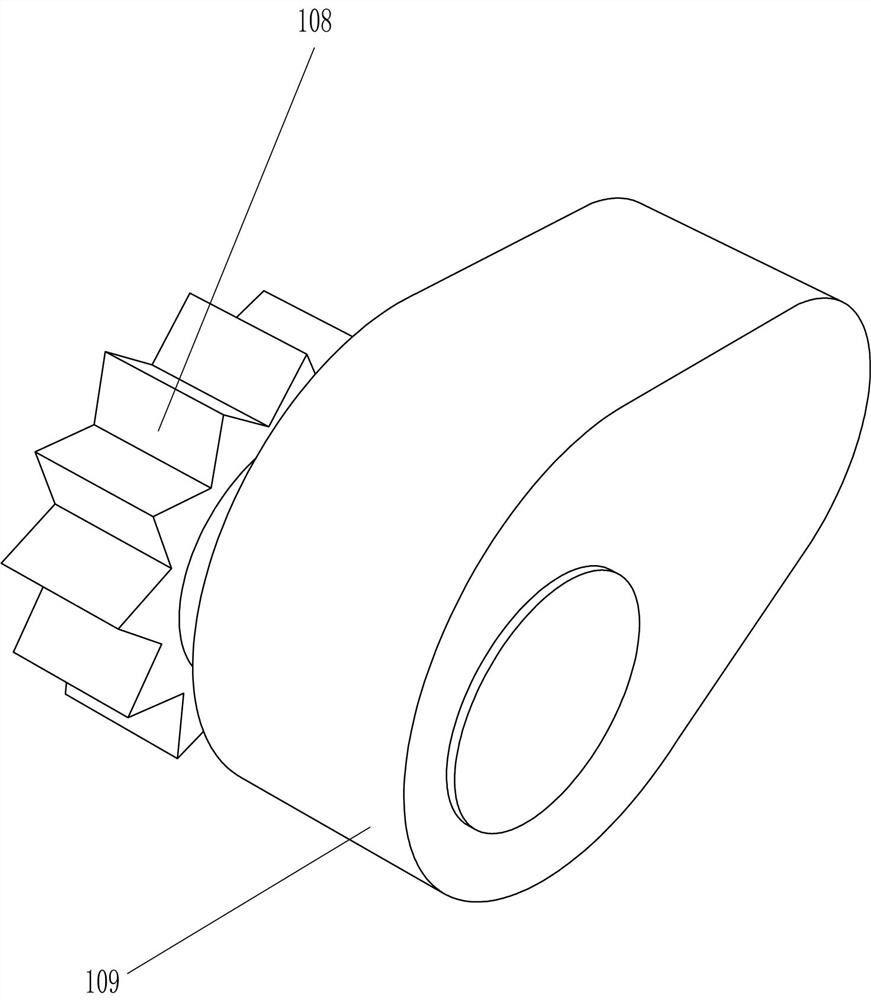

Floor embossing device for road construction

ActiveCN111535125BReduce labor intensityImprove embossing efficiencyRoads maintainenceArchitectural engineeringStructural engineering

The invention relates to an embossing device for road construction, in particular to a floor embossing device for road construction. The technical problem to be solved by the present invention is how to provide a floor embossing device for road construction that can reduce labor intensity and improve embossing efficiency. In order to solve the above technical problems, the present invention provides such a floor embossing device for road construction, comprising: a base, one end of which is connected with a universal wheel, and one end of the base close to the universal wheel is rotatably connected with a connecting shaft, the connecting shaft There are walking wheels connected to the top, and supporting plates are connected to both sides of the other end of the base; a driving mechanism is installed on the other end of the base close to the supporting plate; a moving mechanism is installed on one side of the supporting plate, and the driving mechanism and the moving Mechanism transmission connection. The present invention can emboss the cast-in-place concrete floor by moving and rotating the pressure roller to the right and left, thus eliminating the need for manual hand-held embossing rollers for a long time for embossing.

Owner:临清市宏顺国际贸易有限公司

A multi-station button embossing equipment

The present invention proposes a multi-station button embossing device, which includes a base plate, supports are fixed on the left and right sides of the base plate, support shafts are screwed on the left and right sides of the base plate surface, the bottom of the support shaft and The tops are all in a threaded structure, the support shaft is located inside the support member, the contact surface end of the support shaft and the substrate is also screwed with a sleeve, the upper end of the support shaft is screwed with a cylinder, and the circle The cylinder has a circular through hole that runs through up and down. The inner wall of the circular through hole is also in a threaded structure. The side of the cylinder has an annular groove, and the left and right sides of the fixed platen are protruded with connectors. The connector is in contact with the annular groove and fixes the fixed platen on the cylinder, the lower end of the fixed platen is also provided with a moving assembly, the lower end of the moving assembly is connected with an embossing assembly, and the middle part of the base plate An adjustable button fixing component is fixed on the upper end.

Owner:嘉善梦溪服饰辅料厂(普通合伙)

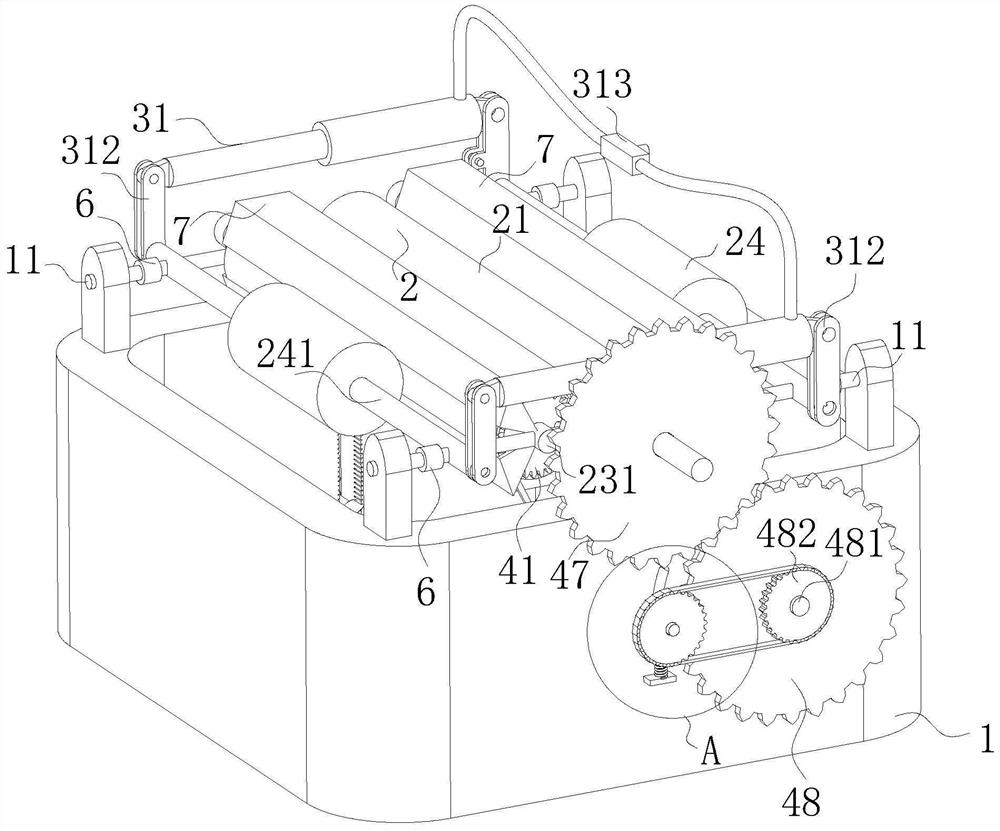

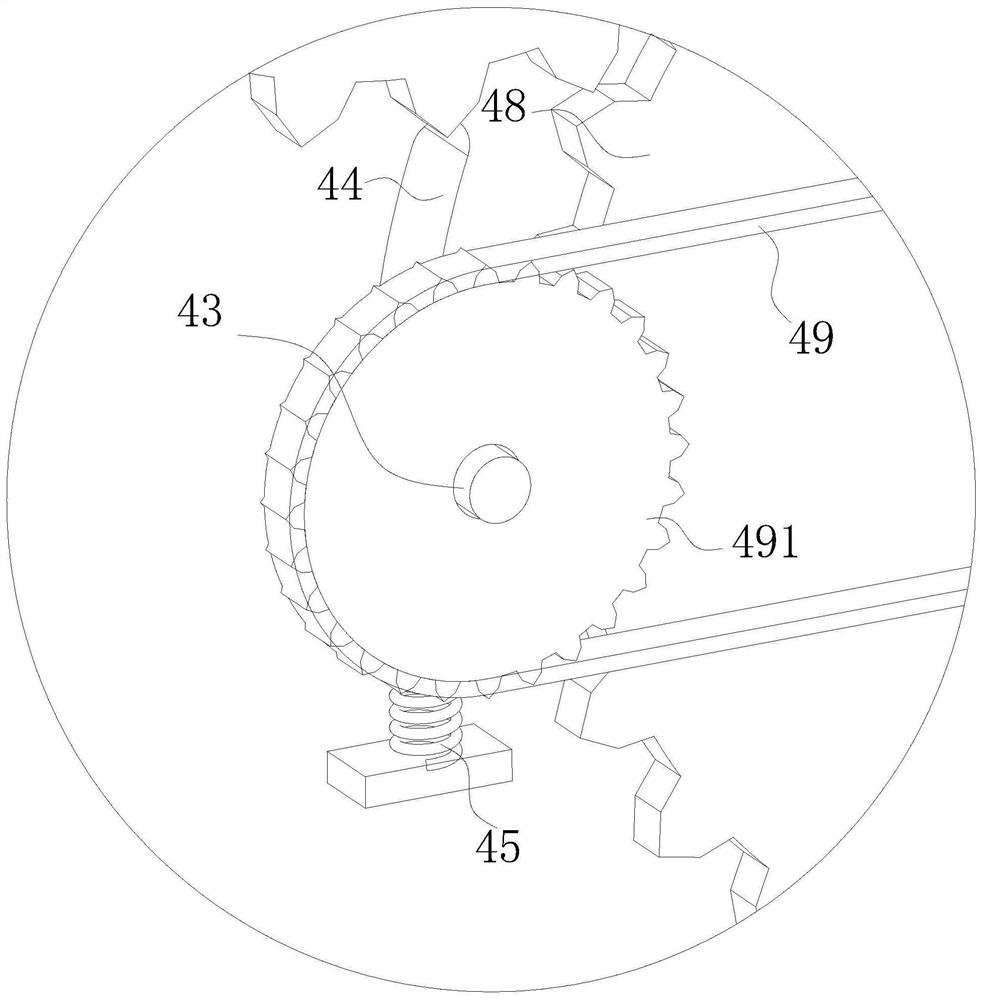

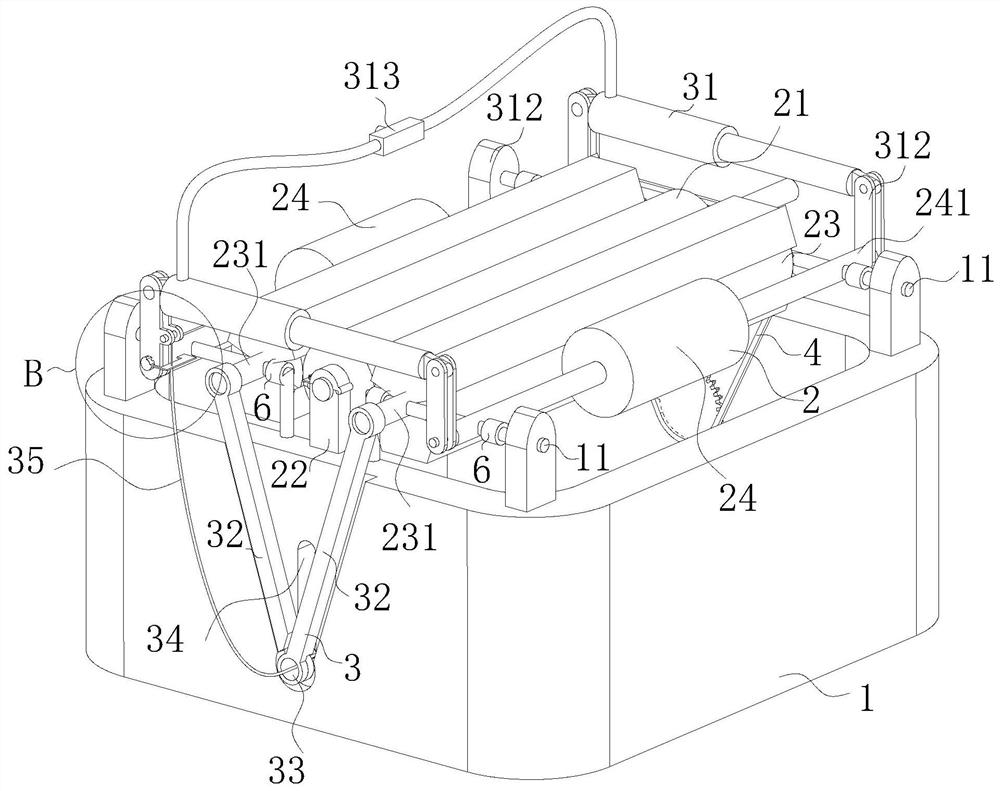

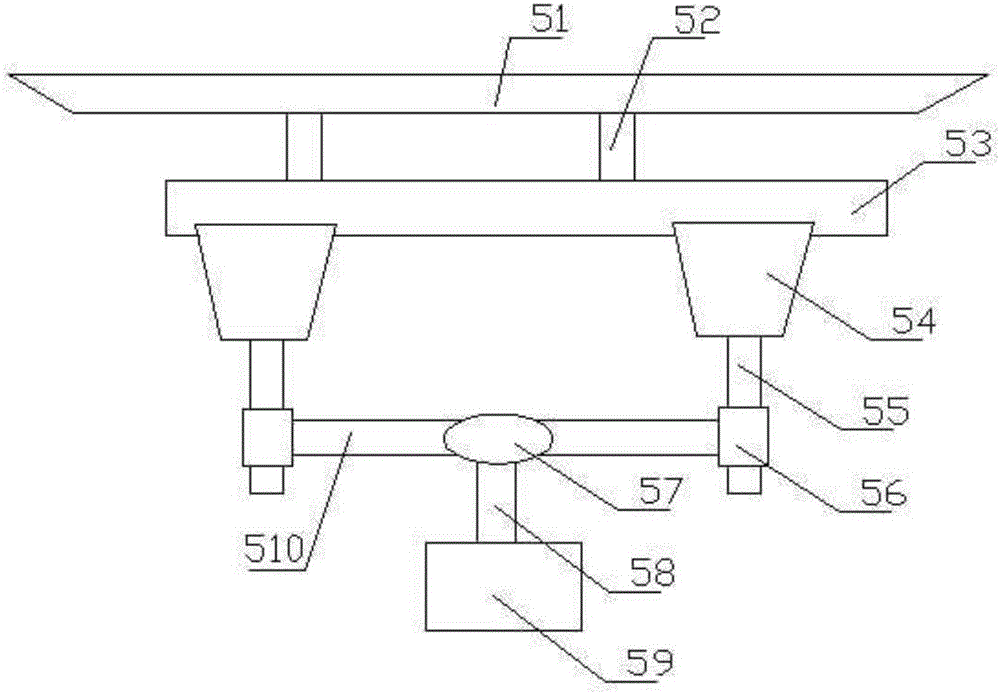

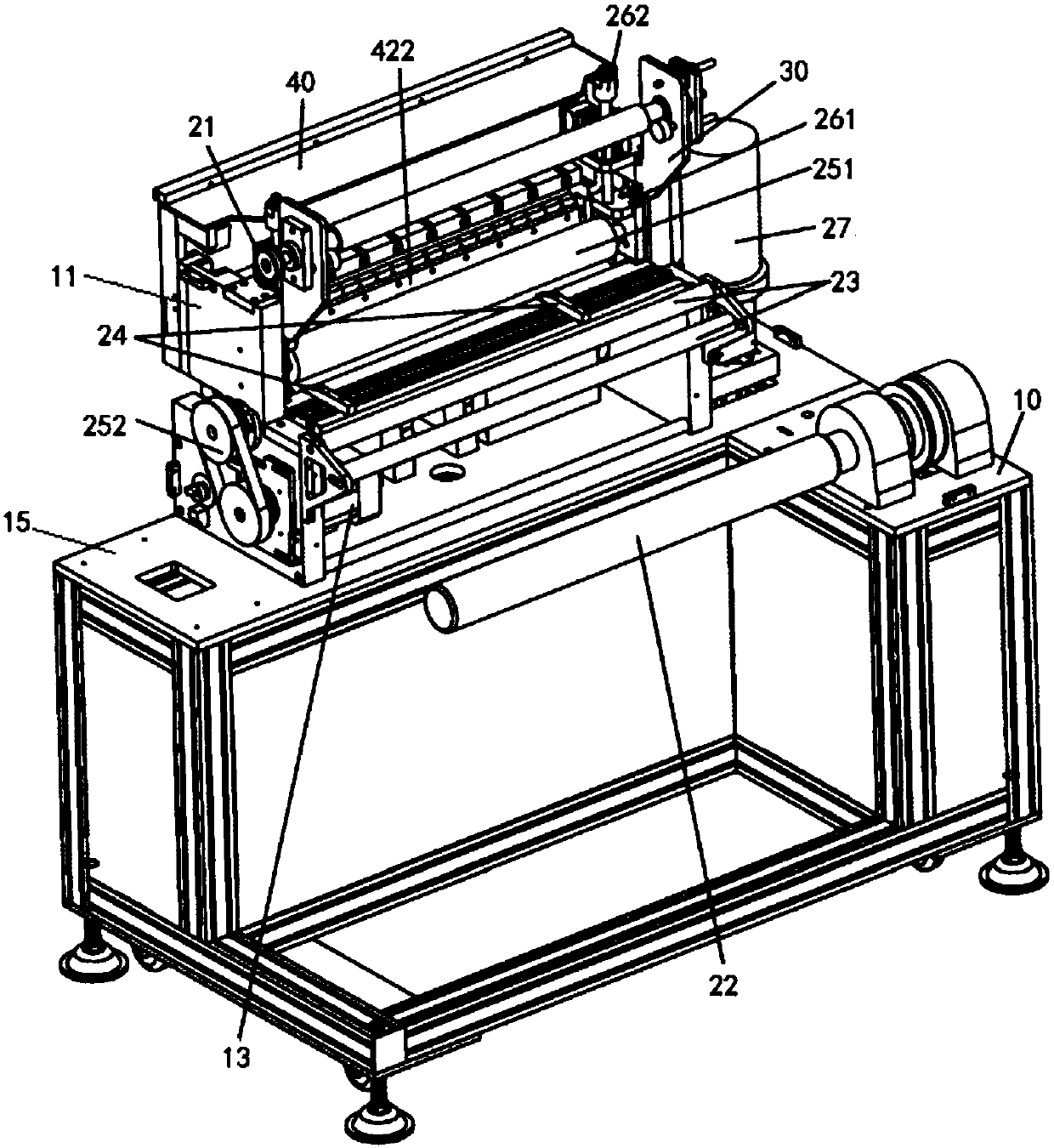

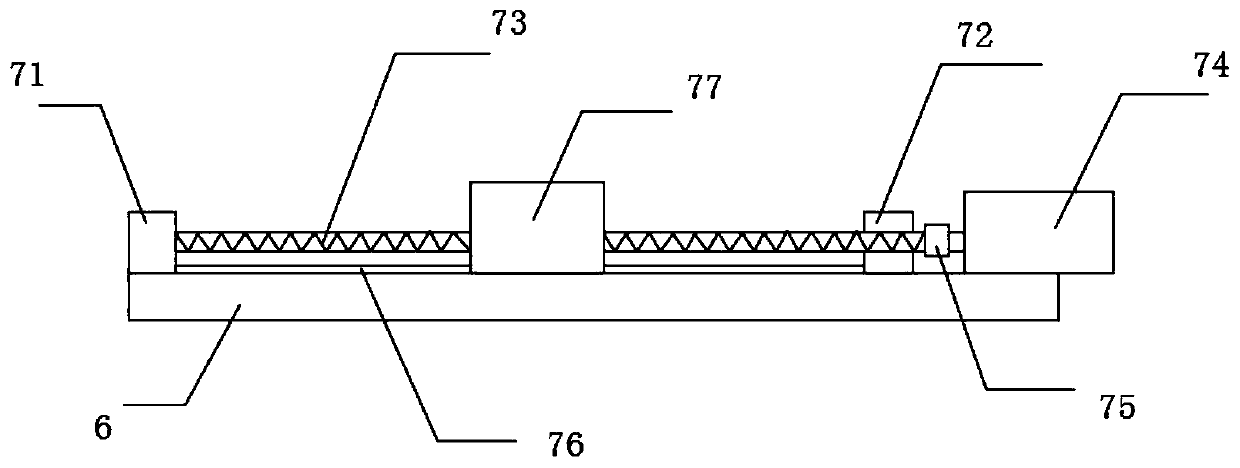

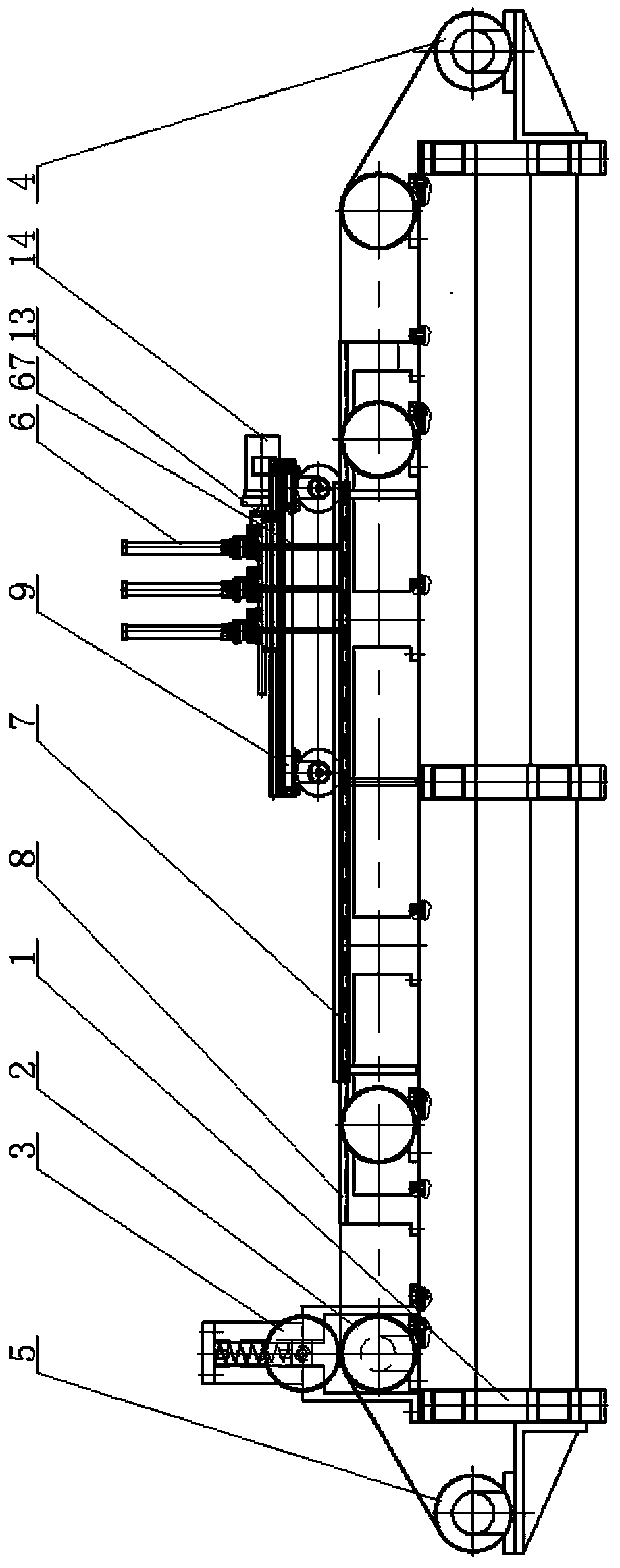

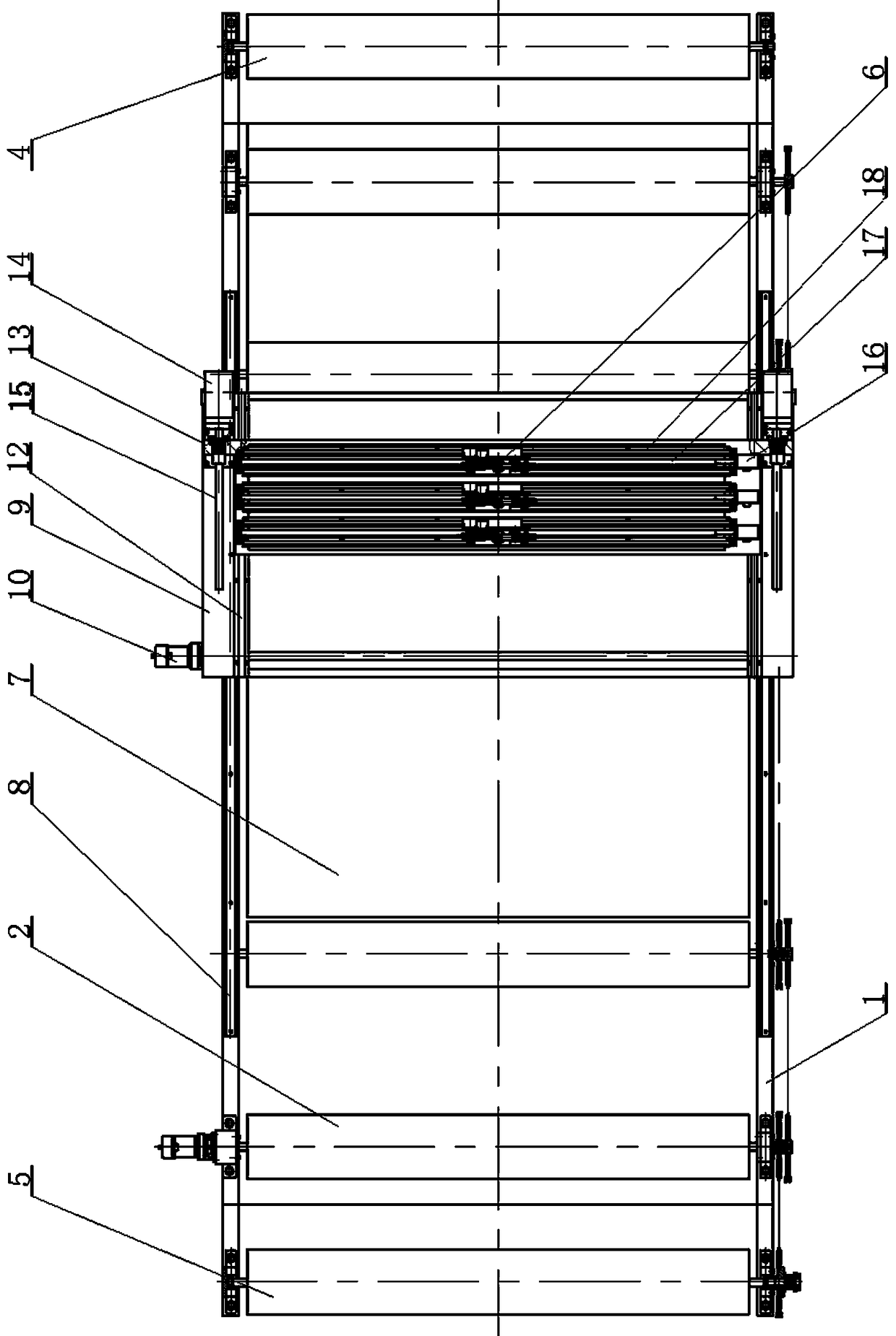

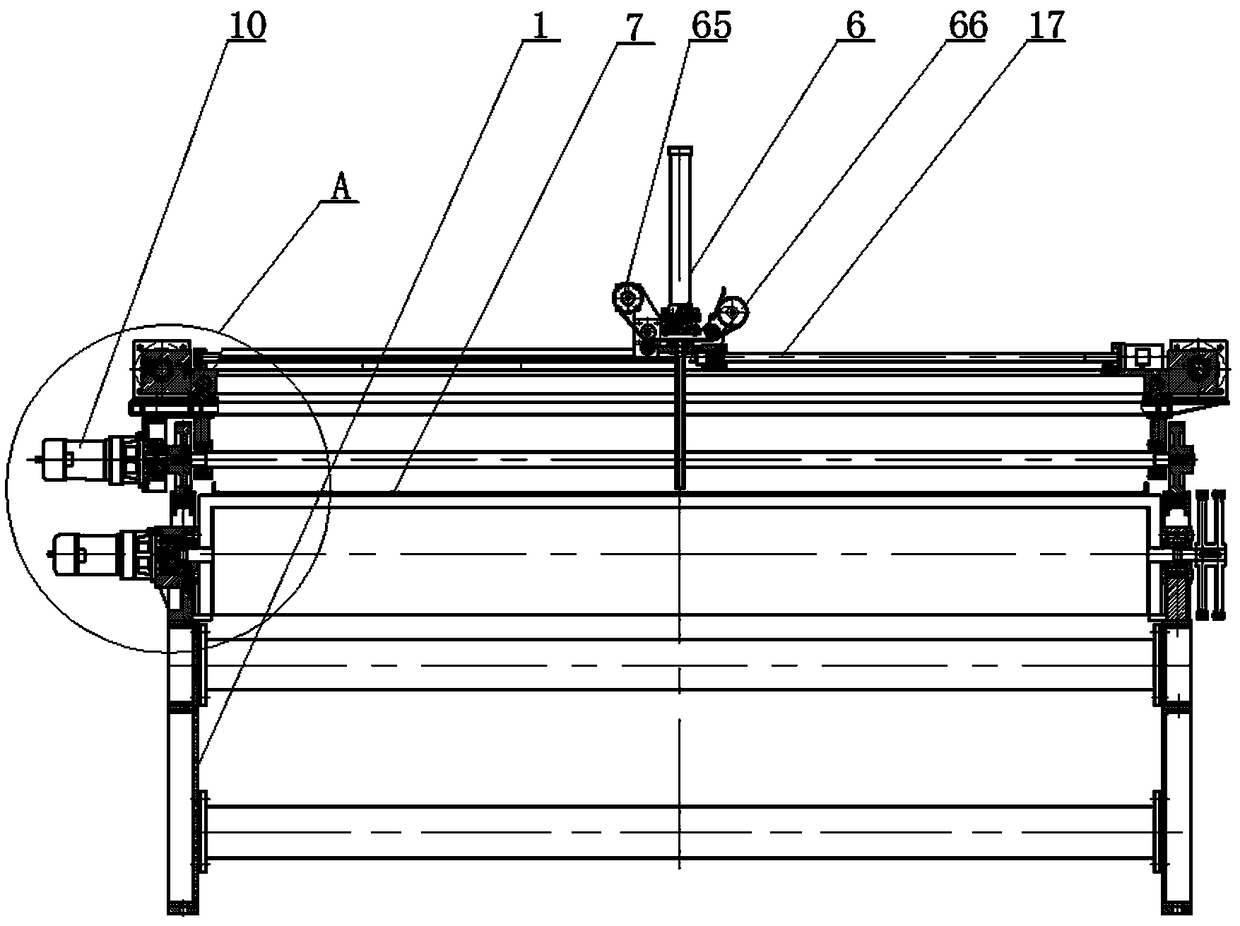

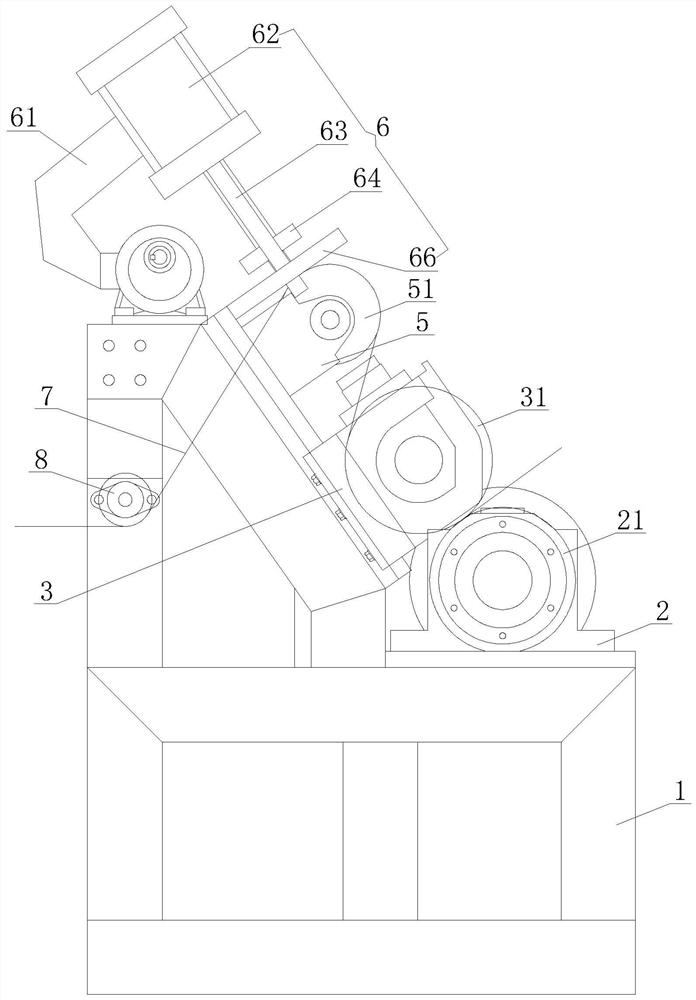

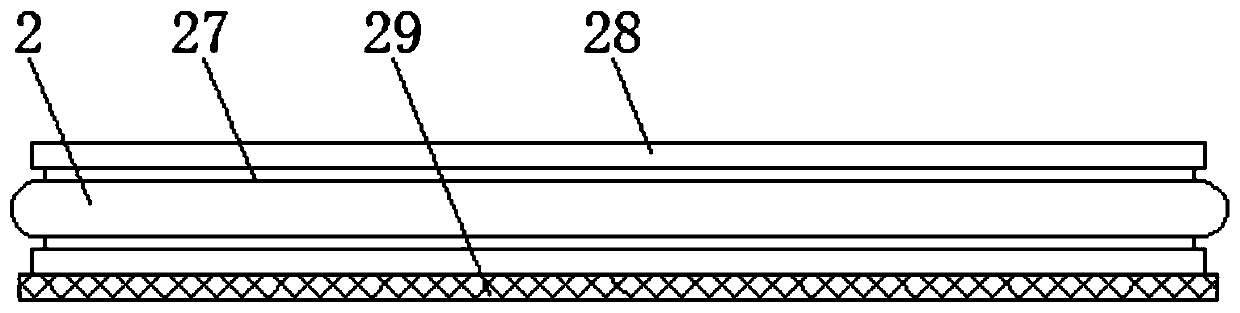

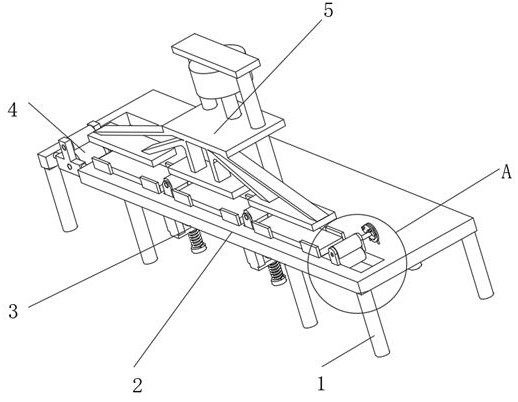

Embosser and method for white pad production

ActiveCN111591075AImprove embossing efficiencyReduce workloadDecorative surface effectsOther artistic work equipmentsManufacturing engineeringManual handling

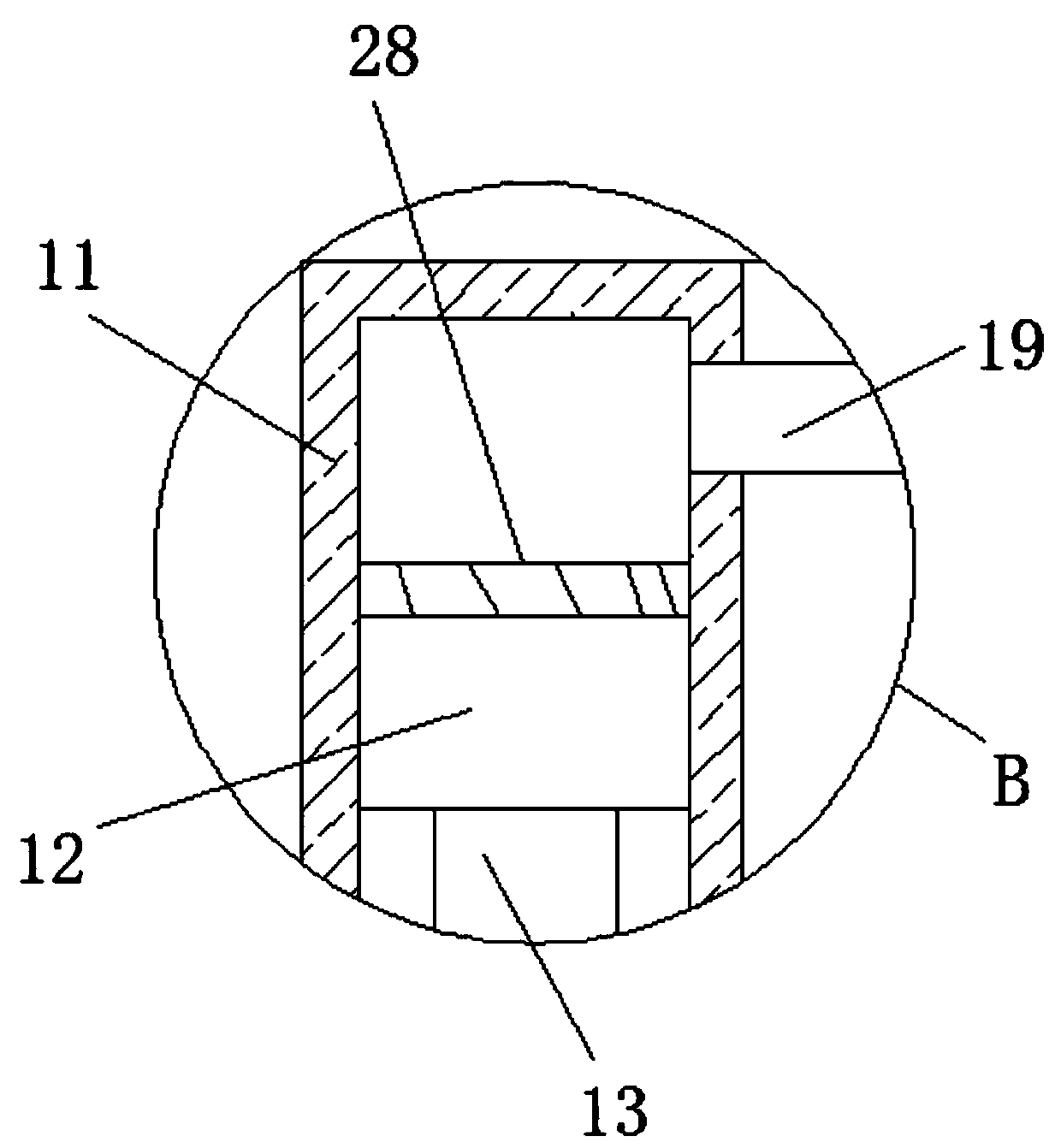

The invention discloses an embosser and a method for white pad production, and belongs to the technical field of embossers. The embosser comprises a machine frame, wherein a supporting base plate A isinstalled on the machine frame, a guide roller A is installed on the supporting base plate A, a supporting base plate B is installed on the side wall of the machine frame, a guide roller B is arranged on the supporting base plate B, and the guide roller B is installed on the supporting base plate B through a supporting mechanism; a tension roller is further installed on the machine frame; an embossing mechanism is arranged on the oblique upper side of the tension roller; and the embossing mechanism comprises a support, a hydraulic cylinder, guide posts, a mounting base, a connecting post andan embossing plate. In the whole embossing process, no manual operation is required, the work burden of operators can be reduced, the embossing efficiency of white pads is improved, when embossing operation is carried out on white pads with different thicknesses, the spacing between the guide roller B and the guide roller A can be adjusted without replacing the guide roller B, use convenience is realized, the usage requirements under different conditions can be met, and the embosser is wide in application range and high in universality.

Owner:ANHUI HECHEN NEW MATERIAL CO LTD

Automatic pattern pasting and pressing device for cloth

ActiveCN109024005AMeet the needs of embossing in large quantitiesAutomate operationTextile decorationEngineeringMechanical engineering

Owner:山东鹤鹏技术有限公司

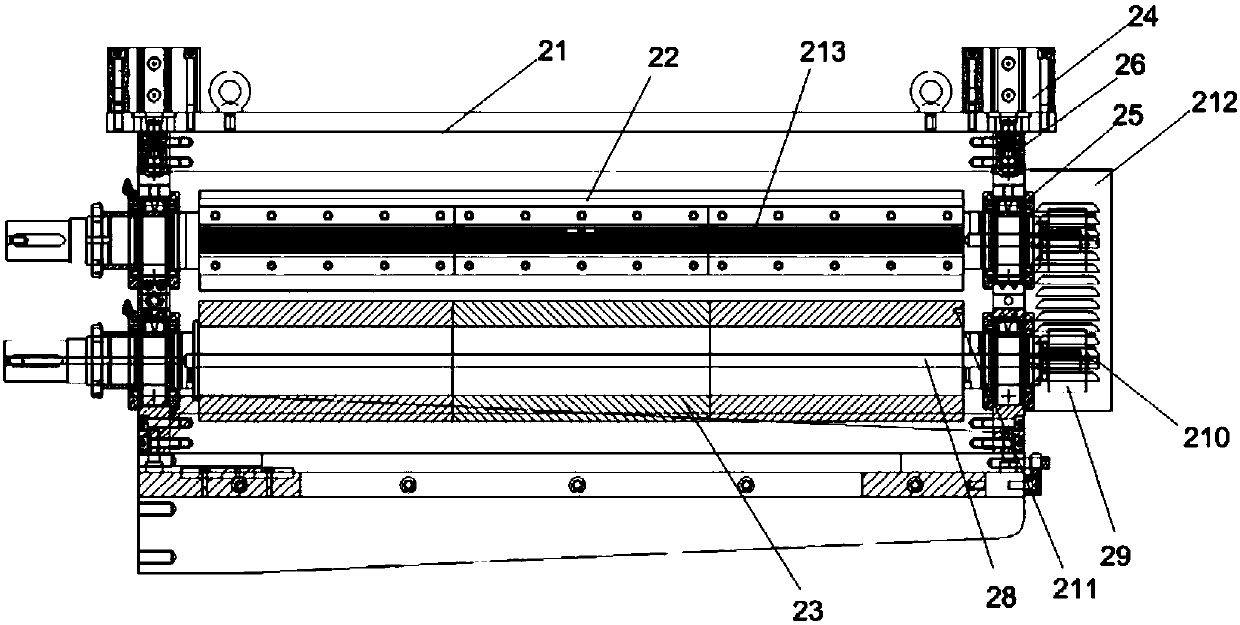

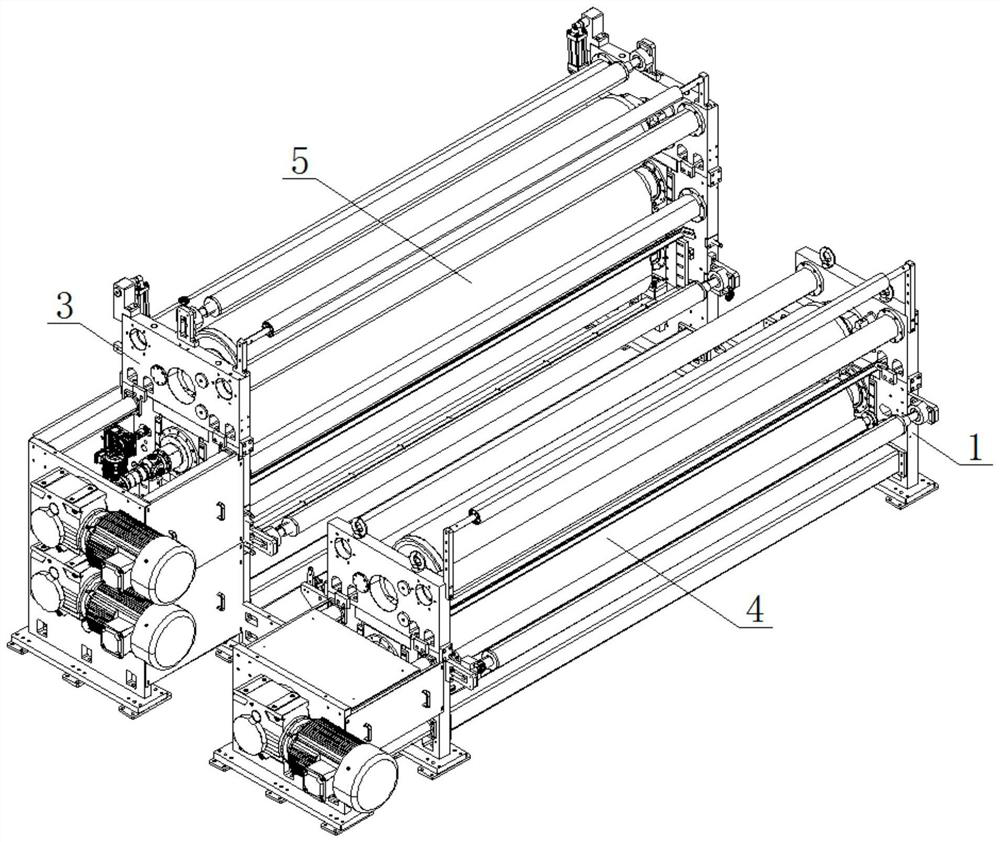

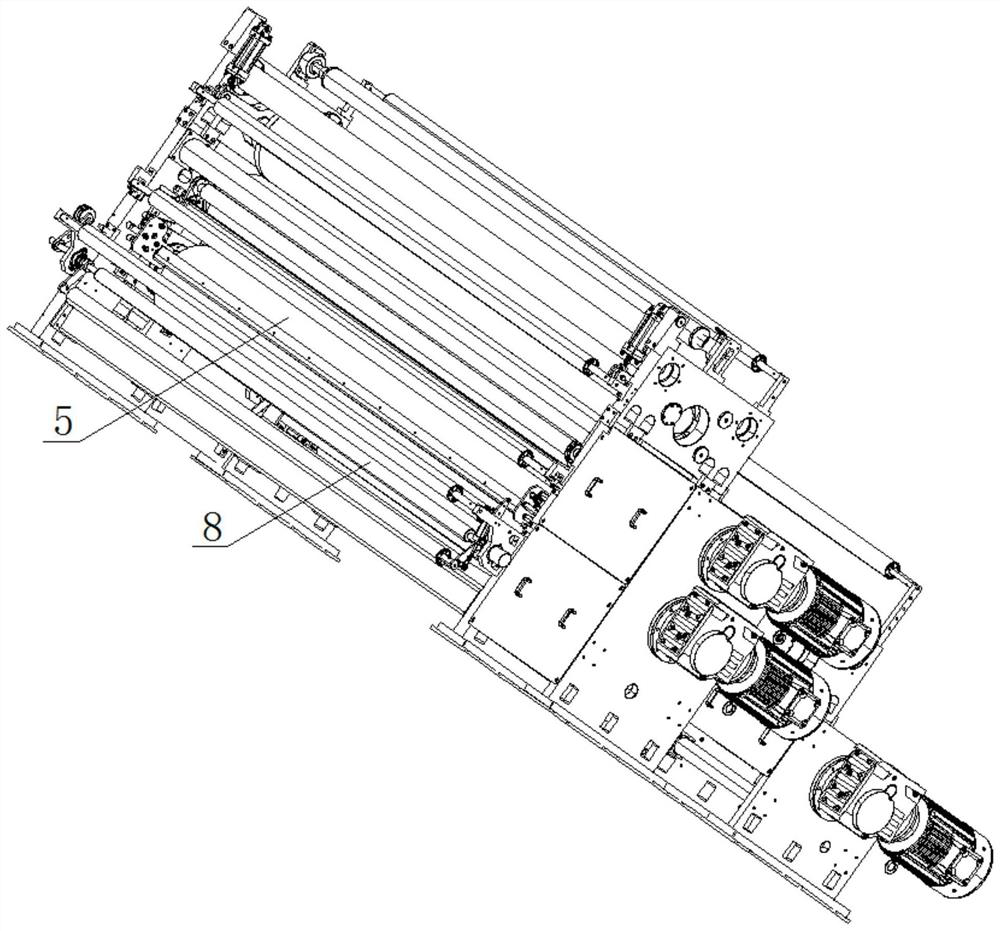

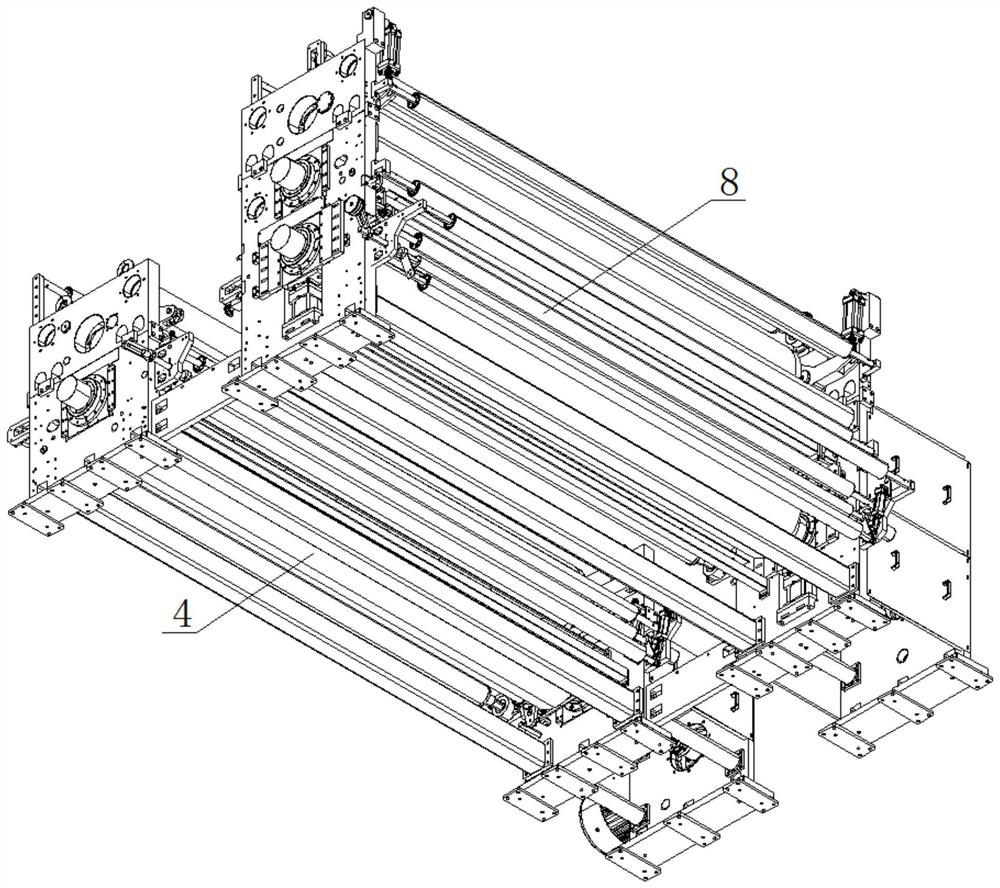

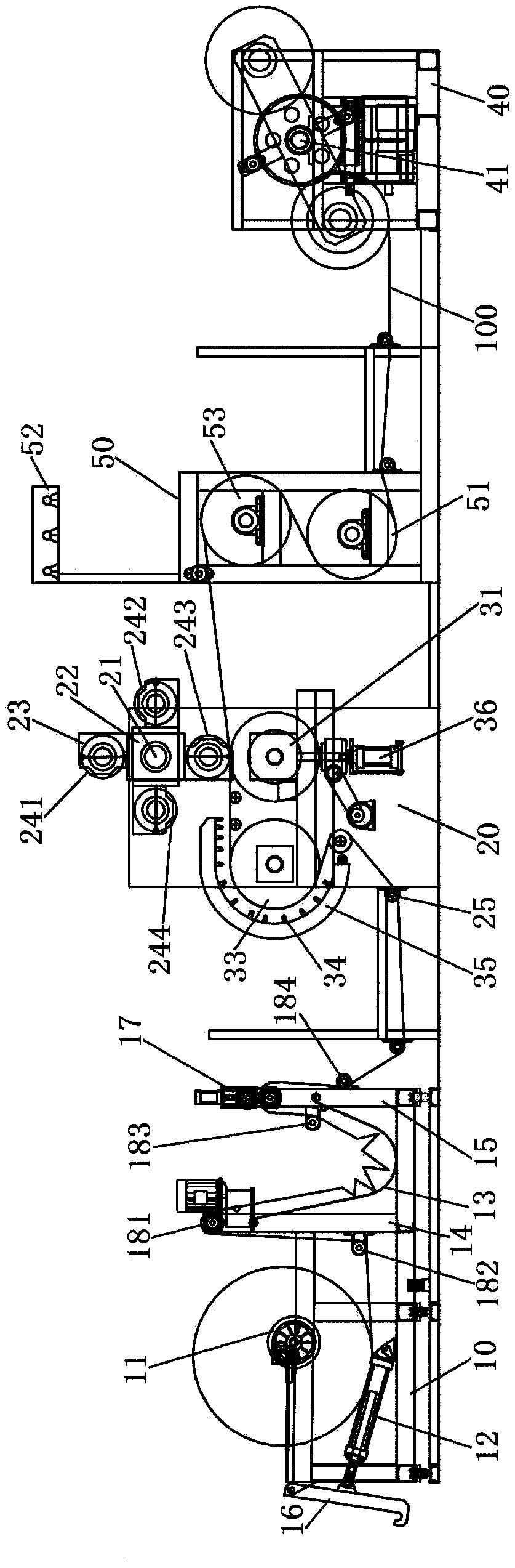

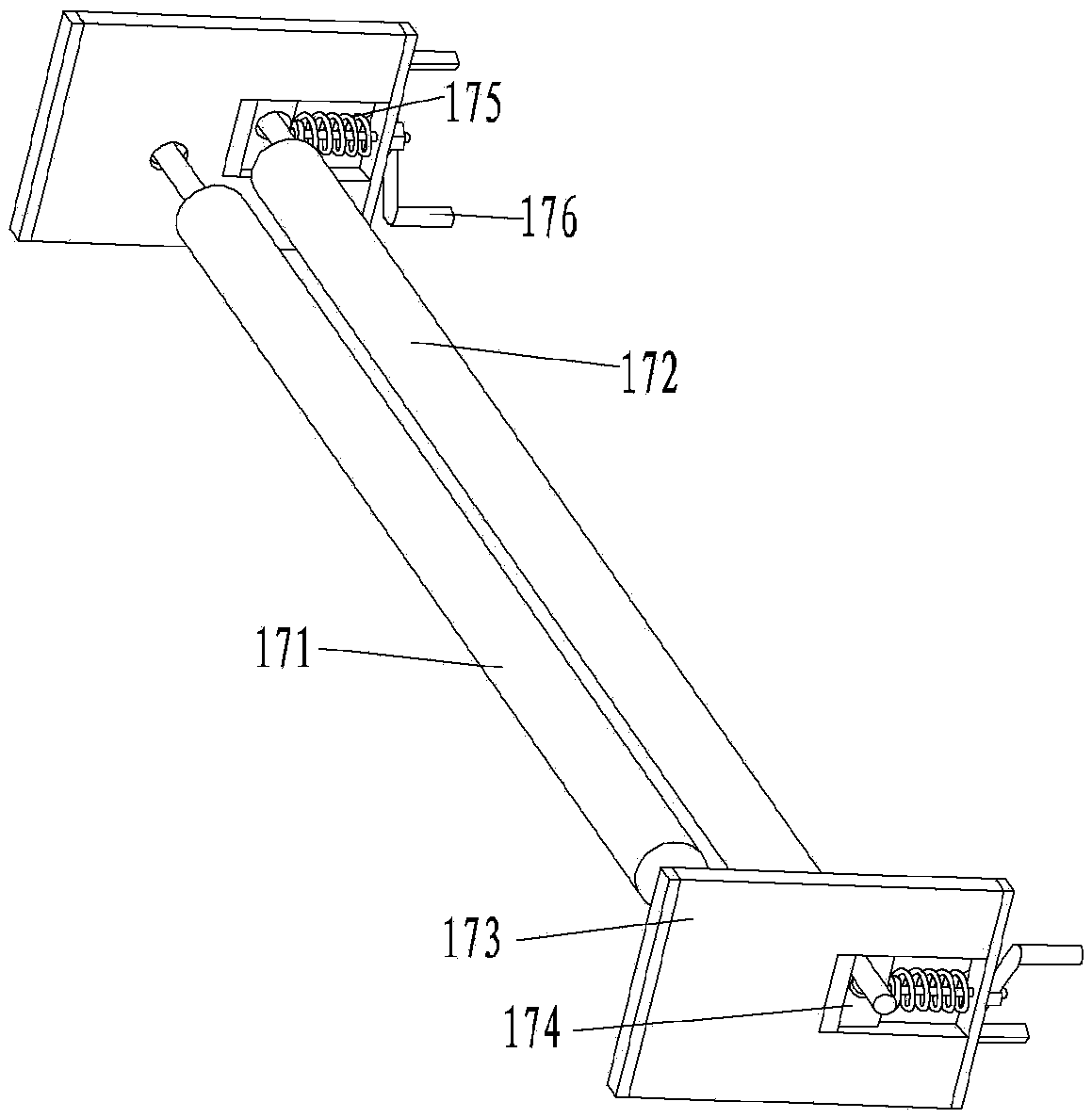

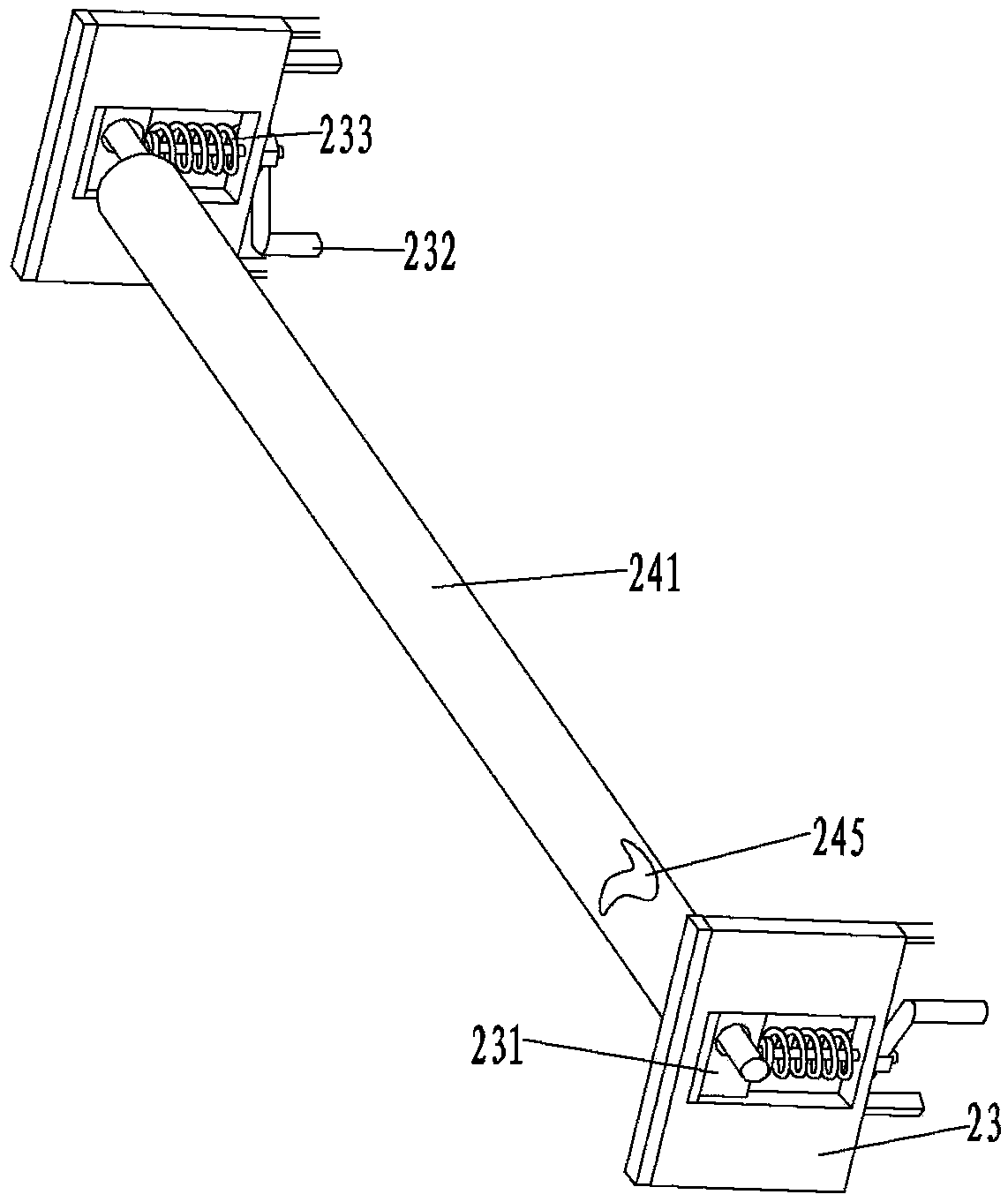

4D complex embossing machine

PendingCN114228261ASpeed up embossingImprove embossing efficiencyMechanical working/deformationPattern makingMachineMachining

The invention discloses a 4D complex embossing machine, and belongs to the technical field of embossing machines, the 4D complex embossing machine comprises a front support seat, a connecting base plate and a rear support seat, the front support seat is fixedly connected with the rear support seat through the connecting base plate, the front support seat is located at the front end of the connecting base plate, the rear support seat is located at the rear end of the connecting base plate, and the connecting base plate is fixedly connected with the rear support seat. A preheating guide mechanism is arranged on the front supporting base, an embossing traction mechanism is arranged on one side of the preheating guide mechanism, and the embossing traction mechanism is installed on the rear supporting base. According to the 4D complex embossing machine, a to-be-machined product is preheated through the upper driven preheating roller and the lower driving preheating roller, the embossing speed of the to-be-machined product can be increased, the embossing efficiency of the to-be-machined product is improved, the preheated to-be-machined product can be embossed through the rotating upper embossing machining roller and the rotating lower embossing machining roller, the embossing effect is good, and the embossing efficiency is improved. And an embossed finished product can be moved to a proper position to be wound, so that the device is convenient to use and can meet the use requirements under different conditions.

Owner:马鞍山市富源机械制造有限公司

Embossing machine and method for white mat production

ActiveCN111591075BImprove embossing efficiencyReduce workloadDecorative surface effectsOther artistic work equipmentsHydraulic cylinderMachine

The invention discloses an embossing machine and method for producing white mats, belonging to the technical field of embossing machines, comprising a frame on which a support substrate A is installed, a guide roller A is installed on the support substrate A, and the frame A support base B is installed on the side wall of the support base B, and a guide roller B is installed on the support base B. The guide roll B is installed on the support base B through a support mechanism, and a tension roller is installed on the frame. The embossing mechanism includes a bracket, a hydraulic cylinder, a guide column, a mounting seat, a connecting column and an embossed plate. The present invention does not require manual operation during the entire embossing process, which can reduce the workload of the operator and improve the embossing efficiency of the white mat. When embossing white mats of different thicknesses, there is no need to replace the guide roller B. The distance between the guide roller B and the guide roller A can be adjusted, which is convenient to use and can meet the use requirements in different situations. It has a wide range of applications and high versatility.

Owner:ANHUI HECHEN NEW MATERIAL CO LTD

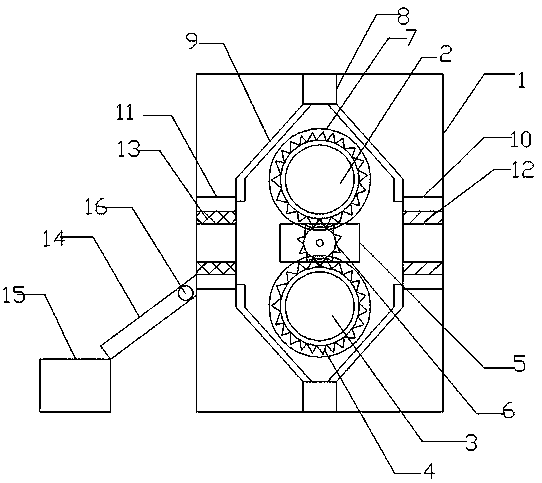

Electric wire embossing device

InactiveCN110600198ASolve slipperyImprove efficiencyApparatus for heat treatmentFormation of corrugations on cables/conductorsGear wheelKnurling

The invention provides an electric wire embossing device comprising a frame. An upper roller and a lower roller are symmetrically arranged on the upper and lower sides of the middle of the frame. A rotating gear is connected on the front end of the upper roller and the lower roller. A drive motor is arranged on the front side of the frame. A linkage gear is connected on the output end of that drive motor. The linkage gear is connected between the upper and lower rotating gears in a meshed way. The surface of the upper rotating roller and the lower rotating roller are provided with a reticulated knurling knife. A hot air pipe is arranged above the upper rotating roller and below the lower rotating roller. The two sides of the hot air pipe are provided with baffles which are respectively attached to the two sides of the upper rotating roller and the two sides of the lower rotating roller. The right side of the frame is provided with a wire inlet base, and the left side of the frame is provided with a wire outlet base. The surface of the upper rotating roller and the lower rotating roller is heated by blowing through the hot air pipes. The drive motor drives the upper rotating rollerand the lower rotating roller to rotate in opposite directions through the linkage gear and the rotating gear, and the reticulated knurling knife on the surface of the upper rotating roller and the lower rotating roller performs embossing on the surface of the electric wire so that the transmission slip of the electric wire can be reduced and the production efficiency can be enhanced.

Owner:WUHU SHUNCHENG ELECTRONICS

Embossed aluminum alloy mosaic and automatic embossing device thereof

PendingCN110593503AImprove efficiencyEasy to replaceCovering/liningsEmbossing decorationsAluminium alloyProtection layer

The invention discloses an embossed aluminum alloy mosaic and an automatic embossing device thereof, and relates to the field of mosaic production equipment. The mosaic comprises an aluminum alloy mosaic main body, the top and the bottom of the aluminum alloy mosaic body are provided with color layers, the sides, away from the aluminum alloy mosaic body, of the two color layers are provided with protection layers, a gridding cloth is pasted on the bottom of the color layer on the bottom of the aluminum alloy mosaic body, a base and a moving plate are included, the bottom of the moving plate issequentially and fixedly connected with a first vertical block, a sliding rail and a second vertical block from left to right, one side of the second vertical block is fixedly connected with a motor,and one end of a motor output shaft is fixedly connected with a thread rod. When the embossed aluminum alloy mosaic is made, rapid embossing is carried out, the embossing efficiency is improved, an embossing mold of the embossing machine can be conveniently replaced, the embossing process is rapid and convenient, time and effort are saved, and the production efficiency of the embossed aluminum alloy mosaic can be greatly improved.

Owner:佛山市南海区科米尼建材装饰有限公司

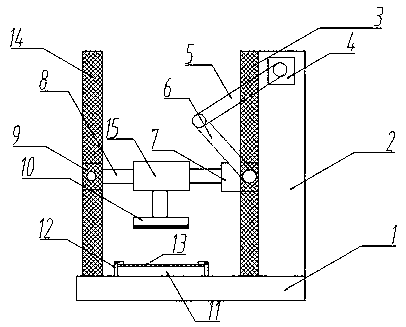

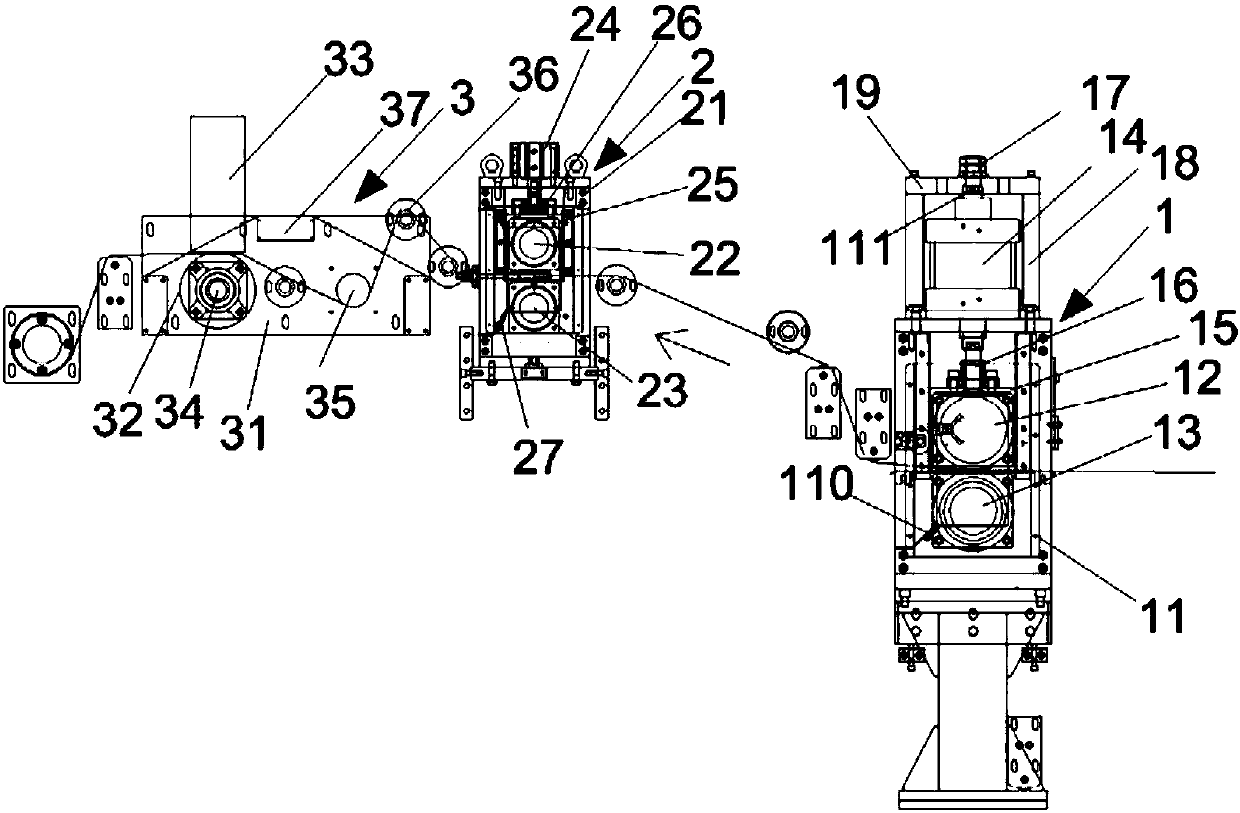

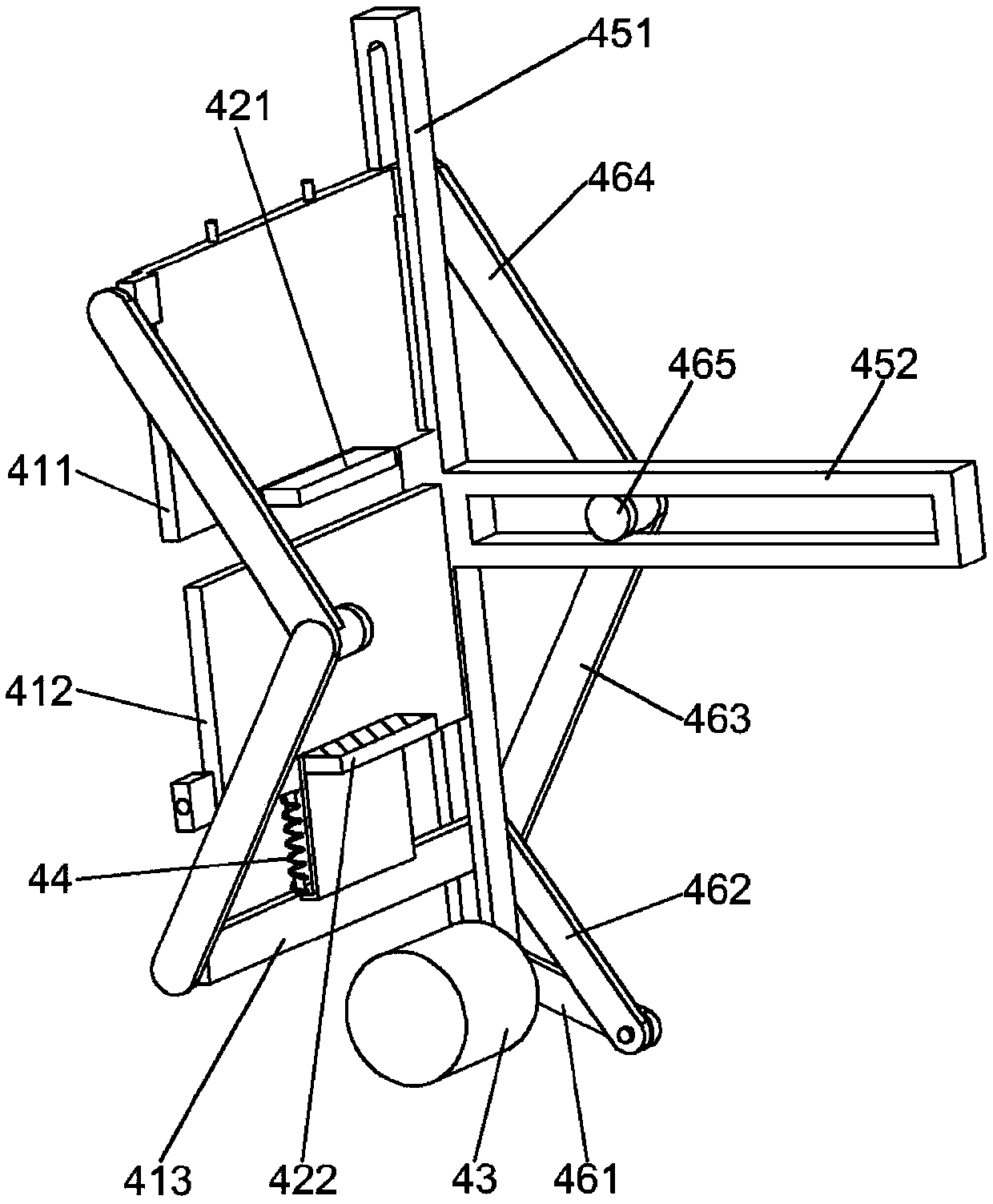

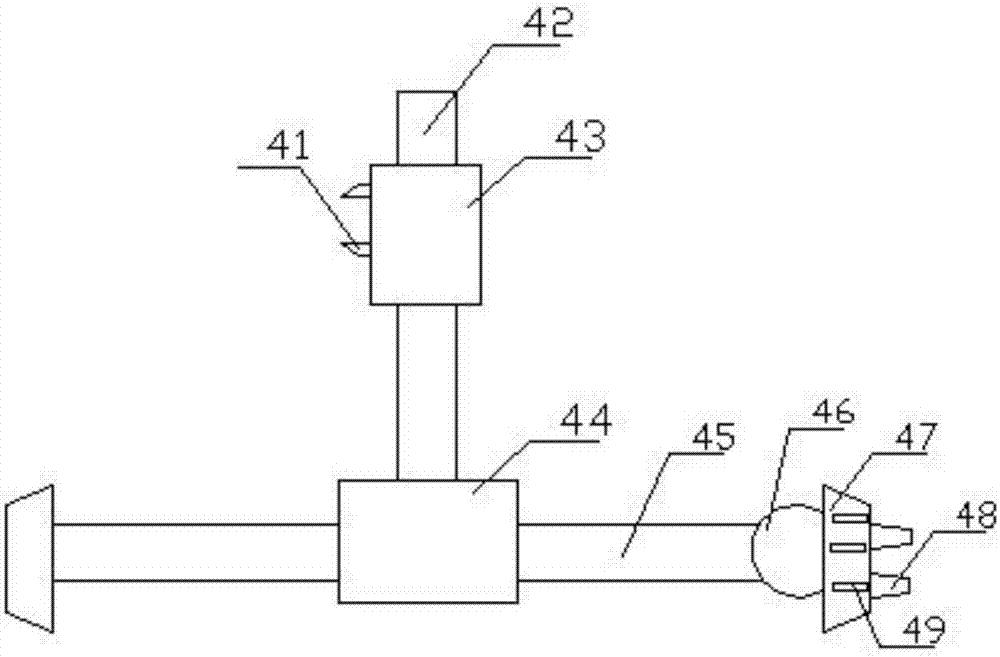

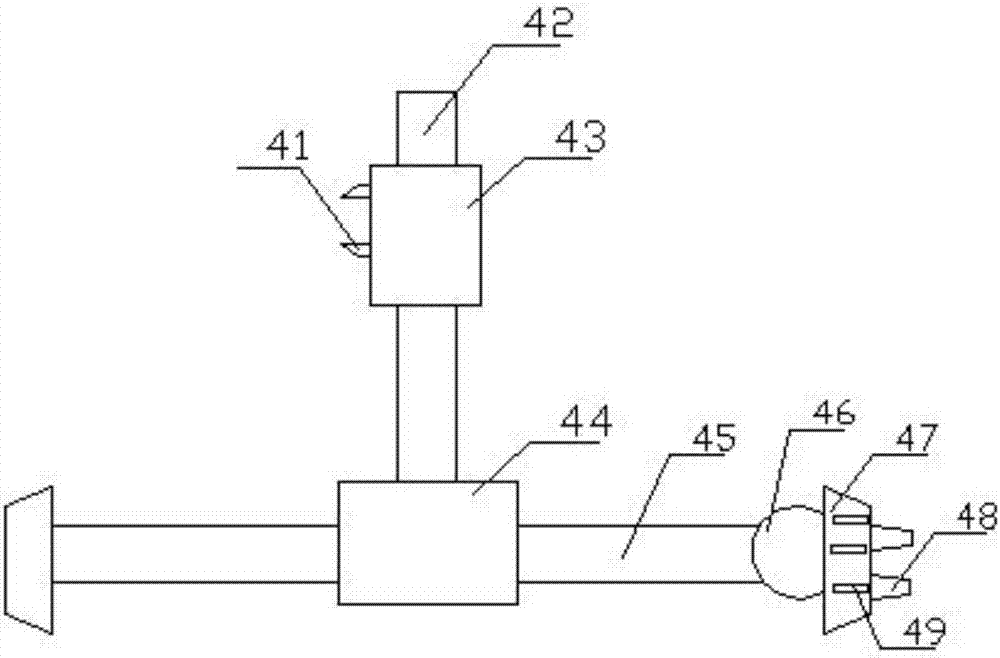

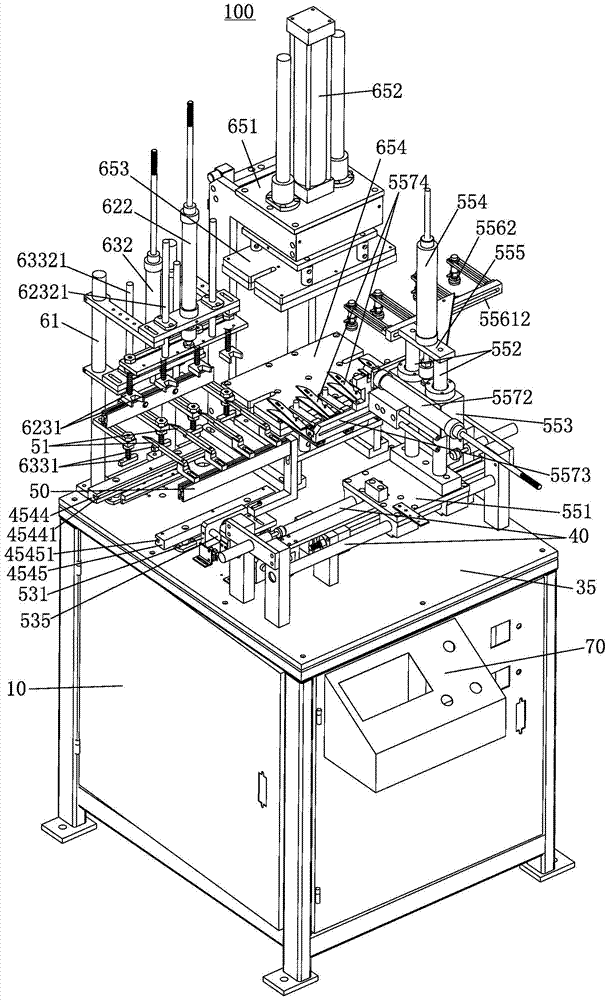

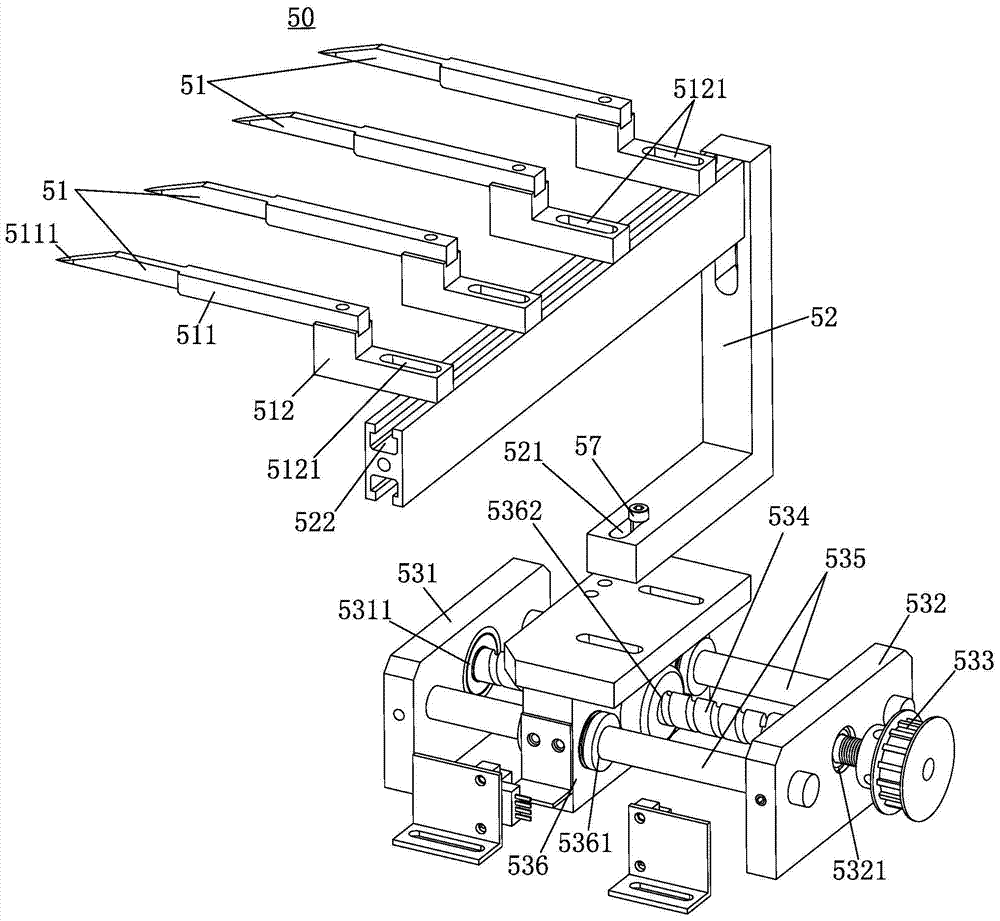

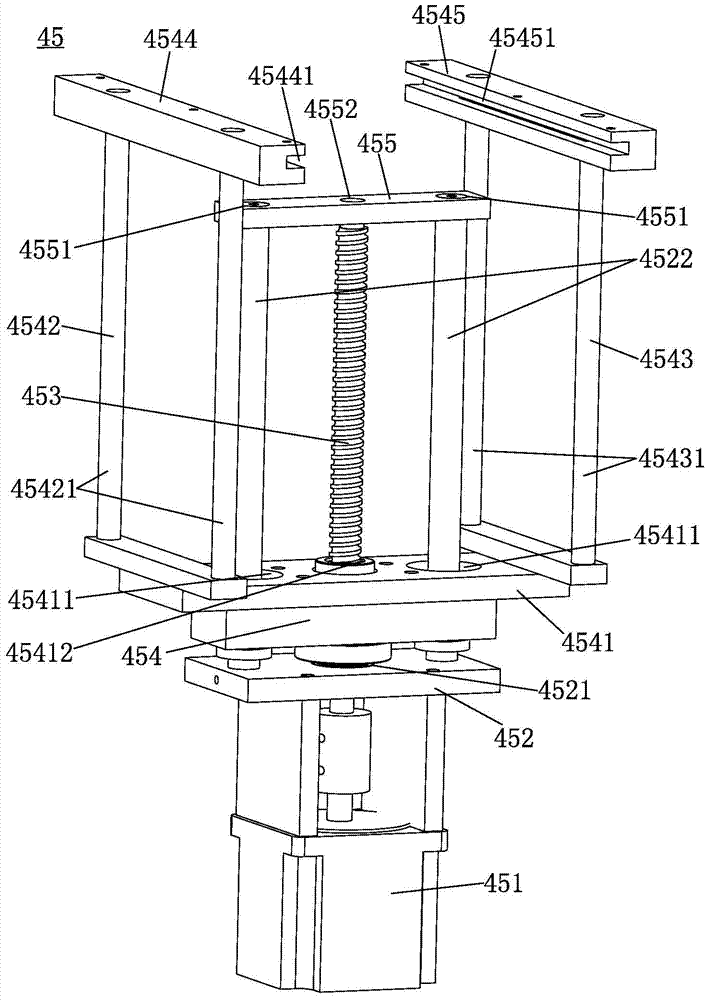

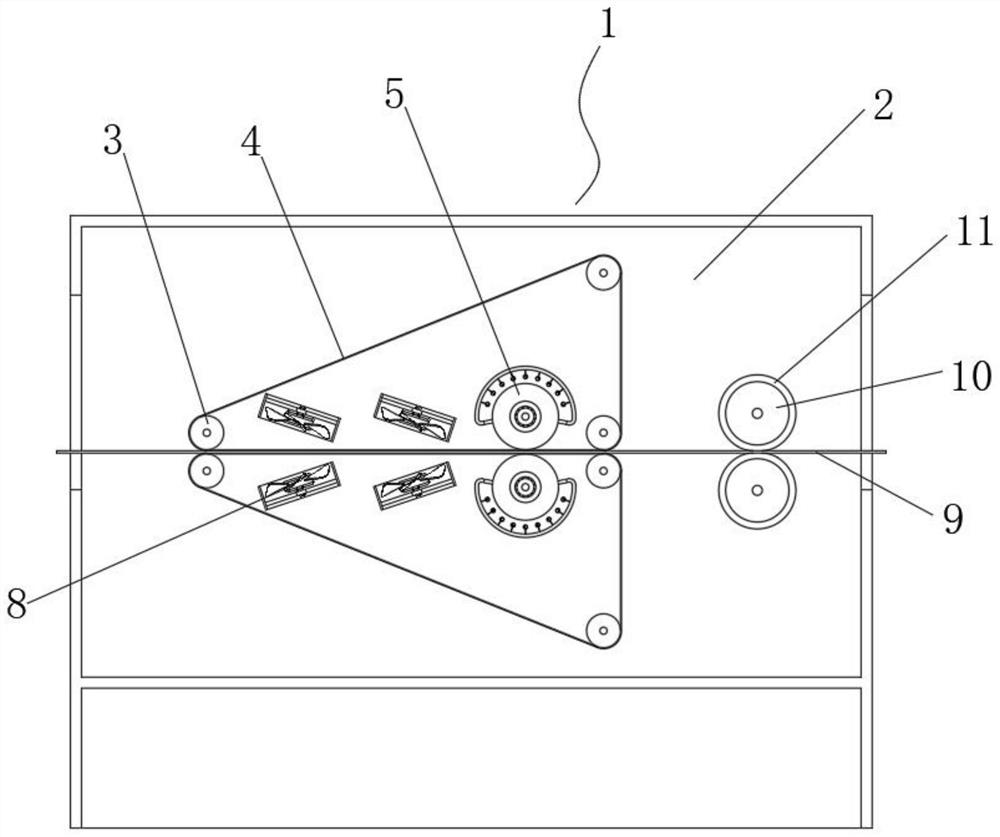

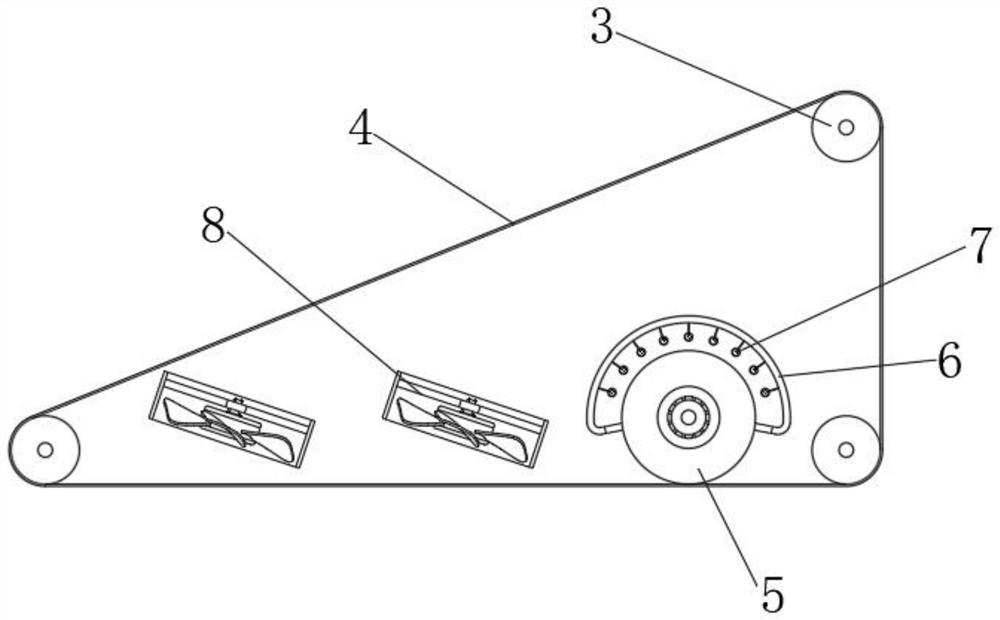

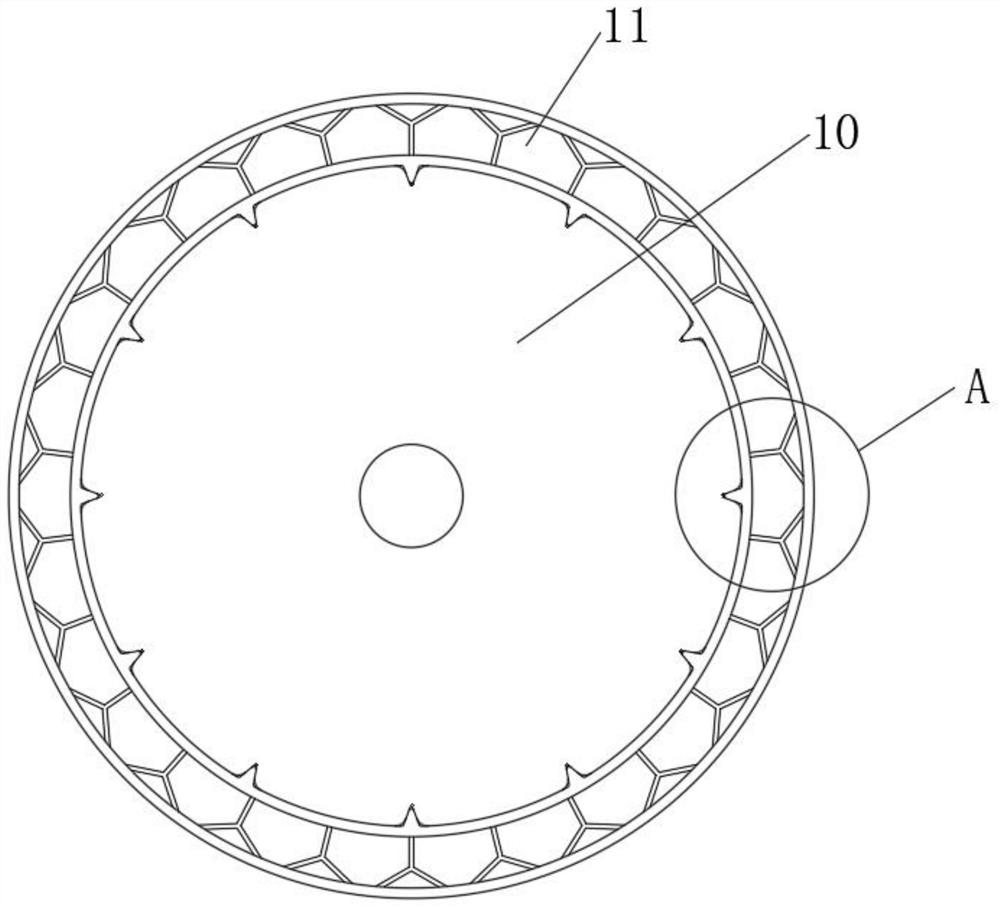

Automatic embossing equipment

ActiveCN104742630BCompact structureHigh pressing shape accuracyEmbossing decorationsPunchingEngineering

The invention discloses automatic embossing equipment. The automatic embossing equipment comprises a rack, a mounting plate installed at the top of the rack, two horizontal sliding rails installed at the top of the mounting plate, a multifunctional embossing mechanical arm, an embossing lifting feeding mechanism, a flower arrangement detaching mechanism, an embossing mechanism, a punching mechanism and a control panel. The flower arrangement detaching mechanism is located at the left middle portion of the mounting plate, the embossing lifting feeding mechanism is installed below the front, corresponding to the flower arrangement detaching mechanism, of the mounting plate, the embossing mechanism is located above the front, corresponding to the embossing lifting feeding mechanism, of the mounting plate, the punching mechanism is located at the right side of the embossing mechanism, and the horizontal sliding rails are horizontally installed at the rear portion of the upper surface of the mounting plate. The multifunctional embossing mechanical arm comprises a horizontal sliding block, two perpendicular guide rails, a perpendicular sliding block, a perpendicular air cylinder, a perpendicular air cylinder mounting plate, a suction nozzle mechanism and a georgette mechanism, and the control panel is installed on the rack. According to the automatic embossing equipment, full automation of the embossing process is achieved, the embossing efficiency is improved greatly, and the precision of flower blank piece suppressing shapes is high.

Owner:中山碧瑞金属制品有限公司

Production process of hydrophobic melt-blown cloth

PendingCN111979684AImprove the heating effectEasy embossingPattern makingHeating/cooling textile fabricsThermodynamicsEngineering

The invention belongs to the technical field of melt-blown cloth, and particularly relates to a production process of hydrophobic melt-blown cloth. The production process comprises a melt-blown clothdouble-sided embossing machine and melt-blown cloth installed in the melt-blown cloth double-sided embossing machine, wherein the melt-blown cloth double-sided embossing machine comprises an outer shell and an embossing assembly, the embossing assembly comprises a driving roller, a steel wire embossing net, a heating roller, a heat collecting cover and a heating resistance wire, the driving rolleris installed on the inner surface of the outer shell, the steel wire embossing net is arranged outside the driving roller in a sleeving manner, and the two ends of the heating roller are rotationallyinstalled on the inner surface of the outer shell. The embossing assembly is composed of the driving roller, the steel wire embossing net, the heating roller, the heat collecting cover and the heating resistance wire, and the embossing assembly is installed inside the outer shell, so that the embossing assembly can conveniently emboss the melt-blown cloth, meanwhile, the steel wire embossing netis wrapped outside the driving roller, the heating roller is in contact with the inner surface of the steel wire embossing net, and meanwhile, the heat collecting cover covers the outside of the heating roller.

Owner:济宁百优特管业有限公司

A fur embossing device capable of automatic discharge

ActiveCN106987659BEasy to adjustImprove embossing efficiencyLeather surface mechanical treatmentEngineeringTransverse beam

The invention relates to the technical field of fur embossing, in particular to a fur embossing device capable of achieving automatic discharging. The fur embossing device capable of achieving automatic discharging comprises a base, and further comprises a supporting frame arranged at the edge of the upper end of the base, a transverse beam arranged at the upper portion of the rising supporting frame, an operation table arranged on the upper side of the base, a transmission component arranged on the lower side of the transverse beam, a motor arranged at the upper end of the transmission component in a rotary manner, an installation barrel arranged on the outer side of the transmission component and an embossing plate arranged on the outer side of the installation barrel.

Owner:JIASHAN SHENGLAISI CASHMERE

Leather embossing equipment

InactiveCN107177704AImprove embossing efficiencyGood embossing qualityLeather surface mechanical treatmentEngineeringDrive shaft

The invention relates to the technical field of leather processing, in particular to leather embossing equipment. The leather embossing equipment comprises a first operating frame and further comprises a second operating frame, a first embossing component, a second embossing component and a support component, wherein the second operating frame is arranged at the end of the first operating frame, and the first embossing component is arranged on the upper portion of the first operating frame in a penetrating manner. The first embossing component comprises a carrying plate, a transmission shaft, a motor, fixing rods, a squeezing component, a mounting disc, a first spring, tool rods, tool aprons and tool bits, wherein the transmission shaft is arranged inside the carrying plate in a penetrating manner; the motor is connected to the upper end of the transmission shaft in a rotary manner; the squeezing component is connected to the lower portion of the transmission shaft in a rotary manner through a thread; the mounting disc is connected to the lower end of the transmission shaft in a rotary manner through a thread; the first spring is arranged on the transmission shaft in a sleeving manner and tightly pressed between the squeezing component and the mounting disc; the tool rods are connected to the lower portion of the mounting disc in a clamped manner; each tool apron is connected to the lower portion of the corresponding tool rod in a rotary manner through a thread; and each tool bit is connected to the lower side of the corresponding tool apron in a clamped manner. The leather embossing equipment is high in embossing efficiency and good in embossing quality.

Owner:JIASHAN SHENGSHIDE FUR GARMENT

Multi-station garment embossing machine for garment equipment

InactiveCN111850915ALow costNo human intervention requiredPattern makingEngineeringMechanical engineering

The invention discloses a multi-station garment embossing machine for garment equipment, which relates to the technical field of garment processing, in order to solve the problem of low efficiency. The multi-station garment embossing machine for the garment equipment specifically includes a worktable, a conveying mechanism, an embossing mechanism, and an adjustable damping material guiding mechanism; the worktable is fixed to the ground by device legs, and the inner wall of the worktable is provided with a conveying groove, a tensioning groove and a material guiding groove respectively; the conveying mechanism is arranged at a position of the worktable close to the conveying groove; the adjustable damping material guiding mechanism is arranged at a position of the worktable close to the material guiding groove; and the embossing mechanism is arranged on the top outer wall of the worktable. When the multi-station garment embossing machine for the garment equipment is in use, one end ofthe garment is fixed by the adjustable damping material guiding mechanism, and then pulled between a lower mold and an upper mold in a parallel manner, and finally fixed by the conveying mechanism; and the conveying mechanism cooperates with the adjustable damping material guiding mechanism to complete the loading and unloading of garment during the entire work process without manual intervention,which greatly improves the efficiency of embossing, thereby reducing the increase in clothing cost.

Owner:安徽工美服装有限公司

Embossing device for garment fabric

The invention discloses an embossing apparatus for a garment material. The embossing apparatus comprises a feeding mechanism, an embossing mechanism, a material recovering mechanism and a drying mechanism, wherein the feeding mechanism comprises a feeding rack, a feeding roll, a feeding cylinder, a storage bin, a pressing and conveying assembly and a conveying roll; the embossing mechanism comprises an embossing frame, an embossing shaft, an embossing motor, an end plate, a station plate, a first embossing roll, a second embossing roll, a third embossing roll, a fourth embossing roll, a lower embossing roller, a conveying roller, a shell cover and a hot steam nozzle; the lower embossing roller is provided with concave patterns respectively matching with a first convex pattern, a second convex pattern, a third convex pattern and a fourth convex pattern; and the drying mechanism comprises a drying rack, a cold-air drier, a drying roller and an auxiliary roll. The embossing apparatus provided by the invention is simple to operate, high in an automation degree, capable of pressing complex and changeable patterns on fabrics, good in embossing quality and high in embossing efficiency.

Owner:JIAXING WANYUAN FASHION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com