Patents

Literature

40results about "Formation of corrugations on cables/conductors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

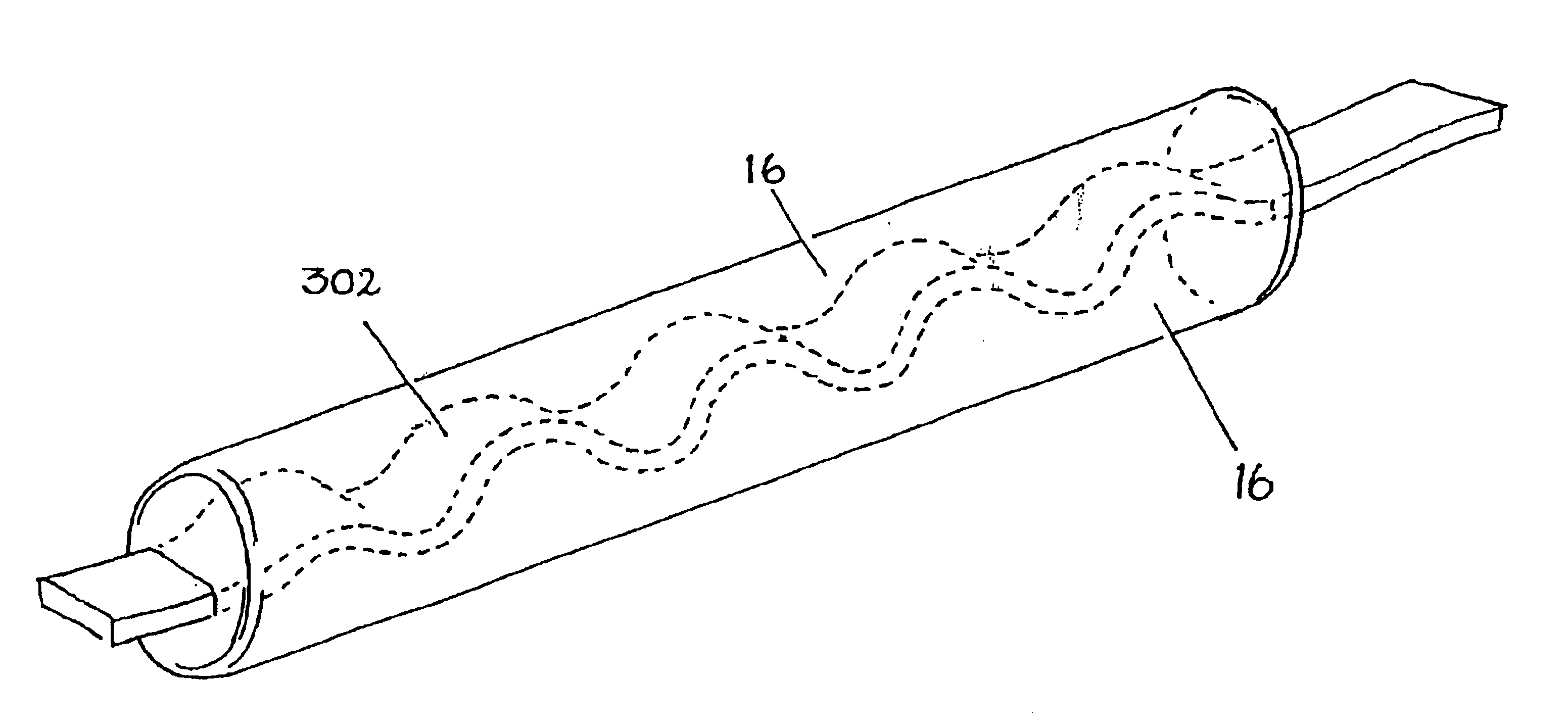

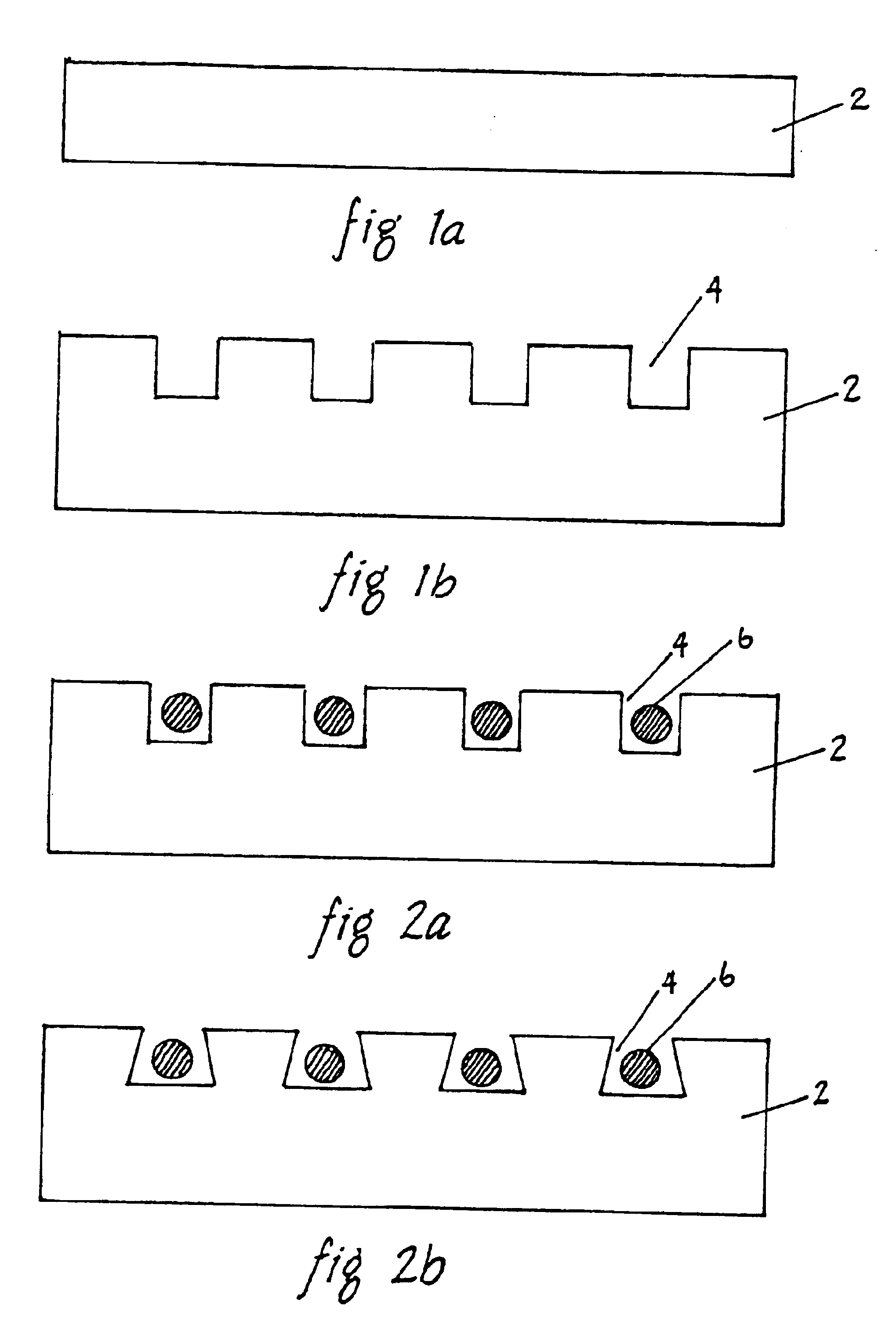

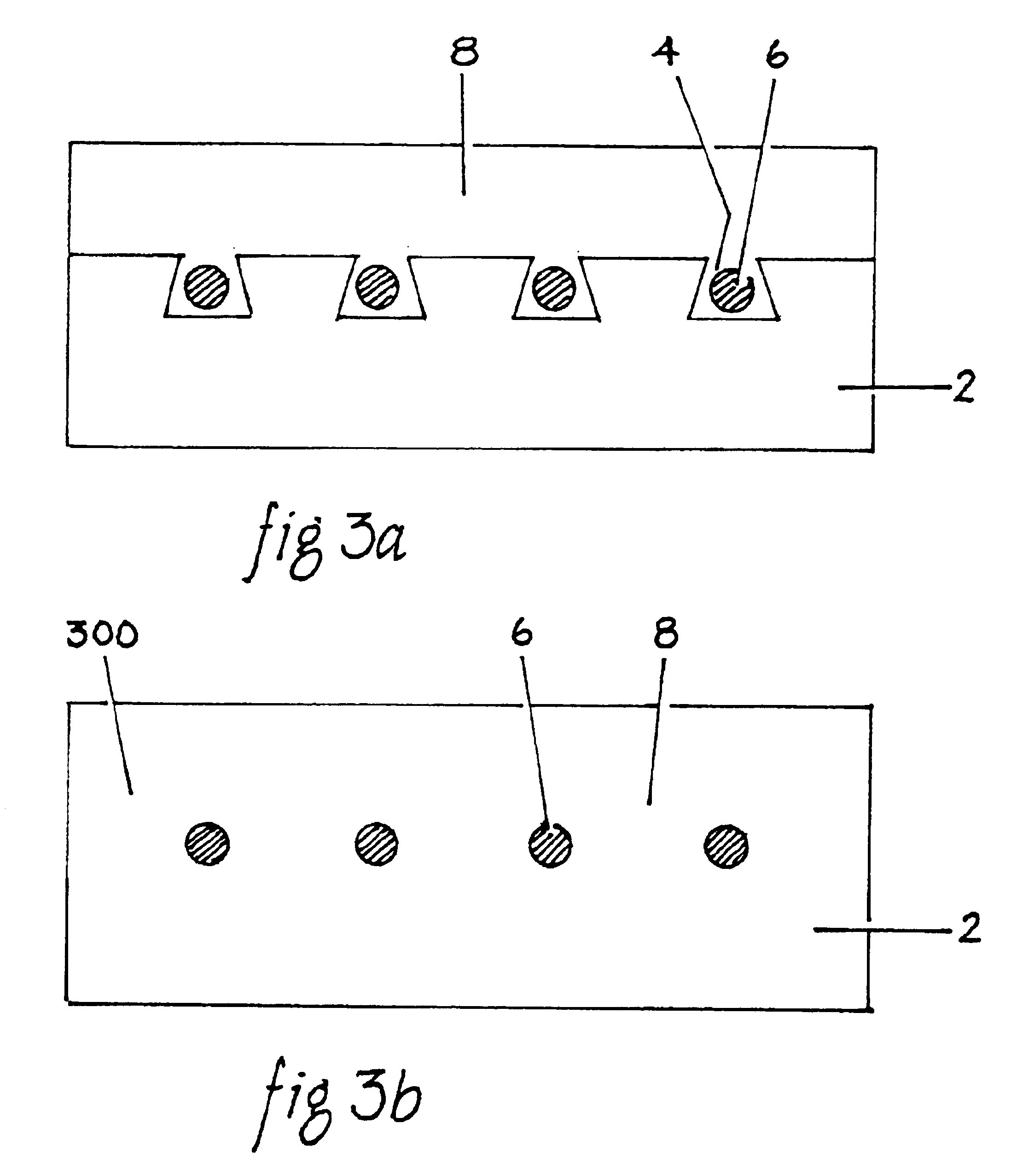

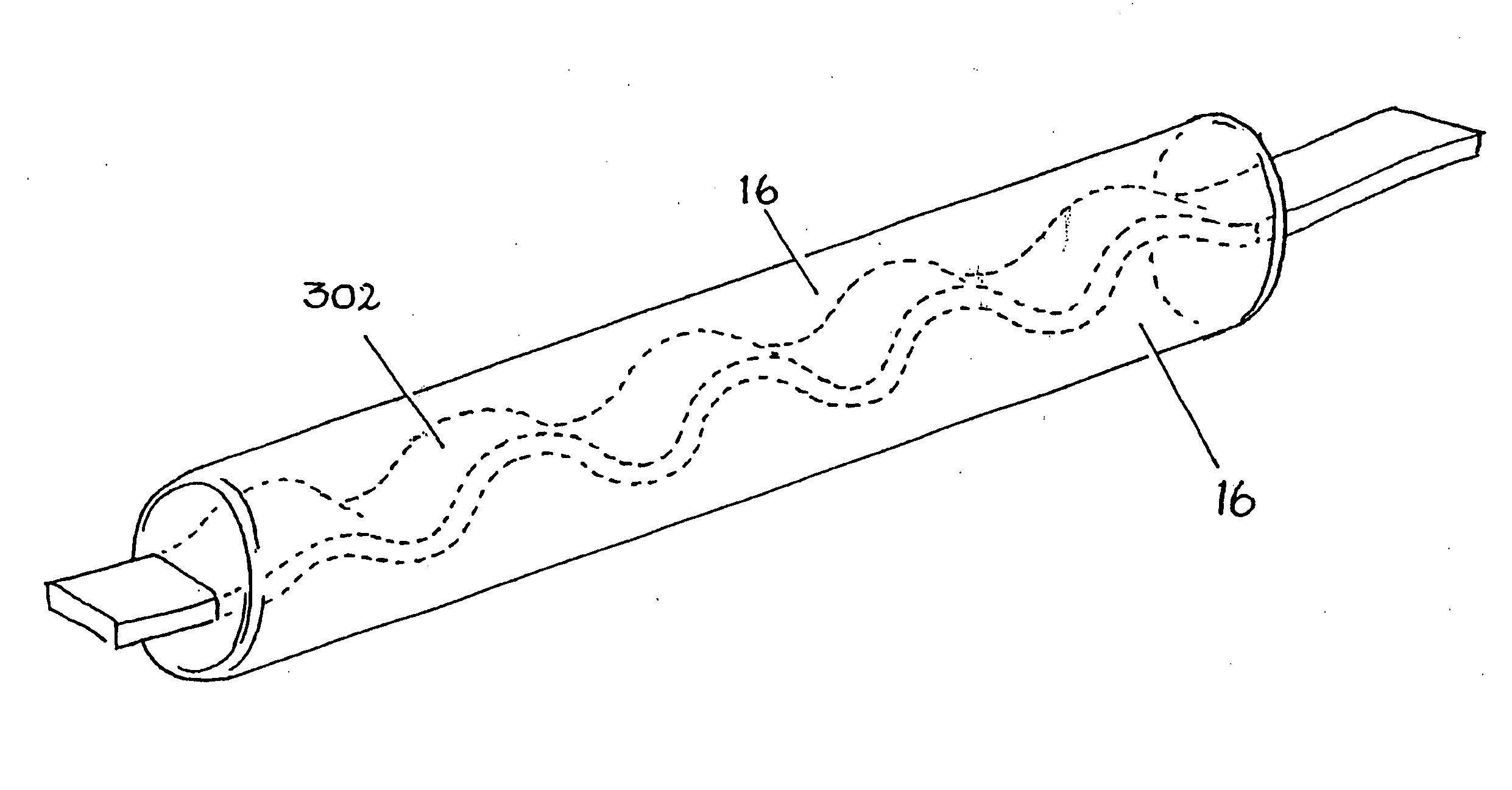

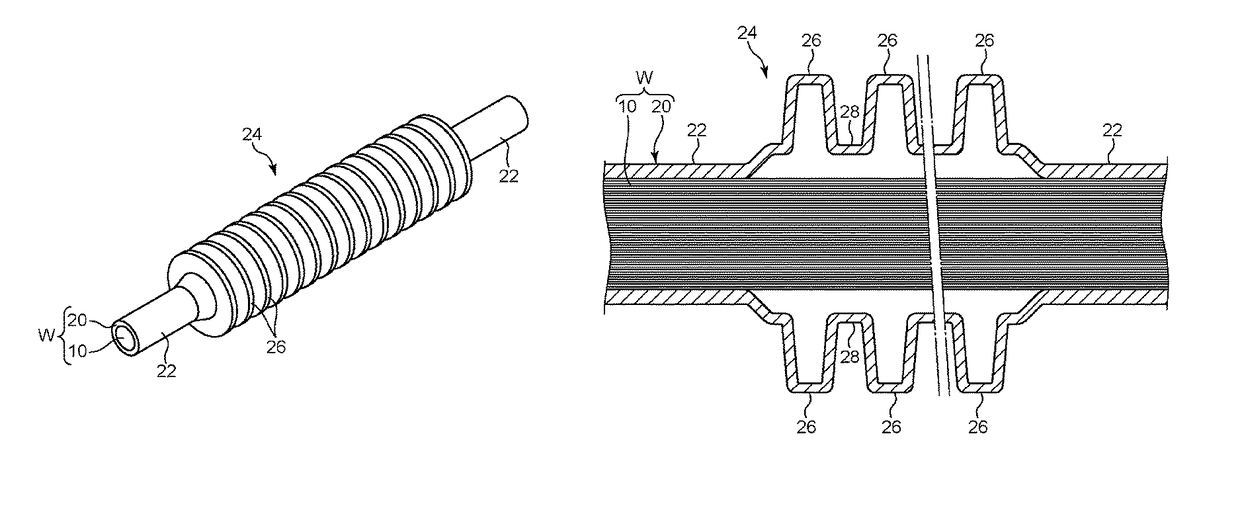

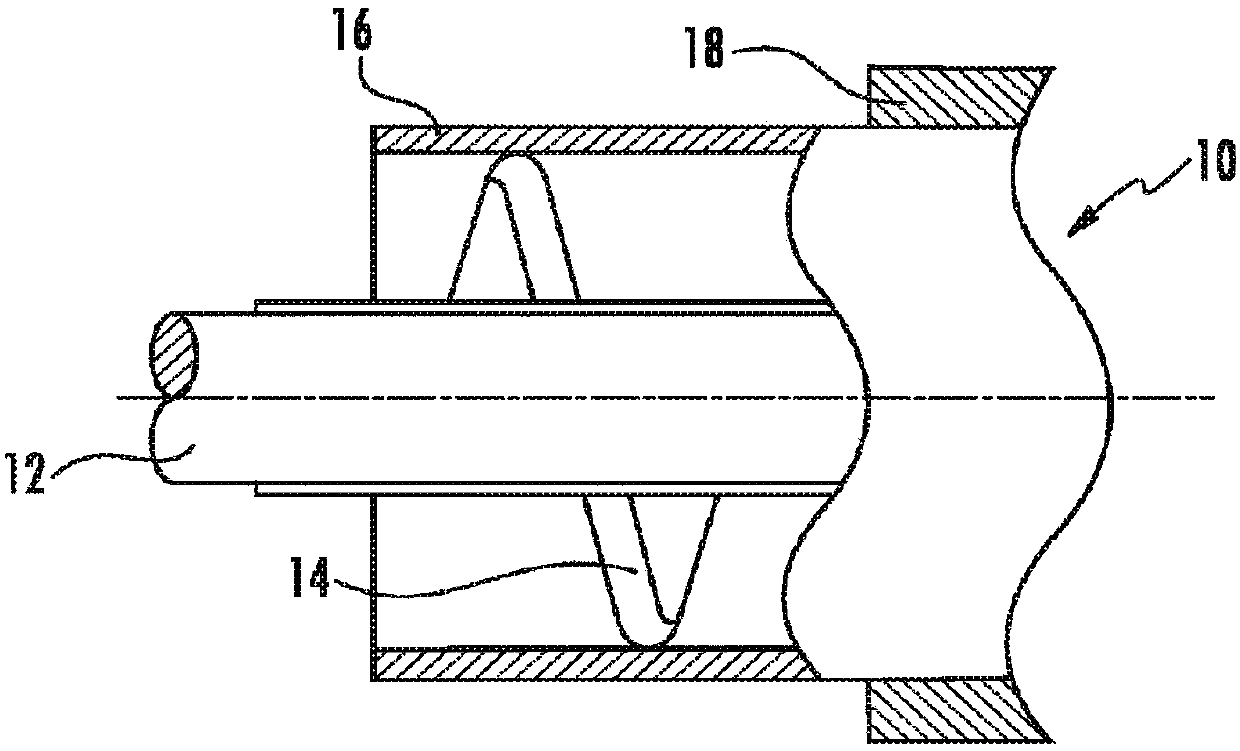

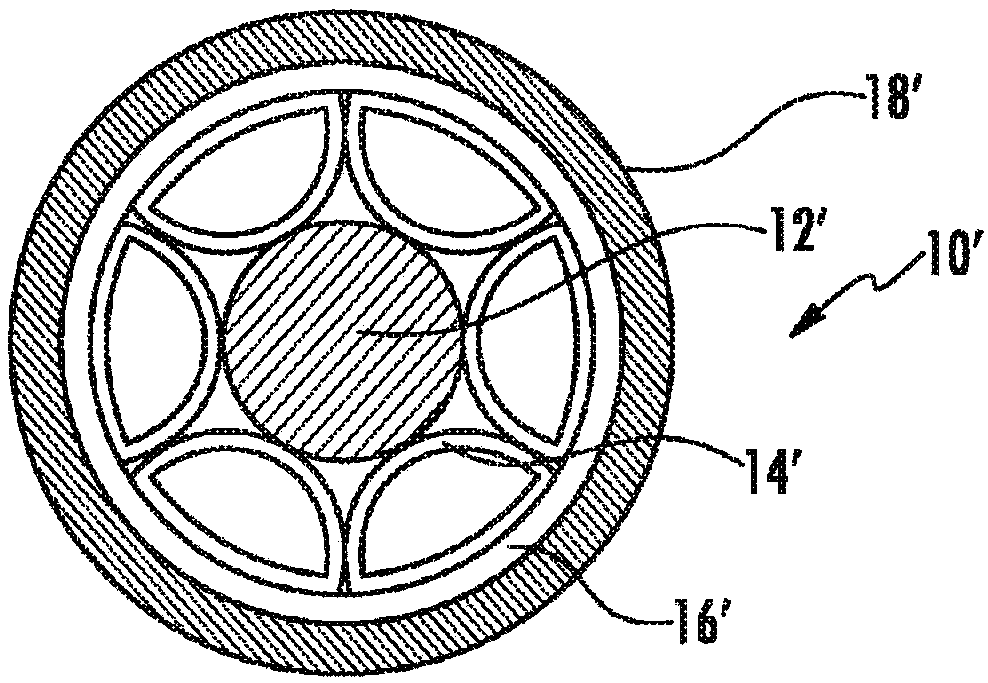

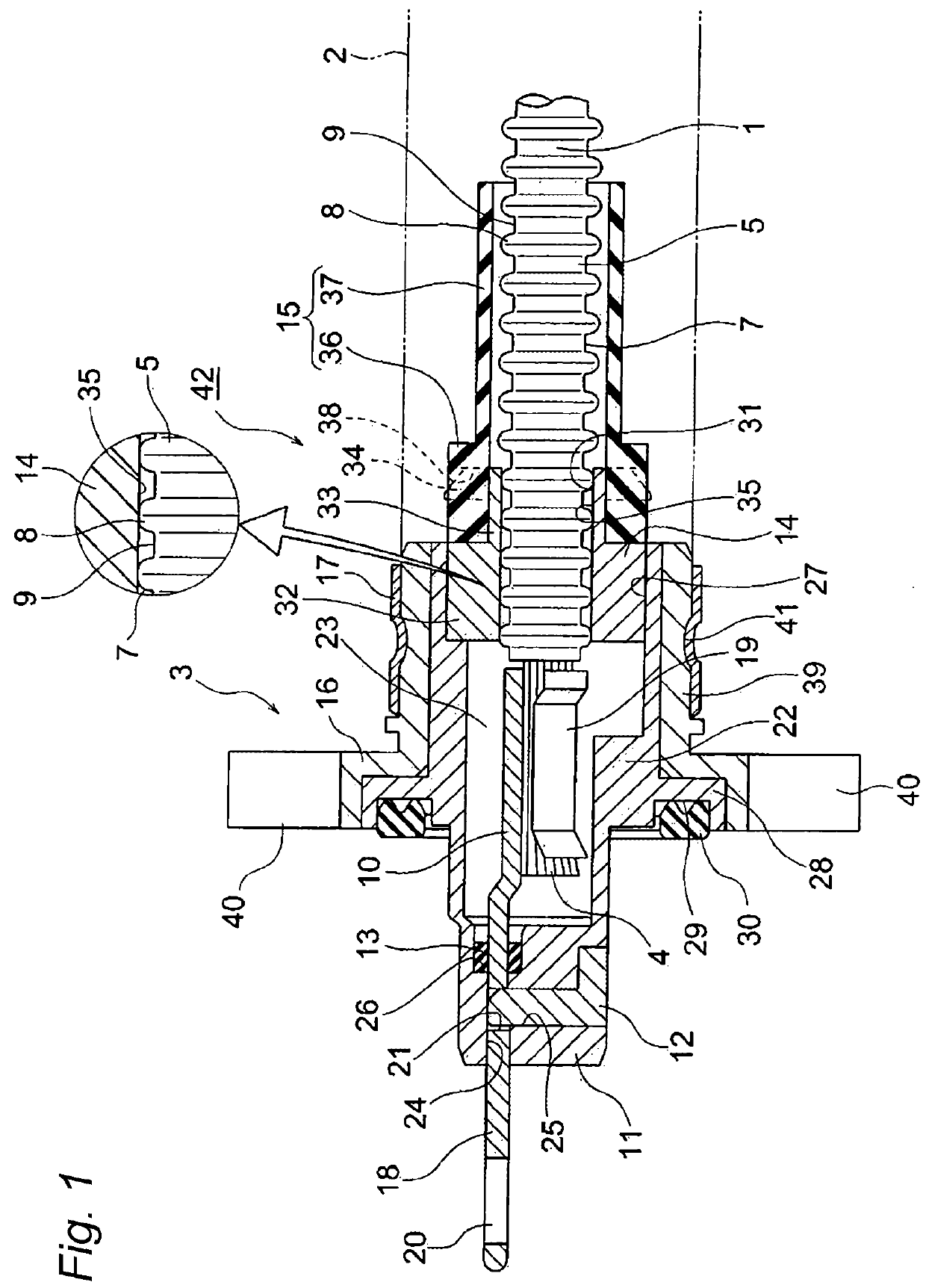

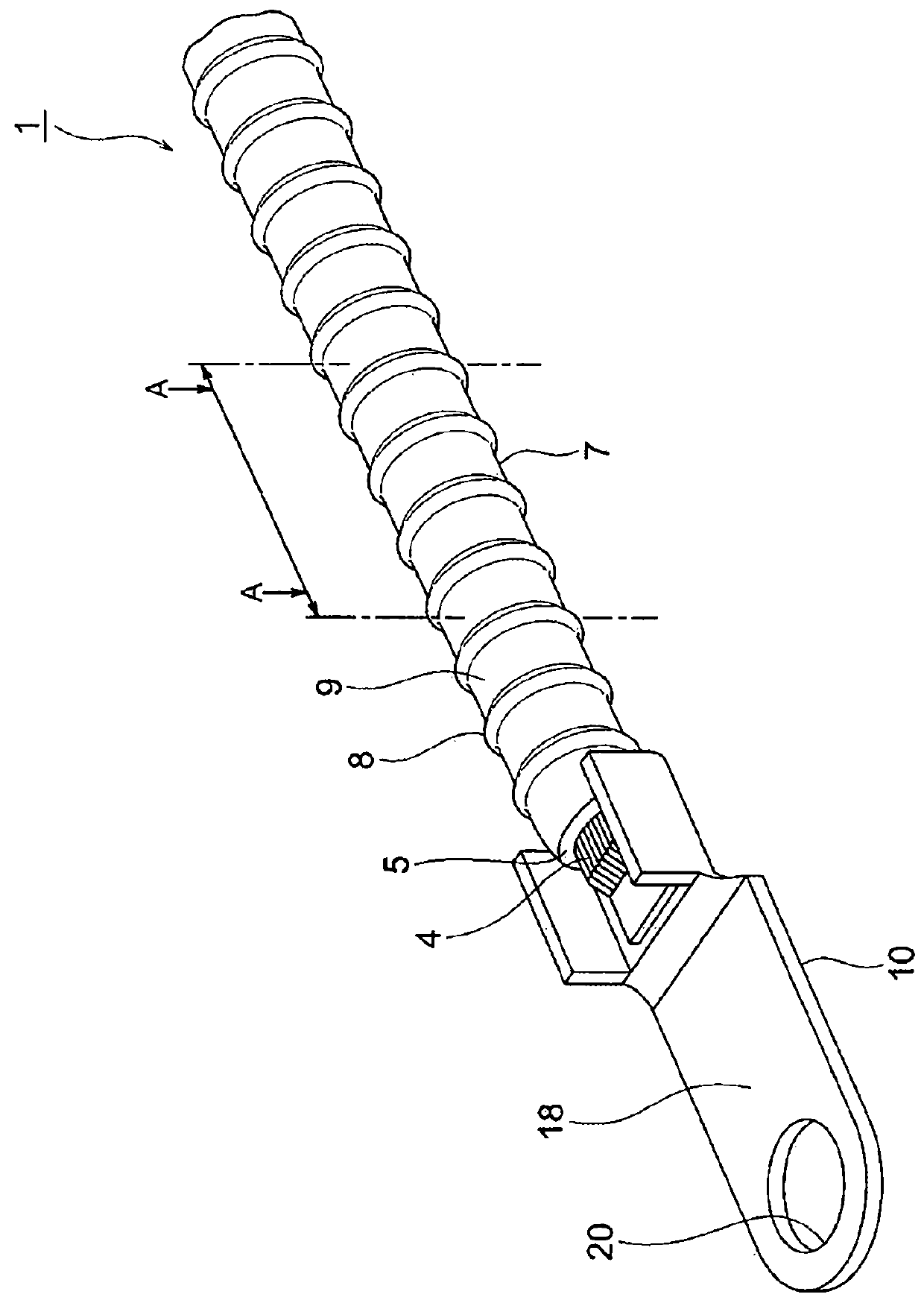

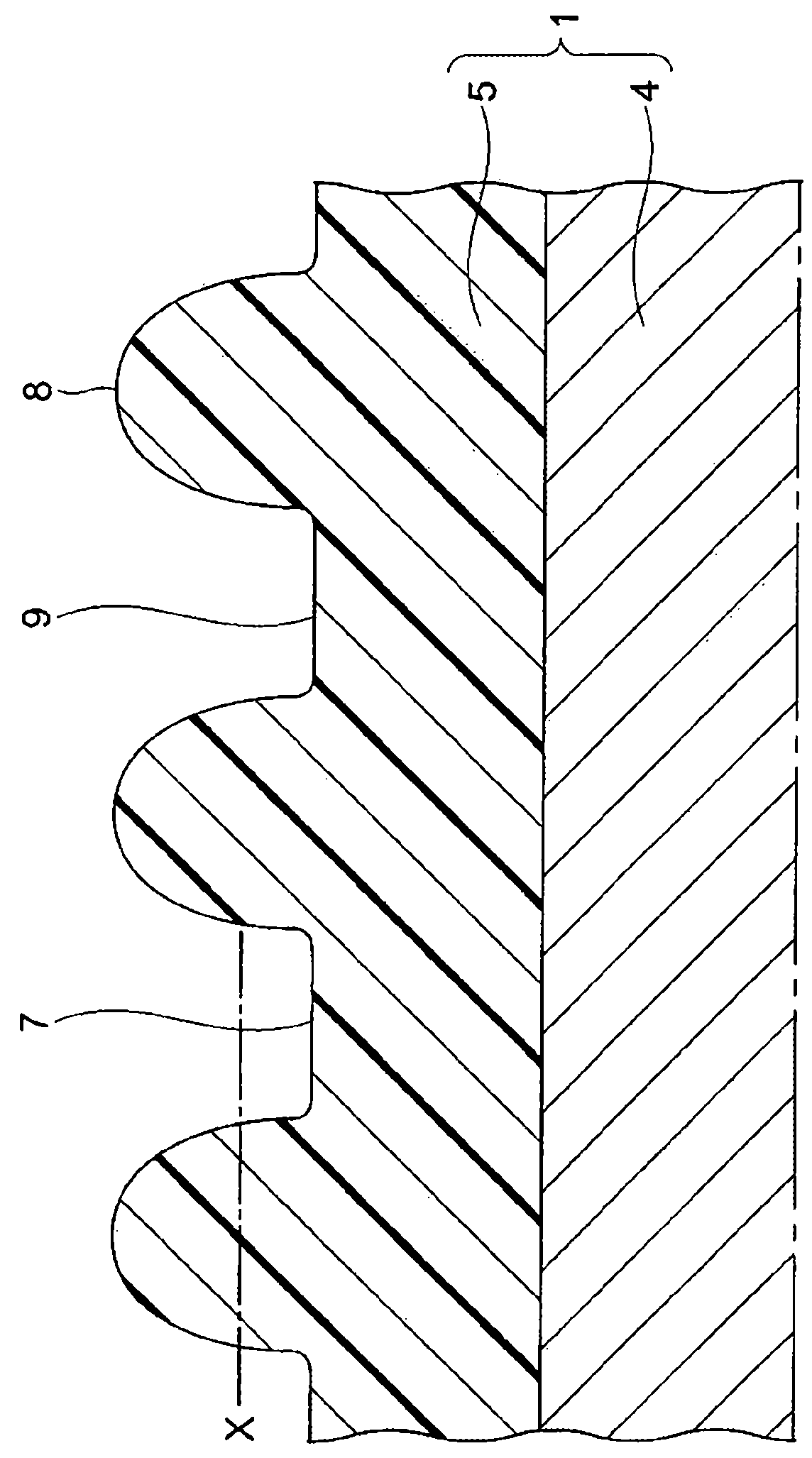

Implantable electrical cable and method of making

ActiveUS6843870B1The method is simple and reliableMechanical working/deformationInternal electrodesPliabilityFluoropolymer

The present invention is an implantable cable and a process to manufacture said implantable cable. The cable is composed of a biocompatible fluoropolymer, in which biocompatible conductor wires are embedded. The entire cable is heat treated at various stages to ensure the wires are securely embedded. The cable is then undulated to enhance its pliability and flexibility. Further treatment activates the outer surface of the cable, following which it may be encapsulated in silicone.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

Implantable electrical cable and method of making

The present invention is an implantable cable and a process to manufacture said implantable cable. The cable is composed of a biocompatible fluoropolymer, in which biocompatible conductor wires are embedded. The entire cable is heat treated at various stages to ensure the wires are securely embedded. The cable is then undulated to enhance its pliability and flexibility. Further treatment activates the outer surface of the cable, following which it may be encapsulated in silicone.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

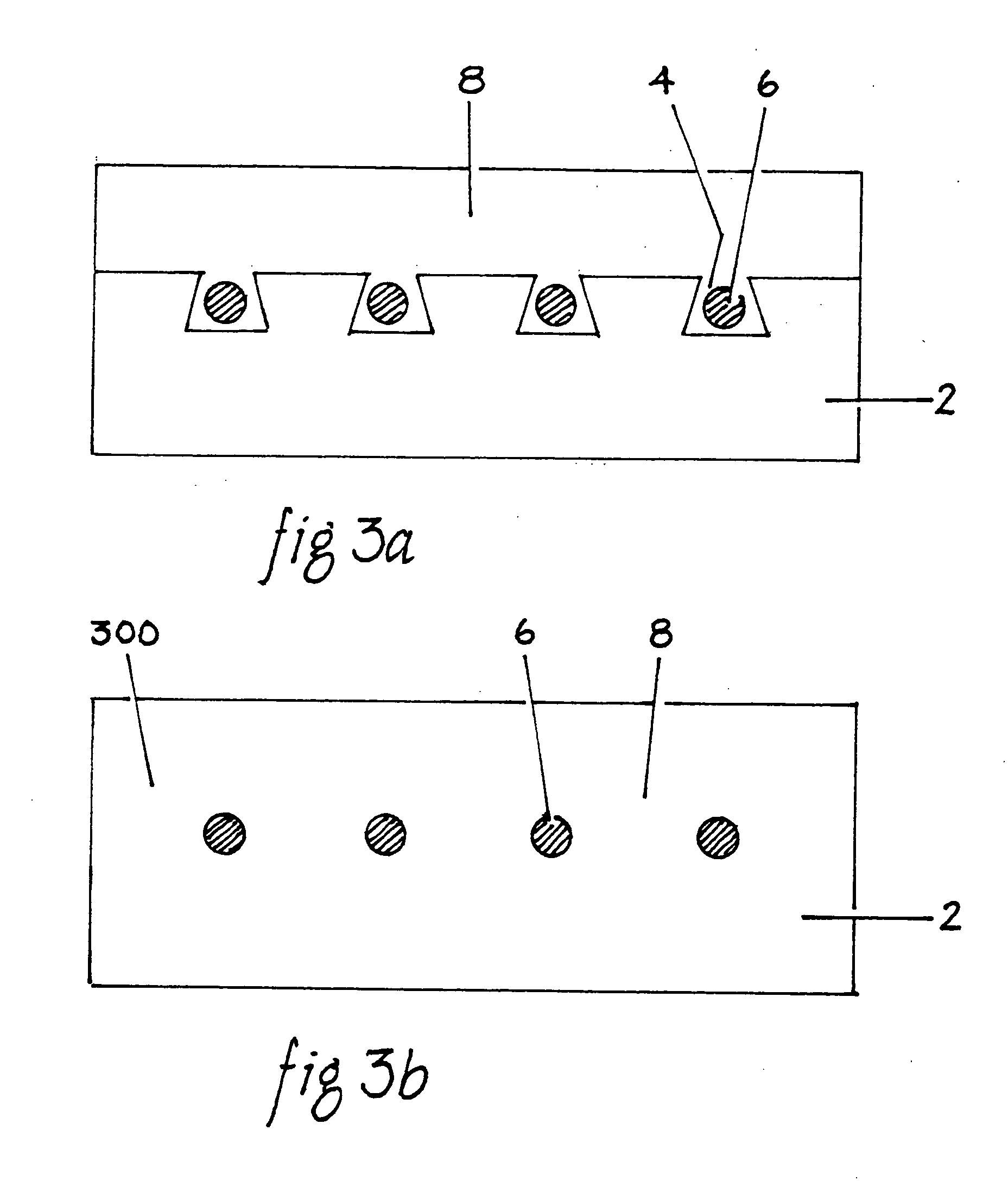

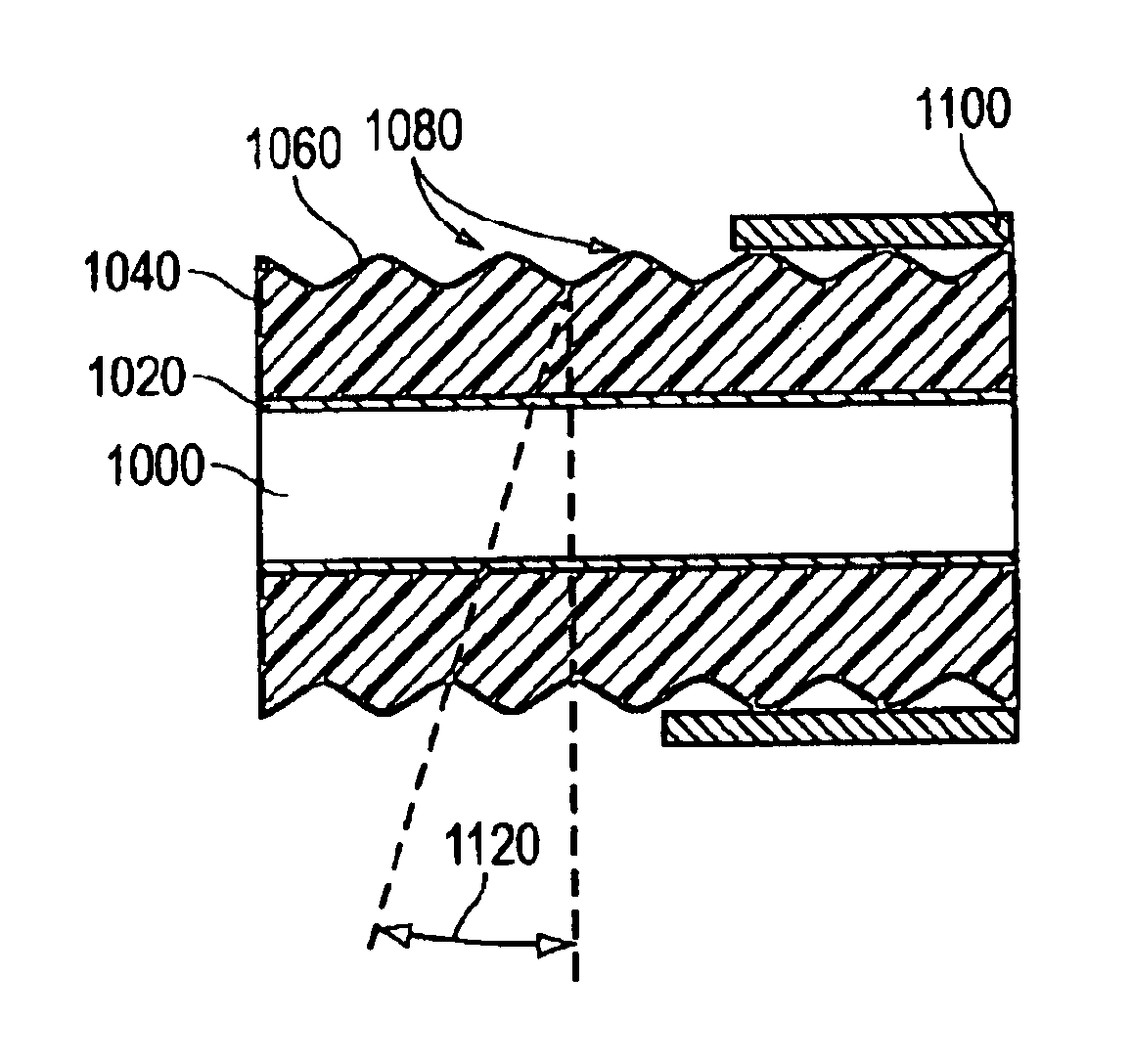

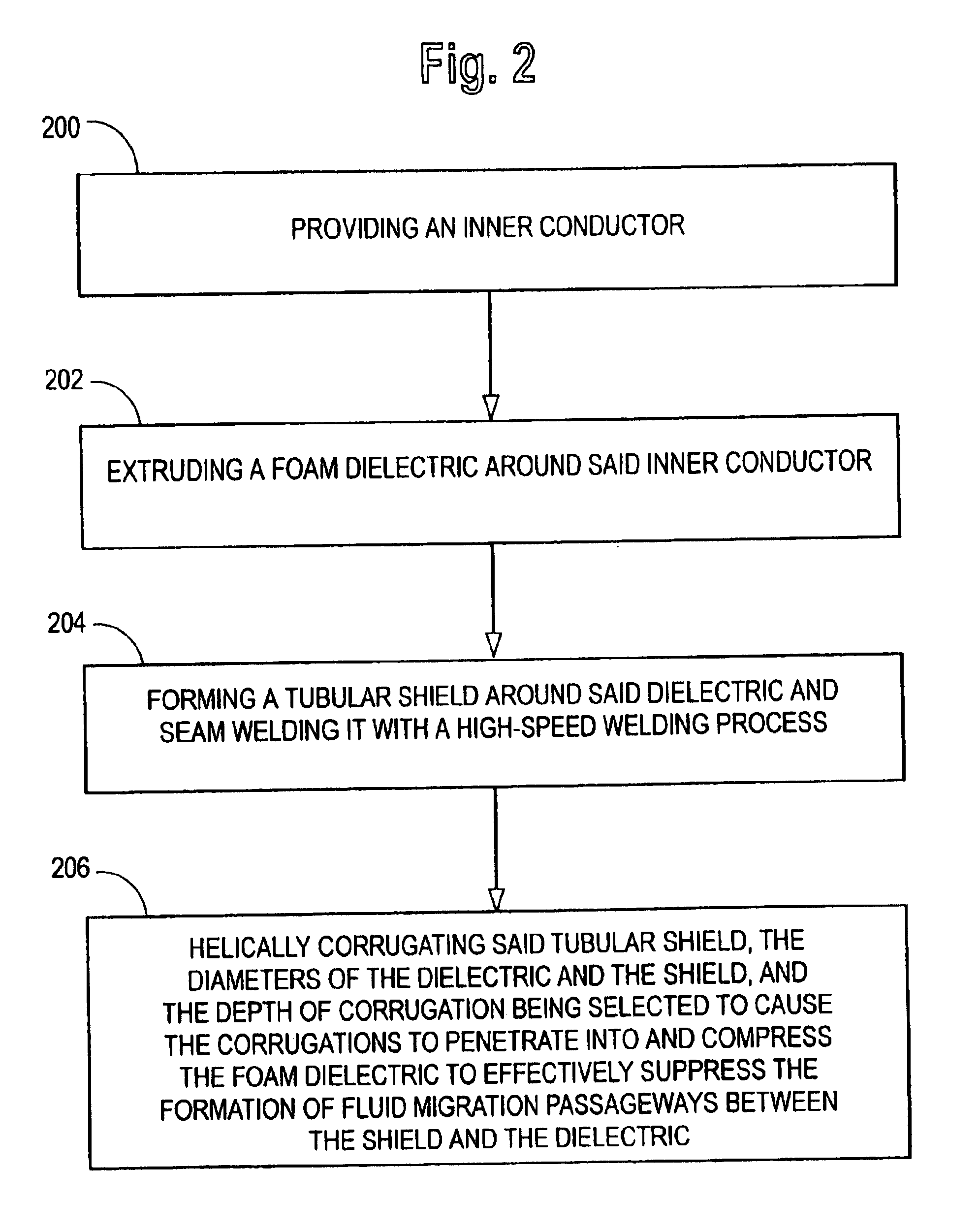

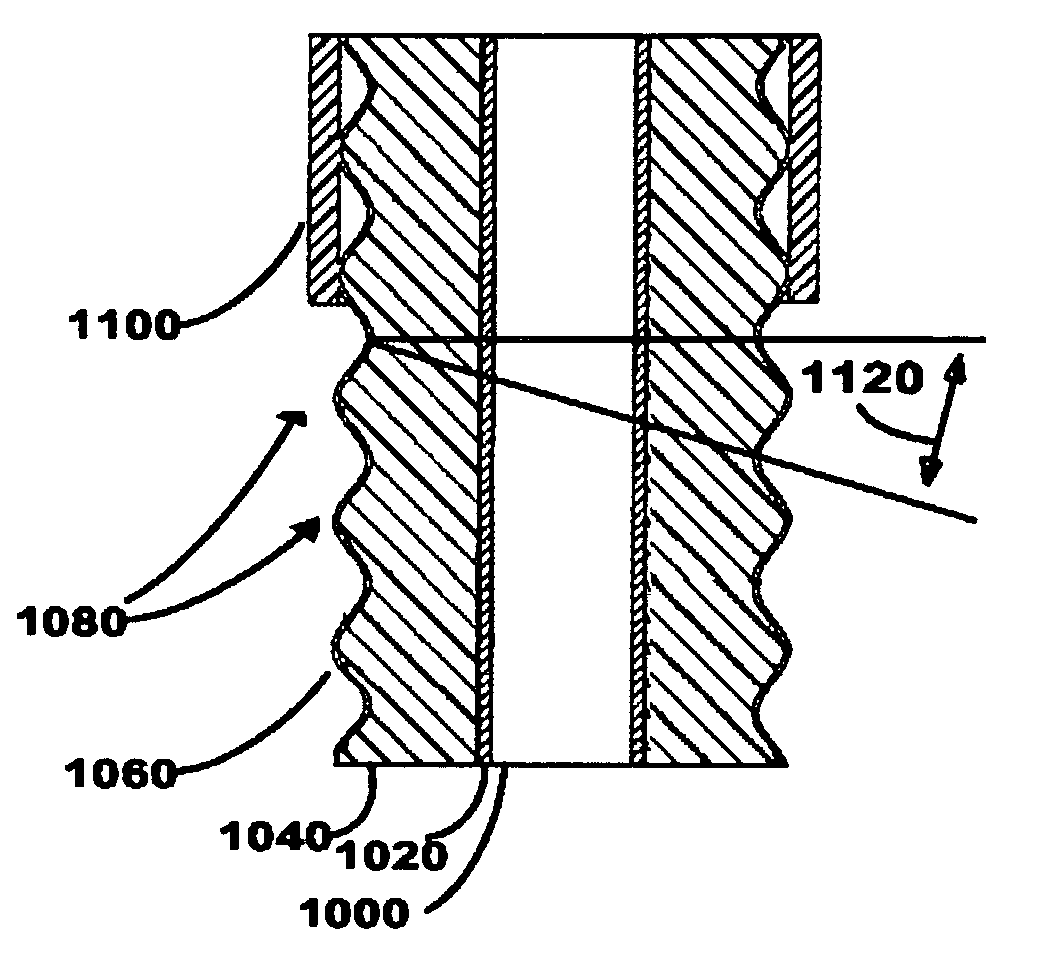

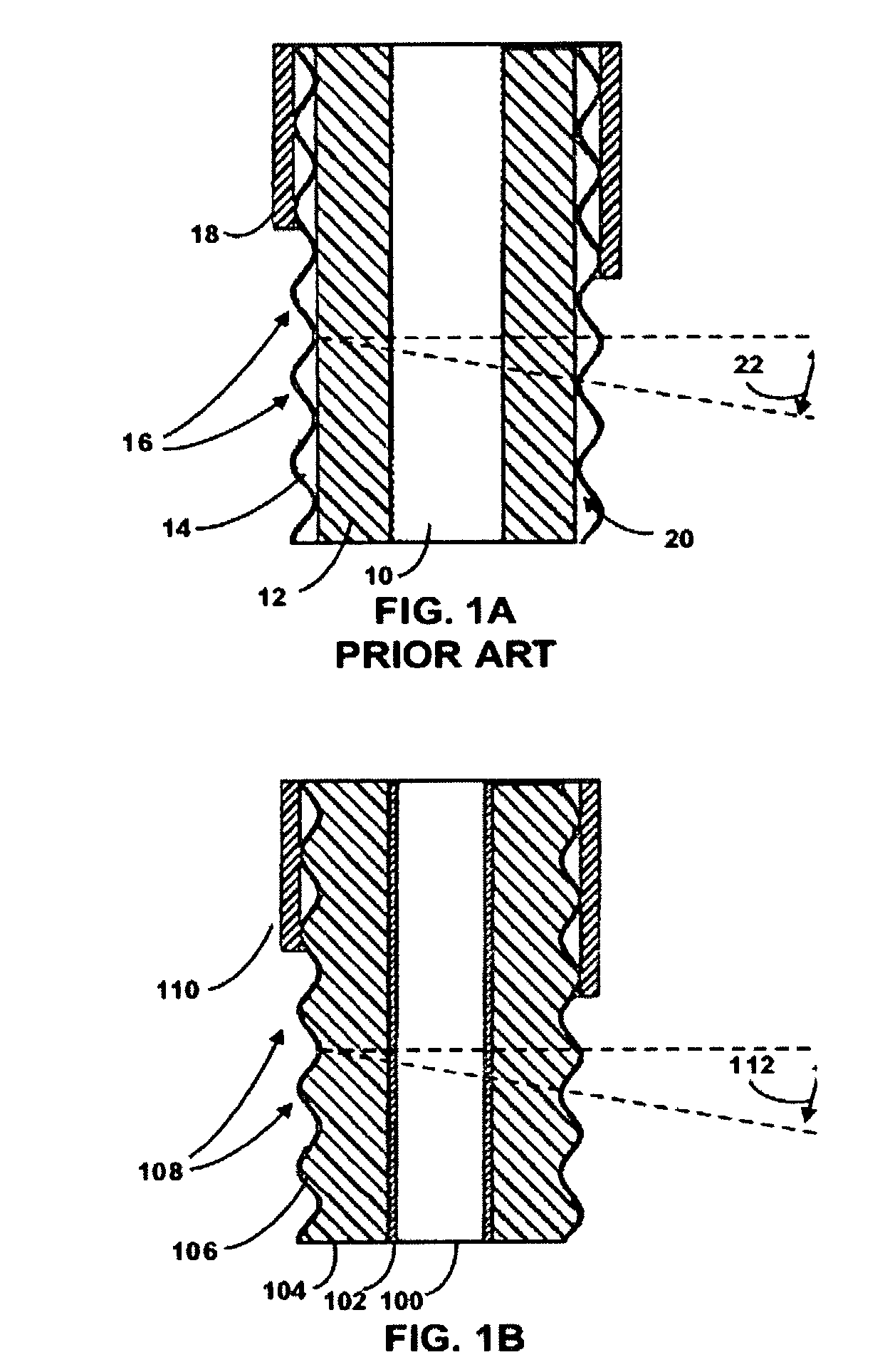

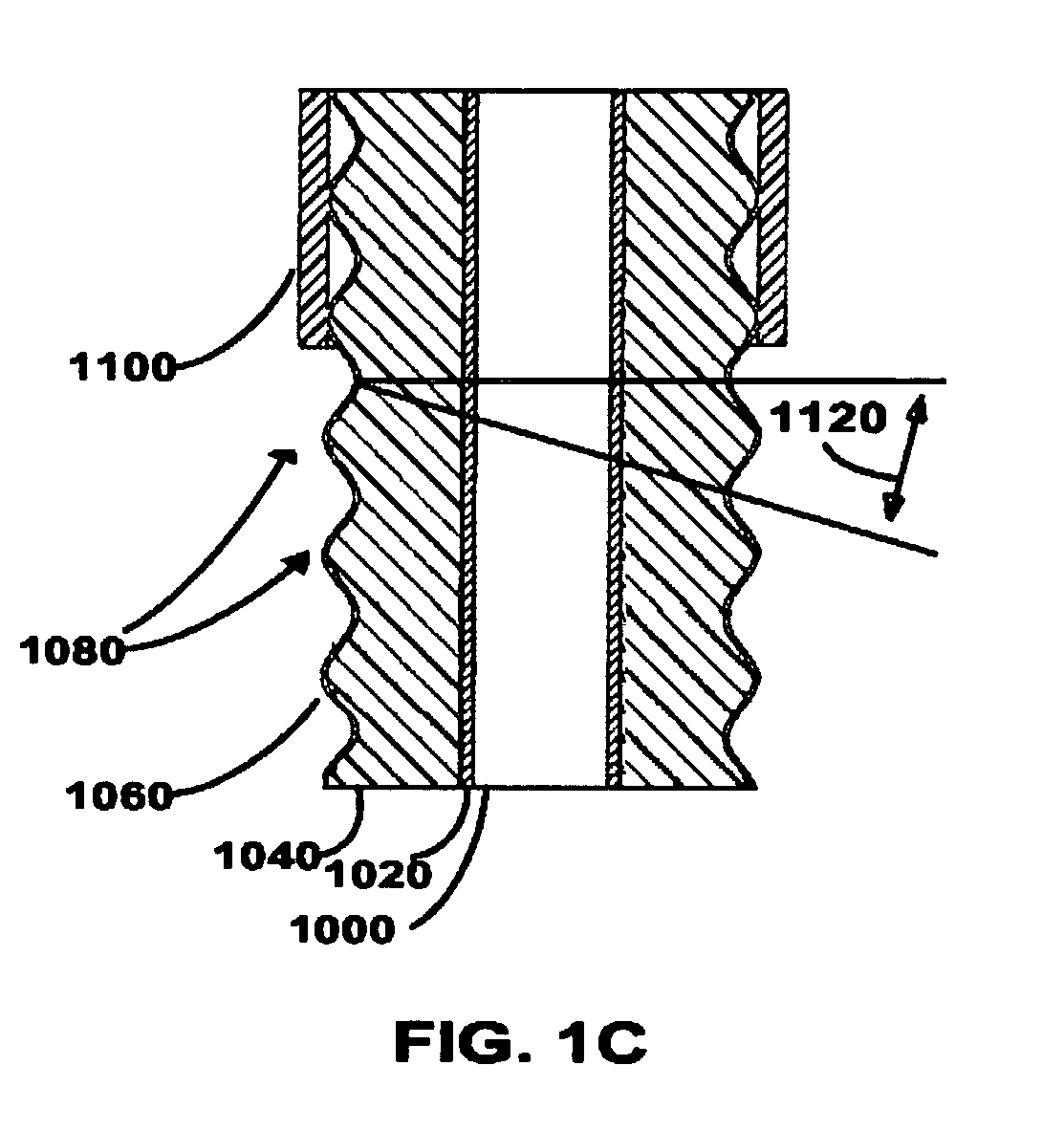

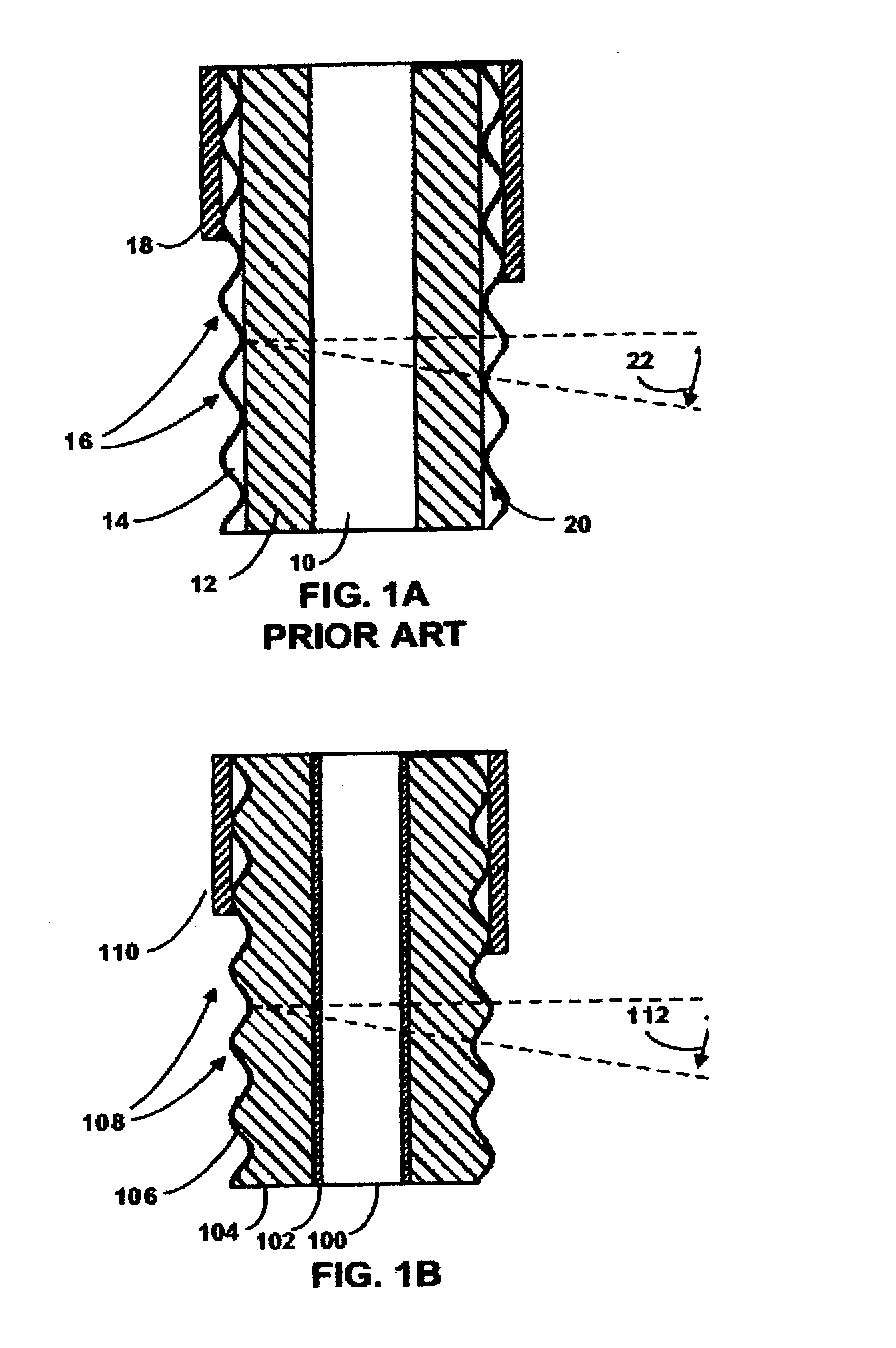

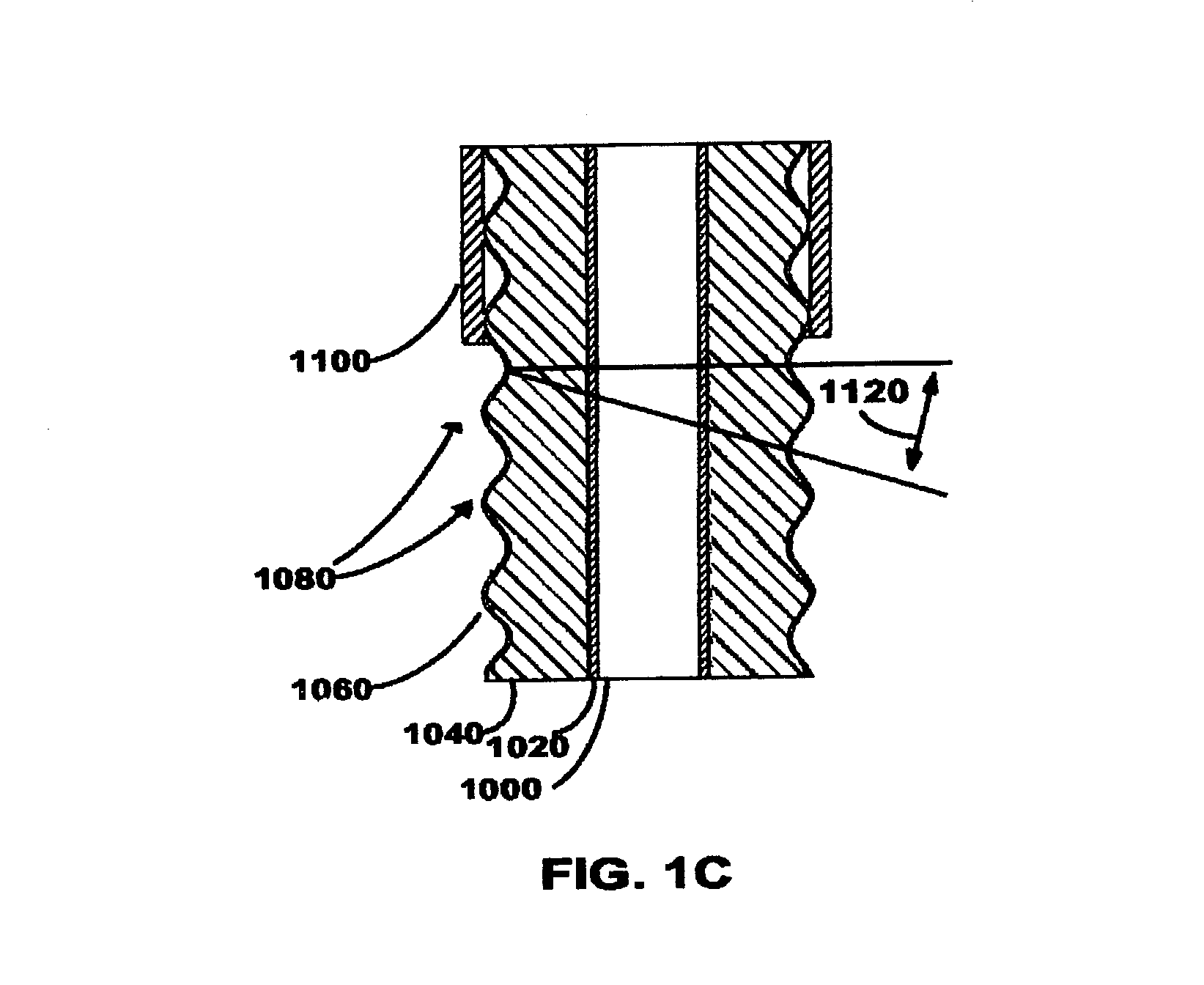

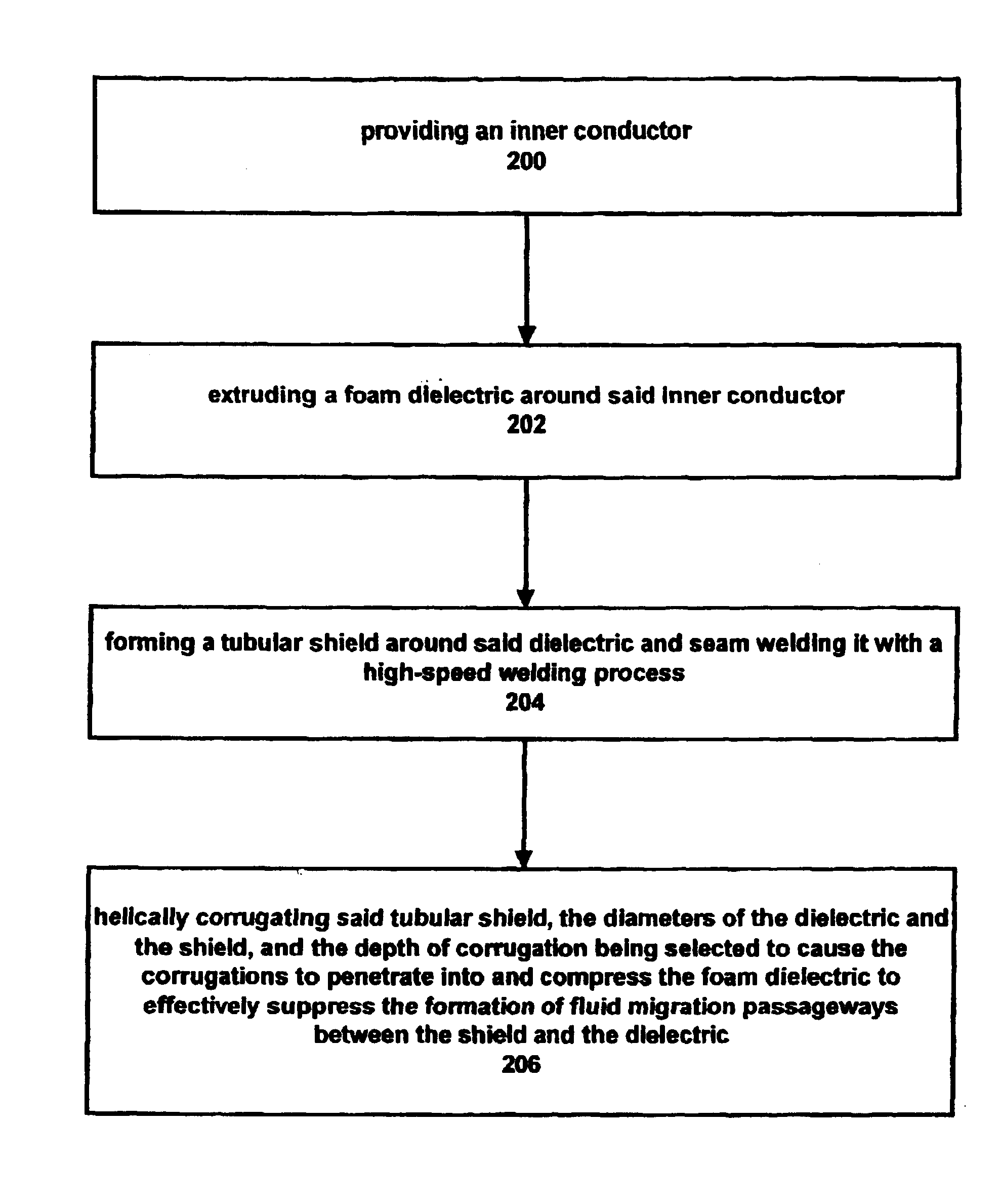

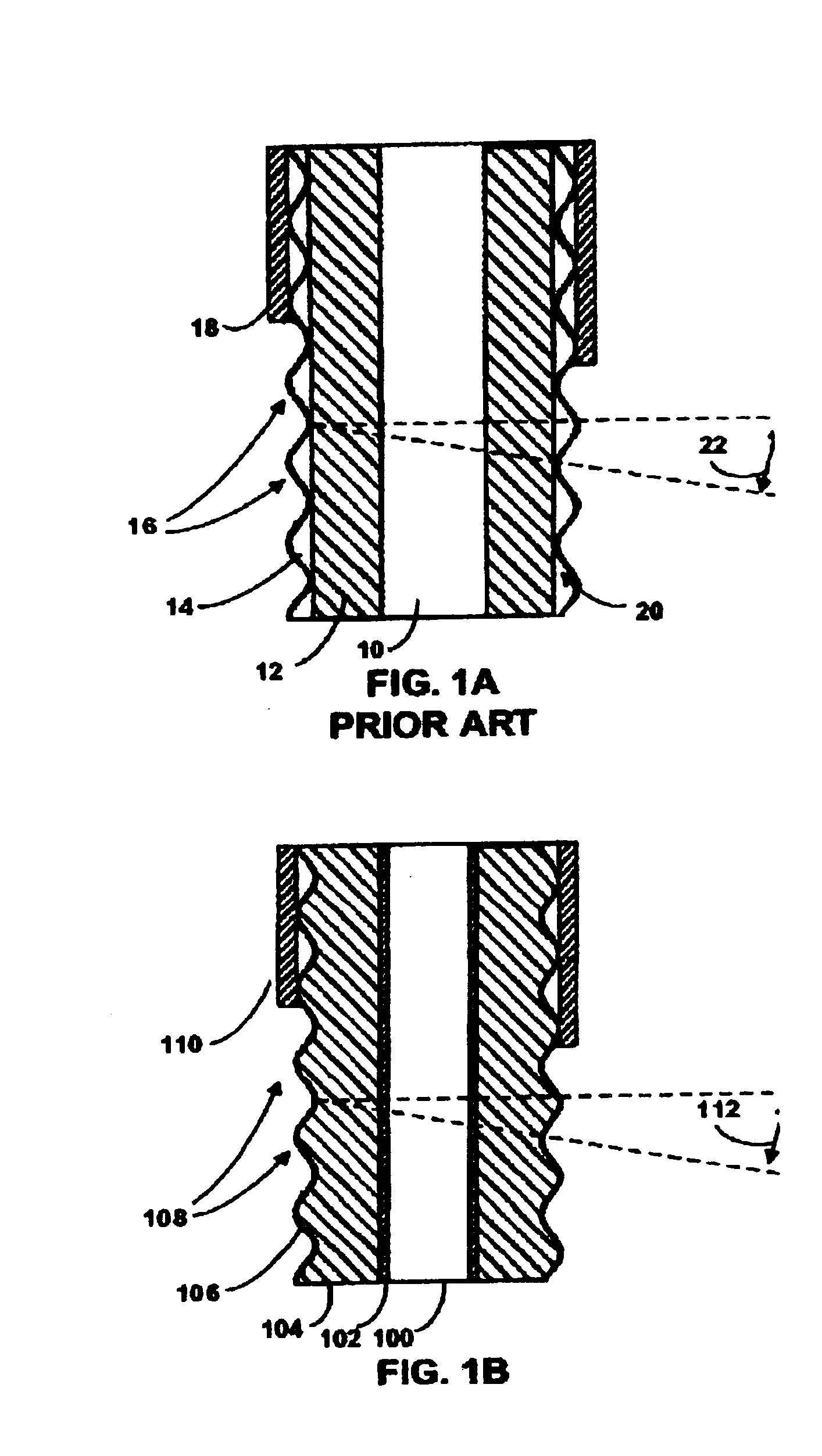

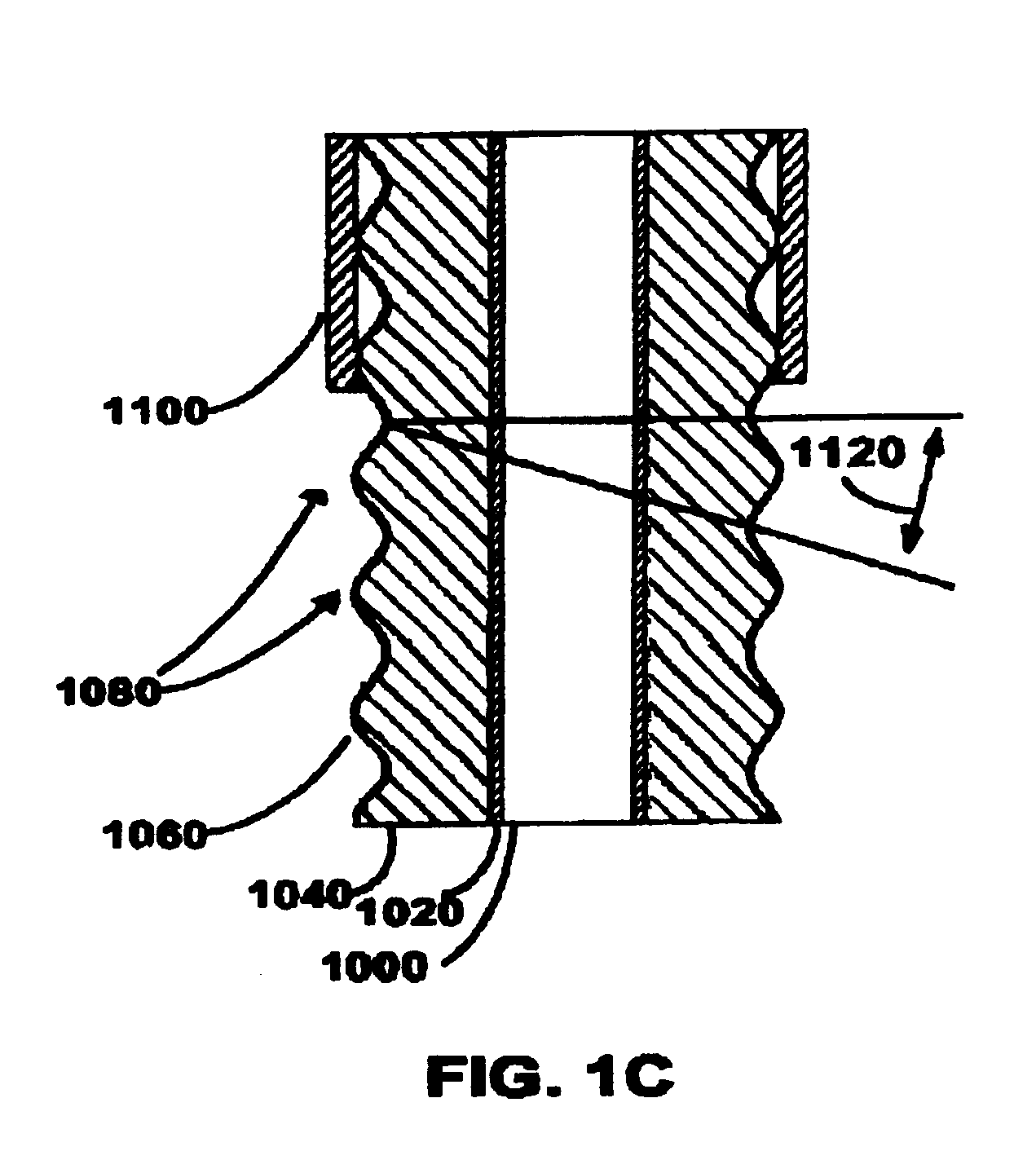

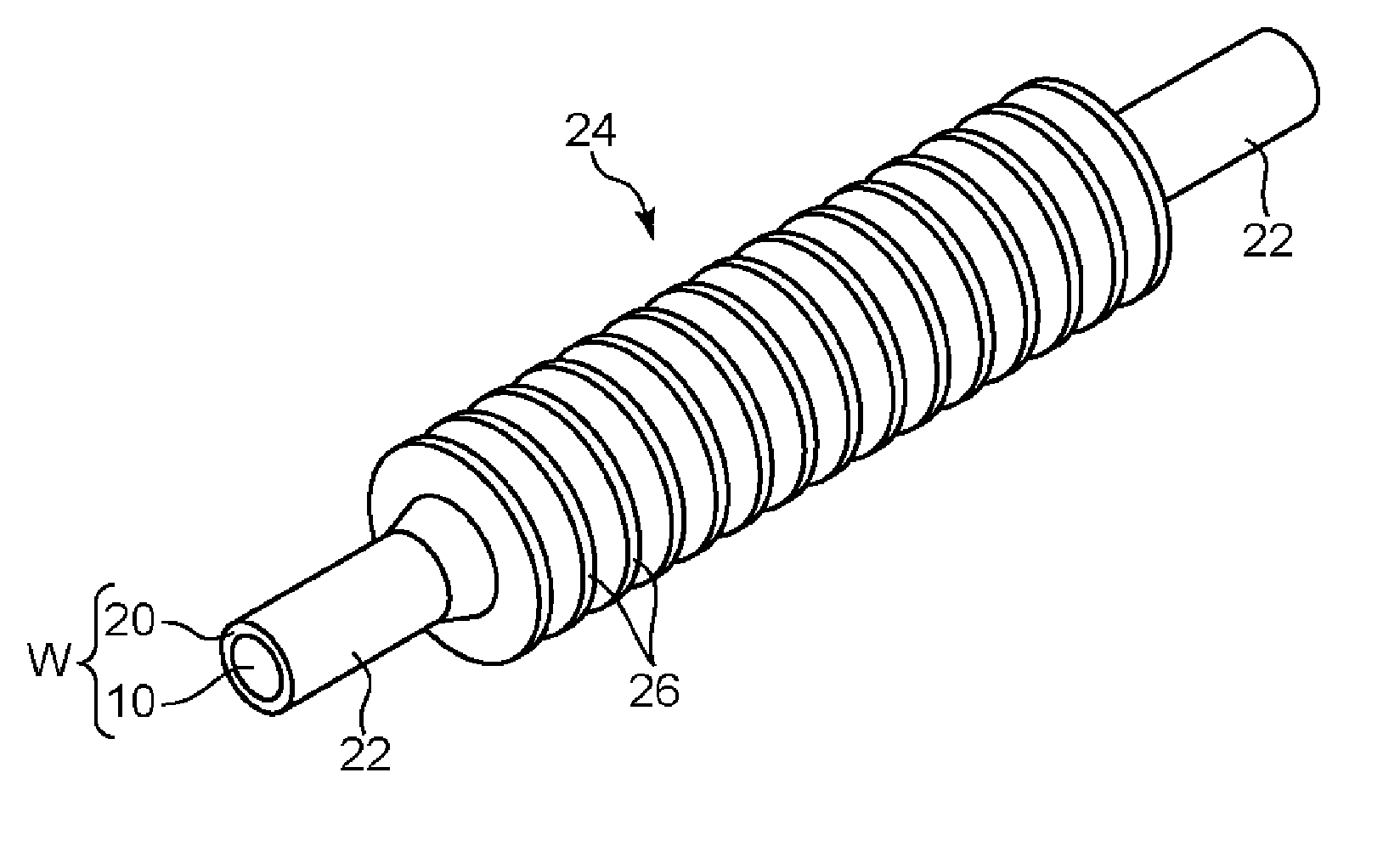

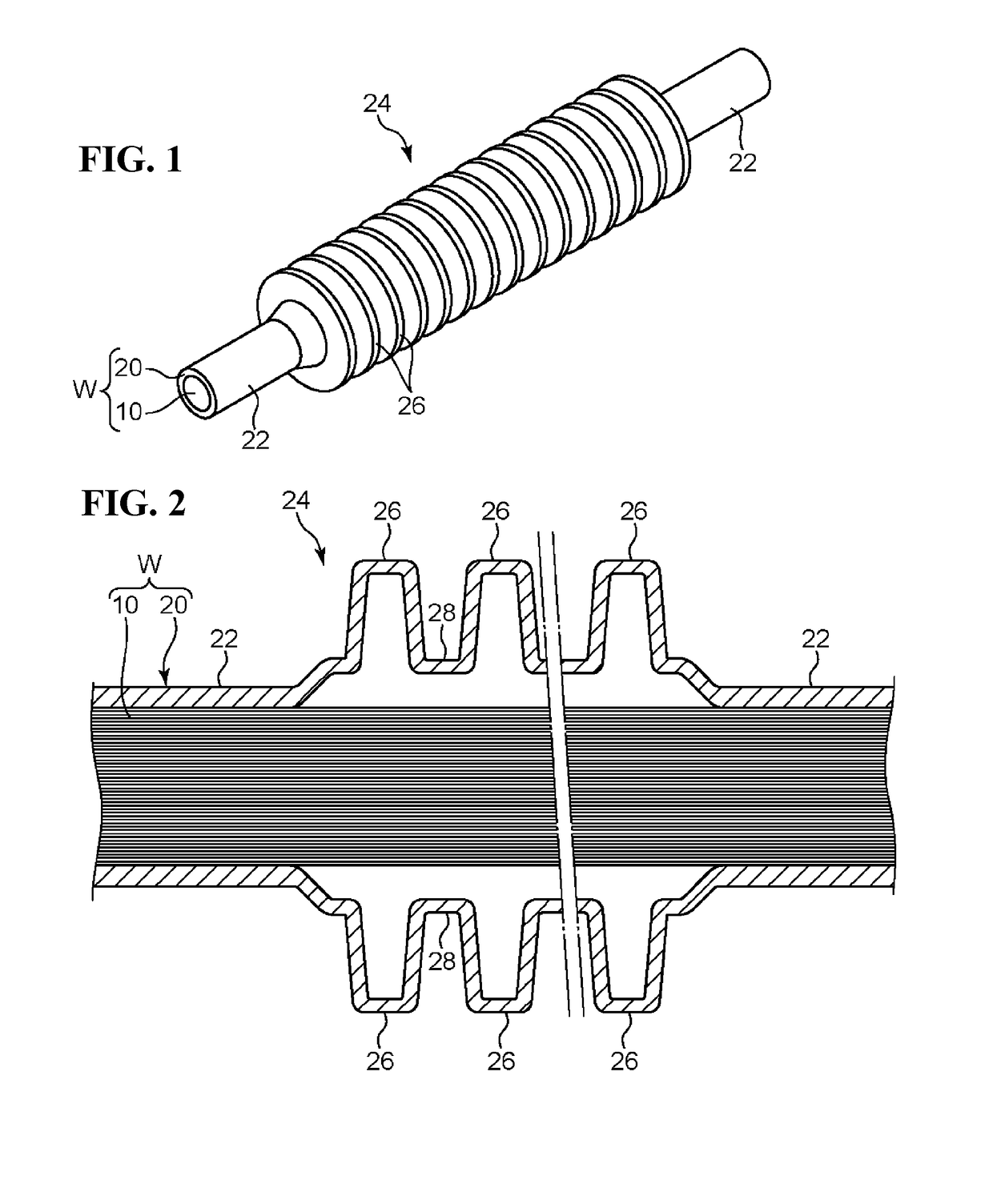

Low-cost, high performance, moisture-blocking, coaxial cable and manufacturing method

InactiveUS6693241B2Low costCable insulation constructionPower cables with screens/conductive layersDielectricShielded cable

A helical corrugated coaxial cable possesses low cost of manufacture comparable to that of braided shield coaxial cable, electrical performance comparable to solid tubular shielded cable, flexibility of helical and annular corrugated cable, and fluid blockage comparable to annular shielded cable. The cable has an inner conductor surrounded by a foam dielectric insulator. A tubular shield surrounds the dielectric and has helical corrugations penetrating into and compressing the foam dielectric to effectively suppress the formation of fluid migration air gaps or passageways between the shield and the dielectric. The shield is preferably composed of aluminum or aluminum alloy. Alternatively, the shield may be annularly corrugated for improved water blocking performance. The manufacturing process employs high speed welding and multi-lead corrugating operations to reduce cost.

Owner:COMMSCOPE TECH LLC

Low-cost, high performance, moisture-blocking, coaxial cable and manufacturing method

InactiveUS20030201115A1Low costCable insulation constructionPower cables with screens/conductive layersDielectricShielded cable

A helical corrugated coaxial cable possesses low cost of manufacture comparable to that of braided shield coaxial cable, electrical performance comparable to solid tubular shielded cable, flexibility of helical and annular corrugated cable, and fluid blockage comparable to annular shielded cable. The cable has an inner conductor surrounded by a foam dielectric insulator. A tubular shield surrounds the dielectric and has helical corrugations penetrating into and compressing the foam dielectric to effectively suppress the formation of fluid migration air gaps or passageways between the shield and the dielectric. The shield is preferably composed of aluminum or aluminum alloy. Alternatively, the shield may be annularly corrugated for improved water blocking performance. The manufacturing process employs high speed welding and multi-lead corrugating operations to reduce cost.

Owner:COMMSCOPE TECH LLC

Method for making tinned copper clad aluminum wire

InactiveCN105355322ATightly boundAvoid separationConductive materialFormation of corrugations on cables/conductorsTinningCopper wire

The present invention relates to the technical field of wires and cables and particularly relates to a method for making a tinned copper clad aluminum wire. The method comprises the steps of (1) making a rare earth aluminum alloy aluminum rod, melting 99.95% fine aluminum through a double-frequency furnace, adding a rare earth alloy component, and carrying out pulling to form an aluminum rod with the diameter of 8.6mm, (2) carrying out copper belt cladding, cladding the aluminum rod with the diameter of 8.6mm by a high pure copper belt with the corresponding thickness and width in the step (1) through a cladding machine, overmoding and pulling the cladded aluminum rod through a pulling machine to the diameter of 2.05mm, (3) carrying out drawing and tinning, carrying out middle pulling firstly, finally carrying out annealing tinning, and carrying out hot-dip type overmode tinning with the accuracy requirement of + / -0.001 of a tinning mold. The method has the advantage of simple structure, copper and aluminum composite and rare earth aluminum alloy materials are employed, the advantages of the high conductivity of copper and the small density of aluminum are fully played, and the purpose of replacing a pure copper wire is achieved.

Owner:JIANGXI ANXUN IND

Flexible conductive thin film, preparation method thereof and display panel

InactiveCN110033900AExtended service lifeGood flexibilityConductive layers on insulating-supportsSynthetic resin layered productsOptoelectronicsMaterials science

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

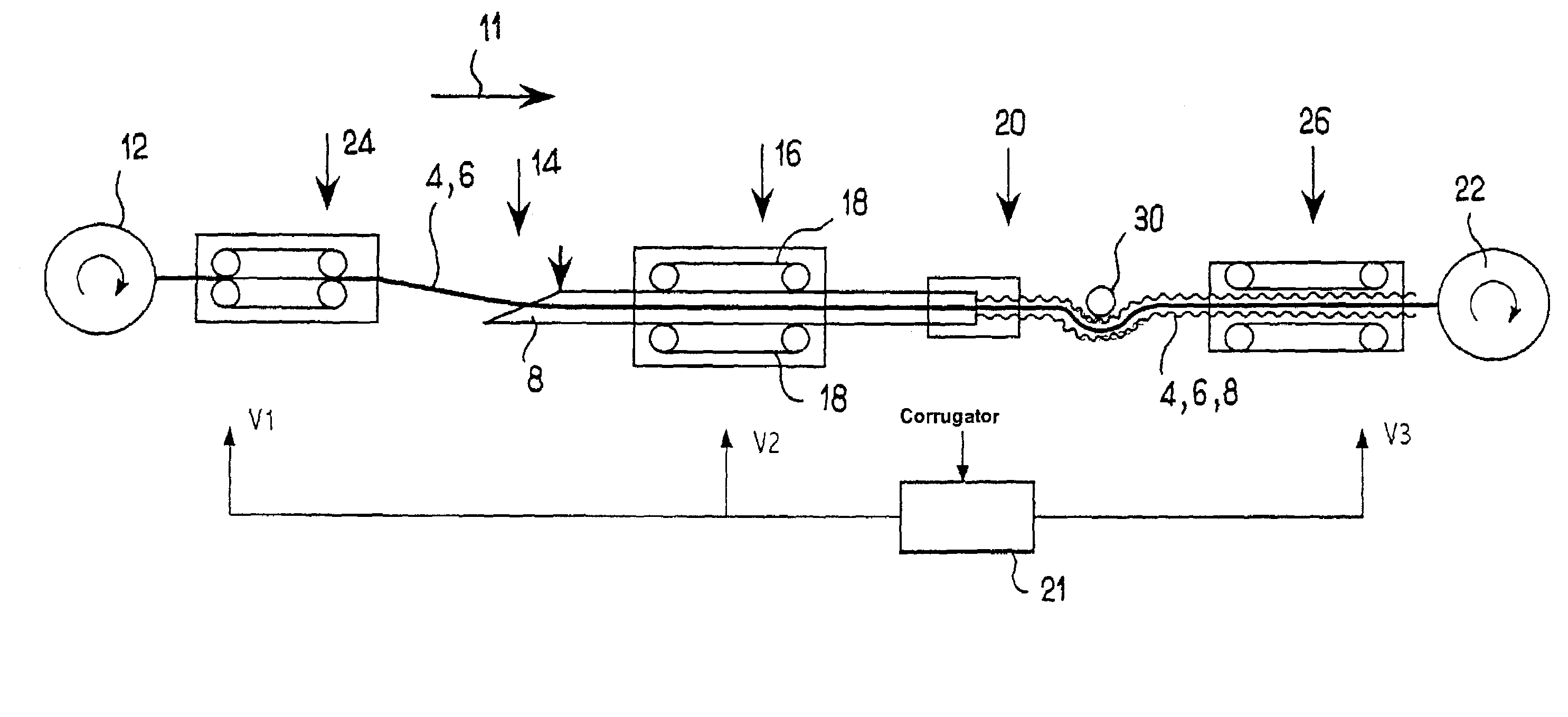

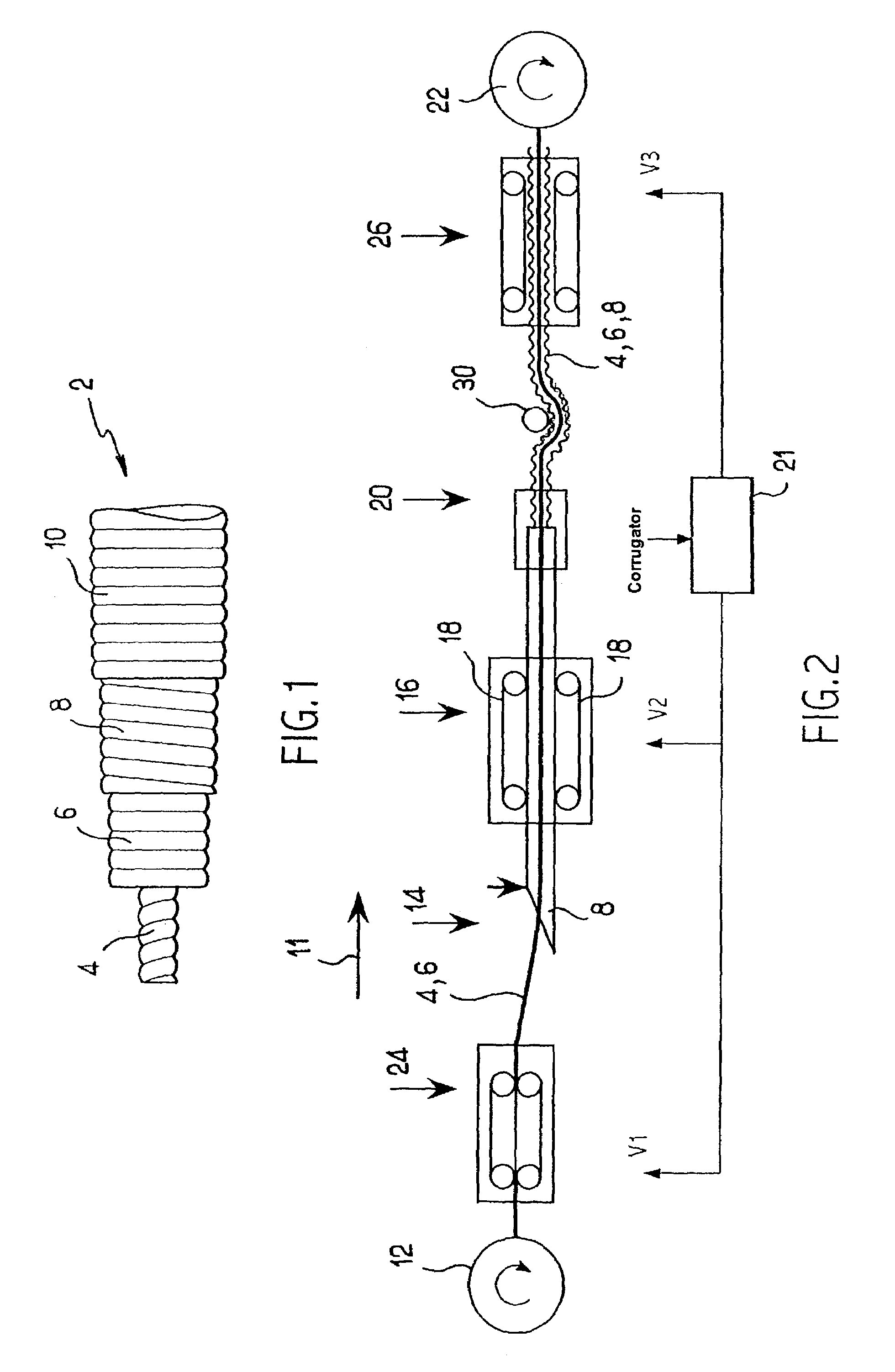

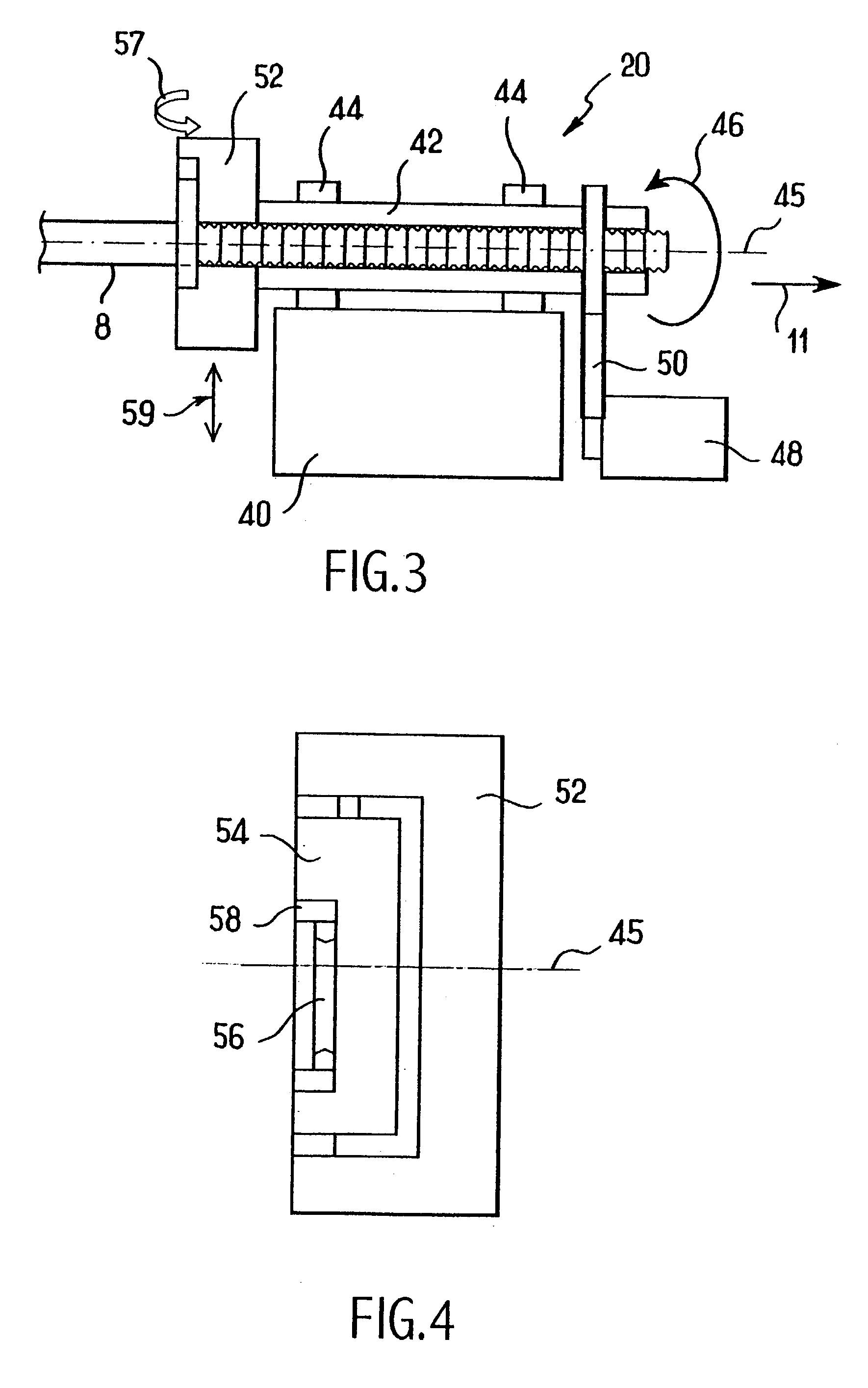

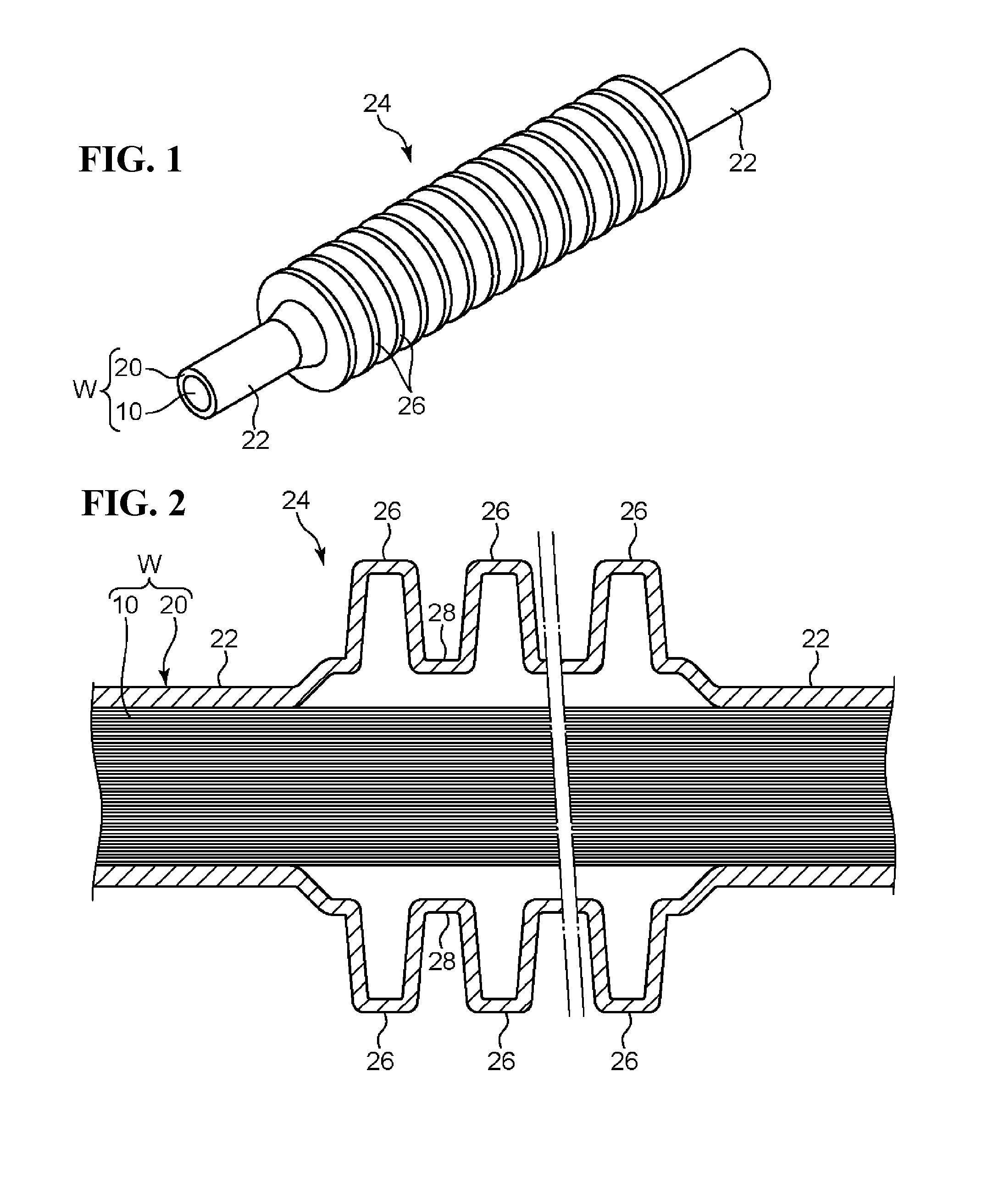

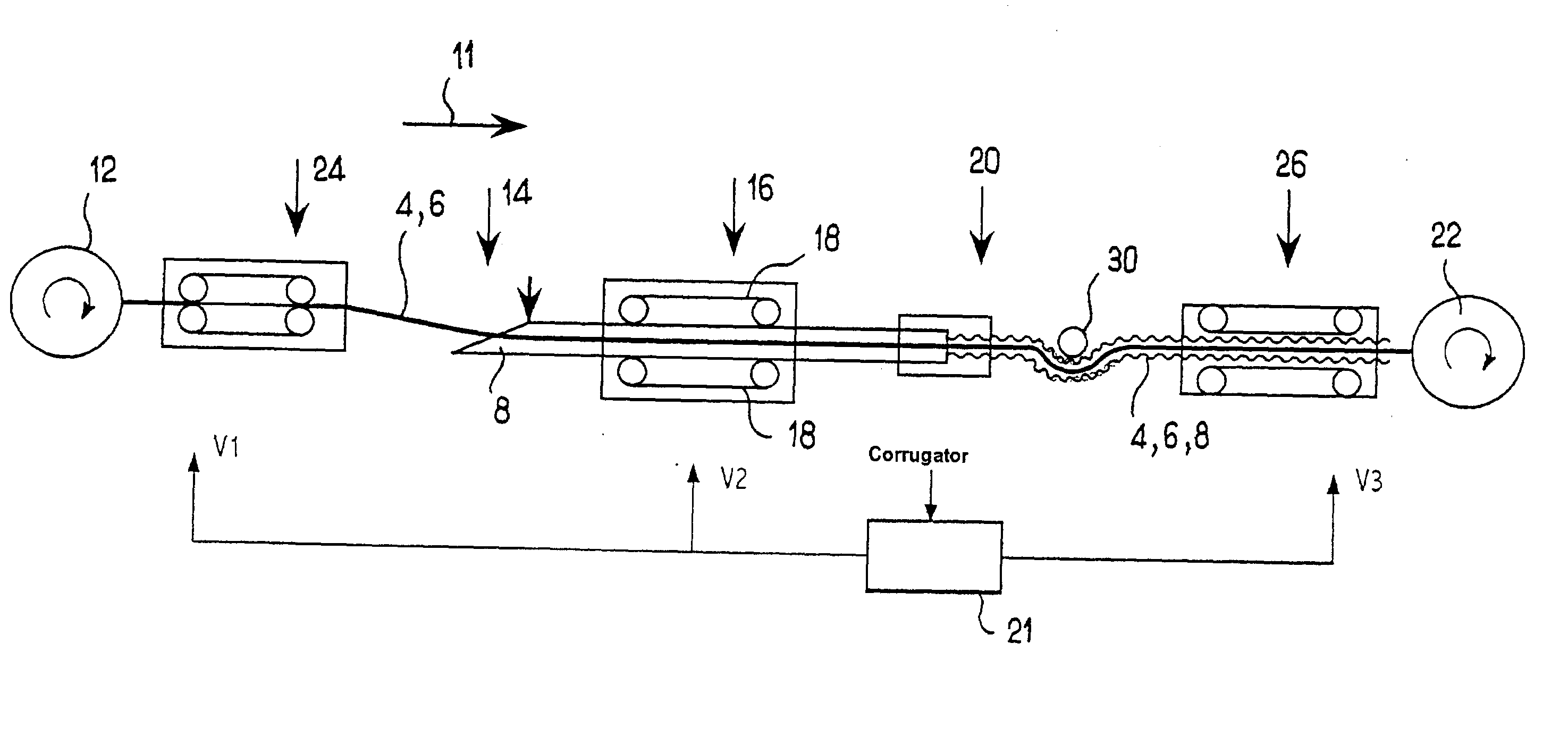

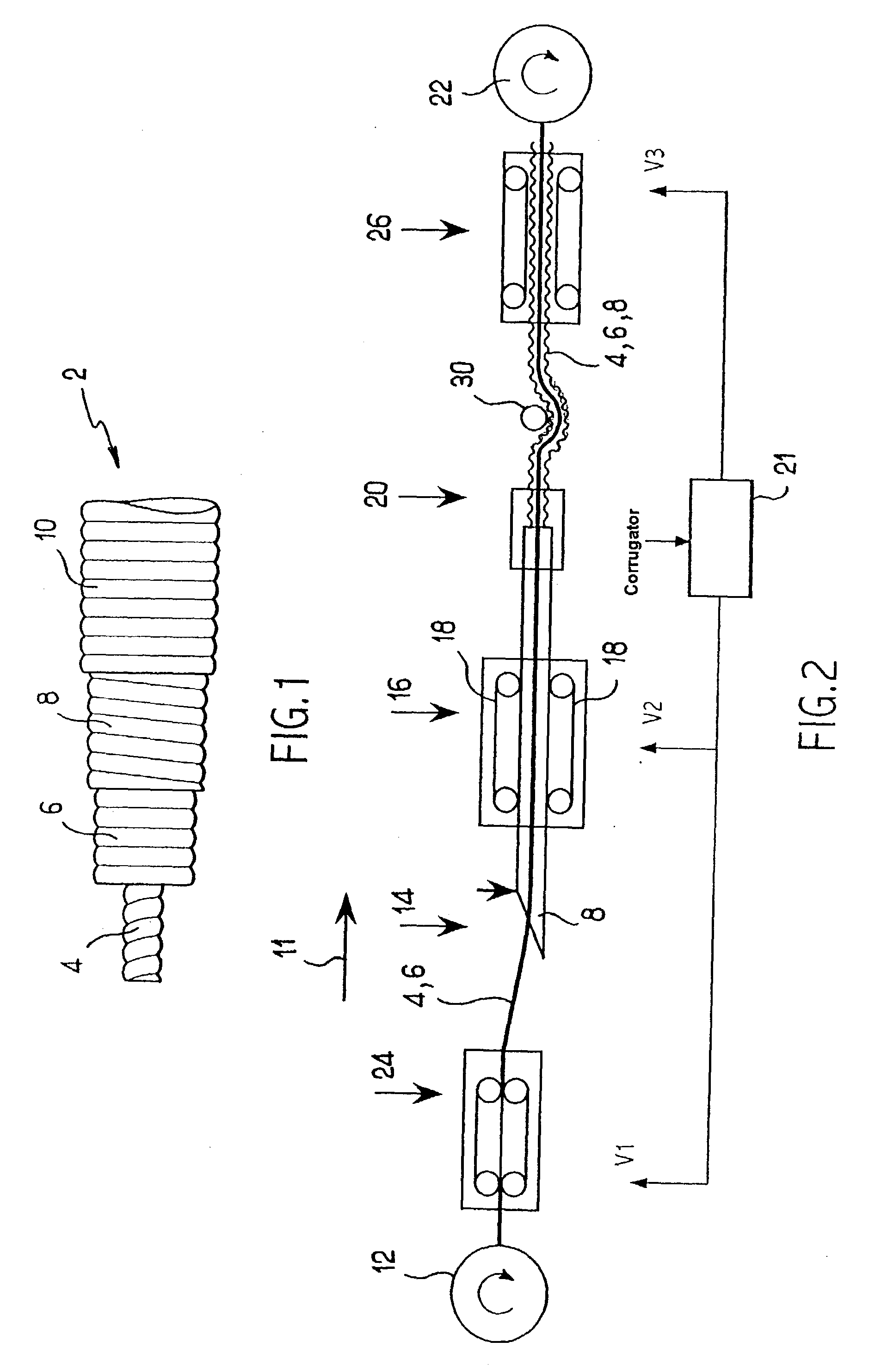

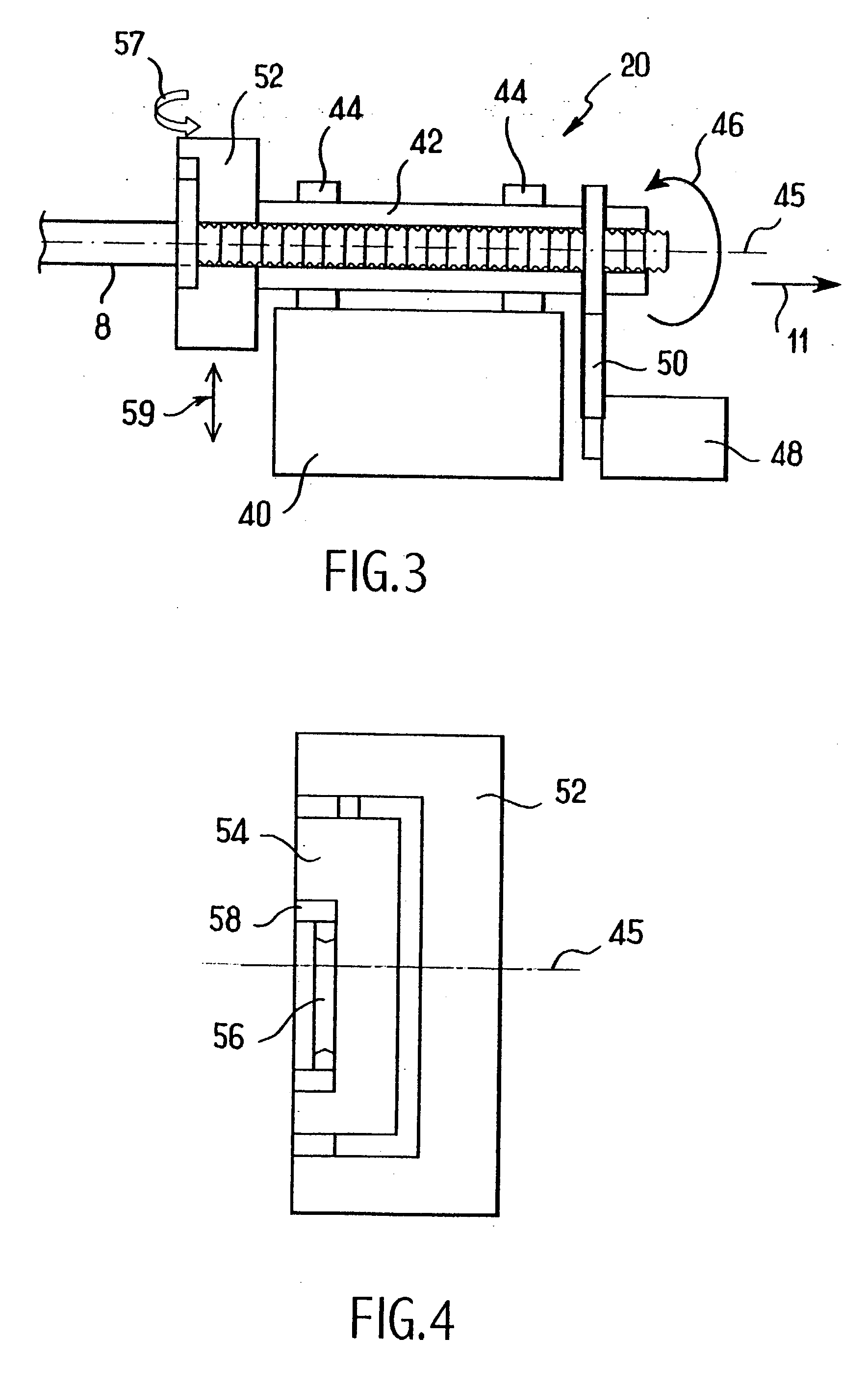

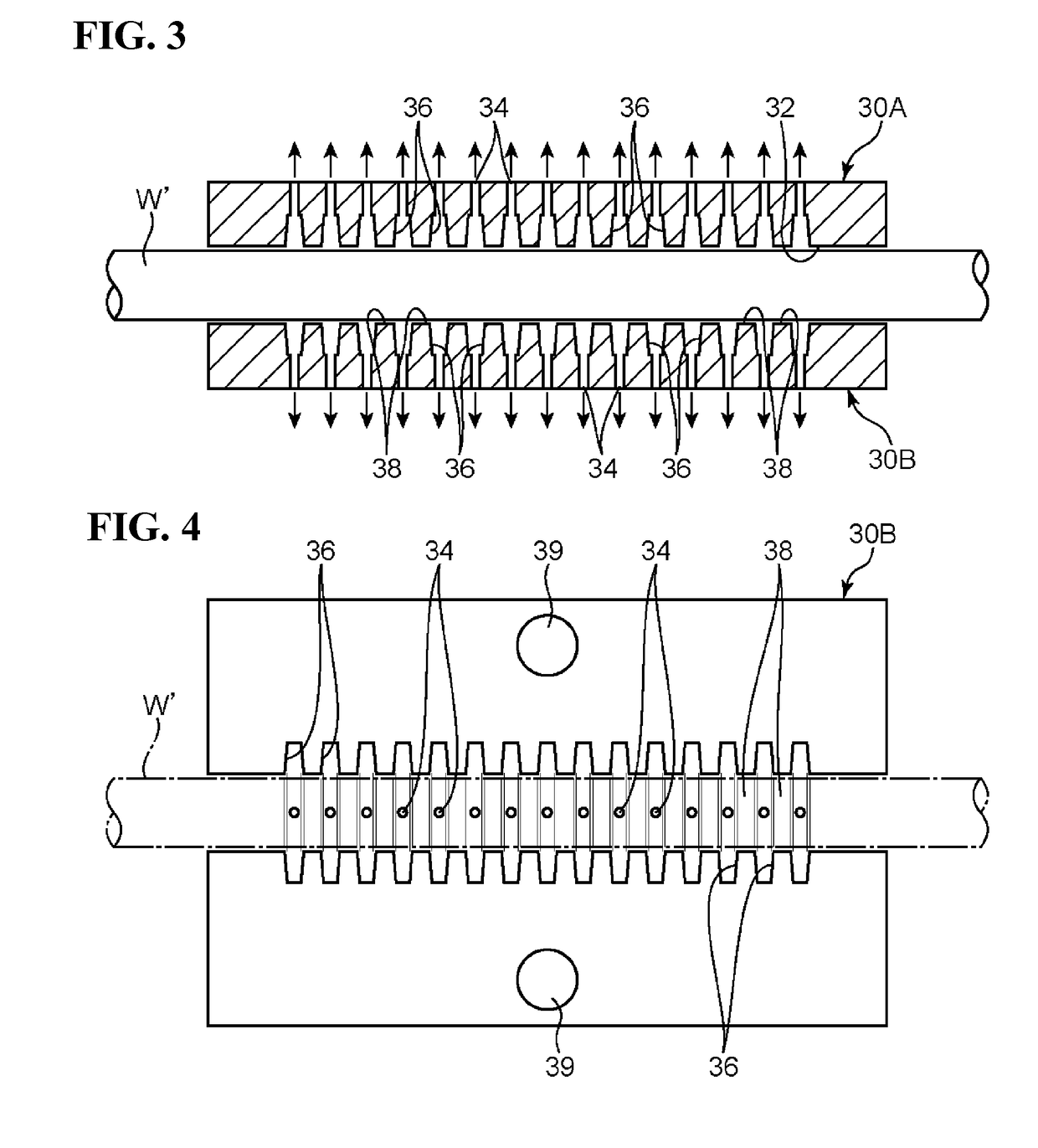

Method of continuously fabricating a corrugated coaxial cable

InactiveUS7266886B2Increase speedReduce riskSoldering apparatusFormation of corrugations on cables/conductorsElectrical conductorCoaxial cable

The invention relates to a method of continuously fabricating a coaxial cable in which ring-shaped corrugations are imparted to a conductor of the cable in a corrugator. The corrugator is made to operate at constant speed.

Owner:ACOME SOC COOP & PARTICIPATIVE COOP DE PRODION A CAPITAL VARIABLE

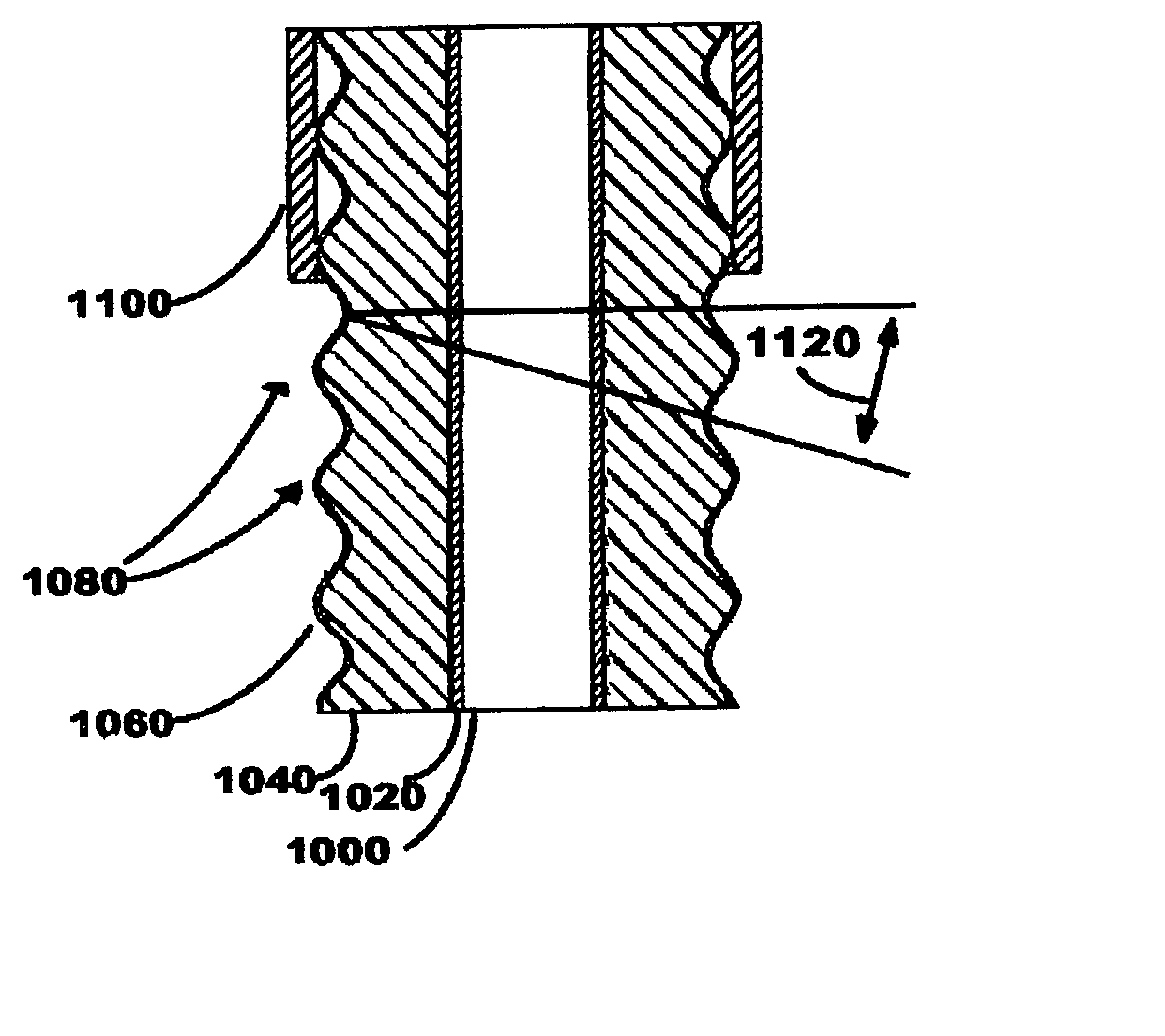

Low-cost, high performance, moisture-blocking, coaxial cable and manufacturing method

InactiveUS20030201116A1Low costMechanical working/deformationCable insulation constructionDielectricShielded cable

A helical corrugated coaxial cable possesses low cost of manufacture comparable to that of braided shield coaxial cable, electrical performance comparable to solid tubular shielded cable, flexibility of helical and annular corrugated cable, and fluid blockage comparable to annular shielded cable. The cable has an inner conductor surrounded by a foam dielectric insulator. A tubular shield surrounds the dielectric and has helical corrugations penetrating into and compressing the foam dielectric to effectively suppress the formation of fluid migration air gaps or passageways between the shield and the dielectric. The shield is preferably composed of aluminum or aluminum alloy. Alternatively, the shield may be annularly corrugated for improved water blocking performance. The manufacturing process employs high speed welding and multi-lead corrugating operations to reduce cost.

Owner:COMMSCOPE TECH LLC

Method of manufacturing a high-performance, water blocking coaxial cable

InactiveUS6912777B2Low costMechanical working/deformationCable insulation constructionShielded cableDielectric

A helical corrugated coaxial cable possesses low cost of manufacture comparable to that of braided shield coaxial cable, electrical performance comparable to solid tubular shielded cable, flexibility of helical and annular corrugated cable, and fluid blockage comparable to annular shielded cable. The cable has an inner conductor surrounded by a foam dielectric insulator. A tubular shield surrounds the dielectric and has helical corrugations penetrating into and compressing the foam dielectric to effectively suppress the formation of fluid migration air gaps or passageways between the shield and the dielectric. The shield is preferably composed of aluminum or aluminum alloy. Alternatively, the shield may be annularly corrugated for improved water blocking performance. The manufacturing process employs high speed welding and multi-lead corrugating operations to reduce cost.

Owner:COMMSCOPE TECH LLC

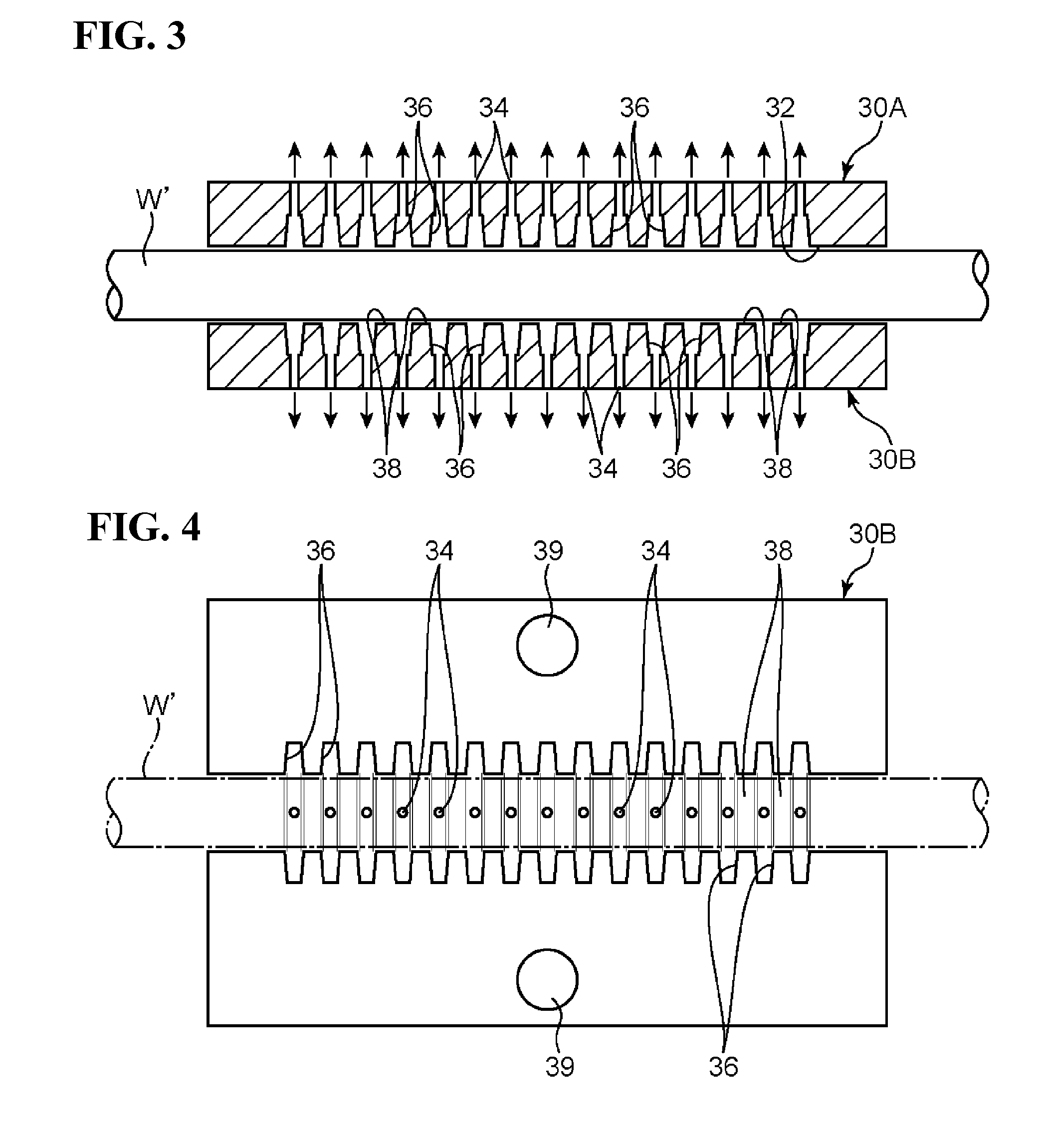

Insulating coated wire and method for manufacturing the same

ActiveUS20150310961A1Easy to manufactureComplex structurePlastic/resin/waxes insulatorsInsulated cablesWire rodElectrical conductor

An insulating coated wire includes a center conductor and an insulating coating. The insulating coating has a bending auxiliary section in which the thickness of the insulating coating is smaller than that of the other portion, and that has a shape in which at least a part thereof protrudes outward in the radial direction. The bending auxiliary section has a shape that facilitates bending of the insulating coated wire by elongation deformation thereof. This insulating coated wire can be manufactured by arranging, on the circumference of an insulating coated wire material, a metal mold that has the inner surface including the section having a shape protruding outward in the radial direction, and forming the bending auxiliary section in the shape along the inner surface of the metal mold by heating the insulating coating within the metal mold and generating a pressure difference between inside and outside of the insulating coating.

Owner:AUTONETWORKS TECH LTD +2

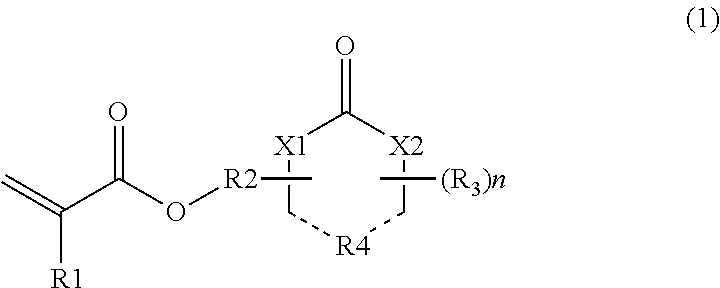

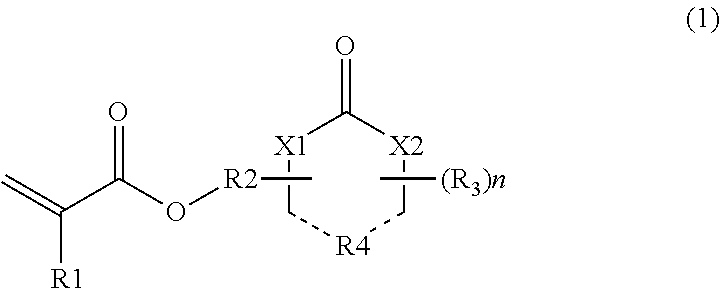

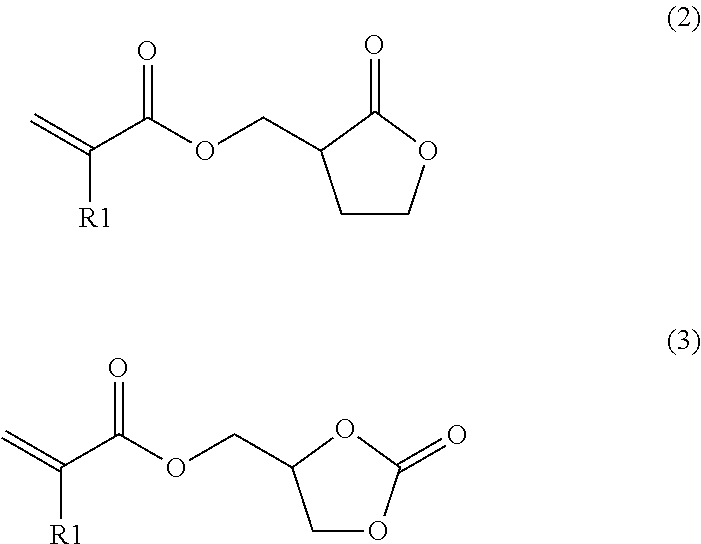

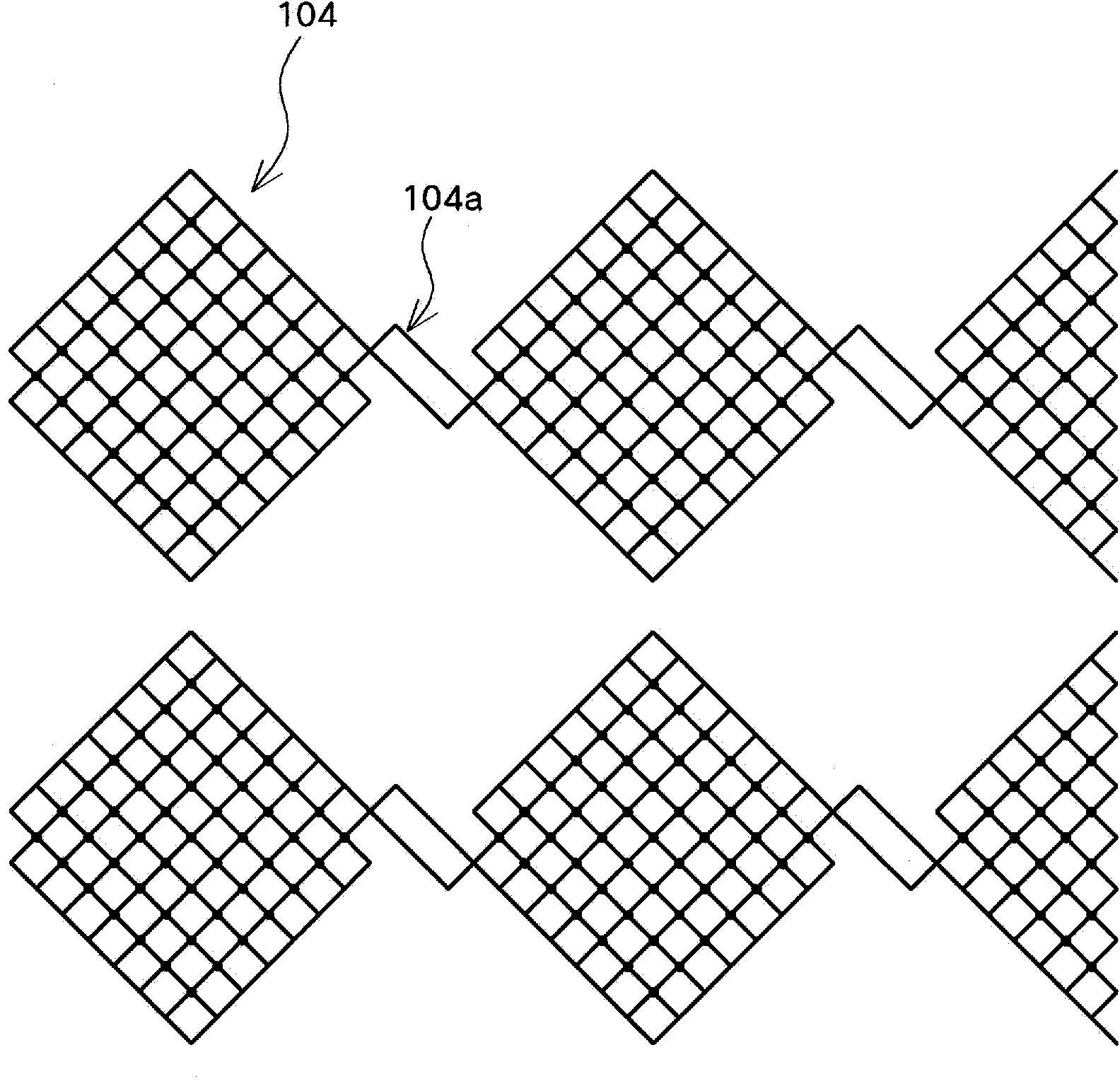

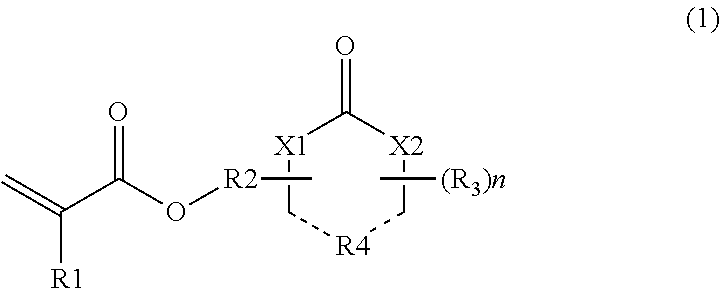

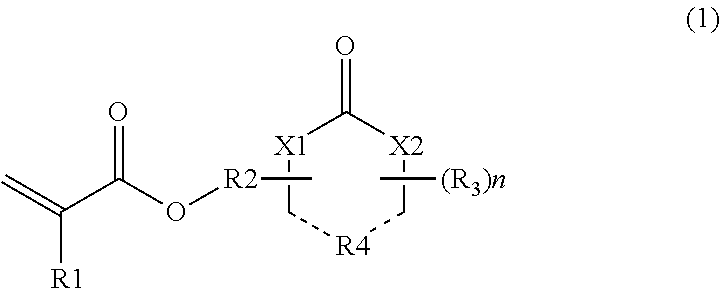

Anisotropic conductive film, connection structure and method of producing the same

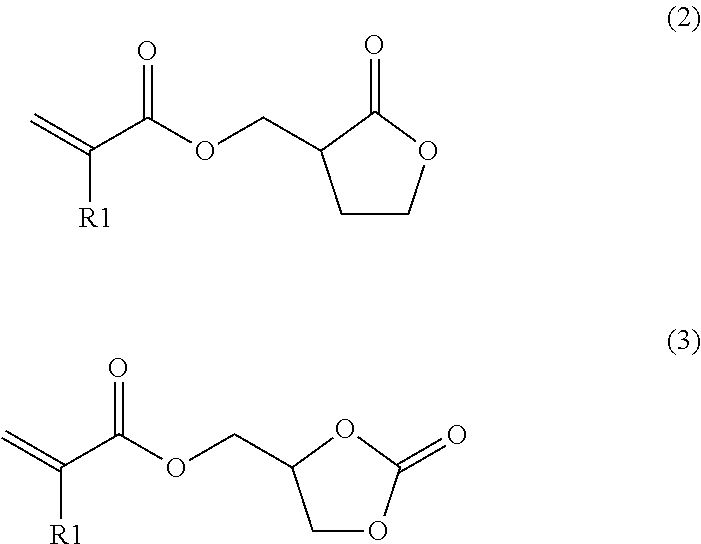

ActiveUS20120228026A1High bonding strengthLower the resistance valueNon-insulated conductorsApparatus for feeding conductors/cablesMonomer compositionAnisotropic conductive film

An anisotropic conductive film is obtained by dispersing conductive particles in an insulating adhesive composition including a (meth)acrylate-based monomer composition, a radical polymerization initiator, and a film-forming resin. The (meth)acrylate-based monomer composition includes a (meth)acrylate-based monomer which has a cyclic ester residue or a cyclic amide residue represented by the formula (1):R1 is a hydrogen atom or a methyl group; R2 is an alkylene group or an alkyloxy group; R3 is an alkyl group, an alkylene group, an aryl group, or a halogen atom; n is an integer of 0 to 3; R4 is absent or an alkylene, dotted lines on both sides of R4 jointly represent a single bond; X1 is absent, or an oxygen atom or a carbon atom; and X2 is an oxygen atom, a nitrogen atom, or a sulfur atom.

Owner:DEXERIALS CORP

Method of continuously fabricating a corrugated coaxial cable

InactiveUS20030111768A1Shorten speedProcess stabilityShaping toolsMechanical working/deformationElectrical conductorCoaxial cable

The invention relates to a method of continuously fabricating a coaxial cable in which ring-shaped corrugations are imparted to a conductor of the cable in a corrugator. The corrugator is made to operate at constant speed.

Owner:ACOME SOC COOP & PARTICIPATIVE COOP DE PRODION A CAPITAL VARIABLE

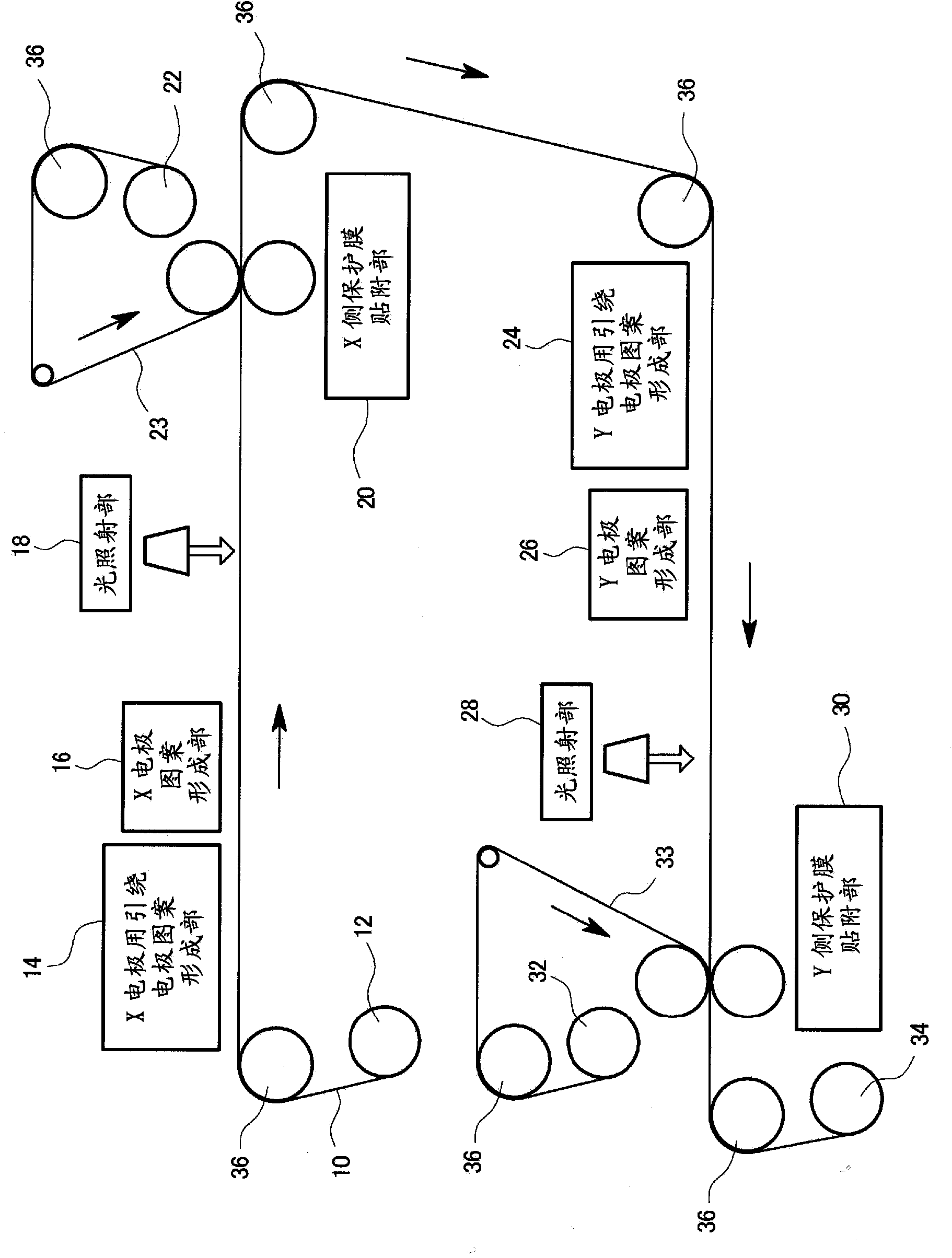

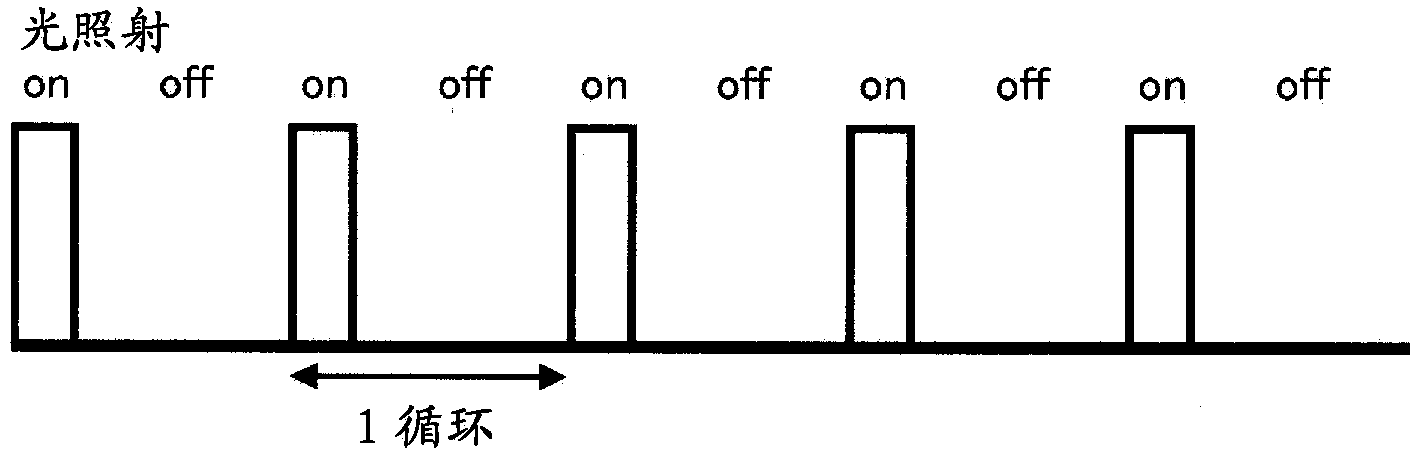

Transparent conductive substrate fabrication method, transparent conductive substrate and electrostatic capacitance-type touch panel

InactiveCN104254823AConductive layers on insulating-supportsTransparent dielectricsCapacitanceConductive paste

Provided are the following: a method that does not involve vacuum processing or wet etching, and uses a simple construction method for fabricating a transparent conductive substrate with high pattern recognition for use in an electrostatic capacitance-type touch panel; a transparent conductive substrate; and an electrostatic capacitance type touch panel. A lead out electrode pattern for an electrode is formed on at least one of the main surfaces of a transparent film using conductive paste; an electrode pattern is printed in the electrode pattern forming section using ink for forming transparent conductive patterns that contains metal nanowires or metal nanoparticles so that the electrode pattern connects with the electrode lead out electrode pattern, and then the electrode pattern is dried; and then, after drying, the electrode pattern is irradiated with pulsed light in an irradiation unit (18) to sinter the metal nanowires or metal nanoparticles contained in the transparent conductive pattern forming ink.

Owner:OSAKA UNIV +1

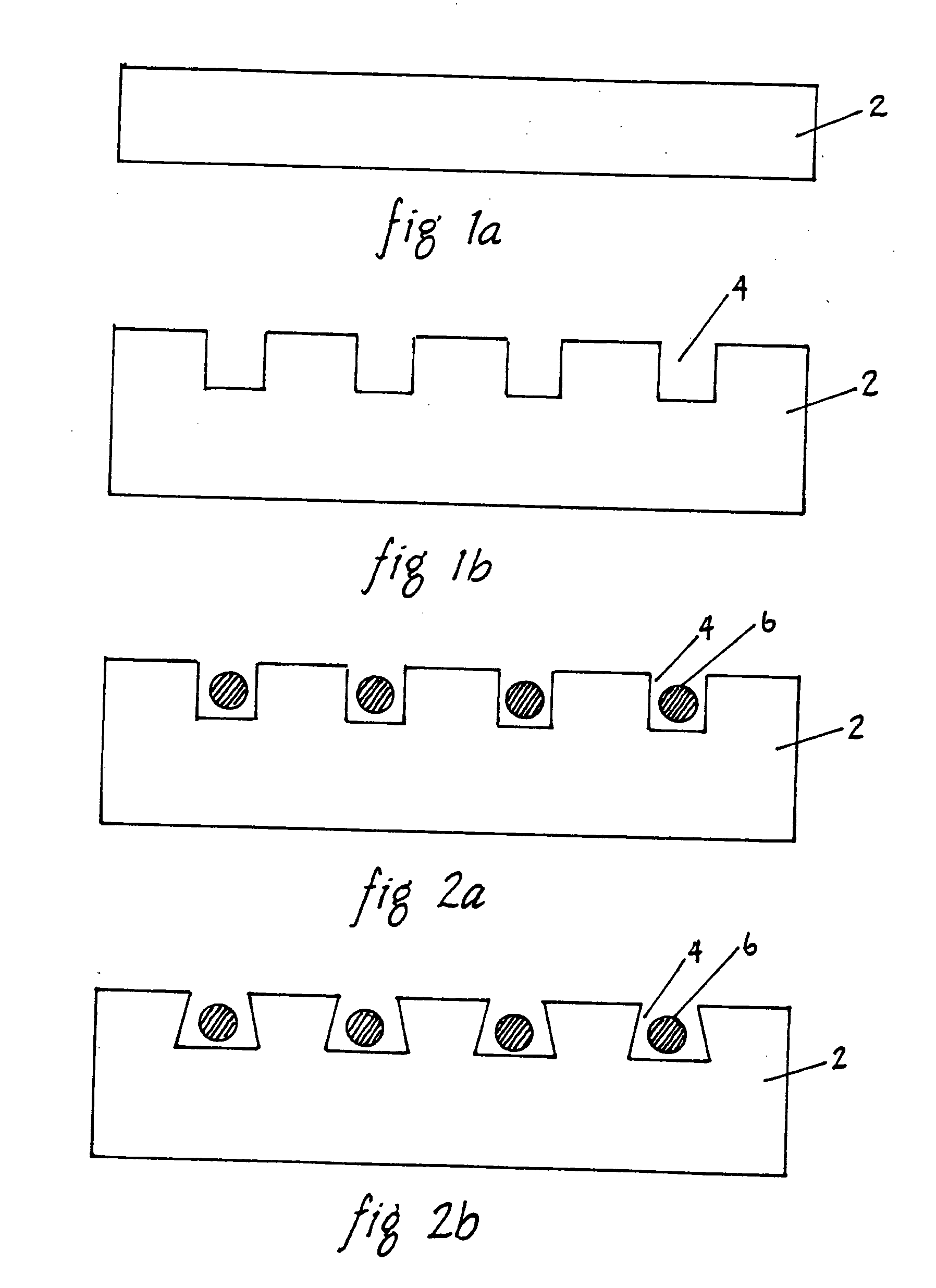

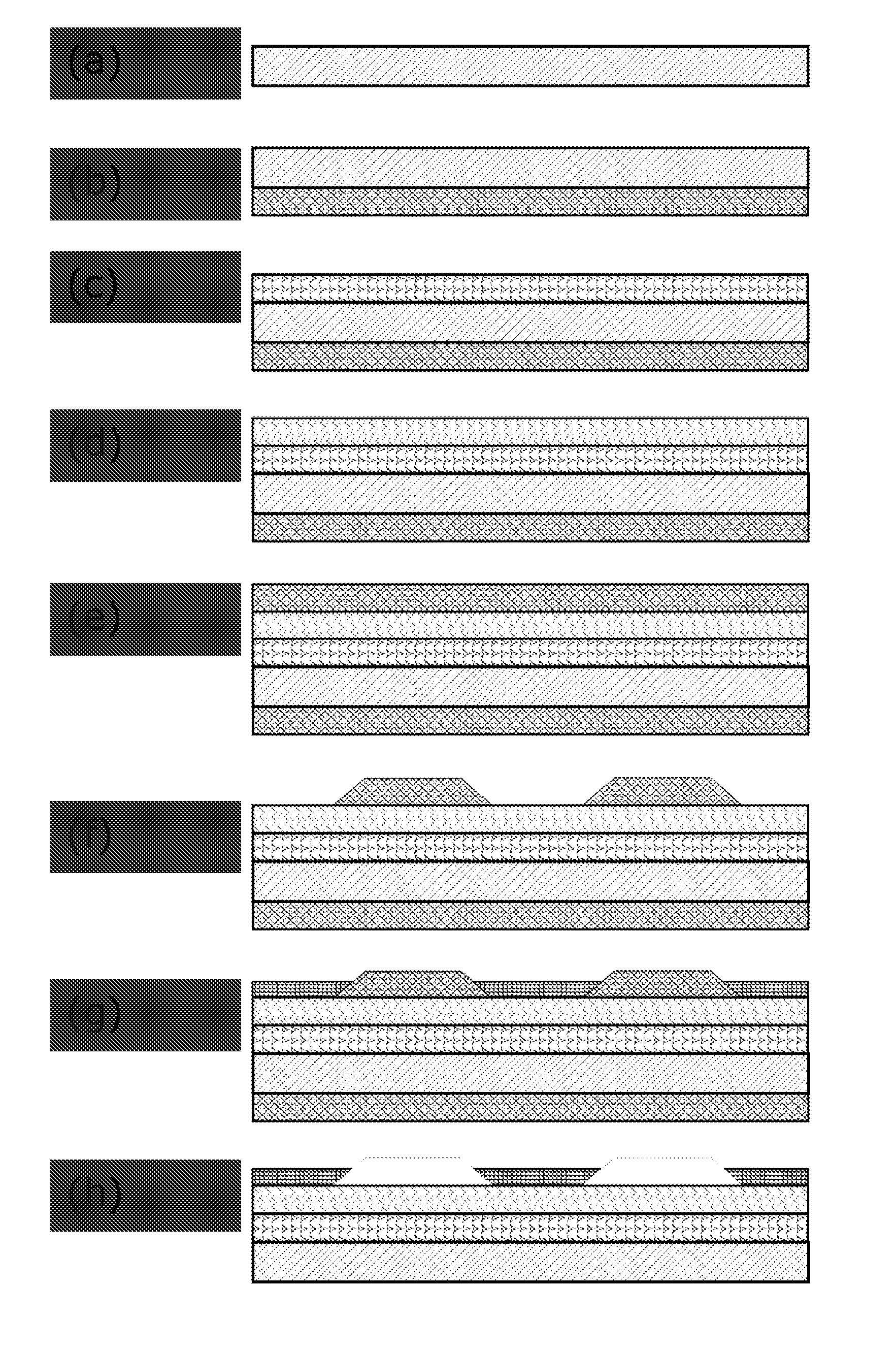

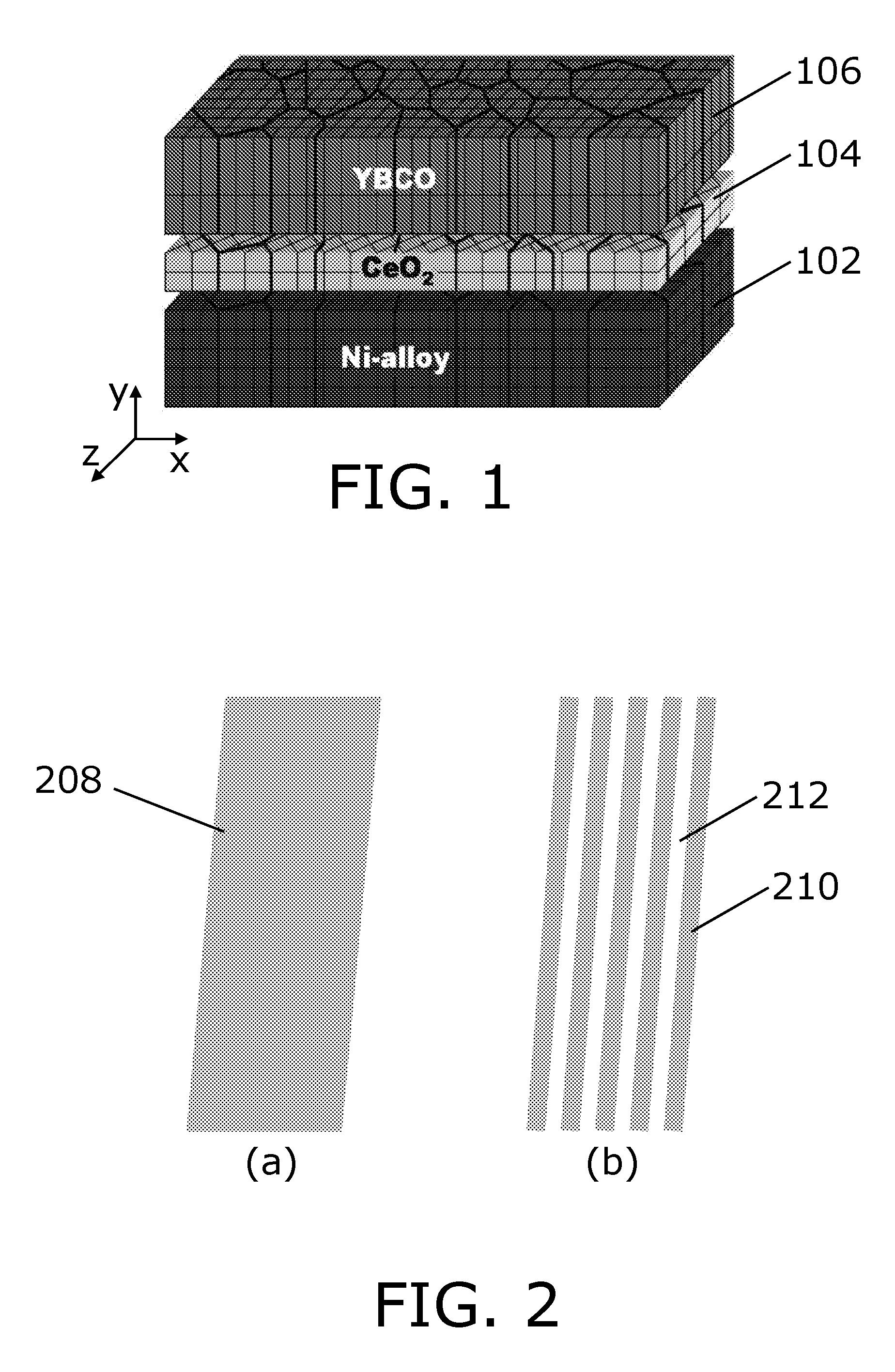

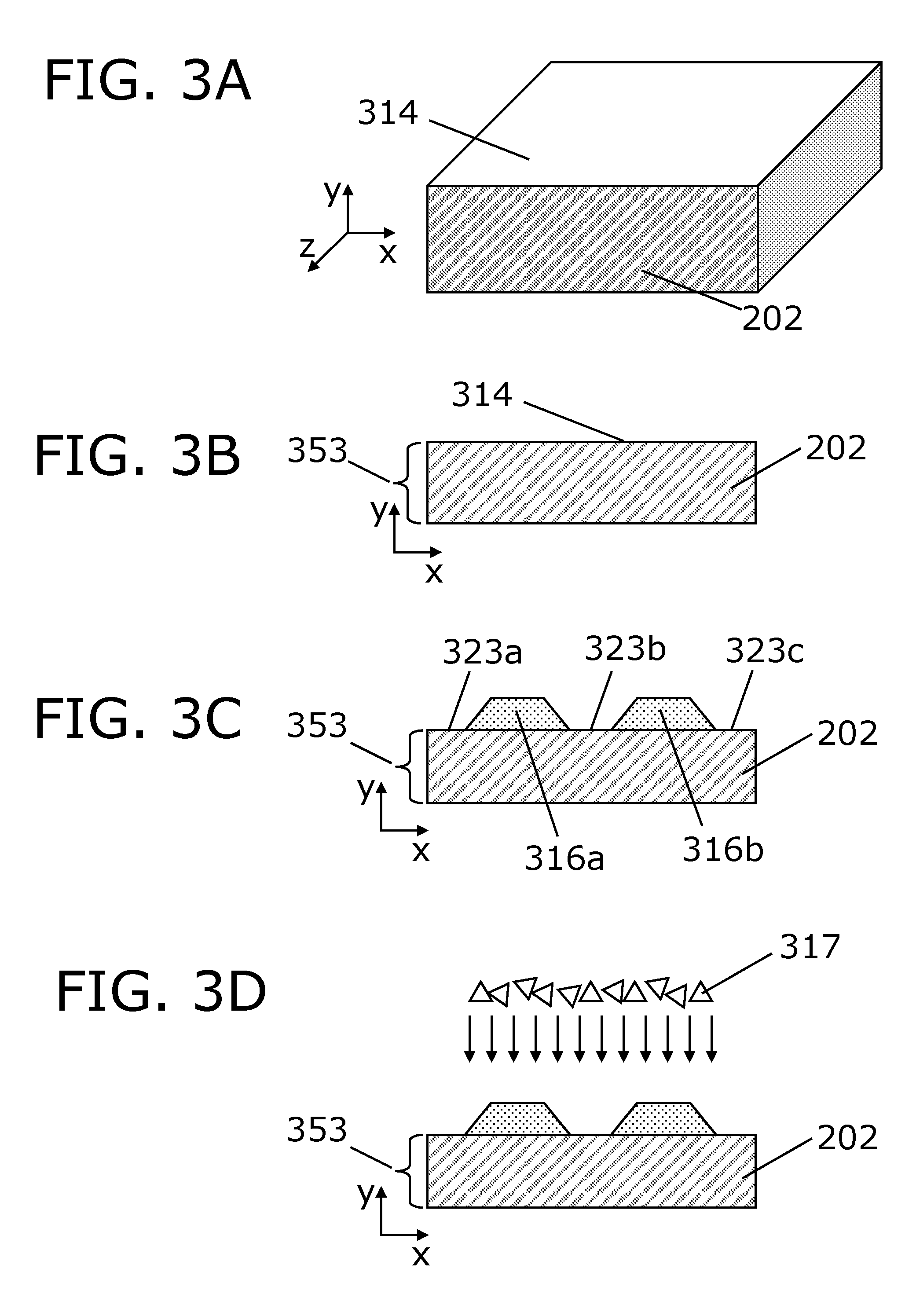

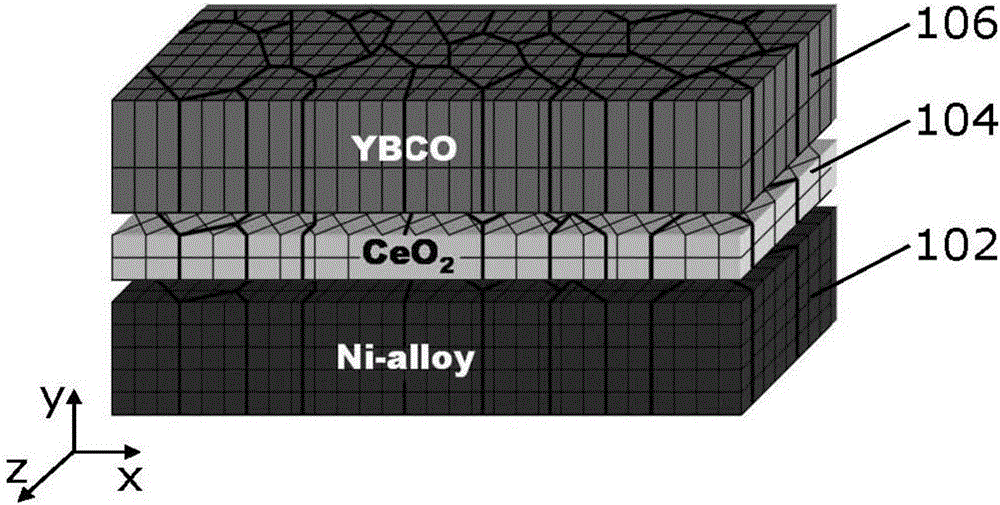

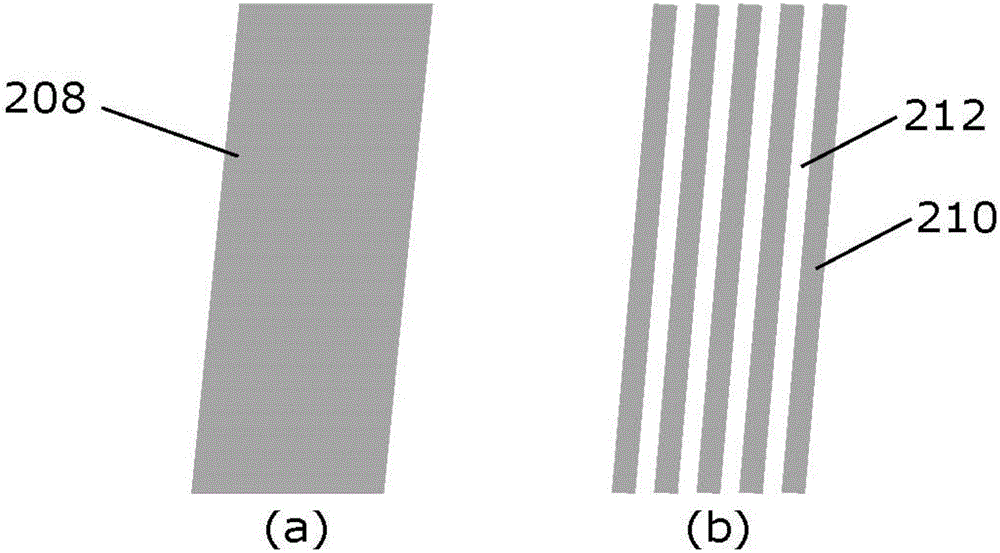

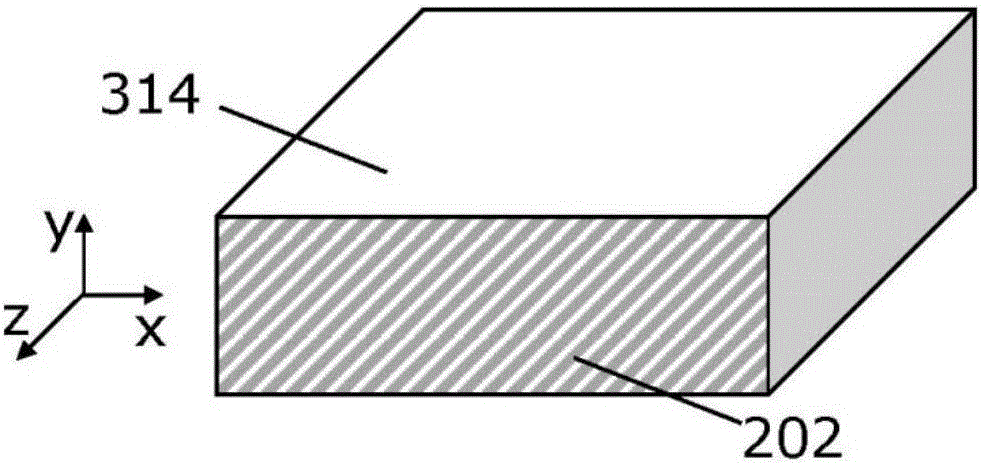

Method for producing substrates for superconducting layers

InactiveUS20160276067A1Large degree of controlLarge degree controlSuperconductors/hyperconductorsSuperconductor detailsFilling materialsPartial filling

There is provided a method for producing a substrate suitable for supporting an elongated superconducting element, wherein one or more elongated strips of masking material are placed on a solid element (202) so as to form one or more exposed elongated areas being delimited on one or two sides by elongated strip of masking material, and placing filling material on the solid element so that each exposed elongated area within the one or more exposed elongated areas is covered by a portion of filling material (318a-c) where each portion of filling material also covers at least a portion of the adjacent elongated strip of masking material and subsequently removing the one or more elongated strips of masking material so as to form one or more corresponding undercut volumes, where each undercut volume within the one or more undercut volumes is formed along a portion of filling material and between the portion of filling material and the solid element. The method may further comprise placing buffer material (640) and or superconducting material (642, 644, 646)) on the substrate, so as to provide a superconducting structure (601) with reduced AC losses.

Owner:DANMARKS TEKNISKE UNIV

Insulating coated wire and method for manufacturing the same

ActiveUS9620260B2Easy to manufactureComplex structurePlastic/resin/waxes insulatorsInsulated cablesElectrical conductorEngineering

Owner:AUTONETWORKS TECH LTD +2

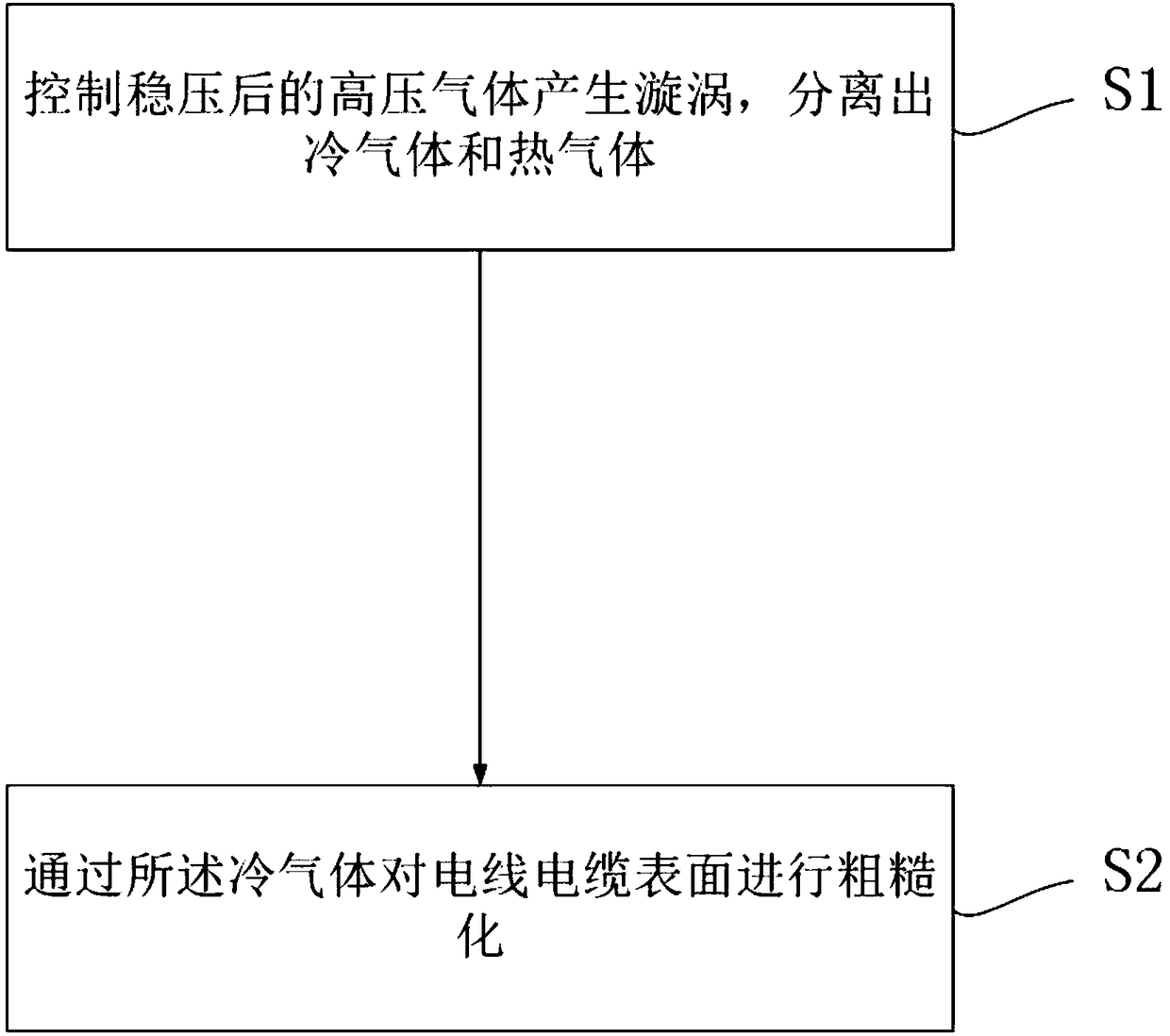

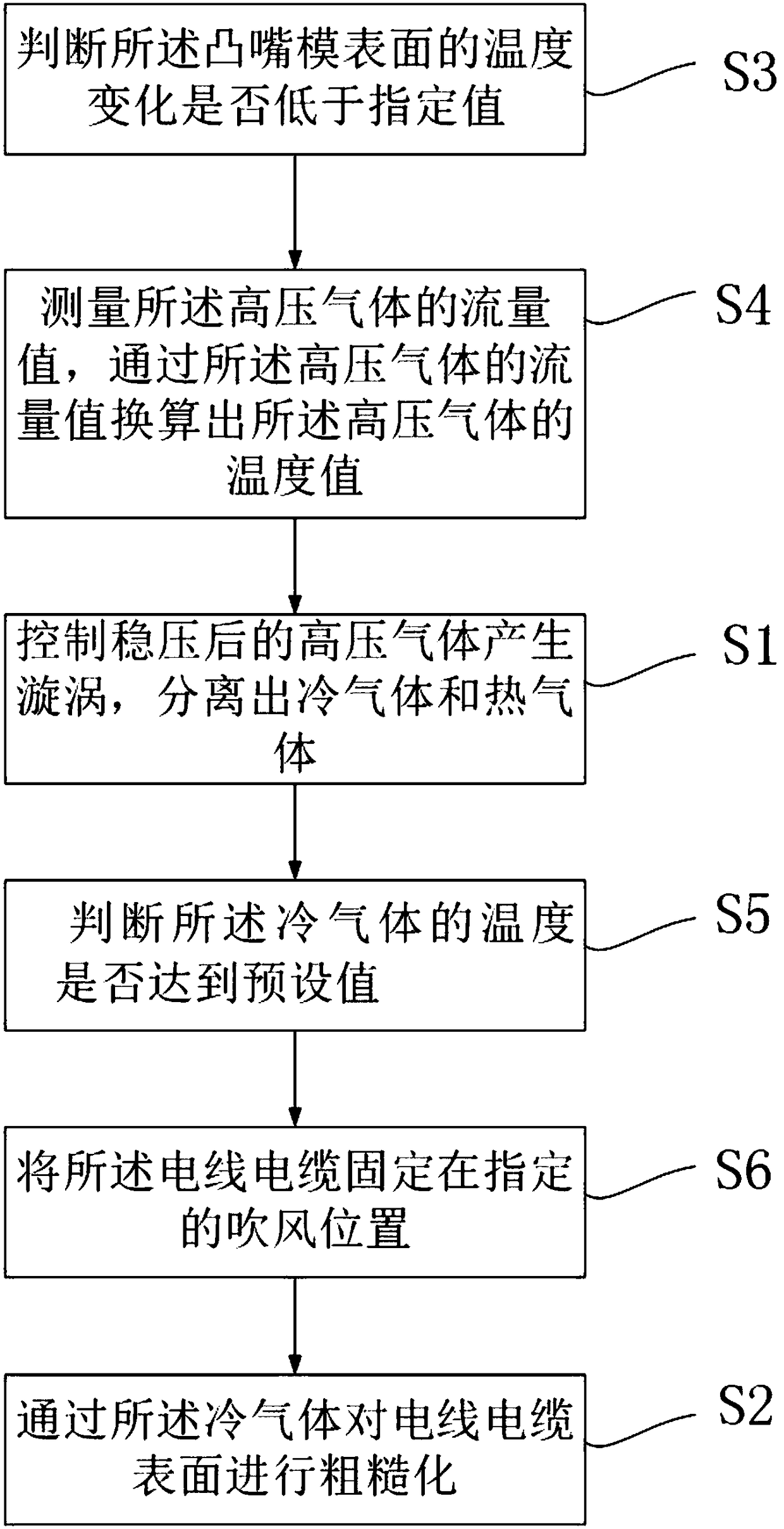

Surface roughing method and device of wire cable

PendingCN108399983AOvercome the problem of inconvenience in productionReduce the temperatureFormation of corrugations on cables/conductorsSurface roughnessEngineering

The invention provides a surface roughing method and device of a wire cable. The surface roughing device comprises an air pressure-limitation device, an air cooling device and an air blowing device, wherein the air blowing device comprises an air blowing device main body and a convex nozzle die, wherein the air pressure-limitation device is used for receiving a high-pressure gas, stabilizing the pressure of the high-pressure gas and transmitting the gas to the air cooling device via an air pipe, the air cooling device is used for controlling the received high-pressure gas to generate eddy, separating a cold gas and a hot gas and transmitting the cold gas to the air blowing device main body via the air pipe, and the air blowing device main body is used for transmitting the cold gas to a groove adaptive to a convex nozzle die structure and uniformly dispersing the cold gas on a surface of the wire cable by a funnel-shaped structure arranged at the convex nozzle die. The surface roughingdevice has the beneficial effects that a chemical reagent is not needed, the surface of the wire cable is roughed by rapidly reducing a temperature of a local environment, and the problem that a conventional surface-roughed wire cable is inconvenient to produce is solved.

Owner:深圳宝新电线电缆制造有限公司

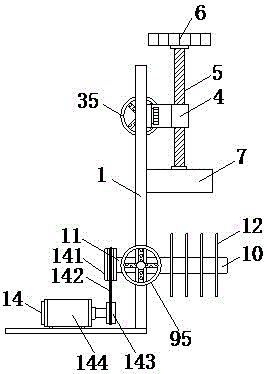

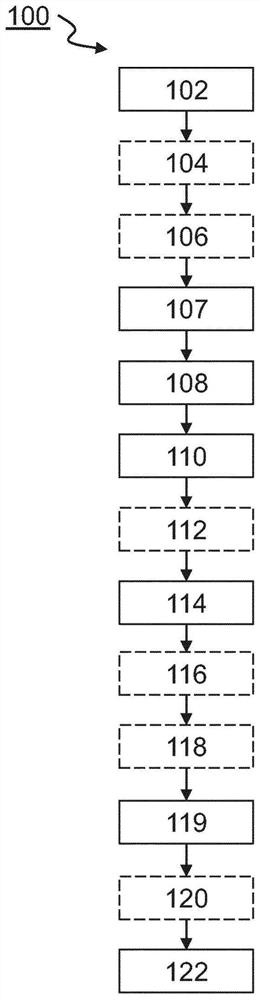

Manufacturing process of embedded metal strip type cable

ActiveCN109637746ALabor savingIncrease productivityApparatus for heat treatmentFormation of corrugations on cables/conductorsMetal stripsLinear motion

The invention discloses a manufacturing process of an embedded metal strip type cable. The process comprises the following steps of: uniformly coating a rubber layer on a bearing cable to form the cable; the released cable entering a rolling groove device; four high-temperature rolling wheel mechanisms are obliquely arranged in the rolling groove device; through uniform linear motion of the cableand revolution motion of the two groups of rolling wheel mechanisms; Two groups of spiral grooves are processed on the cable, when the metal clamping groove strip is close to the spiral groove on thecable, the metal clamping groove strip and the bottom surface of the spiral groove are coated with adhesive by the adhesive coating device and the adhesive coating device, and the adhesive is quicklydried by the cable embedded with the metal clamping groove strip through the drying device. According to the manufacturing process, the spiral guide rail groove and the spiral groove can be automatically formed in the outer surface of the cable sleeve in a rolling mode, the metal clamping groove strip is automatically glued and embedded into the spiral groove, labor is saved, and production efficiency is improved.

Owner:金华市正通线缆有限公司

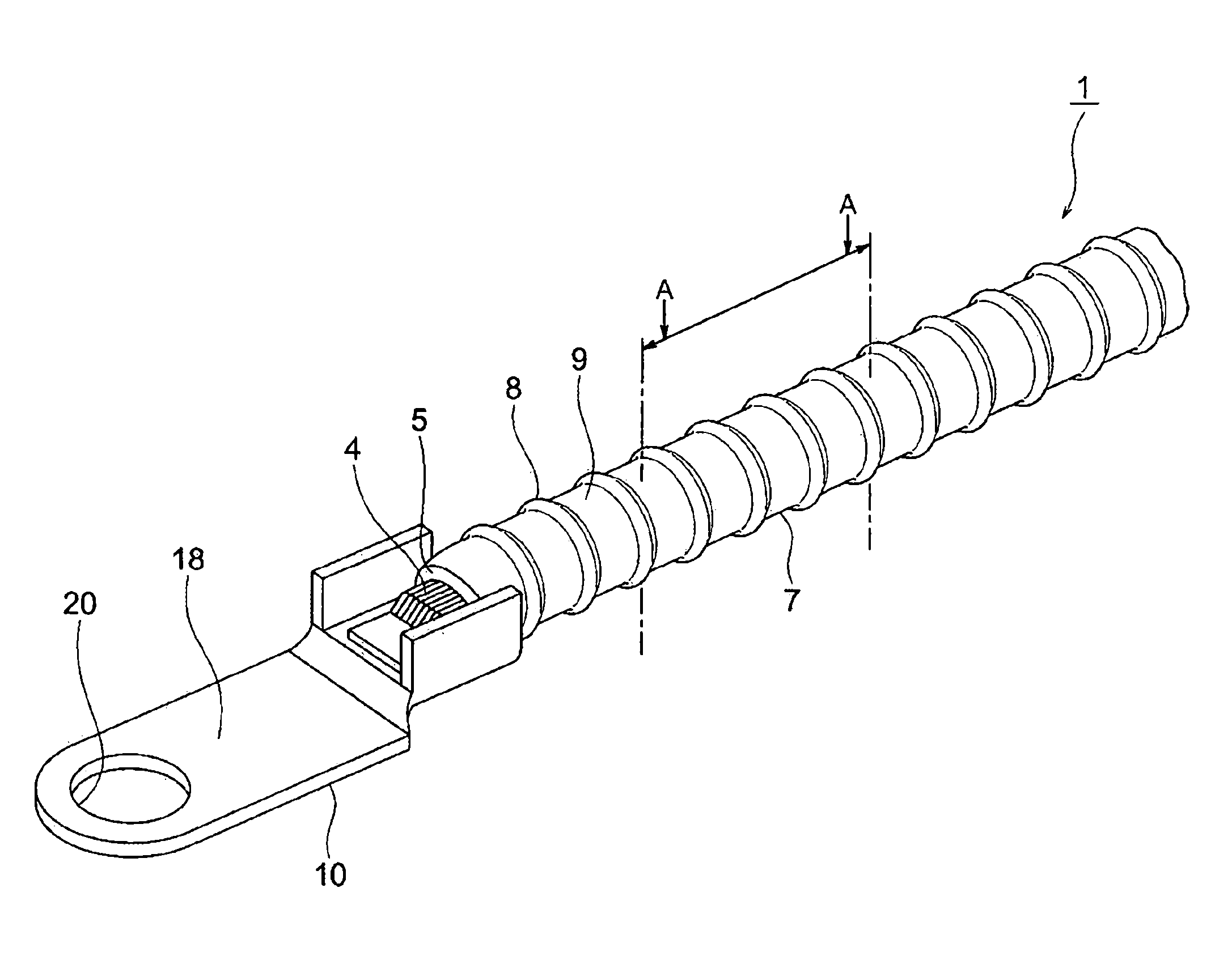

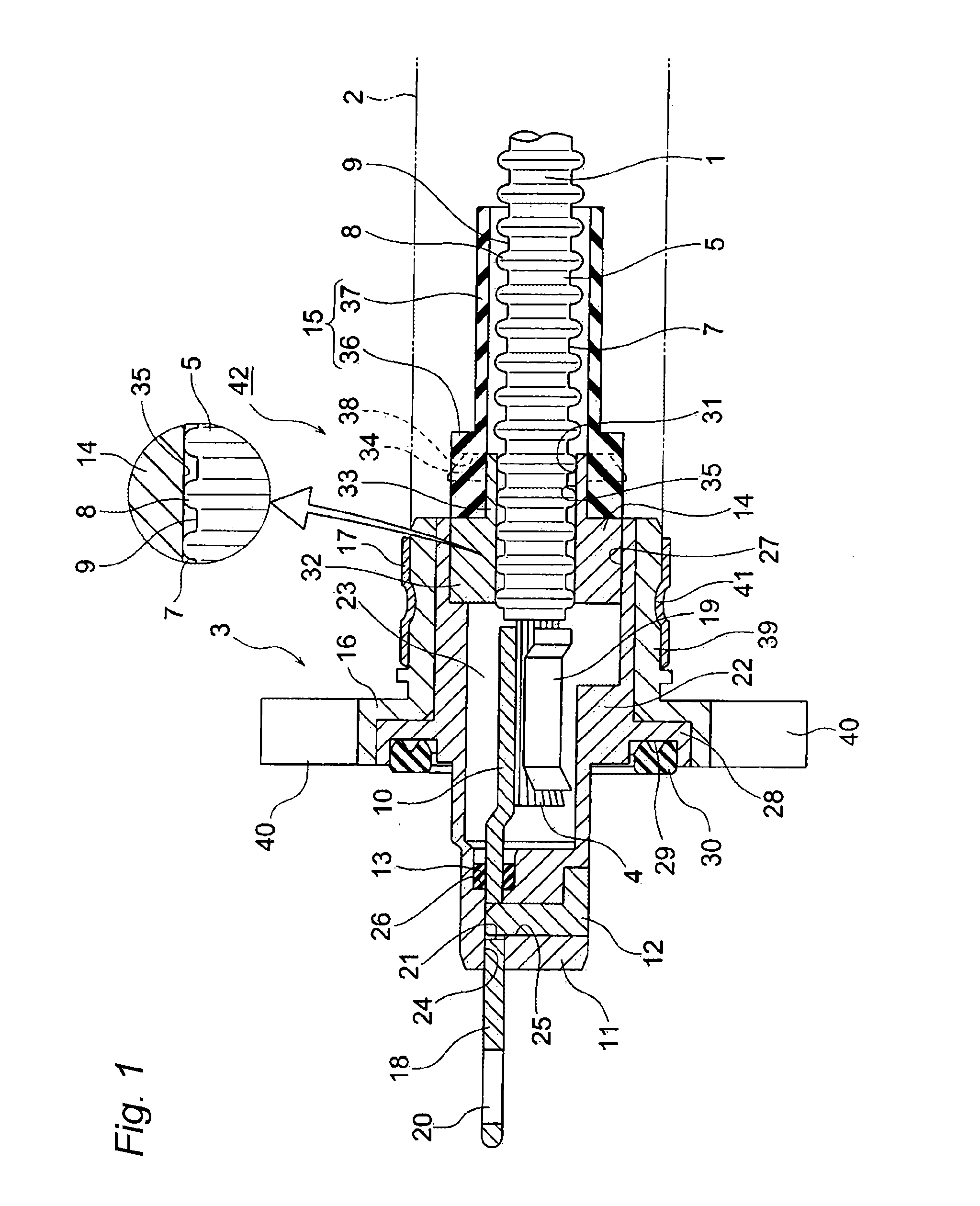

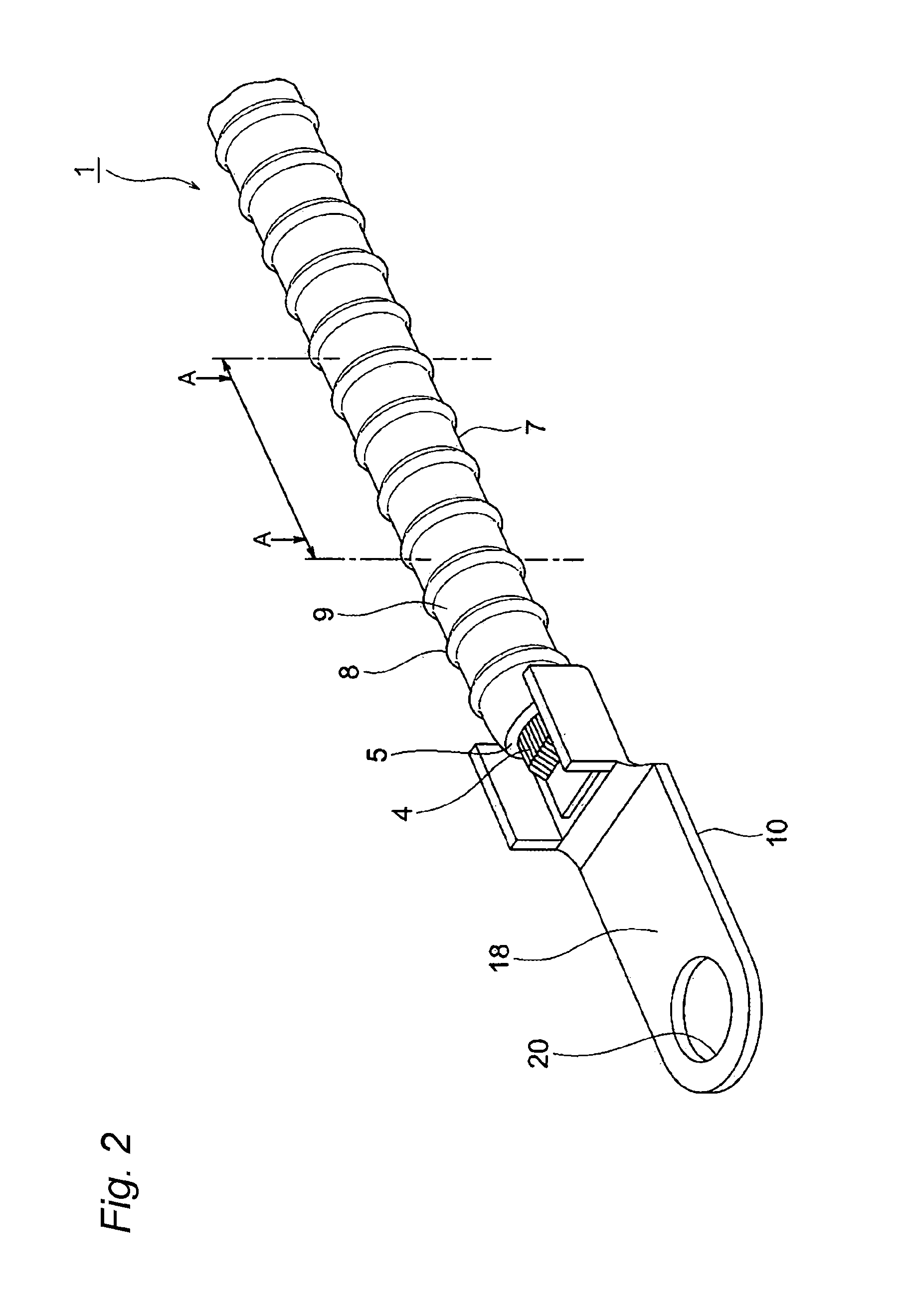

Conductive path

There is provided a conductive path. The conductive path includes a conductor and a sheath. The sheath covers the conductor. The sheath is made of a resin composition. The resin composition has elasticity. There are formed protrusions which are convexly protruded from an outer peripheral surface of the sheath of the conductive path and have elasticity so as to be deformed.

Owner:YAZAKI CORP

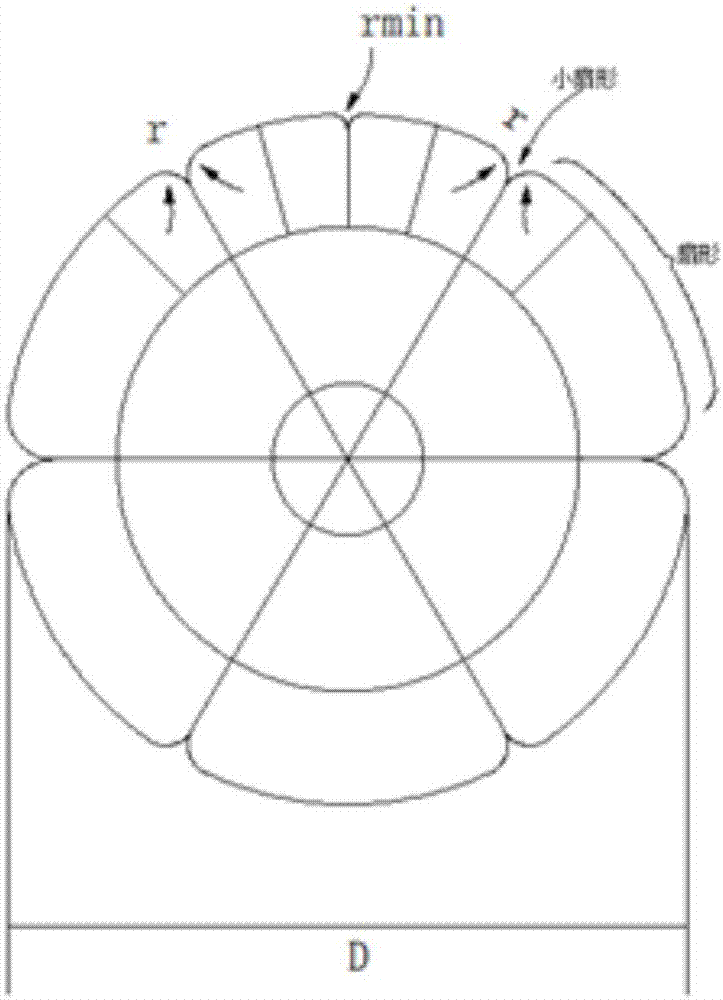

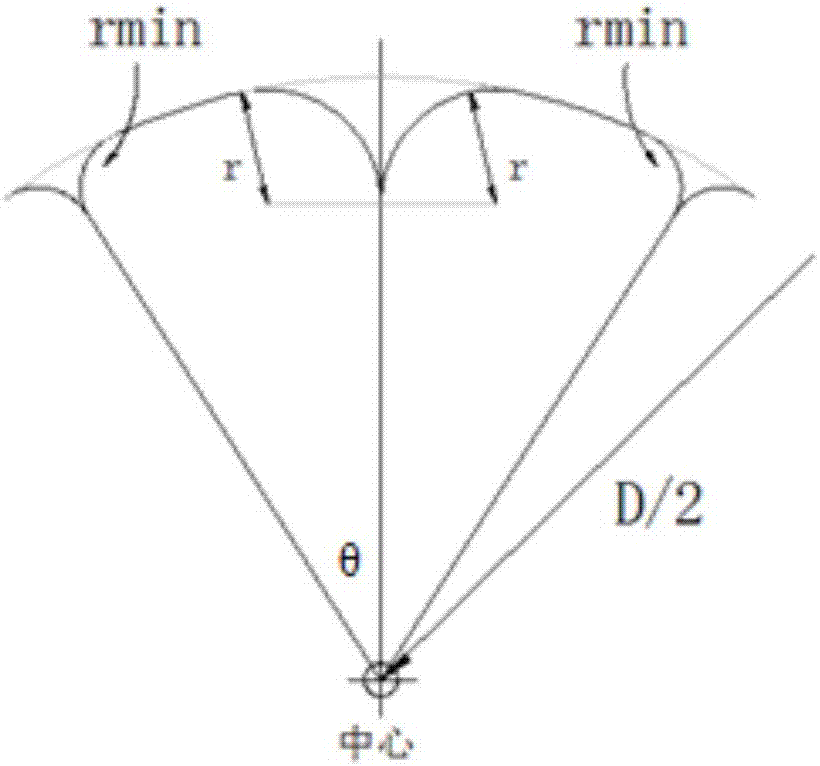

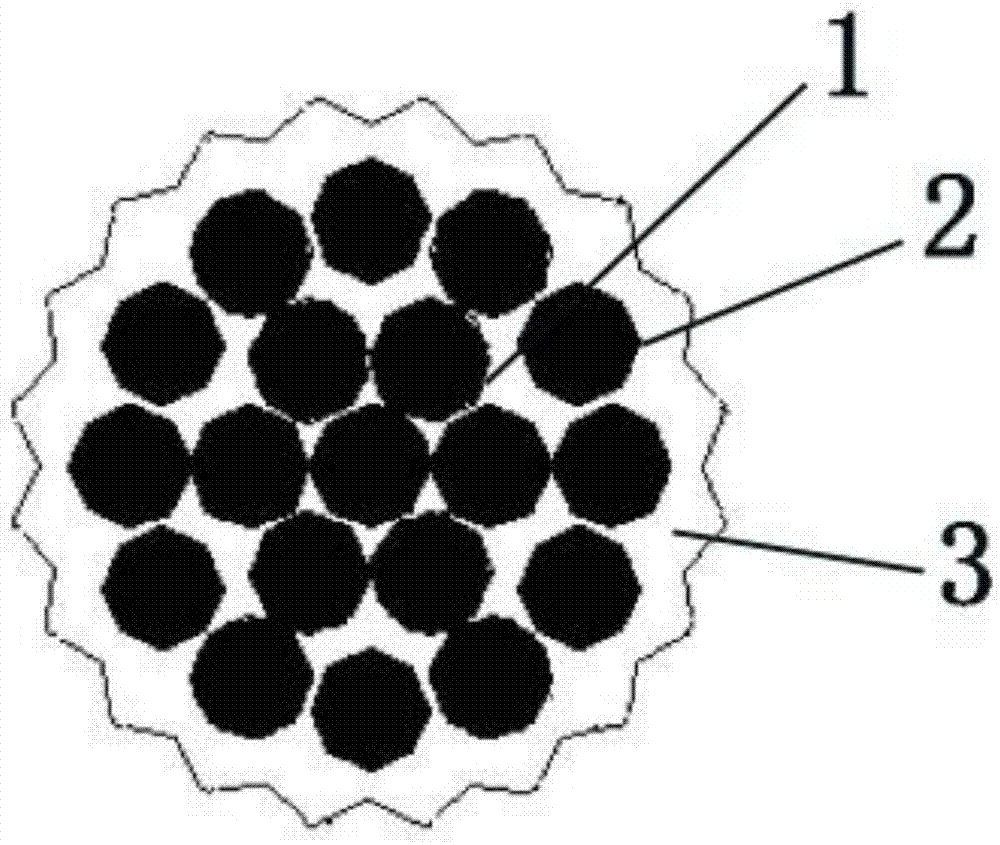

Drag reduced conductor and method for forming spline curves in drag reduced conductor

PendingCN107507659ASure easyMeet the situation of incoming wind speedNon-insulated conductorsPower cables with screens/conductive layersElectrical conductorEngineering

The invention discloses a drag reduced conductor and a method for forming spline curves in the drag reduced conductor. The drag reduced conductor includes an inner conductor layer composed of aluminum wires, an outer conductor layer which wraps the periphery of the inner conductor layer and is composed of aluminum wires, and an aluminum wire layer arranged outside the outer conductor layer; the surface structure of the aluminum wire layer is composed of a plurality of spline curves with the same local structure; and the shape of each spline curve is defined by two control points at the highest points at two ends of the corresponding spline curve and a distance from a point on the angular bisector of the two control points to the outer diameter of the conductor. According to the drag reduced conductor and the method for forming the spline curves in the drag reduced conductor of the invention, the aluminum wire structures of the outermost layer of the conductor are changed in a manner that traditional circular lines and fan-shaped structures are changed into curved line structures, and therefore, the surface of the conductor has a certain roughness, and therefore, drag can be reduced. The structures of the molded lines are monotonous, and therefore, molds for producing the molded lines can be monotonous, the lines will not be disordered when being stranded, and processing and production can be facilitated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +2

Method for producing substrates for superconducting layers

InactiveCN105794007ASuperconductors/hyperconductorsFormation of corrugations on cables/conductorsFilling materialsEngineering

Owner:DANMARKS TEKNISKE UNIV

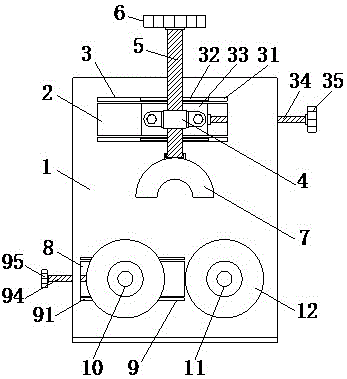

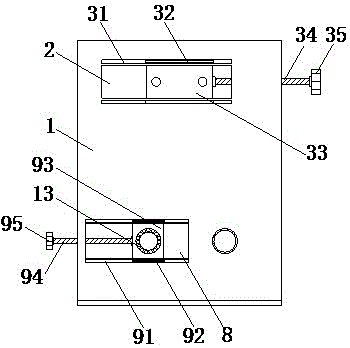

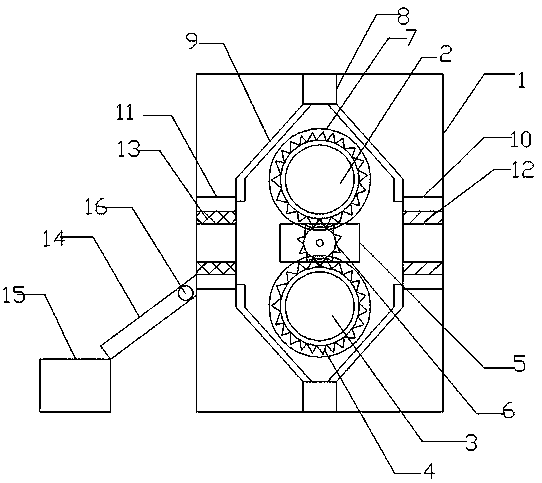

Creasing device for machining of audio cable

InactiveCN106098245AAchieve the purpose of processingReduce volumeFormation of corrugations on cables/conductorsDrive shaftEngineering

The invention discloses a creasing device for machining of an audio cable. The creasing device comprises a fixed plate, wherein a first through groove is formed in the fixed plate, a mobile device is movably arranged in the first through groove, a telescopic screw rod is movably arranged on a side surface of the mobile device by a fixed block, an adjustment handle is fixedly arranged at the top end of the telescopic screw rod, an arc press plate is movably arranged at one end, far away from the adjustment handle, of the telescopic screw rod, a second through groove is formed in the fixed plate below the press plate, an adjustment device is movably arranged in the second through groove, a driven shaft is movably arranged on the adjustment device through a bearing, and a driving shaft is movably arranged on the fixed plate at a side surface of the driven shaft. In the creasing device for the machining of the audio cable, the mobile device is arranged and is matched with the adjustment device, the positions of the press plate and the driven shaft can be manually adjusted, the driving shaft is driven by a power device to rotate so as to machine the audio cable, and the purpose of machining audio cables of different specifications is achieved. The creasing device is high in adaptability.

Owner:CHANGZHOU RONGSHUN ELECTRONICS

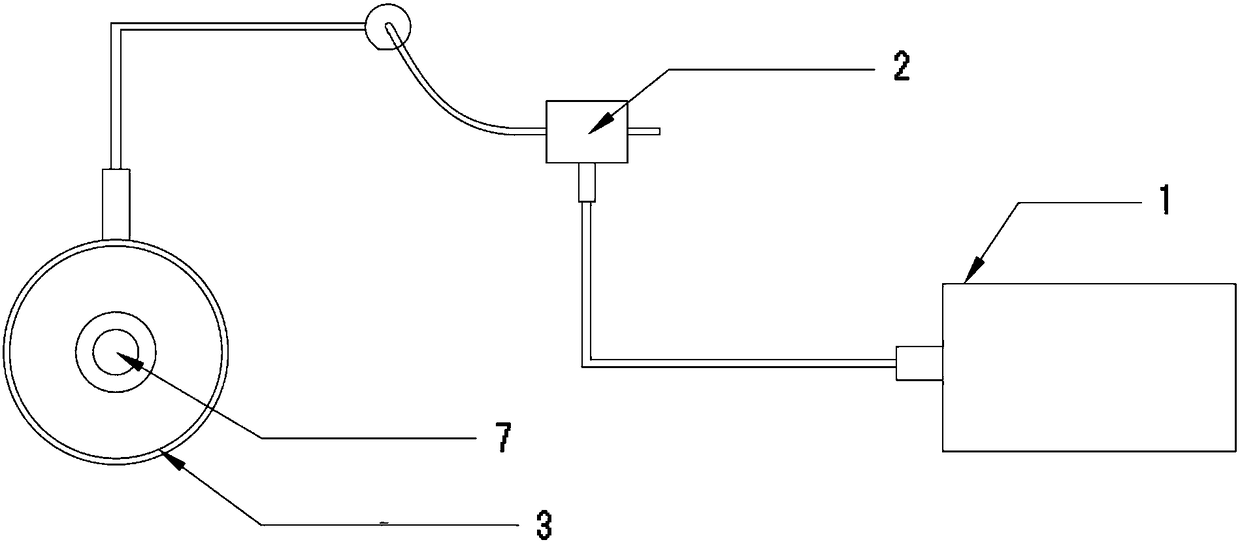

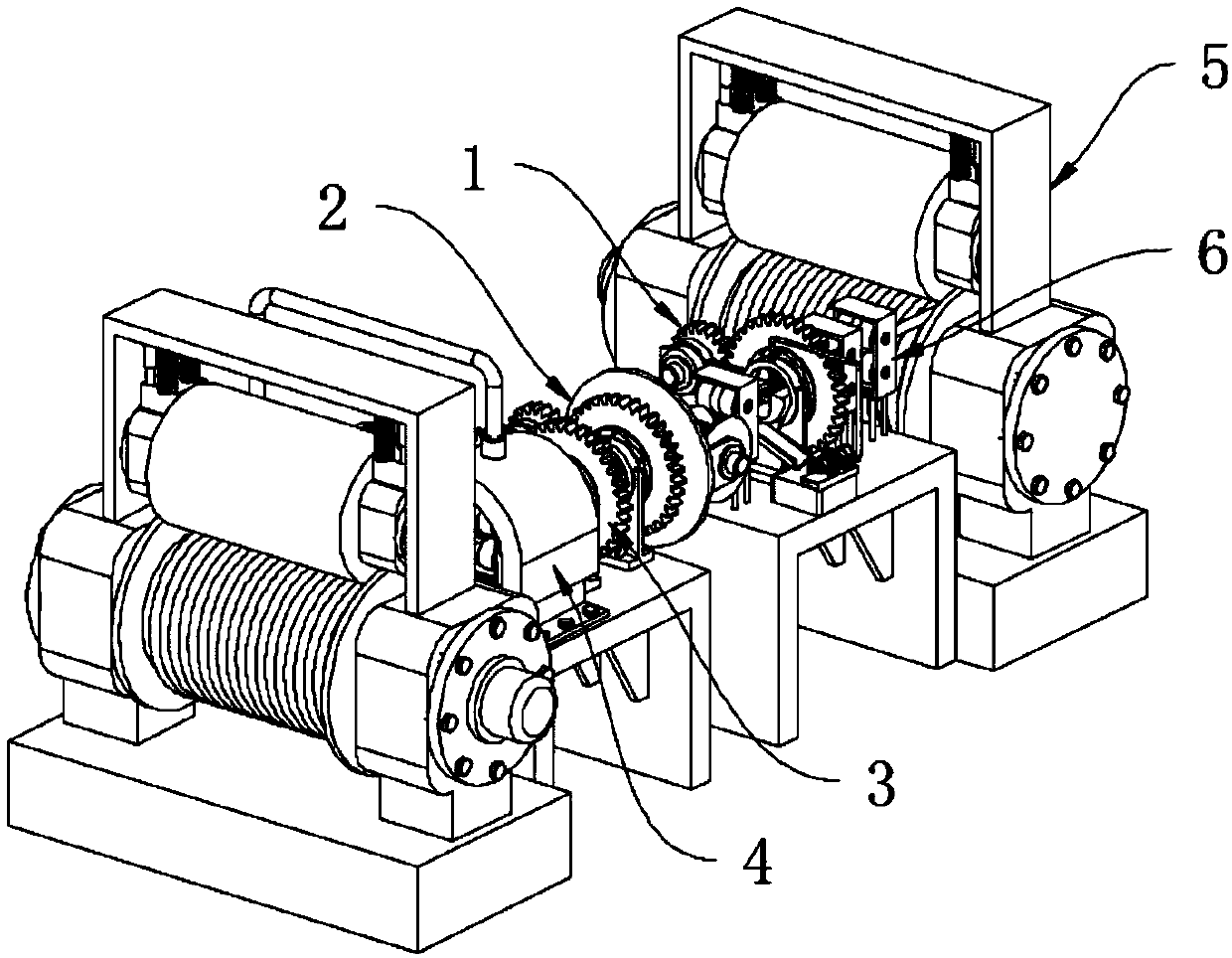

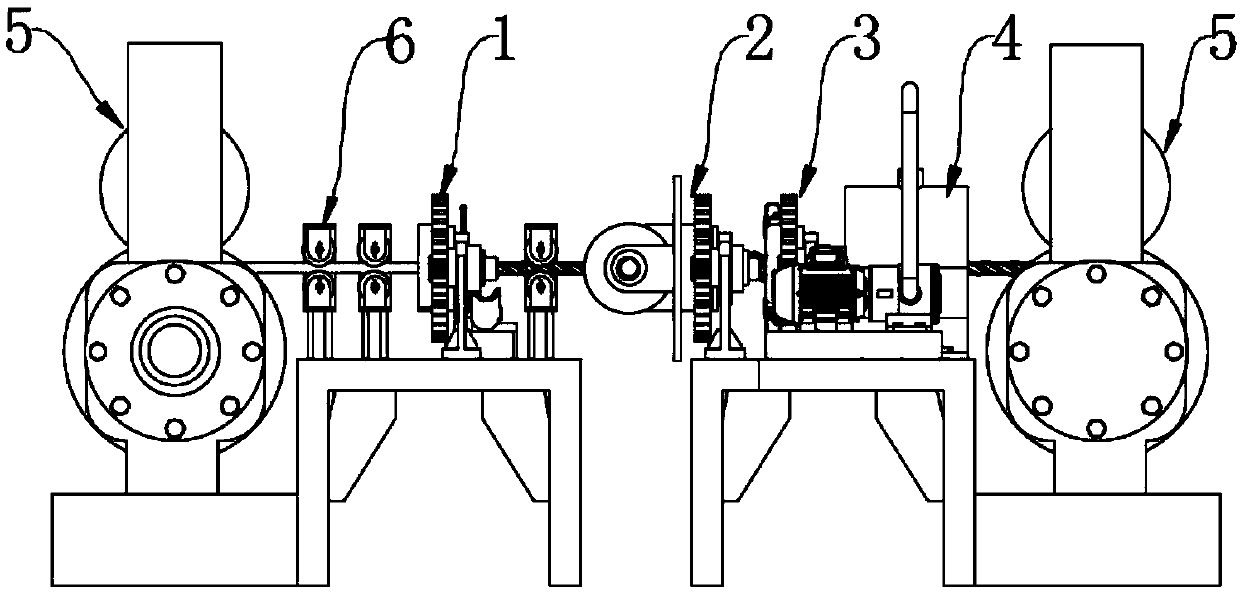

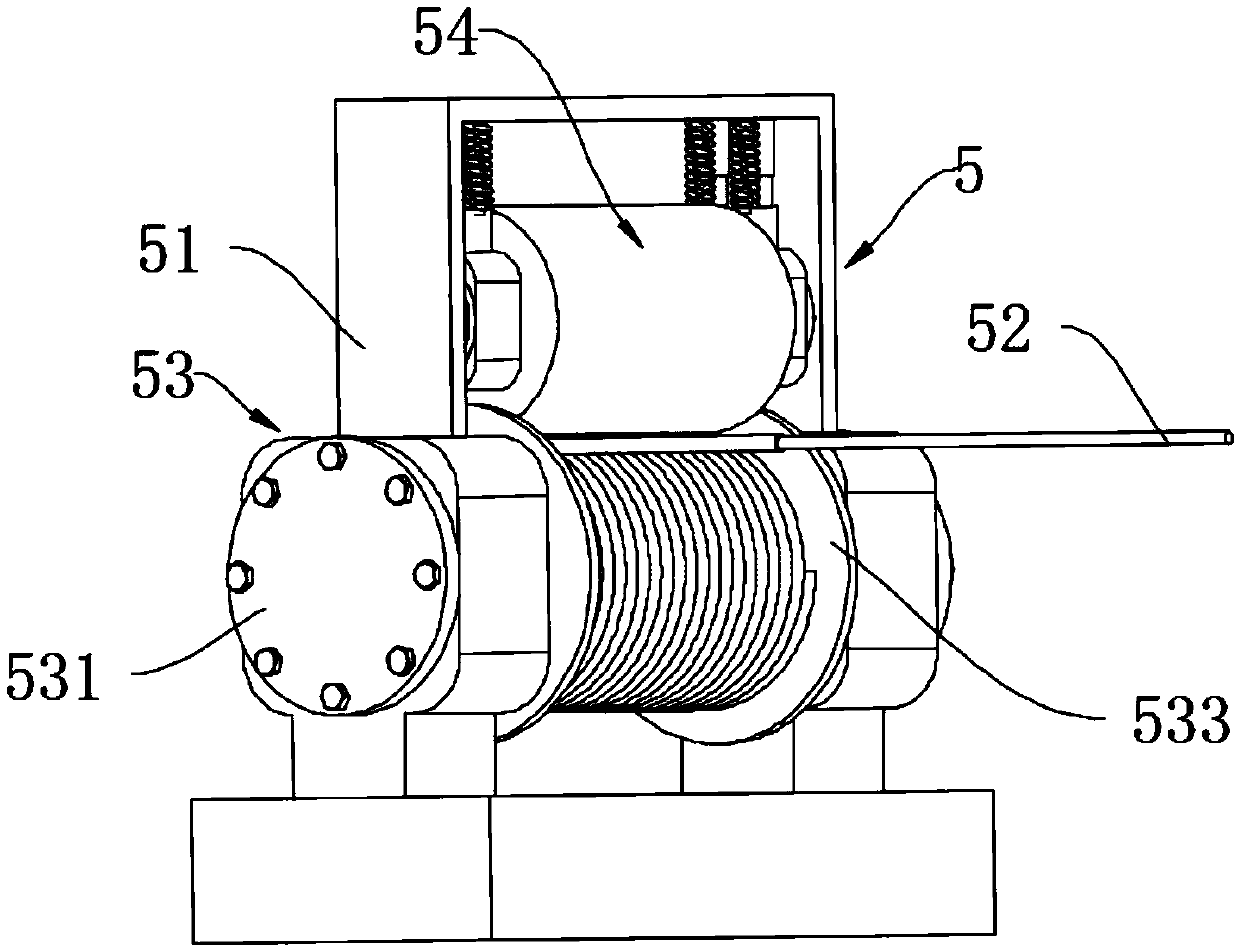

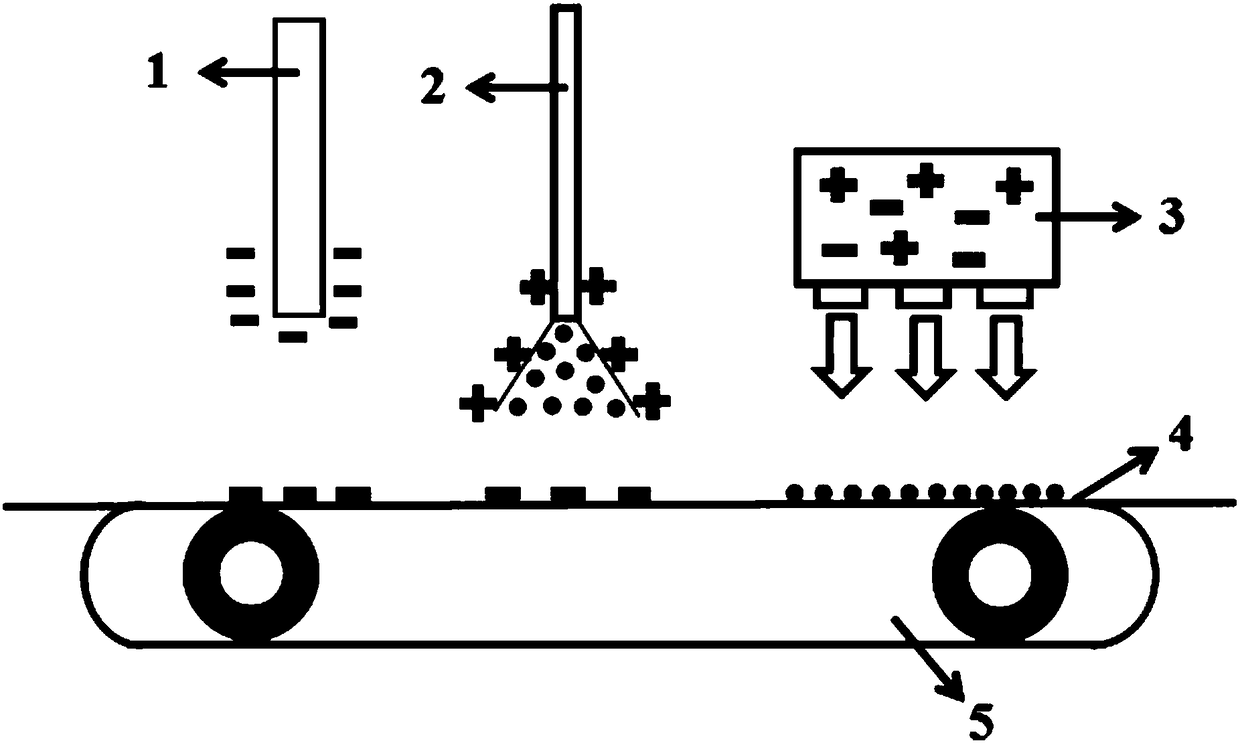

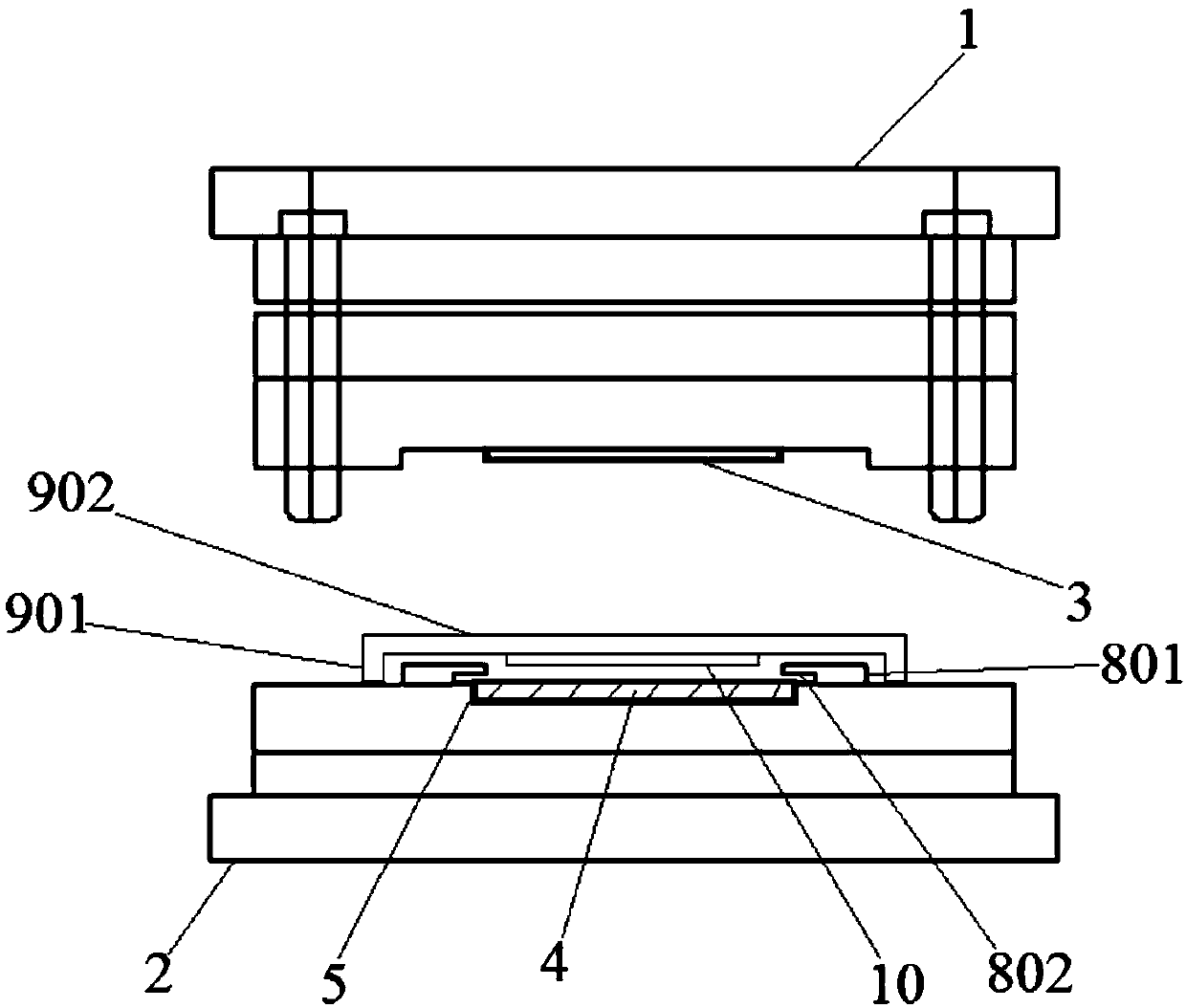

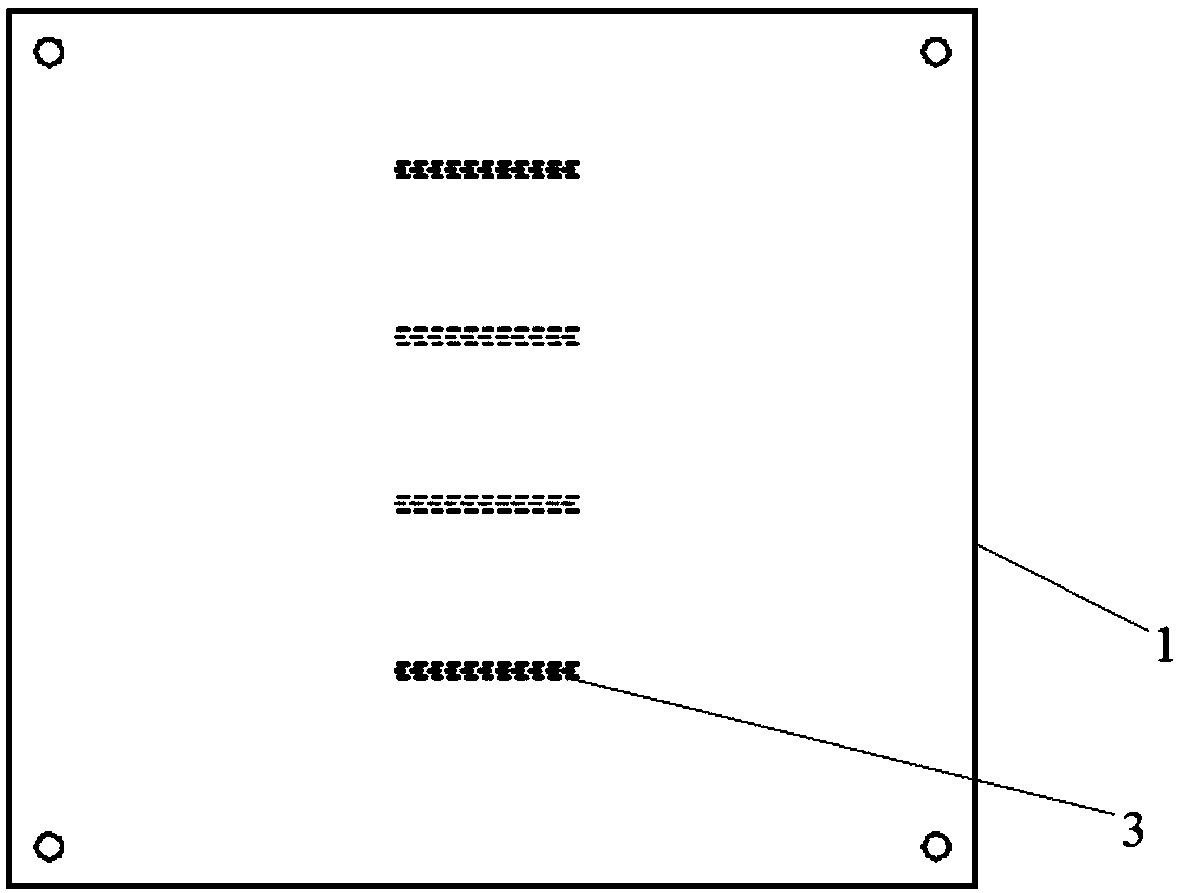

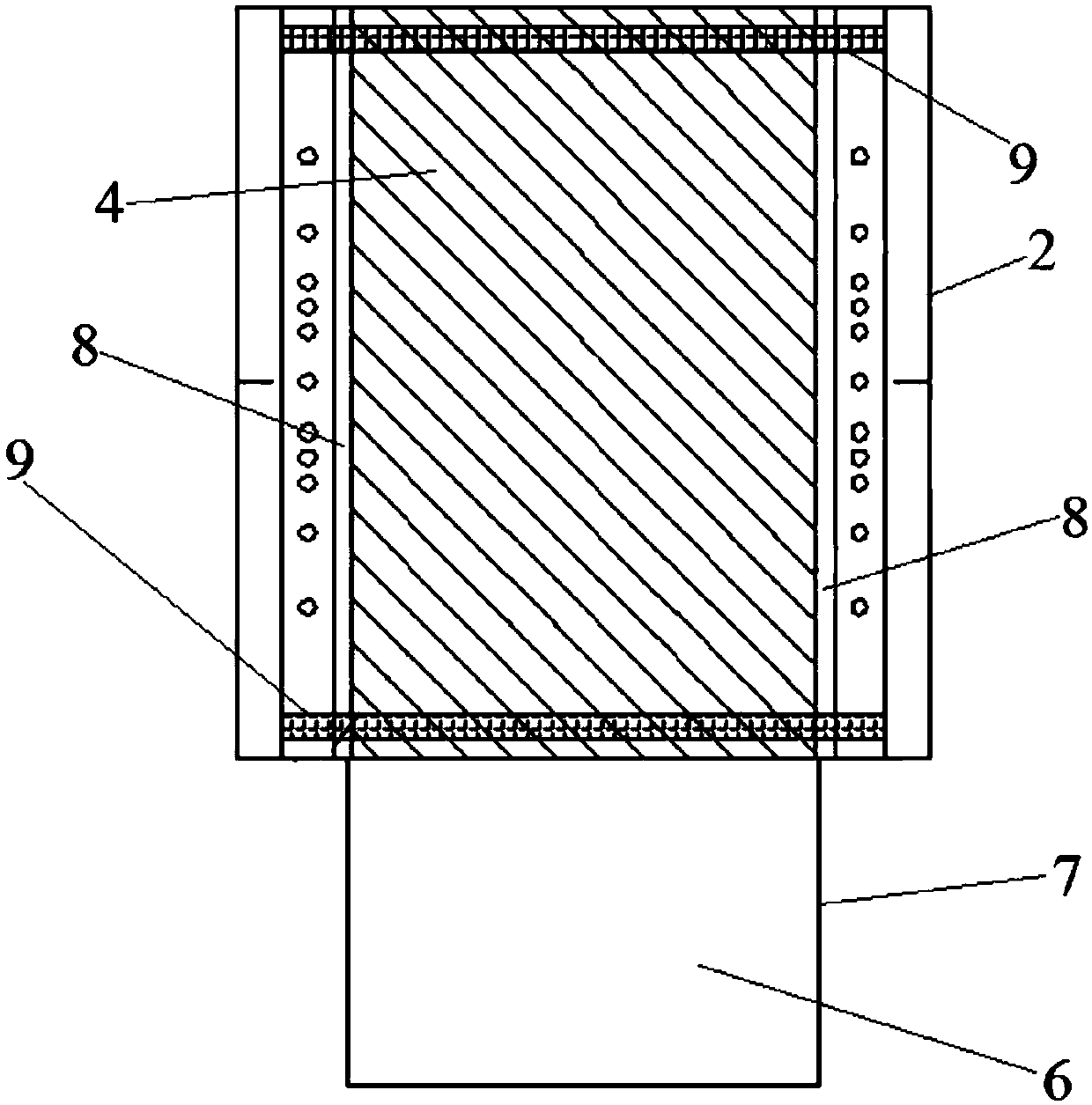

Device and method for preparation of transparent flexible conductive thin film

InactiveCN108492929AIncrease productionImprove performanceFormation of corrugations on cables/conductorsEngineeringStatic eliminators

The present invention discloses a device and a method for preparation of a transparent flexible conductive thin film. The device comprises a static generator (1), a static coating machine (2) and a static eliminator (3) arranged on a transmission device (5) in order. The method comprises the steps of: 1) preparing conductive ink; 2) putting a transparent flexible substrate on the transmission device for transmission, starting the static generator to allow the transparent flexible substrate to have static electricity, adding the conductive ink into the static coating machine to allow the conductive ink to have static electricity with electrical property opposite to that of the transparent flexible substrate, coating the conductive ink to the transparent flexible substrate, starting the static eliminator to remove redundant static electricity on the transparent flexible substrate, performing drying to obtain a transparent flexible conductive film. The device is simple in structure and convenient to operate, is low in cost, high in efficiency and large in yield in the preparation of the transparent flexible conductive thin film, and the prepared transparent flexible conductive thin film is excellent in performance.

Owner:深圳市善柔科技有限公司

Die cutting device for conductive cloth indentation lines

PendingCN109545472AImprove toughnessFast reboundApparatus for manufacturing conducting/semi-conducting layersFormation of corrugations on cables/conductorsEngineeringSilica gel

The invention relates to a die cutting device for conductive cloth indentation lines. The die cutting device is used for carrying out die cutting on indentation lines on a conductive cloth material strip, and comprises an upper die base and a lower die base which is arranged below the upper die base and matched with the upper die base. The lower surface of the upper die base is provided with an indentation line cutter, and the lower die base is provided with a silicone pad matched with the indentation line cutter and a material blocking mechanism matched with the conductive cloth material strip. Compared with the prior art, through arranging the silicone pad on the lower die base, the conductive cloth material strip and the indentation line cutter are supported flexibly from below, the indentation line cutter is ensured to be capable of being pressed into the conductive cloth material strip completely, so that the depth of the indentation lines is obvious, the compactness is good, therebound speed is slow, the imprint is not prone to recede and disappear, the retention is good, and the conductive cloth material strip can be effectively prevented from being lifted by the indentation line die cutter, thereby ensuring the normal proceeding of the continuous die cutting process.

Owner:上海昊佰智造精密电子股份有限公司

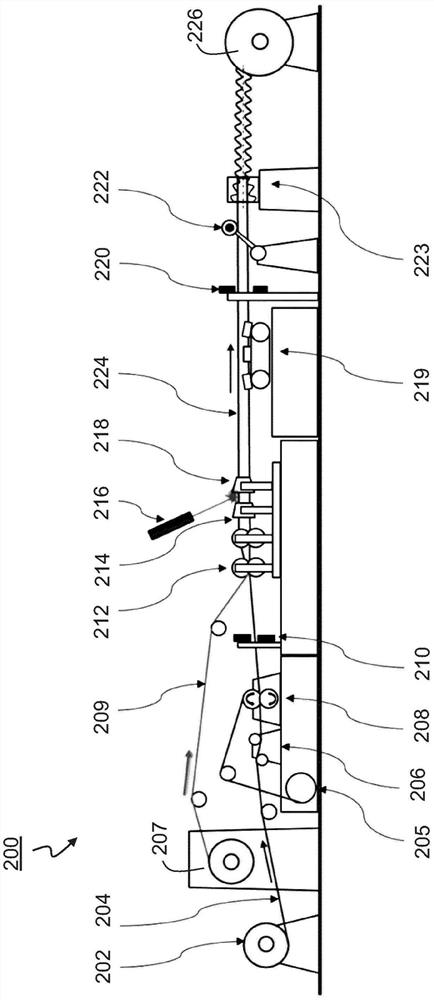

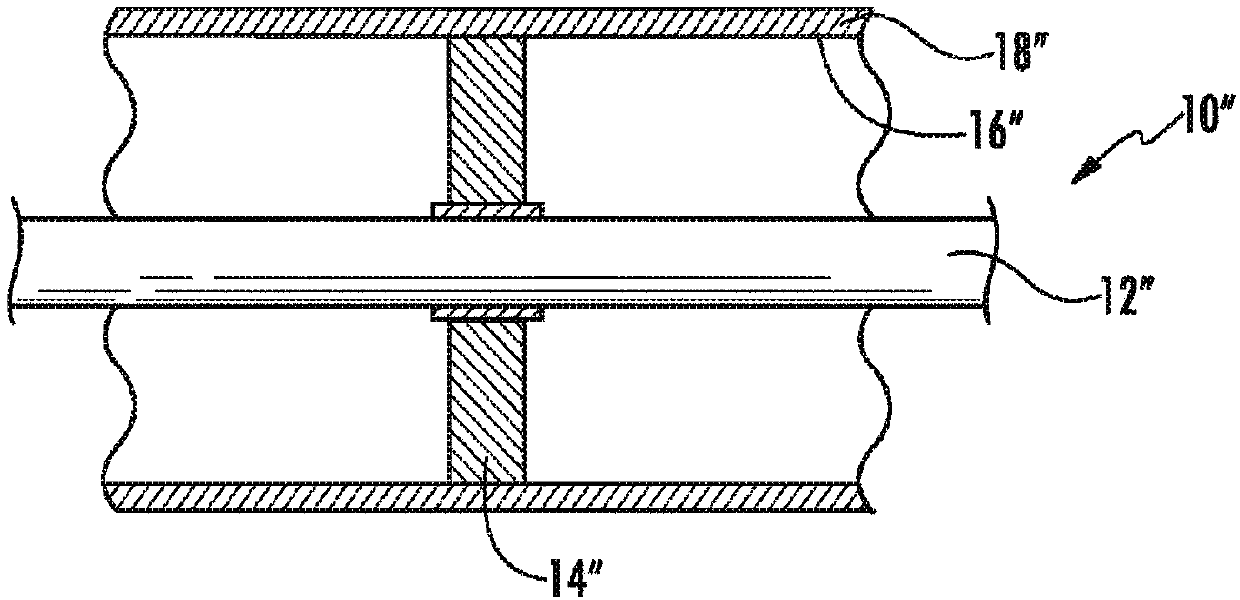

Method for producing coaxial cable having thin-walled, radially closed outer conductor

PendingCN114514587AFormation of corrugations on cables/conductorsConductorsCoaxial cableElectrical conductor

A method for continuously producing a coaxial cable (224) having a thin-walled, radially closed non-ferrous metal outer conductor includes supplying a flat strip of non-ferrous metal to a forming apparatus (212), where a thickness of the strip corresponds to a wall thickness of the coaxial cable. The forming apparatus is configured to continuously form the supplied flat strip into a form corresponding to the outer conductor of the coaxial cable and around the cable core supplied before the outer conductor is closed. After shaping, the two opposite edges of the flat strip lie flush with each other in the contact region and are continuously welded to each other by means of a laser which emits light having a wavelength of less than 600 nm by means of a welding device (216). The laser heats a point in the welding region having a diameter less than 20% of the cross-sectional dimension of the coaxial cable. The welded coaxial cable is withdrawn from the welding region and received in a receiving device (226) after introduction of the parallel or helical corrugations.

Owner:NEXANS

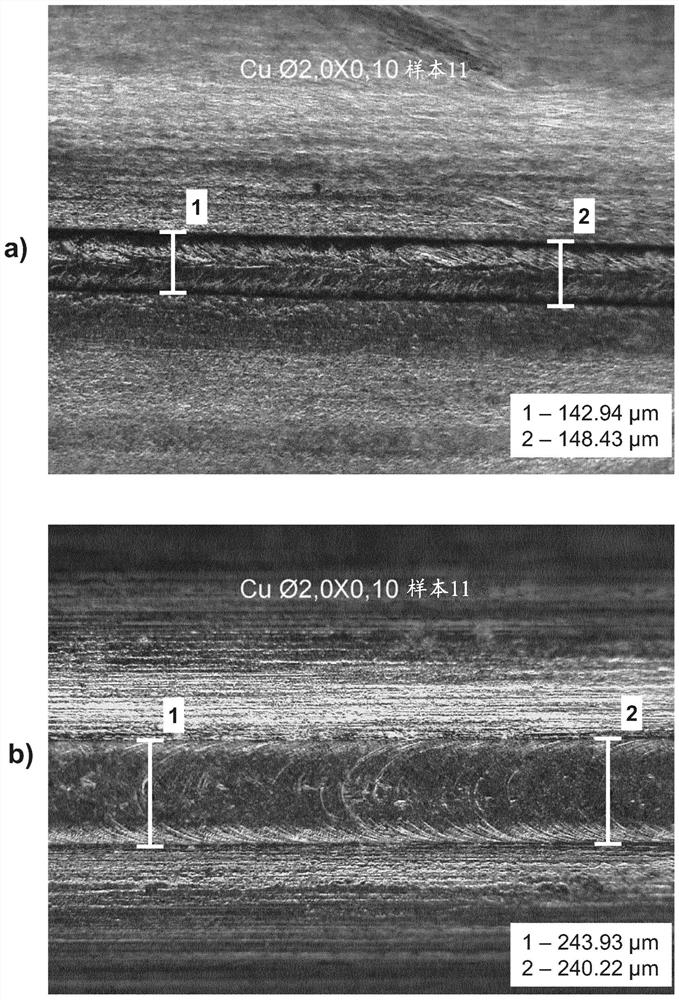

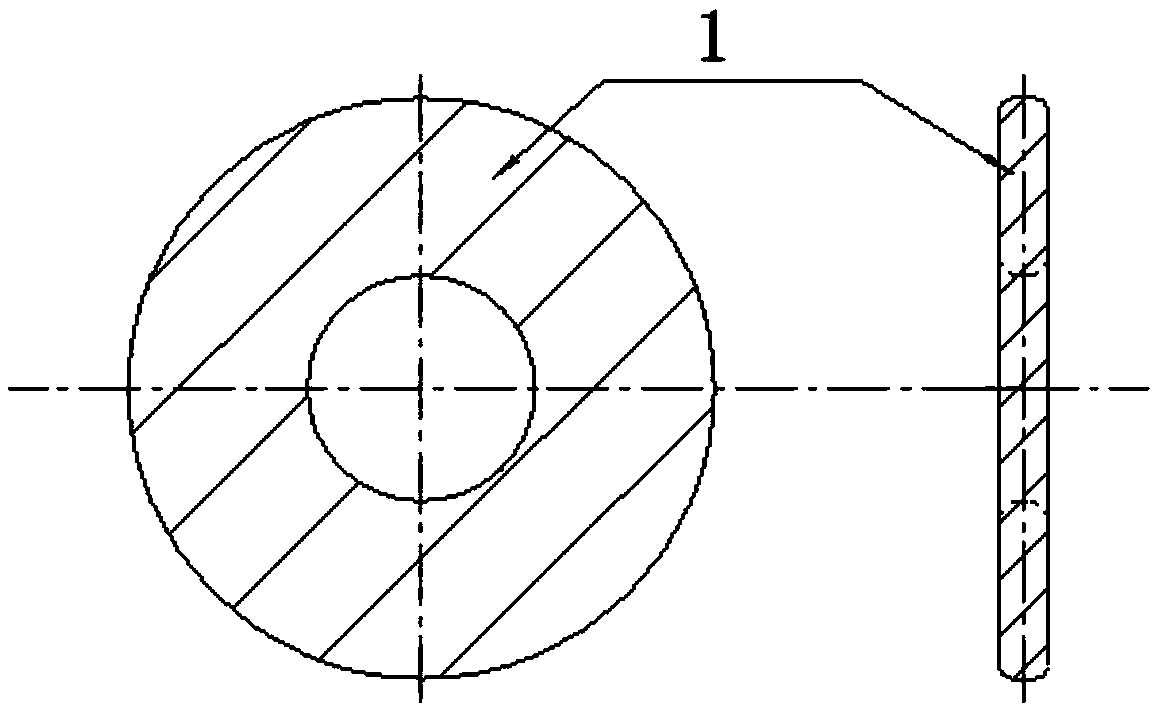

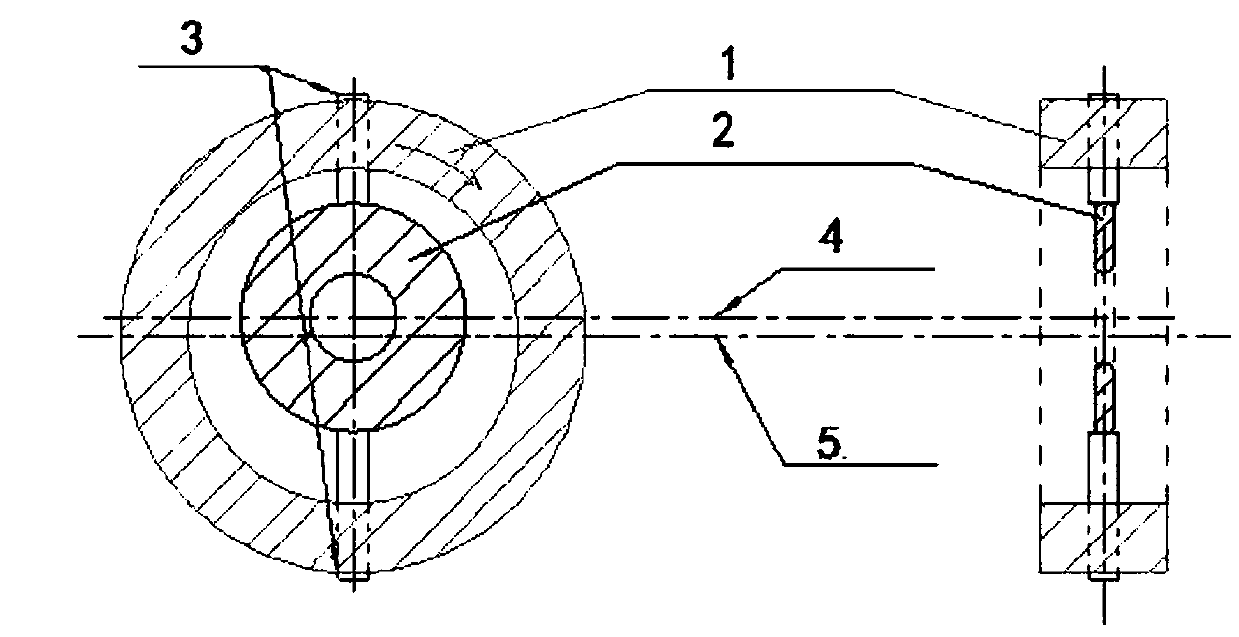

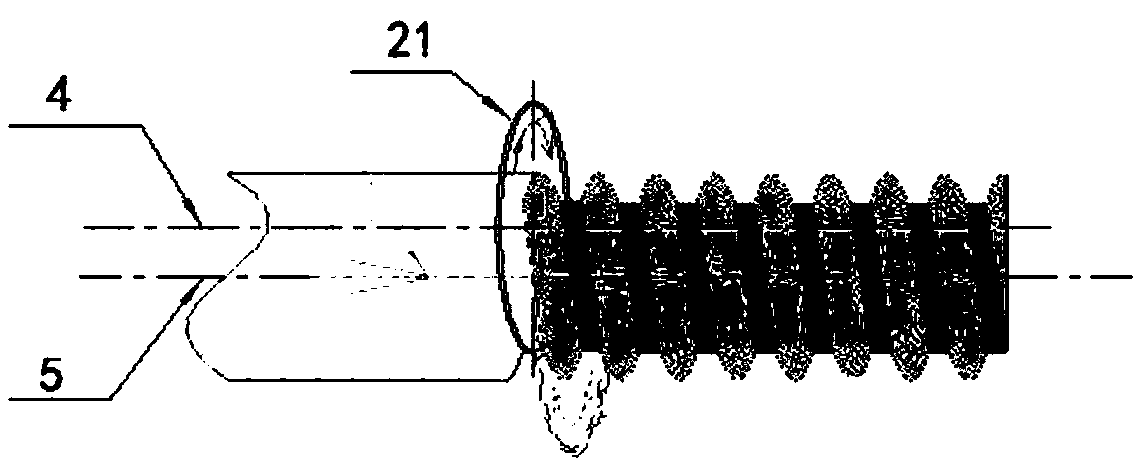

Novel outer conductor embossing mould of super-flexible 1/2 feeder line cable, and method thereof

ActiveCN109559853AReduce wearReduce contact surfaceFormation of corrugations on cables/conductorsElectrical conductorEngineering

The invention discloses a novel outer conductor embossing mould of a super-flexible 1 / 2 feeder line cable, and a method thereof, and relates to the field of cable embossing moulds. The novel outer conductor embossing mould comprises an embossing head which rotates concentrically, wherein an embossing ring is arranged in the embossing head; and the center line of the embossing ring and the center line of the embossing head are not the same line. The embossing method comprises the following steps that the embossing ring is grinded into a regular annular mould; the embossing ring grinded in the step S1 is installed in the embossing head, wherein the embossing ring can freely move in the embossing head; and a novel outer conductor of the super-flexible 1 / 2 feeder line cable is pumped into theembossing ring to finish embossing. According to the mould, an inner hole edge of the embossing ring and the center line of the embossing ring are vertically arranged, so that the contact surface of the embossed cutting edge is small in the embossing process, the embossing resistance is much smaller than that in the prior art, the regular embossing textures can be formed smoothly even if in conditions of a relatively thick or hard copper tube, or a relatively thin or soft copper tube, and the embossing textures can be formed easily.

Owner:CHENGDU DATANG CABLE

Anisotropic conductive film, connection structure and method of producing the same

ActiveUS9515042B2High bonding strengthReduce the valueNon-insulated conductorsApparatus for feeding conductors/cablesMonomer compositionAnisotropic conductive film

An anisotropic conductive film is obtained by dispersing conductive particles in an insulating adhesive composition including a (meth)acrylate-based monomer composition, a radical polymerization initiator, and a film-forming resin. The (meth)acrylate-based monomer composition includes a (meth)acrylate-based monomer which has a cyclic ester residue or a cyclic amide residue represented by the formula (1):R1 is a hydrogen atom or a methyl group; R2 is an alkylene group or an alkyloxy group; R3 is an alkyl group, an alkylene group, an aryl group, or a halogen atom; n is an integer of 0 to 3; R4 is absent or an alkylene, dotted lines on both sides of R4 jointly represent a single bond; X1 is absent, or an oxygen atom or a carbon atom; and X2 is an oxygen atom, a nitrogen atom, or a sulfur atom.

Owner:DEXERIALS CORP

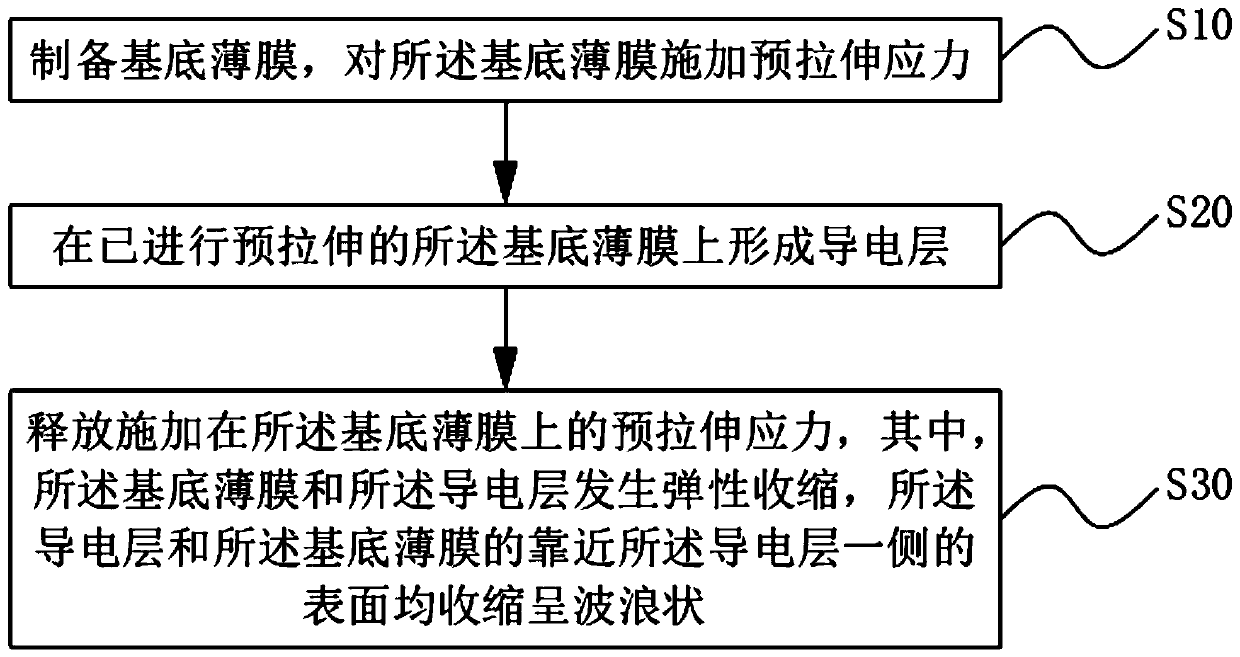

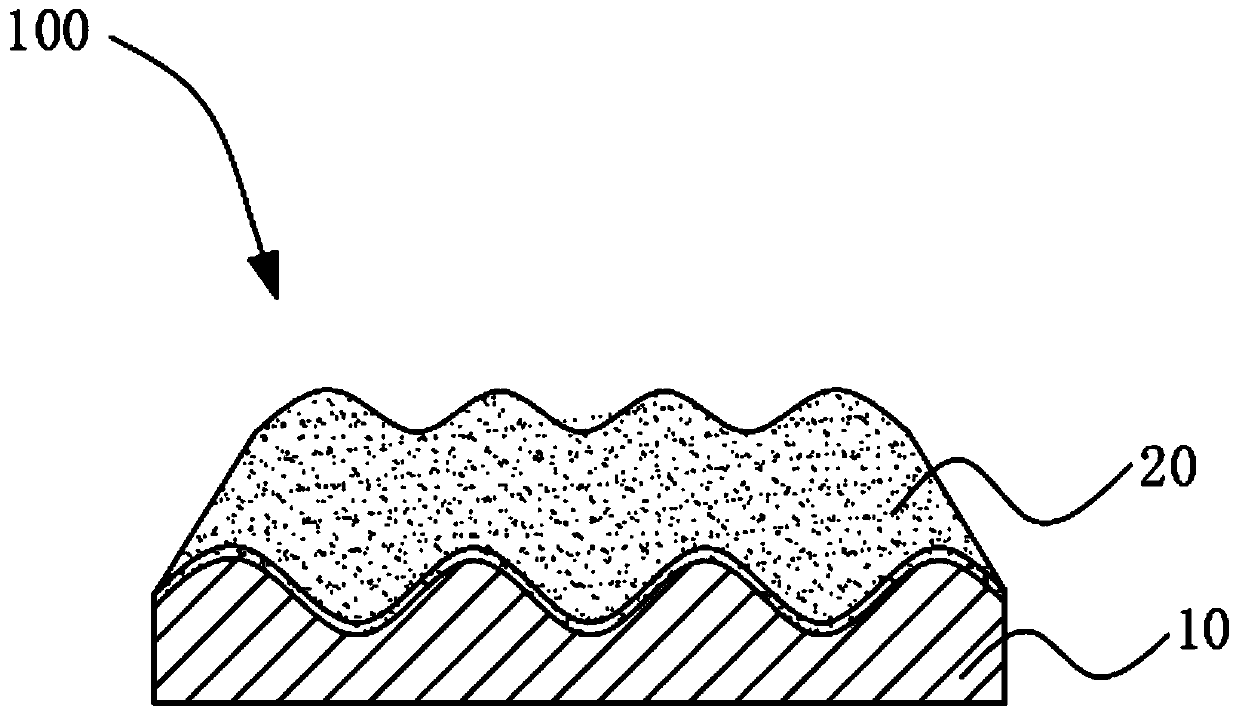

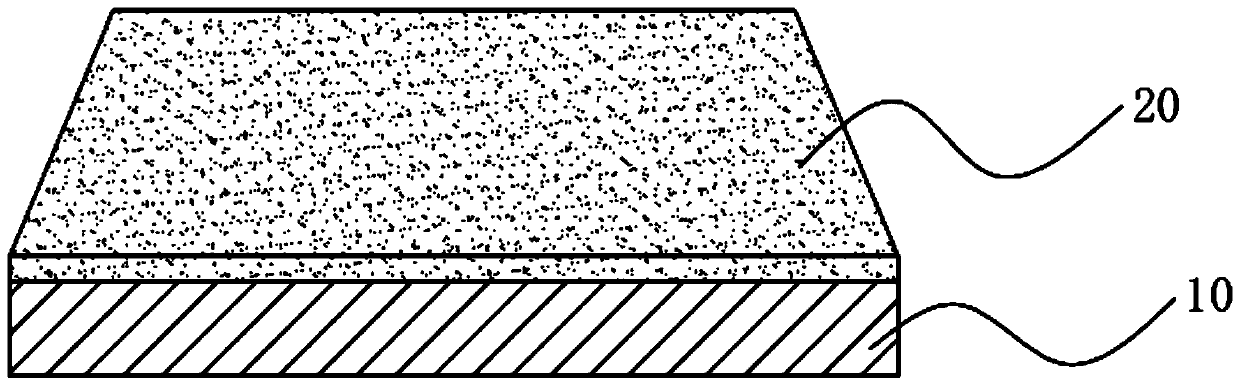

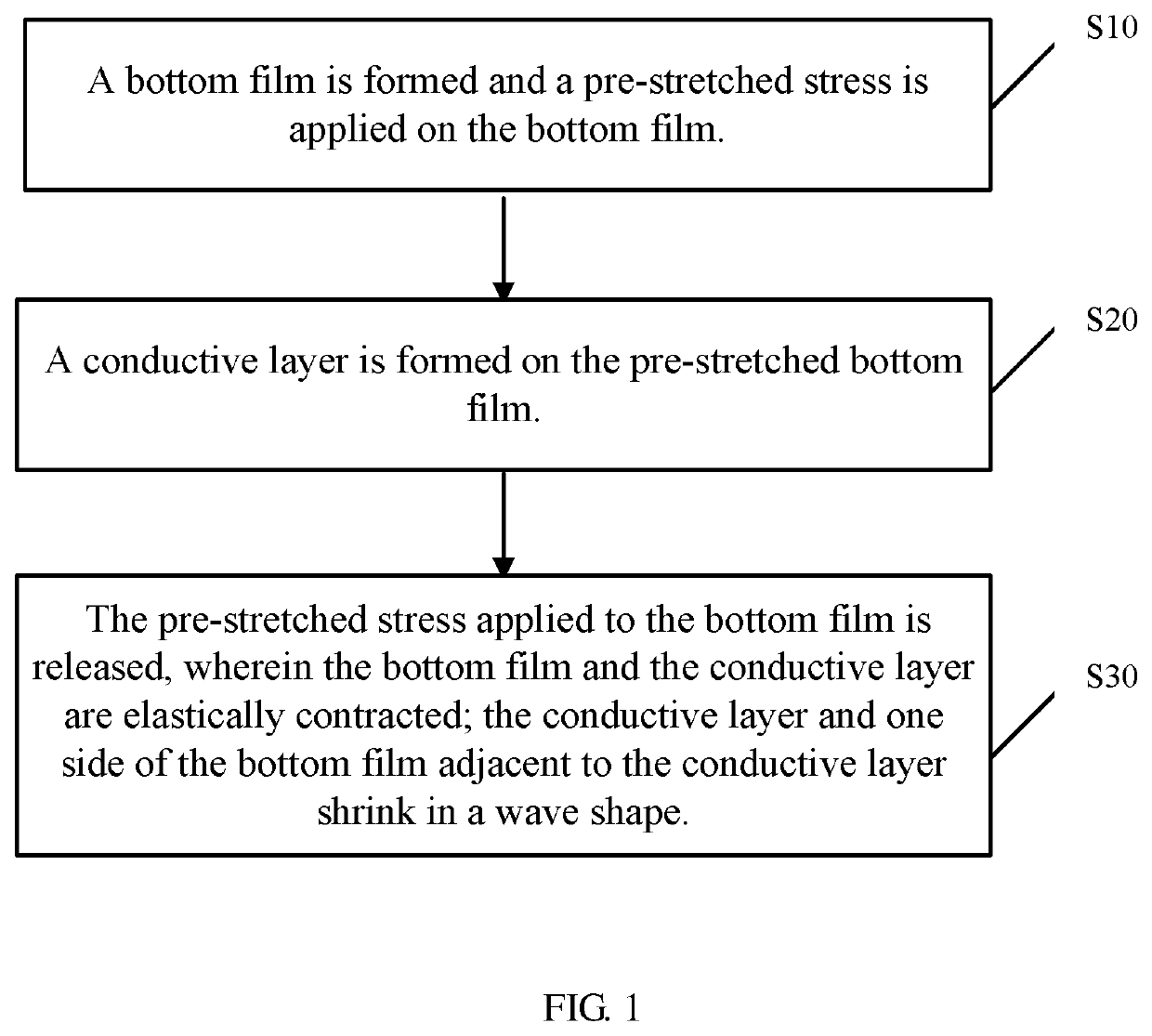

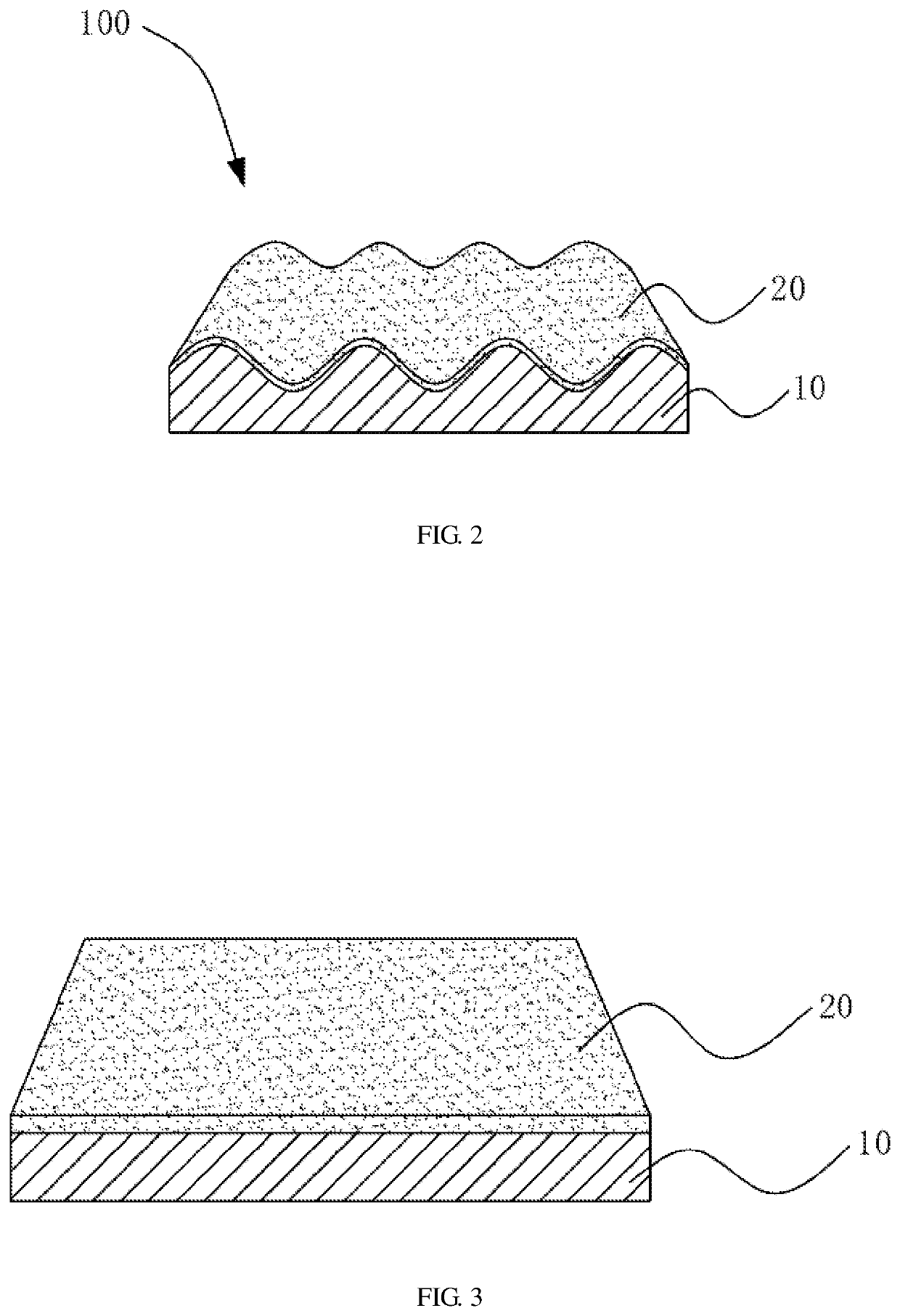

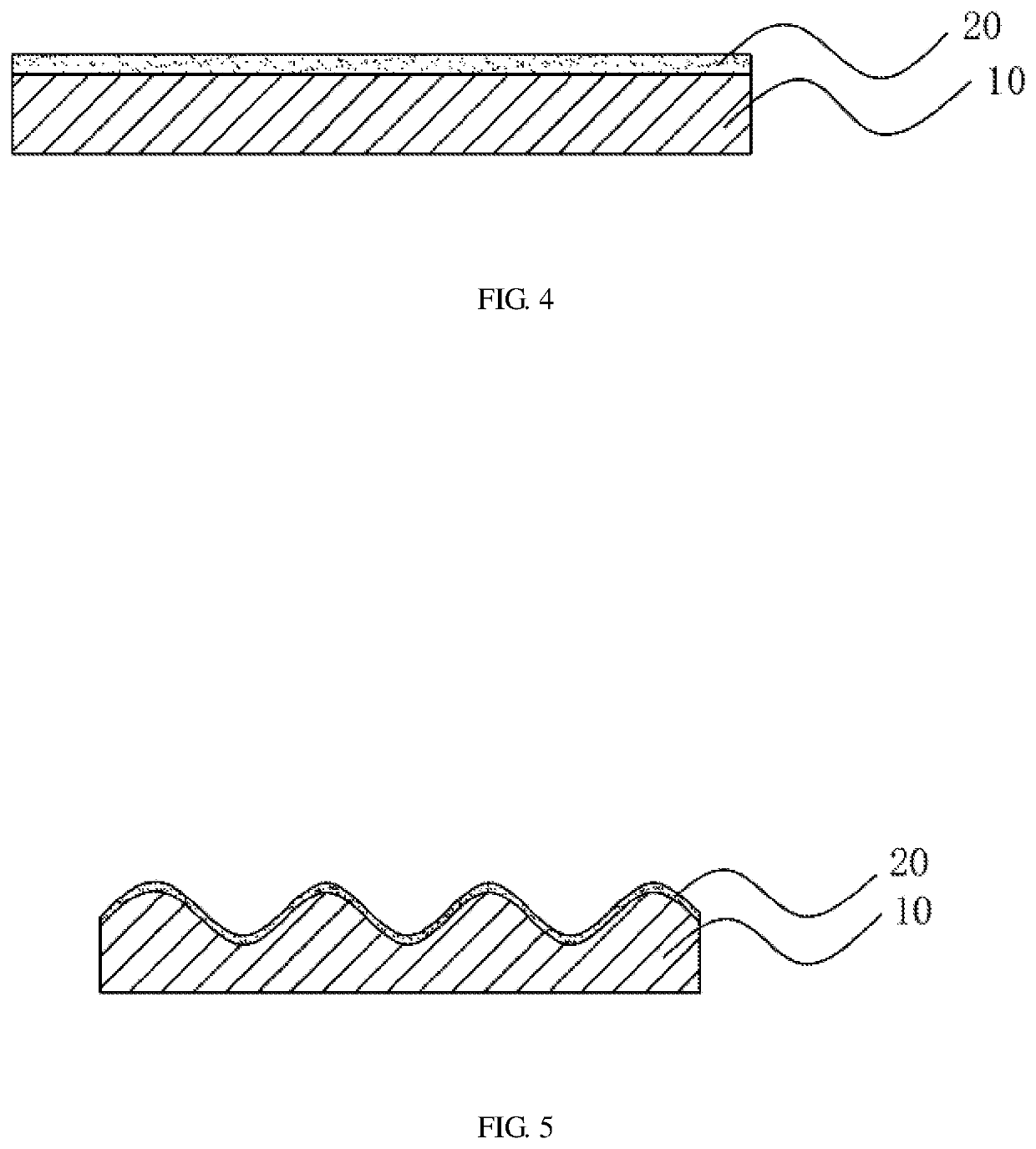

Flexible conductive film, producing method thereof, and display panel

InactiveUS20220016874A1Extended service lifeIncrease flexibilityConductive layers on insulating-supportsConductive materialWave shapeThin membrane

A method of producing a flexible conductive film includes: producing a bottom film and applying a pre-stretched stress on the bottom film; forming a conductive layer on the pre-stretched bottom film; and releasing the pre-stretched stress applied to the bottom film wherein the bottom film and the conductive layer are elastically contracted; the conductive layer and one side of the bottom film adjacent to the conductive layer shrink in a wave shape. The method of producing the flexible conductive film provided by the present disclosure can improve the flexibility and the stability of the conductive layer while the conductive layer is being used, thereby improving the service life of the flexible conductive film.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Electric wire embossing device

InactiveCN110600198ASolve slipperyImprove efficiencyApparatus for heat treatmentFormation of corrugations on cables/conductorsGear wheelKnurling

The invention provides an electric wire embossing device comprising a frame. An upper roller and a lower roller are symmetrically arranged on the upper and lower sides of the middle of the frame. A rotating gear is connected on the front end of the upper roller and the lower roller. A drive motor is arranged on the front side of the frame. A linkage gear is connected on the output end of that drive motor. The linkage gear is connected between the upper and lower rotating gears in a meshed way. The surface of the upper rotating roller and the lower rotating roller are provided with a reticulated knurling knife. A hot air pipe is arranged above the upper rotating roller and below the lower rotating roller. The two sides of the hot air pipe are provided with baffles which are respectively attached to the two sides of the upper rotating roller and the two sides of the lower rotating roller. The right side of the frame is provided with a wire inlet base, and the left side of the frame is provided with a wire outlet base. The surface of the upper rotating roller and the lower rotating roller is heated by blowing through the hot air pipes. The drive motor drives the upper rotating rollerand the lower rotating roller to rotate in opposite directions through the linkage gear and the rotating gear, and the reticulated knurling knife on the surface of the upper rotating roller and the lower rotating roller performs embossing on the surface of the electric wire so that the transmission slip of the electric wire can be reduced and the production efficiency can be enhanced.

Owner:WUHU SHUNCHENG ELECTRONICS

Coaxial cable with dielectric layer having sealed segments and method of making same

InactiveCN107924735ACable insulation constructionPower cables with screens/conductive layersCoaxial cableElectrical conductor

A coaxial cable includes: a center conductor; a dielectric layer circumferentially surrounding the center conductor; and an outer conductor circumferentially surrounding the dielectric layer. The dielectric layer comprises an inner sleeve that circumferentially overlies the center conductor and an outer sleeve that circumferentially overlies the inner conductor. The outer sleeve contacts the innersleeve to form a plurality of longitudinally-spaced seams to create a plurality of sealed segments along a longitudinal axis of the cable.

Owner:COMMSCOPE TECH LLC

Conductive path

There is provided a conductive path. The conductive path includes a conductor and a sheath. The sheath covers the conductor. The sheath is made of a resin composition. The resin composition has elasticity. There are formed protrusions which are convexly protruded from an outer peripheral surface of the sheath of the conductive path and have elasticity so as to be deformed.

Owner:YAZAKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com