Device and method for preparation of transparent flexible conductive thin film

A flexible, conductive and transparent technology, applied in the direction of forming ripples, circuits, electrical components, etc. on conductors/cables, can solve the problems of using, difficult to achieve large-area preparation, difficult to meet production requirements, etc., to achieve high efficiency, The effect of low cost and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

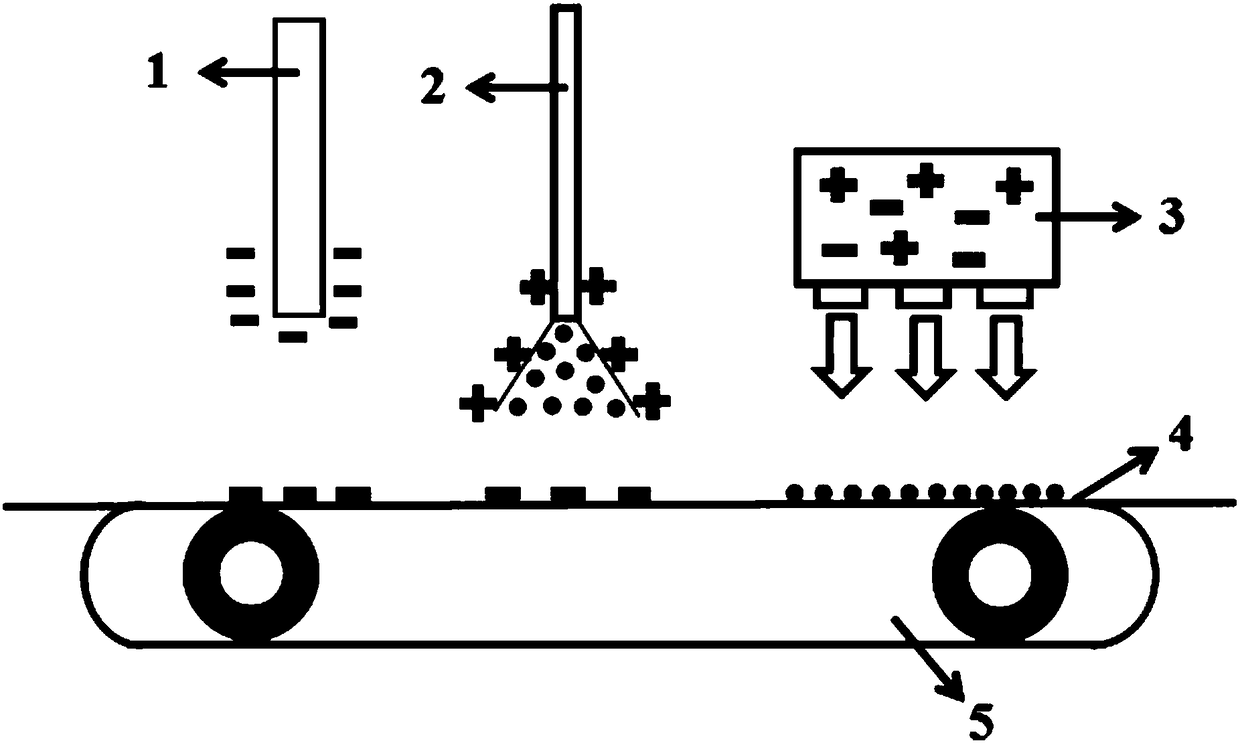

[0043] A method for preparing a transparent flexible conductive film, comprising the following steps:

[0044] 1) preparing an ethanol dispersion of silver nanowires;

[0045] 2) Put the PET with a width of 550mm on the conveying device (the transmission speed is set to 1000mm / min) for transmission, and then turn on the inductive electrostatic generator (set the output voltage to -15kV) to make the PET surface negatively charged, and then put the silver nano The ethanol dispersion liquid of the line is added to the electrostatic spraying machine (8 nozzles are linearly arranged, W-shaped reciprocating motion spraying, the moving speed of the nozzles along the PET conveying direction is 25mm / min, the moving speed of the nozzles in the vertical direction is 1000mm / min, and the working voltage is 14kV) Make it positively charged, then spray on the transparent flexible substrate, then turn on the suspended ion fan (working voltage is set to 5.1kV) to remove excess static electrici...

Embodiment 2

[0049] A method for preparing a transparent flexible conductive film, comprising the following steps:

[0050] 1) preparing an ethanol dispersion of carbon nanotubes with a concentration of 1.5 mg / mL;

[0051] 2) Put the PET with a side width of 500mm on the conveyor (the transmission speed is set to 800mm / min) for transmission, turn on the inductive electrostatic generator (set the output voltage to -13kV) to make the PET surface negatively charged, and then put the carbon nanotubes The ethanol dispersion was added to an electrostatic spraying machine (8 nozzles arranged linearly, Z-shaped reciprocating motion spraying, the moving speed of the nozzles along the PET conveying direction was 30mm / min, the moving speed of the nozzles in the vertical direction was 800mm / min, and the working voltage was 15kV). It is positively charged, and then sprayed onto the transparent flexible substrate, and then the DC ion fan is turned on (the operating voltage is set to 4.8kV) to remove exc...

Embodiment 3

[0055] A method for preparing a transparent flexible conductive film, comprising the following steps:

[0056] 1) preparation concentration is the ethanol dispersion liquid of the graphene of 0.5mg / mL;

[0057] 2) Put the PDMS with a side width of 600mm on the conveying device (the transmission speed is set to 900mm / min) for transmission, and then turn on the inductive electrostatic generator (the output voltage is set to -14kV) to make the PDMS surface negatively charged, and then the graphene The ethanol dispersion liquid is added to the electrostatic spraying machine (the nozzles are arranged in a 3×3 array, spraying back and forth, perpendicular to the transmission direction of PDMS, the speed is 700mm / min, and the working voltage is 14kV) to make it positively charged, and then spray On the transparent and flexible substrate, turn on the desktop ion fan (working voltage is set to 5.2kV) to remove excess static electricity on the transparent and flexible substrate, and dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com