Die cutting device for conductive cloth indentation lines

A technology of indentation line and conductive cloth, applied in the field of conductive cloth, can solve the problems of fast rebound, poor holding force of indentation line, disappearance, etc., and achieve the effect of fast rebound speed, good toughness and easy processing and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

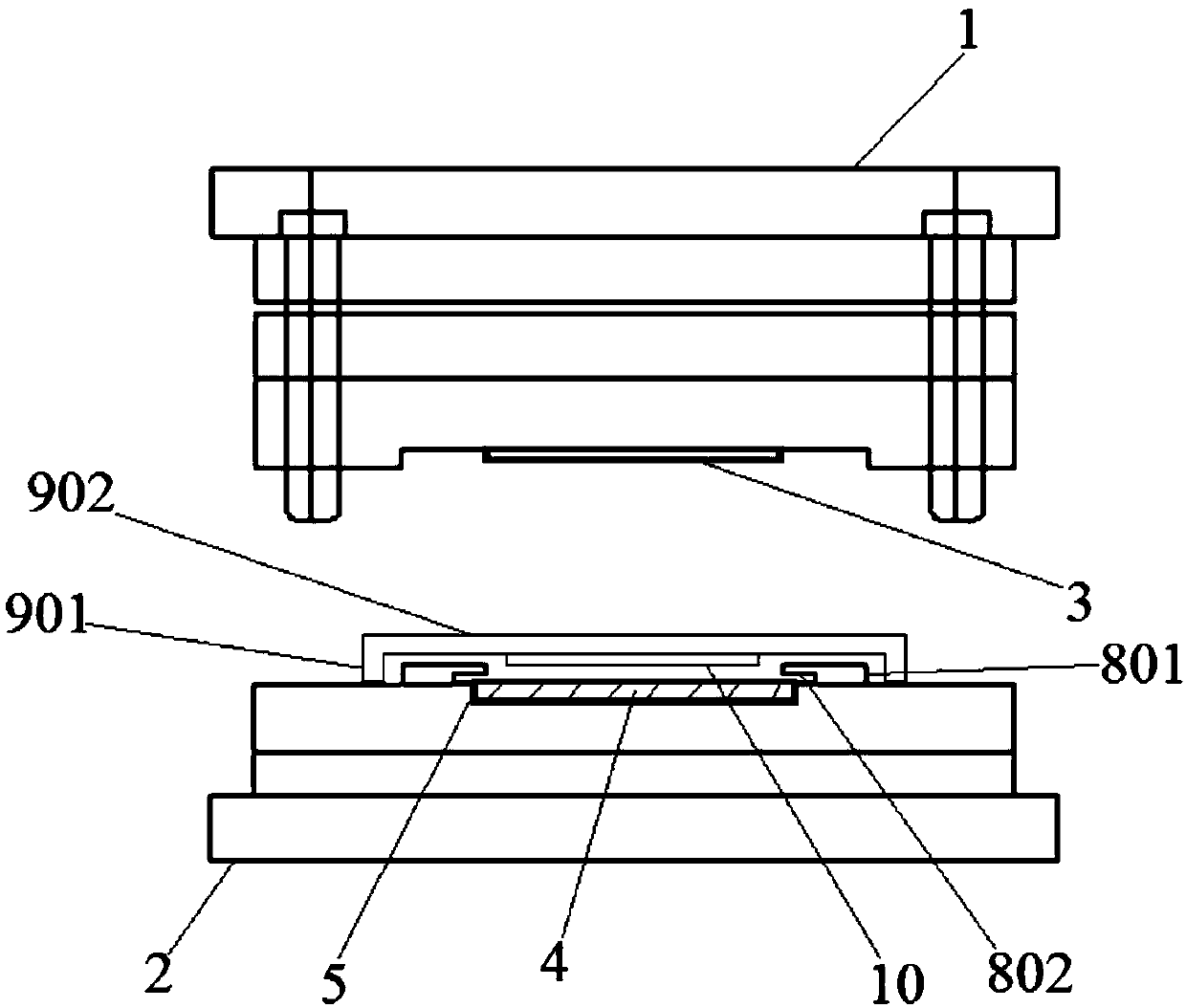

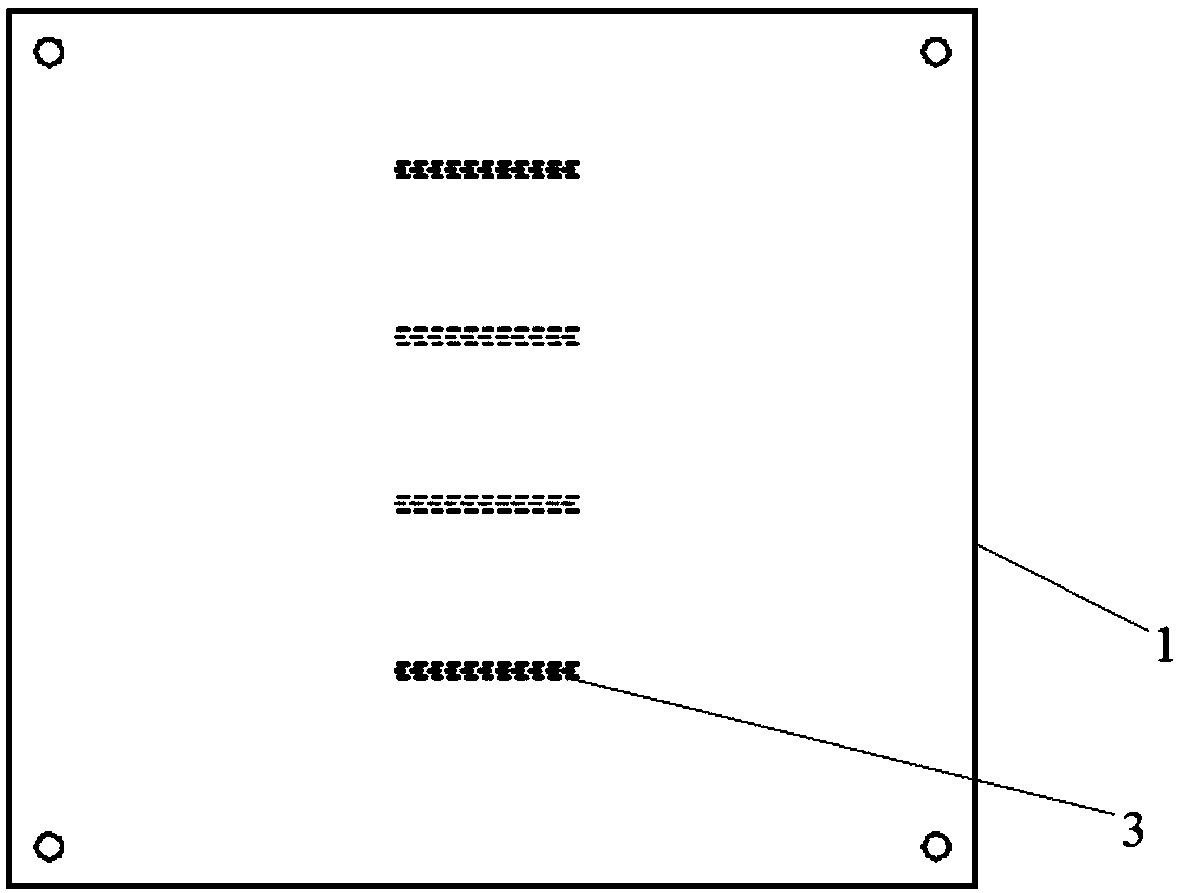

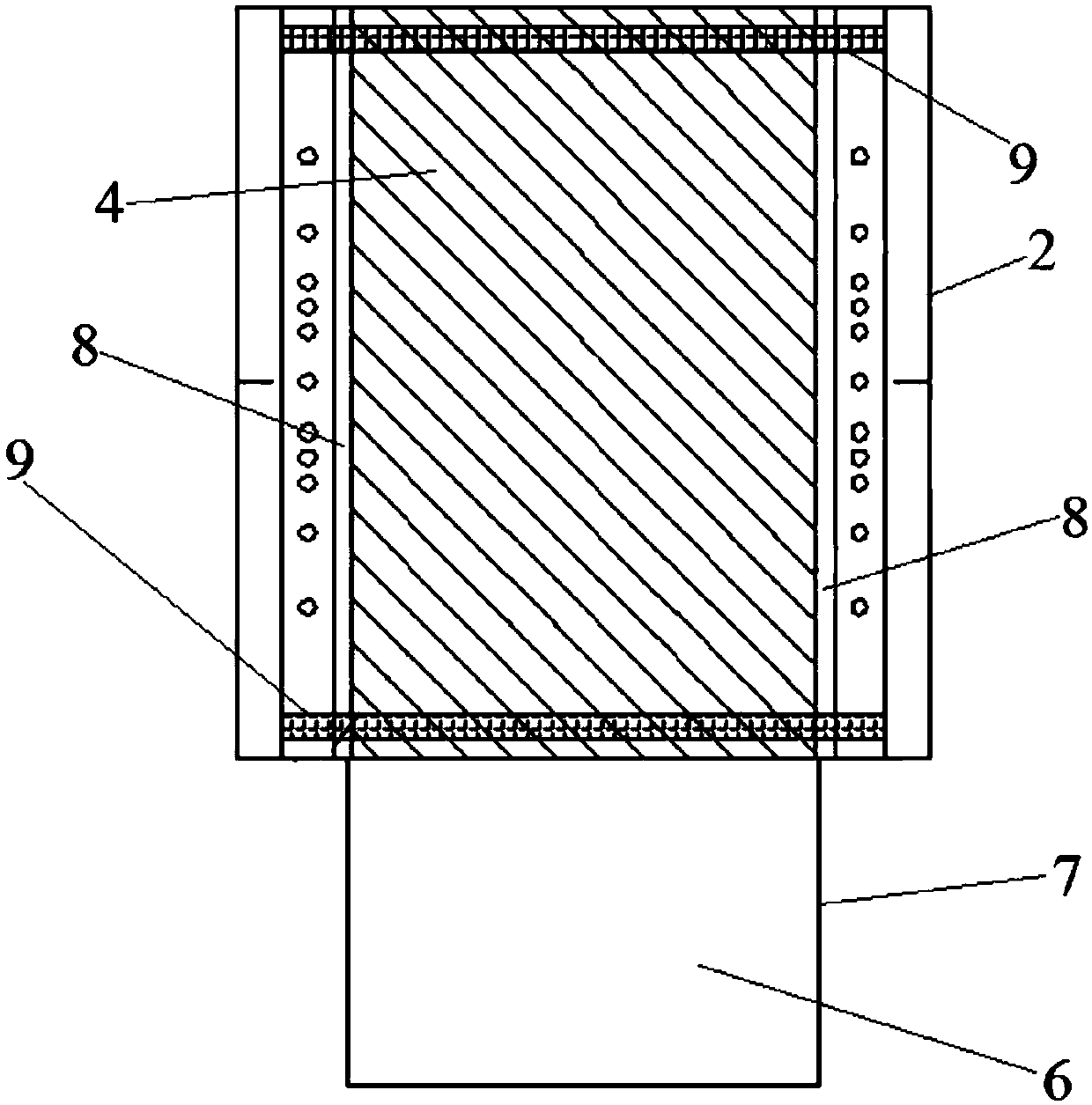

[0031] Such as figure 1 Shown is a die-cutting device for conductive cloth creasing lines, which is used for die-cutting creasing lines on conductive cloth belts. The lower mold base 2 that matches the base 1, such as figure 2 As shown, the lower surface of the upper mold base 1 is provided with an indentation line die cutter 3, and the lower mold base 2 is provided with a silicone pad 4 compatible with the indentation line die cutter 3 and a conductive fabric belt. The blocking mechanism.

[0032] Wherein, the silicone pad 4 is located directly below the die cutter 3 on the creasing line. The lower mold base 2 is provided with a silica gel pad installation groove 5 compatible with the silica gel pad 4, and the silica gel pad 4 is located in the silica gel pad installation groove 5. The depth of the silica gel pad installation groove 5 is 0.7mm, and the thickness of the silica gel pad 4 is 0.7mm.

[0033] The conductive fabric belt includes a conductive fabric belt main b...

Embodiment 2

[0039] In this embodiment, the depth of the installation groove 5 of the silica gel pad is 0.5 mm, the thickness of the silica gel pad 4 is 0.9 mm, and the rest are the same as in Embodiment 1.

Embodiment 3

[0041] In this embodiment, the depth of the installation groove 5 of the silica gel pad is 0.6 mm, the thickness of the silica gel pad 4 is 0.8 mm, and the rest are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com