Patents

Literature

45results about How to "Avoid bringing up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

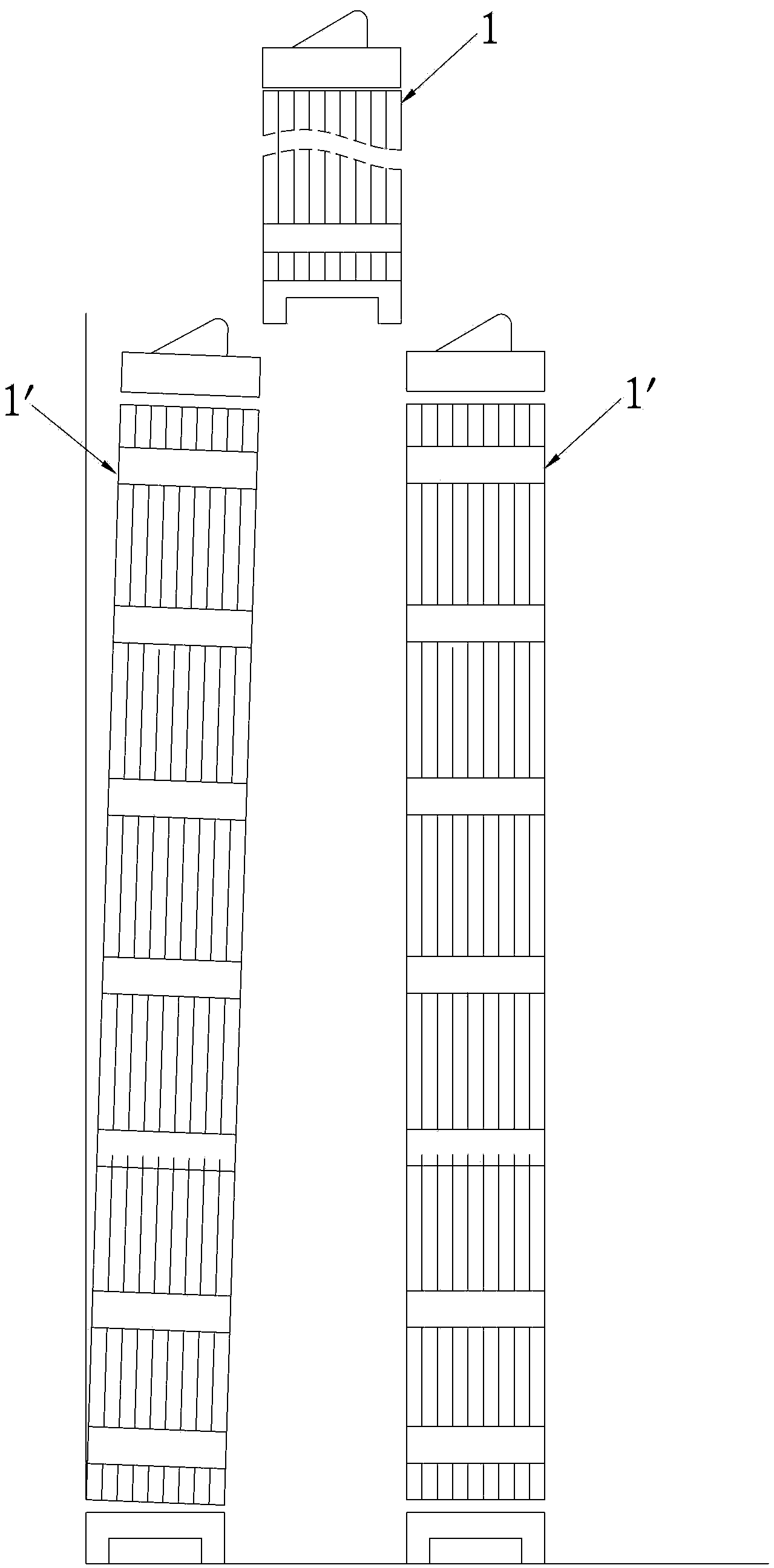

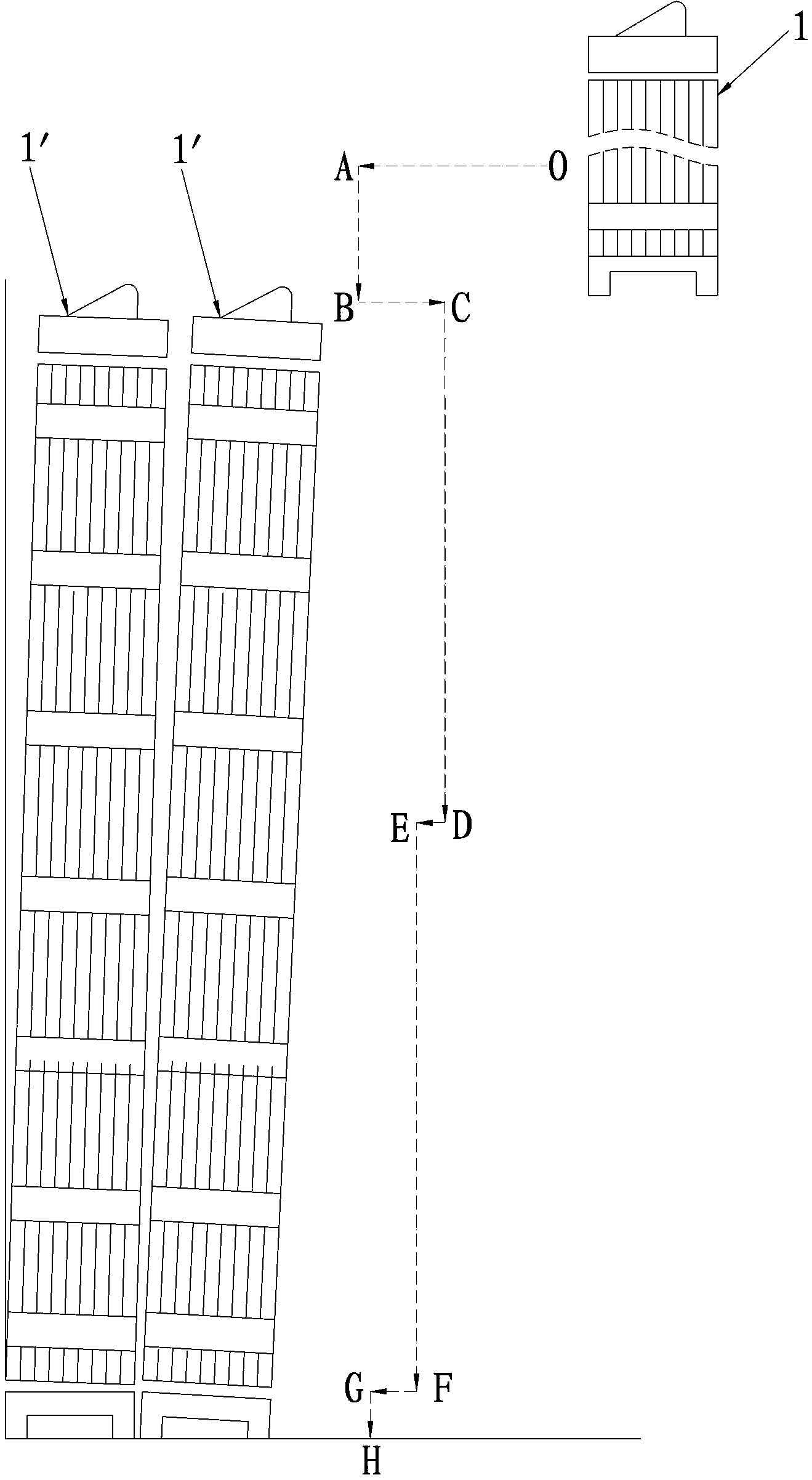

Nuclear power plant reactor core fuel assembly refueling monitoring method and system

ActiveCN103811086AImprove monitoring accuracyPrevent abnormal top positionNuclear energy generationNuclear monitoringNuclear engineeringPressurized water reactor

The invention is applicable to the key technical field of a million kilowatt level advanced pressurized water reactor nuclear power plant, and discloses a nuclear power plant reactor core fuel assembly refueling monitoring method and system, and the method comprises the following steps: capturing a fuel assembly, reading out initial height data of an encoder; calculating theoretical height data for correct position of the fuel assembly; positioning the fuel assembly and reading out actual height data of the encoder; using a computation module to compare the actual height data and the theoretical height data, and if a difference value is greater than a set deviation value, generating an alarm reminding. According to the nuclear power plant reactor core fuel assembly refueling monitoring method and system, whether the fuel assembly is properly installed can be accurately known, different lengths of different fuel assemblies may not interfere, and the method and system can ensure that the fuel assembly can be correctly located on a lower grid plate of a reactor core, further can ensure that the phenomenon that the fuel assembly is taken up by an upper cover can be avoided, completely eradicates safety accidents caused by the phenomenon, and are high in reliability and safety.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

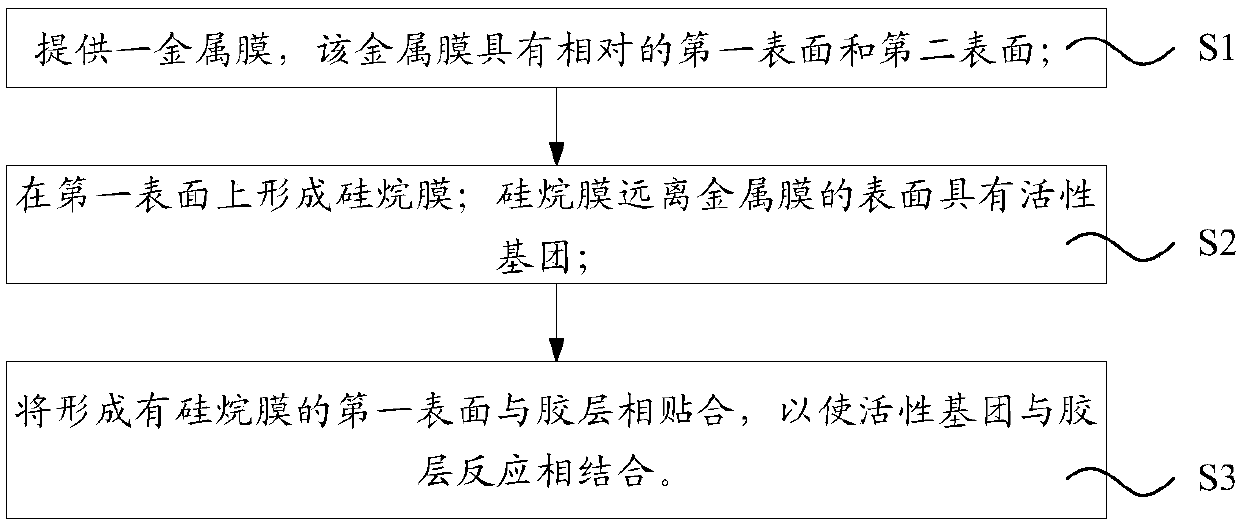

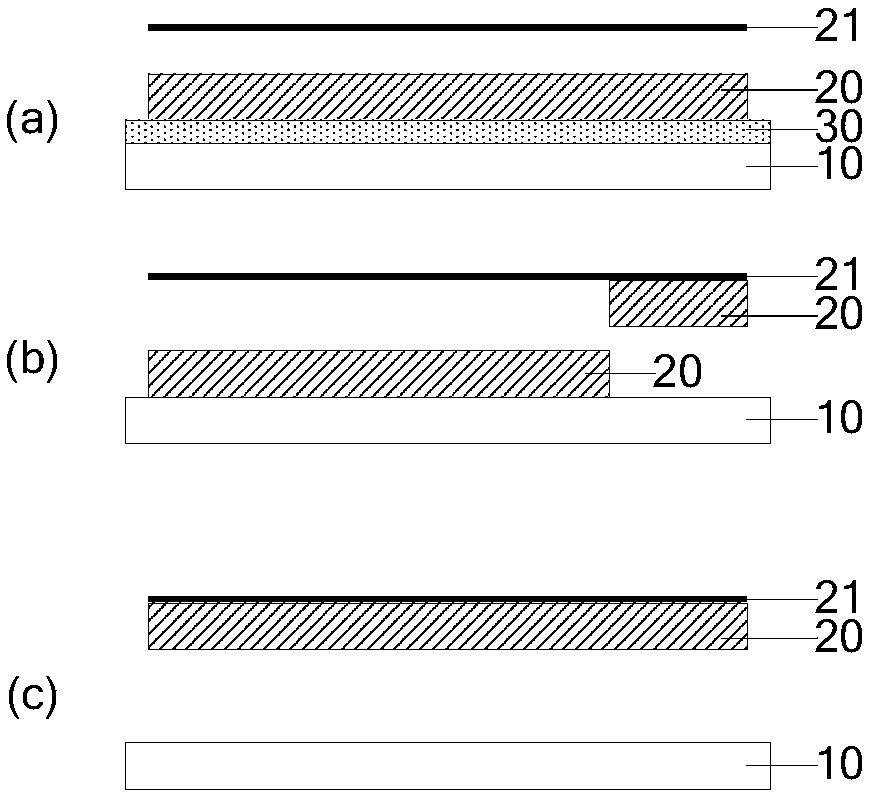

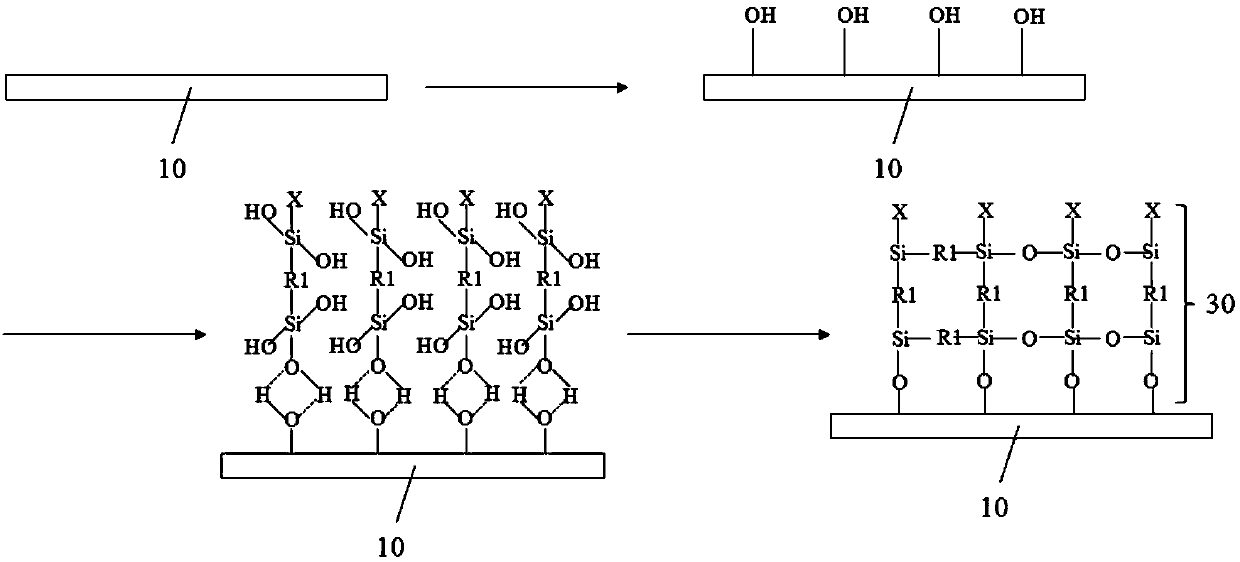

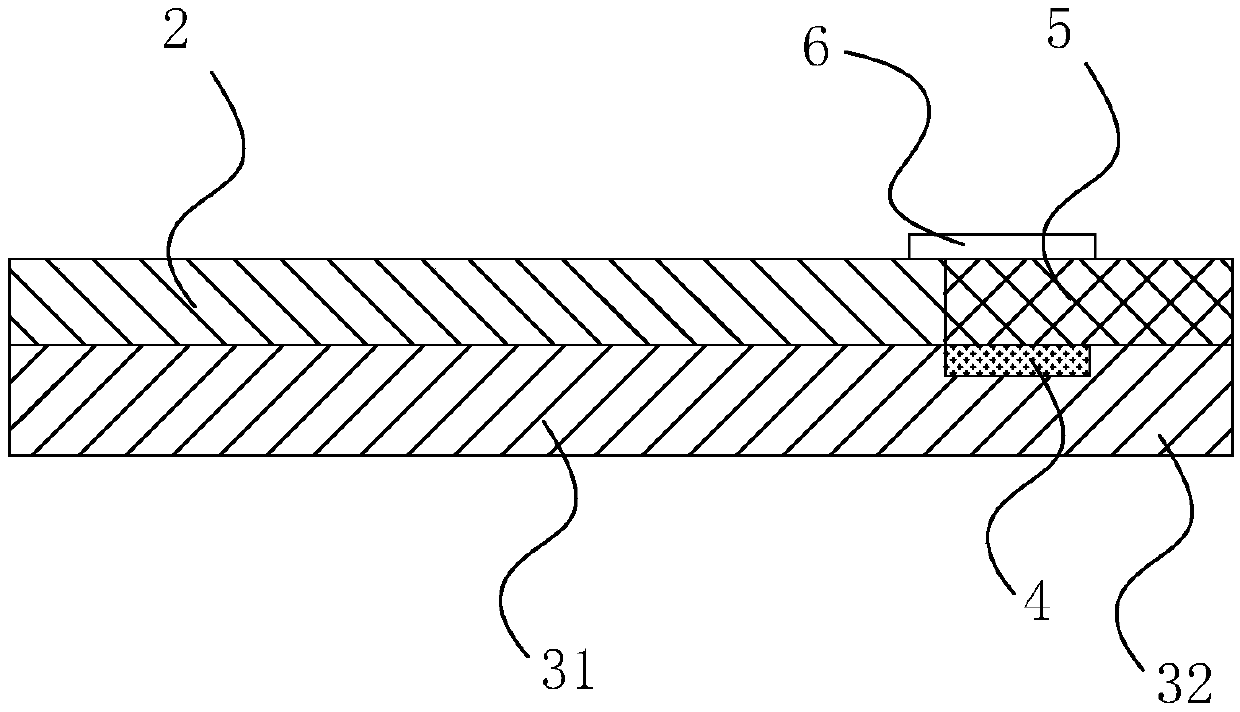

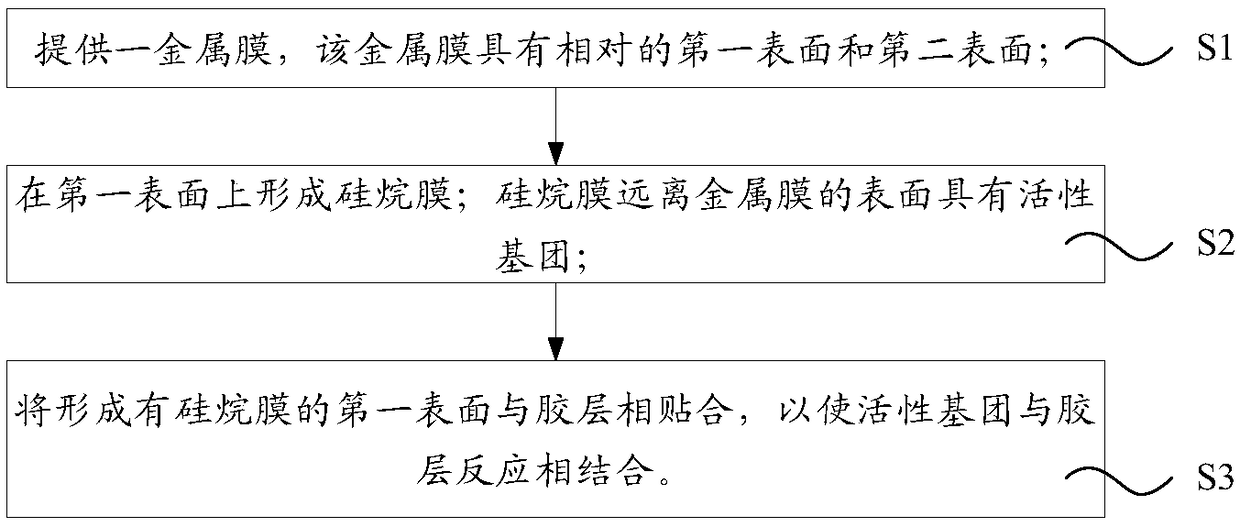

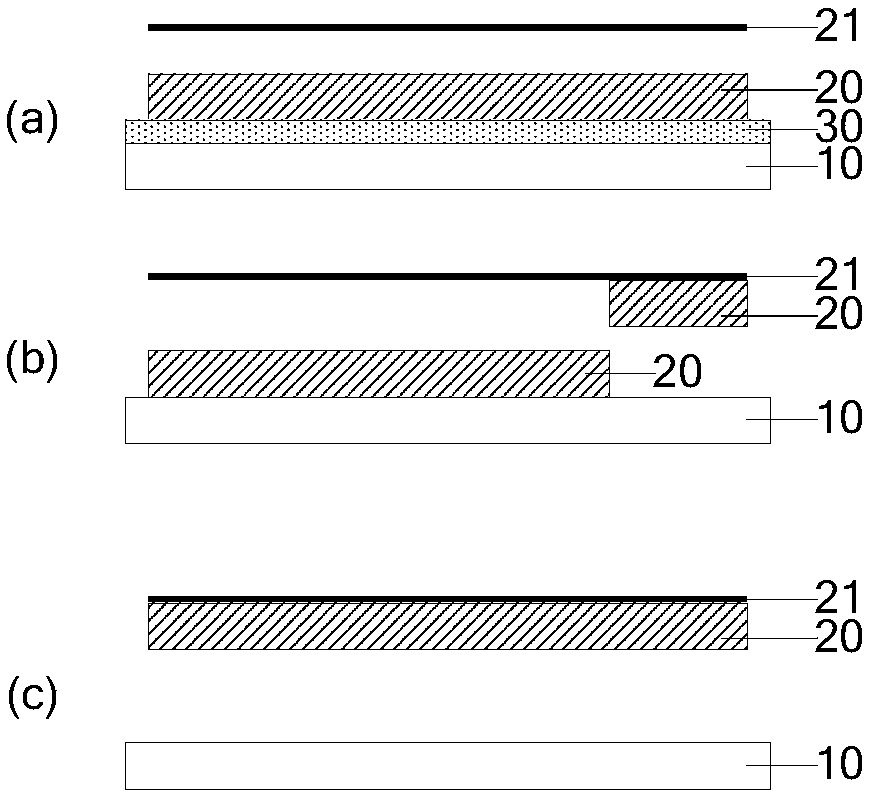

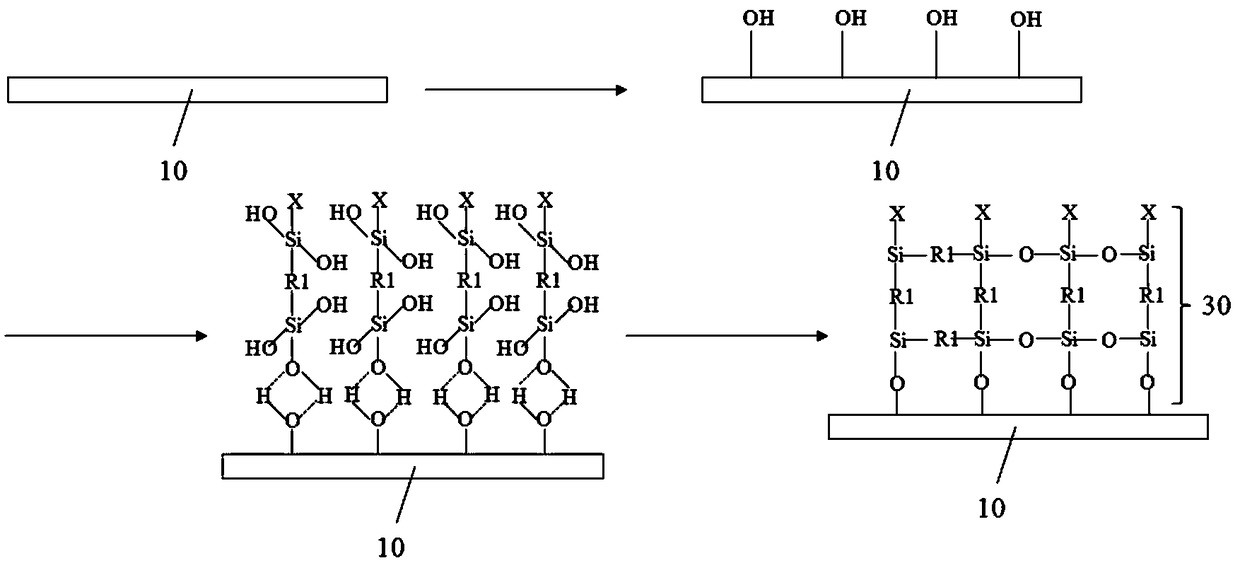

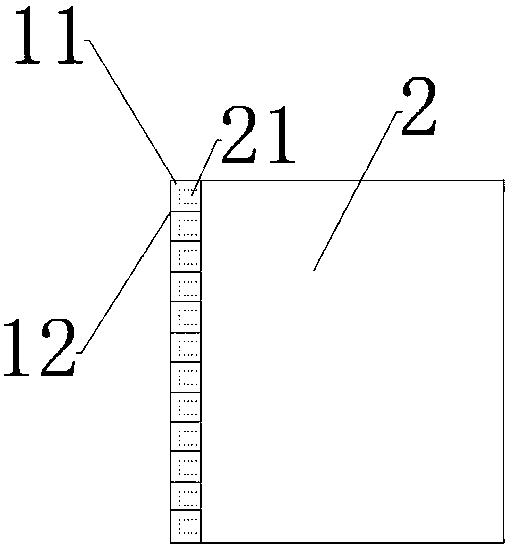

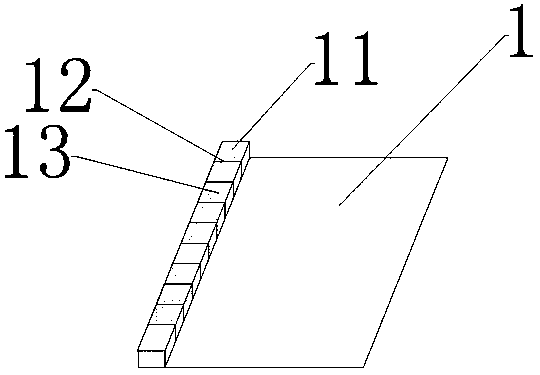

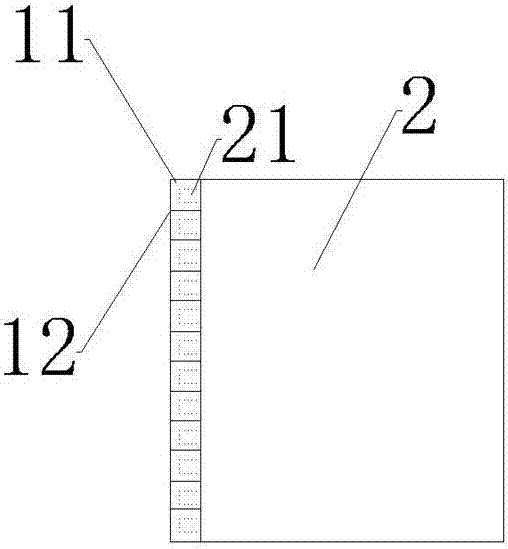

Metal encapsulating structure and preparation method thereof, encapsulating method of display panel and display device

ActiveCN107785503AAvoid bringing upImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingChemistrySurface plate

The invention provides a metal encapsulating structure and a preparation method thereof, an encapsulating method of a display panel and a display device, and relates to the technical field of display.The adhesive force between a metal membrane and a glue layer can be greatly enhanced to prevent a glue membrane from being taken off when a protective membrane on the surface of the glue layer is stripped off, the production cost is reduced, and the production qualification rate is increased. The preparation method includes the steps of providing the metal membrane provided with a first surface and a second surface which are opposite to each other; forming a silicane membrane on the first surface, wherein the surface, away from the metal membrane, of the silicane membrane is provided with active groups; fitting the glue layer with the first surface on which the silicane membrane is formed to make the active groups and the glue layer subjected to an reaction for combination.

Owner:BOE TECH GRP CO LTD +1

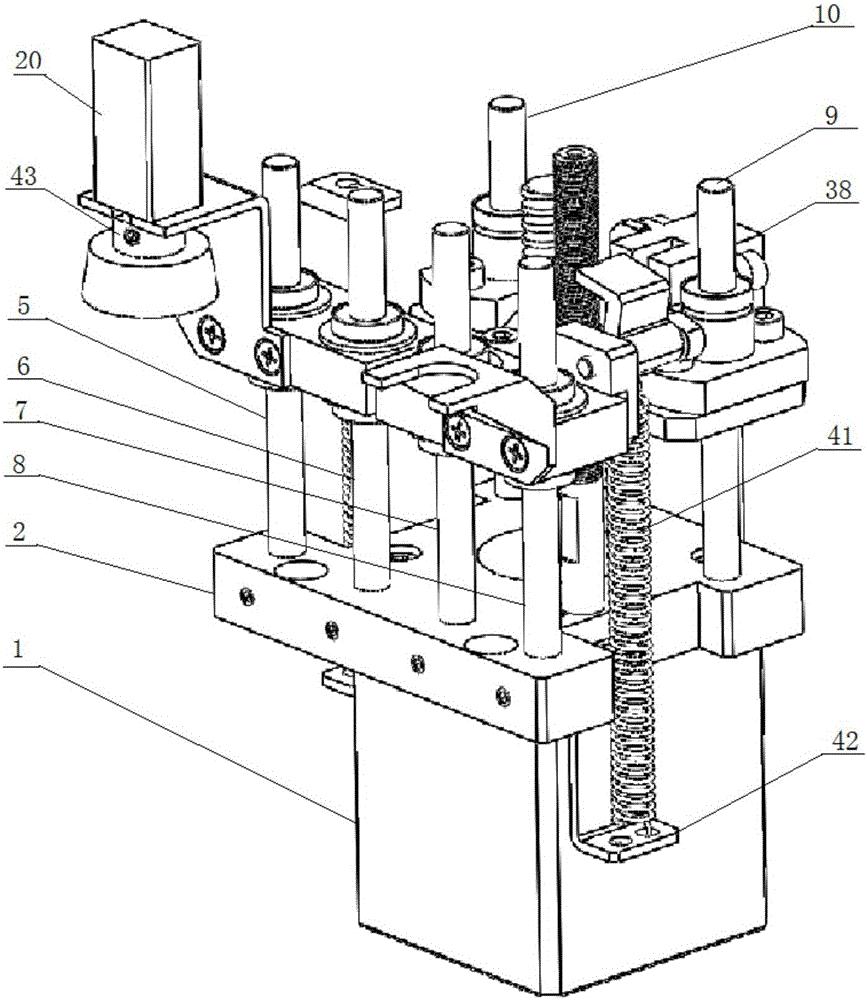

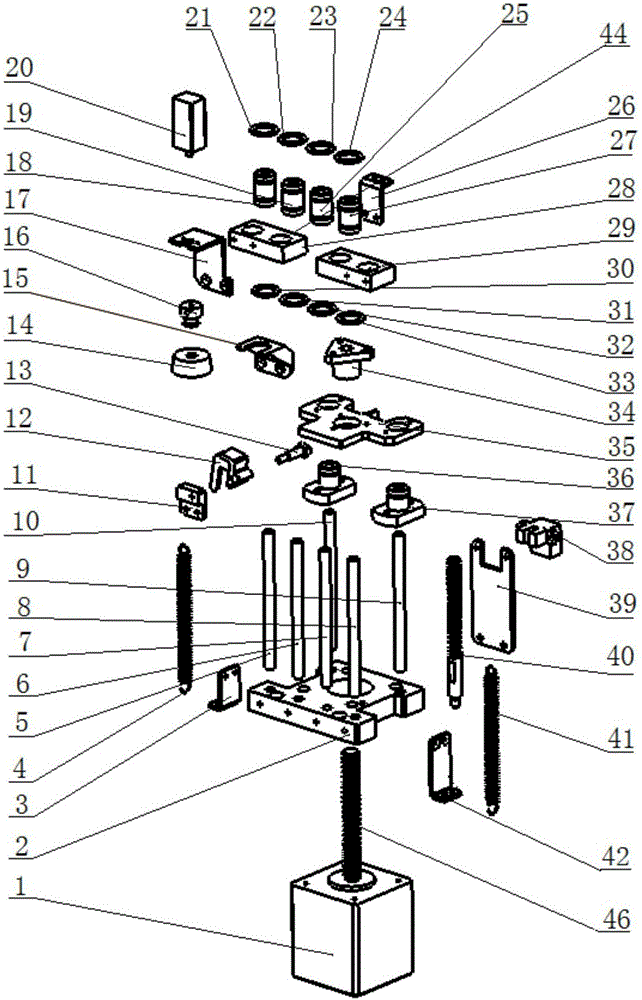

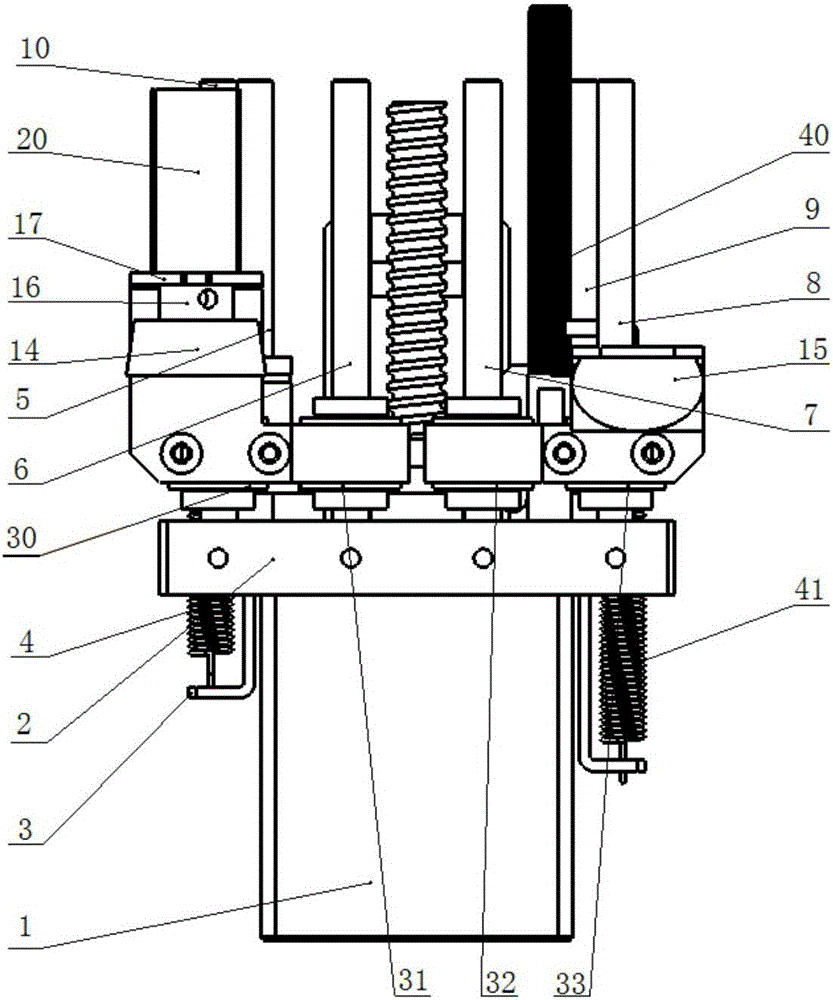

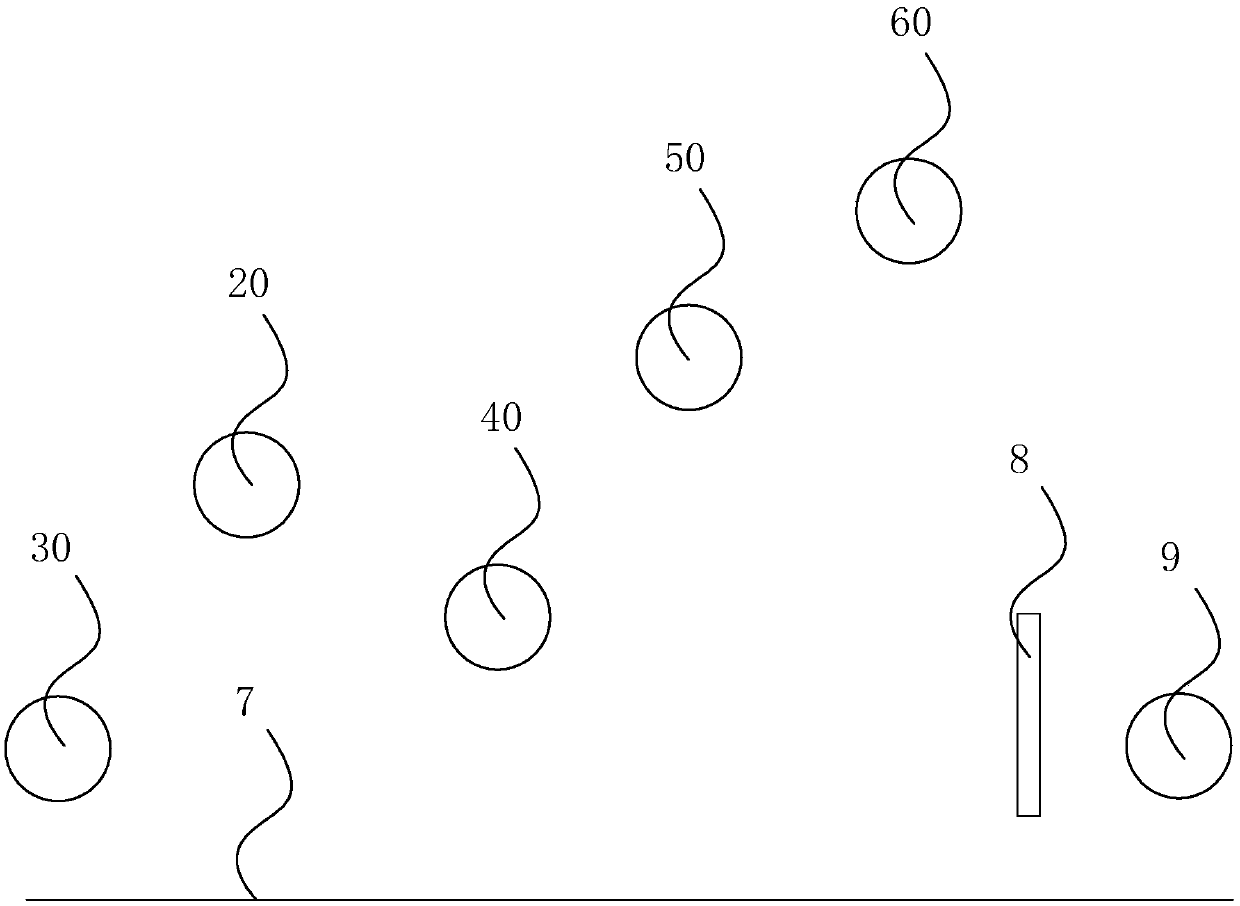

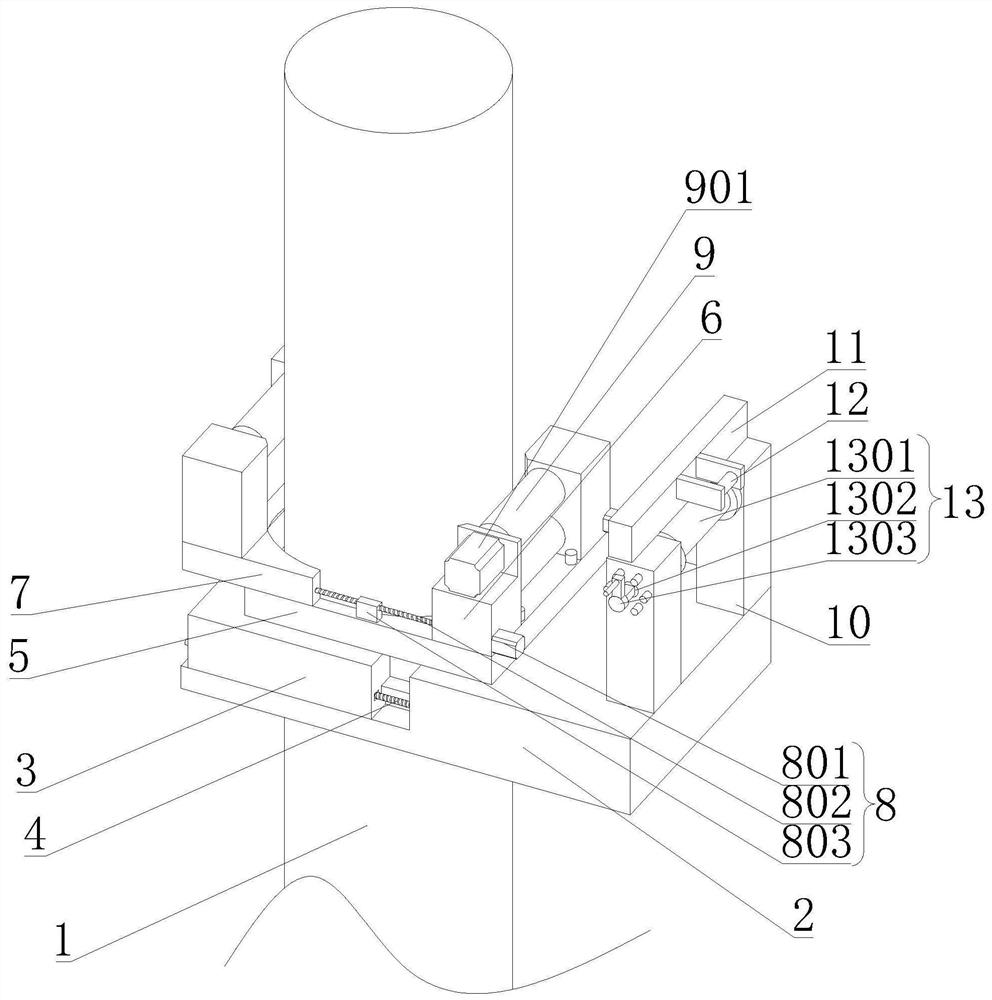

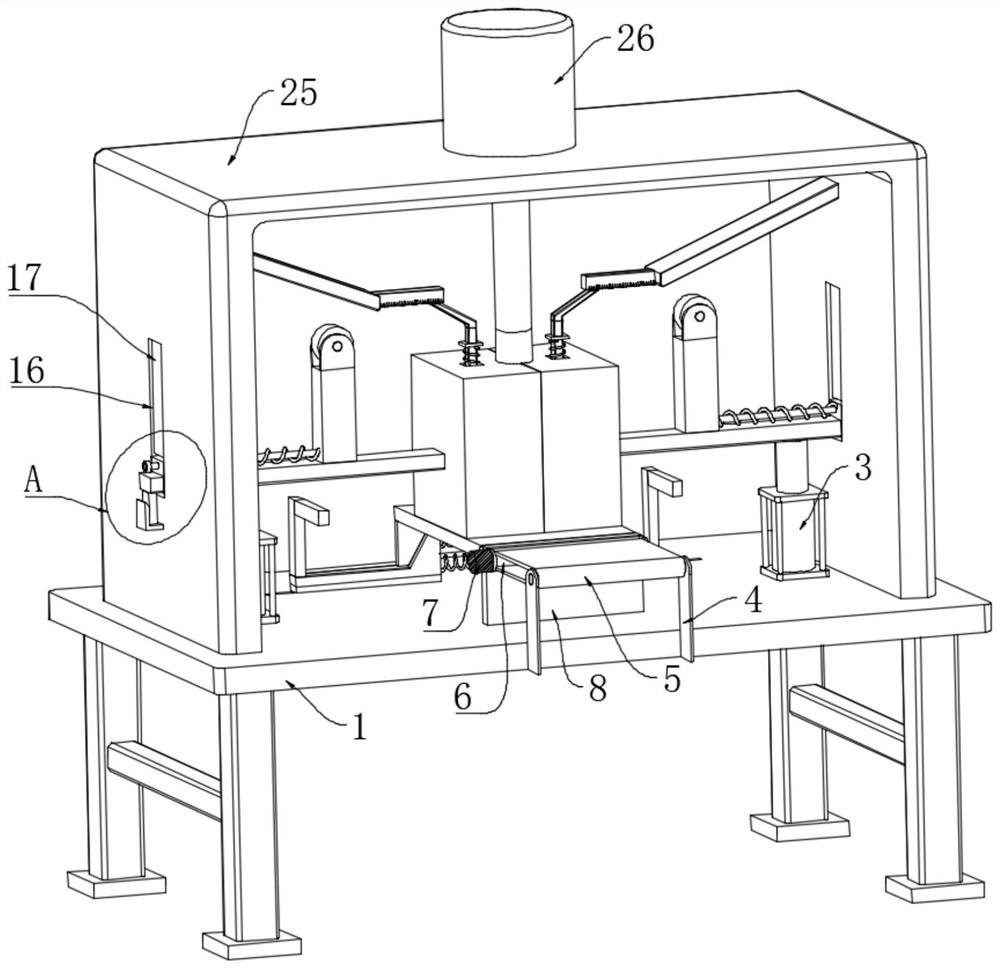

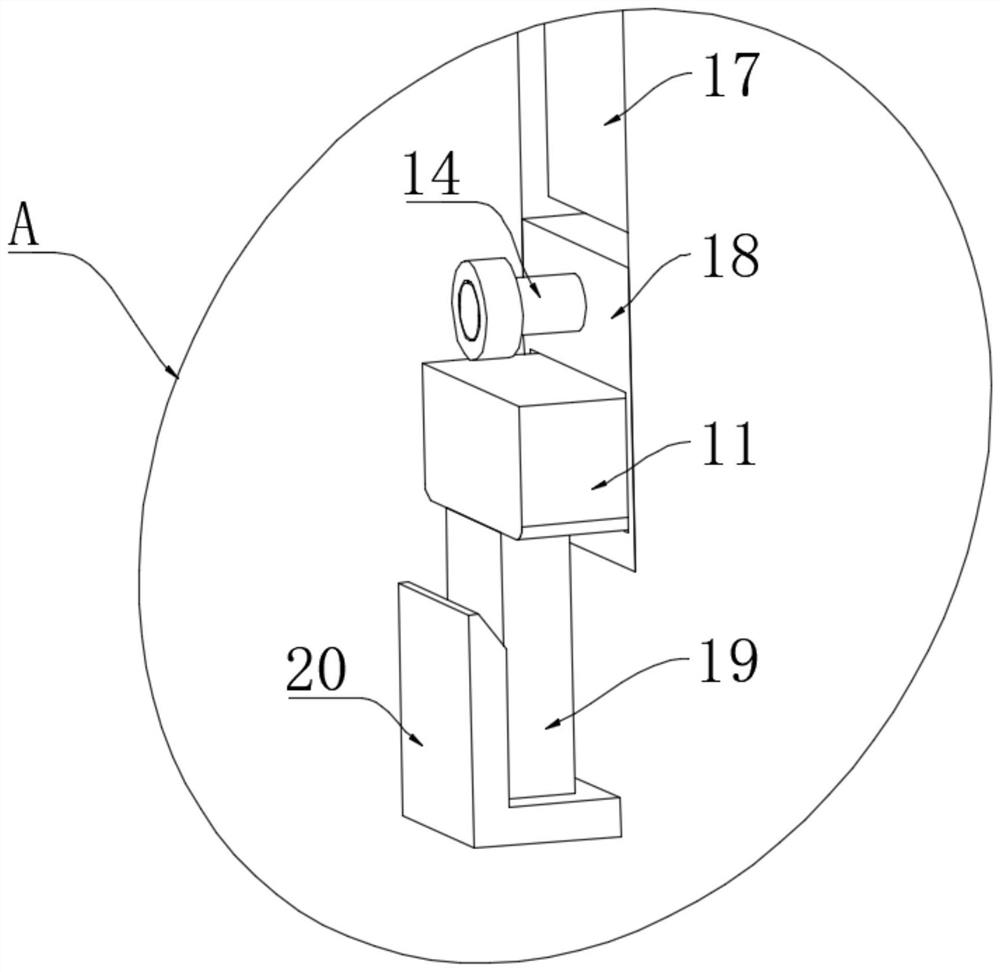

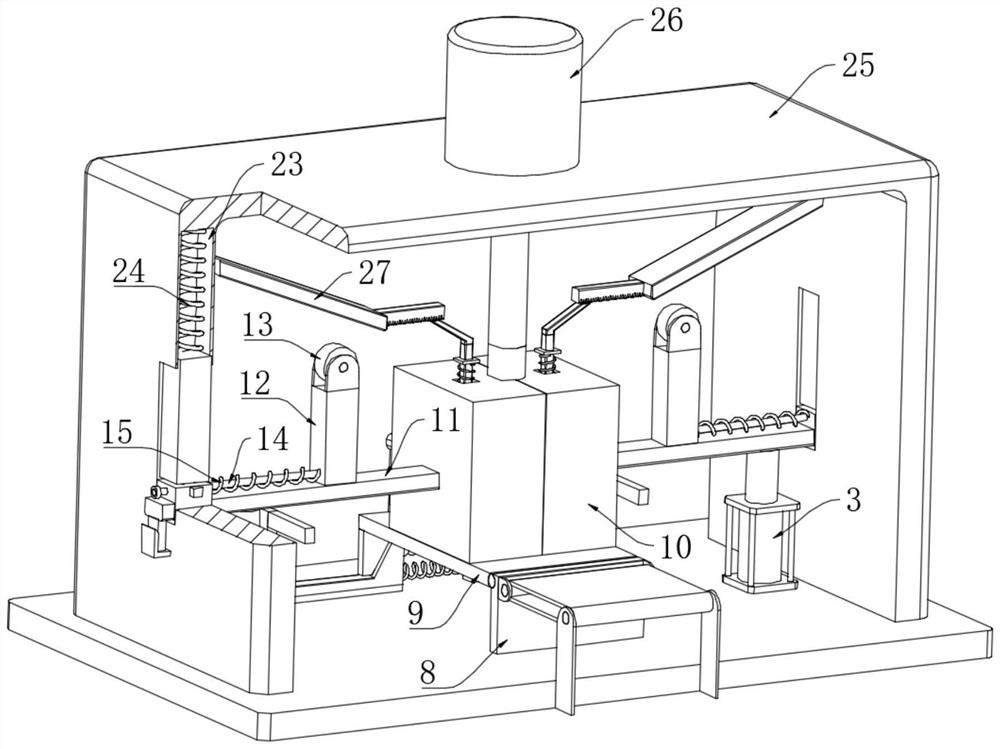

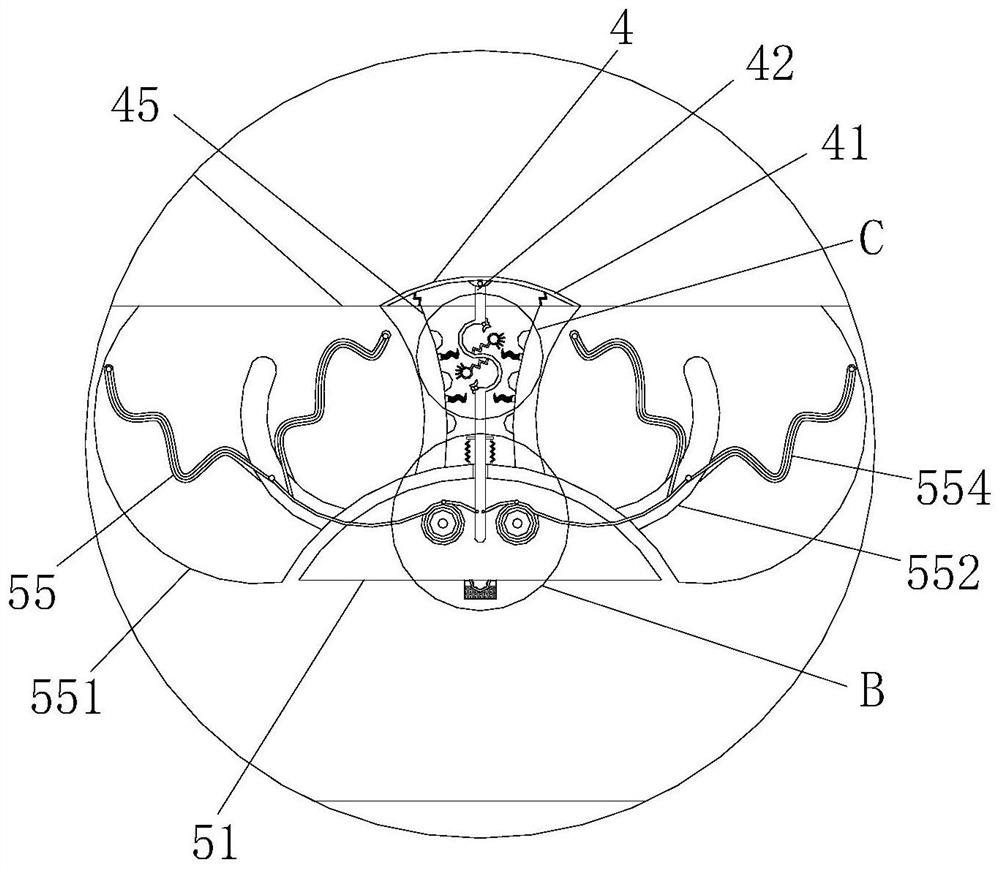

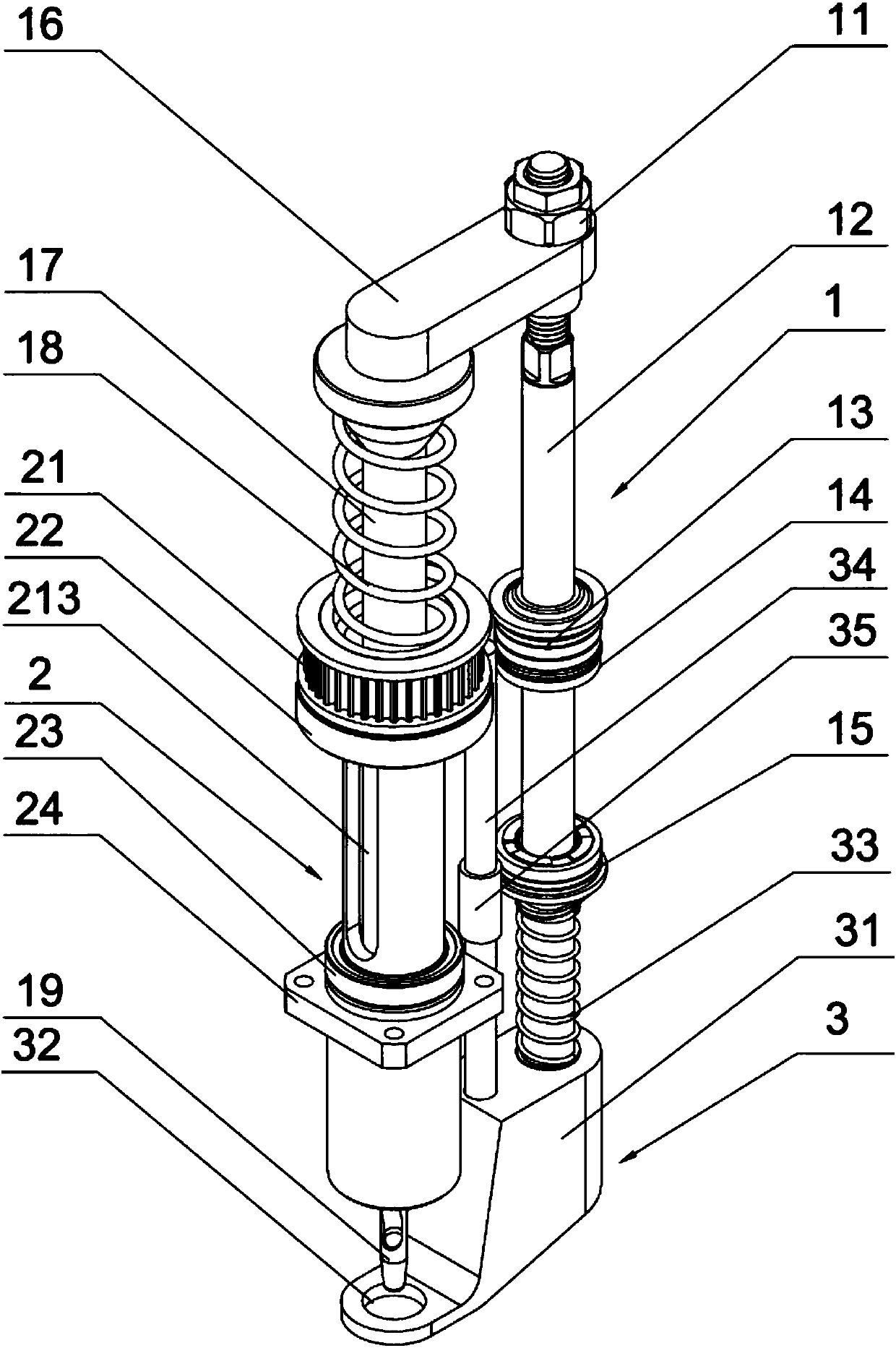

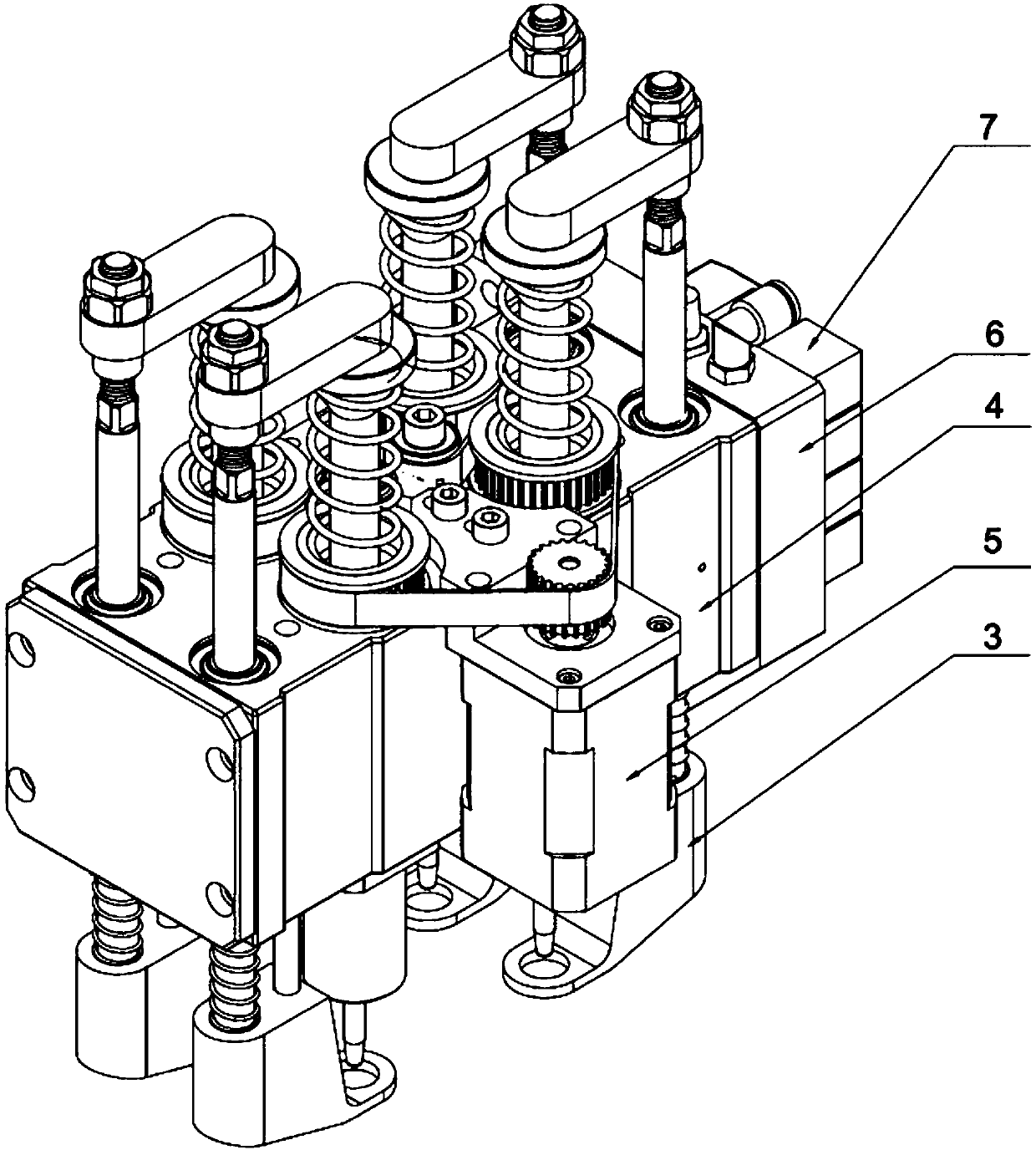

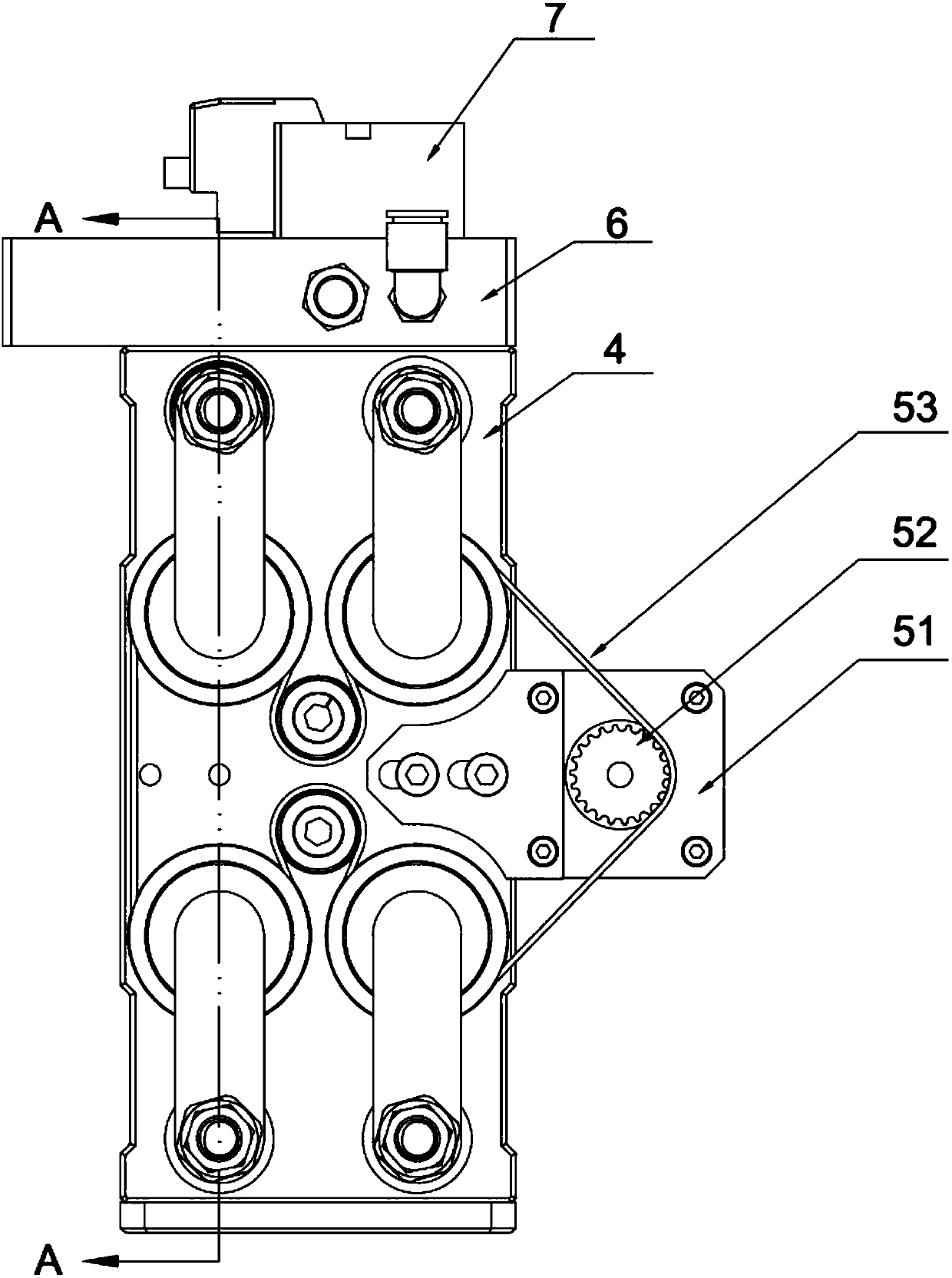

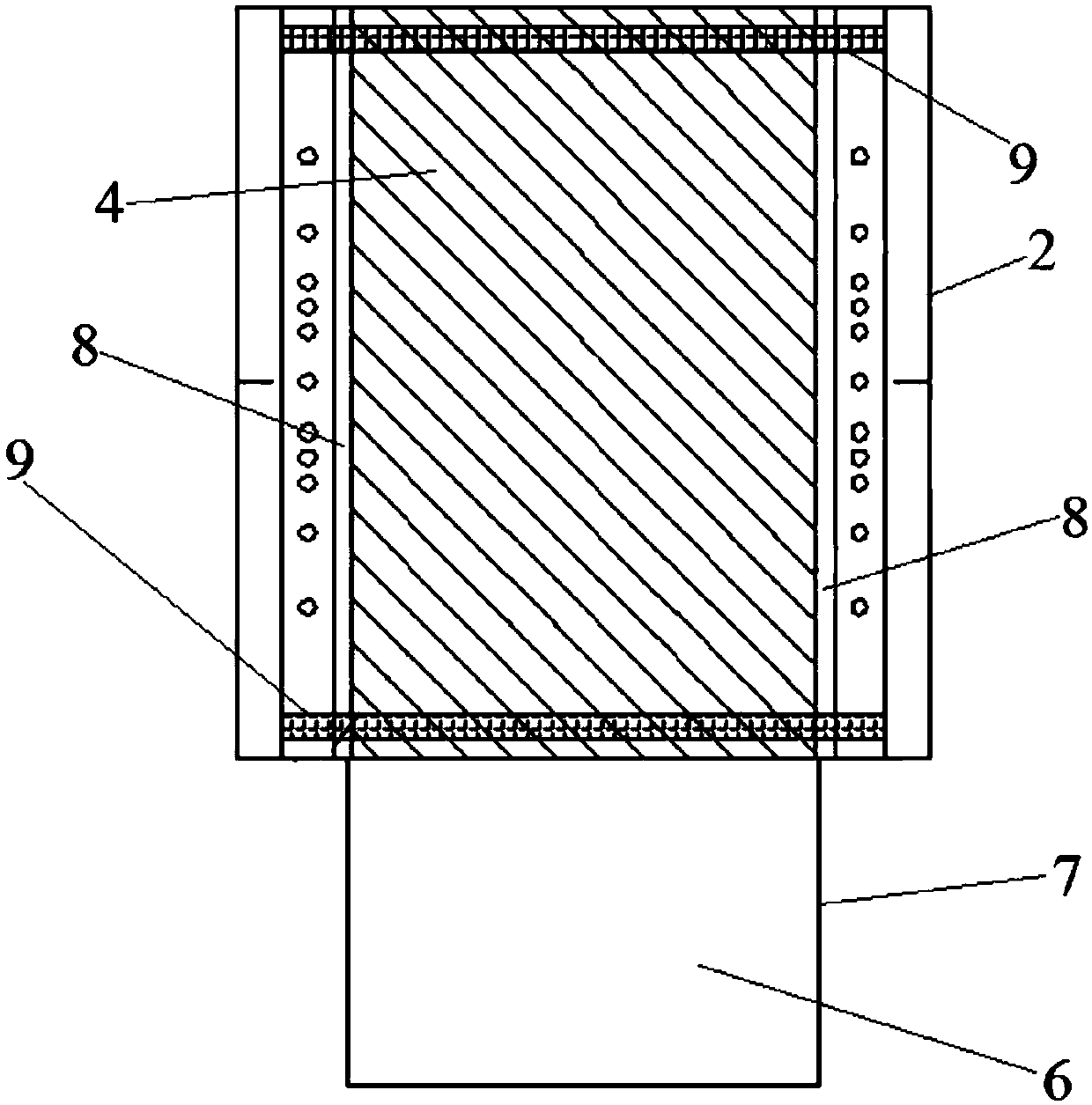

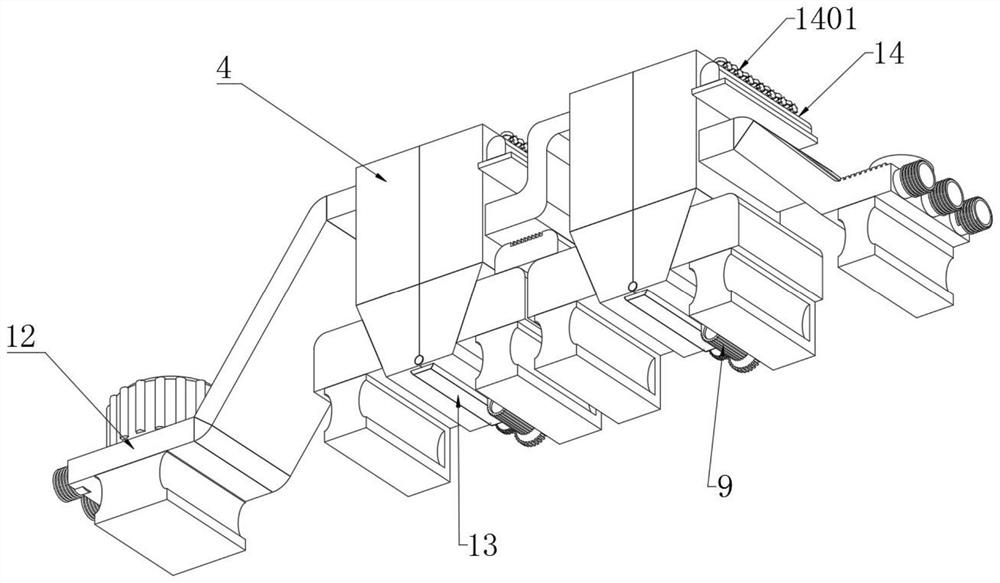

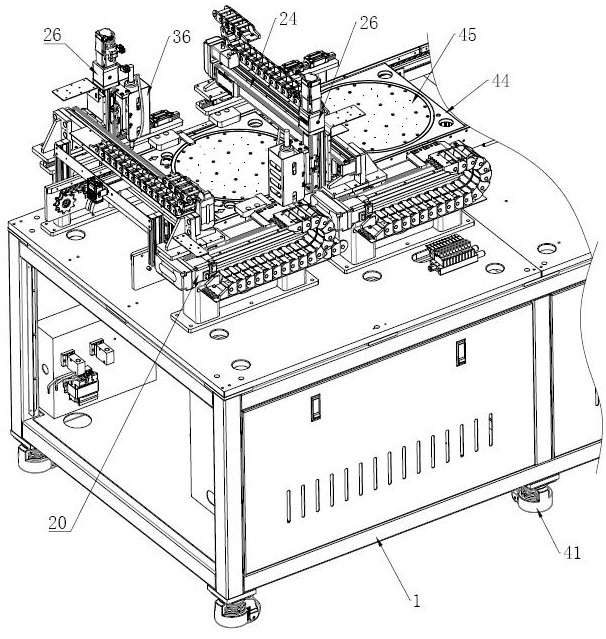

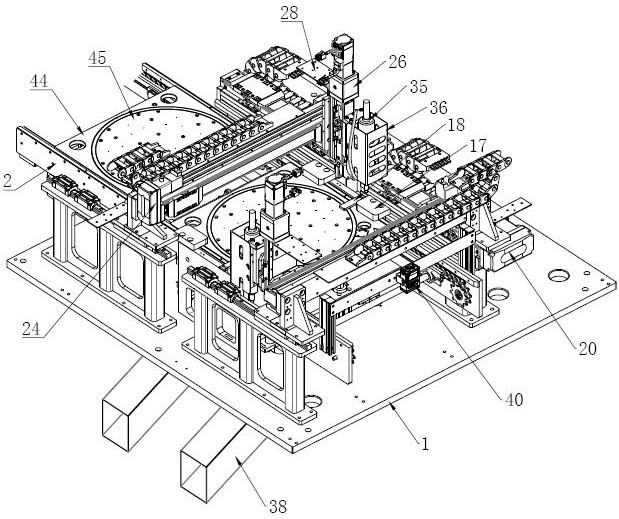

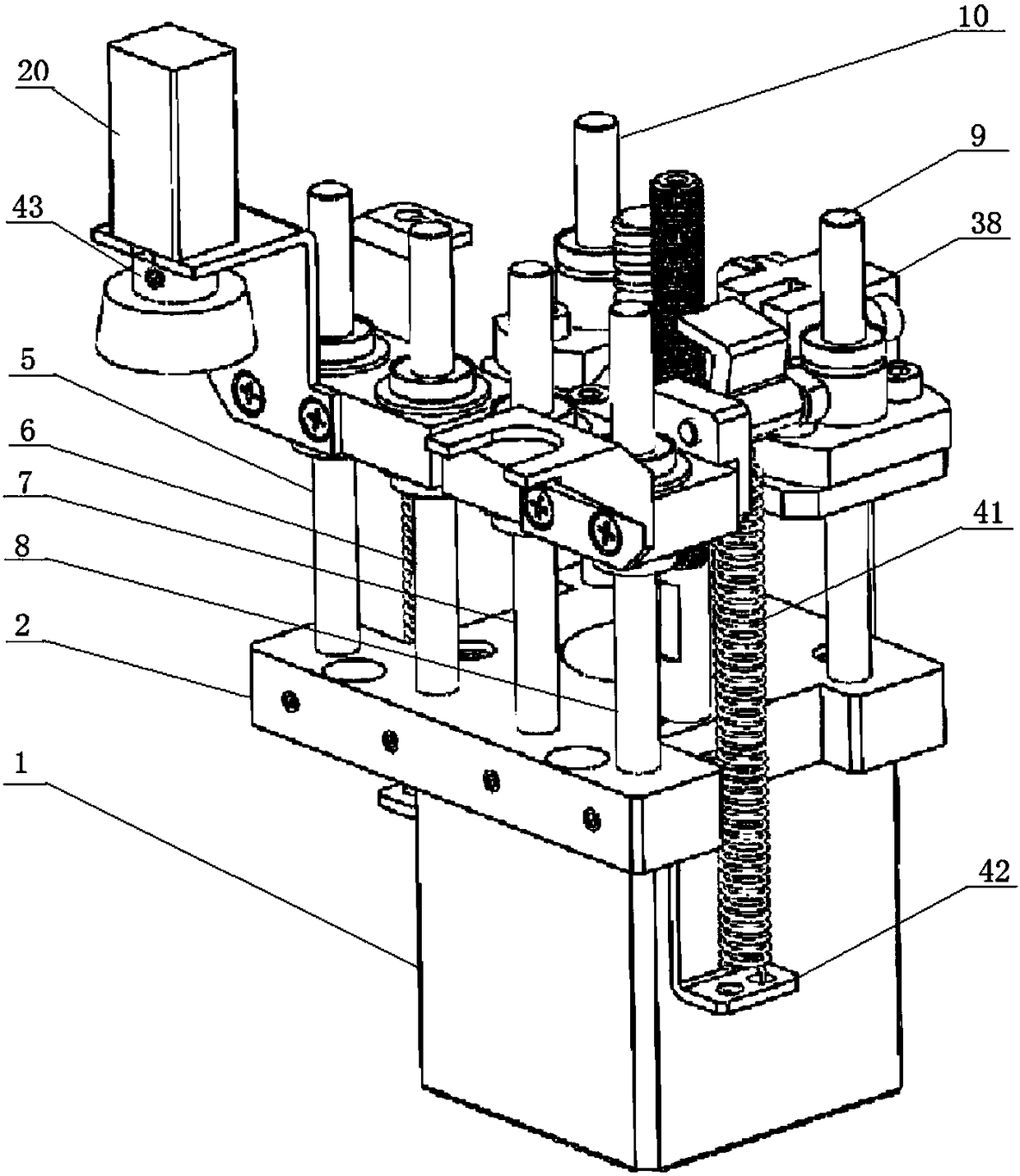

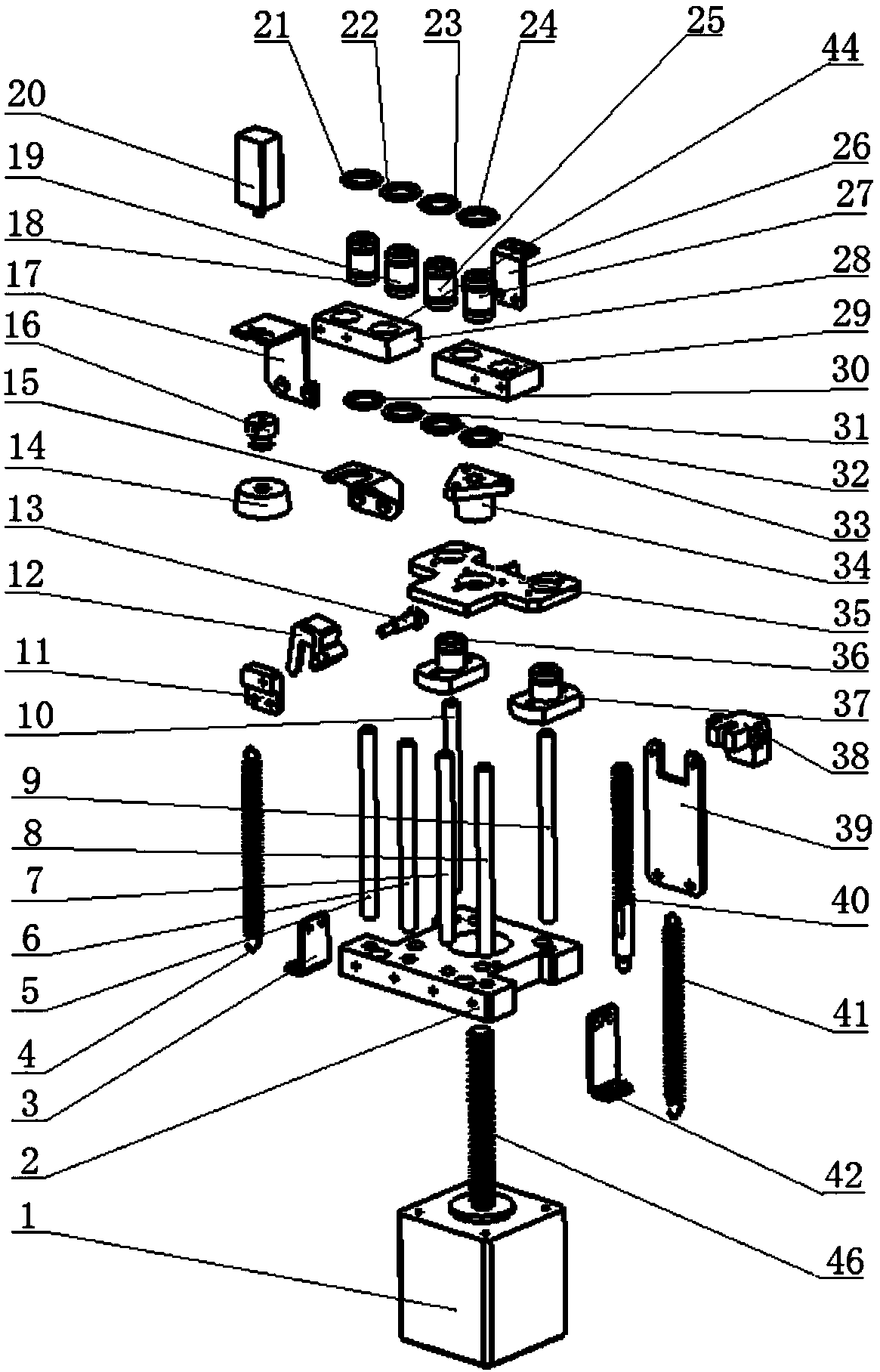

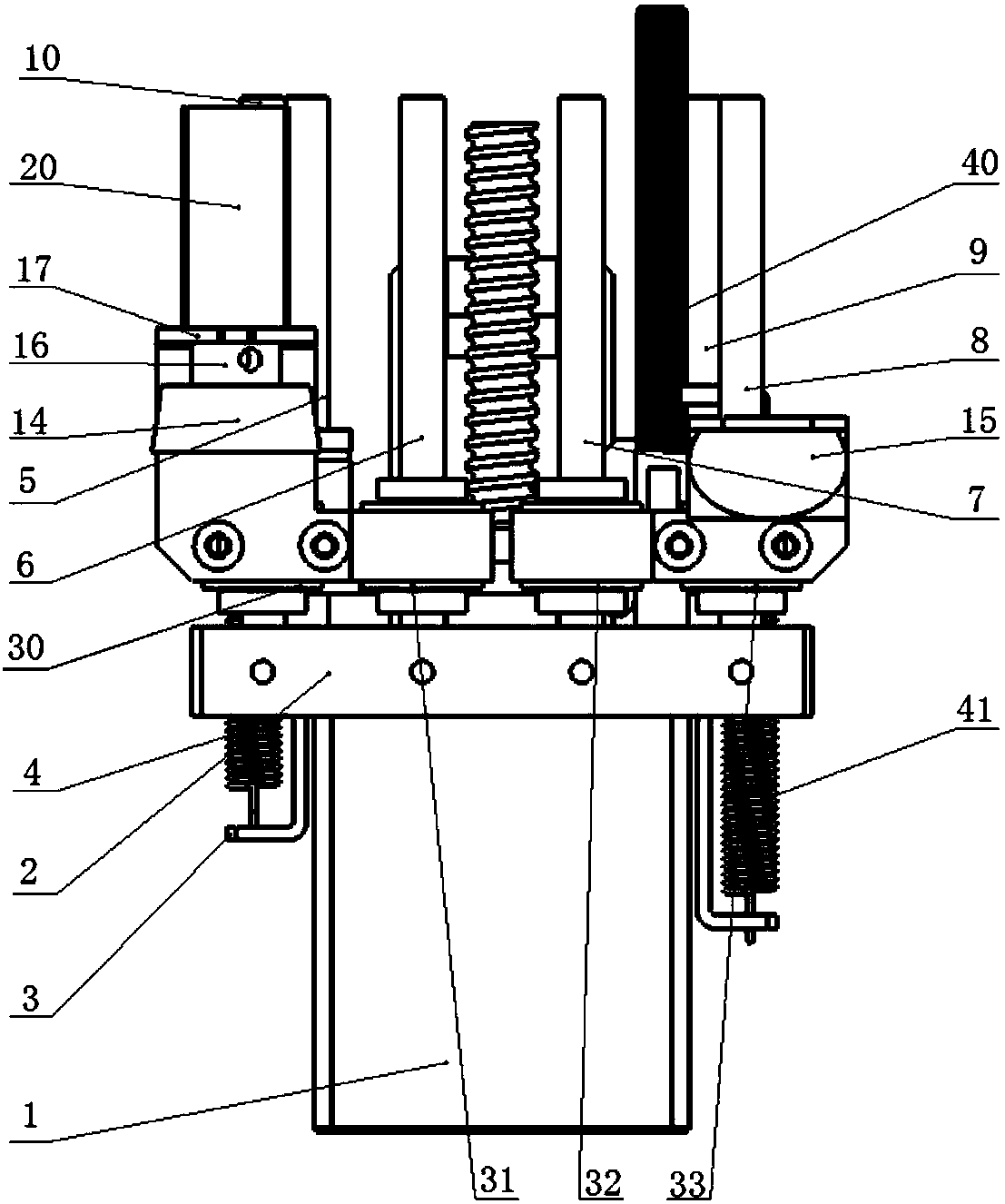

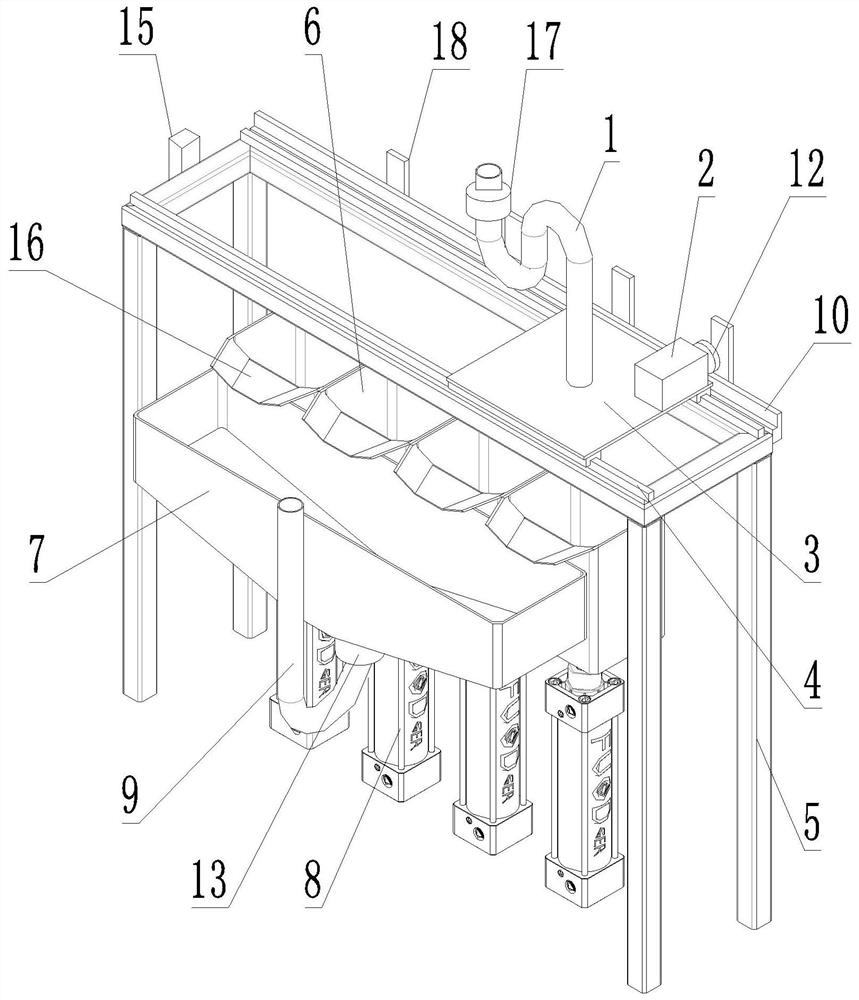

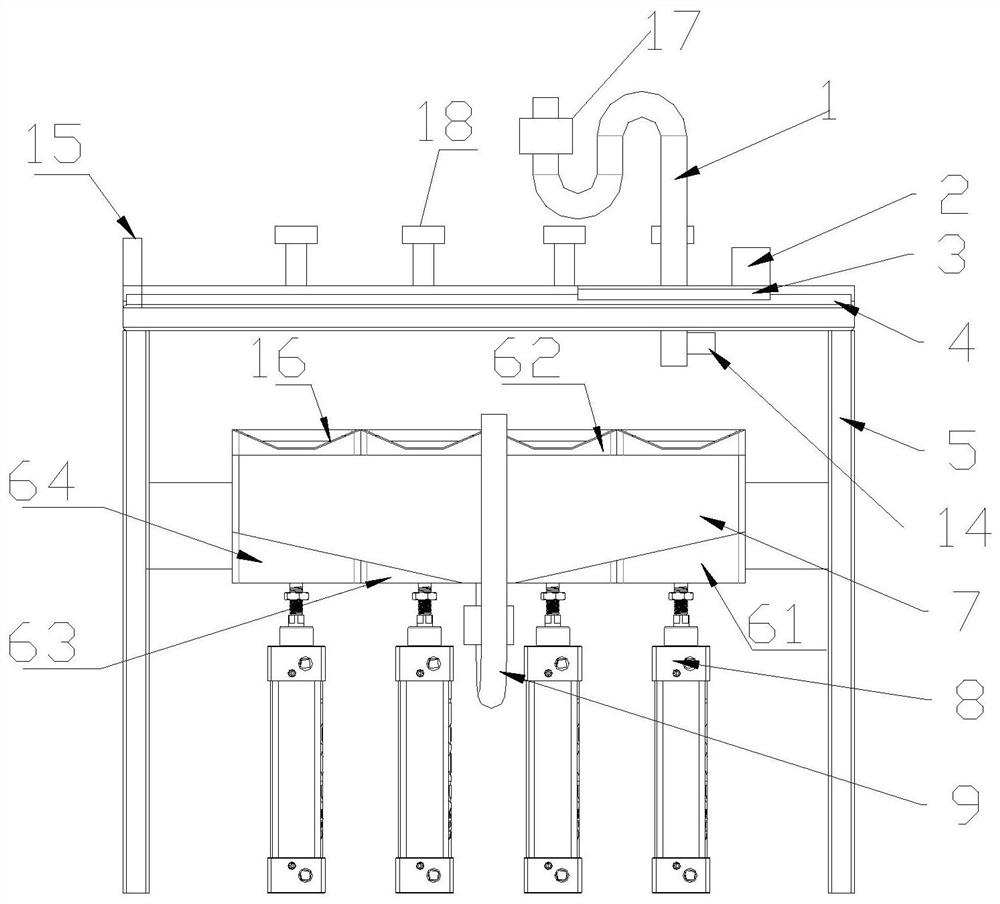

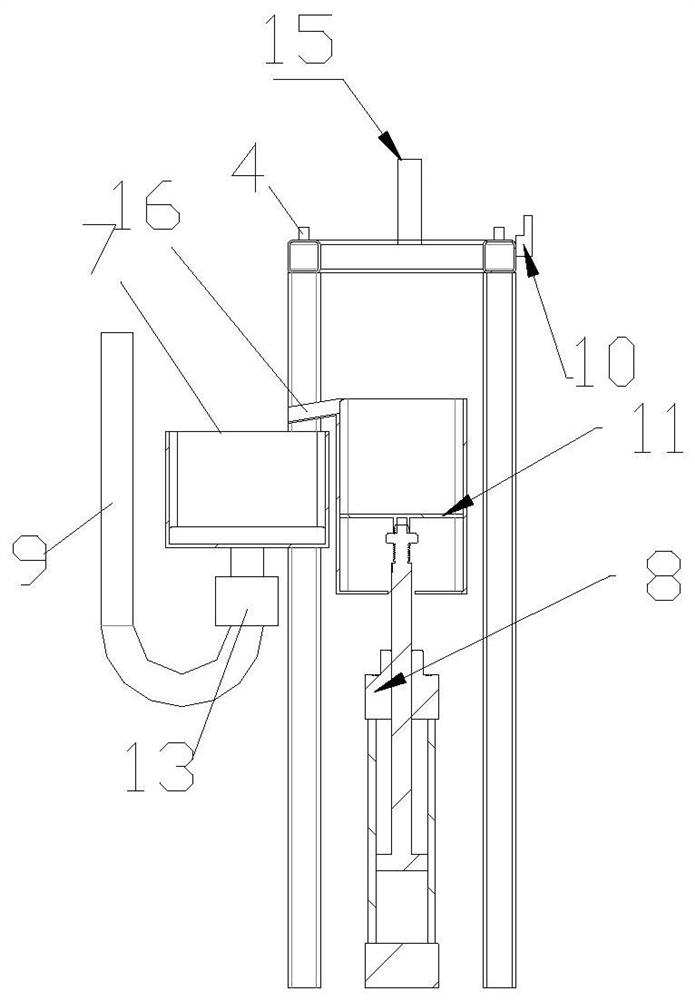

Blood collection tube rotating and compressing device

ActiveCN105758698AThe sampling process is simple and convenientReduce work intensityPreparing sample for investigationSensorsEngineeringBlood Collection Tube

The invention discloses a blood collection tube rotating and compressing device. The blood collection tube rotating and compressing device comprises a driving mechanism, a pushing plate, a first sliding block, a second sliding block, a rotating mechanism, a compressing mechanism, a first elastic piece and a second elastic piece; the pushing plate moves vertically under the driving of the driving mechanism; the first sliding block and the second sliding block move vertically under the driving of the pushing plate; the rotating mechanism is used for vibrating a blood collection tube; the compressing mechanism is used for pressing the blood collection tube; the first elastic piece is used for connecting the driving mechanism and the first sliding block; the second elastic piece is used for connecting the driving mechanism and the compressing mechanism. When blood is sampled, the rotating mechanism and the compressing mechanism work under the control of the driving device; a blood sample is vibrated uniformly through the rotating mechanism; meanwhile, the blood collection tube is prevented from being pulled when a puncture needle is pulled out because of the action of the compressing mechanism. According to the blood collection tube rotating compressing device, the labour intensity caused by vibrating and compressing the blood collection tube manually is avoided; the sampling requirements of the blood collection tubes with different lengths can be met, so that a sampling process is simple and convenient, the labour intensity is reduced, and the work efficiency is improved.

Owner:SHENZHEN GOLDSITE DIAGNOSTICS

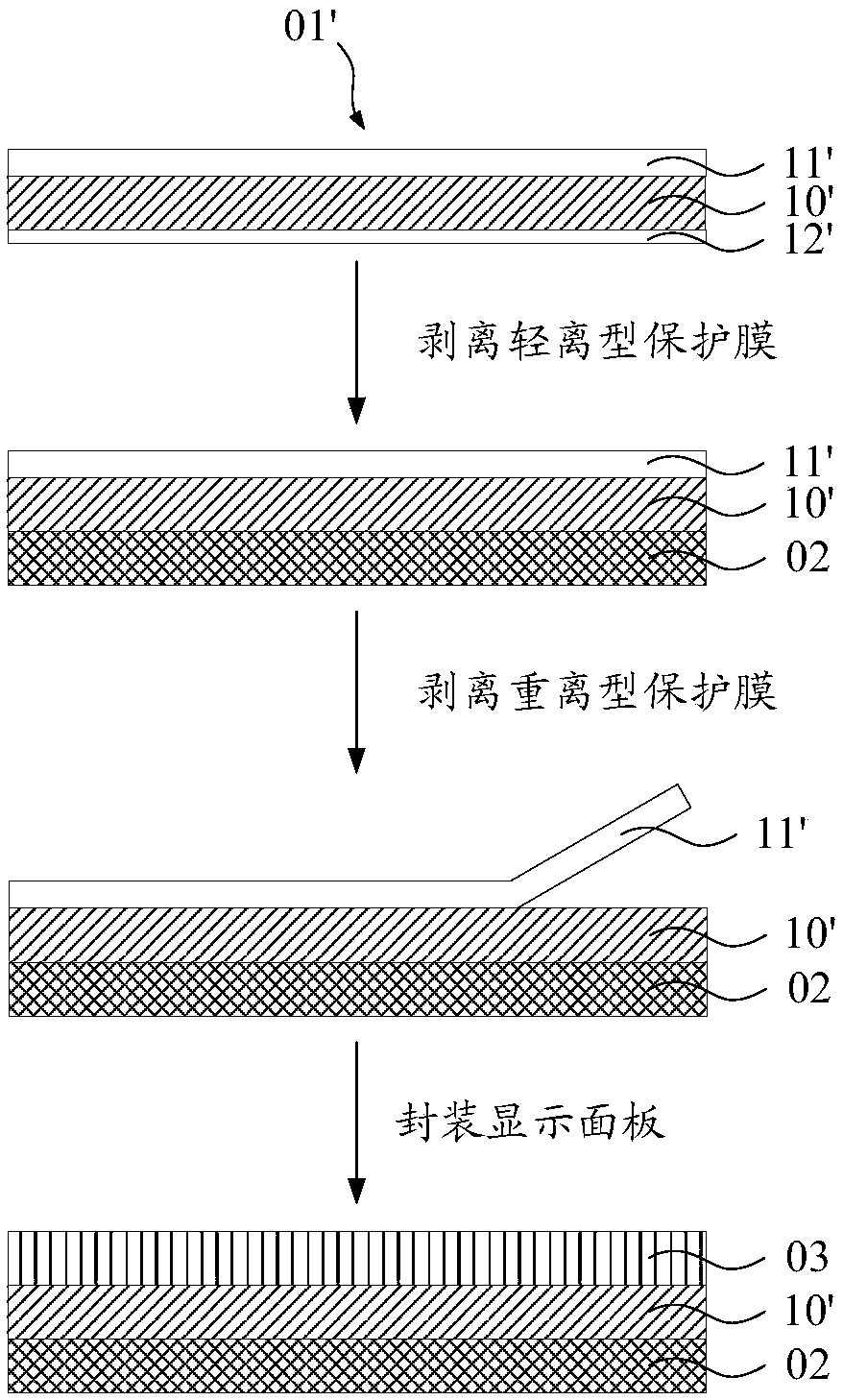

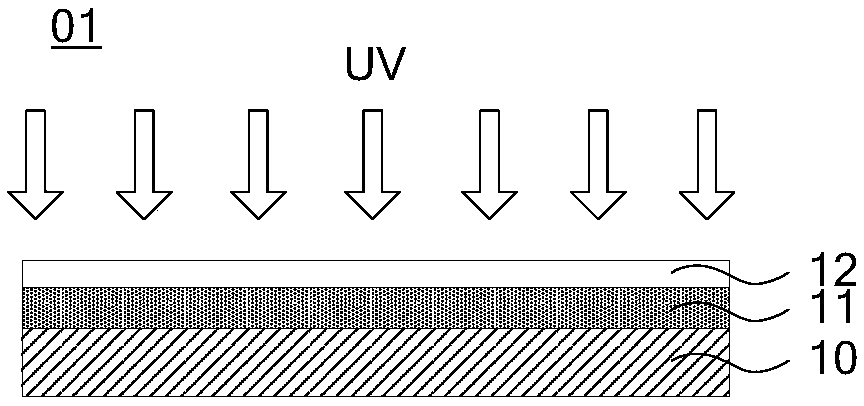

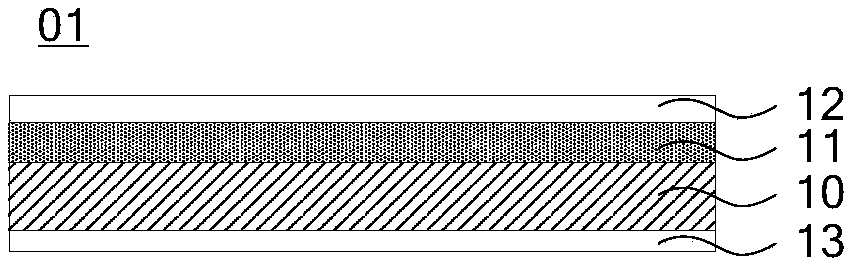

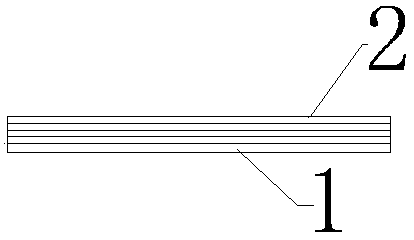

Adhesive film, packaging method of display panel and display device

ActiveCN109456708AFit tightlyLow viscositySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides an adhesive film, a packaging method of a display panel and a display device, and relates to the technical field of displaying. When the adhesive film is applied to packaging, the phenomenon that a main body adhesive layer and a packaging film are separated during stripping of a protective layer on the surface of the main body adhesive layer can be avoided, so that the production progress and the product yield can be improved. The adhesive film comprises the main body adhesive layer, a buffer adhesive layer and a first protective layer which are arranged in sequence along a thickness direction, wherein the side, away from the buffer adhesive layer, of the main body adhesive layer is fitted to the packaging film; the buffer adhesive layer is made of an adhesive material, and the viscosity of the adhesive material is reduced after the adhesive material is irradiated by ultraviolet rays; and the first protective layer is made of an ultraviolet ray-permeable adhesivematerial. The adhesive film is applied to packaging the display panel.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

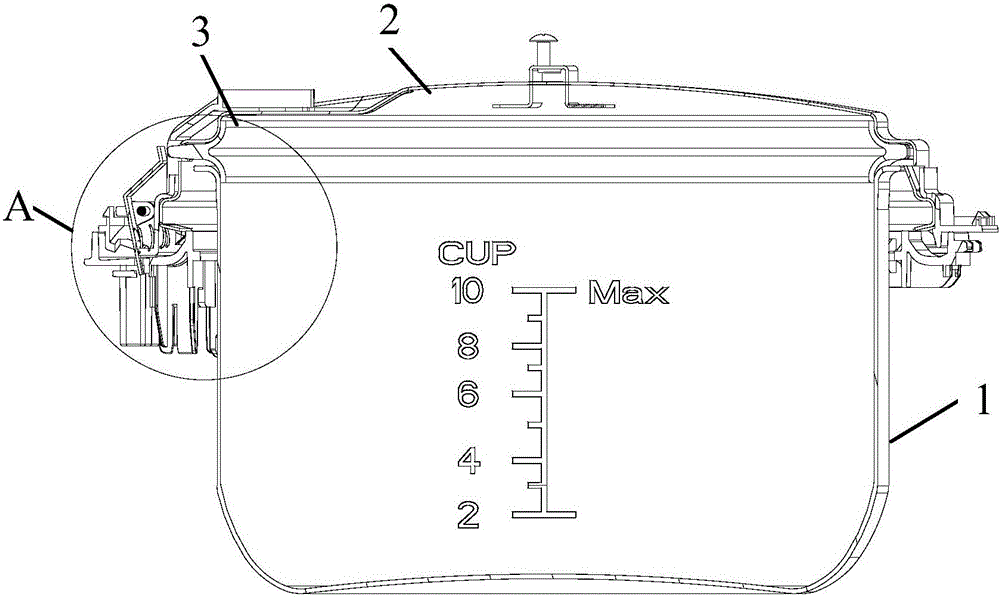

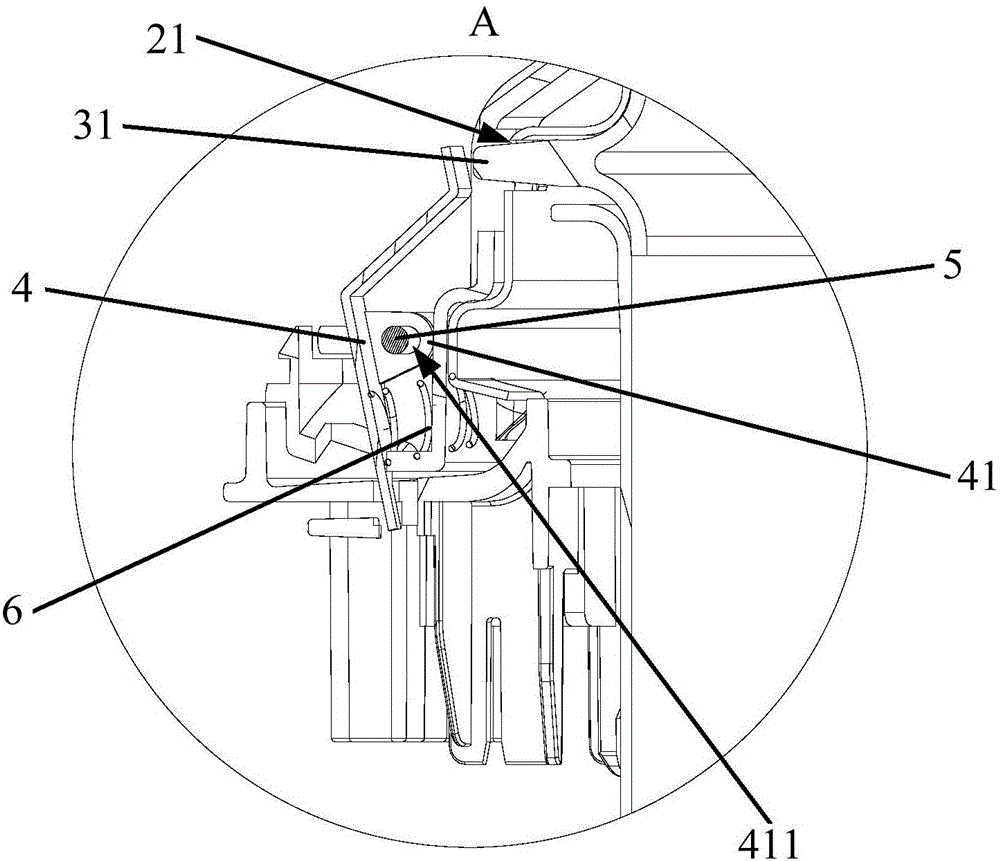

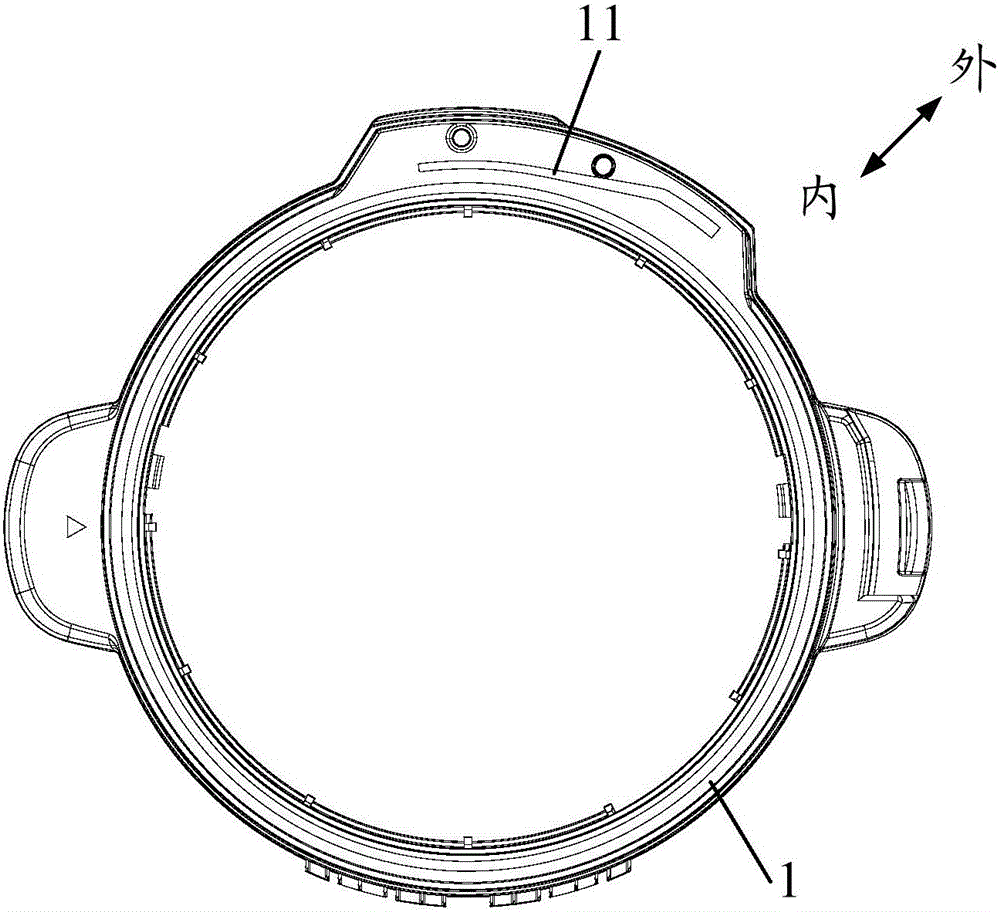

Cookware

The invention provides cookware. The cookware comprises a pot, a pot cover and a sealing ring, wherein the pot cover is rotatably arranged on the pot between the covering position and the uncovering position, a guiding groove extending from the covering position to the uncovering position is formed in the pot, and when the guiding groove extends from the covering position to the uncovering position, the guiding groove extends from the inner edge of the pot to the outer edge of the pot; the pot cover is provided with a through hole and a push rod assembled on the pot cover; the sealing ring is installed in the pot cover and comprises a ring body and a positioning protrusion which is arranged on the ring body and penetrates through the through hole; when the pot cover is rotated to the uncovering position from the covering position, the push rod squeezes the positioning protrusion under the guiding of the guiding groove to enable a gap to be formed between the sealing ring and the through hole. According to the technical scheme, during uncovering, compressional deformation of the sealing ring can be caused and the gap can be formed between the sealing ring and the through hole under the action of the push rod and the guiding groove, so that the interior of the pot can be communicated with outside atmosphere, and then the phenomenon that an inner pot body is lift under the adsorption of the sealing ring and then falls down during uncovering can be avoided, in other words, the pot suction phenomenon can be avoided.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

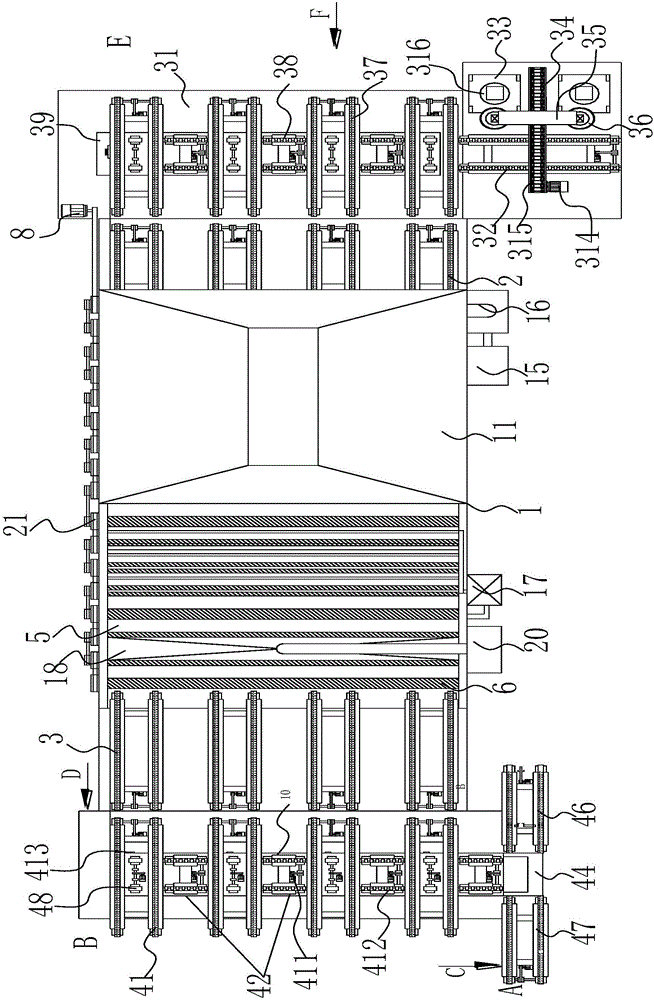

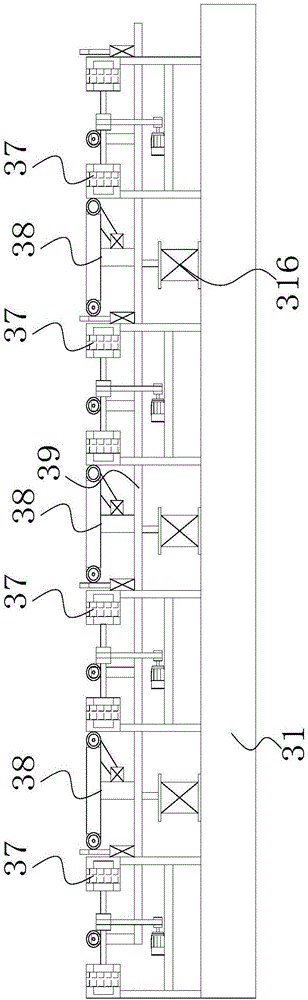

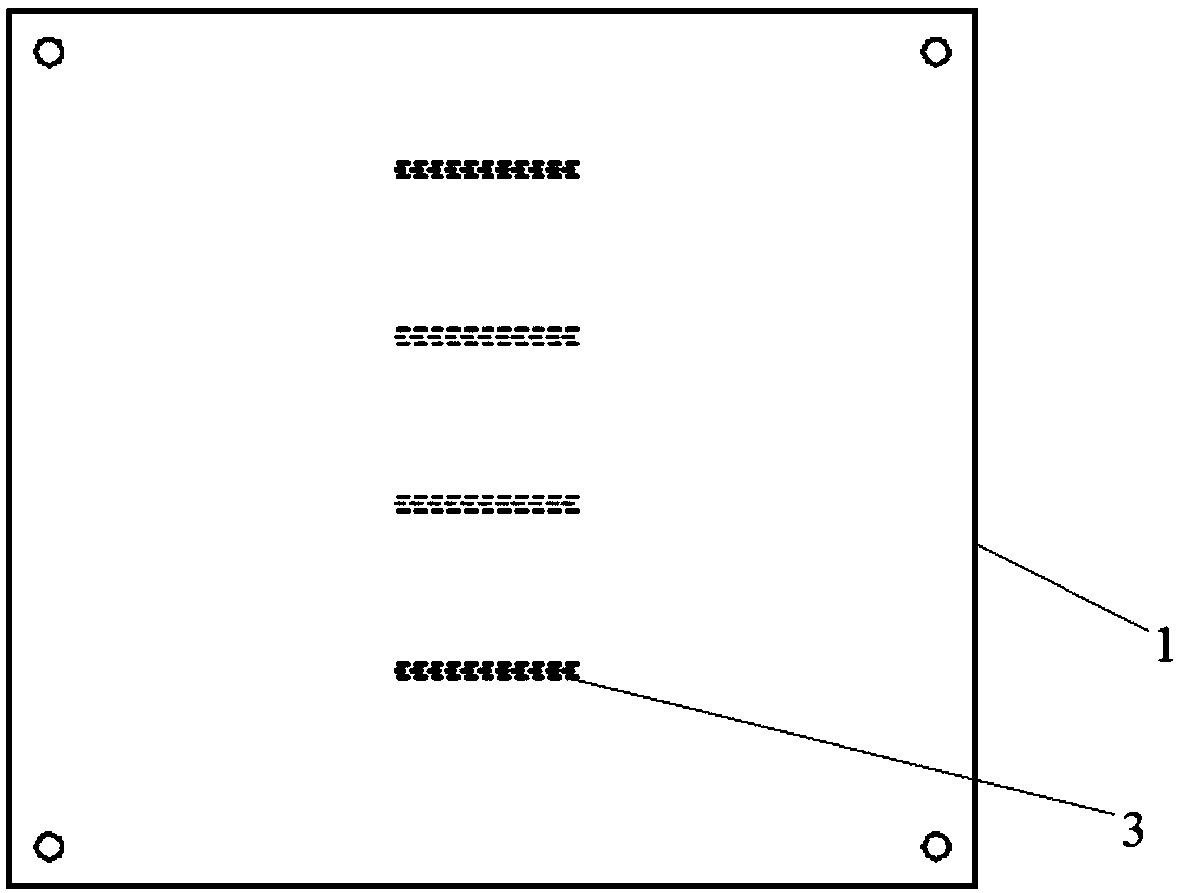

Phosphorosilicate glass removal processing production line for crystalline silicon solar cell processing

ActiveCN106169521ASimple structureAvoid bringing upFinal product manufactureSemiconductor/solid-state device manufacturingProduction lineHydrofluoric acid

The invention discloses a phosphorosilicate glass removal processing production line for crystalline silicon solar cell processing. The phosphorosilicate glass removal processing production line comprises a pool body provided with a feeding belt and a discharging belt, wherein the feeding belt and the discharging belt are evenly and horizontally arranged on two ends of the pool body at an interval; one end of the feeding belt is provided with an even wafer distribution mechanism; one end of the discharging belt is provided with a silicon wafer collection mechanism; the pool body is provided with a corrosion pool with a containing cavity and a cleaning pool with the containing cavity; conveying rollers are in transmission connection via synchronous belts and are connected with a driving motor; each conveying roller is provided with screws distributed along the axle body of the conveying roller; a weep pipe above one conveying roller is arranged in the corrosion pool and is provided with a water outlet; multiple pairs of flushing pipes positioned above and below the conveying rollers of the cleaning pool are arranged in the cleaning pool; and each pair of flushing pipe is provided with symmetrical flushing holes. Compared with the prior art, the production line is characterized in that even wafer distribution and collection is realized, the production line can be prevented from being corroded by acid mist, a conveying roller structure is improved, vibration and hydrofluoric acid splashing can be avoided, and production quality and production efficiency are improved.

Owner:ZHEJIANG LVYUAN PV TECH

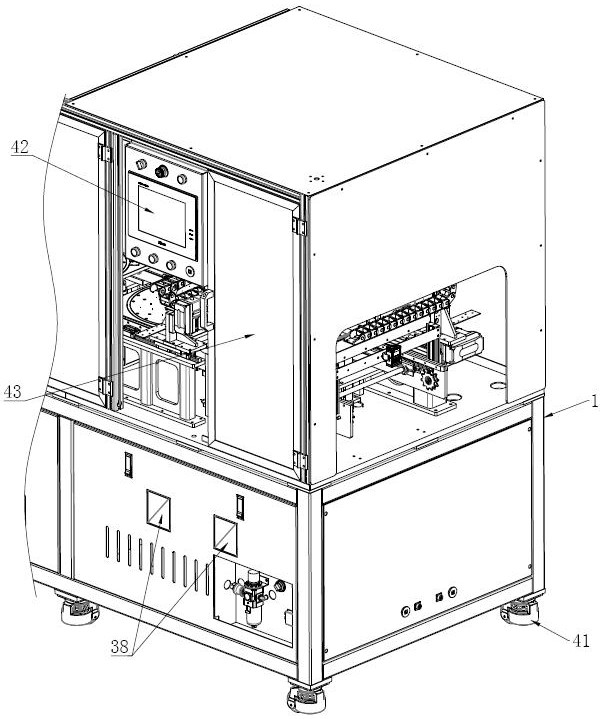

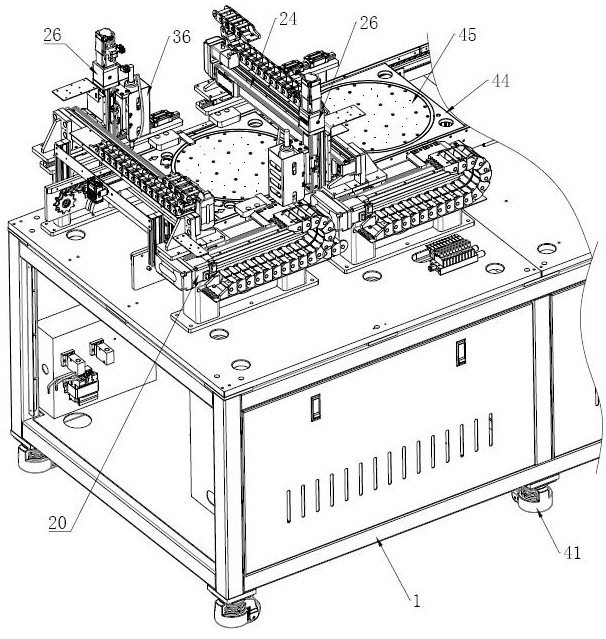

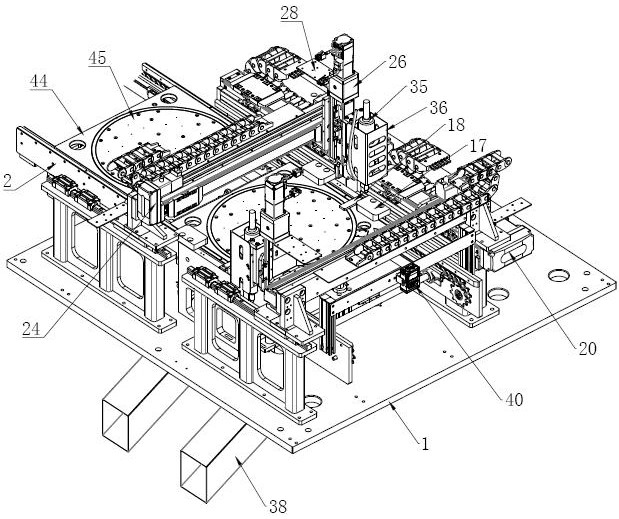

Helium detector for automobile storage battery box

PendingCN112033612AEasy to moveAchieve sealingDetection of fluid at leakage pointEngineeringMechanical engineering

The invention discloses a helium detector for an automobile storage battery box. The detector comprises a table frame, a working part is arranged on the table frame, the working part comprises a mounting plate, the mounting plate is fixedly mounted on the table frame, and a front-back transplanting device, a vacuum box and a leakage detection device are arranged at the top of the mounting plate. The front-back transplanting device is used for installing and moving a storage battery box, the vacuum box is used for fixing and blocking the storage battery box, and the leakage detection device isused for detecting whether the storage battery box leaks air or not. Through arrangement of the front-back transplanting devices, the vacuum box and the leakage detection device, movement, sealing, vacuumizing, helium filling, helium leakage detection and the like of the storage battery box can be realized, so that the airtightness detection of the battery box is realized; meanwhile, helium is used as detection gas, so that the detection is more sensitive and accurate.

Owner:NANTONG GUANGYE AUTOMATION SYST ENG

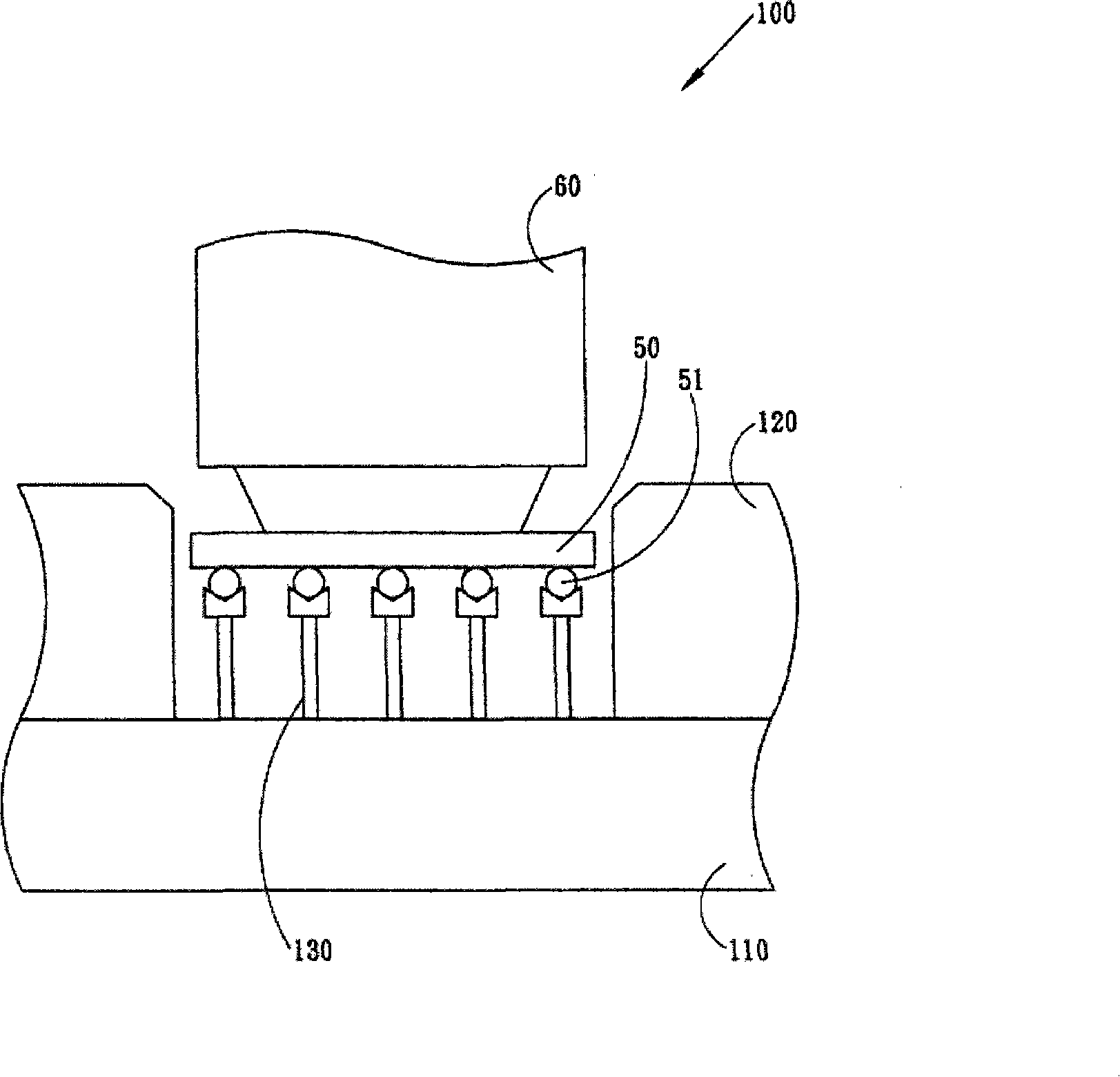

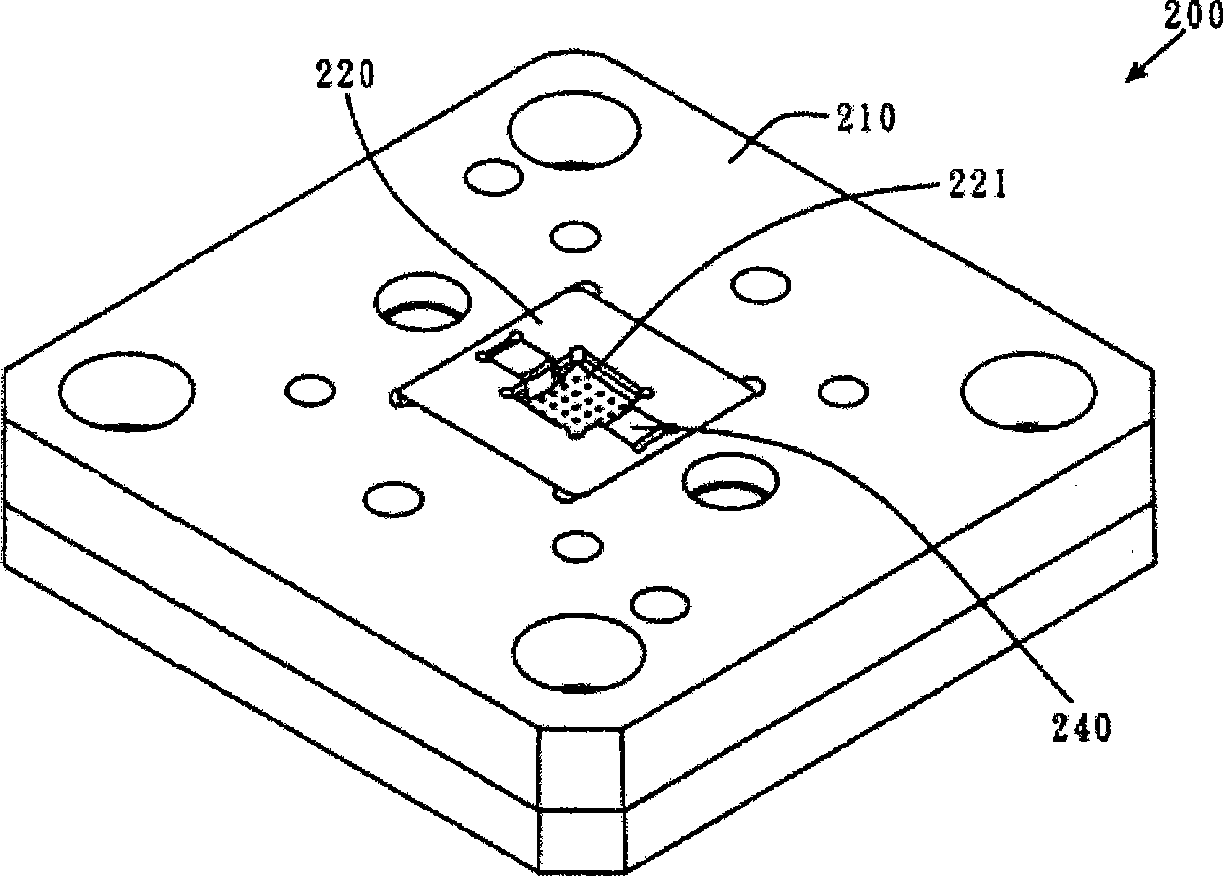

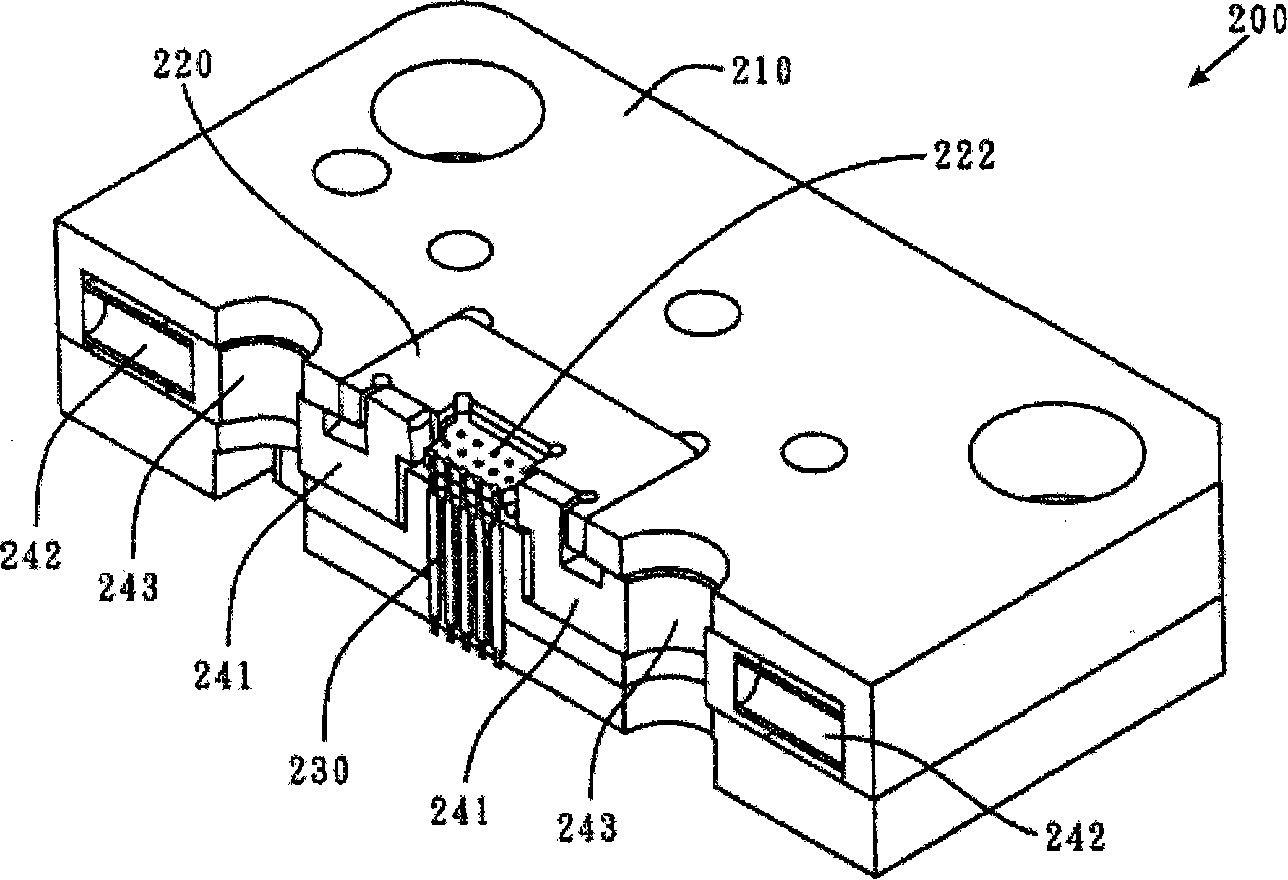

Chip carrier socket

InactiveCN101540465BAvoid bringing upConsistent contact statusElectric discharge tubesCoupling device detailsEngineeringFloating platform

The invention relates to a chip carrier socket. The chip carrier socket can accommodate a chip, and comprises a pedestal, a floating platform, a plurality of probes and a fixing device. The pedestal can be connected to a chip tester; the floating platform is arranged on the pedestal and comprises a positioning plane which is provided with a plurality of positioning holes; the probes are arranged in the positioning holes; and the fixing device is used for fixing the chip. In the chip carrier socket, the chip can be flatly attached to the positioning plane so that a contact point of the chip isconsistent with the contact condition of the probes; therefore, the testing stability can be increased; and meanwhile, the chip carrier socket can fix the chip, so the chip can avoid being pulled outby a chip pick-and-place head, and the chip carrier socket is quite practical.

Owner:KING YUAN ELECTRONICS

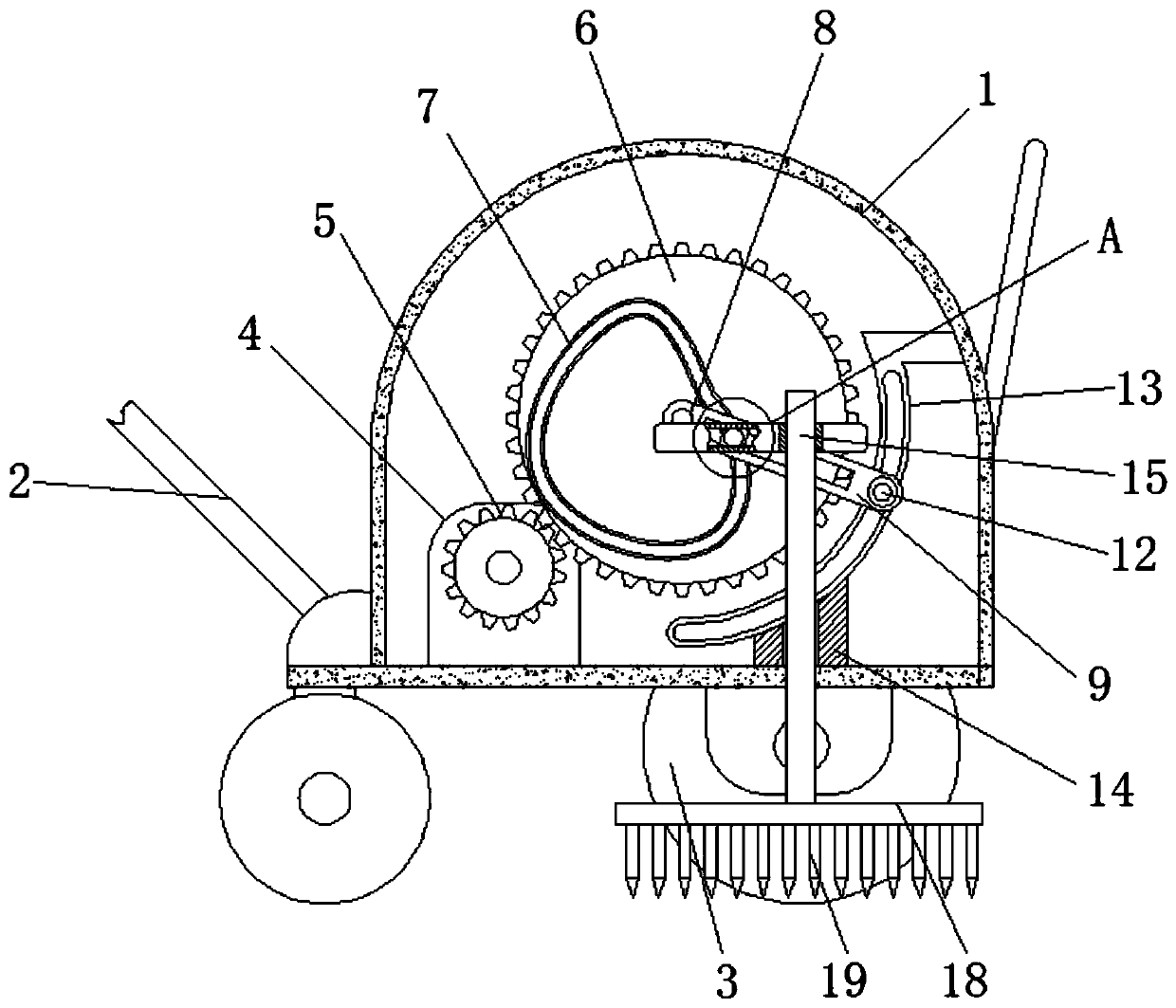

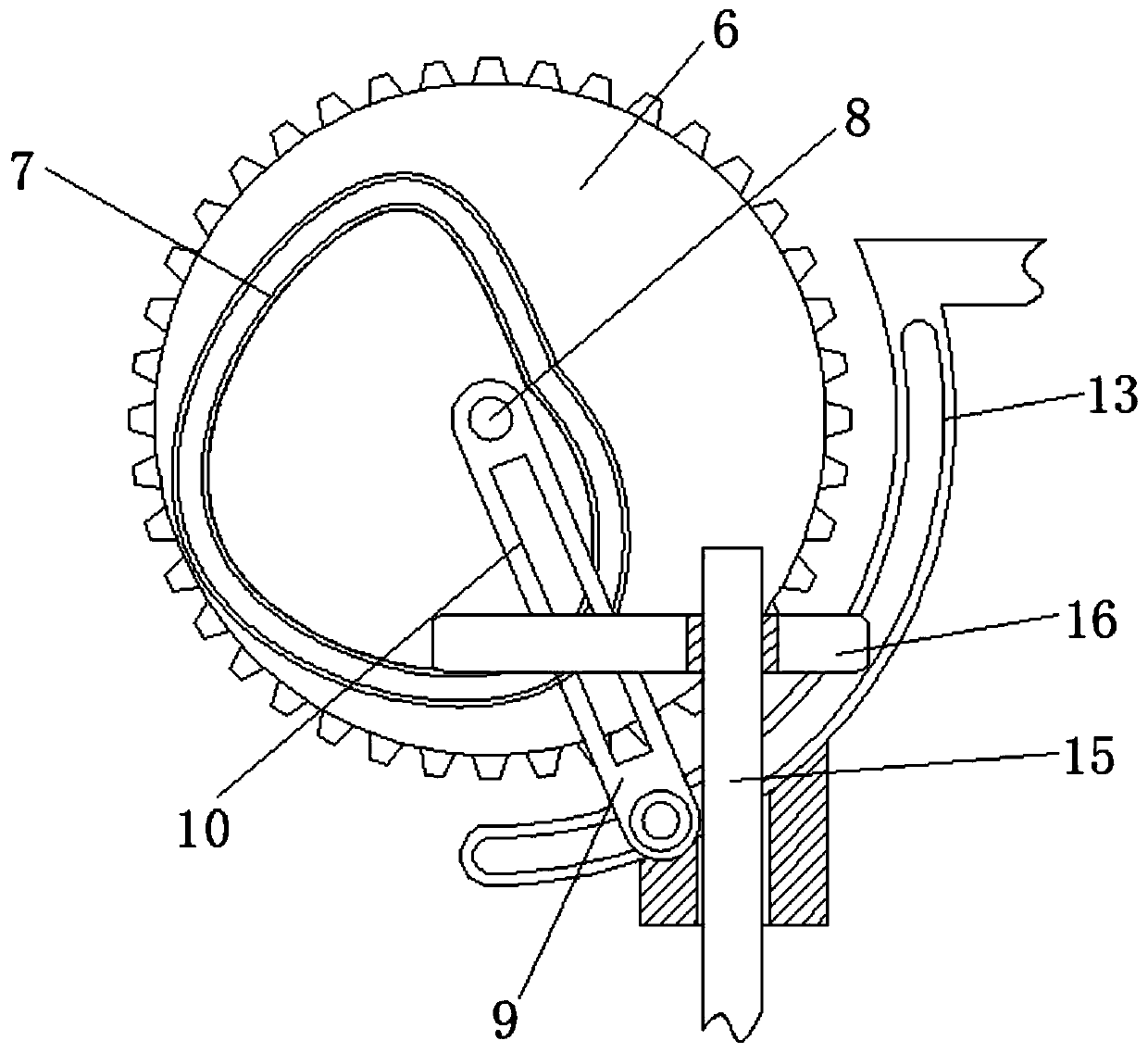

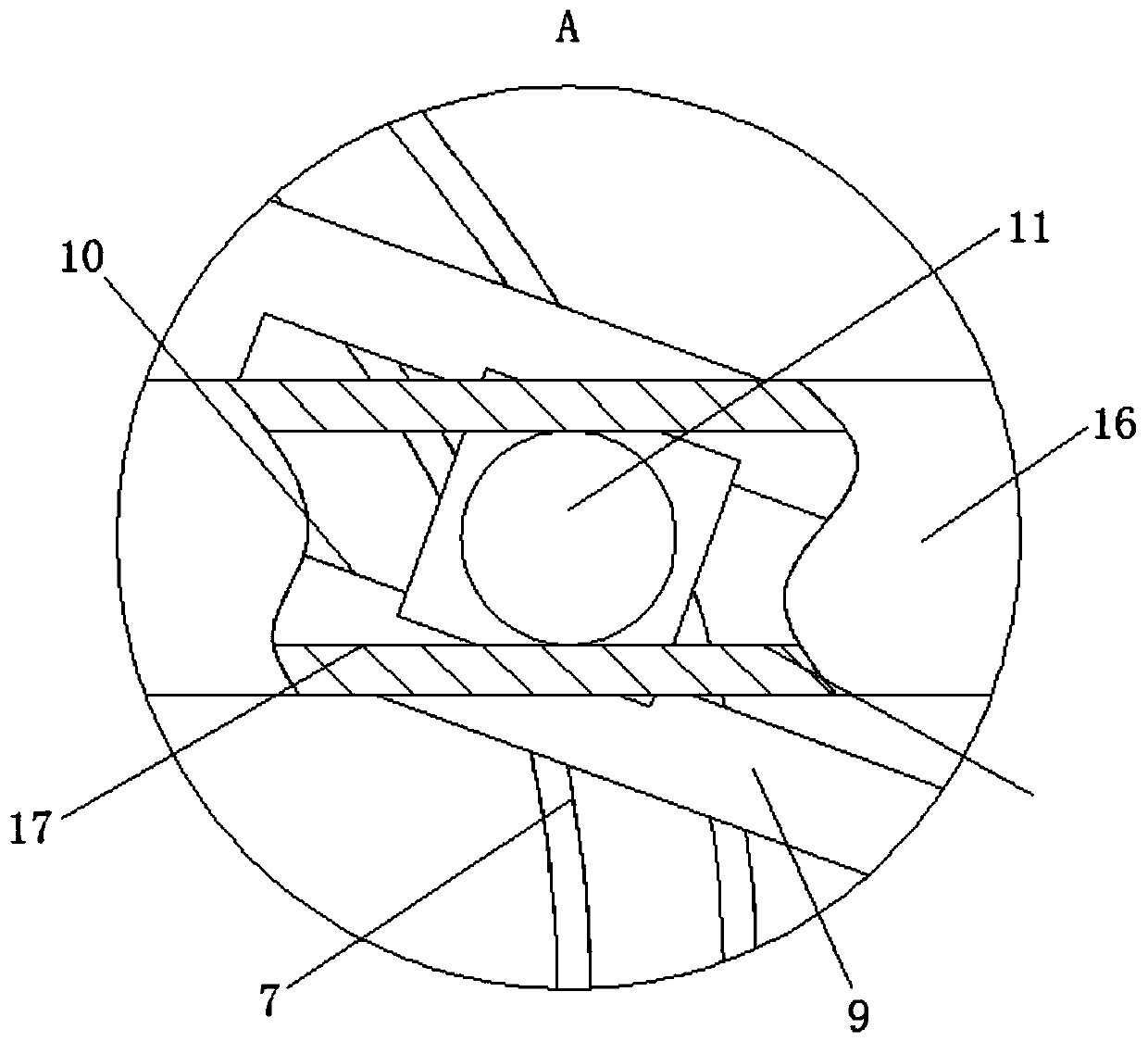

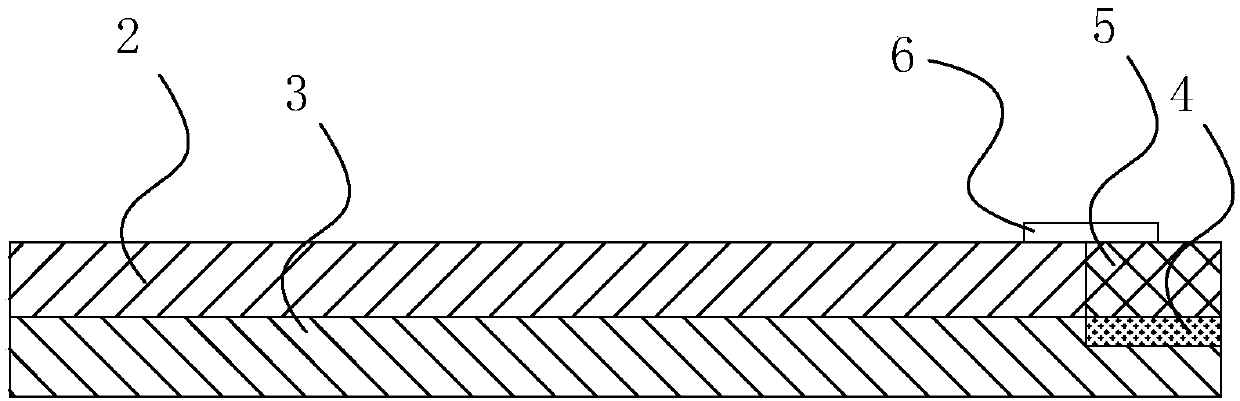

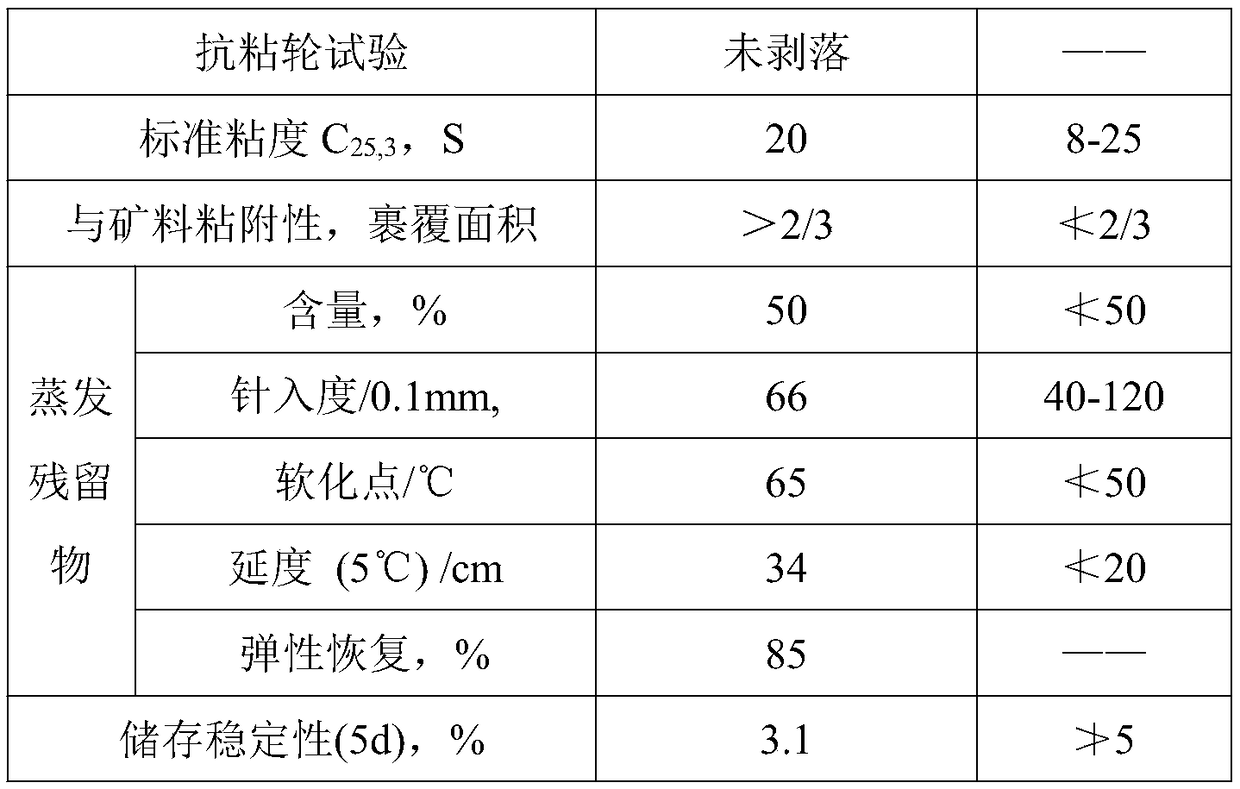

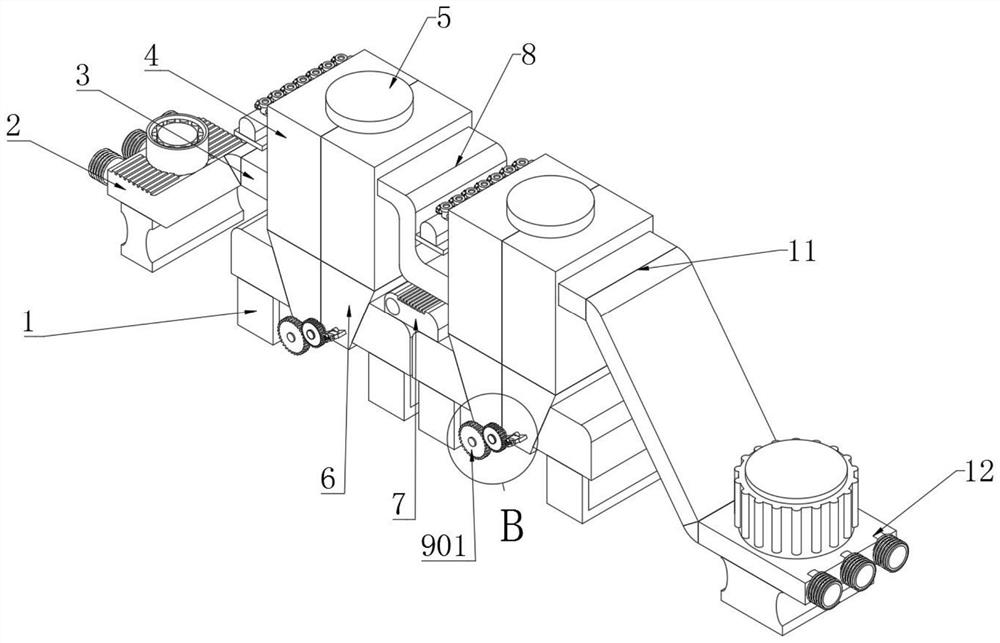

Adjustable lawn aerator based on convex guide rail transmission principle

InactiveCN111201848AGuaranteed punching qualityProtect environmentLawn machinesAgricultural scienceGear wheel

The invention relates to the technical field of environmental protection, and discloses an adjustable lawn aerator based on a convex guide rail transmission principle. The adjustable lawn aerator based on the convex guide rail transmission principle comprises a vehicle body, wherein a handle is fixedly connected outside the vehicle body; wheels are movably connected to the bottom of the vehicle body; a motor is fixedly connected inside the vehicle body; a main gear is fixedly connected outside the motor; a fluted disc is engaged and connected outside the main gear; a guide rail is fixedly connected outside the fluted disc; a connecting shaft is fixedly connected inside the fluted disc; an adjusting rod is movably connected outside the connecting shaft; and a first slide groove is formed inside the adjusting rod. Through the cooperative use of the adjusting rod, a slide block and a transverse rod, the effect of automatically regulating the aeration depth according to different lawns anddifferent soil conditions can be achieved, so that the use range of the device is expanded; the aeration quality of the lawn is ensured, so that the ecological environment of the lawn is protected; and the lawn is enabled to healthily grow.

Owner:ANHUI YINUOQINGCHUN IND DESIGN CO LTD

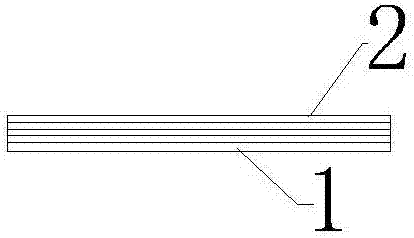

Easy-to-peel insulating double-sided adhesive tape

PendingCN111100579AEasy to useAvoid bringing upFilm/foil adhesive release linersComposite materialPolymer chemistry

The invention discloses an easy-to-peel insulating double-sided adhesive tape which comprises an adhesive tape, the adhesive tape comprises surface release paper and an adhesive layer which are adhered to each other, a non-adhesive tape is arranged on the surface of one end of the adhesive layer, one end, close to the non-adhesive tape, of the surface release paper extends along the length direction of the surface release paper to form a peeling section, and the peeling section is separated from the non-adhesive tape; marking paper is arranged between the stripping section and the surface release paper and is located on the surface of the surface release paper. The easy-to-peel insulating double-sided adhesive tape provided by the invention is convenient for tearing off surface release paper in a use process and avoids damage to the surface of a mica plate.

Owner:浙江荣泰电工器材股份有限公司

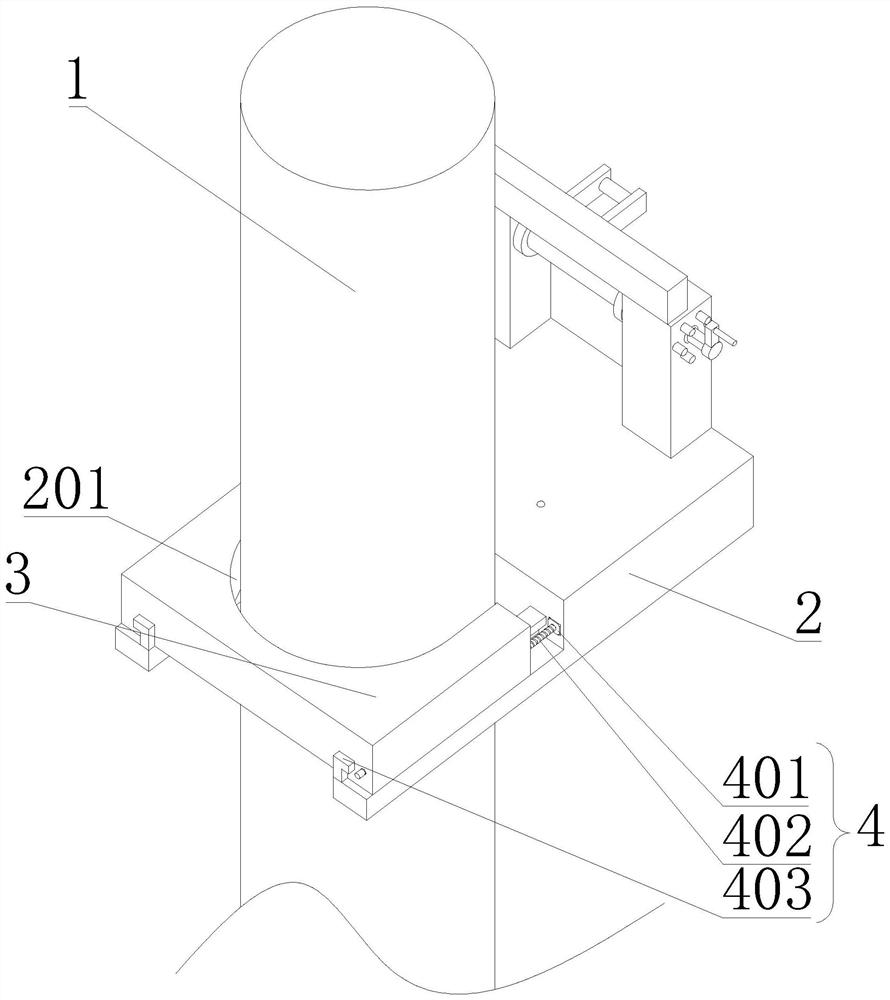

Double-rod type combined transformer rack

ActiveCN112802658AAvoid bringing upReduce labor intensityTransformers/reacts mounting/support/suspensionWinding mechanismsElectric machineTransformer

A double-rod type combined transformer rack comprises a telegraph pole, a mounting frame, a first clamping frame, a connecting frame, a mounting table, a second clamping frame, a rubber wheel, a supporting rod and a take-up mechanism, wherein the first clamping frame is arranged on the mounting frame in a sliding manner; the telegraph pole is located between the first clamping frame and the mounting frame; a first locking mechanism for driving the first clamping frame to move is arranged on the mounting frame; the second clamping frame is arranged on the connecting frame in a sliding manner; the connecting frame is provided with a second locking mechanism used for driving the second clamping frame to move; the mounting table is arranged on the connecting frame and the second clamping frame, and the rubber wheel is rotationally arranged on the mounting table; a third motor for driving the rubber wheel to rotate is arranged on the mounting table; and the supporting rod is arranged on the mounting frame, and the take-up mechanism is arranged on the supporting rod. The third motor drives the rubber wheel to rotate, so that the mounting frame ascends, the mounting frame drives the supporting frame and the take-up mechanism to move, and mounting accessories are conveniently transported to the high altitude through the take-up mechanism.

Owner:SHENYANG HAOCHENG FEICHI ELECTRIC

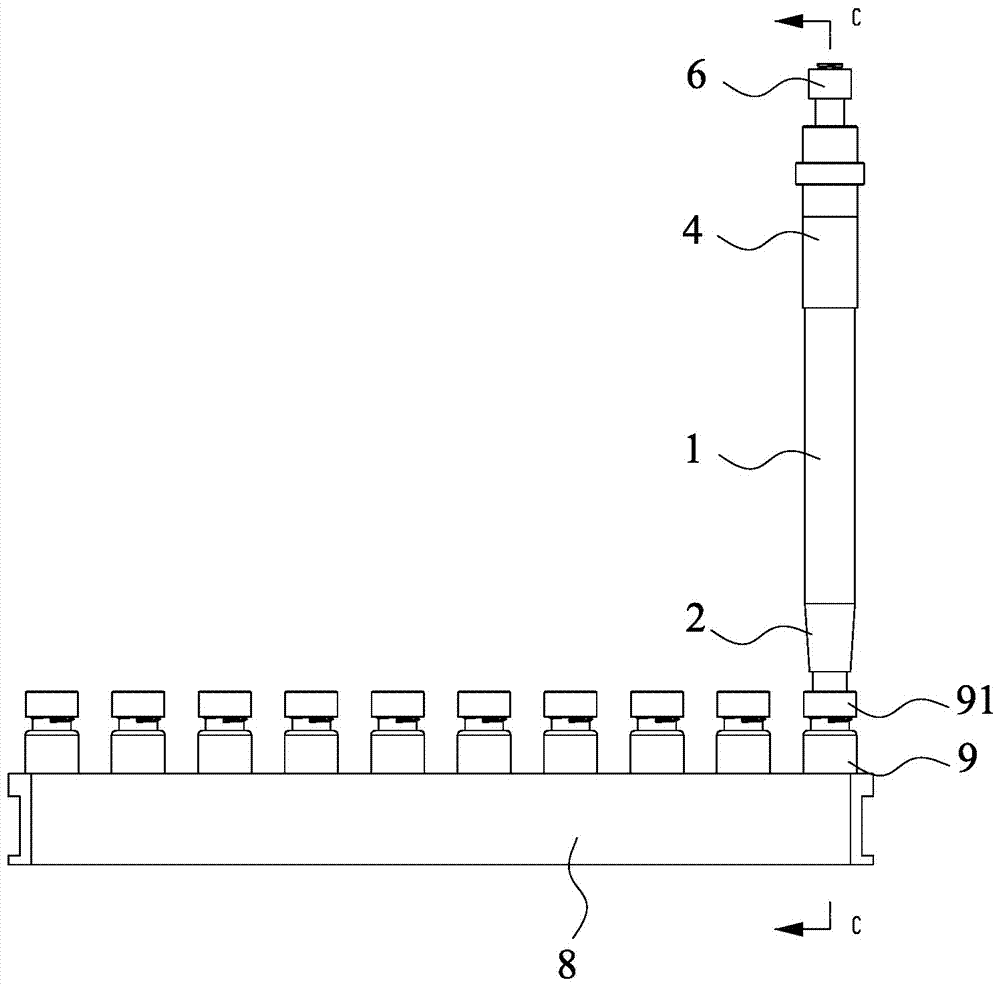

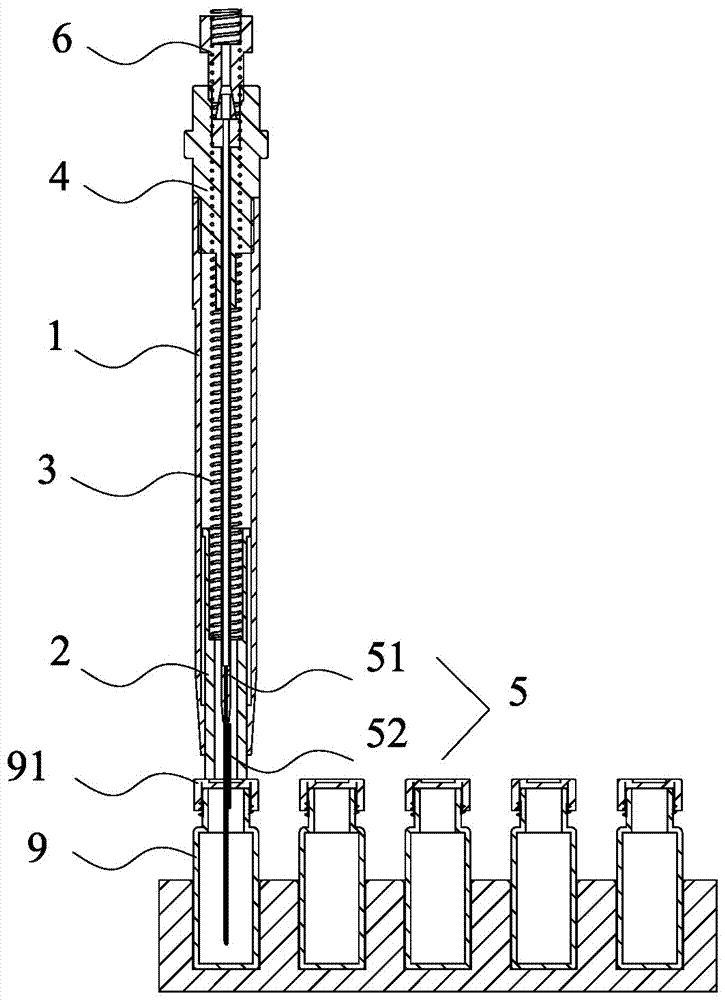

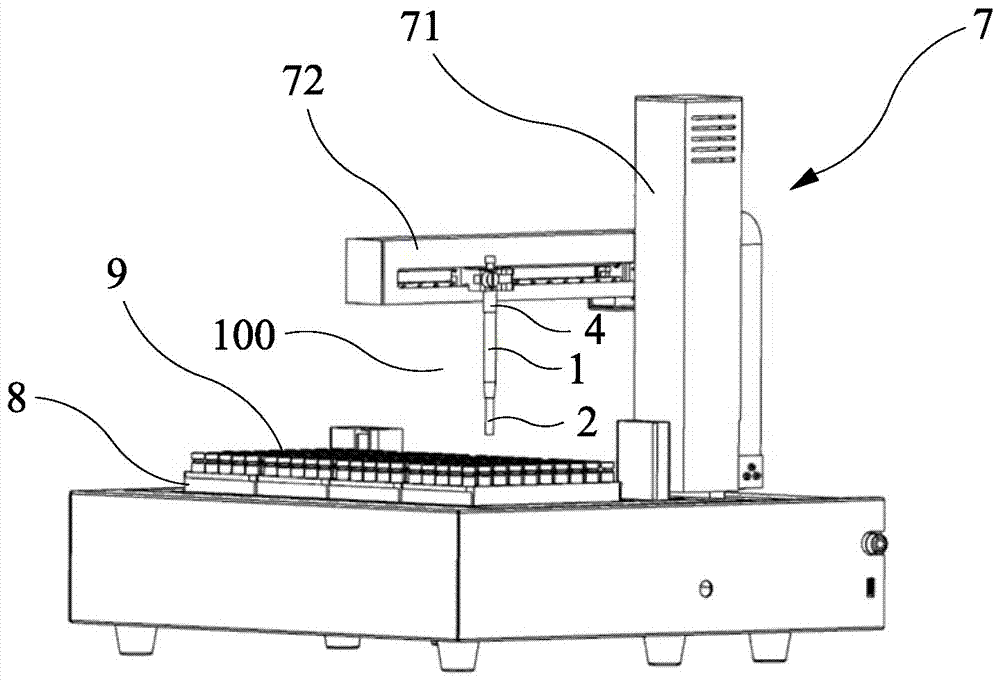

Multichannel plunger pump and using method thereof

The invention provides a multi-channel plunger pump and a using method thereof. The multi-channel plunger pump comprises a pump base unit and a pump head unit. A plurality of conical holes are formedin a locking plate, and the diameters of the conical holes are gradually increased from top to bottom. A locking claw component comprises an integrally-formed locking claw base and a plurality of locking claws located on the locking claw base. The locking claw base is fixed to a driving plate. The locking claws penetrate through driving plate holes, extend to the position above the driving plate and are inserted into the conical holes in the locking plate. The multi-channel plunger pump has the advantages that (1) the pump base unit and the pump head unit are of a split structure, and automatic locking and automatic separation of the pump base unit and the pump head unit are achieved through an automatic locking mechanism; (2) the function of automatically unloading a suction head is realized through a suction head unloading part; (3) the radial automatic aligning function of a plunger is realized through an elastic assembling mode of a plunger component; and (4) effective sealing of aplunger assembly is achieved through multiple sealing modes, and meanwhile the multi-channel plunger pump has the advantages of being good in sealing performance, long in service life, free of maintenance and the like.

Owner:北京罗特思创科技有限公司 +1

Mold for processing plastic products

The invention relates to the technical field of plastic product production, in particular to a mold for processing plastic products. The mold comprises a bottom plate, a fixing plate is fixedly mounted at the top of the bottom plate, a conveying mechanism is arranged on one side of the fixing plate, a bottom mold is hinged to the upper portion of one side of the fixing plate, a jacking mechanism is connected to the lower portion of one end of the bottom mold, and a U-shaped mounting frame is fixedly mounted above the bottom plate. An injection molding machine is fixedly mounted above the U-shaped mounting frame, through openings are symmetrically formed in the two sides of the U-shaped mounting frame, second springs are fixedly connected into mounting grooves, pressing plates are fixedly connected to the lower ends of the second springs, the lower ends of the pressing plates extend into the through openings, rectangular blocks are slidably connected to the side walls of the through openings, and first long blocks are sleeved with the side faces of the rectangular blocks in a penetrating mode. The mold for processing plastic products is reasonable in design, the first long blocks are driven by air cylinders to move upwards, and two mold bodies are driven to move back to back under the action of pressing mechanisms and rolling wheels, so that formed plastic products are conveniently disassembled.

Owner:ZAOZHUANG ZHENGHE BUILDING MATERIAL CO LTD

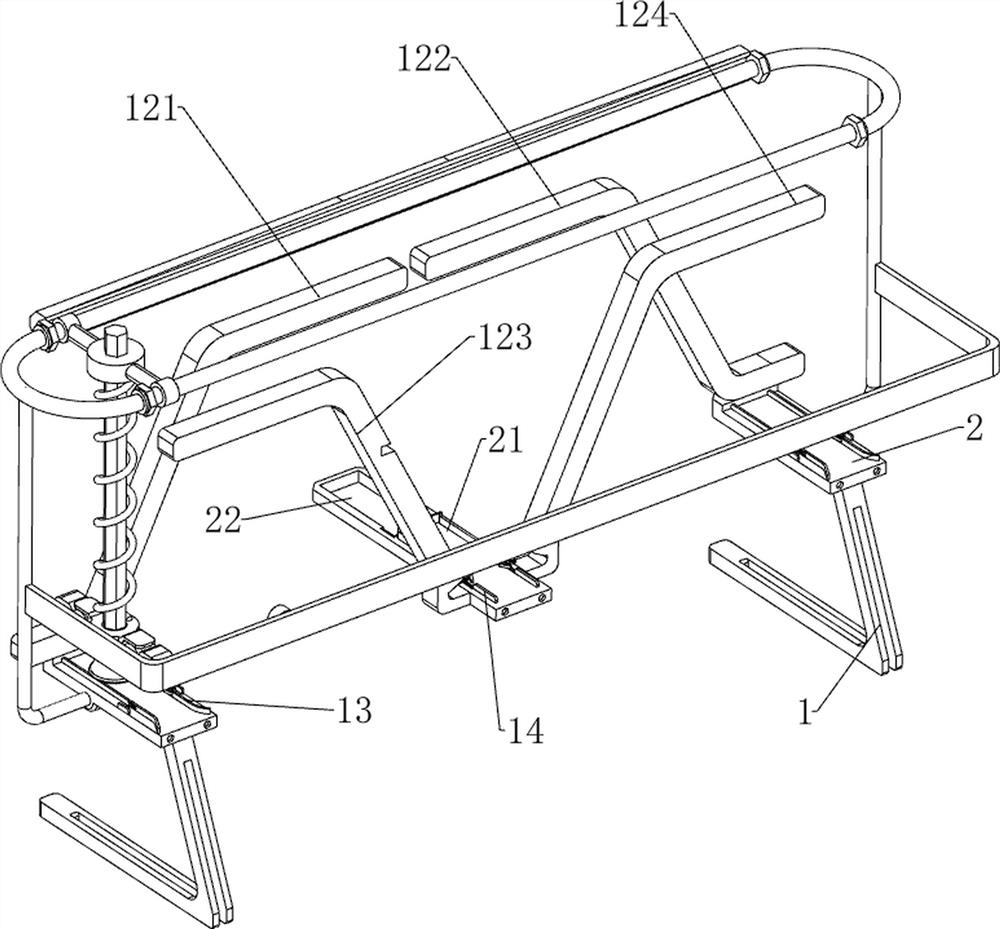

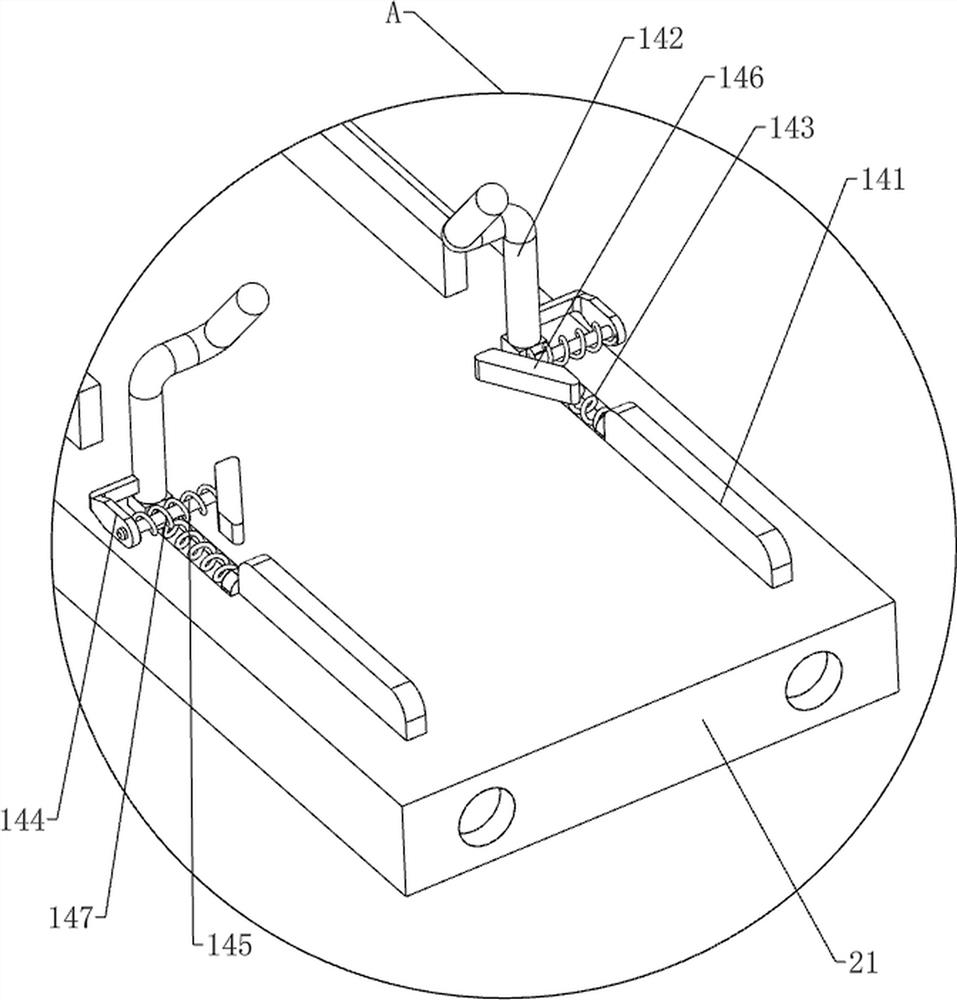

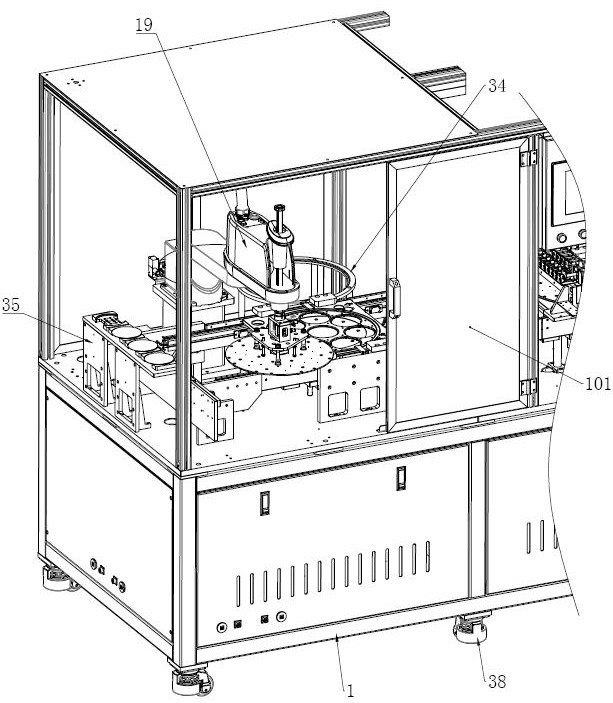

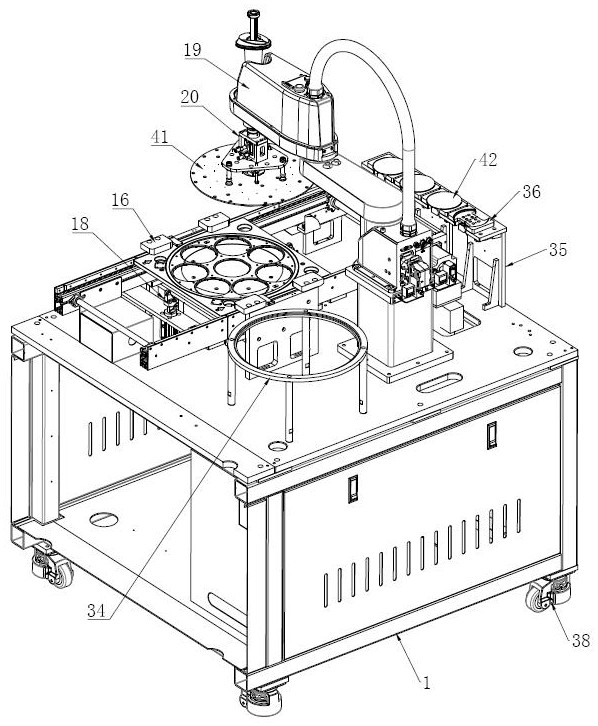

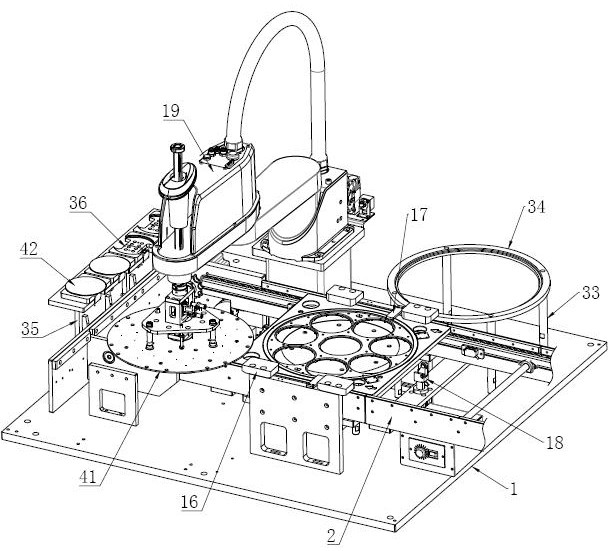

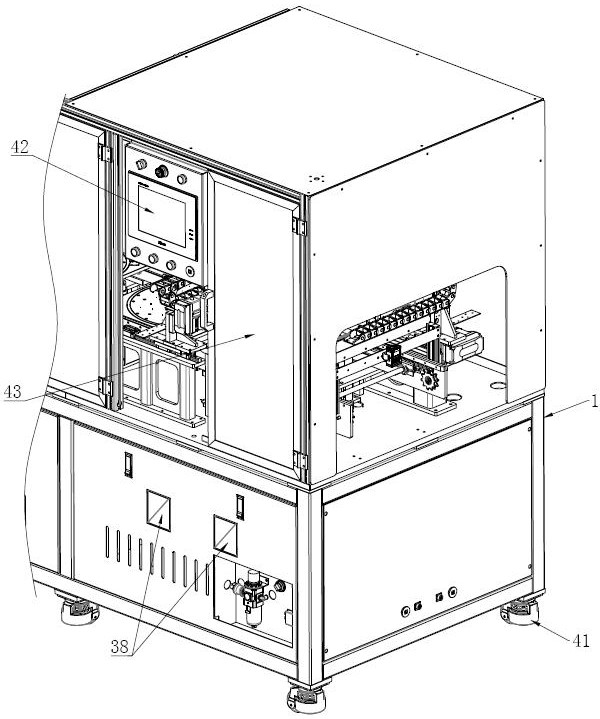

Multi-quantity automatic clamping equipment for producing reagent test boxes

InactiveCN114260855AAvoid pollutionAvoid bringing upMetal-working hand toolsStructural engineeringReagent testing

The invention relates to clamping equipment, in particular to multi-quantity automatic clamping equipment for producing reagent test boxes. The technical problem to be solved by the invention is to provide the multi-quantity automatic clamping equipment for producing the reagent test box, which can prevent reagent cards from being damaged during packaging and can improve the boxing efficiency. In order to solve the technical problem, the invention provides the multi-quantity automatic clamping equipment for producing the reagent test box, which comprises supporting legs, a first supporting plate, a second supporting plate, a baffle plate, a rotating plate and the like, the number of the supporting legs is two, the two supporting legs are bilaterally symmetrical, the tops of the supporting legs on the two sides are both connected with first supporting plates, the first supporting plate on the left side is used for placing a reagent test card, and the first supporting plate on the right side is used for placing a top cover of a reagent test box. When the equipment is used, the rodless cylinder is started to drive the sliding frame to move, and the reagent test card and the top cover can be assembled on the bottom box through cooperation of the swing blocks on the front side and the rear side and the guide rail assembly, and manual assembly by people is not needed.

Owner:李冬梅

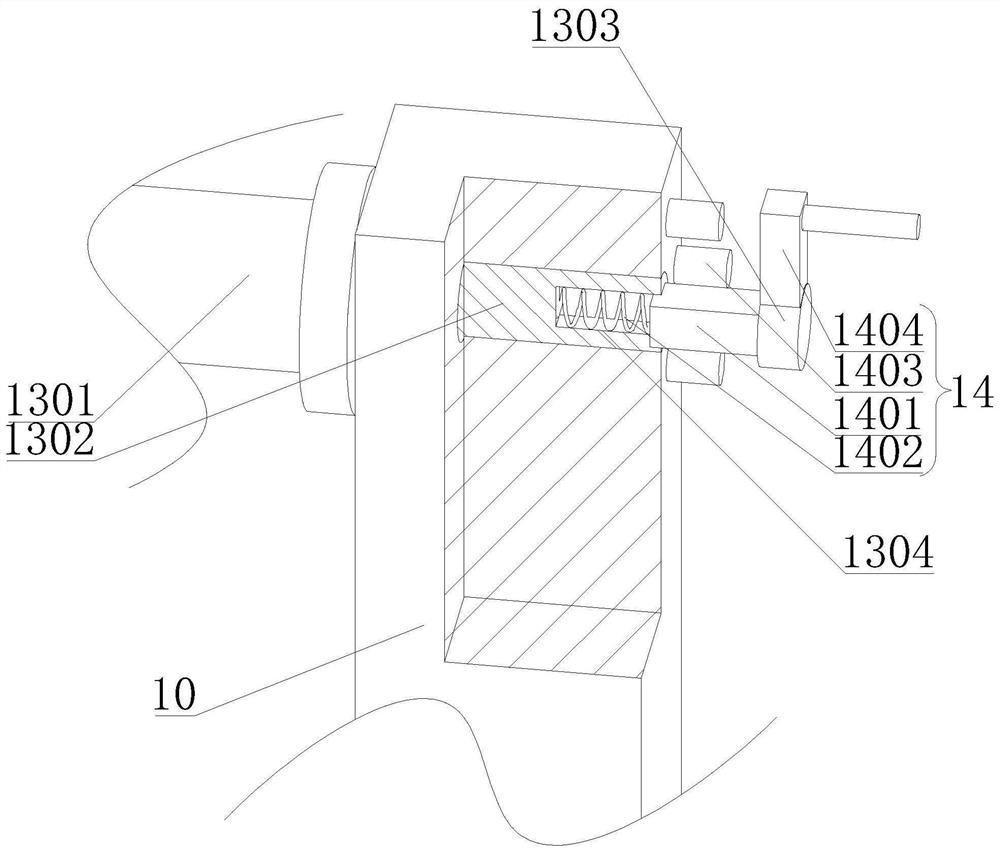

Automatic spring puncture needle sampling structure

Owner:RAYKOL GROUP XIAMEN CO LTD

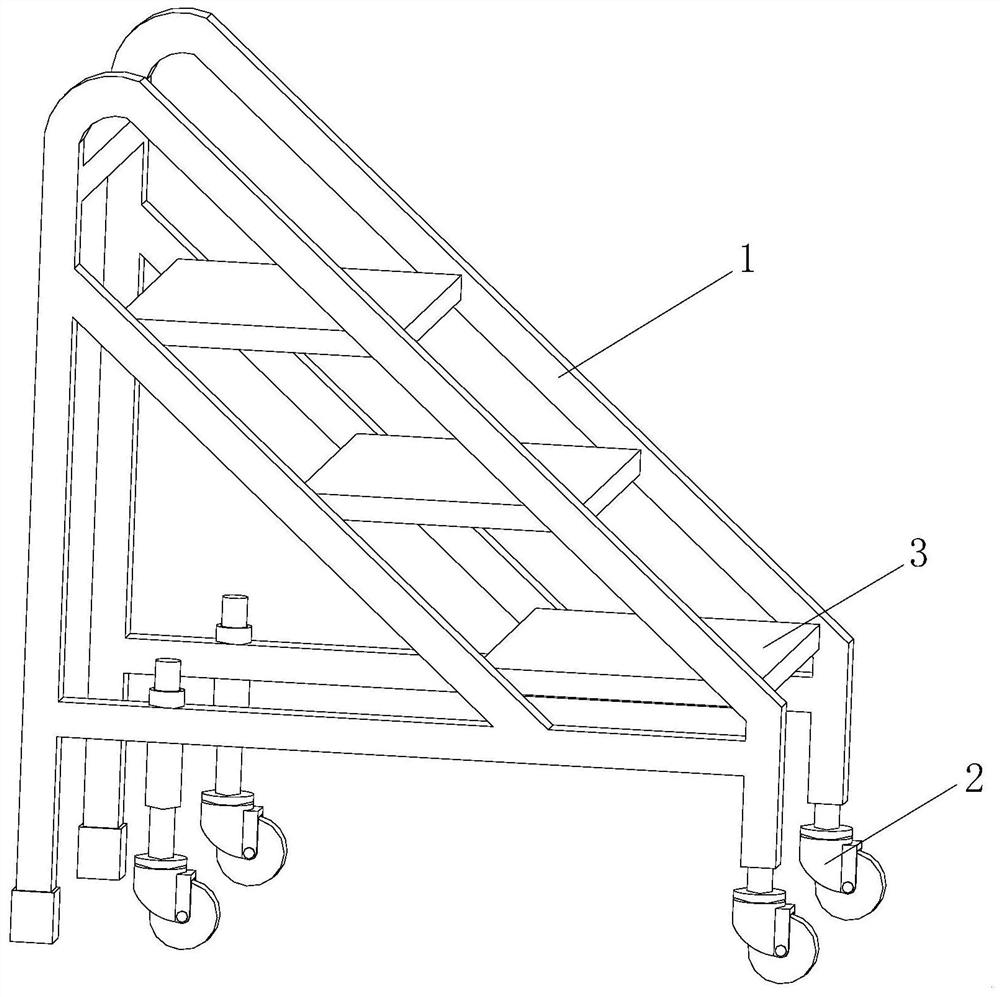

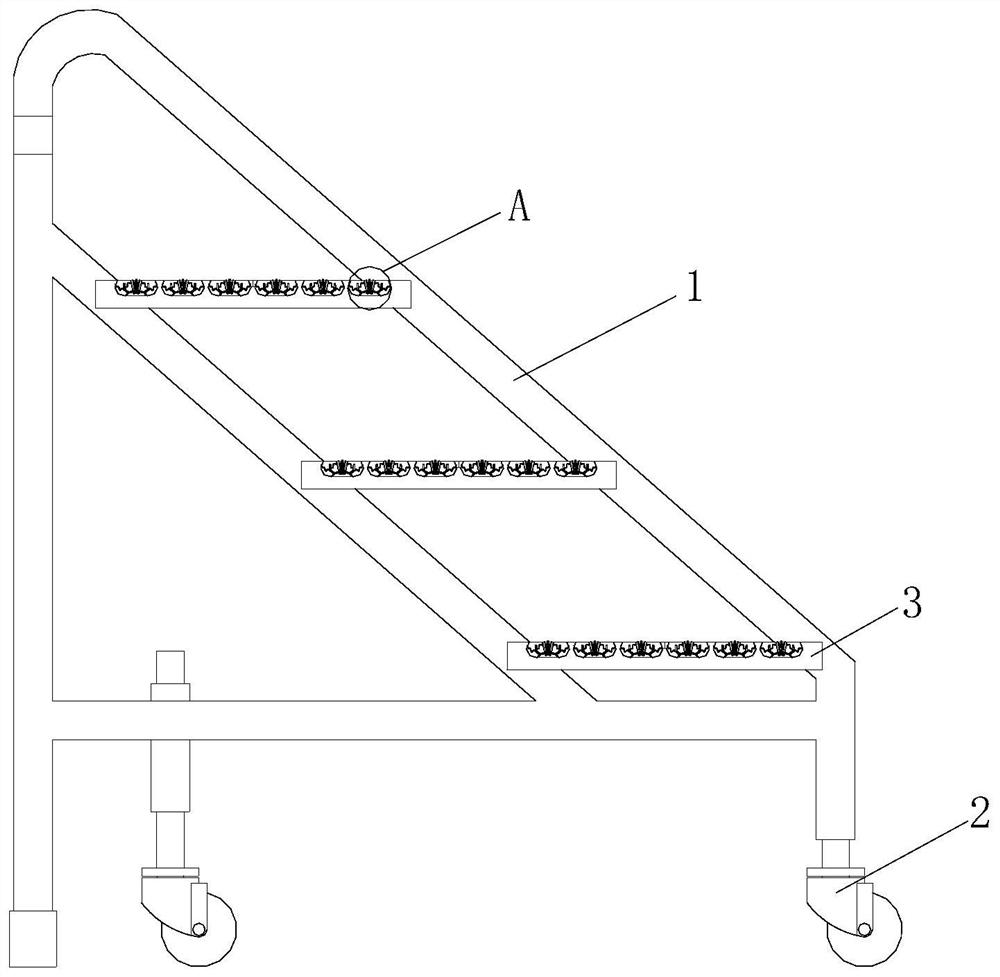

Ladder for file management

InactiveCN113982464AAvoid dust accumulationAvoid accumulationLaddersEngineeringStructural engineering

The invention discloses a ladder for file management, and relates to the technical field of ladder tools for climbing. The ladder for file management comprises a ladder frame, universal wheels are fixedly installed at the bottom of the ladder frame, a transverse pedal is fixedly installed on the inner side of the front face of the ladder frame, a transmission mechanism is fixedly installed at the top of the transverse pedal, a dust collection mechanism is arranged at the top of the transverse pedal, and the dust collection mechanism is arranged on the outer side of the transmission mechanism. The transmission mechanism comprises a movable plate, a movable rod, rebound rubber, a friction piece and a movable groove, the movable plate is movably installed at the top of the transverse pedal through an elastic piece, and the movable rod is movably installed in the center of the bottom of the movable plate. According to the ladder for file management, the transmission mechanism is arranged to be matched with the dust collection mechanism, when the ladder is used, dust on the tops of the transverse pedals is adsorbed, dust carried by soles of a user is prevented from being accumulated on the surfaces of the transverse pedals, and therefore dust accumulation on files due to dust flying is avoided.

Owner:于灏

Soft and hard screen dual-purpose laminating machine and laminating process thereof

PendingCN114132791AAuxiliary easy-to-tear stickersFunctionalPolarising elementsArticle unpackingFilm materialEngineering

The invention discloses a soft and hard screen dual-purpose laminating machine and a laminating process thereof.The soft and hard screen dual-purpose laminating machine comprises a polaroid feeding mechanism, a material taking mechanism, a laminating platform, a detecting and cleaning mechanism, a film tearing mechanism and a laminating mechanism, the polaroid feeding mechanism is arranged on a machine table, and the material taking mechanism is arranged on one side of the polaroid feeding mechanism; the surface mounting platforms are arranged on the side part of the polaroid feeding mechanism at intervals, and a glass substrate to be subjected to surface mounting is placed on the surface mounting platforms; the detecting and cleaning mechanism is erected above the surface mounting platform; the surface mounting mechanism stretches across the machine table and is erected between the surface mounting platform and the polaroid feeding mechanism; the film tearing mechanism is arranged on one side of the surface mounting mechanism and is used for tearing off a film material on the surface of the glass substrate placed on the surface mounting platform and a film material at the bottom of the polaroid. According to the polaroid laminating machine, automatic feeding and transferring, surface detecting and film tearing of polaroids are achieved, a roller belt type laminating mode and a pressing roller laminating mode are integrated, the hard screen and flexible screen compatible function is achieved, universality is high, and laminating bubbles are well reduced.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

Punching device and multi-station punching machine

ActiveCN107932619AHigh punching thicknessSave energyLeather clicking/perforating/clickingMetal working apparatusPunchingEngineering

The invention discloses a punching device and a multi-station punching machine and belongs to the field of processing of leather. The punching device comprises an air cylinder, a punching cutter connection rod, a punching cutter pressing plate, a rotary driving rod, a punching cutter and a driven gear, wherein the air cylinder is provided with a piston rod; the upper end and the lower end of the piston rod extend out of the air cylinder; the upper ends of the piston rod and the punching cutter connection rod are connected with the punching cutter pressing plate; the punching cutter connectionrod is capable of rotating relative to the punching cutter pressing plate; the punching cutter is mounted at the lower end of the punching cutter connection rod; the driven gear comprises gear teeth and a shaft sleeve; the gear teeth are distributed along the circumferential direction of the outer side of the shaft sleeve; the shaft sleeve sleeves the lower part of the punching cutter connection rod; at least one sliding groove is formed in the shaft sleeve along an axial direction; one end of the rotary driving rod is located in the sliding groove; the other end of the rotary driving rod is fixed on the punching cutter connection rod. When the device operates, the rotating feeding and the punching feeding of the punching cutter are carried out simultaneously, so that the punching thickness is higher; the maximum punching thickness can reach 15mm according to different materials; a plurality of punching devices are combined to form a multi-station punching machine; the multi-station simultaneous processing can be achieved; the efficiency is improved.

Owner:DONGGUAN EMMA CNC TECH CO LTD

Die cutting device for conductive cloth indentation lines

PendingCN109545472AImprove toughnessFast reboundApparatus for manufacturing conducting/semi-conducting layersFormation of corrugations on cables/conductorsEngineeringSilica gel

The invention relates to a die cutting device for conductive cloth indentation lines. The die cutting device is used for carrying out die cutting on indentation lines on a conductive cloth material strip, and comprises an upper die base and a lower die base which is arranged below the upper die base and matched with the upper die base. The lower surface of the upper die base is provided with an indentation line cutter, and the lower die base is provided with a silicone pad matched with the indentation line cutter and a material blocking mechanism matched with the conductive cloth material strip. Compared with the prior art, through arranging the silicone pad on the lower die base, the conductive cloth material strip and the indentation line cutter are supported flexibly from below, the indentation line cutter is ensured to be capable of being pressed into the conductive cloth material strip completely, so that the depth of the indentation lines is obvious, the compactness is good, therebound speed is slow, the imprint is not prone to recede and disappear, the retention is good, and the conductive cloth material strip can be effectively prevented from being lifted by the indentation line die cutter, thereby ensuring the normal proceeding of the continuous die cutting process.

Owner:上海昊佰智造精密电子股份有限公司

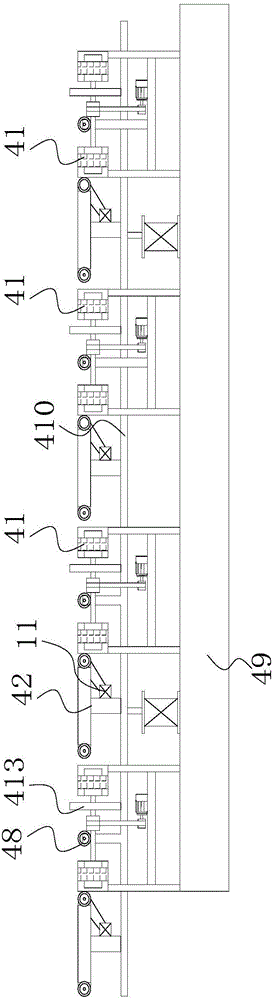

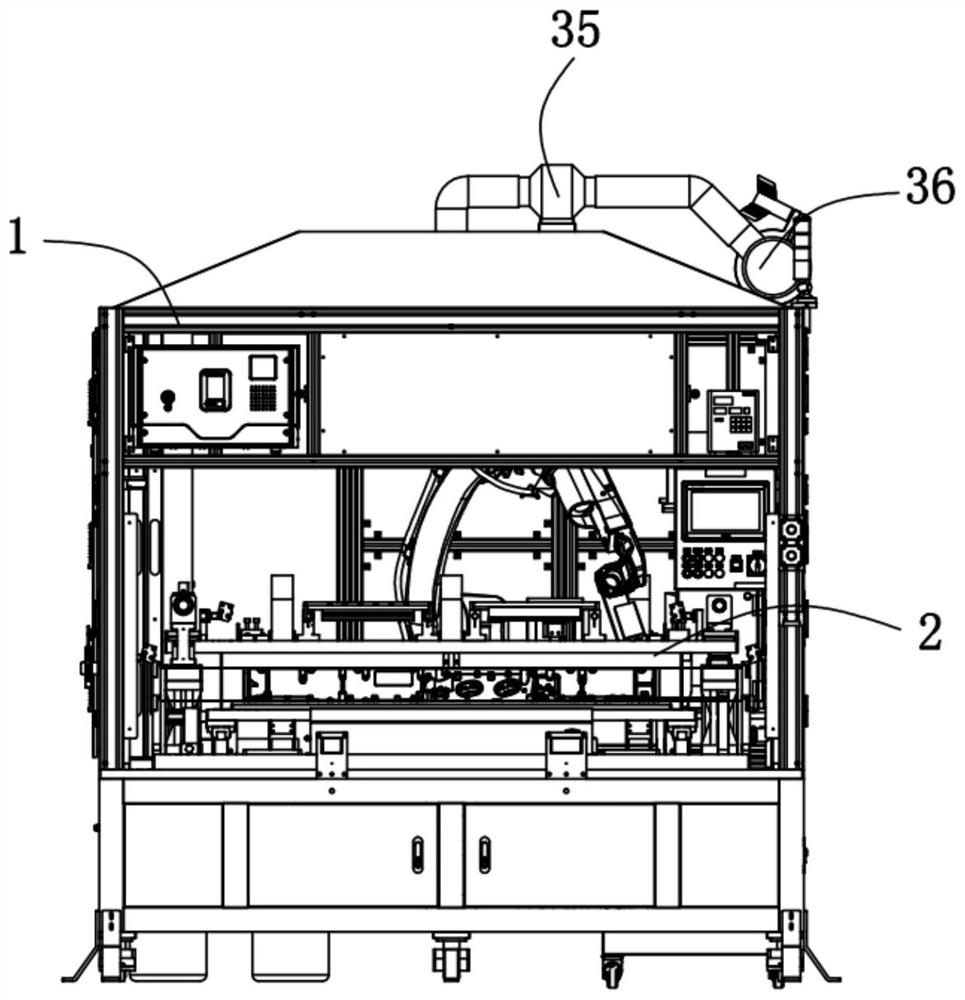

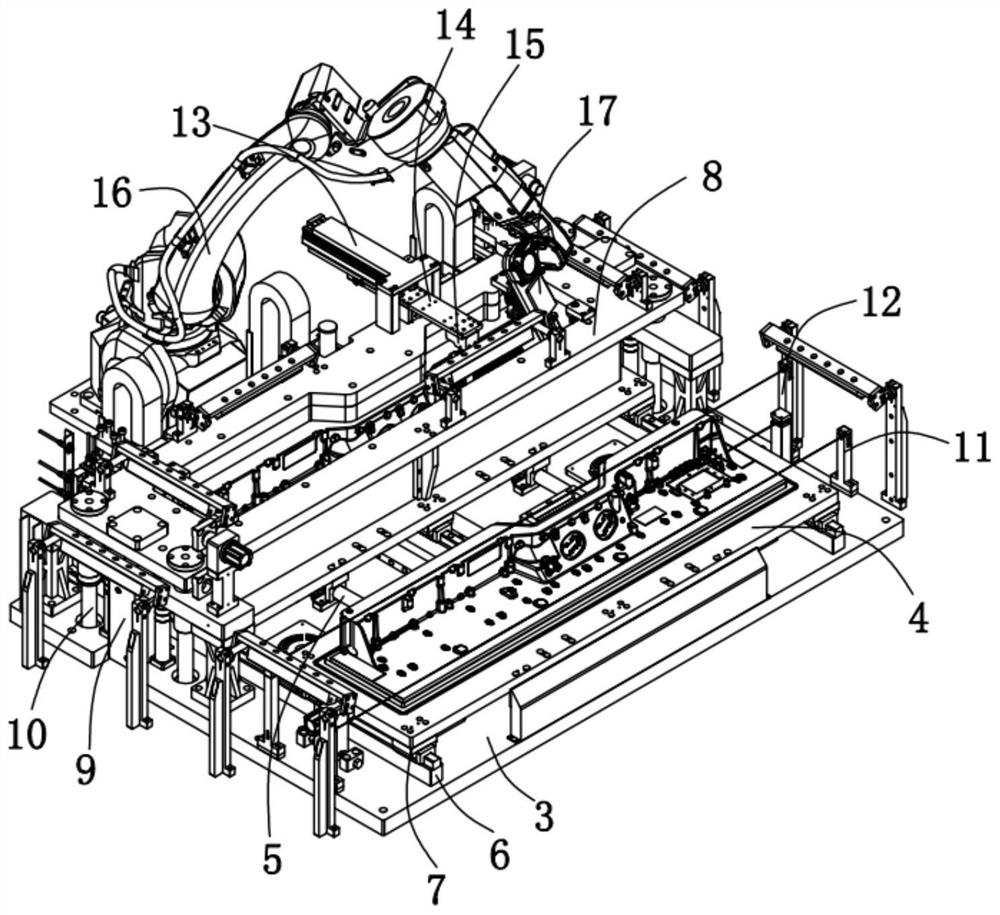

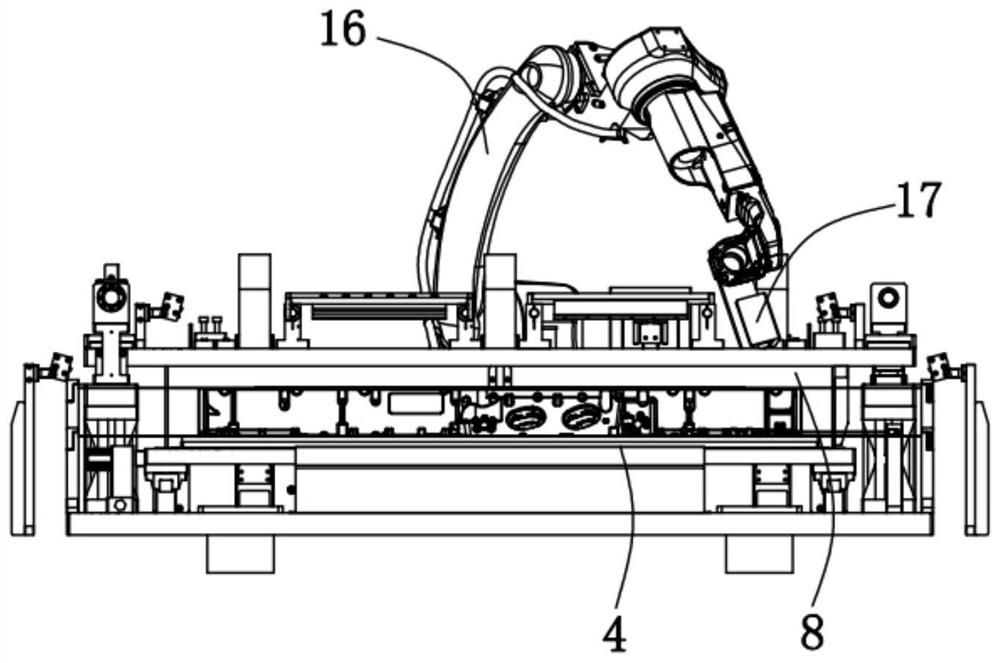

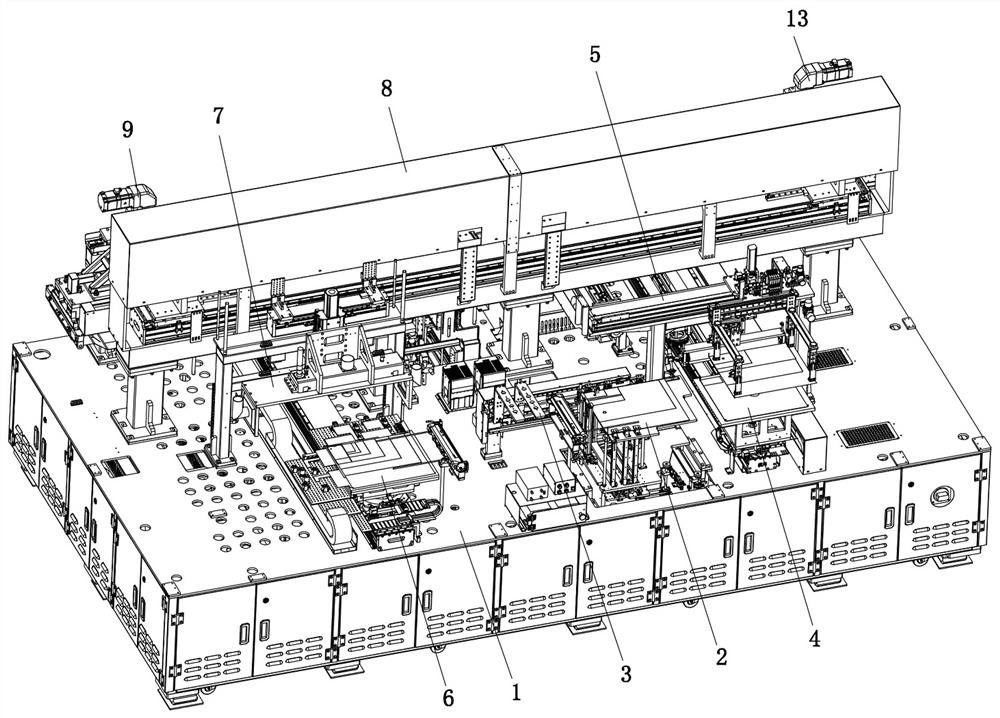

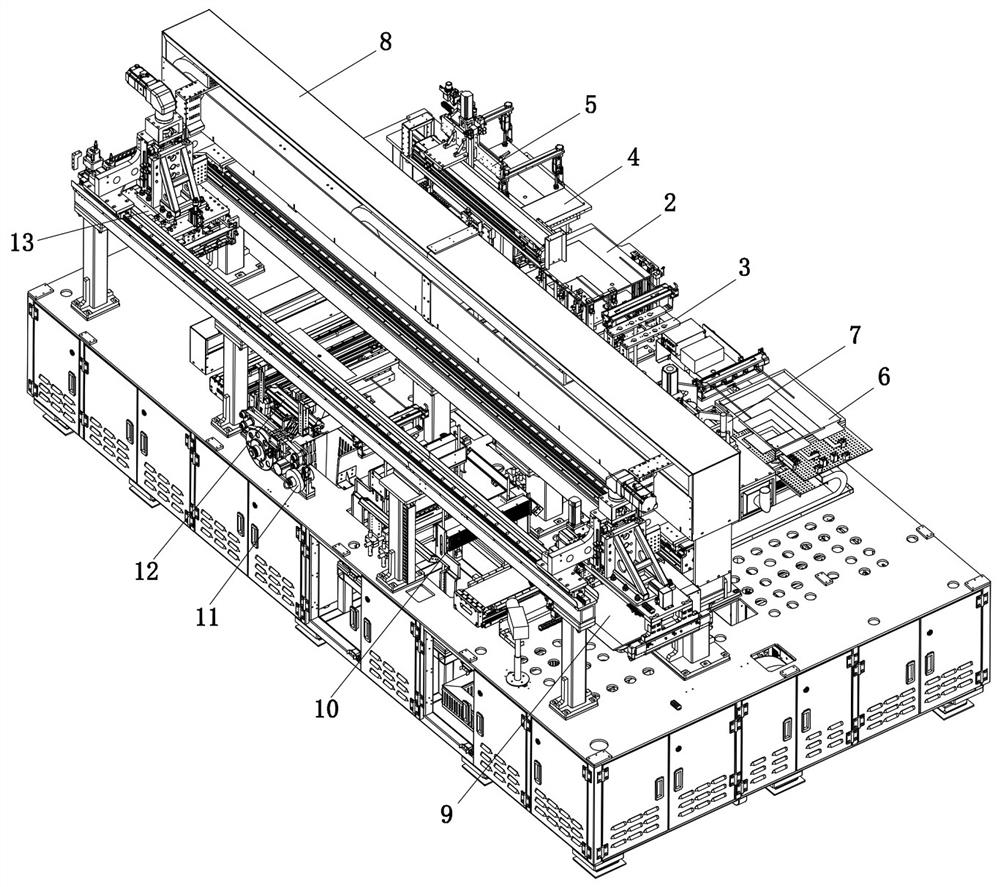

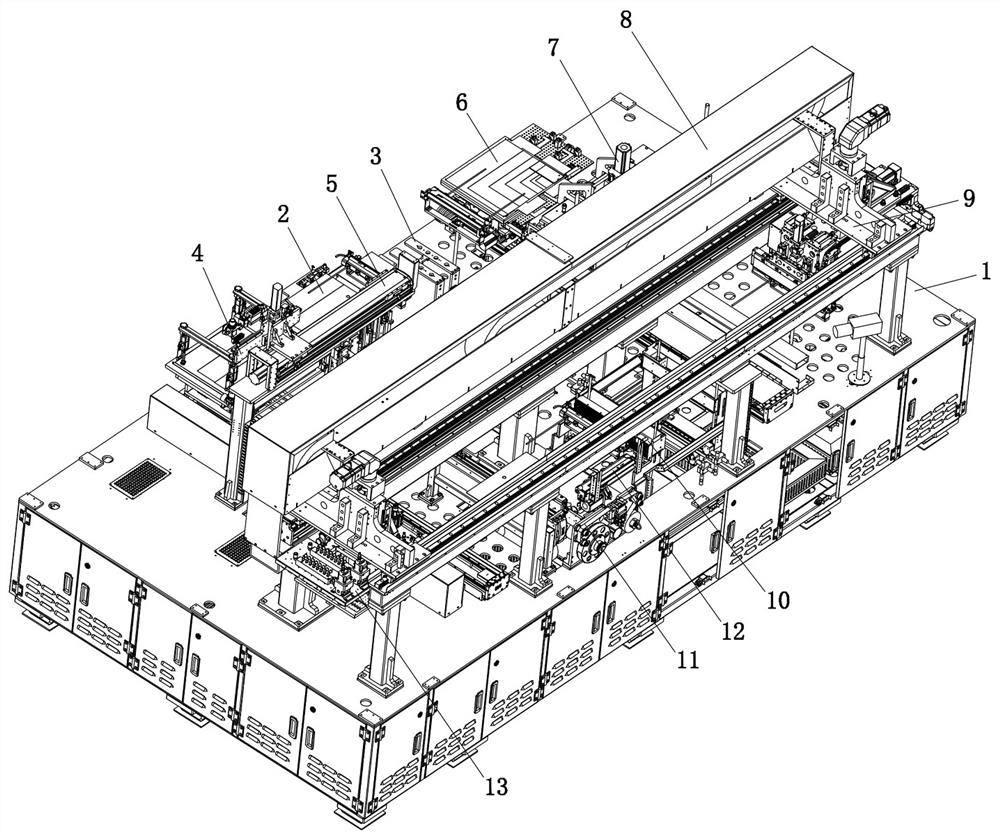

Pick-and-place device for automatic wafer unloading

ActiveCN112420578AAchieve pre-positioningRealize fine positioningSemiconductor/solid-state device manufacturingConveyor partsWaferTransfer line

The invention belongs to the technical field of wafer unloading and provides a taking and placing device for automatic wafer unloading. The taking and placing device comprises a rack, a speed chain conveying line, a carrier positioning mechanism, a taking and placing mechanical arm, a cover plate placing table and a wafer placing table are arranged on the rack, wherein a blocking cylinder is arranged on the speed chain conveying line; the taking and placing mechanical arm and the cover plate placing table are both located on one side of the speed chain conveying line, a taking and placing mechanism is arranged at the shaft end of the taking and placing mechanical arm, and the wafer placing table is located at one end of the speed chain conveying line; the material taking and placing mechanism comprises an installation frame installed on a working shaft of the taking and placing mechanical arm, a Bernoulli suction cup driven by a piece taking air cylinder is installed on the installation frame, a suction nozzle installation plate is further installed at the bottom of the installation frame, and a plurality of cover plate suction nozzles are installed at the bottom of the suction nozzle installation plate. Compared with a traditional manual wafer taking mode, wafer taking efficiency is greatly improved, the phenomenon that the wafer is accidentally scratched in the wafer discharging process is effectively avoided, and it is guaranteed that the quality and the percent of pass of the wafer are not affected in the wafer discharging process.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

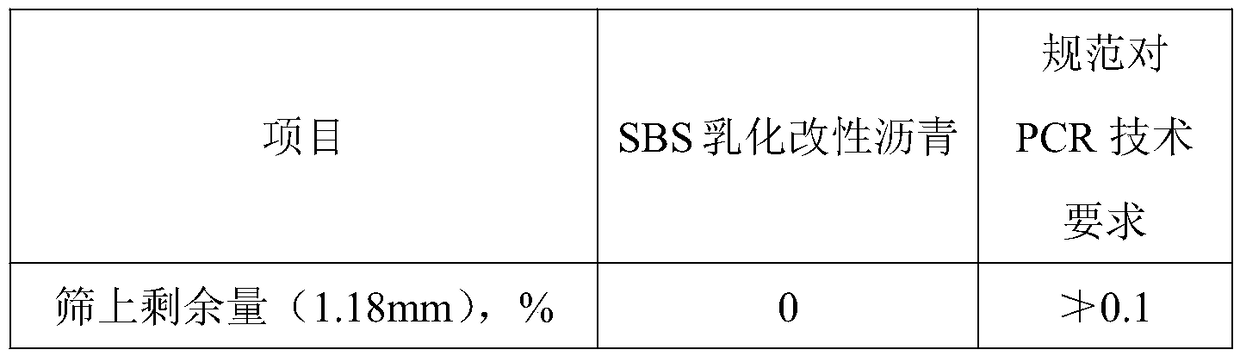

Non-stick wheel modified emulsified asphalt and preparation method thereof

The invention relates to a wheel sticking prevention SBS modified emulsified asphalt used for tack coat. The wheel sticking prevention SBS modified emulsified asphalt is prepared from, by weight, 100-120 parts of asphalt, 1-3 parts of furfural extract oil, 3-5 parts of an SBS high-molecular polymer modifier, 0.3-0.5 parts of a quick-cracking and quick-setting emulsifier, 0.1 parts of an emulsified asphalt stabilizer, 2-5 parts of an organosilicone resin interface reinforcing agent and 100 parts of water. The SBS high-molecular polymer modifier, the quick-cracking and quick-setting emulsifier and the organosilicone resin interface reinforcing agent added to the wheel sticking prevention modified emulsified asphalt commonly improve the pavement performance and the construction performance of the modified emulsified asphalt used for tack coat, make the modified emulsified asphalt be suitable for being used in roads, and can prolong the service life of the roads.

Owner:TIANJIN HIGHWAY ENG GENERAL

Multi-stroke anti-dust pulse bag type dust removal equipment

ActiveCN108404543BAvoid bringing upWill not affect dust removal efficiencyGas treatmentDispersed particle filtrationIsosceles trapezoidThermodynamics

Owner:唐山市灯塔水泥有限公司

Metal packaging structure and preparation method, packaging method of display panel, display device

ActiveCN107785503BAvoid bringing upImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingSilanesDisplay device

The invention provides a metal packaging structure and preparation method, a packaging method of a display panel, and a display device, and relates to the field of display technology, which can significantly improve the adhesion between the metal film and the adhesive layer, and avoid the need to protect the protective film on the surface of the adhesive layer. The adhesive film is lifted up during peeling to reduce production costs and improve production yield. The preparation method includes: providing a metal film, the metal film has an opposite first surface and a second surface; forming a silane film on the first surface; the surface of the silane film far away from the metal film has active groups a group; attaching the first surface formed with the silane film to the adhesive layer, so that the active groups react with the adhesive layer to combine.

Owner:BOE TECH GRP CO LTD +1

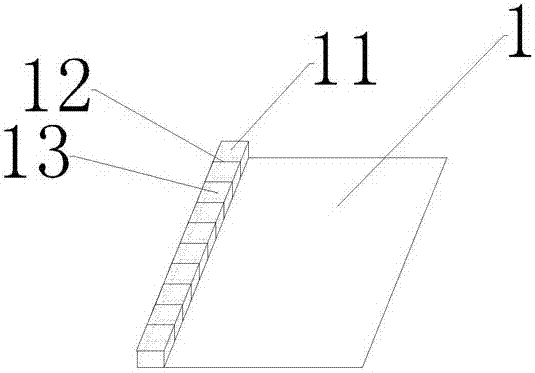

A tear-free cleaning plastic baffle

The invention discloses a tearable cleaning-free plastic baffle. A plurality of layers of tearable films are overlaid on a base plate. The side edges of the tearable films are provided with tear strips used for tearing the tearable films away from the base plate. The tear strips on the tearable films are sequentially arranged in a staggered manner along the side edge from top to bottom. The side edge, on the same side with the tear strips, of the base plate is provided with a protective device used for holding the tear strips. One side of the protective device is open, wherein the tear strips can be placed in the protective device through the open side. The opening faces the base plate. Partition plates are arranged in the protective device and used for separating the tear strips. Broken lines capable of being snapped are arranged at the intersection position between the partition plates and the upper surface of the protective device. The tearable cleaning-free plastic baffle has the advantages of being convenient to use and avoiding misalignment after tearing.

Owner:邱宏声

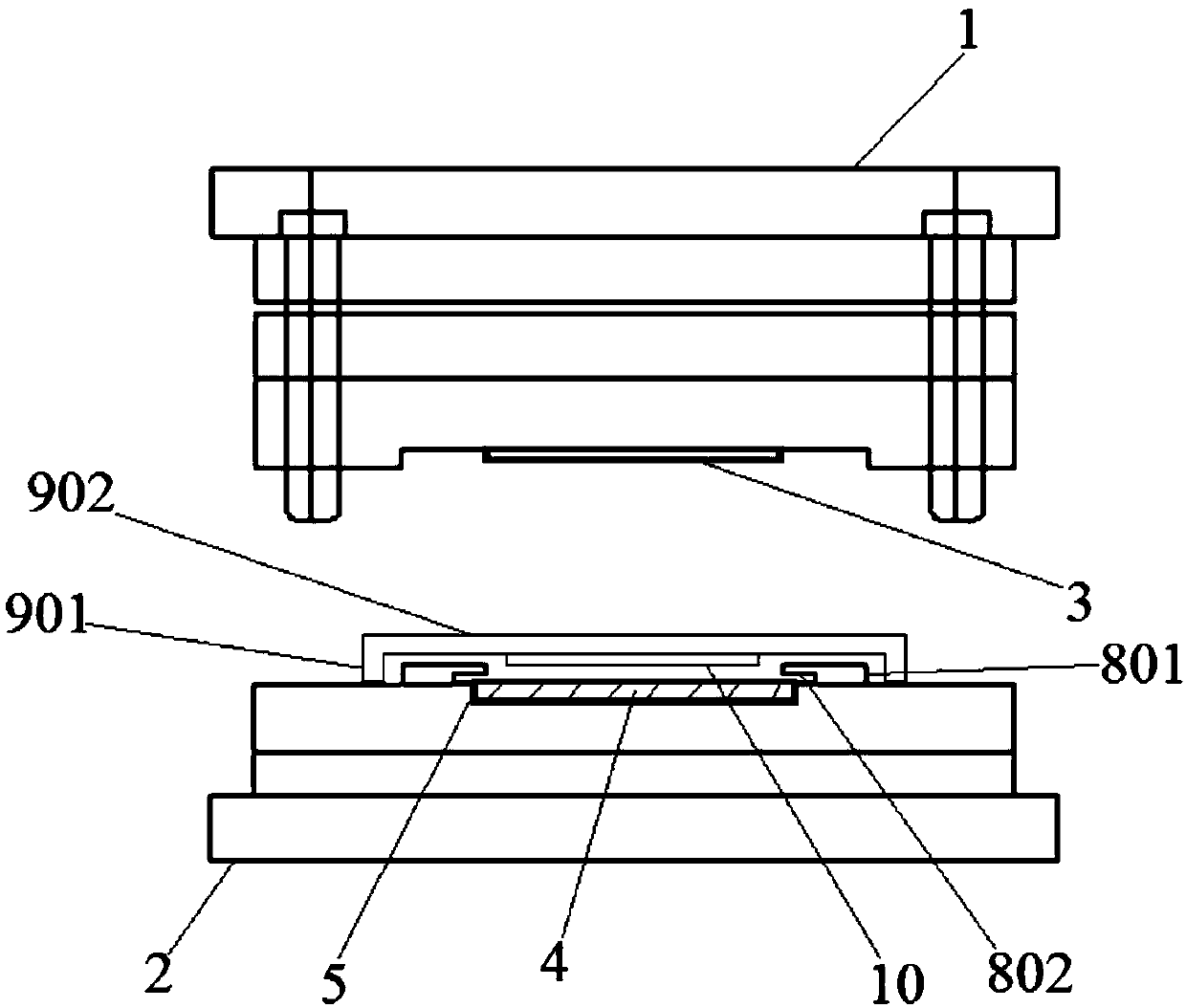

A wafer carrier automatic unscrewing device

ActiveCN112404945BAvoid injury accidentsImprove work efficiencyMetal working apparatusWaferEngineering

The invention belongs to the technical field of wafer unloading, and provides an automatic unloading screw device for a wafer carrier, including a frame on which a double-speed chain conveying line, a carrier positioning mechanism and an automatic screw unloading mechanism are provided, and the double-speed chain conveying There are blocking cylinders on the line, and the blocking cylinders are respectively set at both ends of the carrier positioning mechanism. The automatic screw down mechanism is located above the carrier positioning mechanism; the carrier positioning mechanism includes a lifting pallet driven by a piston cylinder. Positioning pins, there are pallet limiters and cover plate limiters on both sides of the double-speed chain conveyor line. When in the positioning state, the wafer carrier is positioned and clamped between the lifting pallet, the tray limiter, and the cover plate limiter. space, and the tray limit block extends to the tray setting of the wafer carrier, and the cover plate limit plate extends to the cover plate setting. The present invention can realize the automatic unscrewing of the wafer carrier, not only realizes the effective replacement of manual labor, but also greatly improves the work efficiency, and avoids the occurrence of damage accidents to the material tray or the internal wafer.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

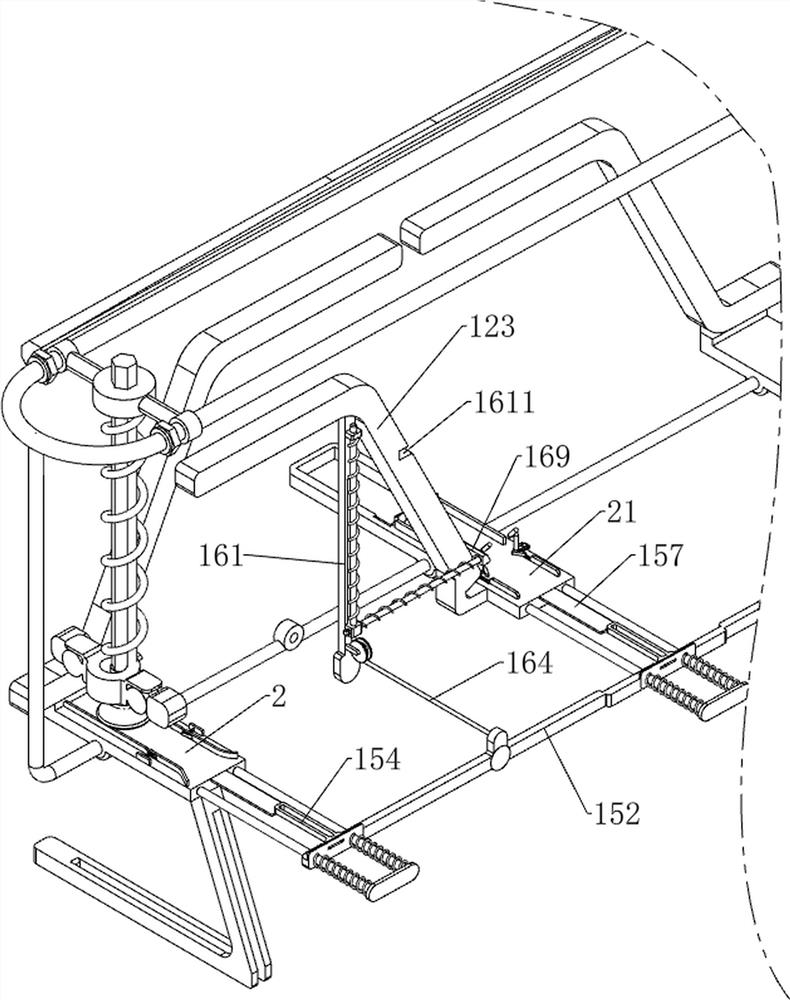

A blood collection tube rotary pressing device

ActiveCN105758698BReduce labor intensityAvoid bringing upPreparing sample for investigationSensorsBlood Collection TubeEngineering

The invention discloses a blood collection tube rotating and compressing device. The blood collection tube rotating and compressing device comprises a driving mechanism, a pushing plate, a first sliding block, a second sliding block, a rotating mechanism, a compressing mechanism, a first elastic piece and a second elastic piece; the pushing plate moves vertically under the driving of the driving mechanism; the first sliding block and the second sliding block move vertically under the driving of the pushing plate; the rotating mechanism is used for vibrating a blood collection tube; the compressing mechanism is used for pressing the blood collection tube; the first elastic piece is used for connecting the driving mechanism and the first sliding block; the second elastic piece is used for connecting the driving mechanism and the compressing mechanism. When blood is sampled, the rotating mechanism and the compressing mechanism work under the control of the driving device; a blood sample is vibrated uniformly through the rotating mechanism; meanwhile, the blood collection tube is prevented from being pulled when a puncture needle is pulled out because of the action of the compressing mechanism. According to the blood collection tube rotating compressing device, the labour intensity caused by vibrating and compressing the blood collection tube manually is avoided; the sampling requirements of the blood collection tubes with different lengths can be met, so that a sampling process is simple and convenient, the labour intensity is reduced, and the work efficiency is improved.

Owner:SHENZHEN GOLDSITE DIAGNOSTICS

Tearable cleaning-free plastic baffle

The invention discloses a tearable cleaning-free plastic baffle. A plurality of layers of tearable films are overlaid on a base plate. The side edges of the tearable films are provided with tear strips used for tearing the tearable films away from the base plate. The tear strips on the tearable films are sequentially arranged in a staggered manner along the side edge from top to bottom. The side edge, on the same side with the tear strips, of the base plate is provided with a protective device used for holding the tear strips. One side of the protective device is open, wherein the tear strips can be placed in the protective device through the open side. The opening faces the base plate. Partition plates are arranged in the protective device and used for separating the tear strips. Broken lines capable of being snapped are arranged at the intersection position between the partition plates and the upper surface of the protective device. The tearable cleaning-free plastic baffle has the advantages of being convenient to use and avoiding misalignment after tearing.

Owner:邱宏声

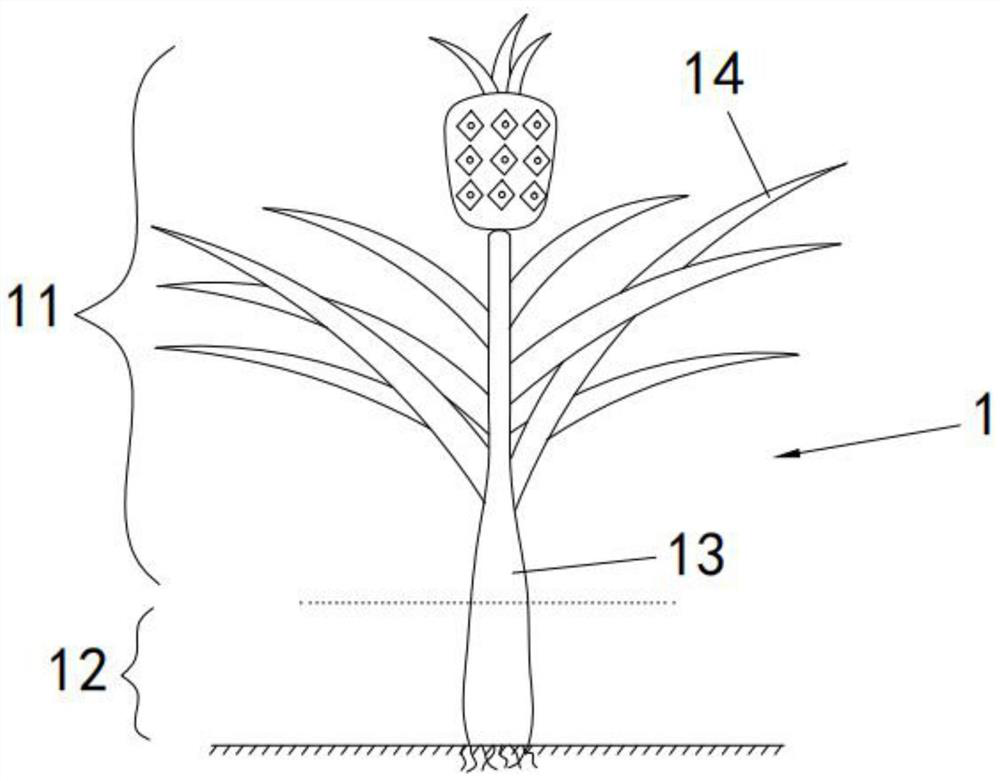

Mechanical two-step harvesting process for pineapple stems and leaves

The invention discloses a mechanical two-step harvesting process for pineapple stems and leaves, which comprises the following steps: (a) cutting pineapple plants into upper sections and lower sections by using a rotary knife type cutting device, and harvesting the upper sections of the pineapple plants; and (b) moving the lower sections of the pineapple plants out of the soil through equipment, and harvesting the lower sections of the pineapple plants. The pineapple plants are cut through the rotary knife type cutting device, rotary knife type cutting can reduce resistance brought by pineapple stems to the cutting device, the whole pineapple plants are prevented from being taken up, and therefore a large amount of soil is prevented from being mixed on the pineapple stems and leaves. besides, the upper sections of the pineapple plants are preliminarily harvested, the upper sections comprise most of pineapple leaves, the upper sections of the pineapple plants are not mixed with soil, and excessive treatment is not needed after harvesting; and then the lower sections of the pineapple plants are harvested, the lower sections of the pineapple plants are mainly pineapple stems and a small part of pineapple leaves, even if the pineapple stems and the pineapple leaves are mixed with soil, the soil can be easily separated out, and the follow-up treatment cost is reduced.

Owner:徐闻昊草农业有限公司

Precipitation-type cutting fluid collecting device for numerical control machining center and using method thereof

InactiveCN112138851AAvoid bringing upCutting effect is smallWet separationNumerical controlHydraulic cylinder

The invention discloses a precipitation-type cutting fluid collecting device for a numerical control machining center and a using method thereof. The precipitation-type cutting fluid collecting devicecomprises a frame body, wherein a sliding rail is arranged at the top of the frame body, a collection pipe is arranged on the sliding rail in a matched mode, and a driving mechanism is connected withthe collection pipe; a plurality of precipitation tanks are arranged below the bottom of the collection pipe side by side; the top of each precipitation tank is connected with an overflow nozzle; a collecting tank is arranged on one side of the precipitation tanks; an ultrasonic liquid level meter is arranged on the outer wall of the bottom of the collection pipe; a plurality of detection mechanisms for detecting and identifying a position of the collection pipe are further arranged at the top of the frame body; a stop switch is further arranged at one end of the frame body, and the collection pipe automatically returns to an initial position after touching the stop switch; a piston plate is arranged in each precipitation tank in a matched mode, and the bottom of each piston plate is connected with a hydraulic cylinder; and the whole device further comprises a controller. According to the device, the plurality of precipitation tanks are arranged, so that impurities in cutting fluid can be fully precipitated, and the problem that the precipitated impurities are stirred up again by liquid stirring caused when the cutting fluid is injected during precipitation in one tank is also avoided.

Owner:ZIBO HIGH TECH ZONE CHENGDA MACHINERY DESIGN INST

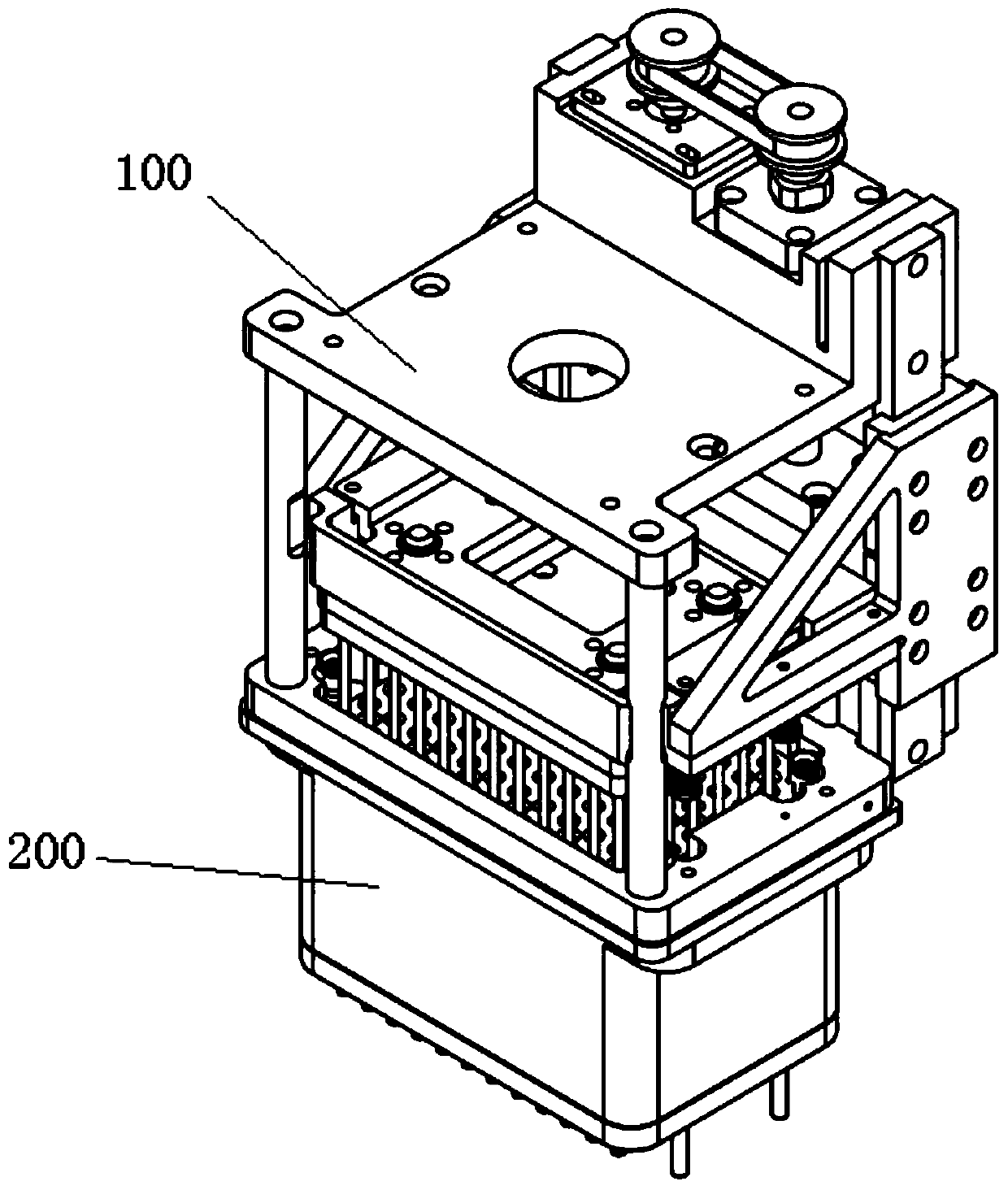

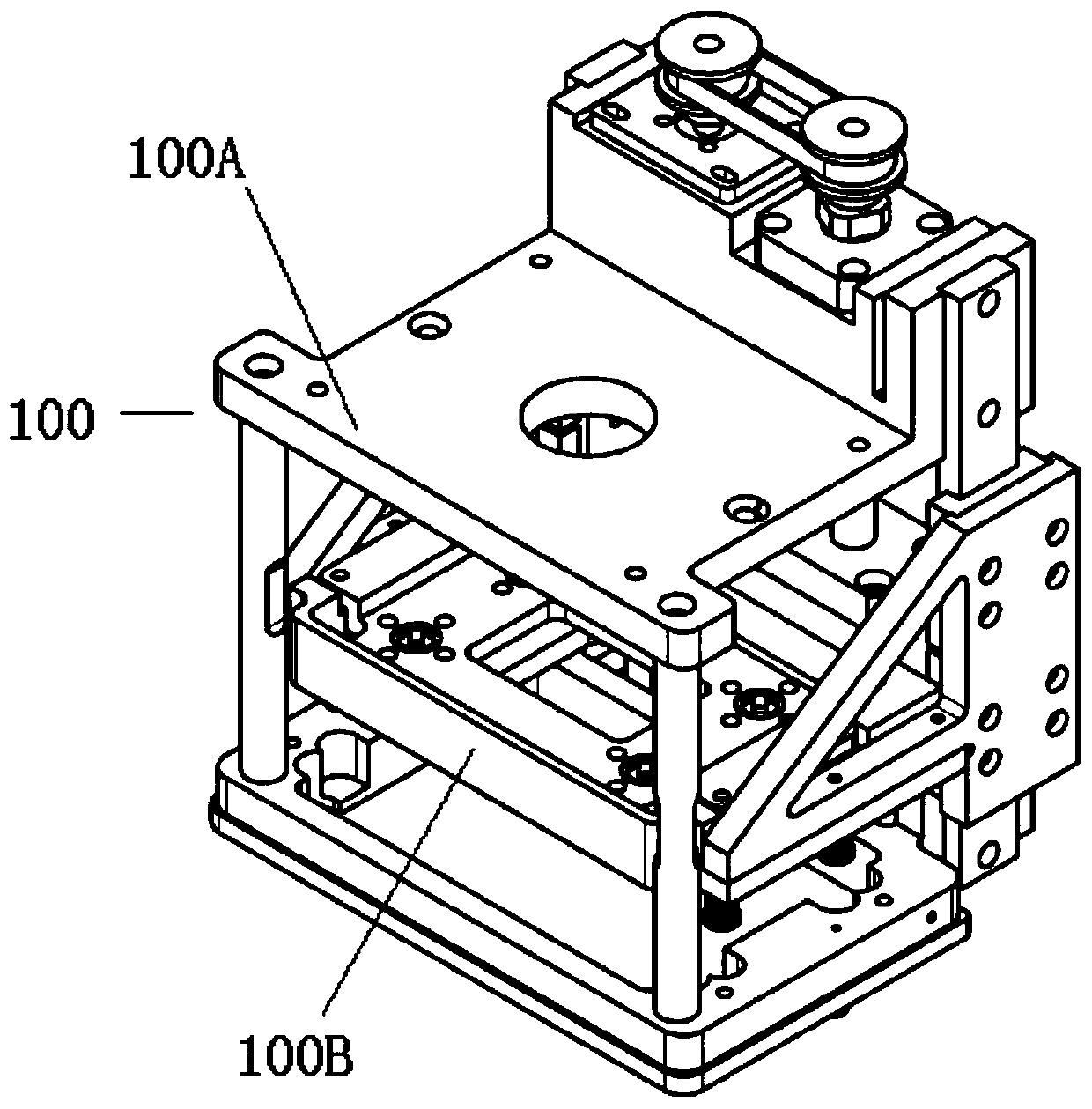

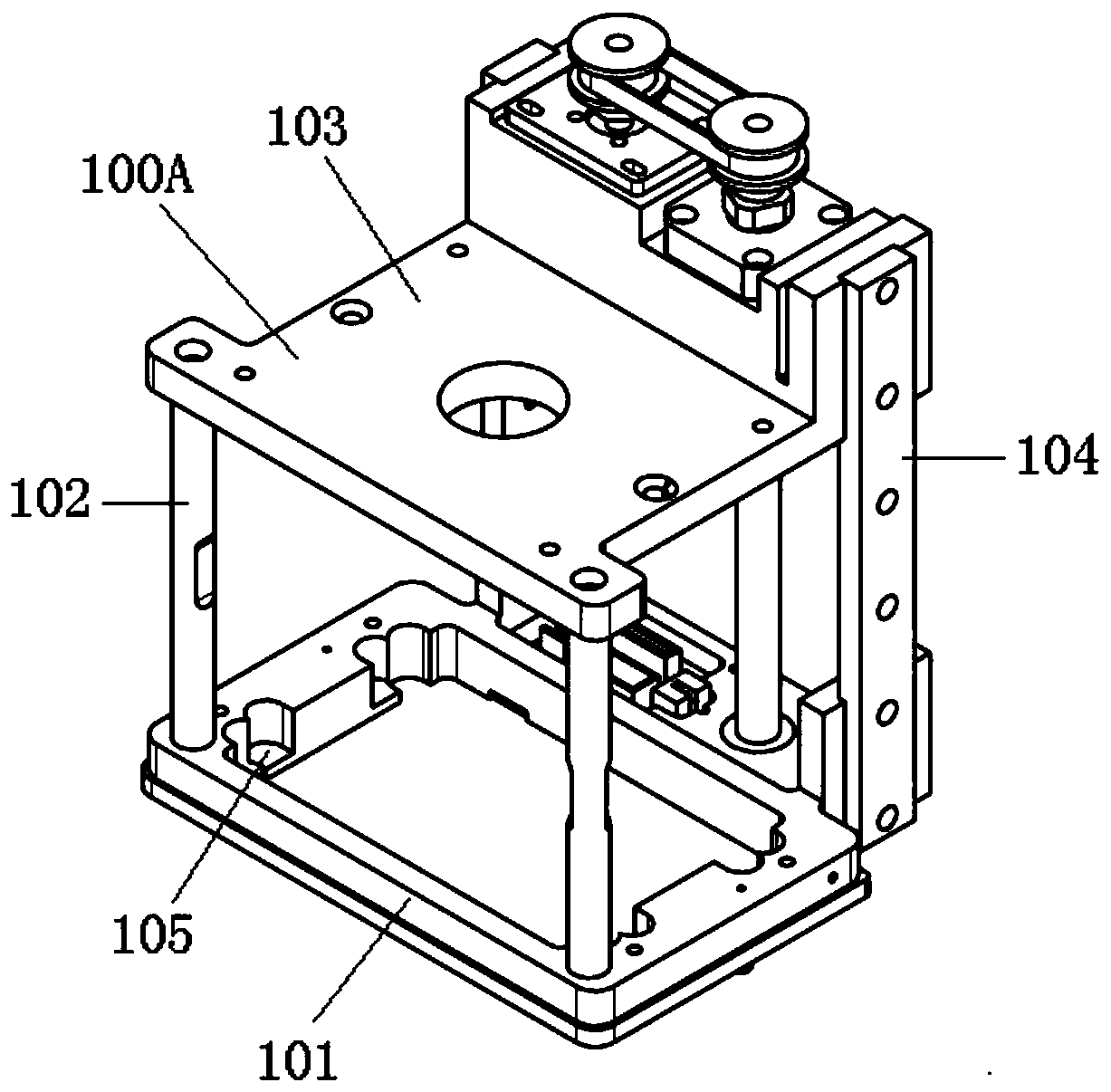

Wafer carrier automatic screwing device

ActiveCN112404945AAvoid over-positioningHigh precisionMetal working apparatusPiston cylinderStructural engineering

The invention belongs to the technical field of wafer unloading, and provides a wafer carrier automatic screw unloading device. The wafer carrier automatic screw unloading device comprises a rack, a double-speed chain conveying line, a carrier positioning mechanism and an automatic screw unloading mechanism are arranged on the rack, blocking air cylinders are arranged on the double-speed chain conveying line, and the blocking air cylinders are arranged at the two ends of the carrier positioning mechanism separately. The automatic screw unloading mechanism is positioned above the carrier positioning mechanism. The carrier positioning mechanism comprises a lifting supporting plate driven by a piston cylinder, a positioning pin is arranged on the top face of the lifting supporting plate, a tray limiting block and a cover plate limiting plate are arranged on the two sides of the double-speed chain conveying line, in the positioning state, a wafer carrier is positioned and clamped between the lifting supporting plate and the tray limiting block and between the lifting supporting plate and the cover plate limiting plate, the tray limiting block extends to a tray of the wafer carrier, andthe cover plate limiting plate extends to a cover plate. According to the wafer carrier automatic screw unloading device, automatic screw unloading of the wafer carrier can be achieved, effective replacement of manual labor force is achieved, the working efficiency is greatly improved, and damage accidents caused to a material disc or an internal wafer are avoided.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com