Multi-stroke anti-dust pulse bag type dust removal equipment

A technology of pulse cloth bag and dust removal equipment, which is applied in separation methods, gas treatment, and separation of dispersed particles. It can solve the problems of dust explosion, increase the dust content of flue gas, and anti-dust in the dust removal box, so as to increase contact opportunities and improve dust removal. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

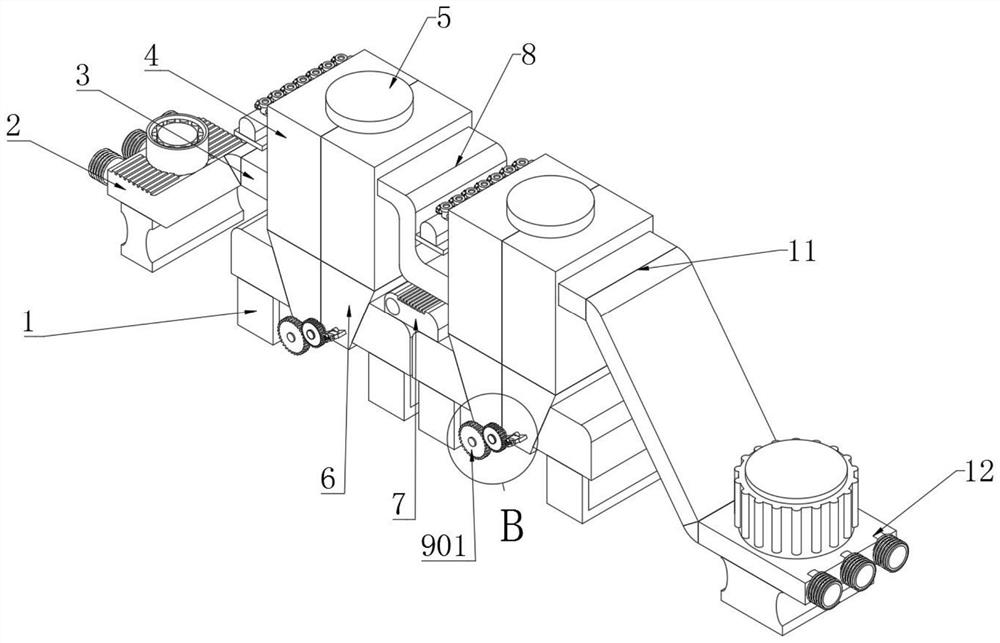

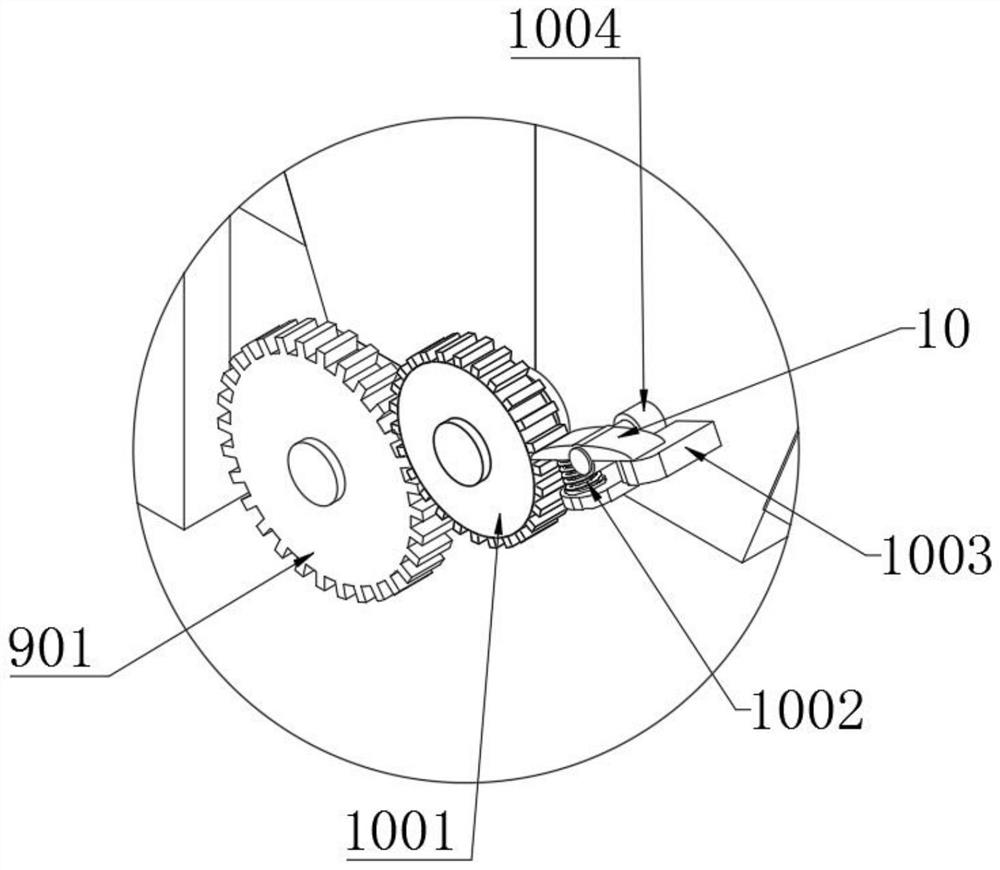

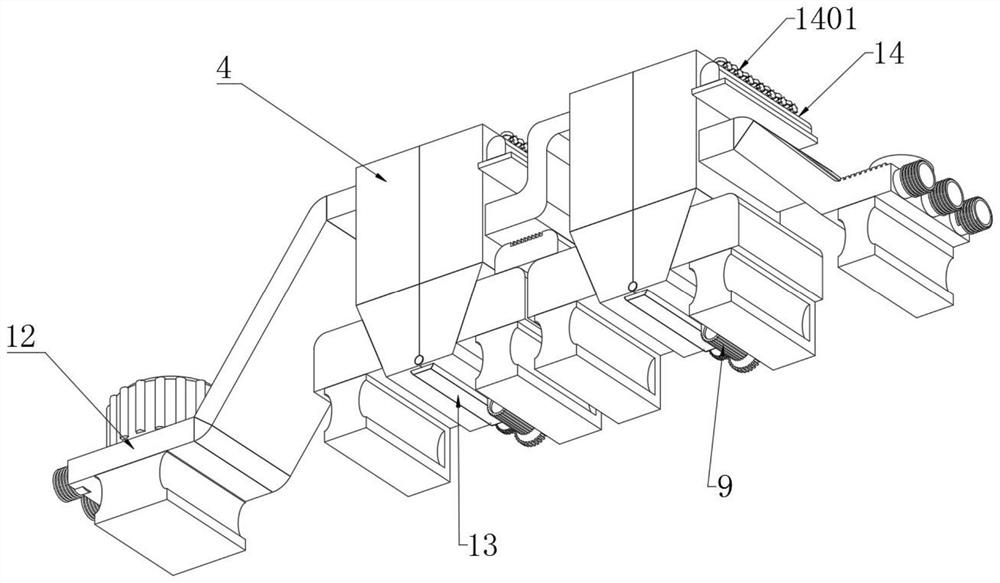

[0040] as attached figure 1 to attach Figure 9 Shown:

[0041] The invention provides multi-stroke anti-dust pulse bag-type dust removal equipment, including a support base 1, an air inlet 2, an air inlet 3, a dust removal box 4, an inspection well 5, a dust storage box 6, a PLC controller 7, and a connecting air duct 8 , servo motor 9, motor gear plate 901, non-return body 10, driven gear plate 1001, return spring 1002, limit fixed block 1003, rotating shaft 1004, air outlet 11, exhaust fan 12, stop body 13, air compression tank 14. PLC program-controlled pulse valve 1401, air inlet guide plate 15, injection box 16, high-pressure blowpipe 1601, purification chamber 17, exhaust end guide plate 18, dust collecting plate 19, barb plate 20, arc plate 21, Support plate 22, vent hole 2201, dust removal filter rod 23, sleeve 2301 and travel plate 24; the top of the support base 1 is fixedly connected to the bottom of the entire dust removal equipment by bolts; the left end plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com