Automatic spring puncture needle sampling structure

A puncture needle and automatic technology, which is applied in the field of automatic spring puncture needle sampling structure, can solve the problems of complex structure of two independent needles, occupying space for operation, difficulty in ensuring sample suction accuracy, etc., so as to reduce cross-contamination and realize low cost. , the effect of preventing contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

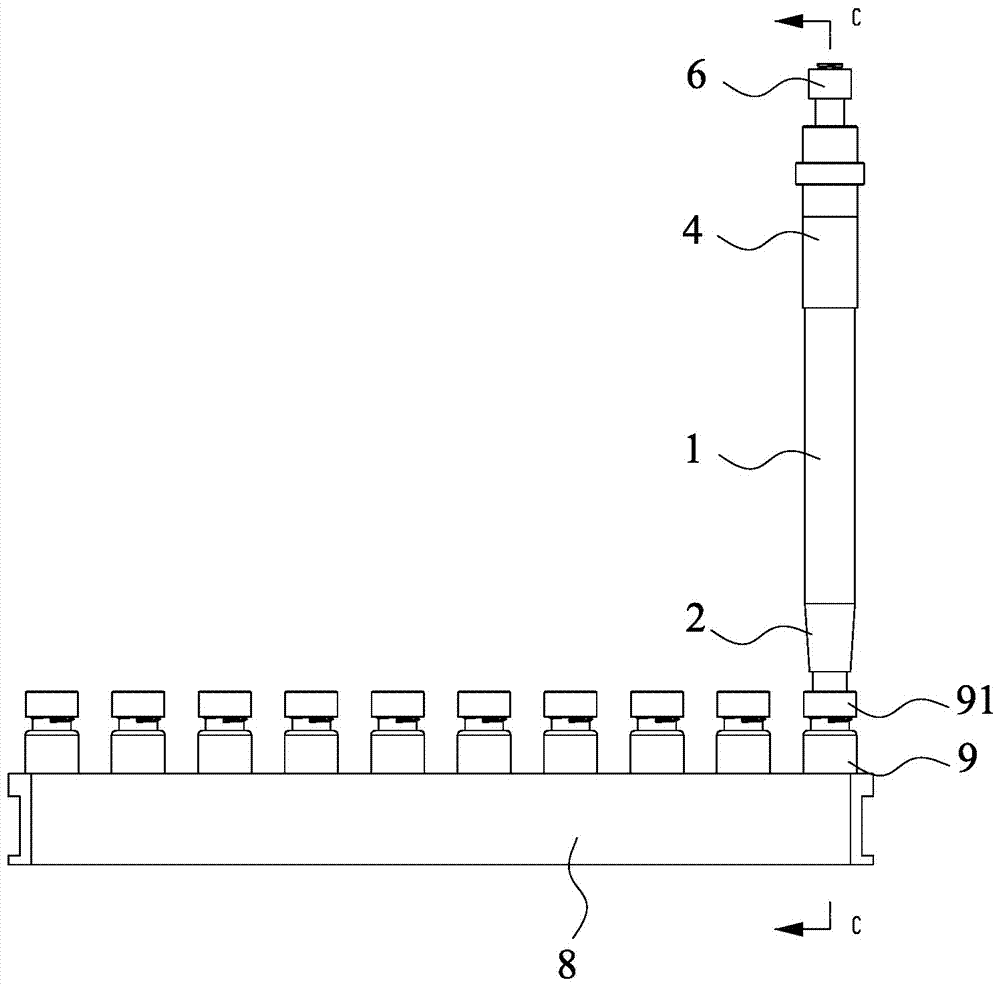

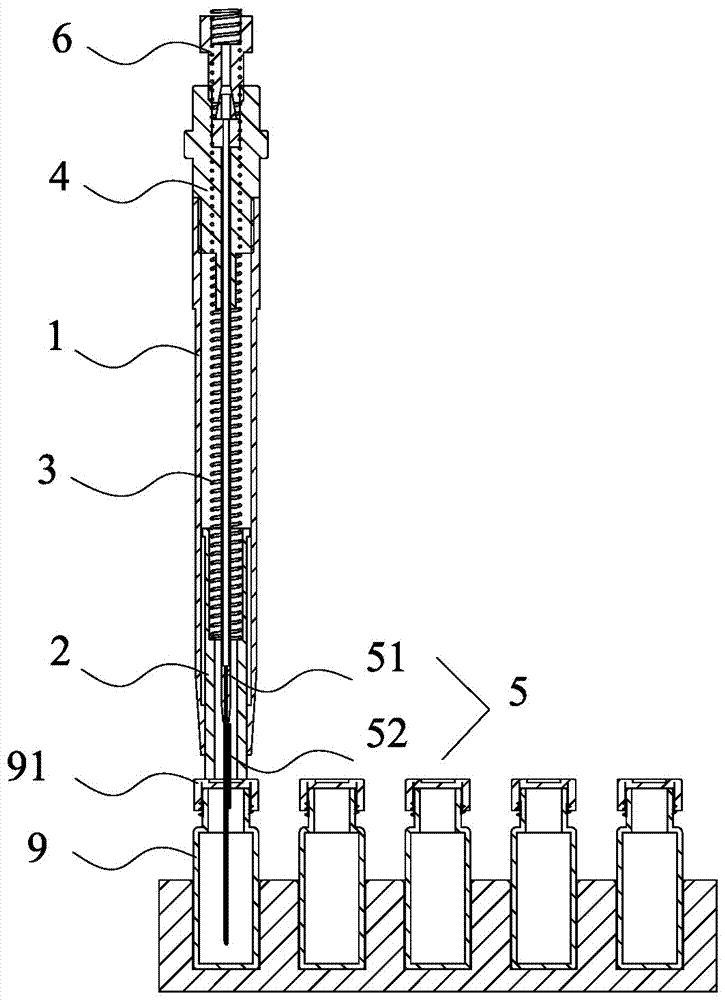

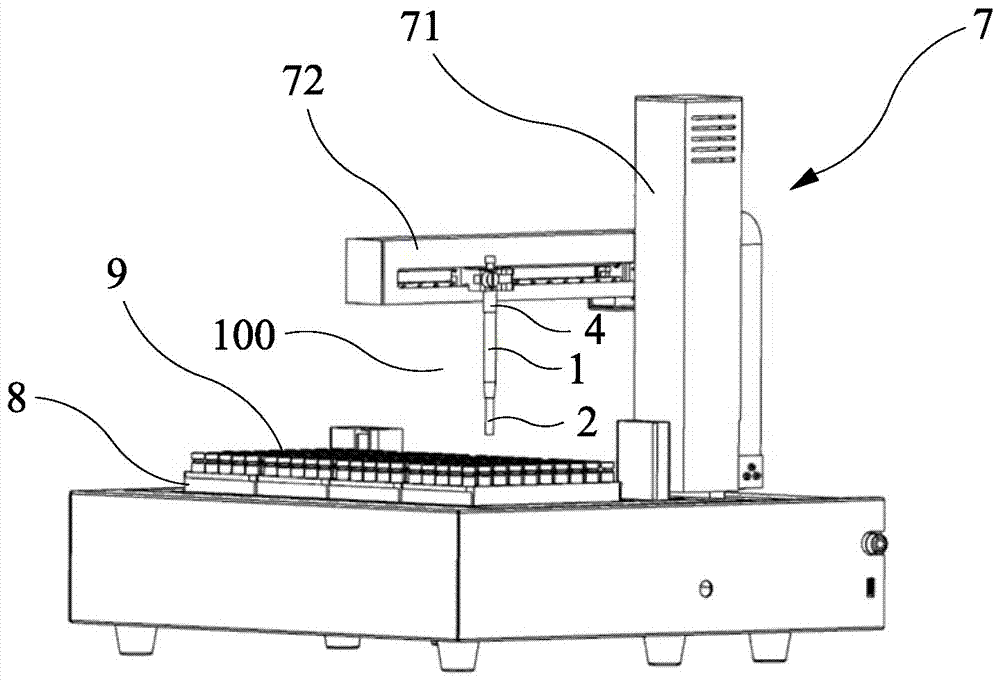

[0023] Such as Figure 1-3 As shown, an automatic spring puncture needle sampling structure 100 disclosed in the present invention includes an upper guide sleeve 1, a lower guide sleeve 2, an automatic spring 3, a needle holder 4 and a puncture needle 5; the lower guide sleeve 2 is slidably sleeved on the upper The lower end of the guide sleeve 1, and the lower guide sleeve is sleeved on the lower end of the upper guide sleeve; the lower end of the needle holder 4 is fixedly sleeved on the upper end of the upper guide sleeve 1; the automatic spring 3 is set in the upper guide sleeve 1, and the upper end of the automatic spring 3 is connected to the needle The lower end of the fixing seat 4 is connected to the lower guide sleeve 2; the puncture needle 5 includes a long needle 51 and a short needle 52, the long needle 51 is set in the upper guide sleeve 1, and the upper end of the long needle 51 is pierced and fixed on the needle fixing seat 4 Among them, the lower end of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com