Multi-quantity automatic clamping equipment for producing reagent test boxes

A technology for test boxes and reagents, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of low efficiency of reagent card boxing, difficult to control grasping force, and inability to cover the packaging box, so as to improve the efficiency of card loading. , the effect of reducing labor intensity and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

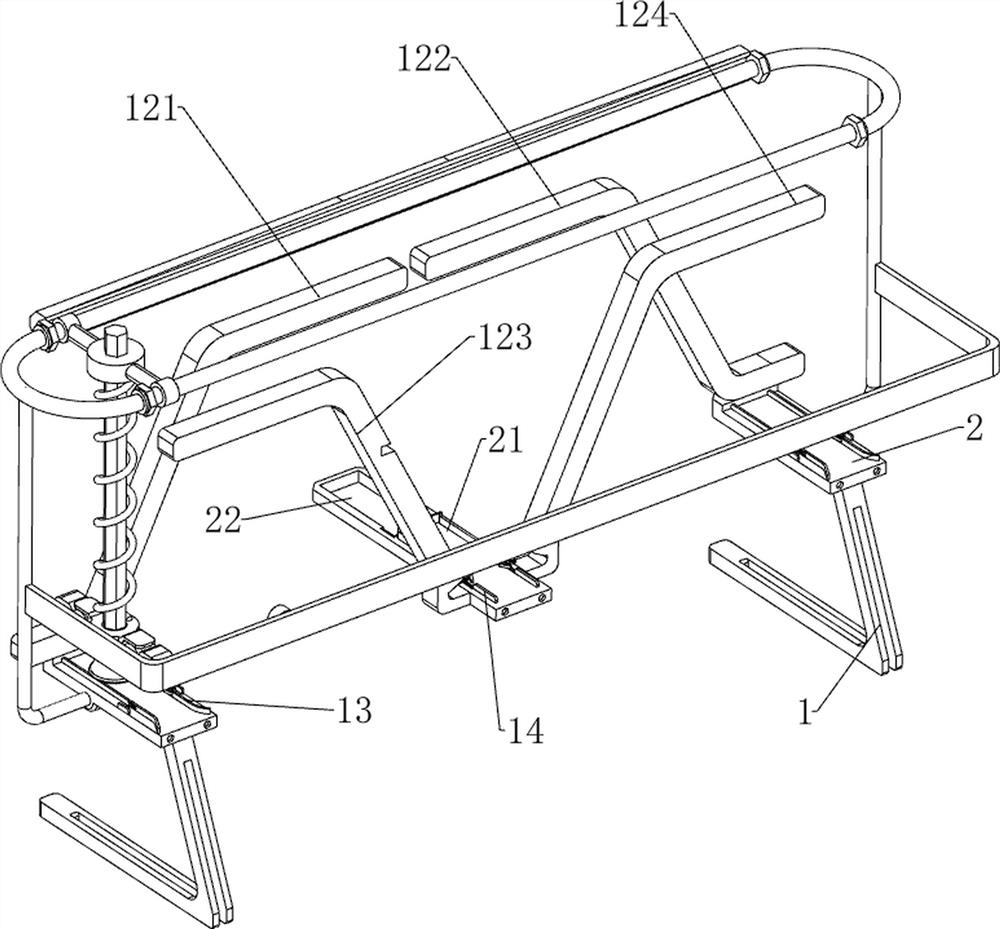

[0034] A large amount of automatic card loading equipment for producing reagent test boxes, such as Figure 1-3 As shown, it includes a leg 1, a first support plate 2, a second support plate 21, a baffle plate 23, a rotating plate 24, a connecting frame 3, a rodless cylinder 4, a sliding frame 5, a lifting rod 6, an electric suction cup 7, The first guide block 8, the swing block 9, the limit plate 10, the first return spring 11 and the guide rail assembly 12, there are two supporting legs 1, and the two supporting legs 1 are left and right symmetrical, and the tops of the supporting legs 1 on both sides are all passed by bolts The way of connection is connected with the first support plate 2, the first support plate 2 on the left is used to place the reagent test card, the first support plate 2 on the right is used to place the top cover of the reagent test box, and the first support plate 2 on both sides A connecting frame 3 is connected between the plates 2, and the middle ...

Embodiment 2

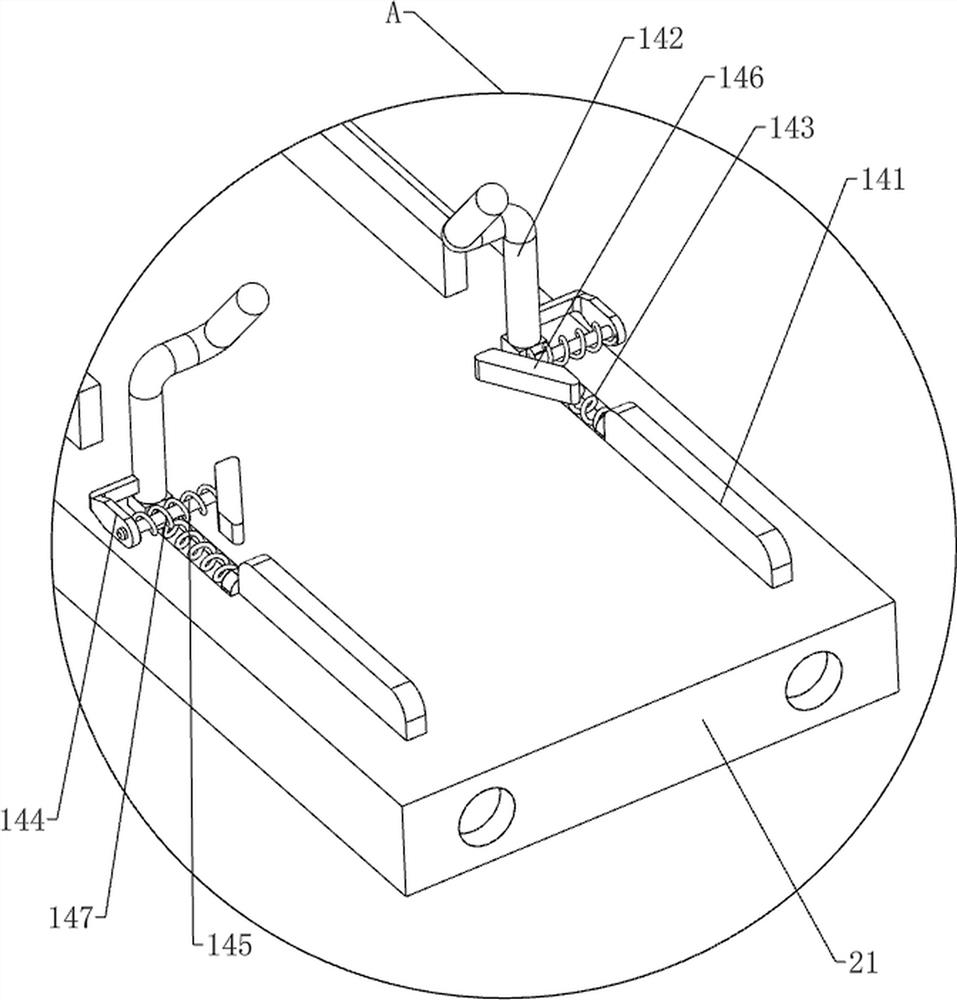

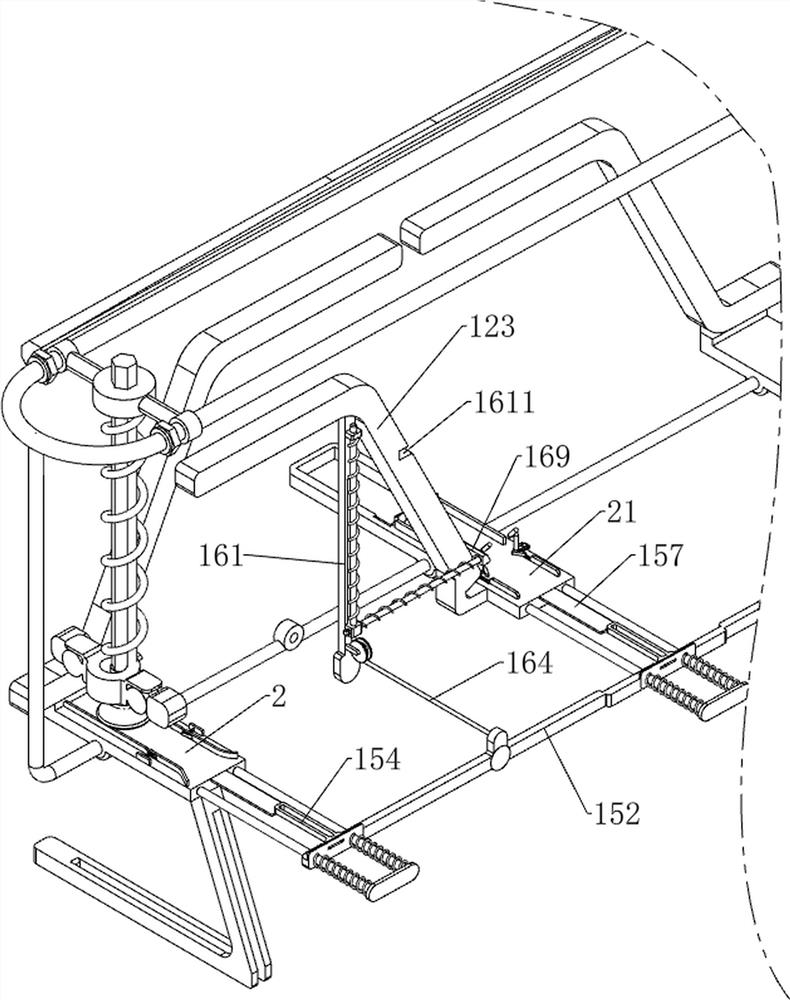

[0038] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a guide assembly 13 is also included, and the guide assembly 13 includes a fixed bar 131, a guide bar 132, a fixed block 133, a wedge block 134 and a second return spring 135, and the left and right sides of the rear part of the upper end surface of the first support plate 2 Both are connected with fixing strips 131 by bolt connection, the left and right sides of the upper end face of the first support plate 2 are connected with guide strips 132 by bolt connection, and the left and right sides of the upper end surface of the first support plate 2 are passed through The fixed block 133 is connected by bolt connection, the wedge block 134 is hingedly connected to the rear side of the guide bar 132 , and the second return spring 135 is connected between the wedge block 134 and the fixed block 133 by lap connection.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com