Patents

Literature

63results about How to "Realize fine positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

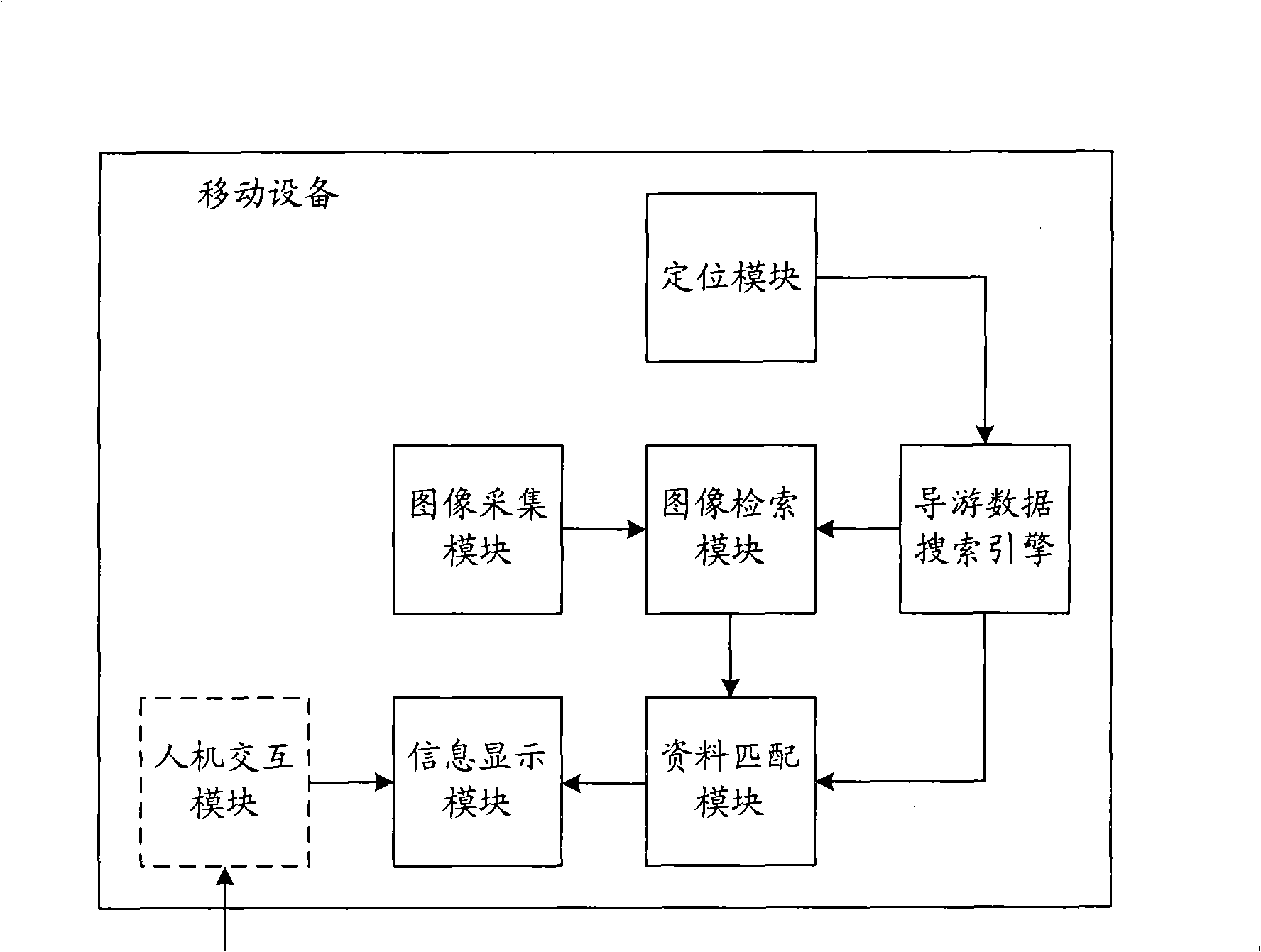

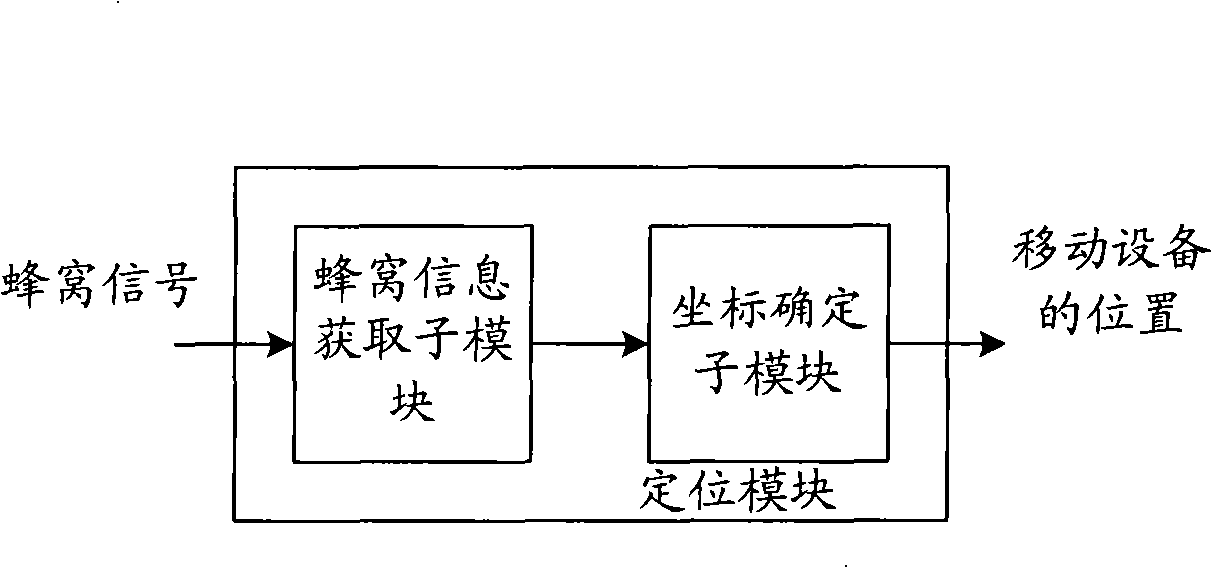

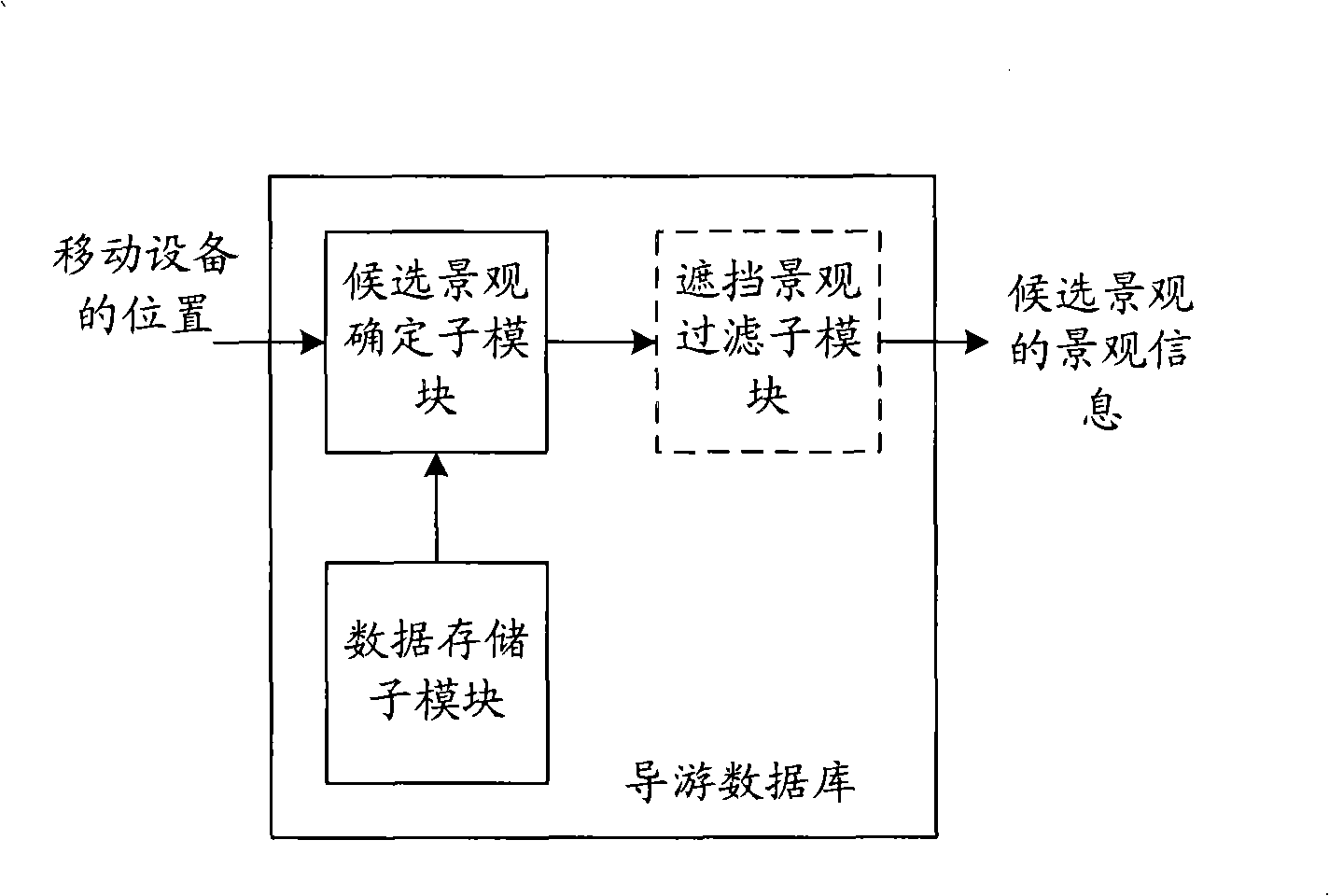

Guide control implementing mobile apparatus and server, guide control method

ActiveCN101340661AWith tour guide functionAchieve coarse positioningData switching by path configurationRadio/inductive link selection arrangementsComputer graphics (images)Computer vision

The invention discloses a mobile device for realizing guide controlling, a server for realizing the guide controlling based on the mobile device and a method of the guide controlling based on the mobile device, wherein, position information of the mobile device is firstly determined, and in all scenes, all scene information of all candidate scenes within a position area in which the mobile device is positioned is searched for realizing the coarse positioning of guide data; and according to the matching degree of images of all candidate scenes and discretional scene images taken at the position of the mobile device, at least one concerned scene is determined for realizing the fine positioning of the guide data, and then the scene information of the concerned scene is displayed and output to a user, thereby ensuring that the mobile device has guide function based on a duplex-option mode of mobile device positioning and image searching.

Owner:VIMICRO ELECTRONICS CORP

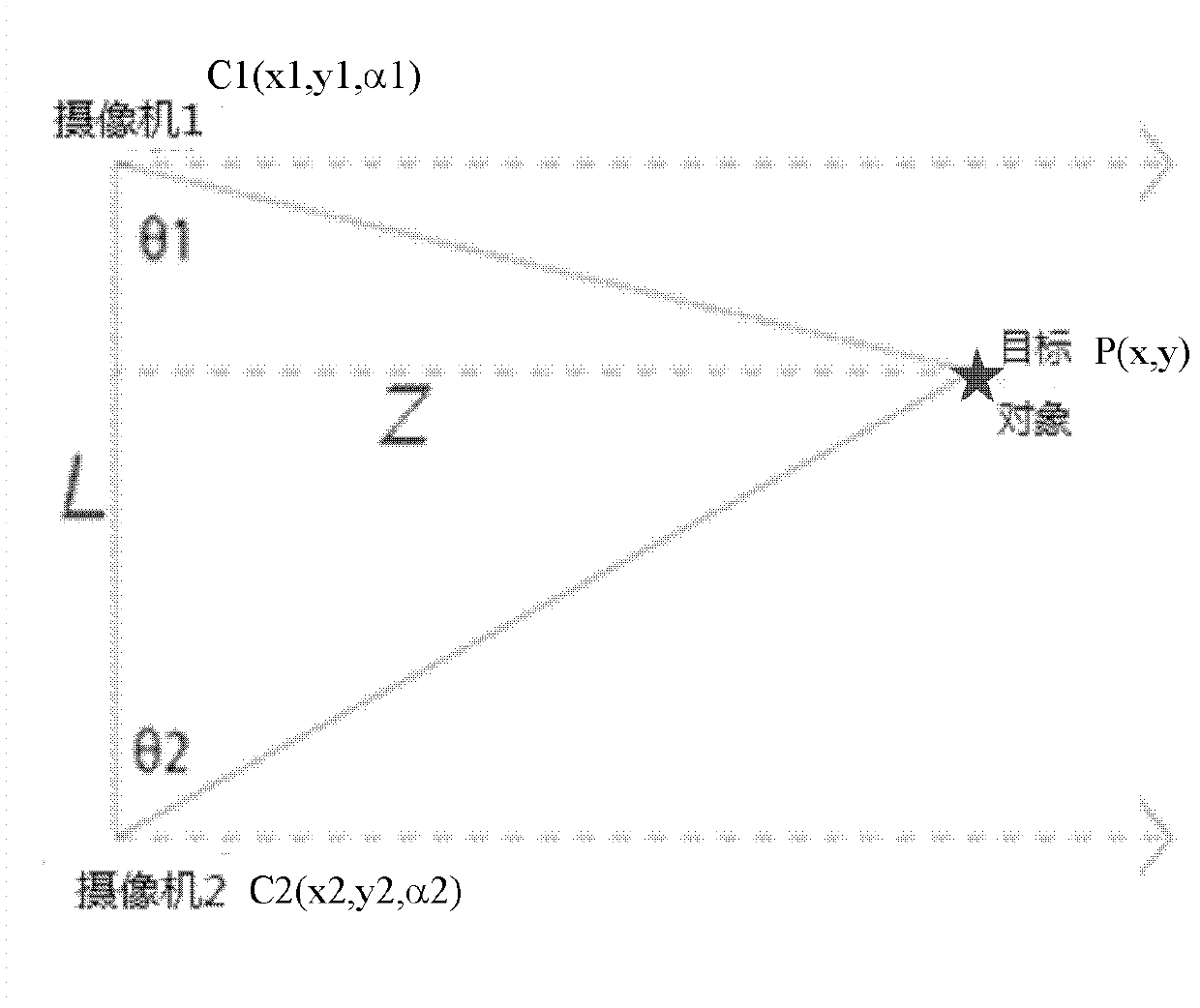

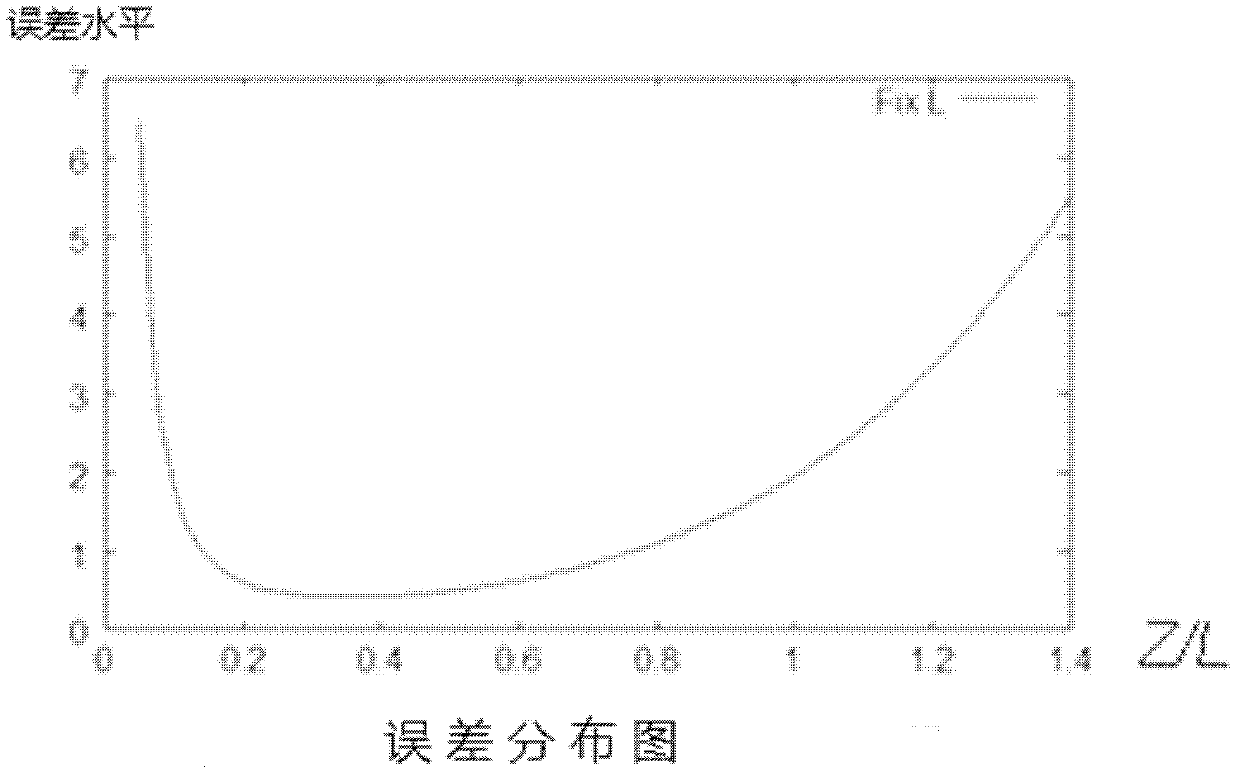

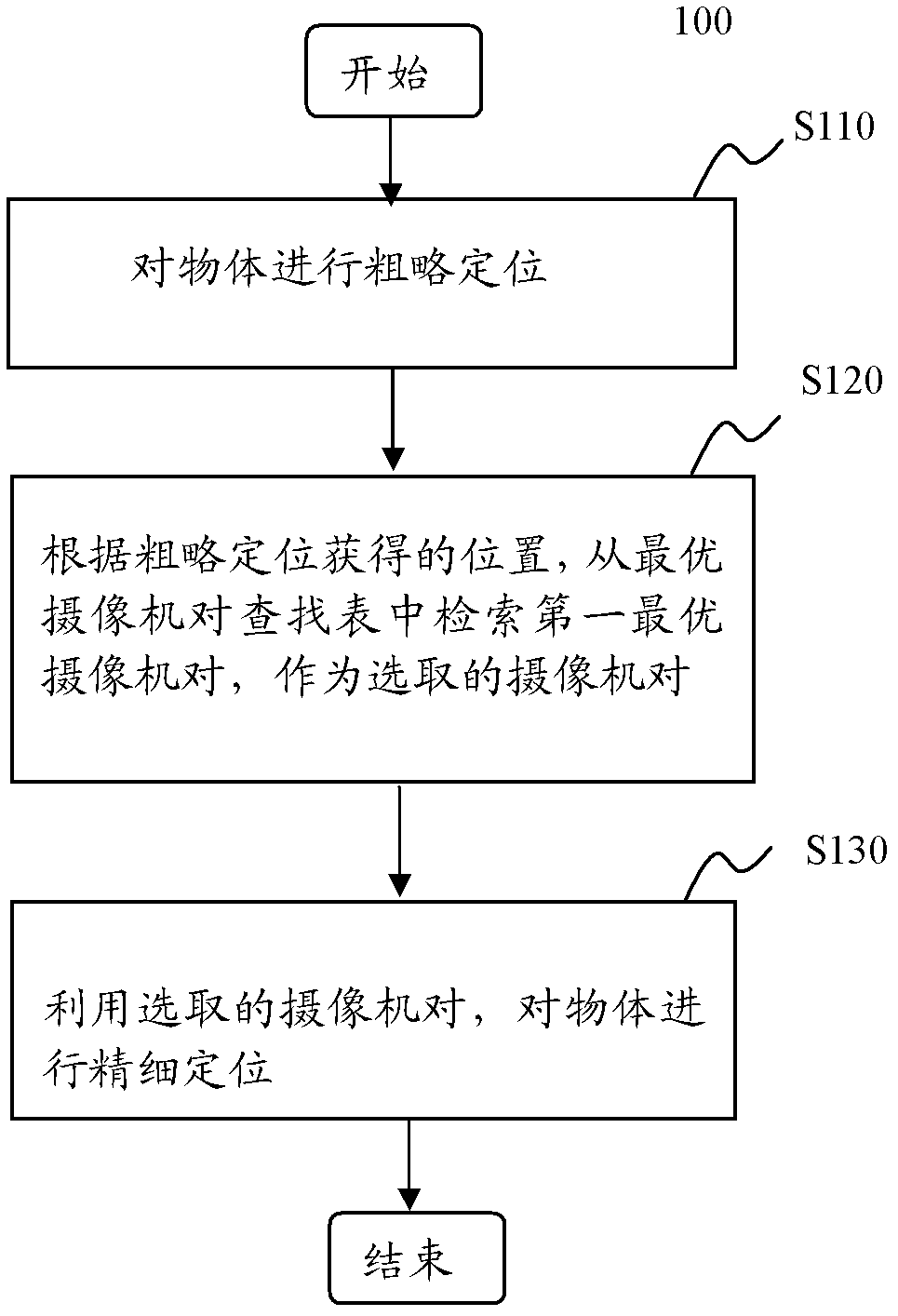

Method and device for object positioning, and method and device for determining optimal camera pair

ActiveCN103377471ARandom arrangementSave processing resourcesTelevision system detailsImage analysisComputer vision

Owner:RICOH KK

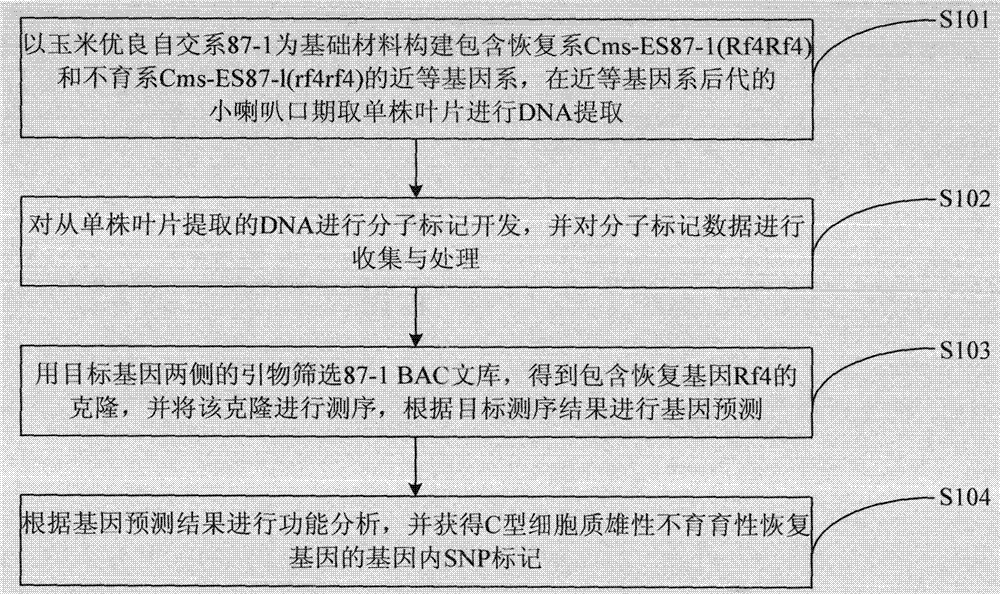

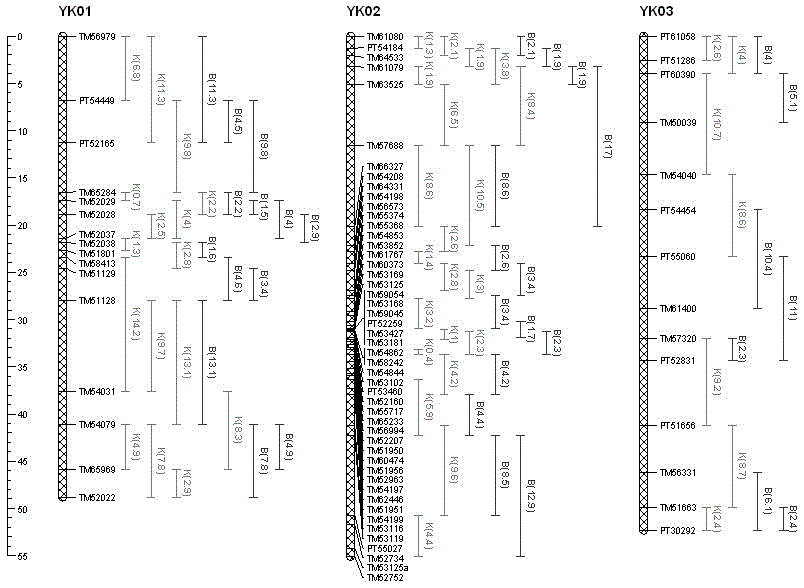

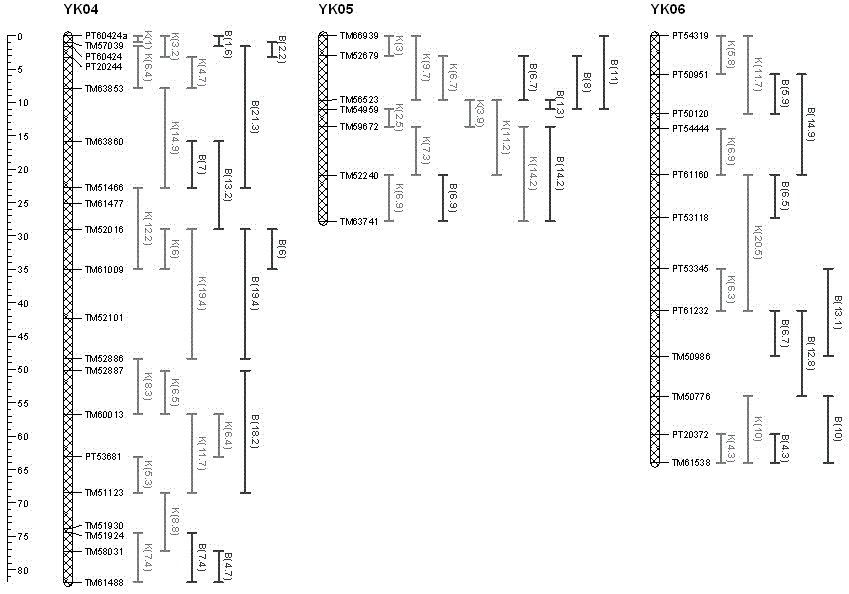

Intragenic single nucleotide polymorphism (SNP) mark of male sterility restoring gene RF4 of C-type cytoplasm of corn

InactiveCN103088018ASolving Molecular Detection Technology ProblemsRealize fine positioningMicrobiological testing/measurementDNA preparationCytoplasmic StructureSnp markers

The invention discloses an intragenic single nucleotide polymorphism (SNP) mark of a male sterility restoring gene RF4 of C-type cytoplasm of corn. The intragenic SNP mark is obtained by the following steps of: constructing a near-isogenic line by using a good inbred line 87-1 of corn as a basic material, and performing DNA (deoxyribonucleic acid) extraction on leaves of a single plant of an offspring of the near-isogenic line; performing molecular marker development on the extracted DNA, and acquiring and processing molecular marker data; screening an 87-1 BAC library by using primers on two sides of a target gene to obtain a clone containing the restoring gene RF4, sequencing the clone, and performing gene prediction according to a target sequencing result; and performing functional analysis according to the result of gene prediction, and obtaining the intragenic SNP mark of the male sterility restoring gene of the C-type cytoplasm. According to the invention, fine positioning of the male sterility restoring gene of the C-type cytoplasm and the intragenic SNP mark of a fertility restoring gene are realized, and the technical problem in molecular detection of the male sterility restoring gene of the C-type cytoplasm of corn is solved.

Owner:HENAN AGRICULTURAL UNIVERSITY

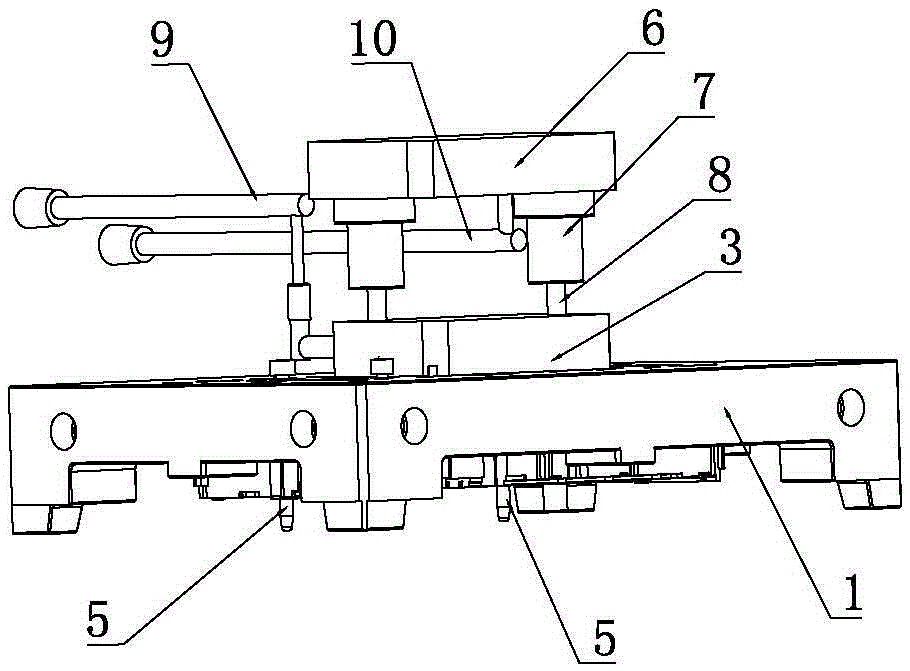

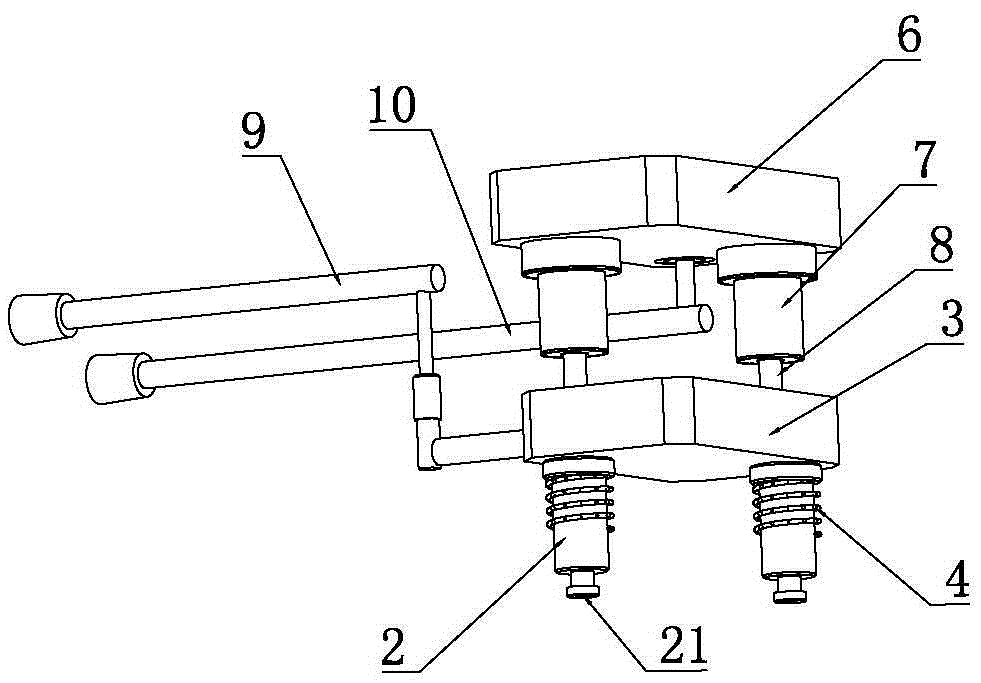

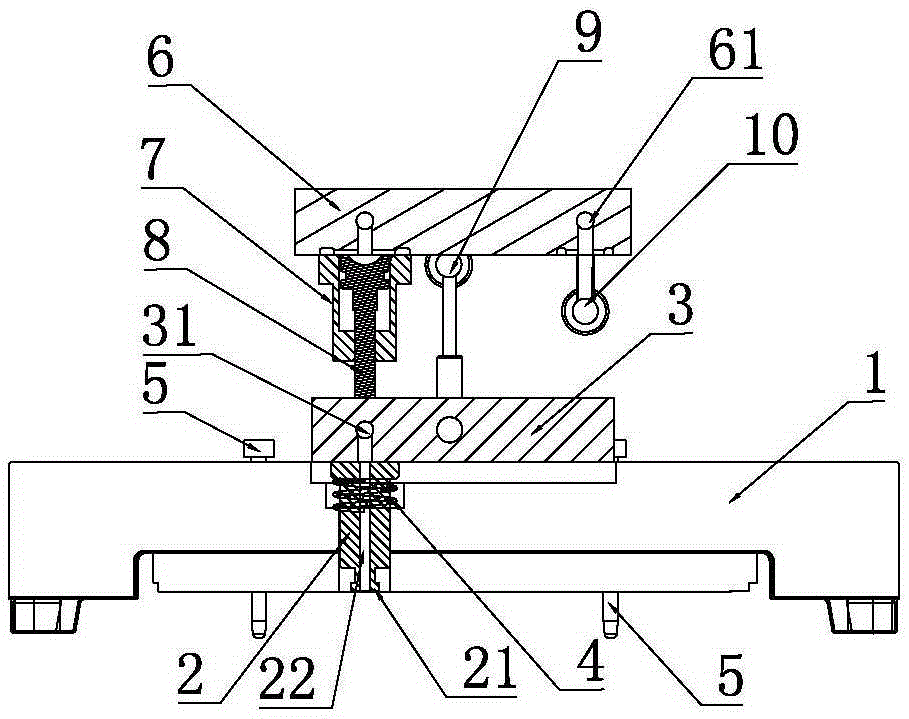

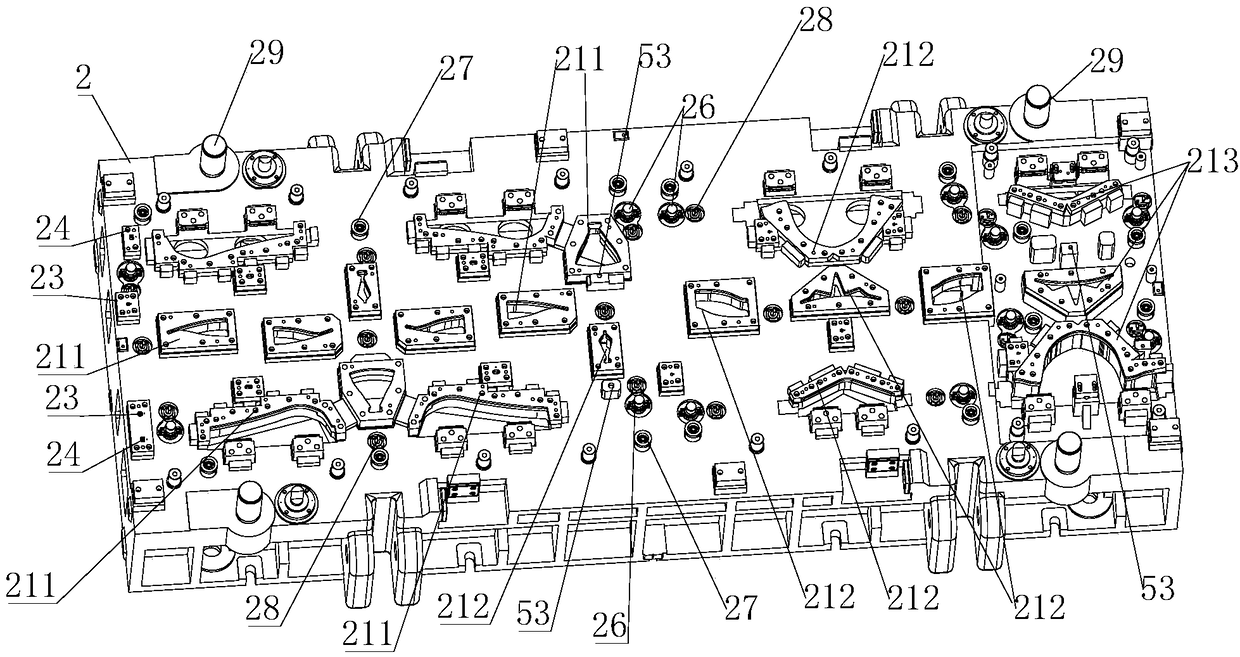

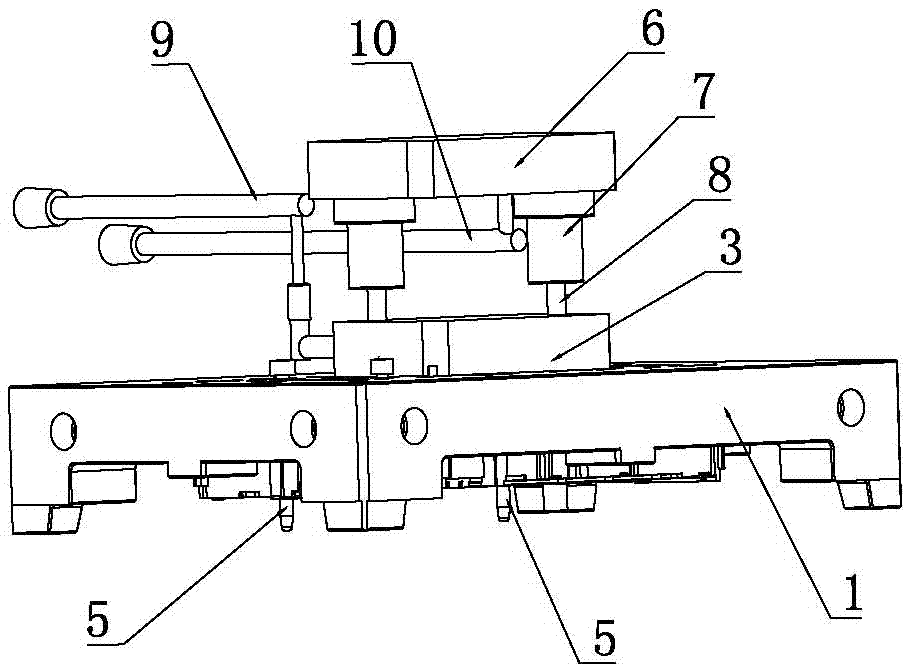

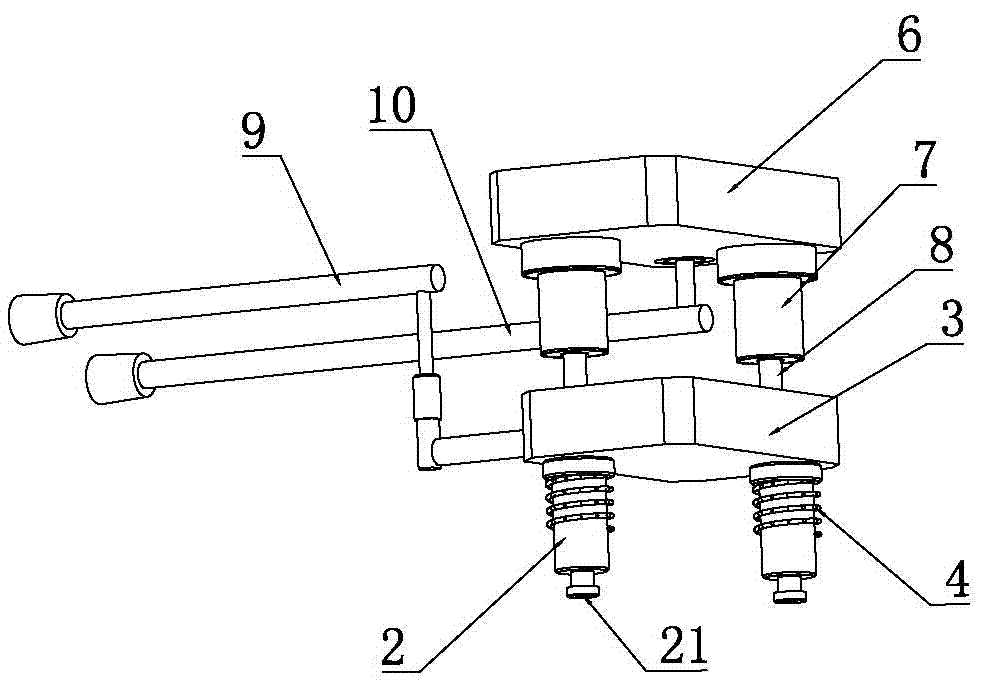

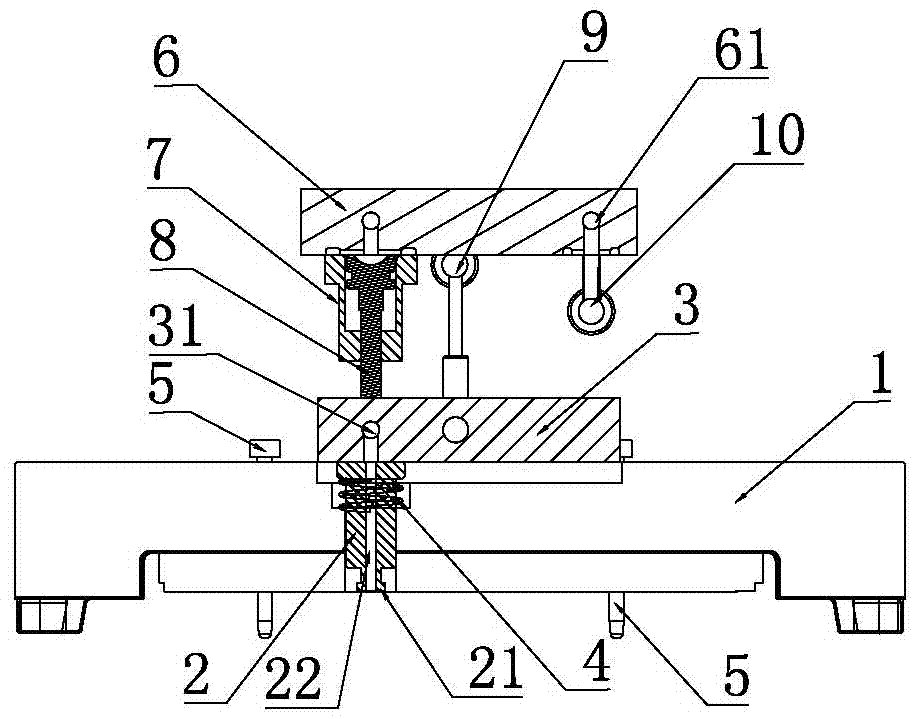

Movable sucker device for die

The invention discloses a movable sucker for a die. The movable sucker structurally comprises a sucker, a positioning part and an ejecting assembly. The ejecting assembly can eject the adsorption end of the sucker out of a forming face of the die. In the process that a mechanical arm conveys hardware to be injected to the adsorption end of the sucker, the hardware to be injected can be primarily positioned through the positioning part, the sucker acts to adsorb the hardware to be injected to the sucker, and then the sucker retracts and resets; in the reset process, the hardware to be injected slightly moves relative to the sucker under limiting of the positioning part, so that the hardware to be injected is accurately positioned, the hardware to be injected is placed in place, and the risk of film pressing is effectively lowered; and in addition, due to the fact that the adsorption end of the sucker stretches out of the forming face of the die, when the mechanical arm conveys the hardware to be injected to the sucker, the mechanical arm does not need to make contact with the forming face of the die so that the mechanical arm can be prevented from damaging the forming face of the die, and meanwhile the space cross depth of the mechanical arm and the positioning part is effectively reduced so that the interference between the mechanical arm and the positioning part can be effectively avoided.

Owner:东莞华誉精密技术有限公司

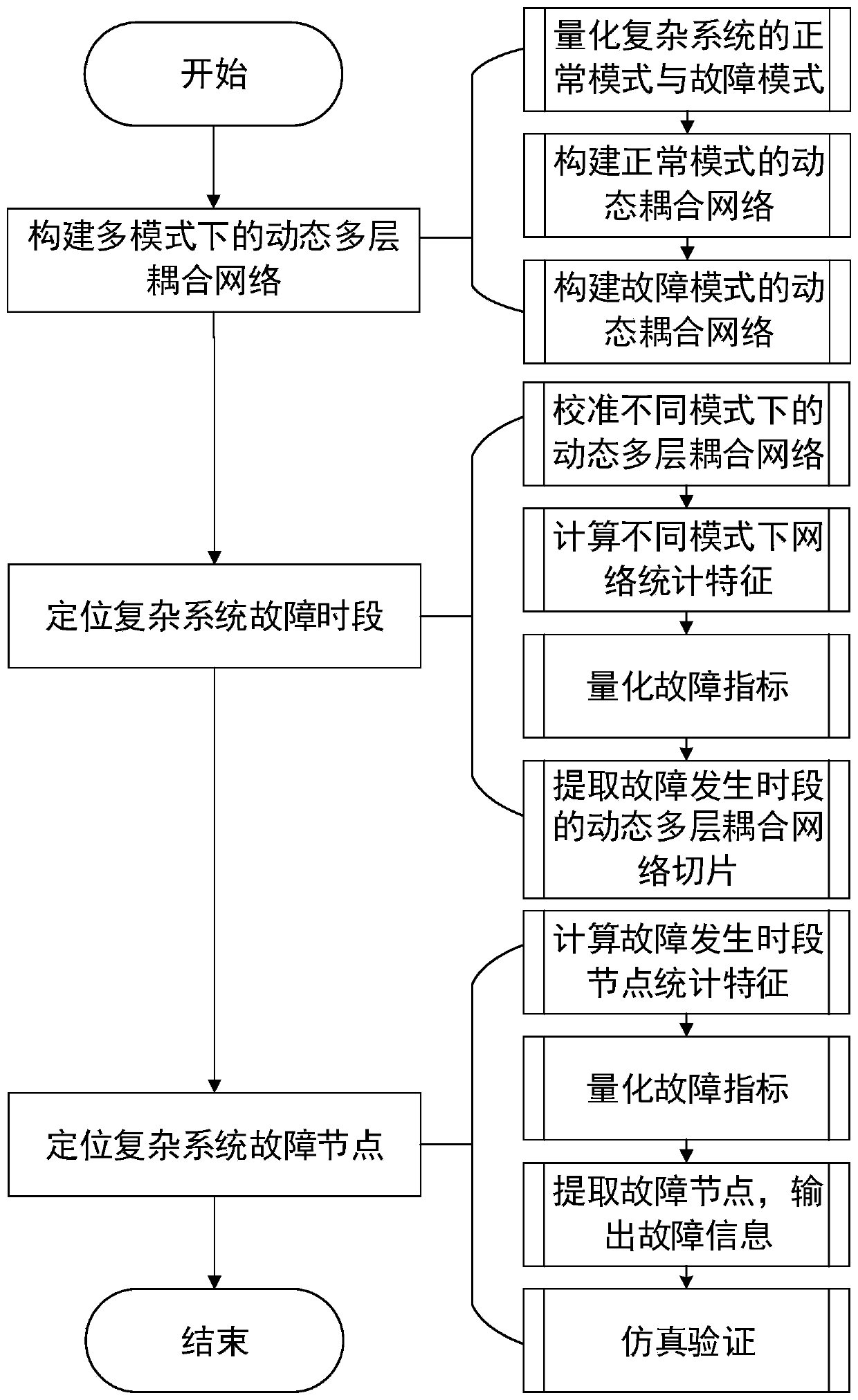

Complex system fault positioning method based on dynamic multilayer coupling network

ActiveCN110213087ARealize fine positioningAvoid the disadvantage of slow positioningData switching networksCascading failureCoupling

The invention provides a complex system fault positioning method based on a dynamic multilayer coupling network. The method comprises the following steps: step A, constructing the dynamic multilayer coupling network in multiple modes; step B, positioning a complex system fault time period; and step C, positioning a complex system fault node. Aimed at a scene that a traditional reliability analysismeans is usually applied to a single-fault-source and static analysis, the invention provides a complex system fault positioning method based on a dynamic multilayer coupling network by applying a complex network theory in order to solve the problem that it is difficult to realize fault positioning on a complex system with the characteristics of dynamic propagation, cascade failure, multivariatefaults, uncertainty and the like. The method does not need to calculate and compare all node feature information, can quickly locate the fault node of the complex system on the premise of occupying less computer computing power, and has good practical application value.

Owner:BEIHANG UNIV

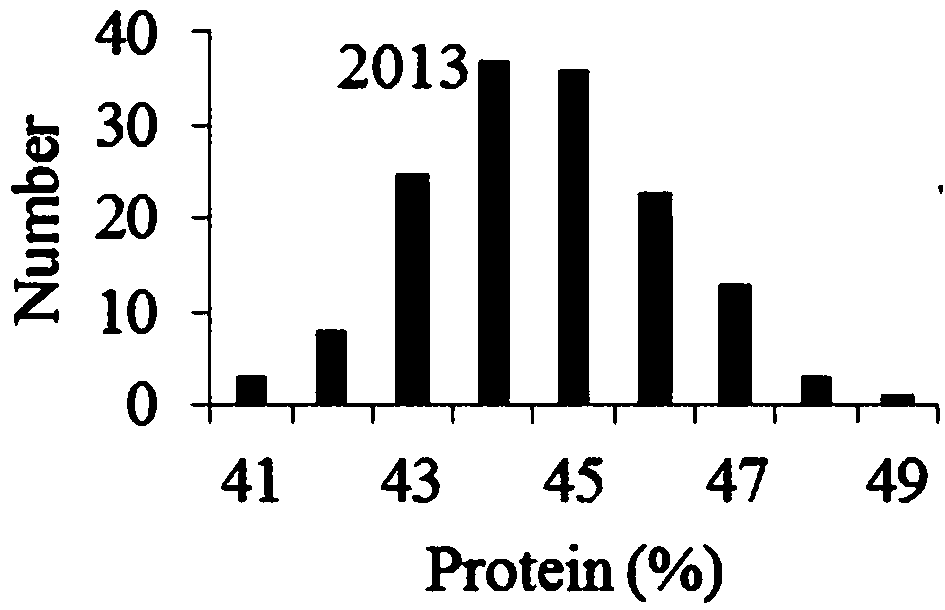

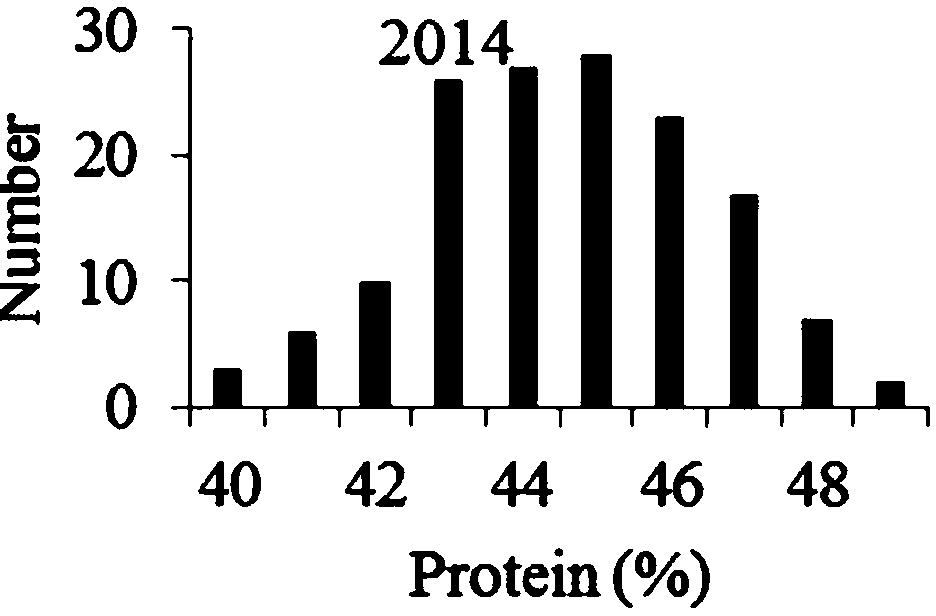

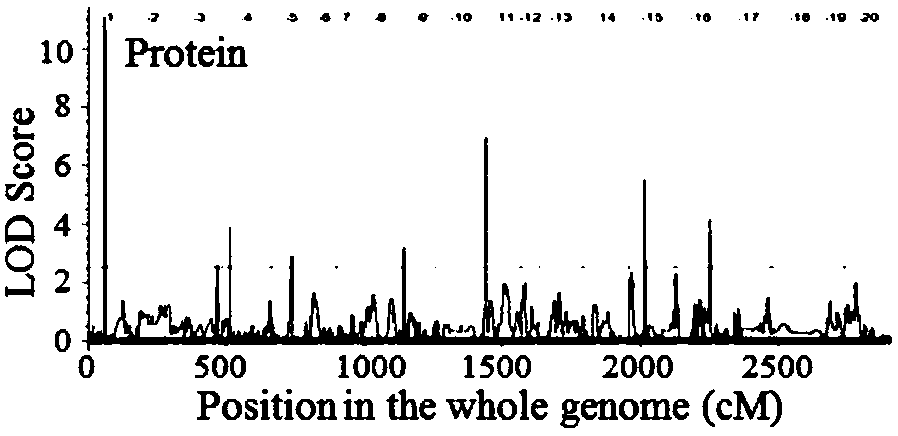

Molecular marking method for improving content of soybean protein and marking combination thereof

InactiveCN108165659AReduce selection workloadDownscalingMicrobiological testing/measurementDNA/RNA fragmentationPopulationProtein content

The invention relates to a molecular marking method for improving the content of soybean protein. The molecular marking method comprises the following steps of: 1) distribution of the protein contentof RIL (Recombinant Inbred Line) populations of the soybean: carrying out continuous planting for two years on the advanced-generation RIL populations of smooth-skin soybeans and Qihuang 26, and calculating the protein content thereof; 2) QTL (Quantitative Trait Loci) location of the content of the soybean protein: utilizing a high-density genetic map constructed by an SLAF-seq technology to carryout QTL location on the protein content of the RIL populations of the soybean, and obtaining 8 QTL site associated with the protein content of the soybean. The molecular marking method has the beneficial effects that the marking combination provided by the invention is utilized for carrying out low-generation marking selection on breeding materials, so that the benefit for aggregating excellent genes of the protein in the breeding materials at low generations is achieved, the workload of advanced-generation breeding selection is reduced, the breeding scale is shrunk, and the breeding time isshortened.

Owner:CROP RES INST SHANDONG ACAD OF AGRI SCI

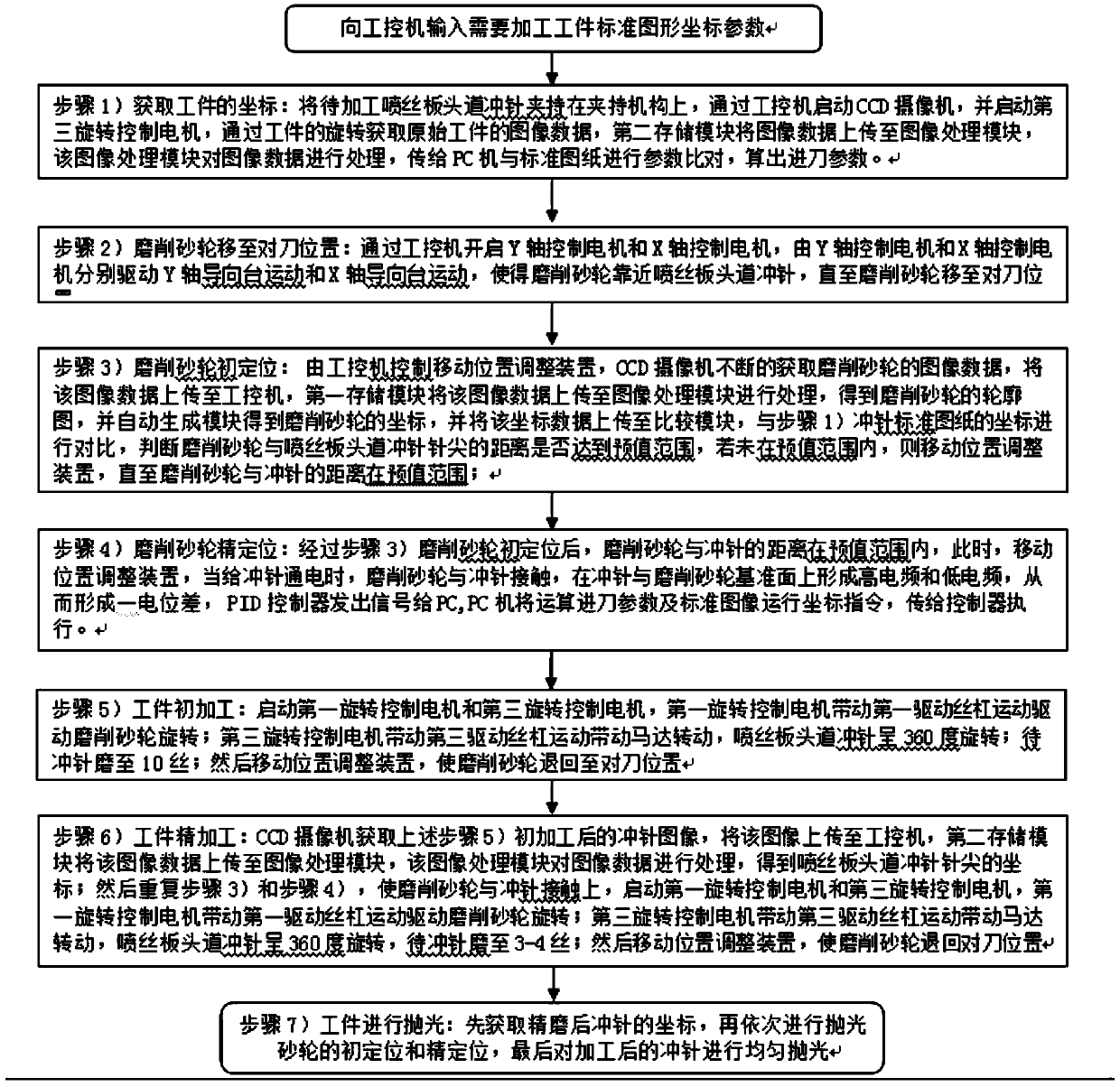

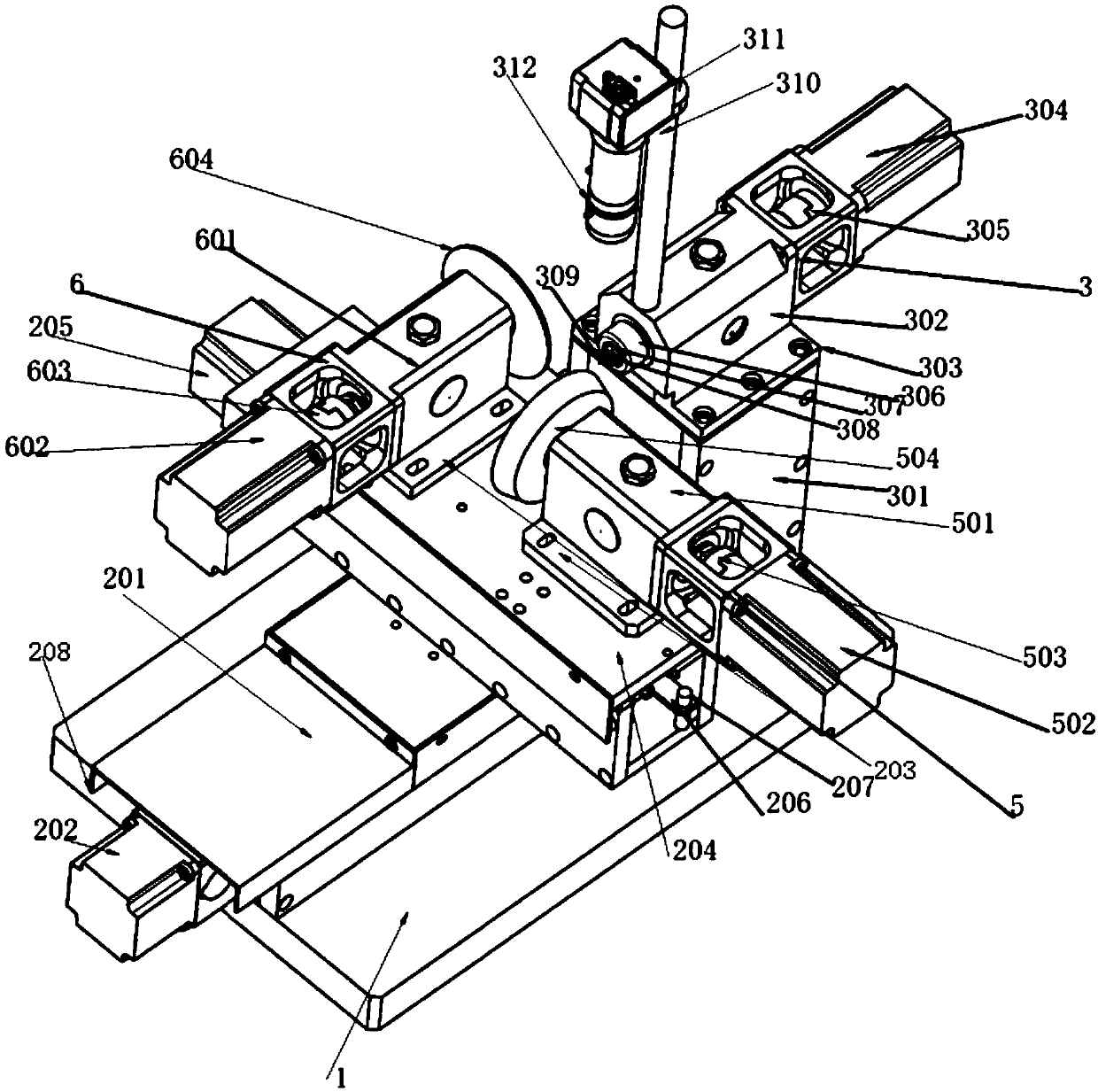

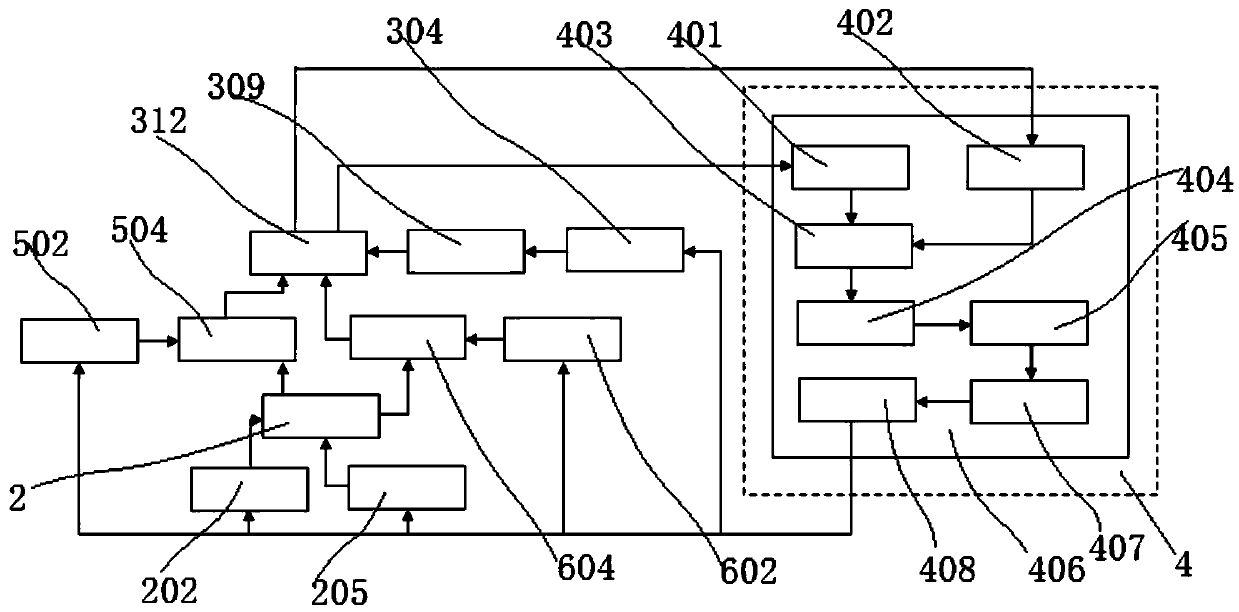

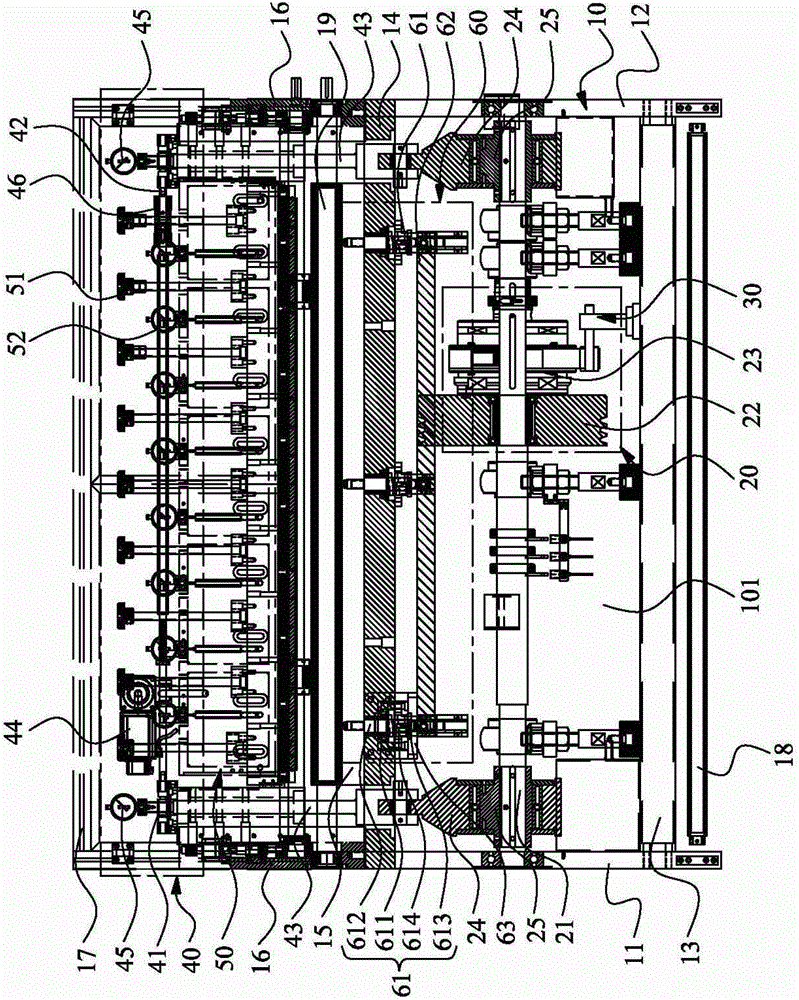

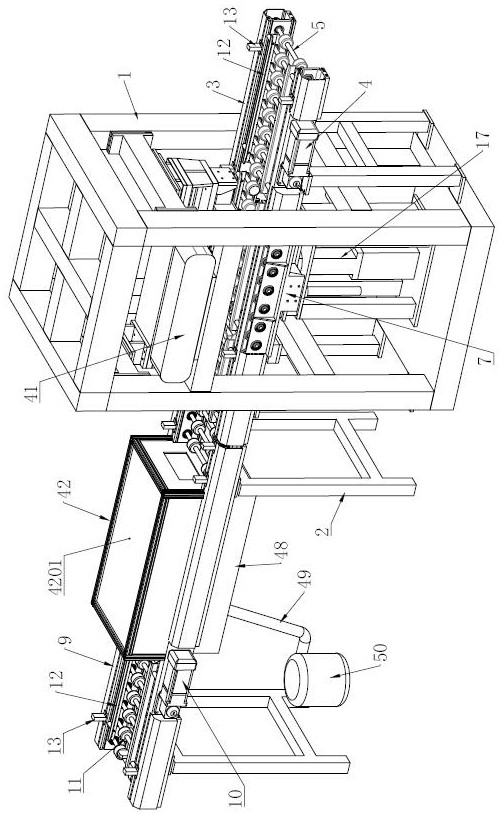

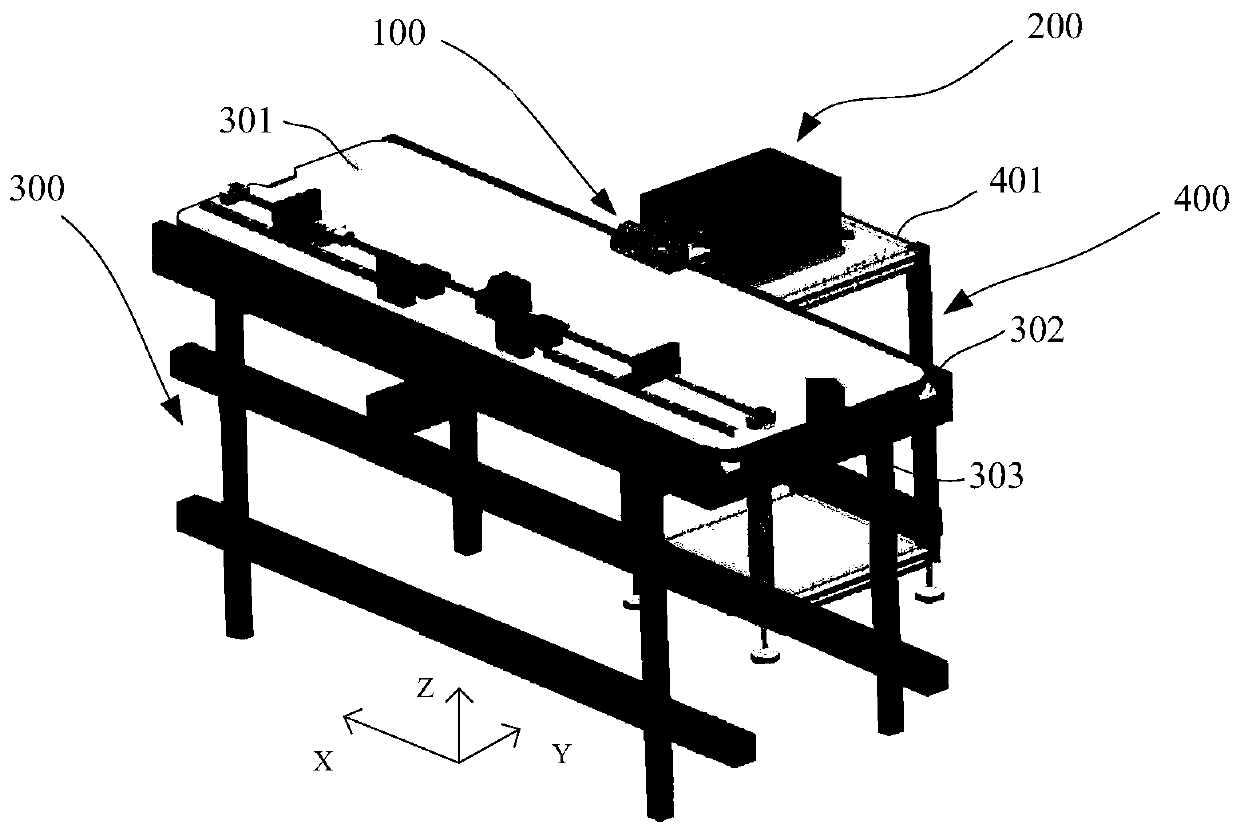

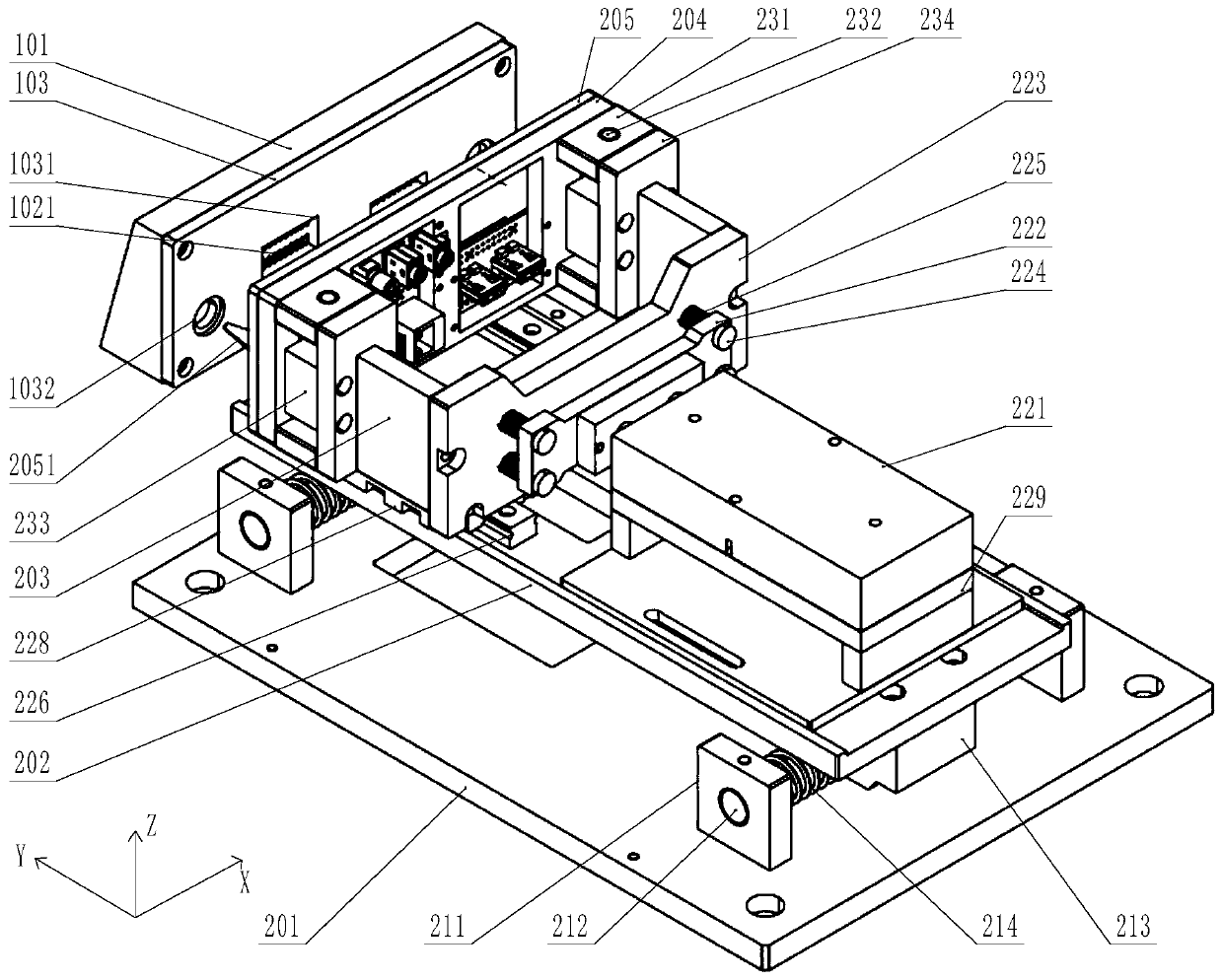

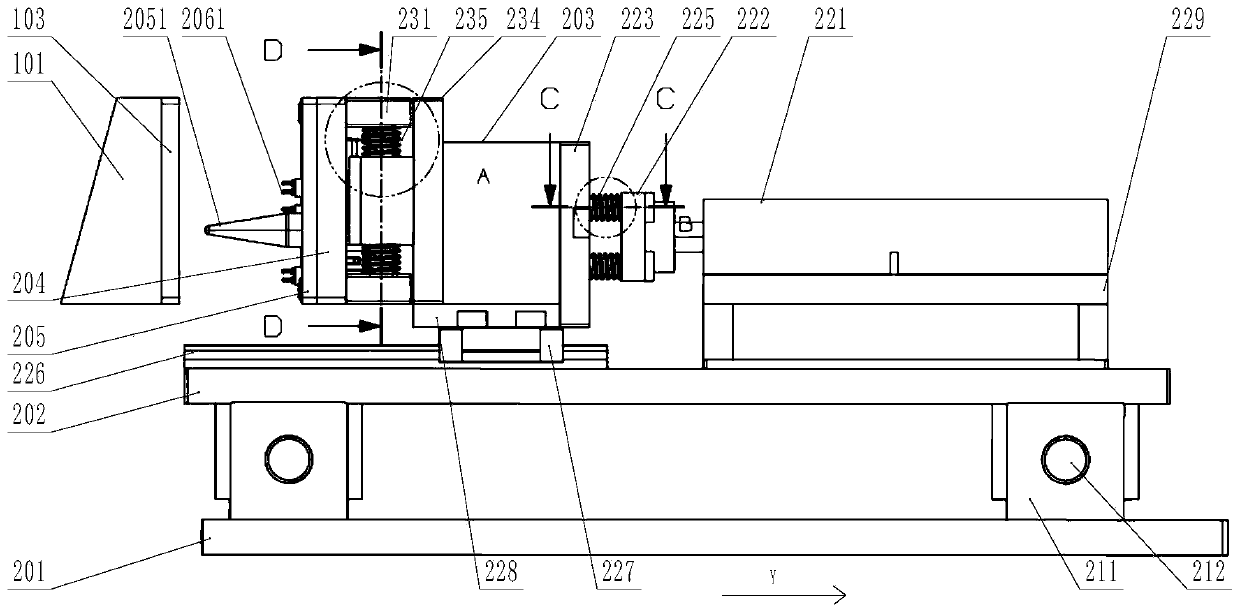

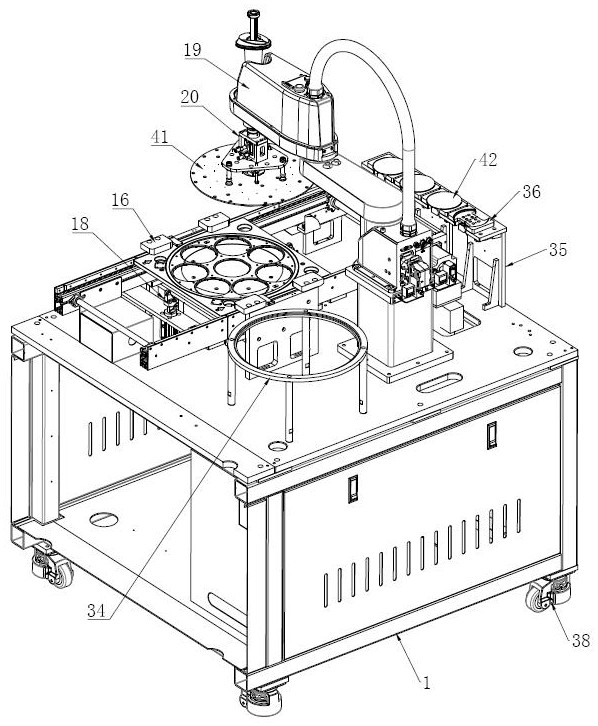

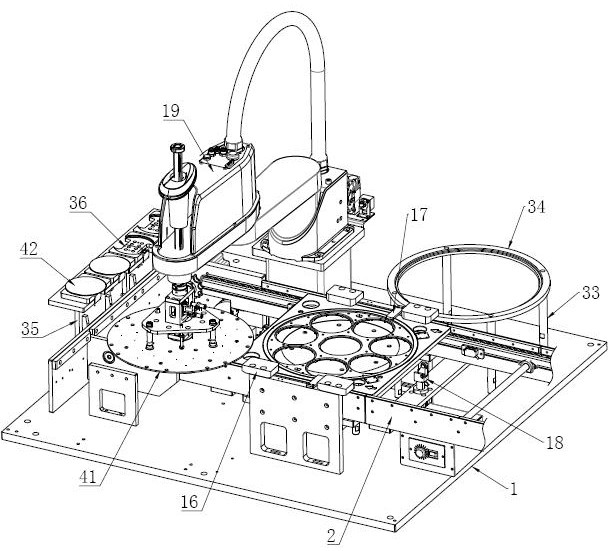

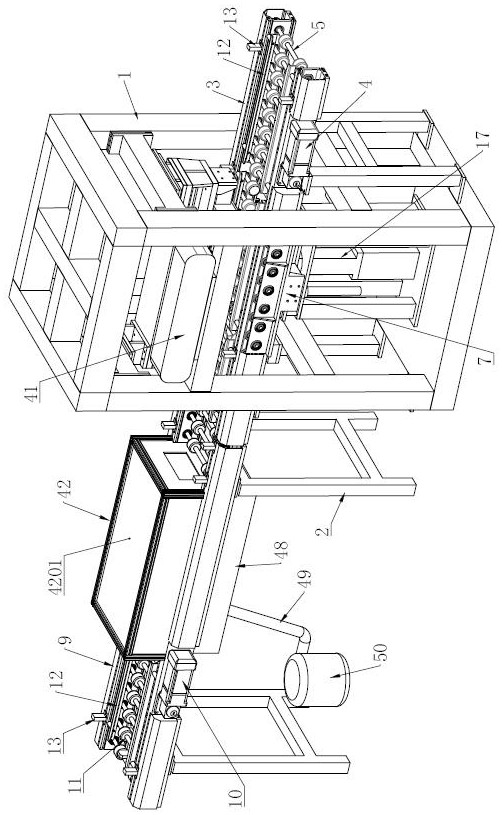

CCD full automatic high-precision needle grinding machine and needle grinding control method

ActiveCN109623578APrecise positioningRealize fine positioningEdge grinding machinesAutomatic grinding controlEngineeringCcd camera

The invention relates to a full automatic needle grinding technology, in particular to a CCD full automatic high-precision needle grinding machine and a needle grinding control method. The method comprises the following steps: step 1) obtaining the coordinates of a workpiece; step 2) shifting a grinding wheel to the tool setting position; step 3) initially positioning the grinding wheel; step 4) finely positioning the grinding wheel; step 5) initially processing the workpiece; step 6) finishing the workpiece; and step 7) polishing the workpiece. The needle grinding machine comprises a base, and a position adjusting device disposed on the base, wherein the position adjusting device includes a Y-axis moving mechanism, and an X-axis moving mechanism disposed on the Y-axis moving mechanism; apunch pin holding mechanism is disposed at the rear end of the Y-axis moving mechanism; the punch pin holding mechanism is provided with a CCD camera capable of scanning a thick needle; the CCD camerais connected with an industrial computer; and the X-axis moving mechanism is provided with a primary grinding mechanism and a fine grinding mechanism in mutual perpendicular arrangement along a horizontal square shaft. The invention improves the precision of the grinding of the product and realizes the purposes of automatic precise positioning and grinding.

Owner:高文祥 +1

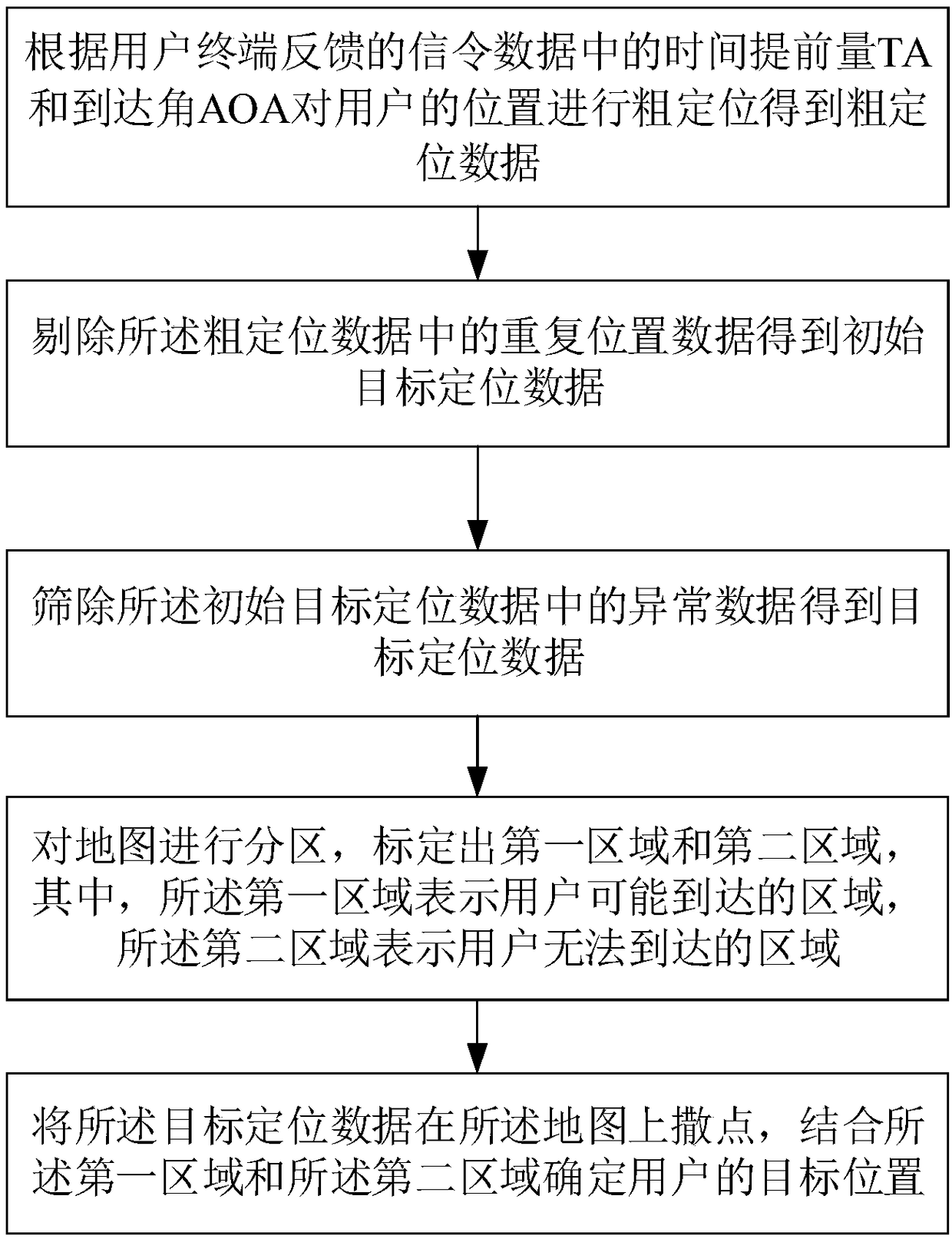

User positioning method and system based on network signaling data analysis

ActiveCN108093361AHigh positioning accuracyRealize fine positioningPosition fixationLocation information based serviceData feedNetwork data

The invention discloses a user positioning method and system based on network signaling data analysis, and belongs to the technical field of data analysis and processing. The method comprises the following steps: performing coarse positioning on the position of a user according to a time advance amount and an arrival angle in signaling data fed back by a user terminal to obtain coarse positioningdata; removing repeated position data in the coarse positioning data to obtain the initial target positioning data; screening abnormal data in the initial target positioning data to obtain target positioning data; dividing a map, and marking a first area and a second area, wherein the first area expresses an area where the user may arrive, and the first area expresses an area where the user cannotarrive; and scattering the target positioning data on the map, and determining a target position of the user in combination with the first area and the second area. Compared with other positioning technologies, the design method of the invention has the advantages of high estimation accuracy and wide application range. At the same time, the method of the invention makes full use of the operator network data and reduces the cost.

Owner:HUAZHONG UNIV OF SCI & TECH

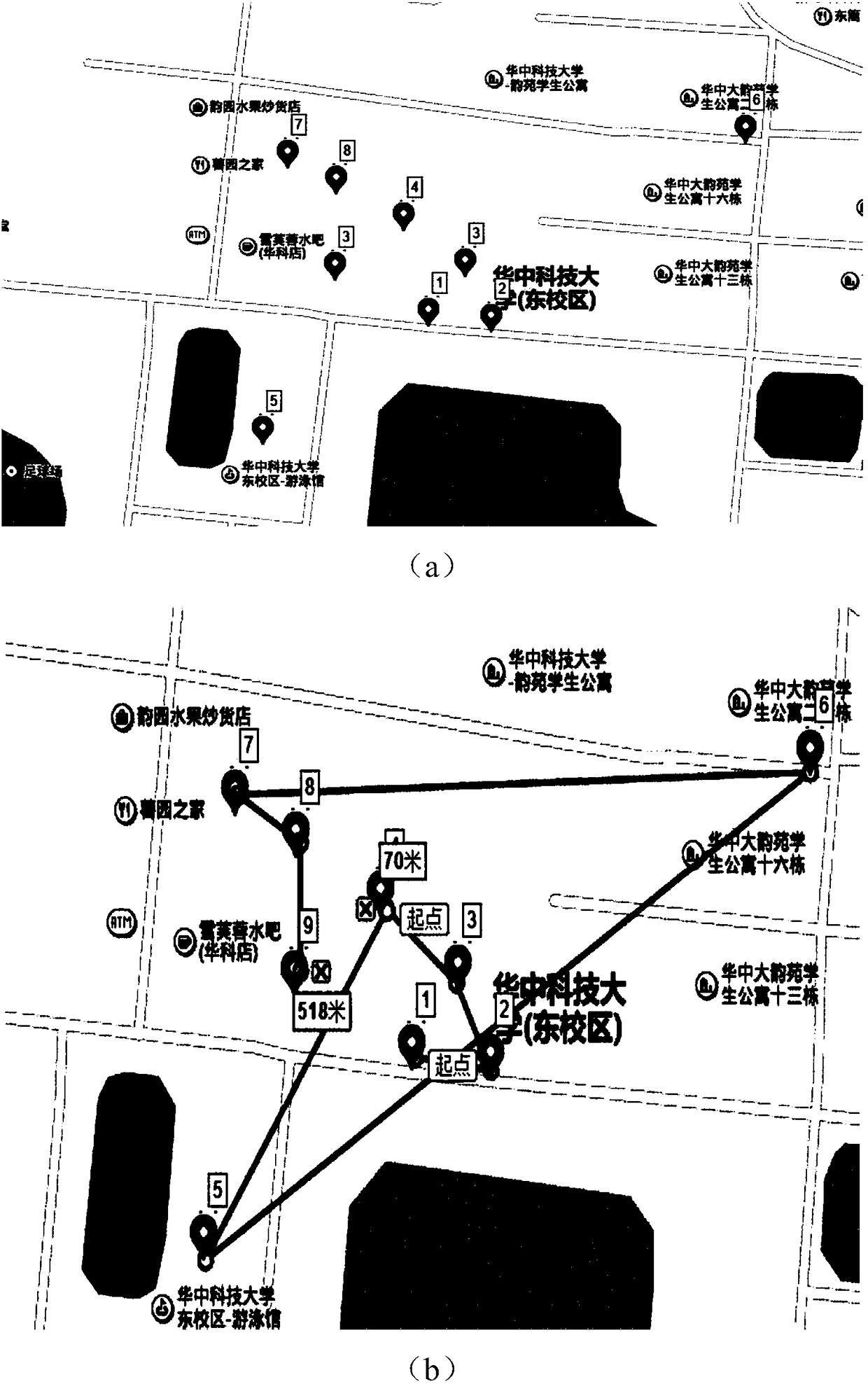

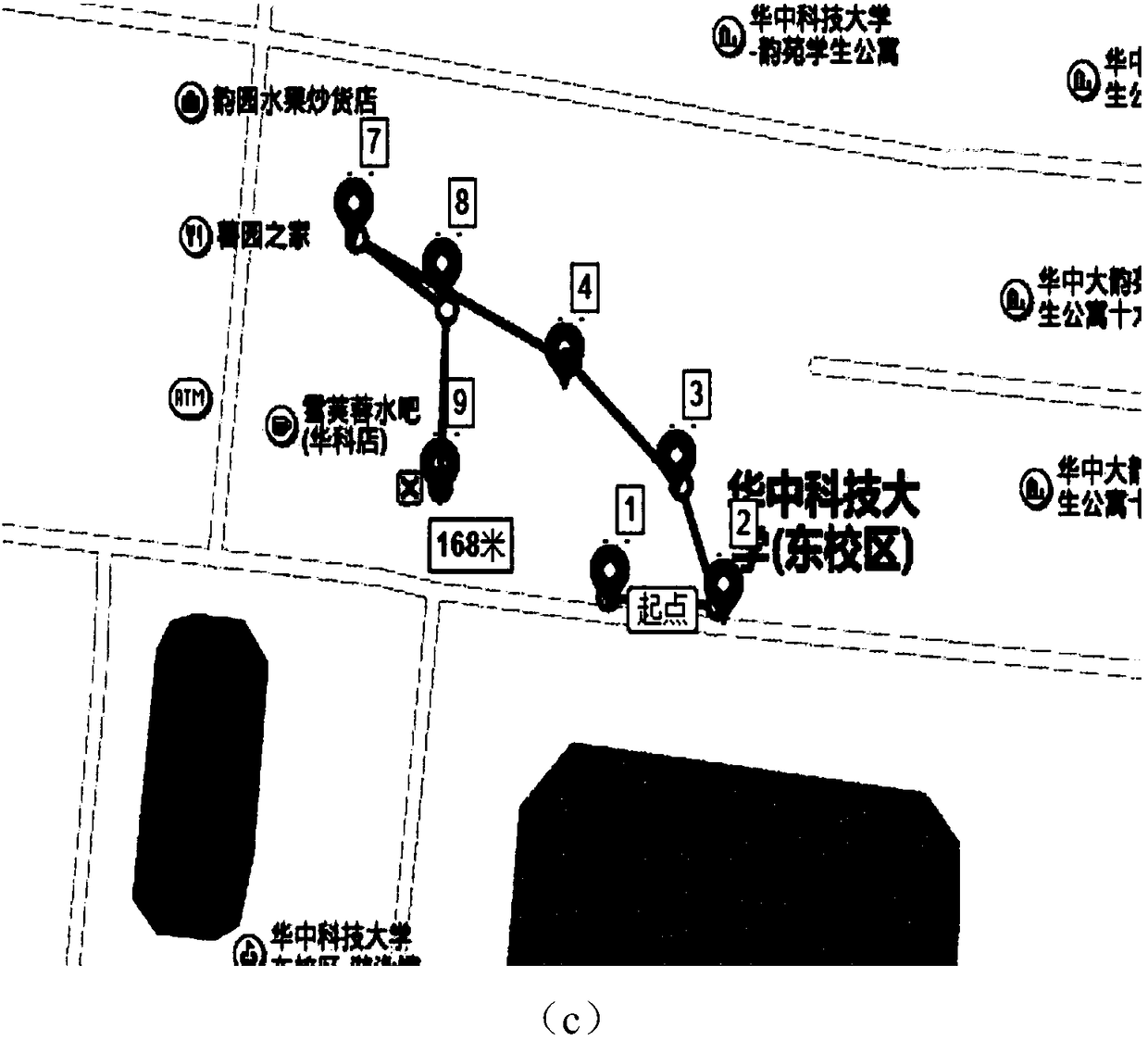

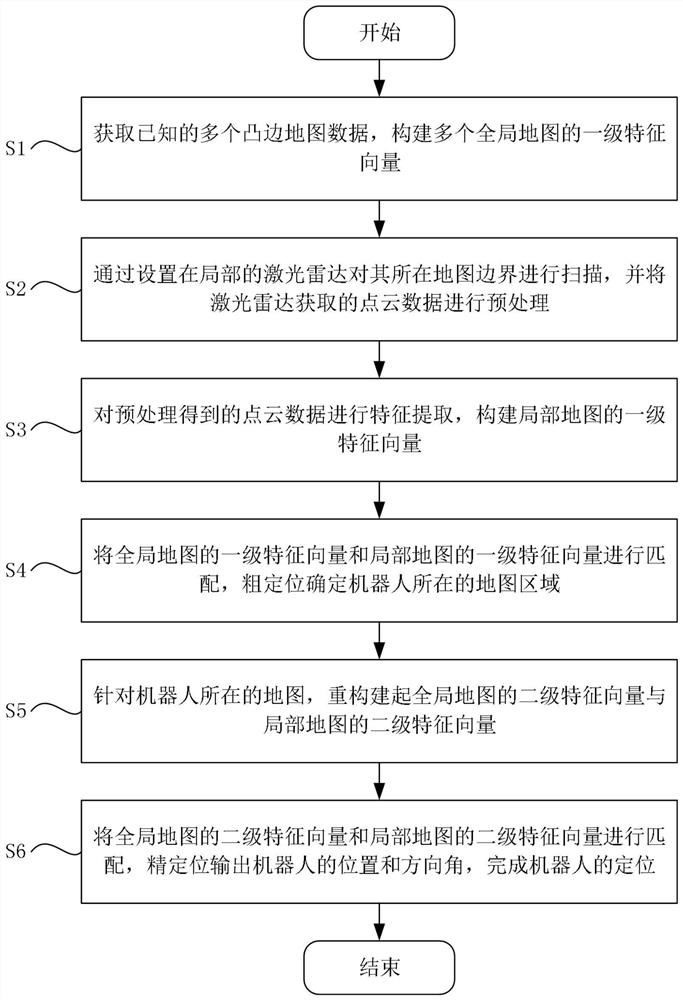

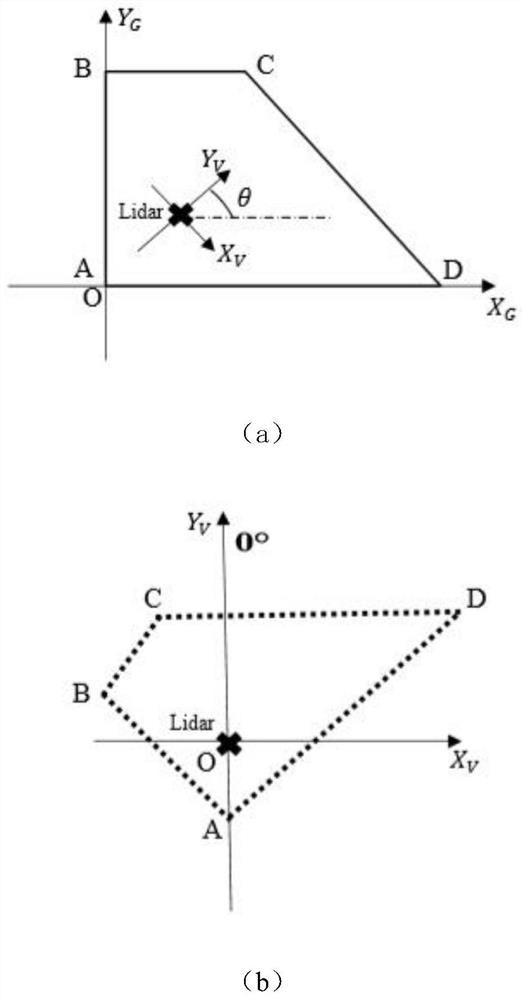

Bounded area rapid global positioning method based on laser radar

ActiveCN111678516ARealize fine positioningReduce complexityNavigational calculation instrumentsElectromagnetic wave reradiationFeature vectorRobot position

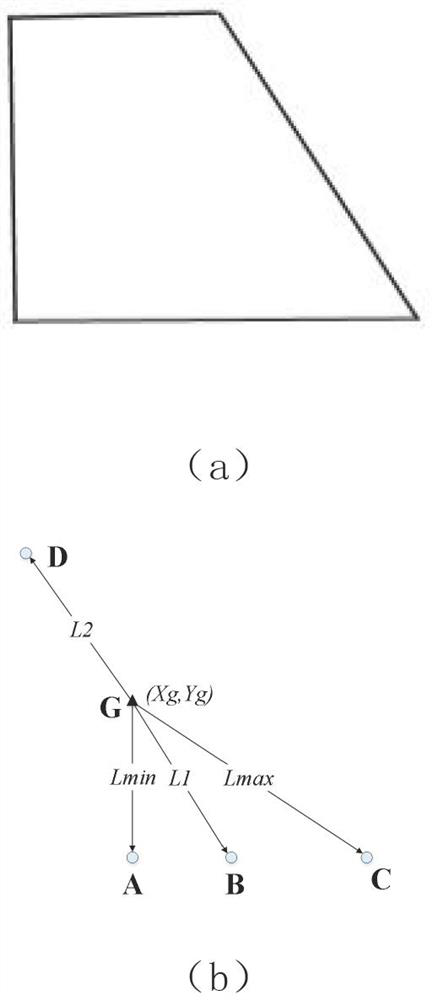

According to the rapid global positioning method for the bounded area of the laser radar, coarse positioning of the map area where the robot is located is achieved by constructing and matching the first-level feature vectors of the global map and the local map; further according to a map where the robot is located, a secondary feature vector of the global map and a secondary feature vector of thelocal map are constructed; the precise positioning of the robot position and azimuth angle is realized, influence of illumination on positioning precision is effectively avoided, the convex polygon geometric map is utilized as map representation, the laser radar positioning algorithm based on map feature vector matching is acquired, algorithm complexity is reduced, and rapid global positioning ofthe robot in a bounded area is realized.

Owner:SUN YAT SEN UNIV

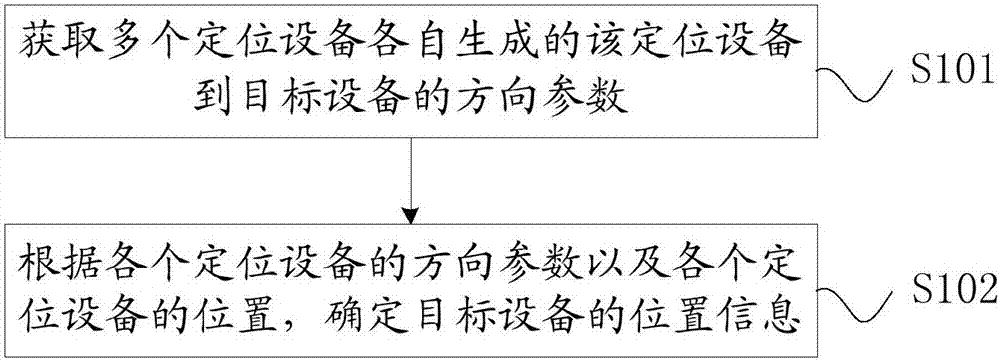

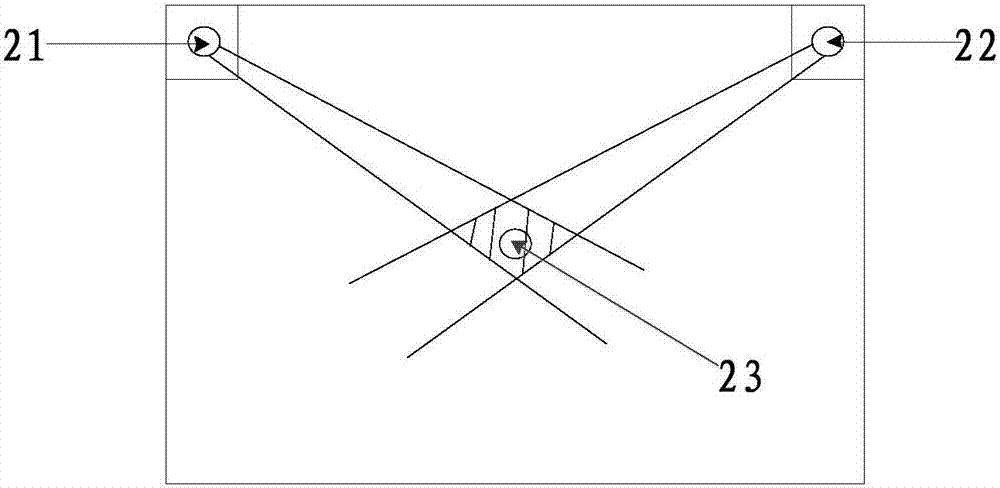

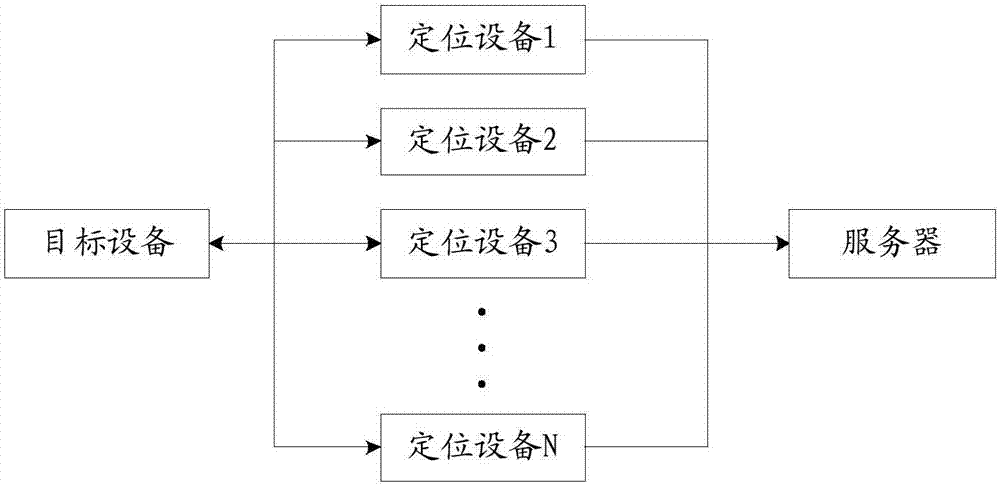

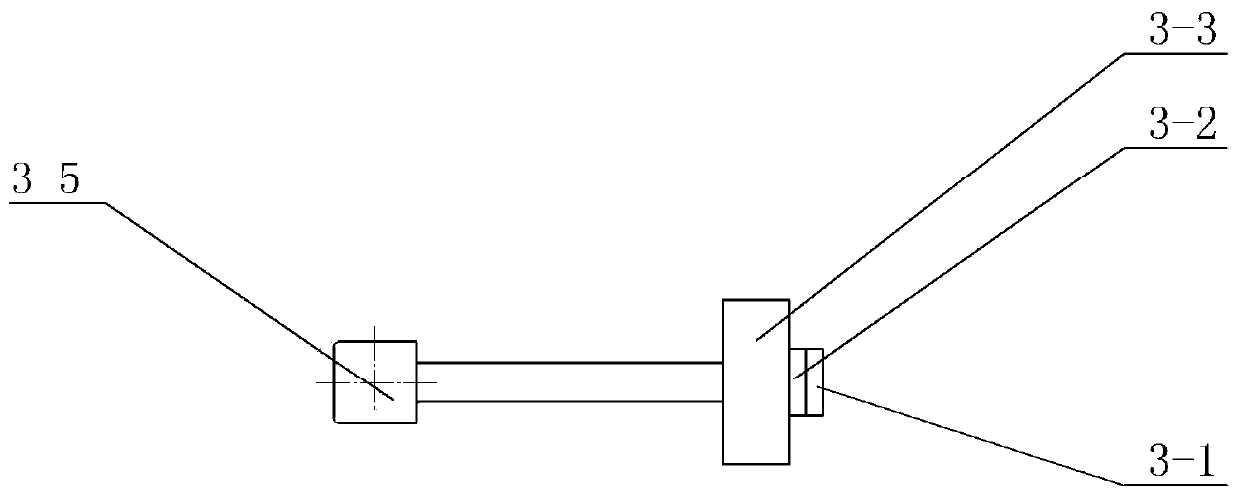

Positioning method, positioning device and positioning equipment

InactiveCN107346012ARealize fine positioningHigh speedPosition fixationPhase controlLocation Equipment

The invention discloses a positioning method, a positioning device and positioning equipment. The positioning method comprises the steps of: acquiring direction parameters, from a plurality sets of positioning equipment to target equipment, respectively generated by the positioning equipment, wherein each positioning equipment comprises a phase-controlled arrayed antenna, the direction parameters comprise an antenna main lobe direction when the phase-controlled arrayed antenna is in a first antenna array phase, and the first antenna array phase is an antenna array phase when the intensity of a signal received by the phase-controlled arrayed antenna from the target equipment is at the maximum; and determining position information of the target equipment according to the direction parameters of the positioning equipment and positions of the positioning equipment. The positioning method and the positioning device based on the phase-controlled arrayed antennas can realize rapid and precise positioning by means of a small amount of the positioning equipment.

Owner:ZTE CORP

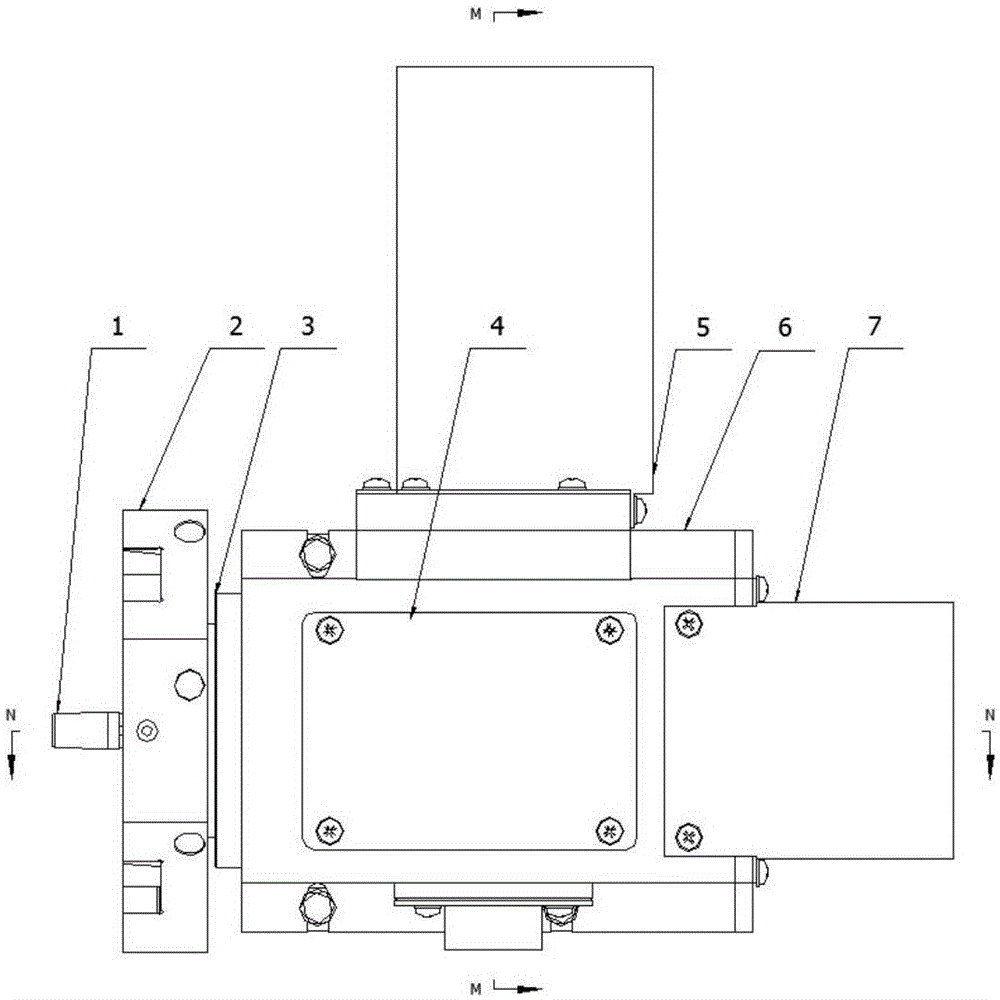

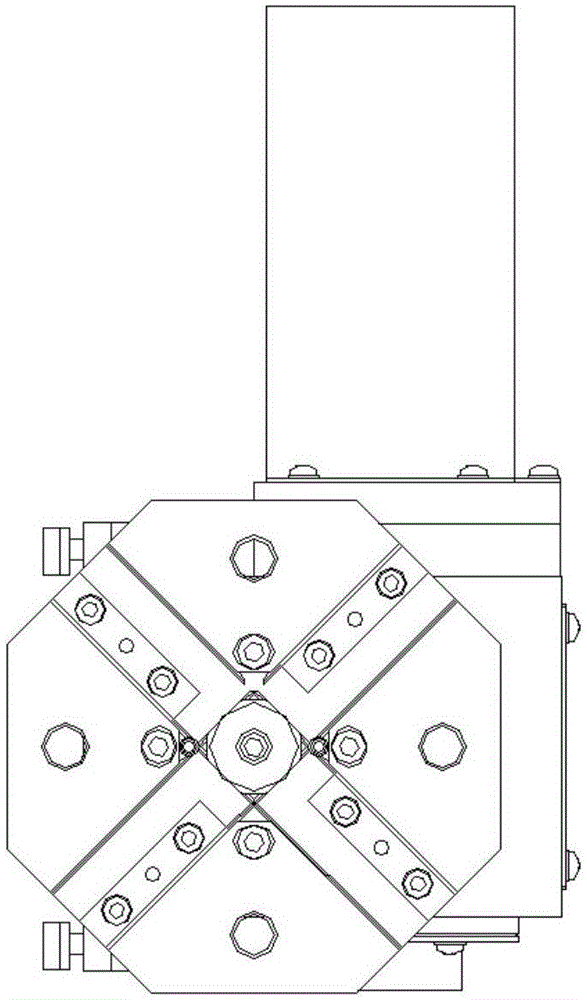

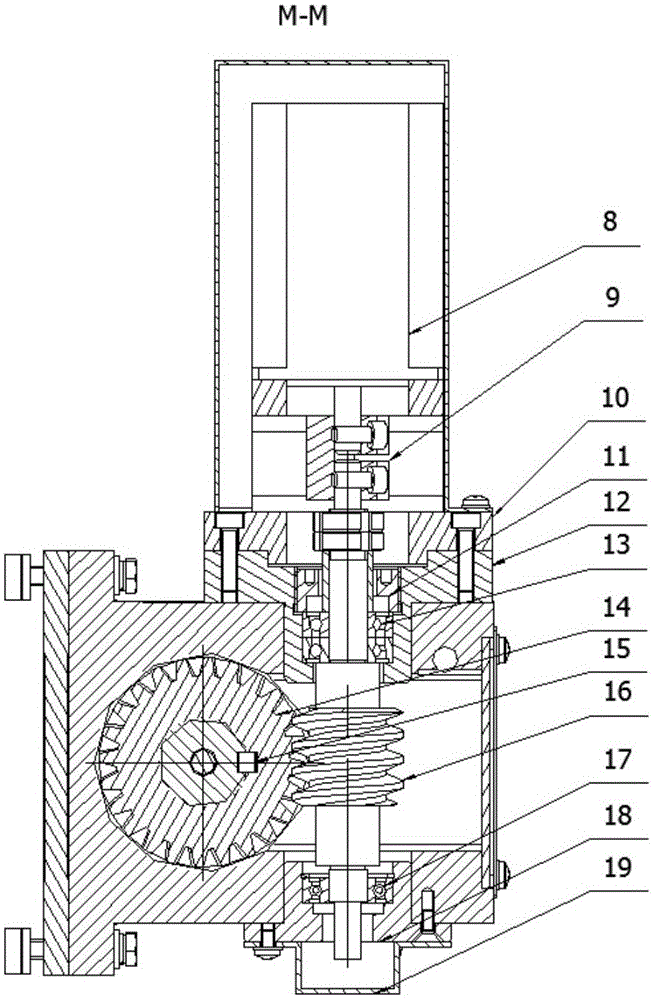

Cutter rest assembly

ActiveCN105269008ARealize fine positioningHigh positioning accuracyLarge fixed membersEngineeringSelf locking

The invention discloses a cutter rest assembly. The cutter rest assembly comprises a cutter disc part, a main shaft part, a worm part, a cutter rest box body part and an ejection mechanism part, wherein a fixed end tooth I is installed at the front end of the cutter rest box body; a fixed end tooth II matched with the fixed end tooth I is installed at the front end of the main shaft and connected with a main shaft through keys; a moving end tooth is further installed on the front portion of the main shaft and connected with the main shaft through a straight pin shaft and a key and achieves axial movement through an ejection rod and a compression spring installed inside the main shaft; the end, far away from the cutter disc part, of the cutter rest box body is provided with a power driving mechanism for driving the ejection rod to rotate forwards and reversely. The cutter rest assembly is more useful for small or micro numeral control inclined guide rail lathes, and the positioning accuracy and cutting force are greatly improved compared with a square cutter frame. Primary positioning is achieved mainly through matching of an eight-equal-part ratchet wheel and a supporting foot assembly on the main shaft. Accurate positioning is achieved through meshing of the moving end tooth and the fixed end teeth. A worm has a self-locking function, and finally a cutter disc is fixed and used for machining a part.

Owner:上海西马特机械制造有限公司

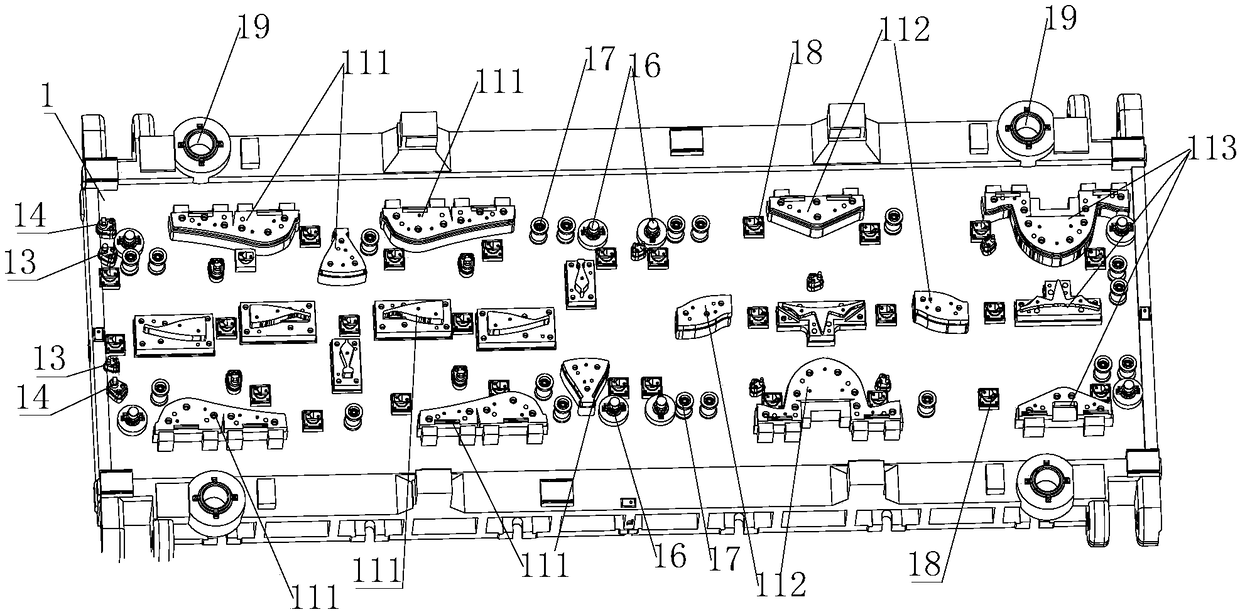

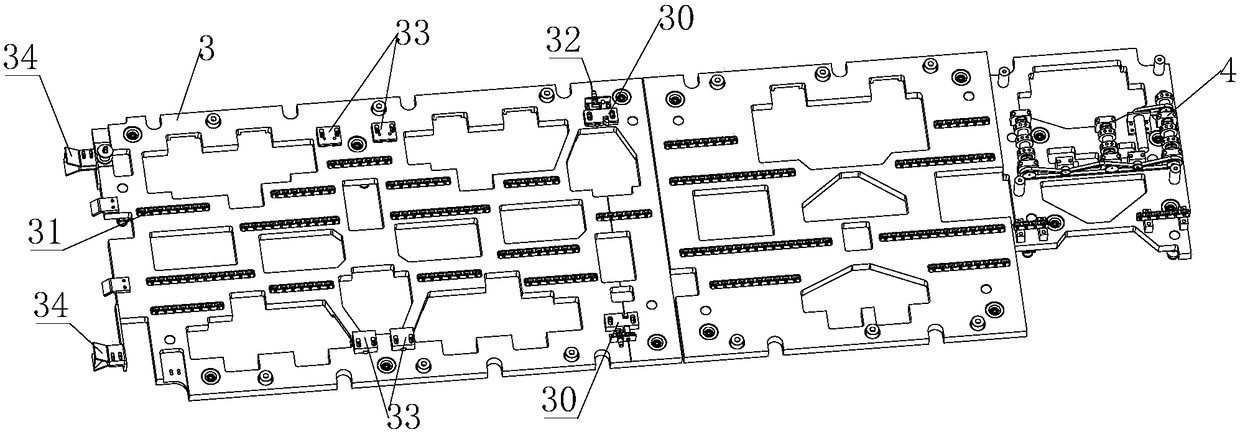

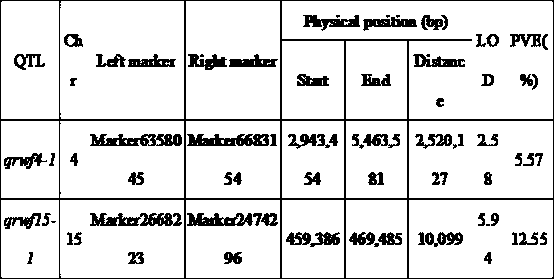

Uncoiling punching die and punching technology

InactiveCN108480475AContinuous StampingRealize fine positioningShaping toolsMetal-working feeding devicesPunchingMachine tool

The invention discloses an uncoiling punching die. The die comprises an upper die holder fixed to a machine tool upper table board and doing motion close to or away from a lower die holder along withthe machine tool upper table board, a part erecting plate, an opening male mold, a first punching male mold, a positioning assembly and a pressing plate. The upper die holder and the lower die holderare sequentially provided with three forming die blocks according to the machining sequence, the opening male mold and an opening female mold are matched to punch a positioning opening in a coil, thefirst punching male mold and a first punching female mold are matched to punch a positioning hole, the positioning assembly is fixed to the part erecting plate, and comprises a positioning plate and amovable rod, the movable rod slides along a sliding groove in the positioning plate to enable the movable rod to be close to or away from the coil, the side wall of the positioning assembly is in sliding connection with the coil, and when the movable rod slides to the positioning opening of the coil, positioning of the coil is finished. The invention further discloses a punching process of the uncoiling punching die. Compared with the prior art, continuous punching molding is achieved, through arranging of inserts, multiple blanks can be punched at a time, and production efficiency is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

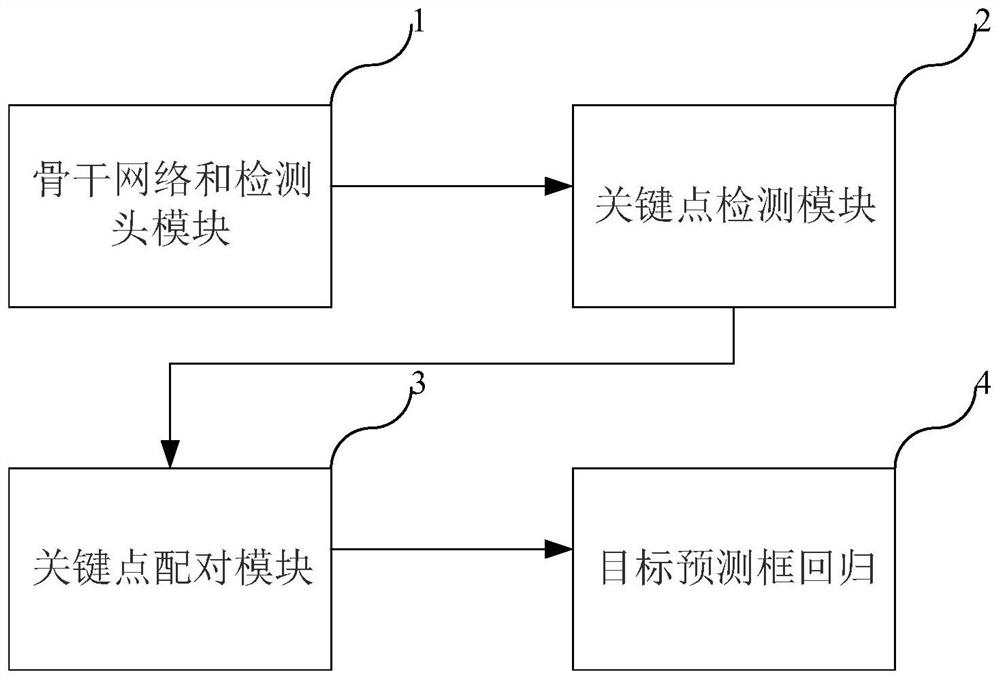

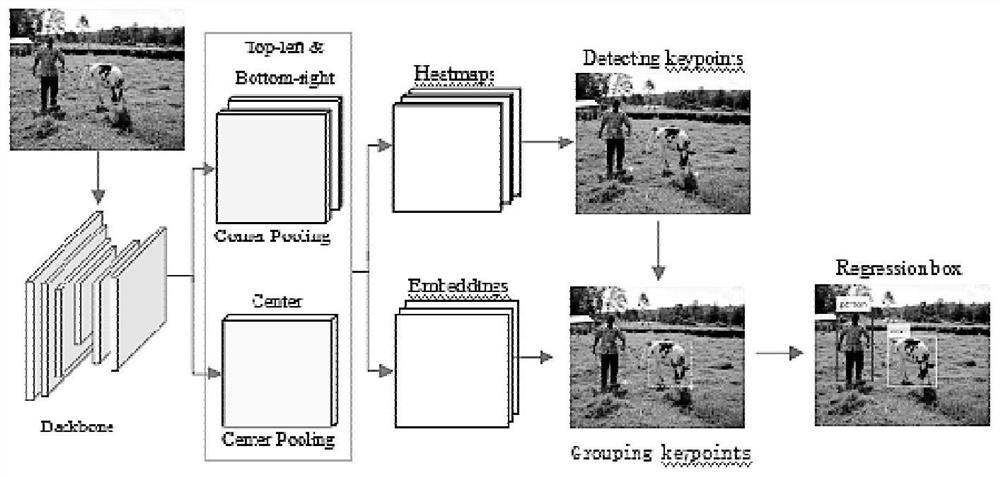

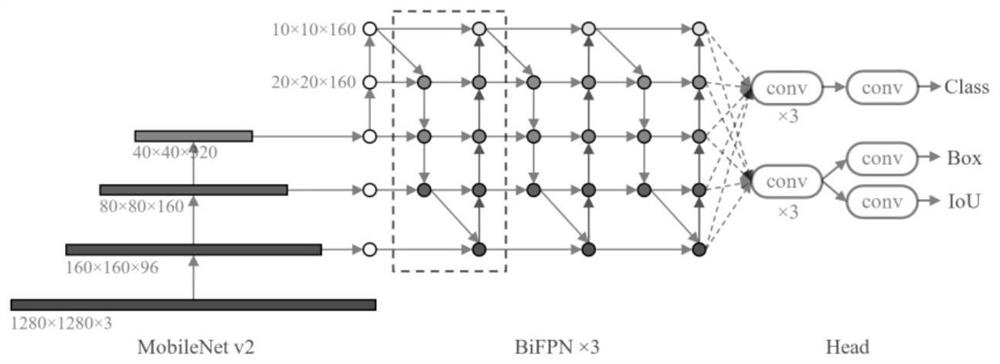

Anchor-frame-free target detection method and system based on diagonal network

PendingCN114863136AReduce target false detection rateHigh precisionCharacter and pattern recognitionFeature vectorAlgorithm

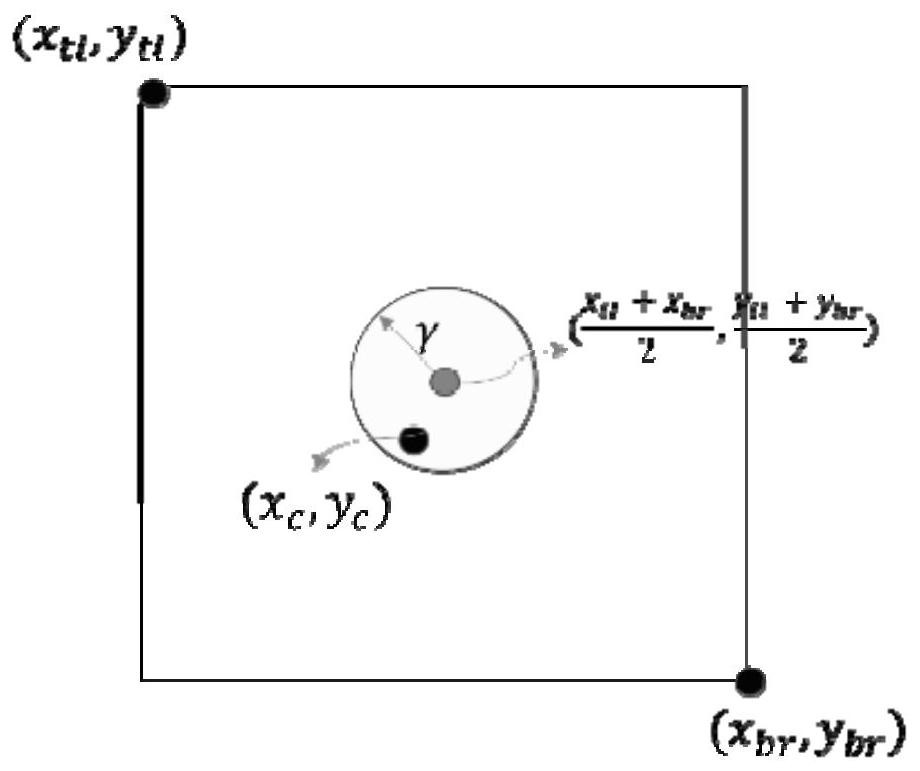

The invention provides a diagonal network-based anchor-frame-free target detection method and system. The method comprises the following steps of: extracting depth features of an input image by using an hourglass network and carrying out pooling operation so as to obtain a key point thermodynamic diagram, an embedded feature vector feature diagram and an offset feature diagram; processing the key point thermodynamic diagram by using a diagonal network, sorting the key points according to confidence coefficients, selecting the key points of the first k confidence coefficients as target key points, and obtaining key point positions and key point category information of the upper left corner, the lower right corner and the central point; based on a Fisher criterion, designing an embedded vector learning loss function to carry out key point combination pairing training, and further discriminating a preliminary pairing result by using a central key point; and using the distance, the length and the slope measurement loss of the diagonal center points of the prediction rectangle and the annotation rectangle frame to design the diagonal loss for regression training of the target prediction frame. The technical problems that the anchor frame is difficult to design, samples are unbalanced and the detection precision is low are solved.

Owner:中国人民解放军陆军炮兵防空兵学院

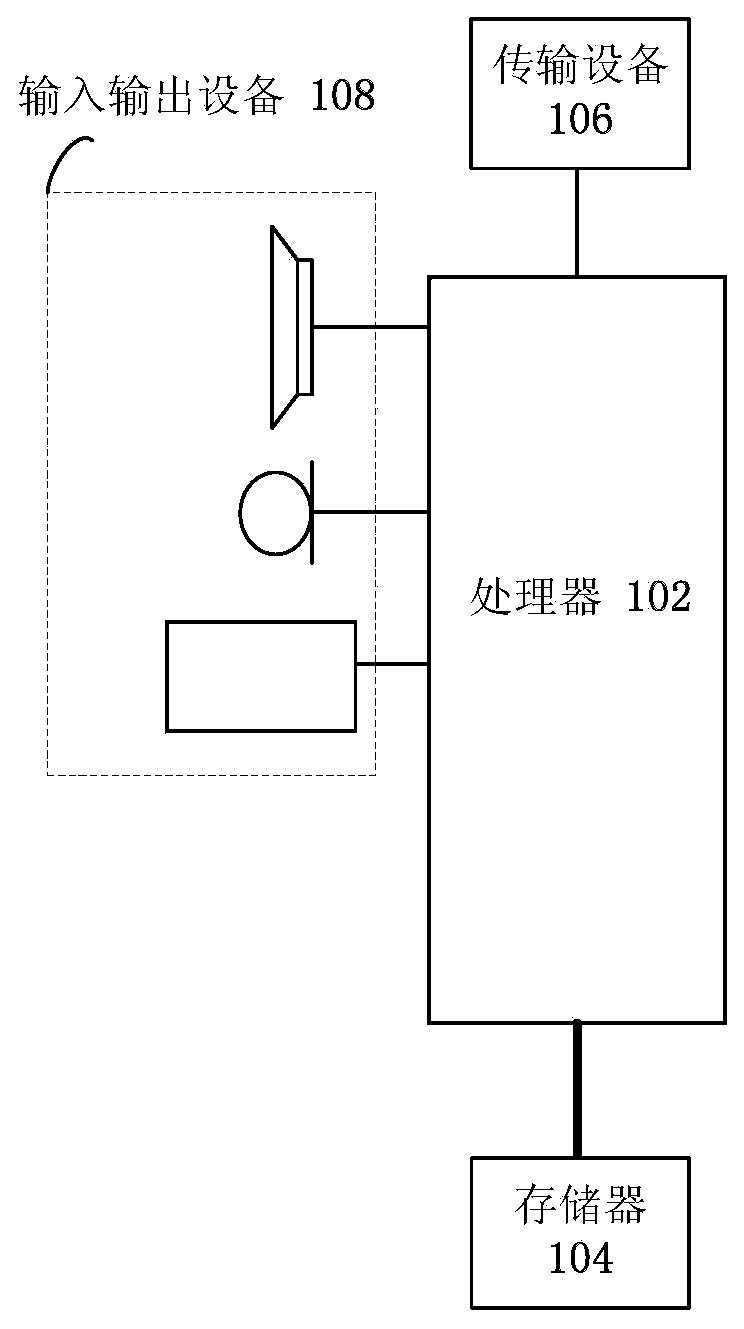

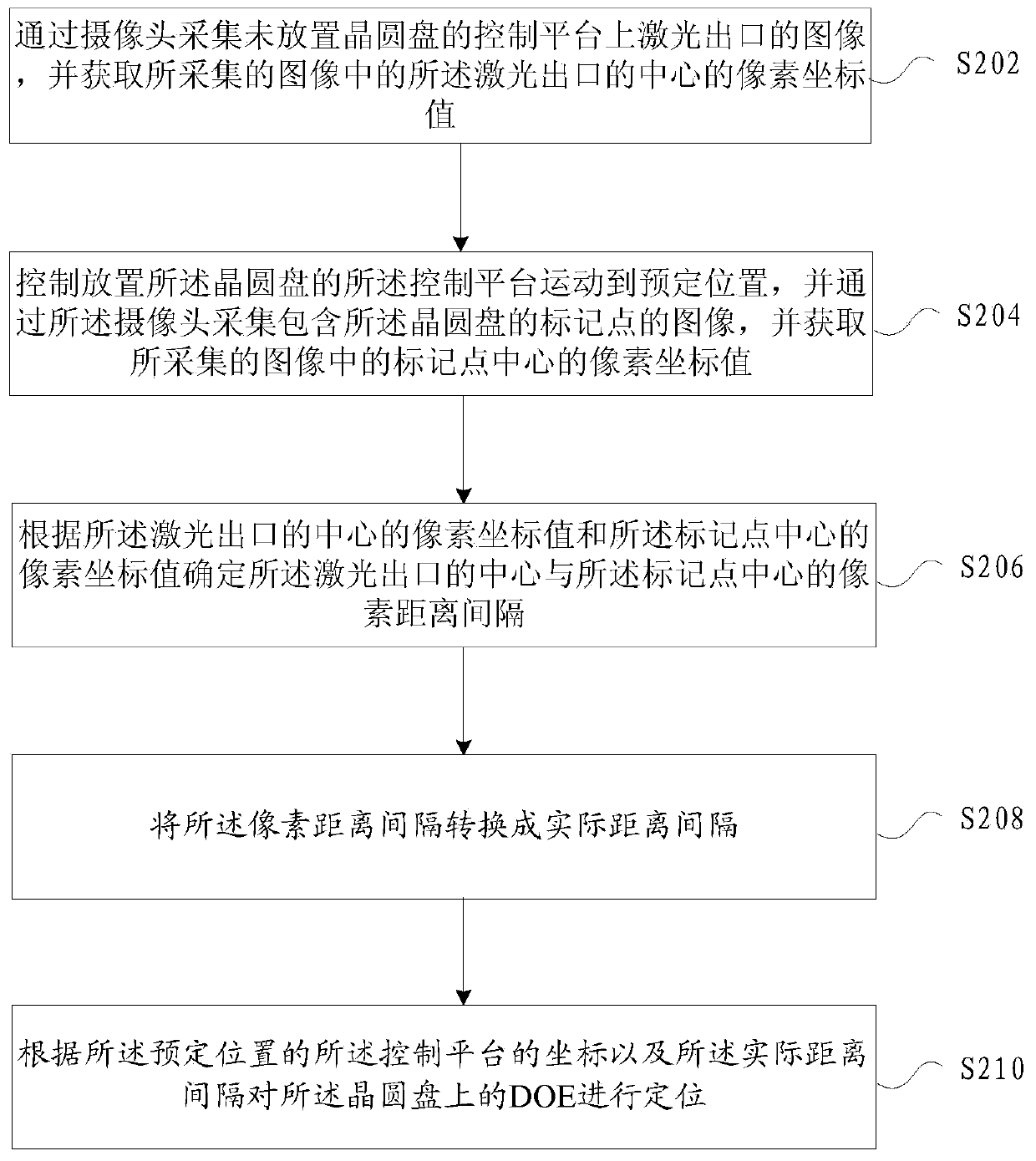

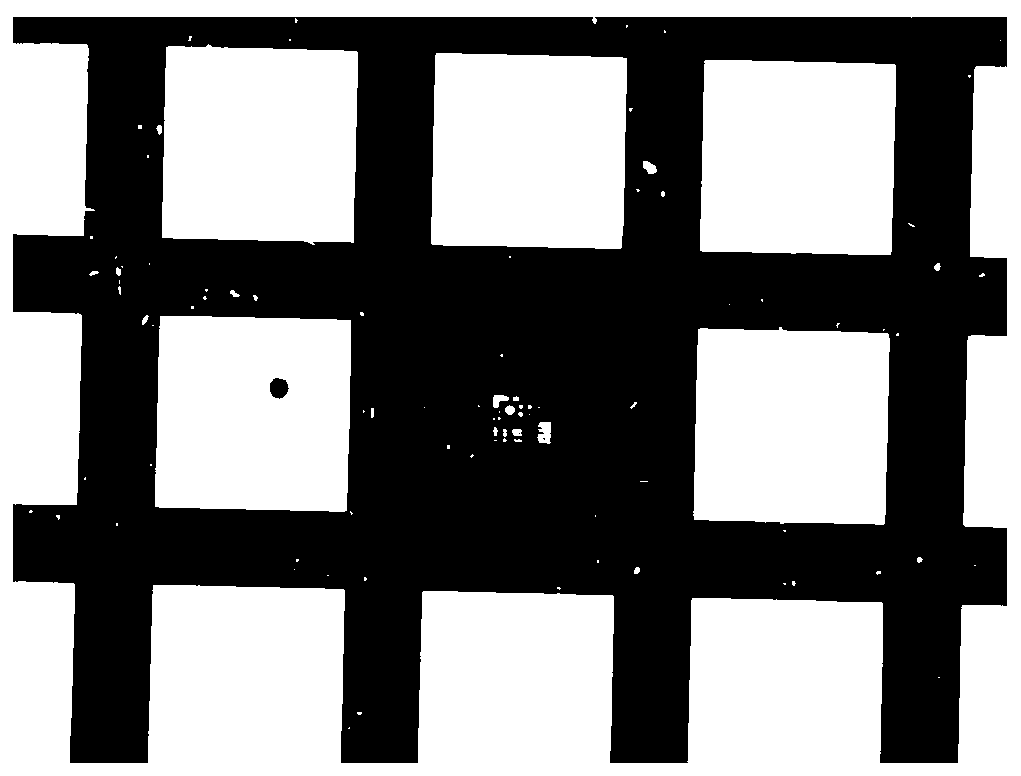

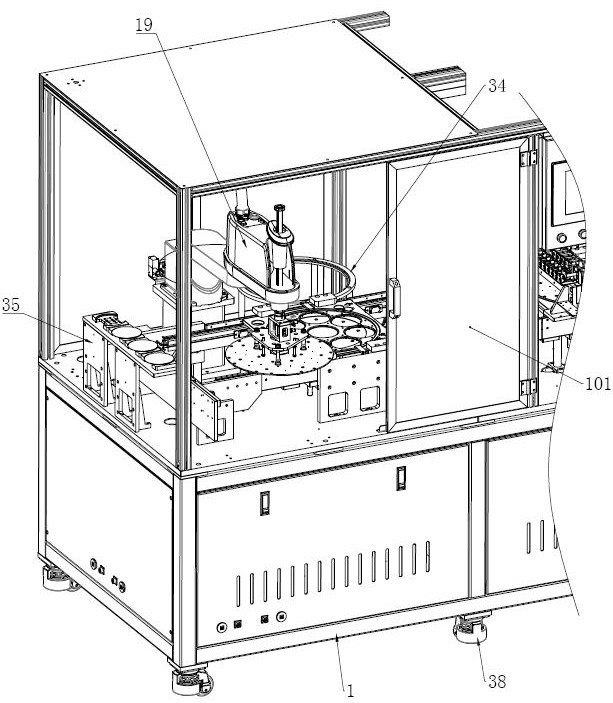

A wafer disc positioning method and device

ActiveCN109886917ASolve the problem of high-precision fine positioningSolve the problem of fine positioningImage analysisMachine visionMechanical engineering

The invention provides a wafer disc positioning method and device, wherein the method comprises the steps of collecting an image of a laser outlet in a control platform where a wafer disc is not placed through a camera, and obtaining a pixel coordinate value of the center of the laser outlet; controlling the control platform on which the wafer disc is placed to move to a preset position, collecting an image containing a mark point of the wafer disc through a camera, and obtaining a pixel coordinate value of the center of the mark point; determining a pixel distance interval between the centerof the laser outlet and the center of the mark point according to the pixel coordinate value of the center of the laser outlet and the pixel coordinate value of the center of the mark point; converting the pixel distance interval into an actual distance interval; and positioning the wafer disc according to the coordinates of the control platform at the predetermined position and the actual distance interval, so that the problem of how to realize high-precision fine positioning of the wafer disc through machine vision in the prior art can be solved, and the effect of high-precision fine positioning of the wafer disc is realized.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Two-dimensional code positioning method and mobile robot positioning method based on two-dimensional code

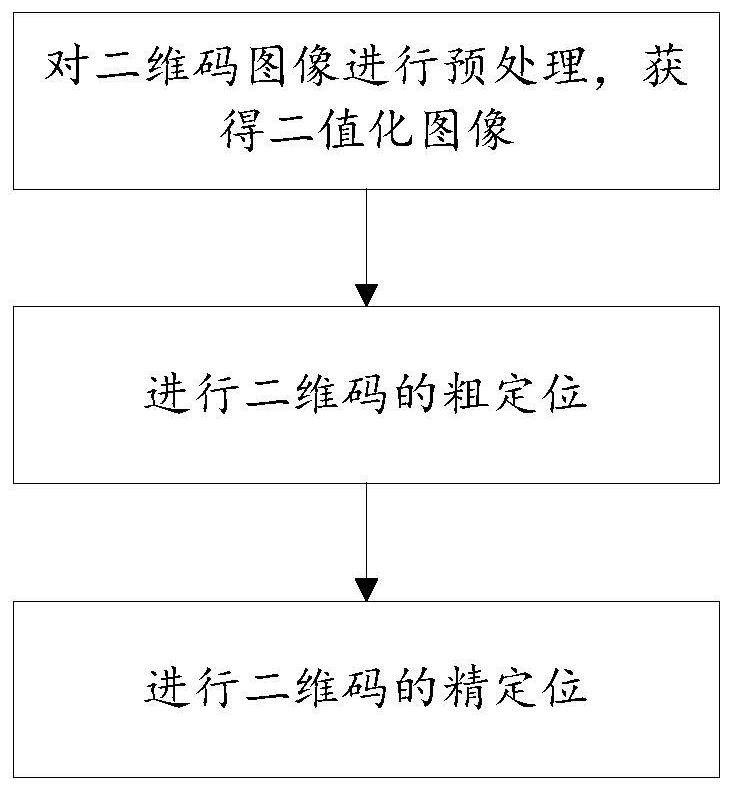

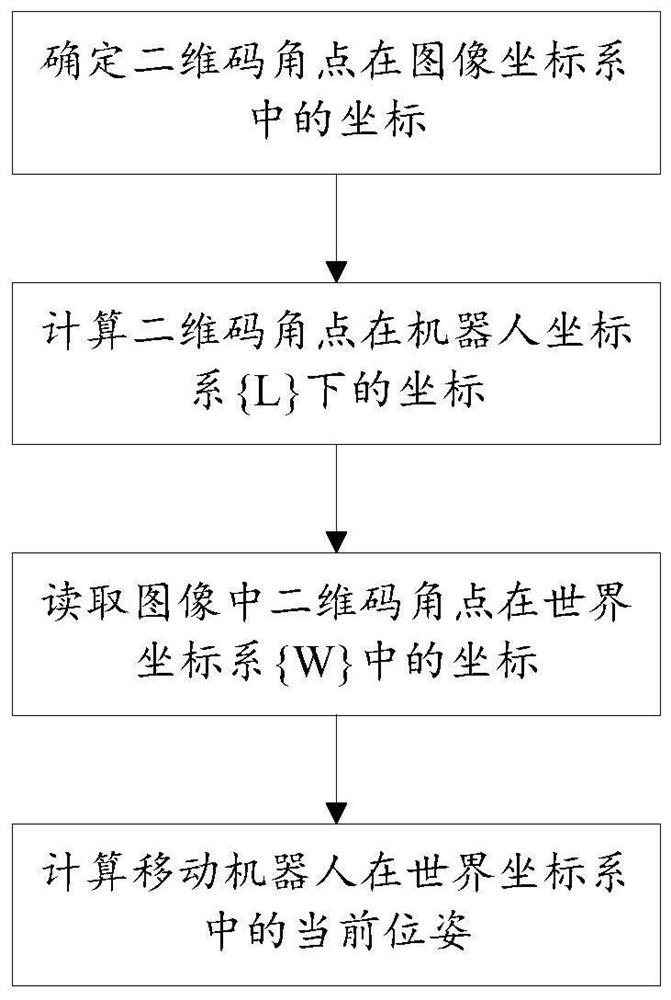

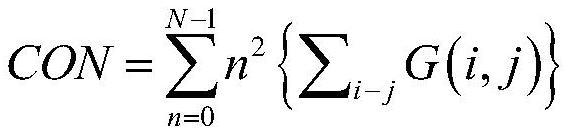

PendingCN112651259AAchieve smooth denoising effectImprove accuracyImage enhancementNavigational calculation instrumentsComputer graphics (images)Angular point

The invention discloses a two-dimensional code positioning method, and the method comprises the steps: S11, carrying out the preprocessing of a two-dimensional code image, and obtaining a binary image; S12, coarse positioning of the two-dimensional code: calculating the contrast ratio of adjacent pixel points in the binarized image, and if the contrast ratio is close to a contrast ratio threshold value, determining that the adjacent pixel points are two-dimensional code areas, and completing coarse positioning of the two-dimensional code areas; and S13, fine positioning of the two-dimensional code: extracting an edge contour of the coarse positioning two-dimensional code image area, performing straight line fitting on the extracted edge contour, fitting into four straight lines, taking an intersection point of the four straight lines as an angular point of the two-dimensional code, and taking a connection line intersection point of two groups of diagonal angular points as a midline point of the two-dimensional code, thereby finishing fine positioning of the two-dimensional code. Two-dimensional code coarse positioning and two-dimensional code fine positioning are carried out in sequence, accurate positioning of two-dimensional code intersection points in an image is achieved, preliminary extraction of two-dimensional code contour coarse is achieved through contrast, contour lines are combined based on straight line fitting, and accurate positioning of two-dimensional code angular points in the image is achieved.

Owner:WUHU HIT ROBOT TECH RES INST

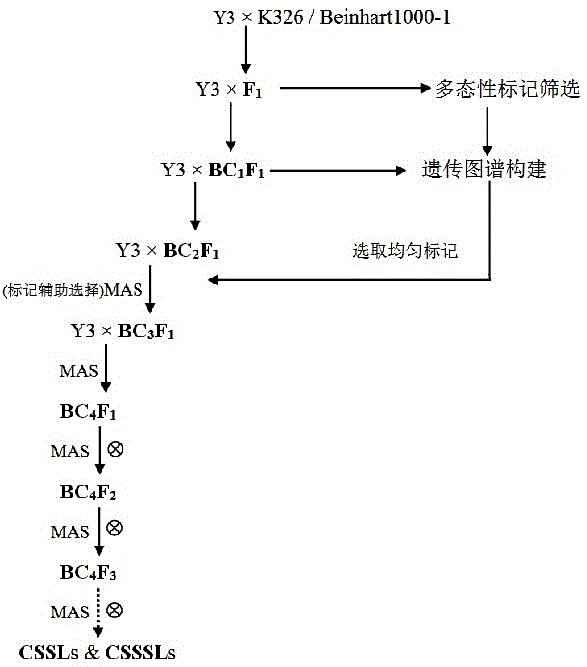

Culture method for stable and homozygous tobacco chromosome single fragment substitution line

ActiveCN105850722ABroaden the genetic baseHigh selectivityPlant genotype modificationAgricultural scienceNicotiana tabacum

The invention discloses a culture method for a stable and homozygous tobacco chromosome single fragment substitution line. The culture method comprises the steps that tobacco germplasm Y3 with a good comprehensive form serves as a recurrent parent, the high-quality tobacco variety K326 and the disease-resistant cigar variety Beinhart 1000-1 serve as donor parents, the technologies of hybridization, backcrossing and molecular marker-assisted selection are adopted, molecular markers obtained through an established tobacco genetic linkage map are used for carrying out assisted selection on the backcrossing second generation and the subsequent backcrossing generations thereof, and the self-crossing first generation and the later generations thereof, chromosome substitution fragment features are identified, and the stable and homozygous tobacco chromosome single fragment substitution line is obtained. By means of the culture method, the genetic basis of tobacco varieties can be expanded, permeation of exogenous good germplasm to culture varieties can be rapidly achieved, a convenient, practical, scientific and efficient approach is provided for the high-quality and disease resistance polymerization oriented improvement on tobacco, the selectivity of the breeding process is improved, the breeding efficiency is improved, and the culture process of new high-quality and disease resistance tobacco varieties and the seed industrialization process are accelerated.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Cylinder cover dry-type air tightness detection device

ActiveCN112284625APlay a guiding roleAchieve positioningFluid-tightness measurement using fluid/vacuumHydraulic cylinderEngineering

The invention belongs to the technical field of cylinder cover detection equipment, and provides a cylinder cover dry-type air tightness detection device. The device comprises a rack, a roller way conveying line driven by a driving device is arranged on the rack, and a guide slideway and a sensor for realizing cylinder cover position detection are arranged on the roller way conveying line; a positioning stop block driven by a first cylinder and a lower sealing plate driven by a hydraulic cylinder are arranged at the bottom of the rack; an upper sealing plate is installed at the top of the rack, the two ends of the upper sealing plate are provided with side sealing plates which are driven by a second air cylinder respectively, the clamping faces of the lower sealing plate, the upper sealingplate and the side sealing plates are provided with sealing rings corresponding to cylinder cover holes in position, and the clamping face of the sealing plate on one side is provided with an air tightness detection hole communicated with an air supply device. And an air tightness detector is further mounted at the top of the rack. According to the invention, automatic airtightness detection of the cylinder cover can be realized, the detection efficiency and the detection precision are greatly improved, the leakage amount can be detected, and the tedious process of treatment after immersion of a test piece is omitted.

Owner:潍坊思博精工科技有限公司

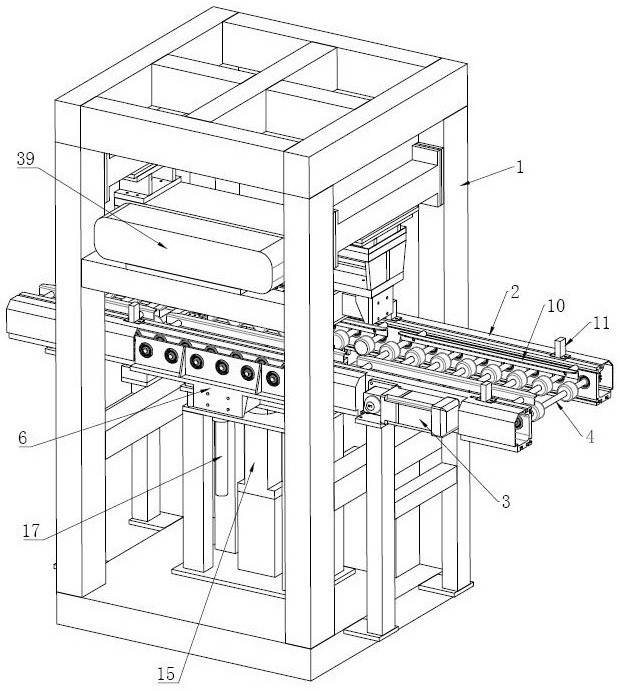

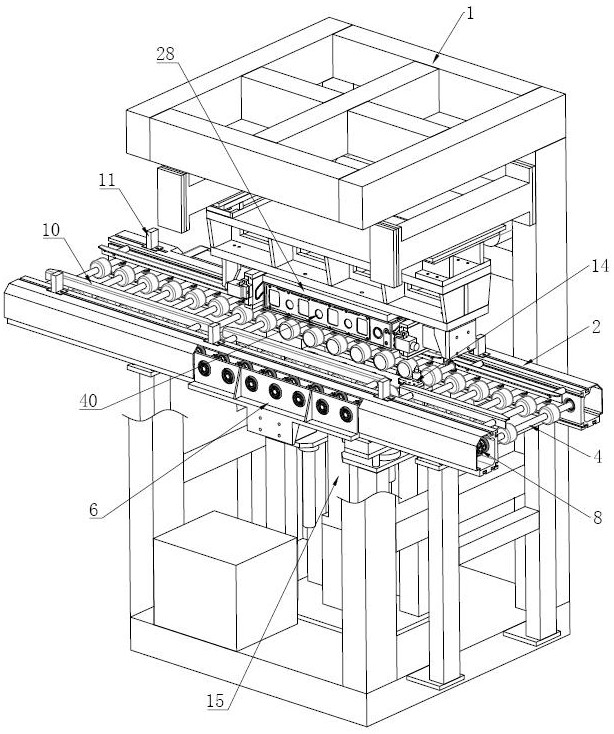

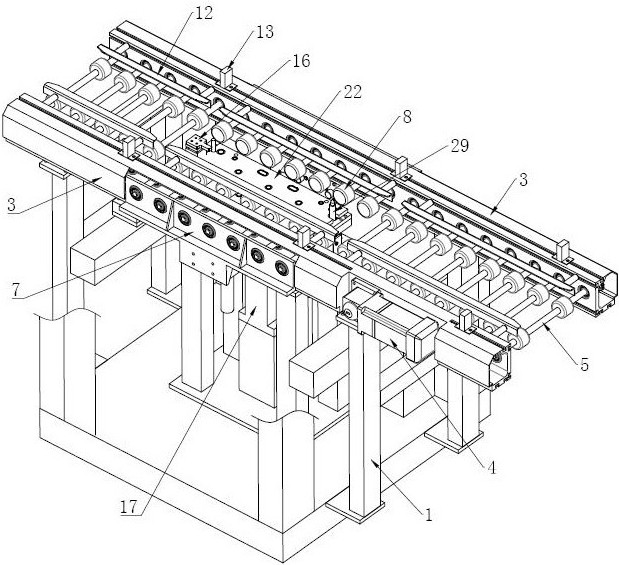

Automatic CNC Jump Cutting Machine

ActiveCN103252809BEasy to cutRealize electric pressurizationMetal working apparatusNumerical controlTurbine

The invention discloses a full-automatic numerical control jump cutting machine which comprises a machine body, a transmission mechanism, a main motor, a pressurizing mechanism and an upper die base. A jump cutting platform is arranged on a bottom plate of the machine body. A tool ejecting mechanism is arranged on the bottom plate and corresponds to the jump cutting platform. Therefore, firstly, the vertical position of the upper die base is adjusted slightly through matching of a servo motor, a turbine and a worm, so that electric pressurization and numerical control automatic operation are realized, manual adjustment and pressurization are eliminated, and the operation is convenient and flexible; secondly, the parallelism between the jump cutting platform and the upper die base is adjusted slightly through matching with the tool ejecting mechanism, so that accurate positioning is realized, the stability is better, and high-precision machining of all-cut or half-cut large-width materials and specialty materials (thick) for both coiled materials and sheet materials can be realized; thirdly, due to the arrangement of a clutch, a common motor can be used as the main motor, so that the cost is lower, the speed is faster, the ton force is larger, and the materials can be cut off more easily.

Owner:东莞市合硕精密五金科技有限公司

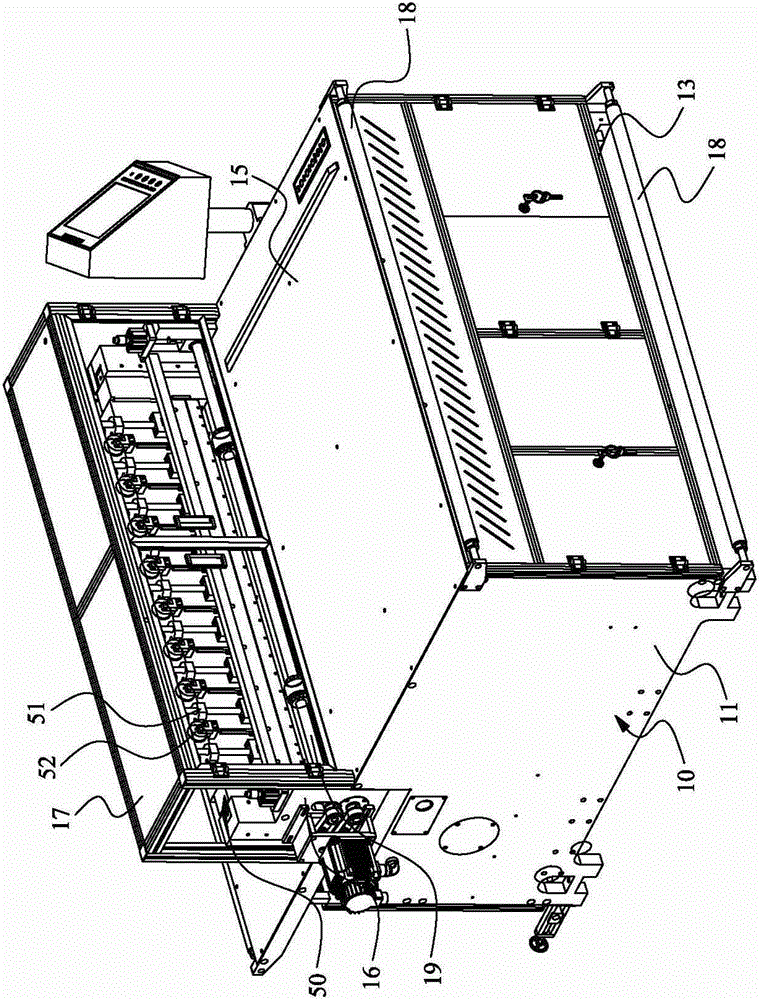

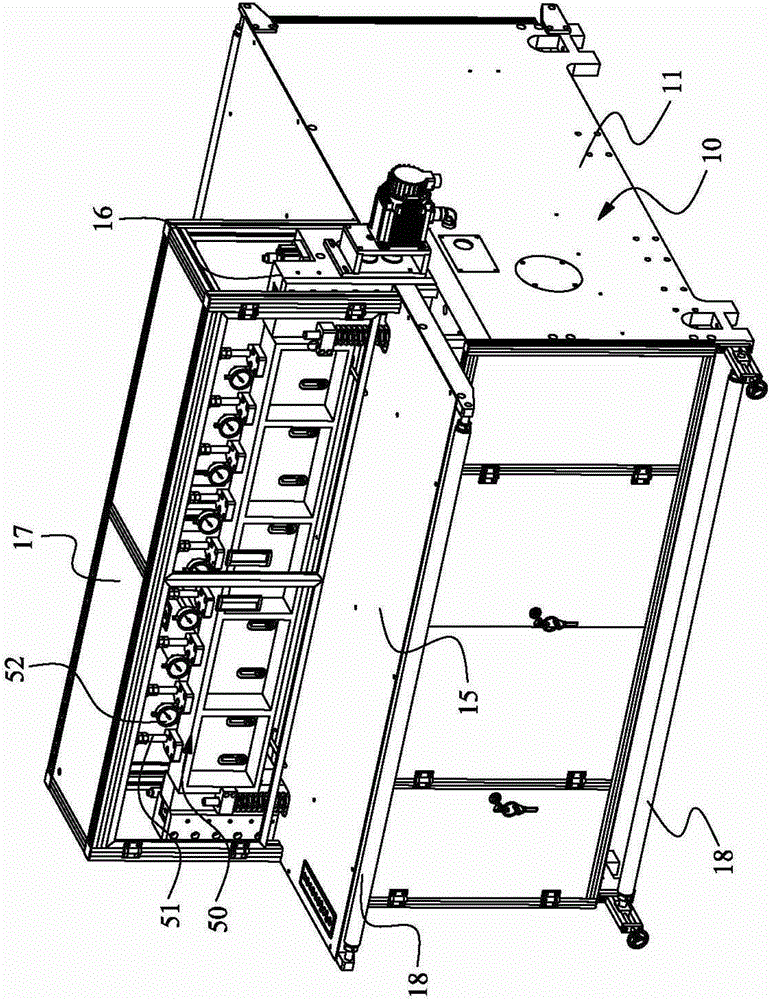

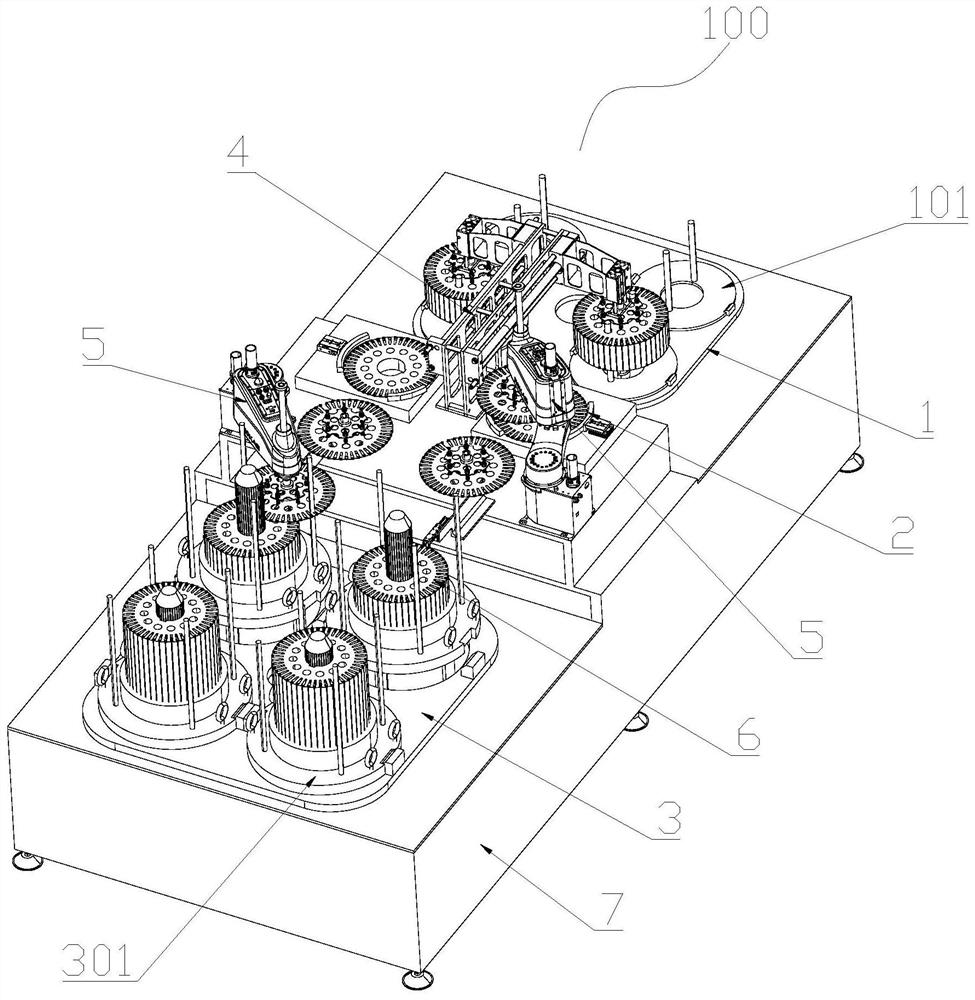

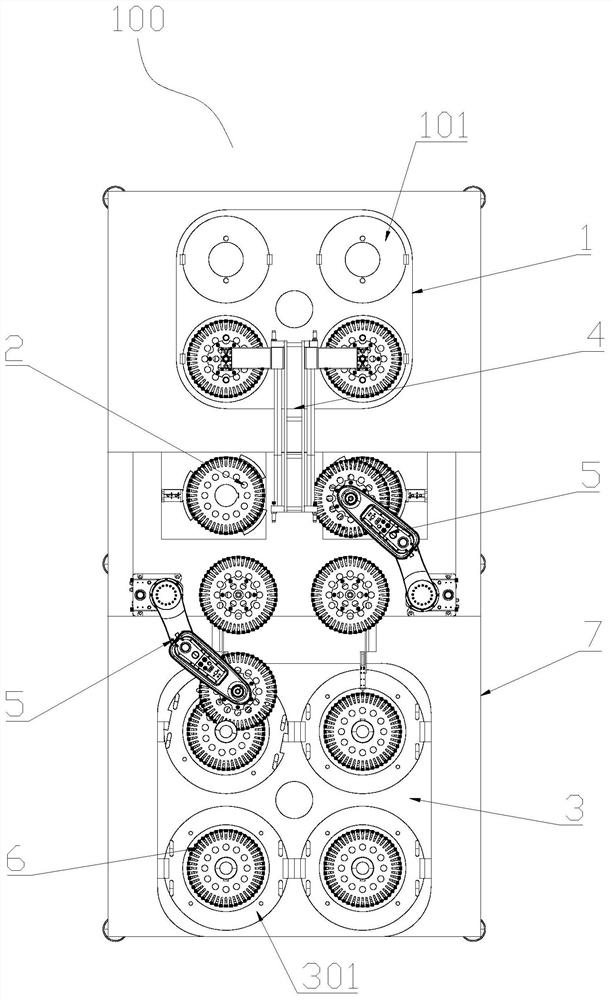

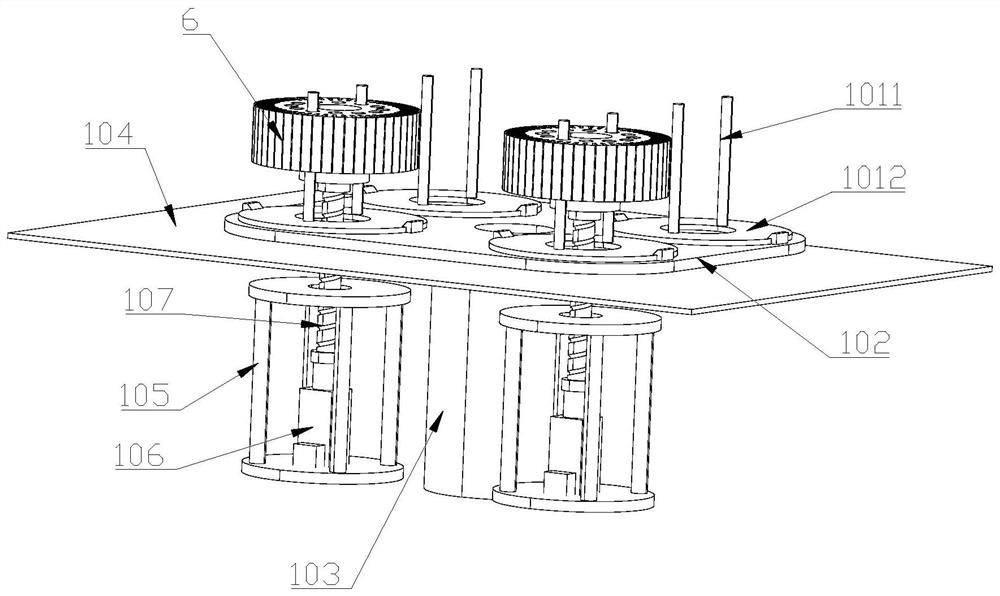

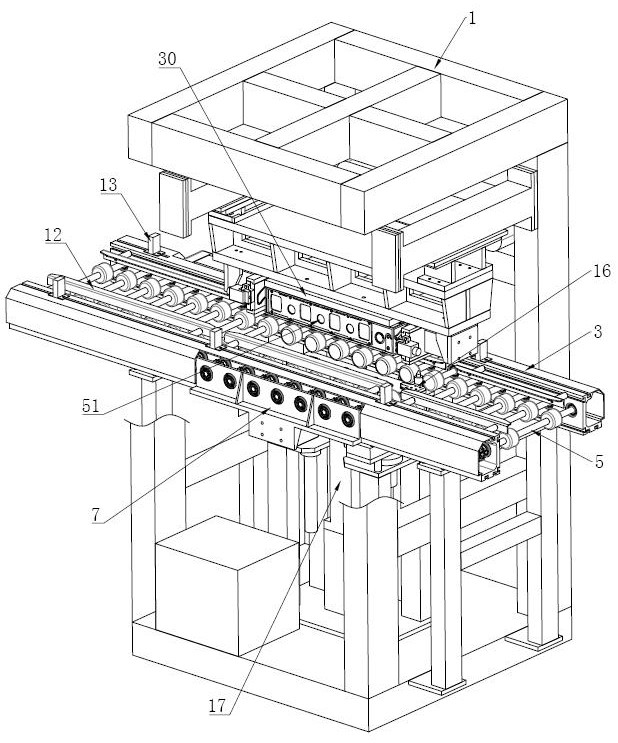

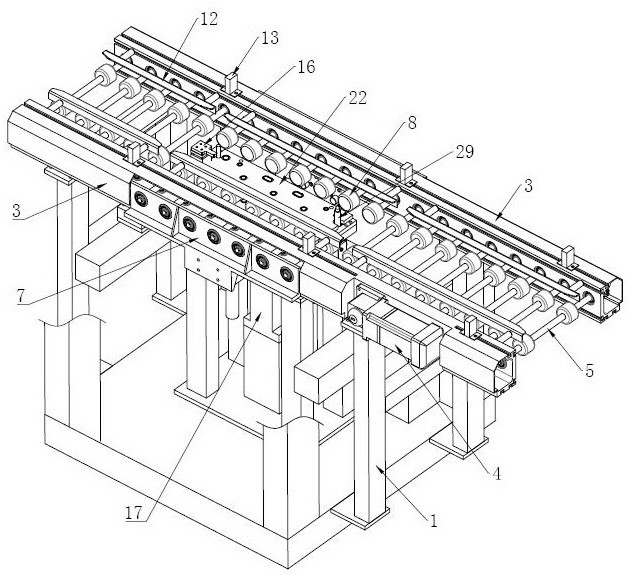

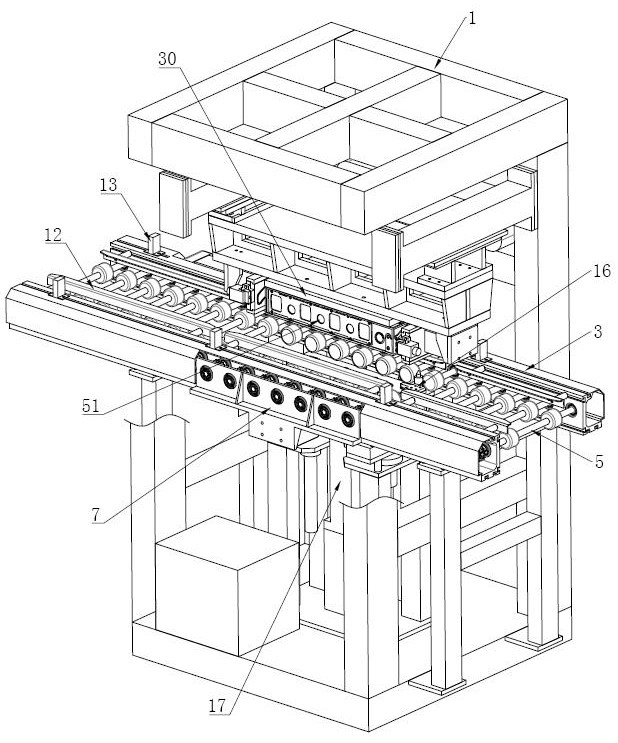

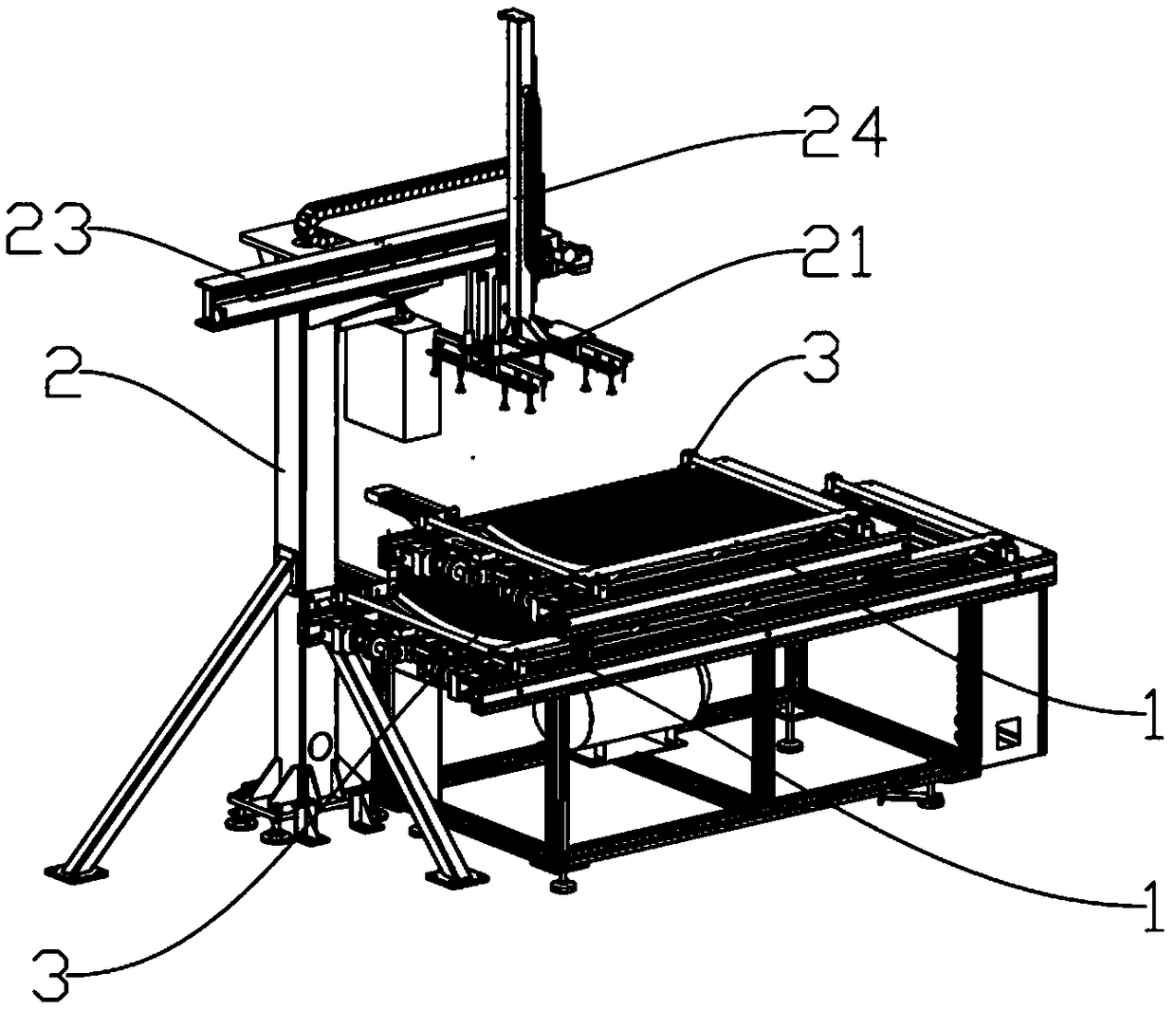

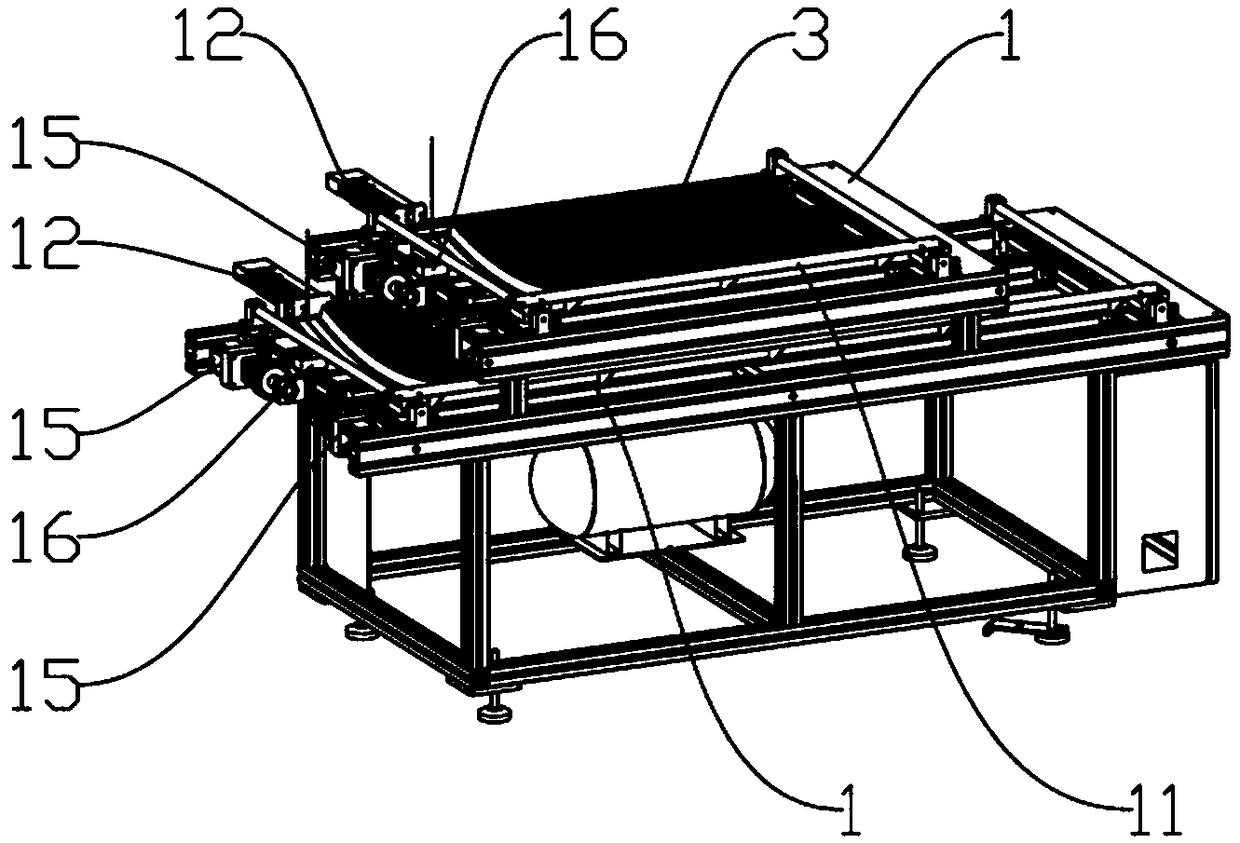

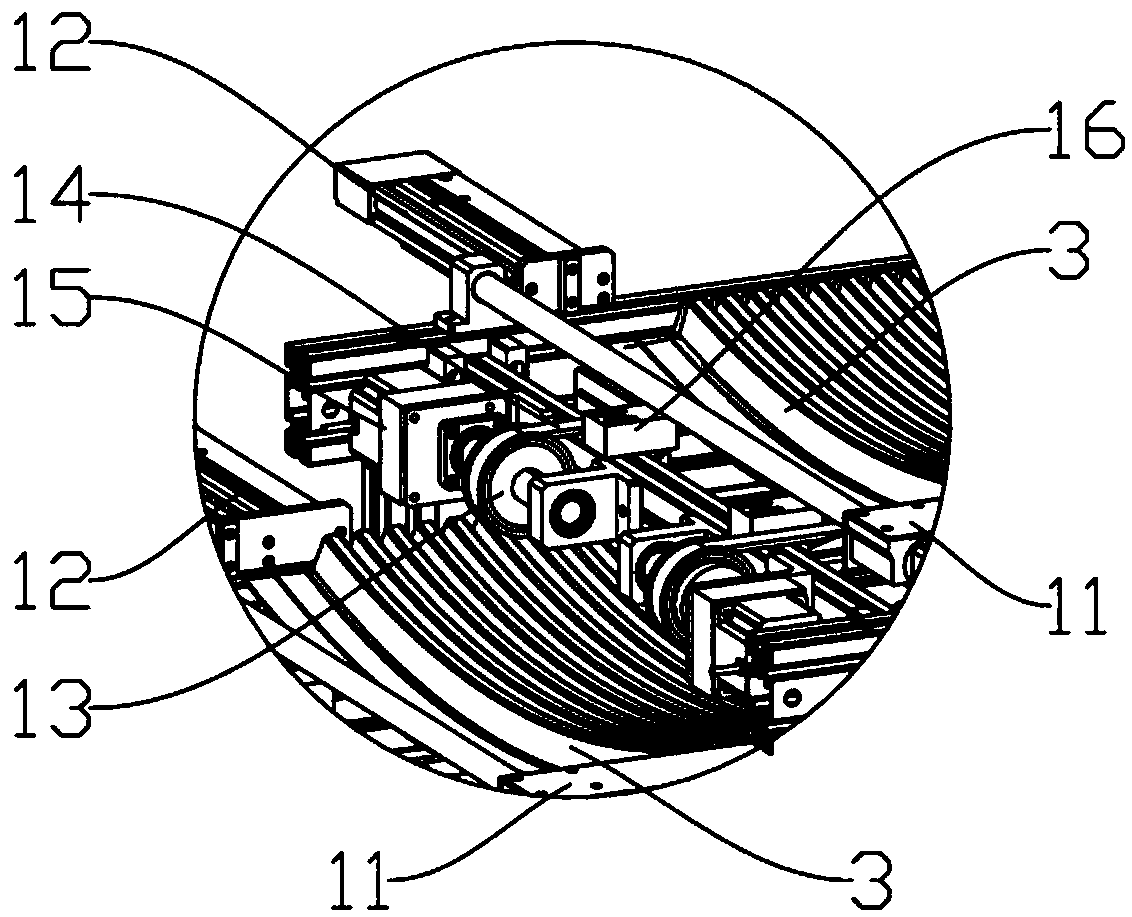

Silicon steel sheet lamination device

ActiveCN113387190ARealize fine positioningReduce labor intensityStacking articlesDe-stacking articlesRobotic armStructural engineering

The invention discloses a silicon steel sheet lamination device, and relates to the field of silicon steel sheet lamination, and the silicon steel sheet lamination device comprises: a feeding mechanism which comprises a first positioning device, wherein the first positioning device comprises a plurality of first axial positioning columns, the first axial positioning columns are in one-to-one correspondence with circumferential holes, and the plurality of first axial positioning columns respectively penetrate through the circumferential holes at different positions; a fine positioning mechanism which is used for circumferentially positioning the silicon steel sheets; a discharging mechanism which comprises a second positioning device, wherein the second positioning device comprises a center positioning column used for being matched with center holes of the silicon steel sheets; a transferring mechanism which is used for moving the silicon steel sheets arranged on the first axial positioning columns to the fine positioning mechanism; an imaging device; and a camera device which is in communication connection with a robotic arm, wherein the robotic arm adjusts the angles of the silicon steel sheets according to the key groove square opening characteristics shot by the imaging device and moves the silicon steel sheets to the center positioning column. The silicon steel sheet lamination device can effectively reduce the labor intensity of workers and improve the lamination efficiency.

Owner:温天哲

Cylinder cover automatic detecting and spraying production line

ActiveCN112221799AIncreased detection and spraying efficiencyImprove detection accuracySpray boothsHydraulic ramAssembly line

The invention belongs to the technical field of cylinder cover machining, and provides a cylinder cover automatic detecting and spraying production line. A first roller way conveying line and a secondroller way conveying line which are connected are arranged on a detecting rack and a spraying rack correspondingly; a positioning stop block driven by a first cylinder and a lower sealing plate driven by a hydraulic oil cylinder are arranged at the bottom of the detecting rack, an upper sealing plate is installed at the top of the rack, side sealing plates driven by a second cylinder are arrangedat the two ends of the upper sealing plate correspondingly, sealing rings are arranged on the clamping faces of the sealing plates, an air tightness detecting hole is formed in the clamping face of one side sealing plate, and an air tightness detector is further installed at the top of the rack; and an anti-rust oil spraying chamber is arranged on the second roller way conveying line, and a plurality of atomizing nozzles are arranged in the anti-rust oil spraying chamber. The automatic assembly line work of air tightness detecting and anti-rust oil spraying of cylinder covers can be achieved,the detecting and spraying efficiency is greatly improved, the complex procedure of treatment after a test piece is soaked in water is omitted, and environmental pollution and harm to human health during spraying are effectively avoided.

Owner:潍坊思博精工科技有限公司

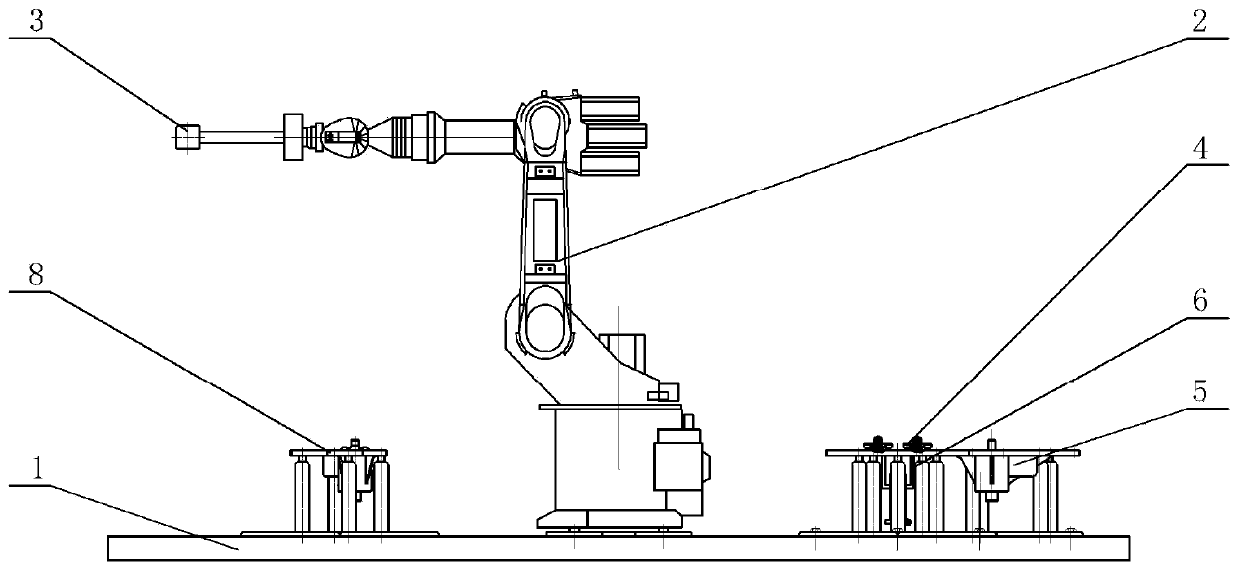

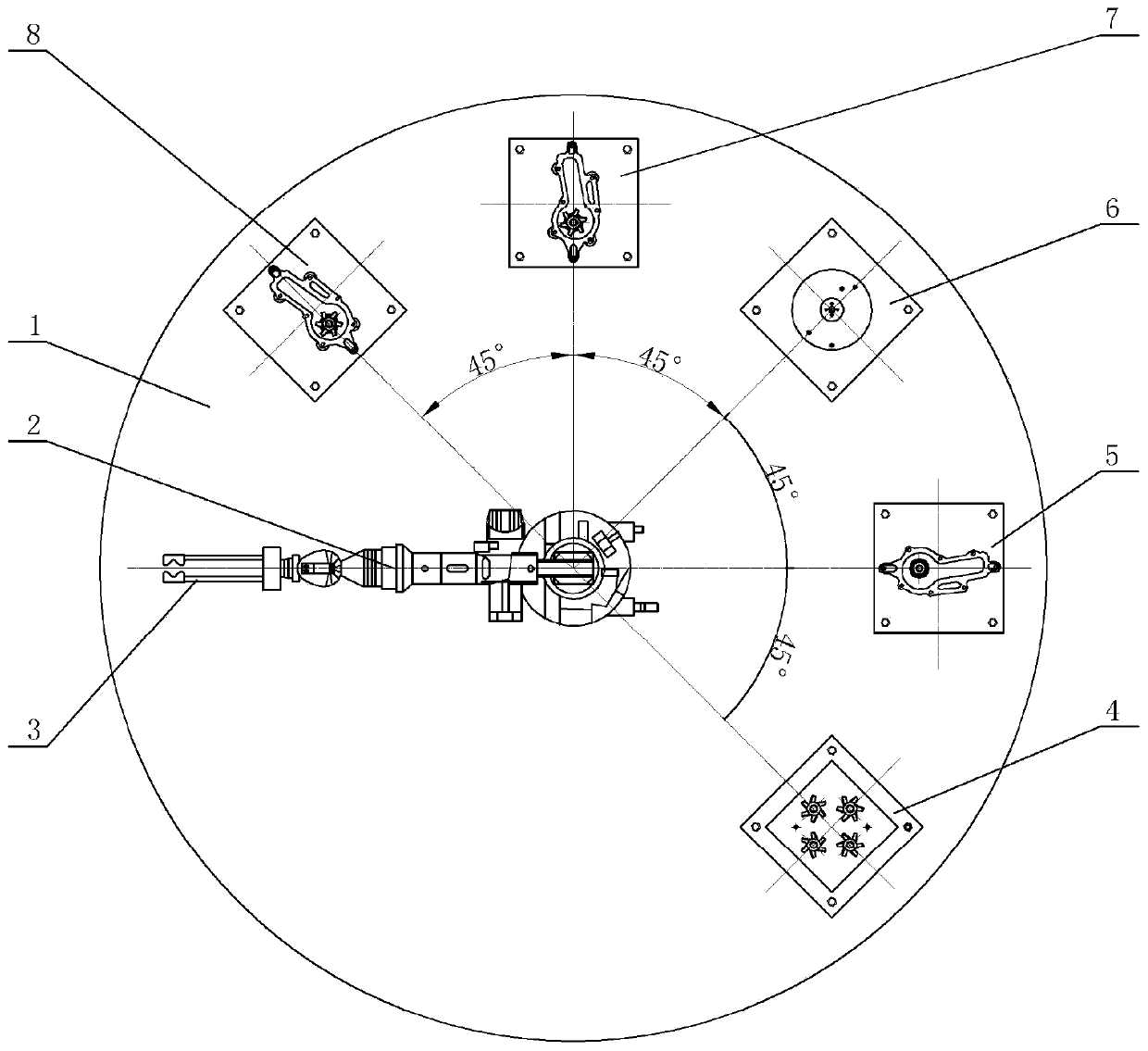

Intelligent industrial robot device for assembling automobile water pump impeller

InactiveCN111015158ARealize fine positioningAchieve precise positioningPump componentsPumpsProcess engineeringStress sensors

The invention discloses an intelligent industrial robot device for assembling an automobile water pump impeller. The intelligent industrial robot device is characterized in that a robotic arm is arranged on a base and fixed to the base, a clamping claw is arranged at the front end of the upper portion of the robotic arm, an impeller feeding station clamp, a water pump shell feeding station clamp and an impeller pre-assembling station clamp are arranged on the right portion of the base, an impeller press-fitting station clamp is arranged on the base, a discharging station clamp is arranged at the left portion of the base, a pressure sensor and a connecting plate are arranged on the right portion of a driver, an upper clamping claw body and a lower clamping claw body are arranged on the leftportion of the driver, four first stand columns are arranged on a first bottom plate, and first impeller pre-assembling plate positioning pins are arranged on the first stand columns. The intelligentindustrial robot device has intelligence, reliability, high efficiency and energy conservation, unmanned operation in the whole process is achieved through the six-degree-of-freedom industrial robotarm, the impeller is automatically pressed on a shaft connection bearing of a water pump shell through an impeller press-fitting auxiliary clamp, and the device is applied to the technical field of automobile part assembling equipment.

Owner:刘亦晴

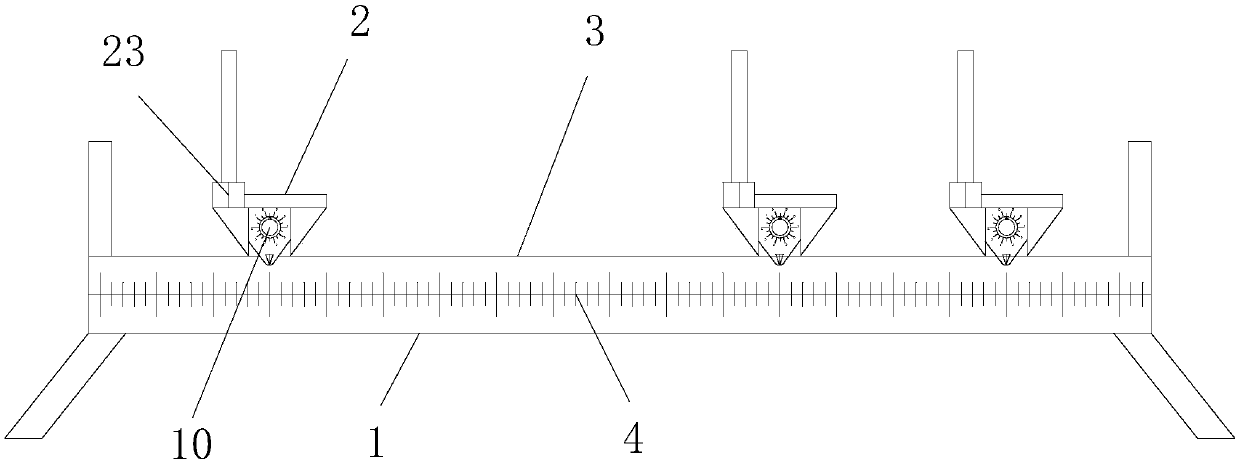

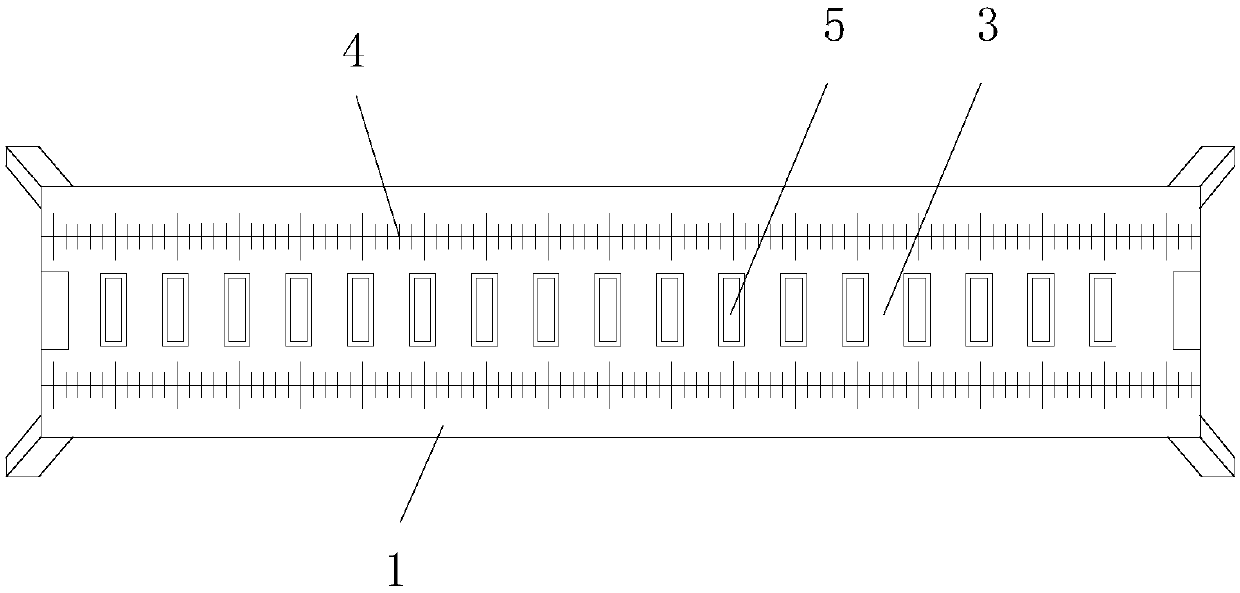

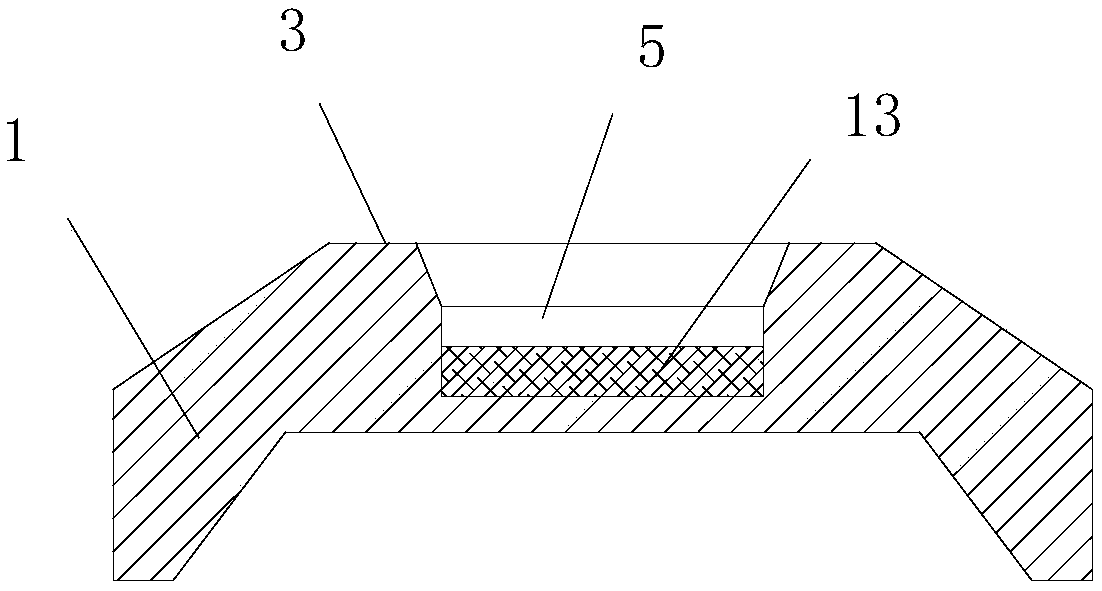

Optical bench

InactiveCN107085274BRotate at a constant speedRealize fine positioningMountingsGear wheelEngineering

The invention discloses an optical bench, which includes a base and a plurality of fixing parts for installing experimental components, the base is provided with a connection surface extending along a first direction, and the base is provided with a connection surface along the connection surface. For the first scale, a plurality of first plug-in parts are evenly spaced on the connecting surface, and second plug-in parts are arranged on the fixing part, and the first plug-in parts of each fixing part can be plugged with any second plug-in parts Cooperate; one end of the transmission rod on the outside of the housing is connected with a knob, the transmission rod is connected to a gear on the inside of the housing, the gear and the rack are meshed, and the fixed block is fixedly connected to the rack; the housing is surrounded by a knob As for the second scale, the distance between two adjacent first plug joints is not greater than the distance that the transmission rod rotates to drive the fixed block to move, and the first scale is an order of magnitude larger than the second scale. The optical bench provided by the present invention is not only easy to rotate at a constant speed when the knob connected to the gear is controlled, but also can be rotated to the target position more conveniently at one time.

Owner:周峙

Abut-joint device

InactiveCN111453359ARealize fine positioningReduce the problem of shortened lifespanConveyor partsPhysical medicine and rehabilitationEngineering

The embodiment of the invention provides an abut-joint device. The abut-joint device comprises an abut-joint female end and an abut-joint male end, wherein the abut-joint female end comprises a femaleend panel, an abut-joint guide hole and a female end abut-joint connector are mounted, the abut-joint male end comprises a male end panel, a propelling mechanism and a buffer adjusting mechanism, thepropelling mechanism and the buffer adjusting mechanism are connected with the male end panel, an abut-joint guide part is mounted at the position, corresponding to the abut-joint guide hole, of themale end panel, a male end abut-joint connector is formed in the position, corresponding to the female end abut-joint connector, of the male end panel, the propelling mechanism is used for propellingthe male end panel to move in the direction perpendicular to the abut-joint female end, the buffer adjusting mechanism is used for adjusting the position of the male end panel so as to buffer the vibration of the female end panel, through the abut-joint guide part and the abut-joint guide hole, abut-joint rough positioning is achieved, through the propelling mechanism, abut-joint precise positioning is achieved, the abut-joint precision is improved, through the buffer adjusting mechanism, the abut-joint male end can carry out buffer and automatic guide on deviation and vibration of the abut-joint female end, the problem that abut-joint stability is poor can be solved, and the test pass rate and the test efficiency can be improved.

Owner:HISENSE VISUAL TECH CO LTD

Pick-and-place device for automatic wafer unloading

ActiveCN112420578AAchieve pre-positioningRealize fine positioningSemiconductor/solid-state device manufacturingConveyor partsWaferTransfer line

The invention belongs to the technical field of wafer unloading and provides a taking and placing device for automatic wafer unloading. The taking and placing device comprises a rack, a speed chain conveying line, a carrier positioning mechanism, a taking and placing mechanical arm, a cover plate placing table and a wafer placing table are arranged on the rack, wherein a blocking cylinder is arranged on the speed chain conveying line; the taking and placing mechanical arm and the cover plate placing table are both located on one side of the speed chain conveying line, a taking and placing mechanism is arranged at the shaft end of the taking and placing mechanical arm, and the wafer placing table is located at one end of the speed chain conveying line; the material taking and placing mechanism comprises an installation frame installed on a working shaft of the taking and placing mechanical arm, a Bernoulli suction cup driven by a piece taking air cylinder is installed on the installation frame, a suction nozzle installation plate is further installed at the bottom of the installation frame, and a plurality of cover plate suction nozzles are installed at the bottom of the suction nozzle installation plate. Compared with a traditional manual wafer taking mode, wafer taking efficiency is greatly improved, the phenomenon that the wafer is accidentally scratched in the wafer discharging process is effectively avoided, and it is guaranteed that the quality and the percent of pass of the wafer are not affected in the wafer discharging process.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

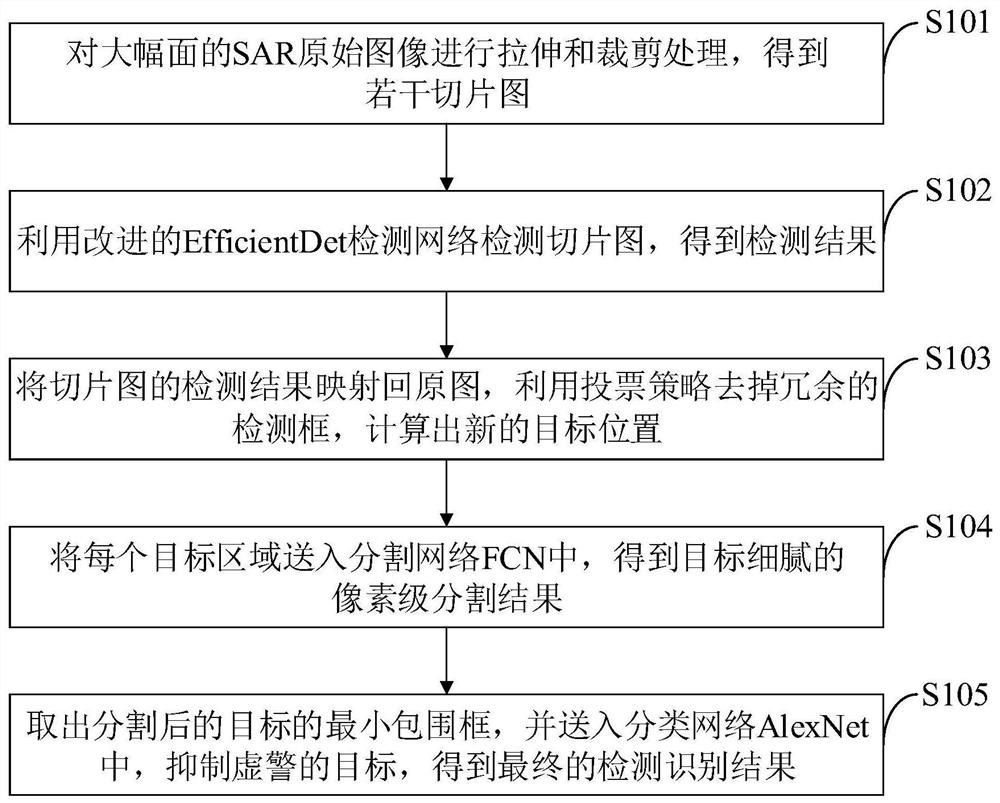

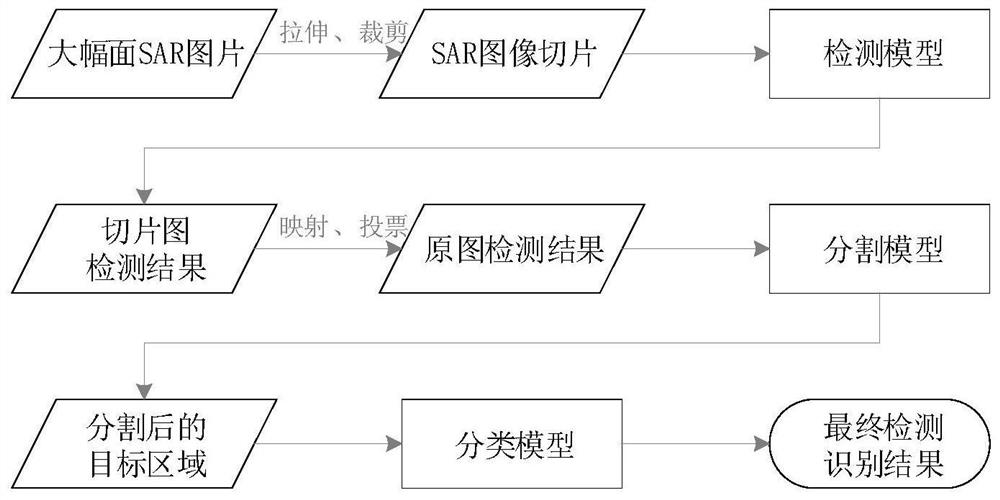

Large-breadth SAR image ship target detection and identification method based on fine segmentation

ActiveCN113409325AHigh positioning accuracyDetection speedImage enhancementImage analysisMinimum bounding boxEngineering

The invention belongs to the technical field of SAR ship target detection and identification, and discloses a large-breadth SAR image ship target detection and identification method based on fine segmentation. The method comprises the following steps: carrying out stretching and cutting of a large-breadth SAR original image, and obtaining a plurality of slice images; detecting the slice images to obtain a detection result, mapping the detection result back to the original image, fusing redundant detection frames by utilizing a voting strategy, and calculating a new target position; sending each target area into a segmentation network FCN to obtain a fine pixel-level segmentation result of a target; and taking out a minimum bounding box of a segmented target, sending the minimum bounding box into a classification network AlexNet, and suppressing a false alarm target to obtain a final detection and identification result. According to the method, the positioning precision and the detection speed of the target are effectively improved in the detection stage, after segmentation and classification network processing, the accuracy of a prediction frame is further improved, the false alarm rate is reduced, and detection and identification of SAR ship fine positioning are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

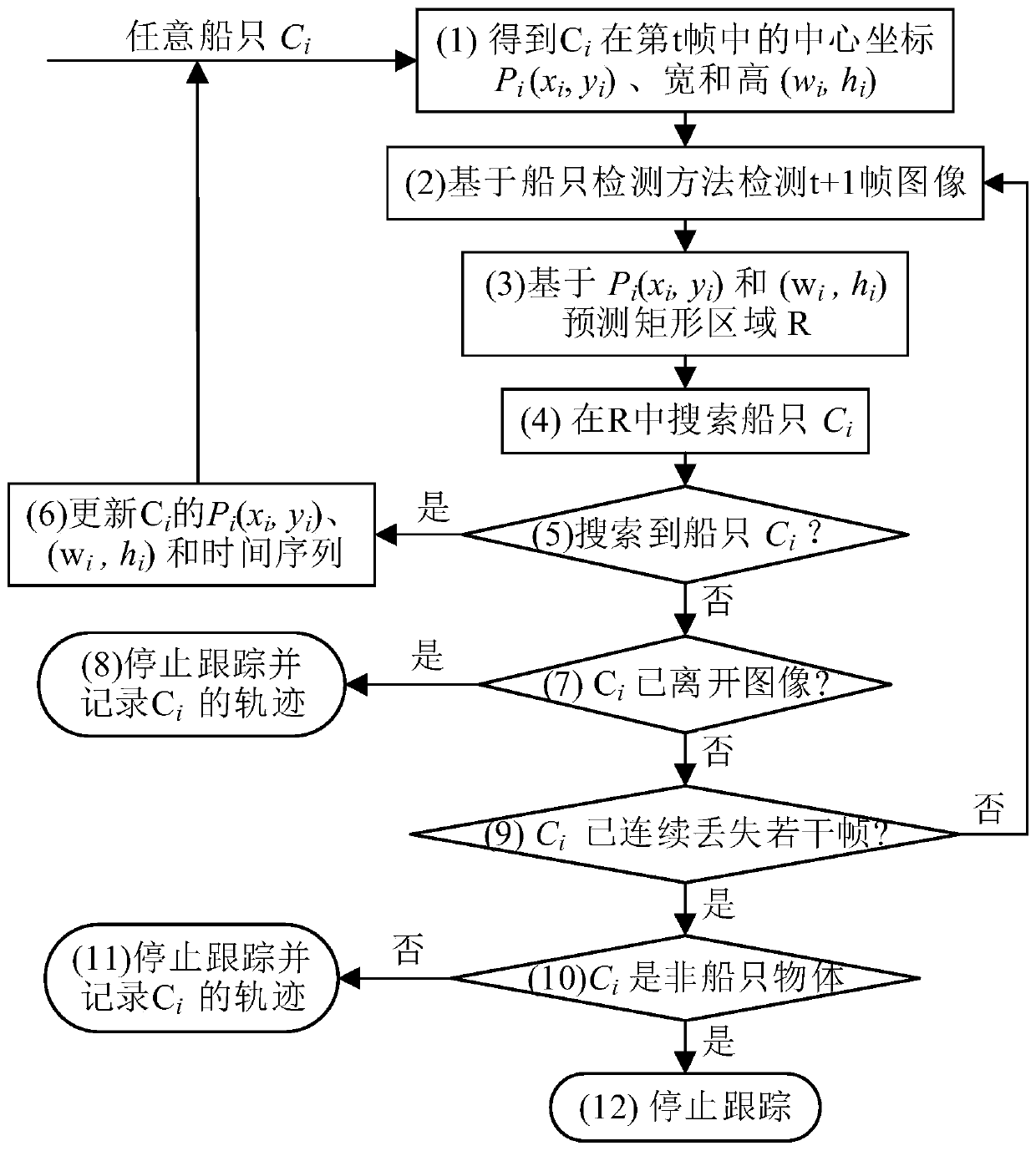

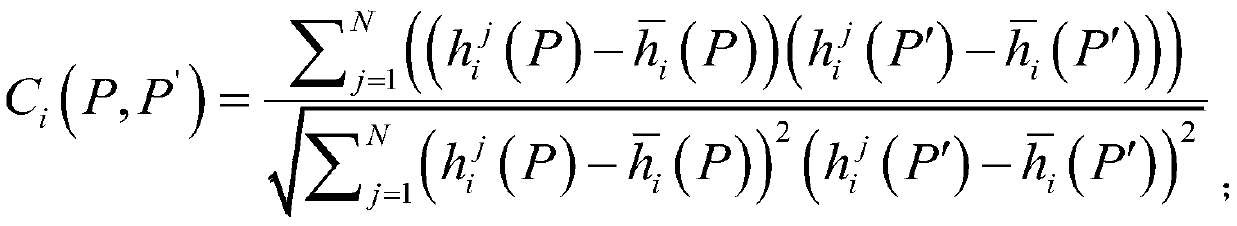

Ship tracking method based on position prediction and color similarity

The invention discloses a ship tracking method based on position prediction and color similarity, and the method comprises the following steps: step 1, carrying out the aerial photography of a ship video needing to be tracked through an unmanned aerial vehicle, and extracting P (x, y) and (w, h) of a ship needing to be tracked in a t frame in the video; step 3, predicting a rectangular region R based on P (x, y) and (w, h) extracted in the step 1; step 4, searching a ship needing to be tracked in R; 5, judging whether the ship needing to be tracked leaves the image or not; 6, continuously judging whether the detection ship continuously loses a plurality of frames or not; and step 7, continuously judging whether the ship is a non-ship object or not. According to the ship tracking method based on the position prediction and the color similarity, through the setting of the first to seventh steps, the offshore ship can be effectively tracked in a mode of carrying out prediction through aerial photography of the unmanned aerial vehicle, and compared with a mode of adopting GPS positioning tracking in the prior art, the problem of position lag is avoided.

Owner:HAINAN UNIVERSITY +1

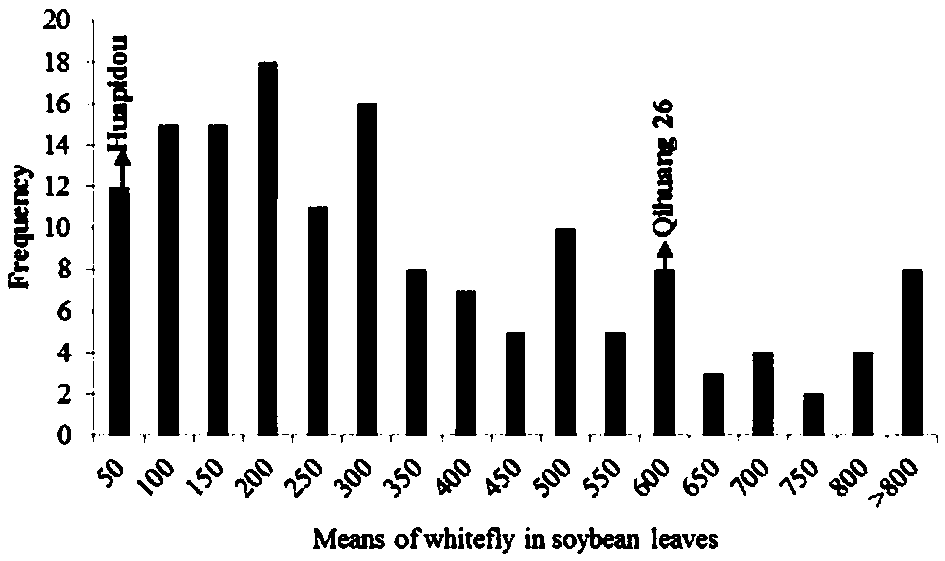

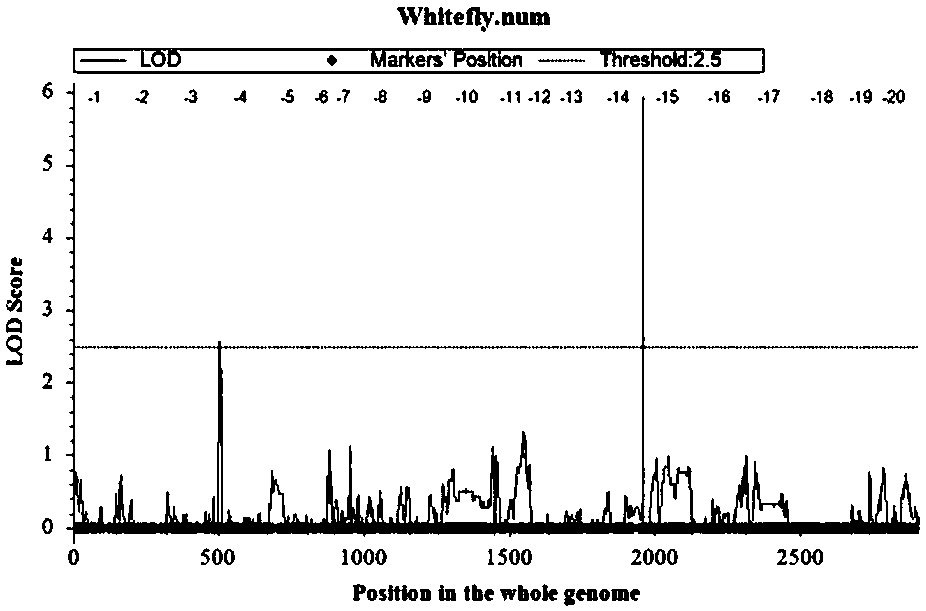

Molecular marker for soybean bemisia tabaci resistance breeding and marking method of molecular marker

InactiveCN108148926AReduce the workload of high-generation breeding selectionDownscalingMicrobiological testing/measurementDNA/RNA fragmentationHigh densityMarker selection

The invention relates to a molecular marking method for soybean bemisia tabaci resistance breeding. The molecular marking method comprises the following steps of 1, distribution of resistances to bemisia tabaci by soybean RIL groups, wherein high generation RIL groups such as huapidou and qihuang 26 are planted for 2 years continuously, the resistances to bemisia tabaci by the soybean RIL groups are identified, and the operation is repeated twice; the quadratic mean is analyzed; 2, QTL locating of the resistances to bemisia tabaci by soybeans, wherein a high-density genetic map built through an SLAF-seq technology is utilized to conduct QTL locating on the resistances to bemisia tabaci by the soybean RIL groups to obtain two QTL loci related to the resistances to bemisia tabaci by the soybeans. Through the marking combination, a breeding material is subjected to marking and selecting of the low generations, superior genes of the resistances to bemisia tabaci in the breeding material are easily aggregated in the low generations, the workload of breeding selection of high generations is lowered, the breeding scale is reduced, and the breeding age limit is shortened.

Owner:CROP RES INST SHANDONG ACAD OF AGRI SCI

A cylinder head automatic detection spraying production line

The invention belongs to the technical field of cylinder head processing, and provides a cylinder head automatic detection and spraying production line. The detection frame and the spraying frame are respectively provided with a first roller conveyor line and a second roller conveyor line; the detection machine The bottom of the frame is equipped with a positioning block driven by the first cylinder and a lower sealing plate driven by a hydraulic cylinder. The upper sealing plate is installed on the top of the frame. The two ends of the upper sealing plate are respectively equipped with side sealing plates driven by the second cylinder. There are sealing rings on the clamping surface, and an airtight detection hole is opened on the clamping surface of one side of the sealing plate, and an airtightness detector is installed on the top of the frame; Rust oil spraying room, anti-rust oil spraying room is equipped with a number of atomizing nozzles. The invention can realize the automatic assembly line operation of cylinder head air tightness detection and anti-rust oil spraying, the efficiency of detection and spraying is greatly improved, the cumbersome process of treatment after soaking the test piece is saved, and the environmental pollution and personal injury during spraying are effectively avoided. health hazard.

Owner:潍坊思博精工科技有限公司

Movable sucker device for mold

The invention discloses a movable sucker for a die. The movable sucker structurally comprises a sucker, a positioning part and an ejecting assembly. The ejecting assembly can eject the adsorption end of the sucker out of a forming face of the die. In the process that a mechanical arm conveys hardware to be injected to the adsorption end of the sucker, the hardware to be injected can be primarily positioned through the positioning part, the sucker acts to adsorb the hardware to be injected to the sucker, and then the sucker retracts and resets; in the reset process, the hardware to be injected slightly moves relative to the sucker under limiting of the positioning part, so that the hardware to be injected is accurately positioned, the hardware to be injected is placed in place, and the risk of film pressing is effectively lowered; and in addition, due to the fact that the adsorption end of the sucker stretches out of the forming face of the die, when the mechanical arm conveys the hardware to be injected to the sucker, the mechanical arm does not need to make contact with the forming face of the die so that the mechanical arm can be prevented from damaging the forming face of the die, and meanwhile the space cross depth of the mechanical arm and the positioning part is effectively reduced so that the interference between the mechanical arm and the positioning part can be effectively avoided.

Owner:东莞华誉精密技术有限公司

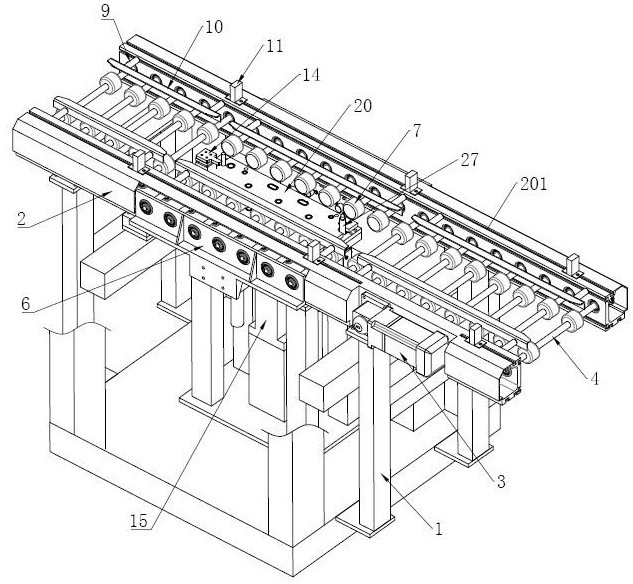

Locatable material transfer component

InactiveCN109332513ARealize fine positioningMetal-working feeding devicesPositioning devicesEngineeringRelative slip

The invention relates to the field of workpiece conveying, in particular to a locatable material transfer component. A conveying device of the locatable material transfer component can carry and convey a workpiece. One side edge of the conveying device is provided with a limit guide rail and one end of the workpiece movably abuts against the limit guide rail. At the same time, the workpiece and the limit guide can slide relative to each other to realize coarse positioning of the workpiece. When the workpiece is transferred to the tail end of the conveying device, a positioning mechanism startsand pushes one end of the workpiece to force the other end of the workpiece to be tightly attached on the limit guide rail to realize precise positioning of the workpiece. A pickup part of a pickup device is used to pick up the workpiece from the conveying device and transfer the workpiece to the next process.

Owner:GREATOO (GUANGZHOU) ROBOTS & INTELLIGENT MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com