Uncoiling punching die and punching technology

A technology of uncoiling blanking and coiling, which is applied in the field of parts stamping, which can solve the problems of increasing the chance of workers scratching, low material utilization, and bumping on the surface of the plate, and achieves simple structure, convenient transfer, and improved efficiency and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

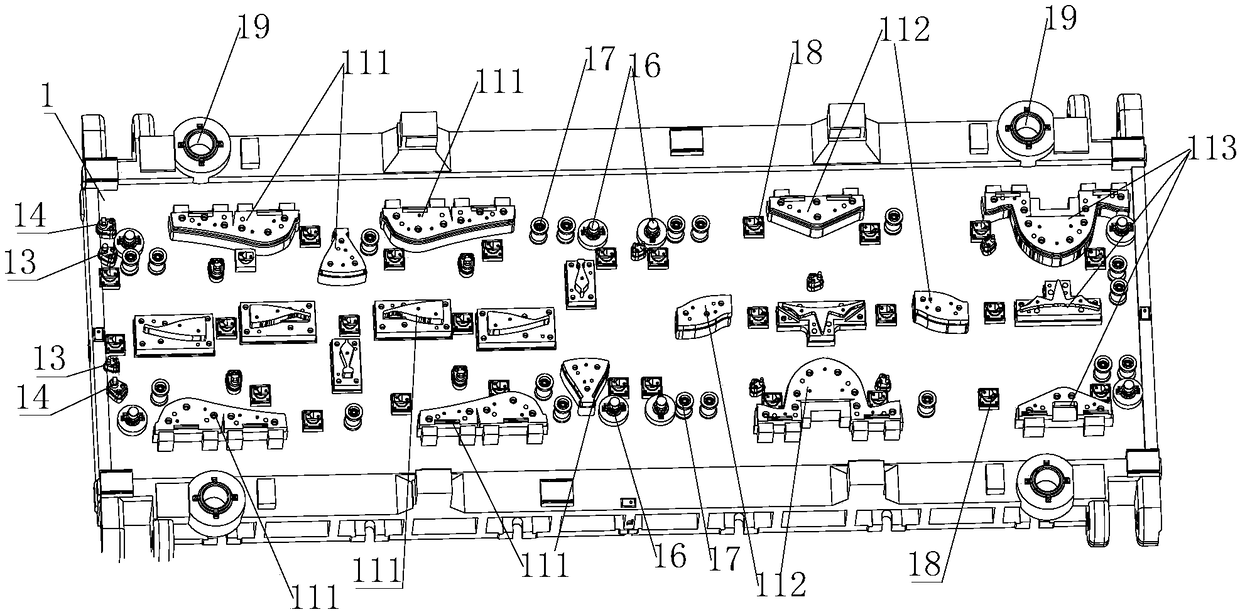

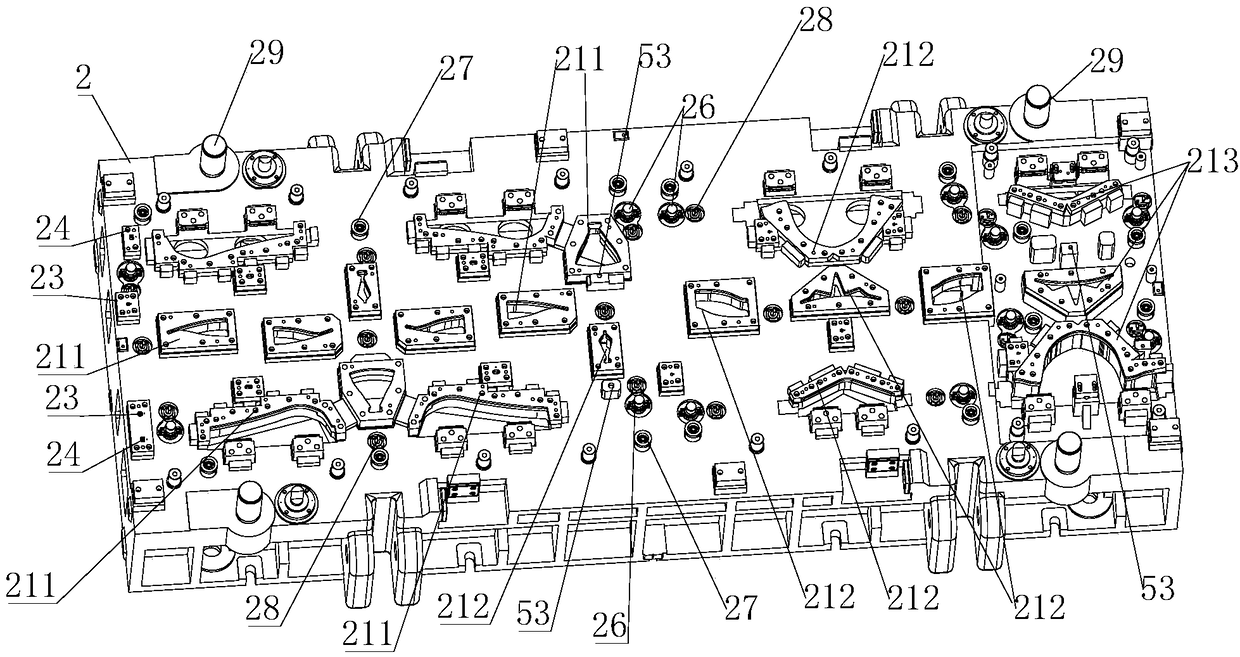

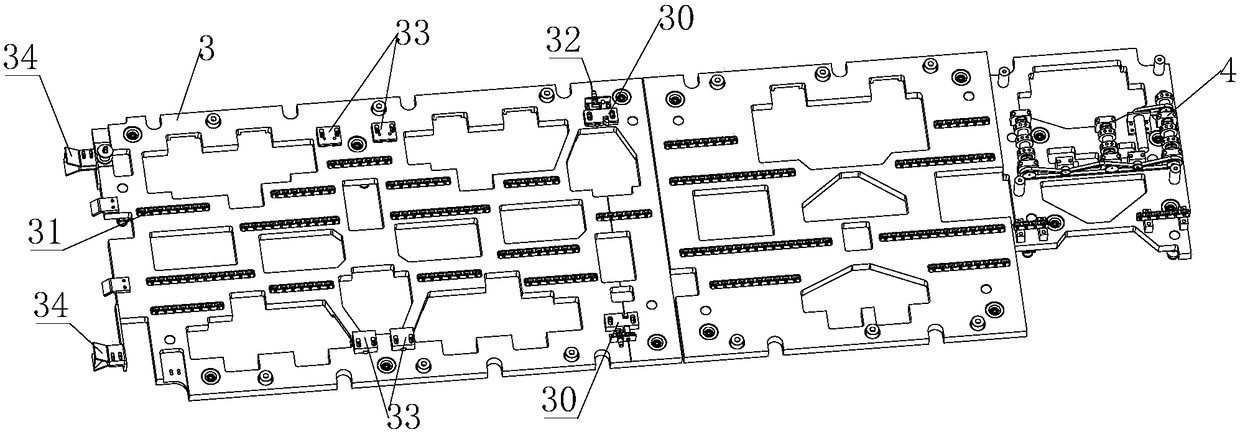

[0060] Embodiments of the present invention: as Figure 1-Figure 2 As shown, a kind of uncoiling blanking die has been announced, comprising: an upper die base 1, a lower die base 2, a lifter plate 3 and a binder plate 5, and the upper die base 1 is fixed on the upper table of the machine tool. The upper table top moves close to or away from the lower mold base 2. Specifically, the four corners of the upper mold base 1 are provided with four guide sleeves 19, and the four corners of the lower mold base 2 are provided with The four guide posts 29 corresponding to the four guide sleeves 19, the upper die base 1 and the lower die base 2 slide relatively through the cooperation of the guide posts 29 and the guide sleeves 19; The order is divided into the first molding station, the second molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com