High-precision convex part machining method based on heating stamping

A processing method and high-precision technology, applied in the field of mechanical processing, can solve the problems of affecting the service life of precision molds, increasing the cost of stamping processing, and reducing the precision of stamping workpieces, so as to achieve the effects of improving universality, efficiency, and positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

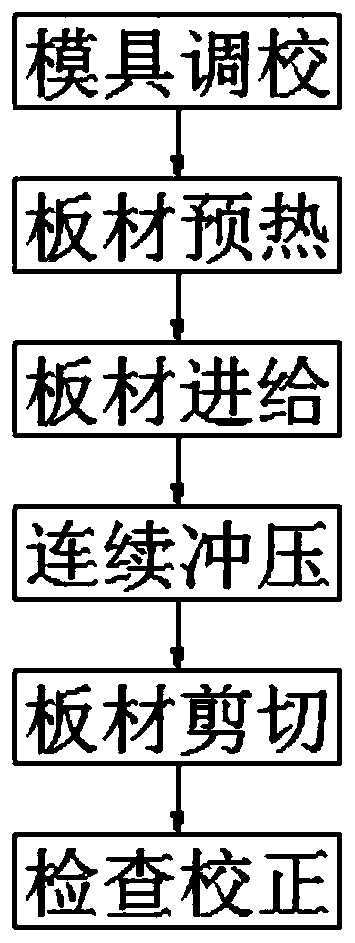

[0047] see figure 1 , a high-precision convex processing method based on heated stamping, the specific steps are as follows:

[0048] S1. Die adjustment: adjust the stamping die used for hot stamping, correct its positional relationship, and fix it to prevent accidents that cause stamping offset;

[0049] S2. Plate preheating: place the plate to be stamped in the preheating device for preheating to reduce the heating power consumption during hot stamping operations, and at the same time reduce the time required to heat the plate before stamping and improve the work of hot stamping processing efficiency;

[0050] S3. Plate feeding: transport the preheated plate to the stamping die, and continuously feed the plate to realize multiple stamping of the same plate at different positions, and improve the utilization efficiency of the plate;

[0051] S4. Continuous stamping: After the preheated plate is transported to the stamping die, during the continuous feeding of the plate, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com