Patents

Literature

69results about How to "Rapid stamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

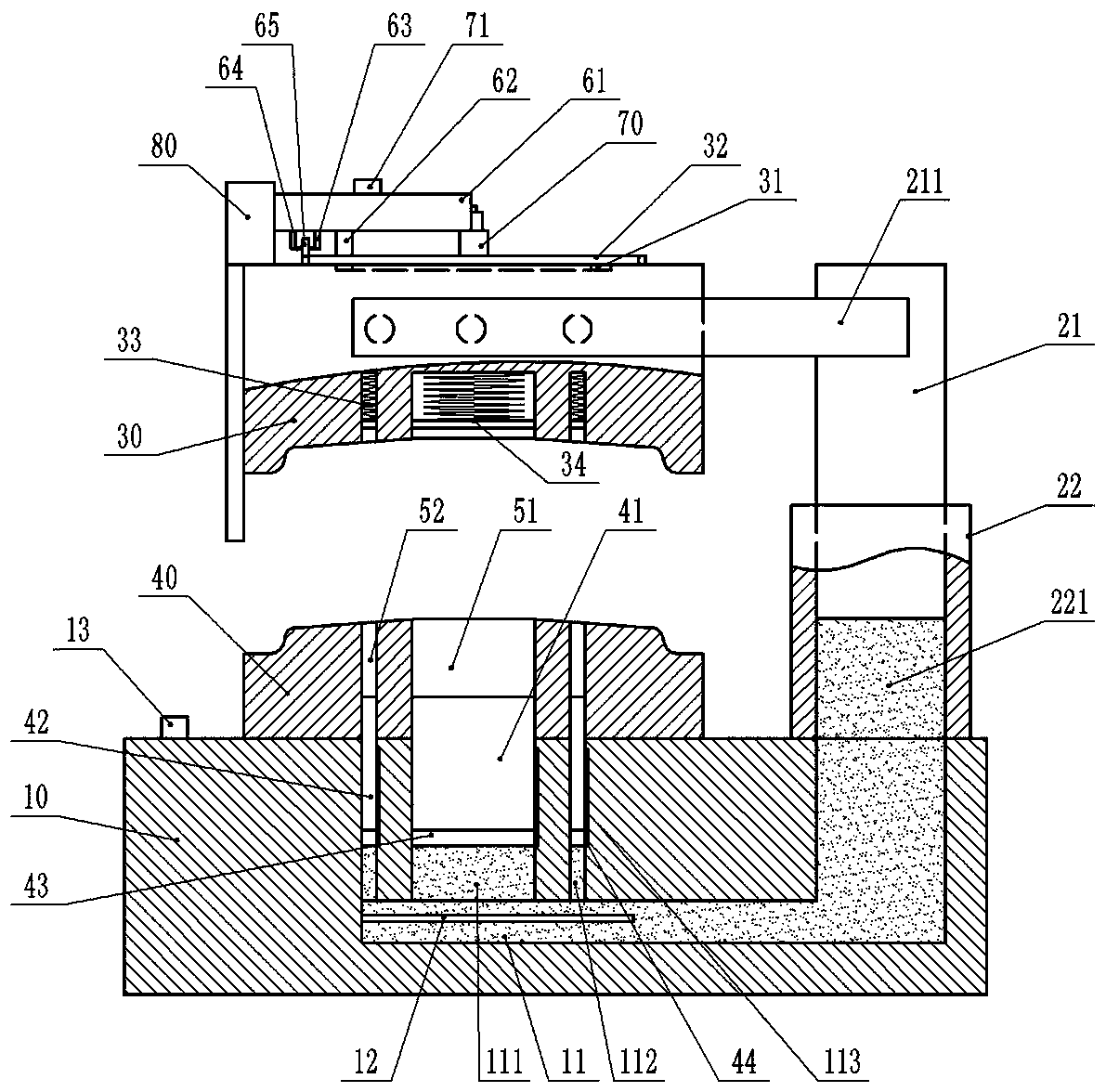

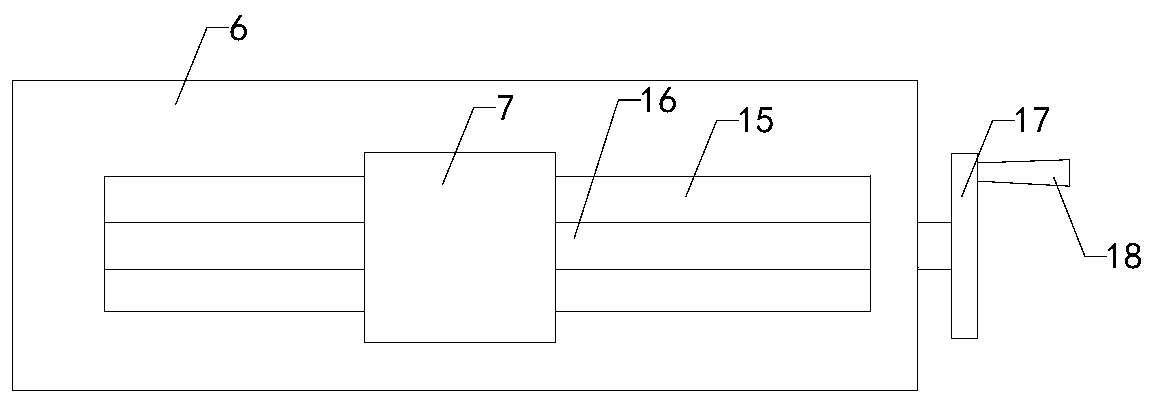

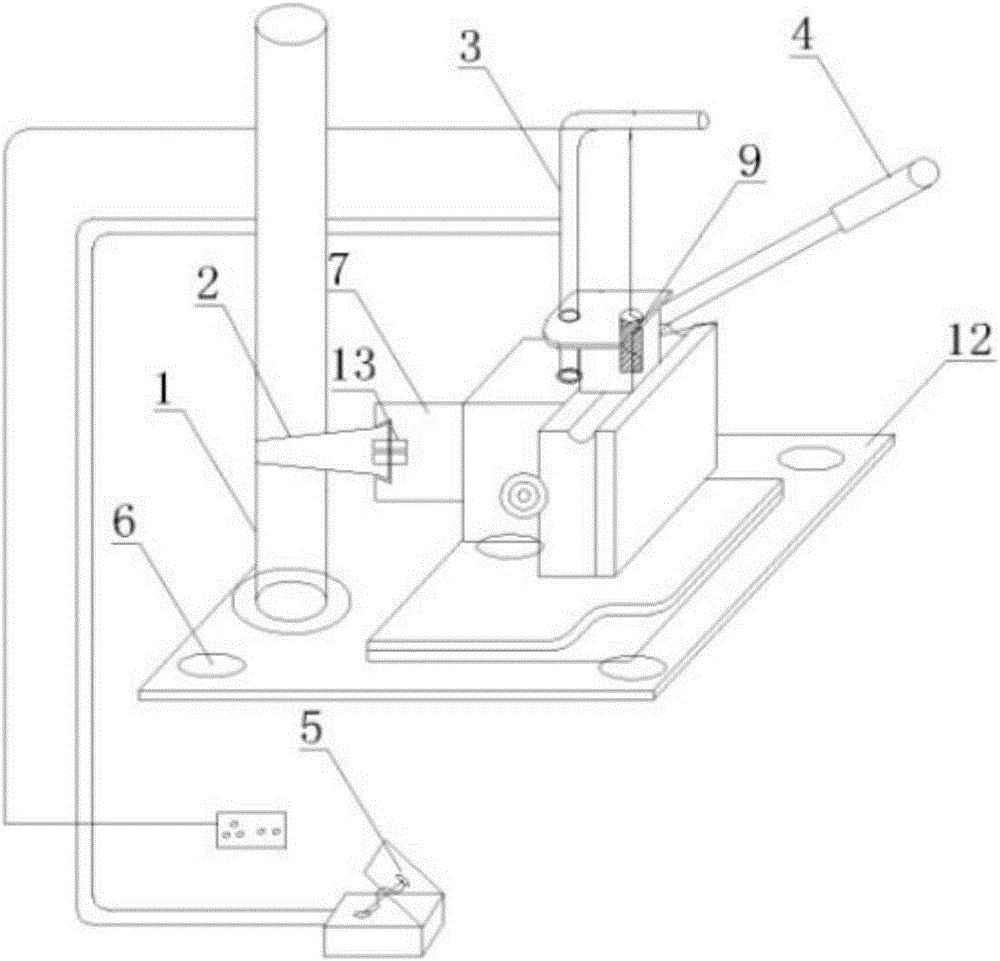

Steel plate hot forming method based on anti-oxidation coating and production line for implementing same

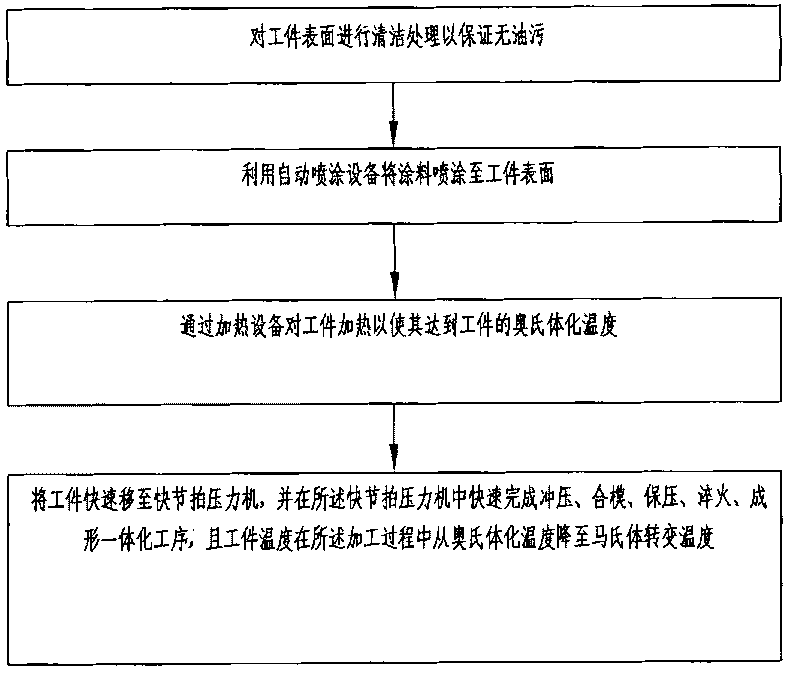

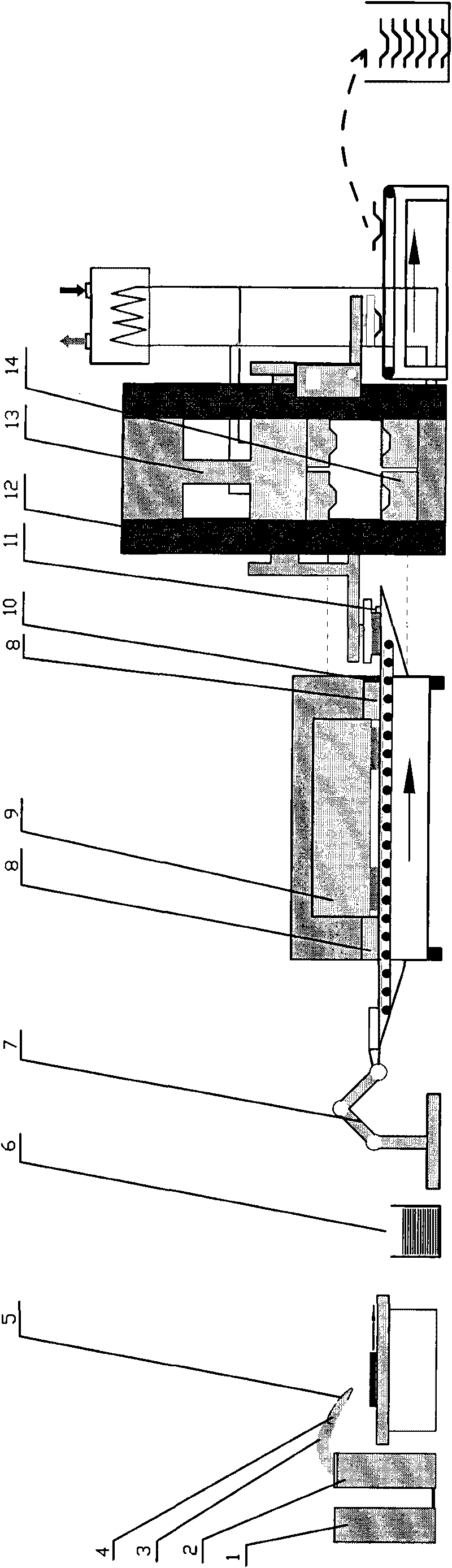

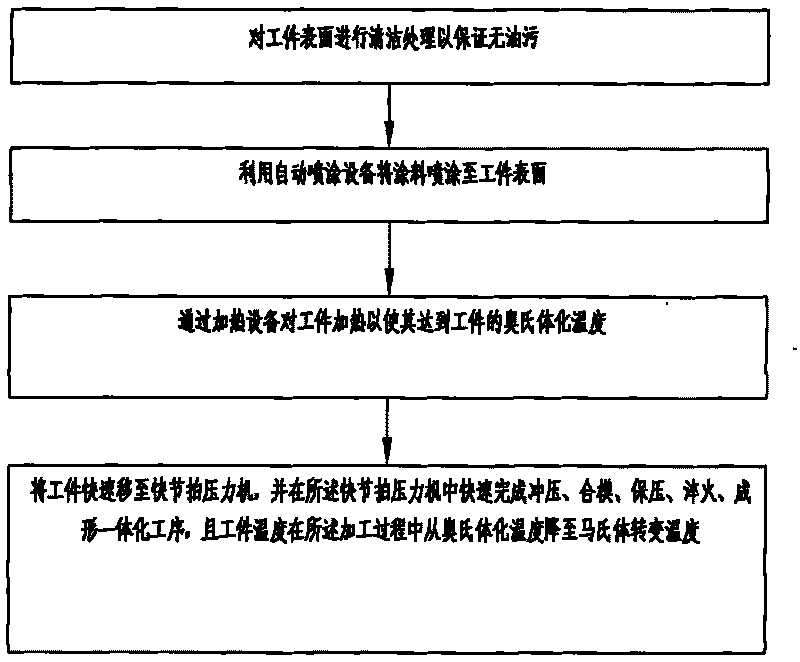

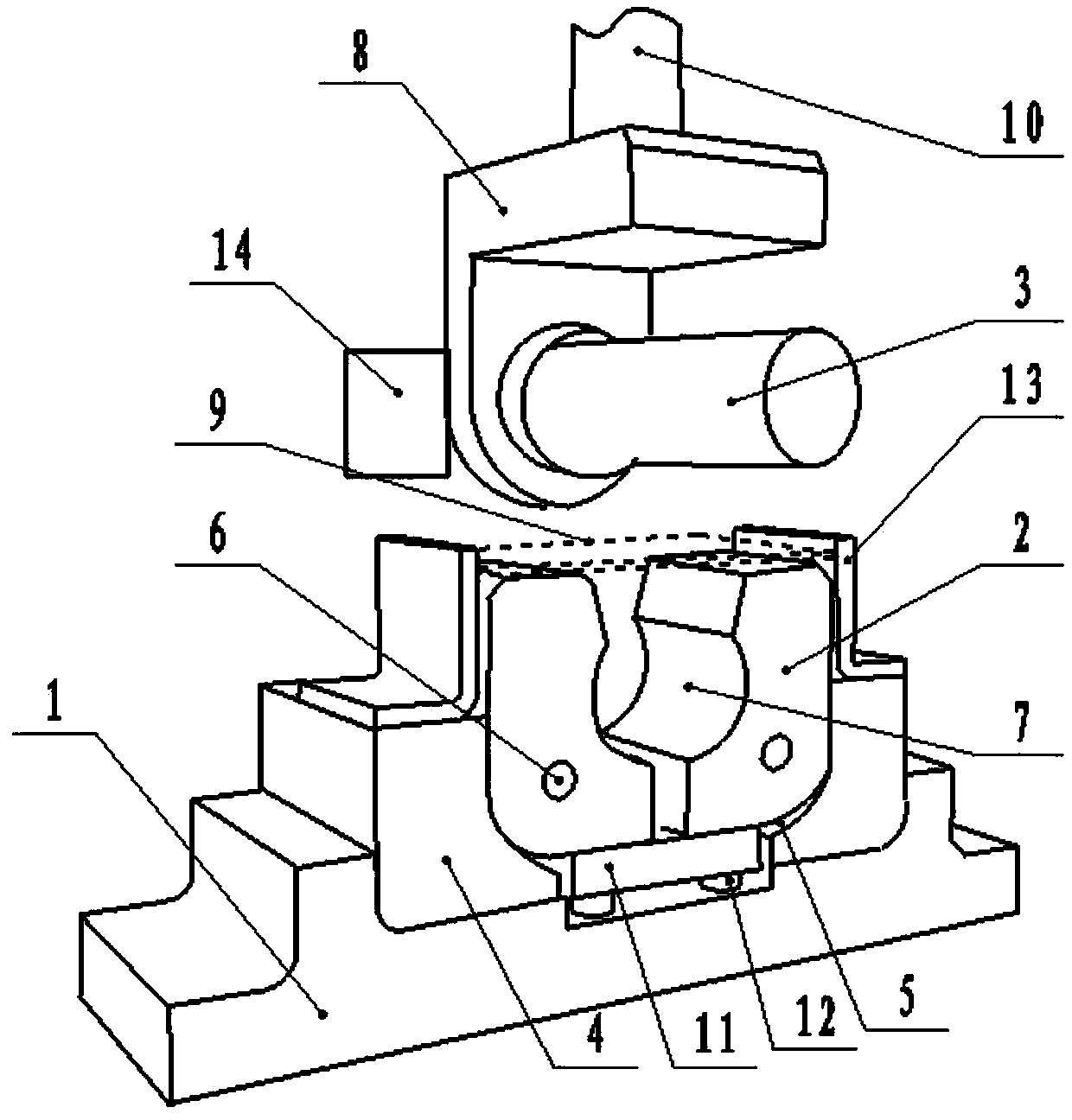

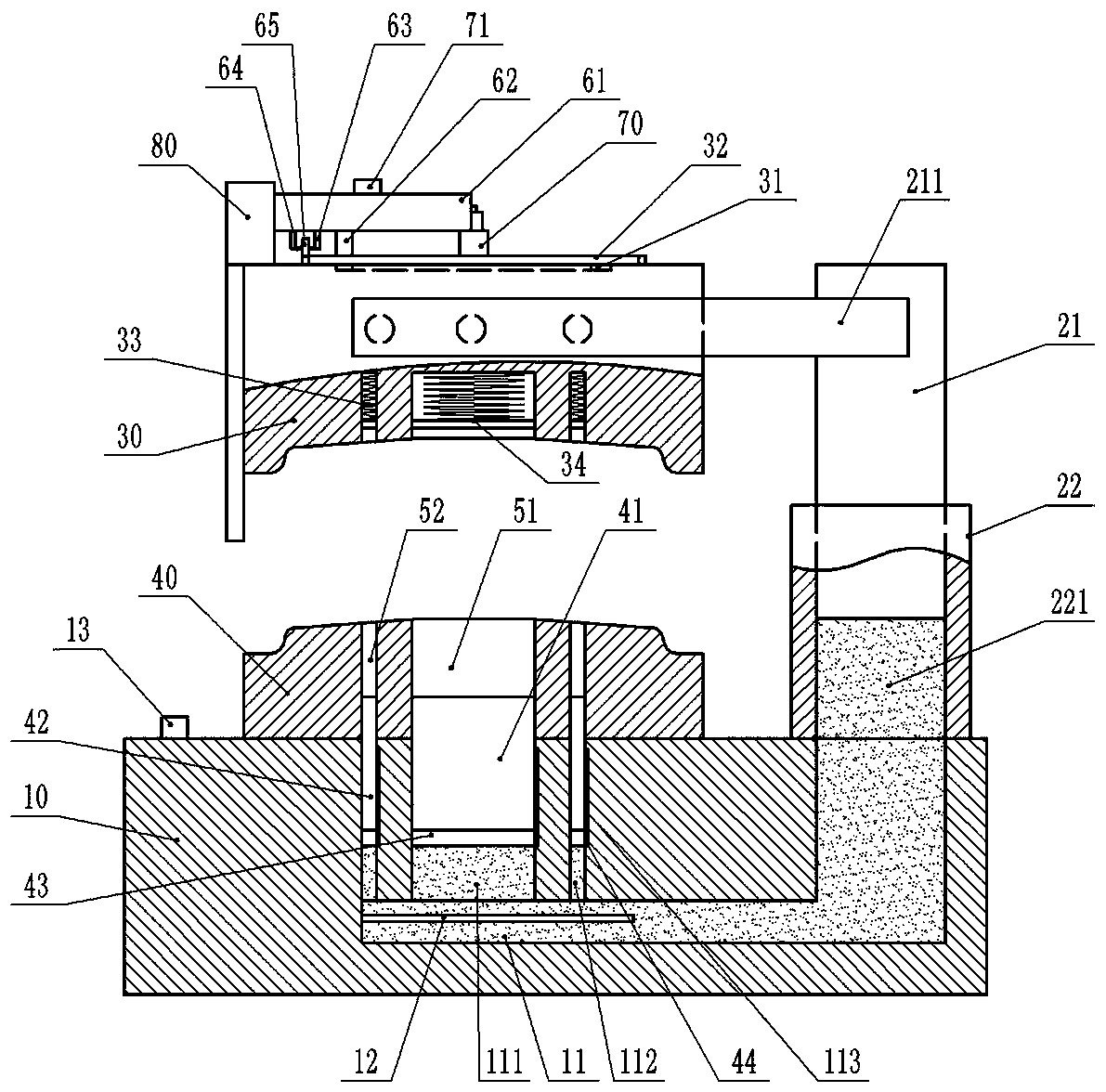

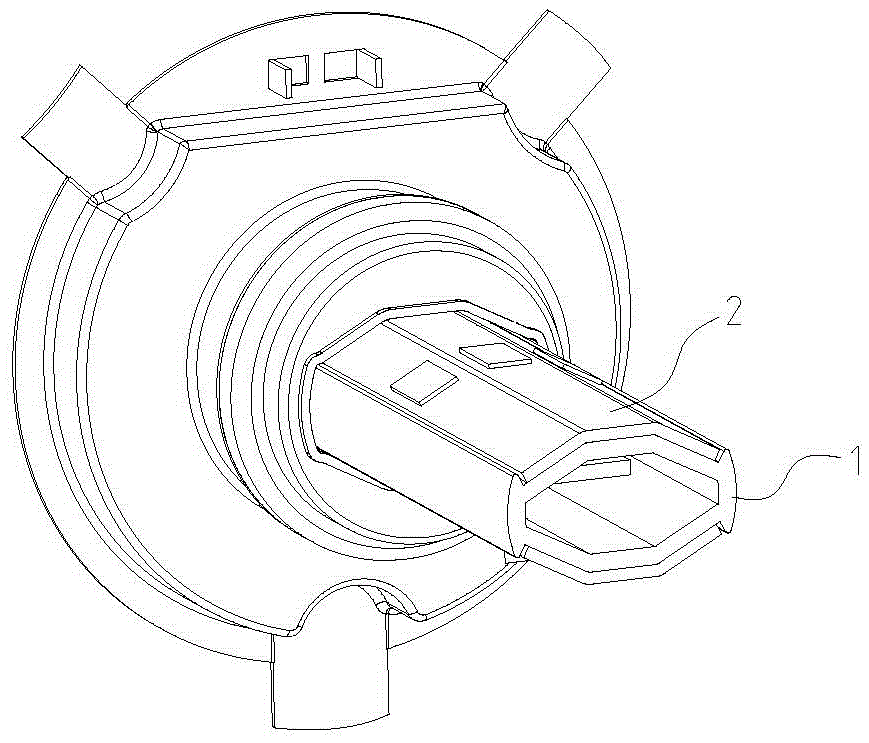

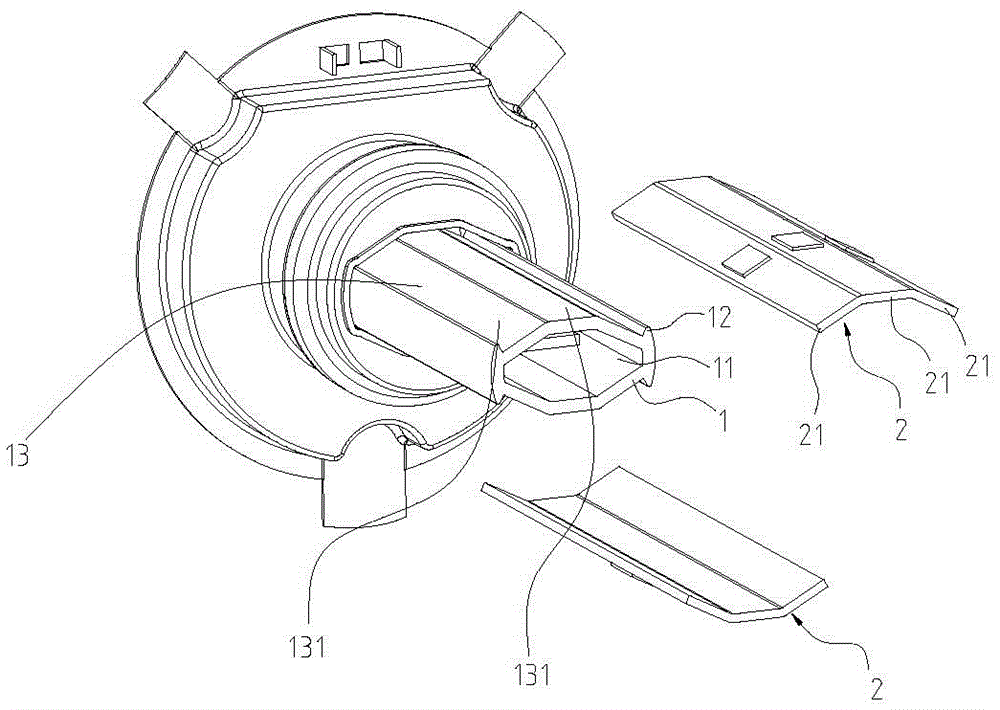

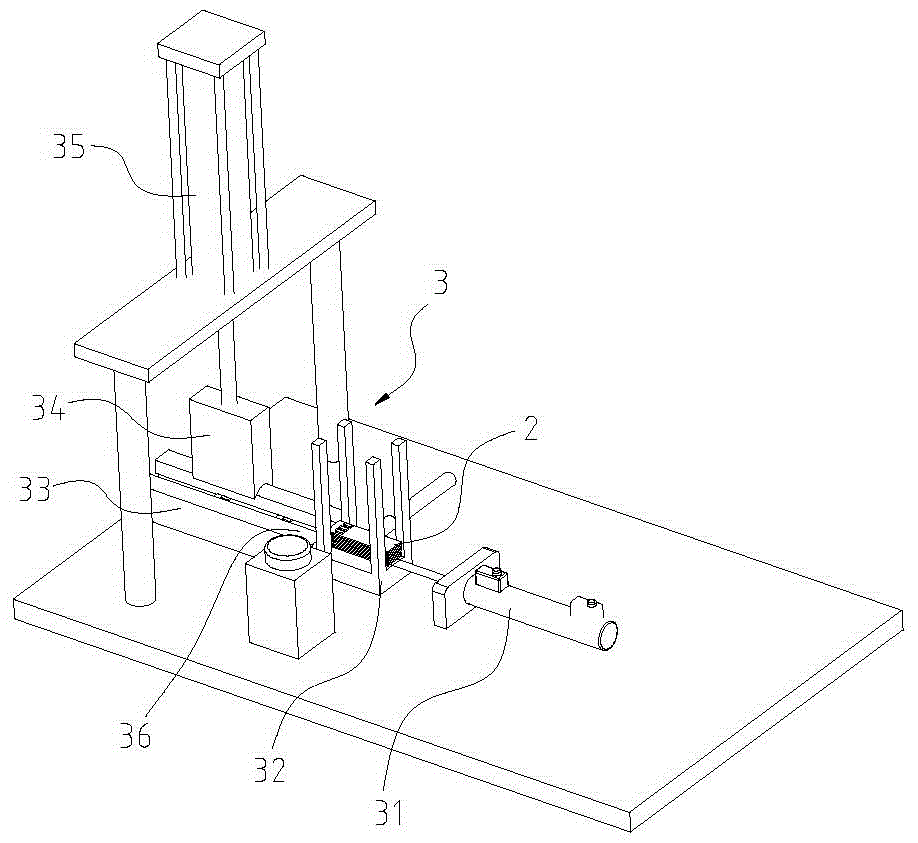

The invention discloses a steel plate hot forming method based on an anti-oxidation coating and a specifically designed hot forming production line for implementing the method. The method comprises the following steps: cleaning the surface of a workpiece to ensure that no oil contamination exists; utilizing automatic spraying equipment to spray coating on the surface of the workpiece; heating the workpiece by heating equipment to ensure the workpiece to reach austenitizing temperature thereof; transferring the workpiece to a rapid press machine, and rapidly finishing integration working procedures of pressing, compound die, pressure maintaining, quenching and forming in the rapid press machine; and lowering the temperature of the workpiece from austenitizing temperature to martensitic transformation temperature in the processing procedure. The hot forming production line comprises automatic spraying equipment, heating equipment, the rapid press machine and a transmission mechanism. The invention has the following beneficial effects of solving the problems of oxide skin generation in hot forming and causing the hot forming method to have lower cost, higher accuracy and simpler operation.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

3004 aluminum foil and preparing method and application thereof

The invention discloses 3004 aluminum foil and a preparing method and application thereof. The aluminum foil comprises chemical elements: by mass, 0.15-0.25% of Si, smaller than or equal to 0.55% of Fe, 0.14-0.2% of Cu, 1.02-1.15% of Mn, 0.95-1.1% of Mg, smaller than or equal to 0.05% of Cr, smaller than or equal to 0.15% of Zn, 0.015-0.025% of Ti, smaller than 0.1% of other chemical elements andthe balance Al. The 3004 aluminum foil is obtained by performing 3004 aluminum alloy smelting, refining, standing, online degassing and deslagging, casting, face-milling, uniform heating treatment, hot rolling, cold rolling, intermediate annealing, cold foil rolling and finished product annealing. With the combination of the various elements and the preparing process, the prepared aluminum foil has high strength and toughness, the thickness is greatly reduced when the aluminum foil is used as a container, use is convenient, and the consumption of the raw materials is reduced; and waste ring-pull cans can be adopted as a raw material, the consumption of the raw material is reduced, resources are reutilized, the source of the raw materials for preparing the aluminum foil is widened, meanwhile the burdens on the environment are avoided, the production cost is reduced, and the 3004 aluminum foil has quite good social economic benefits.

Owner:河南明泰科技发展有限公司

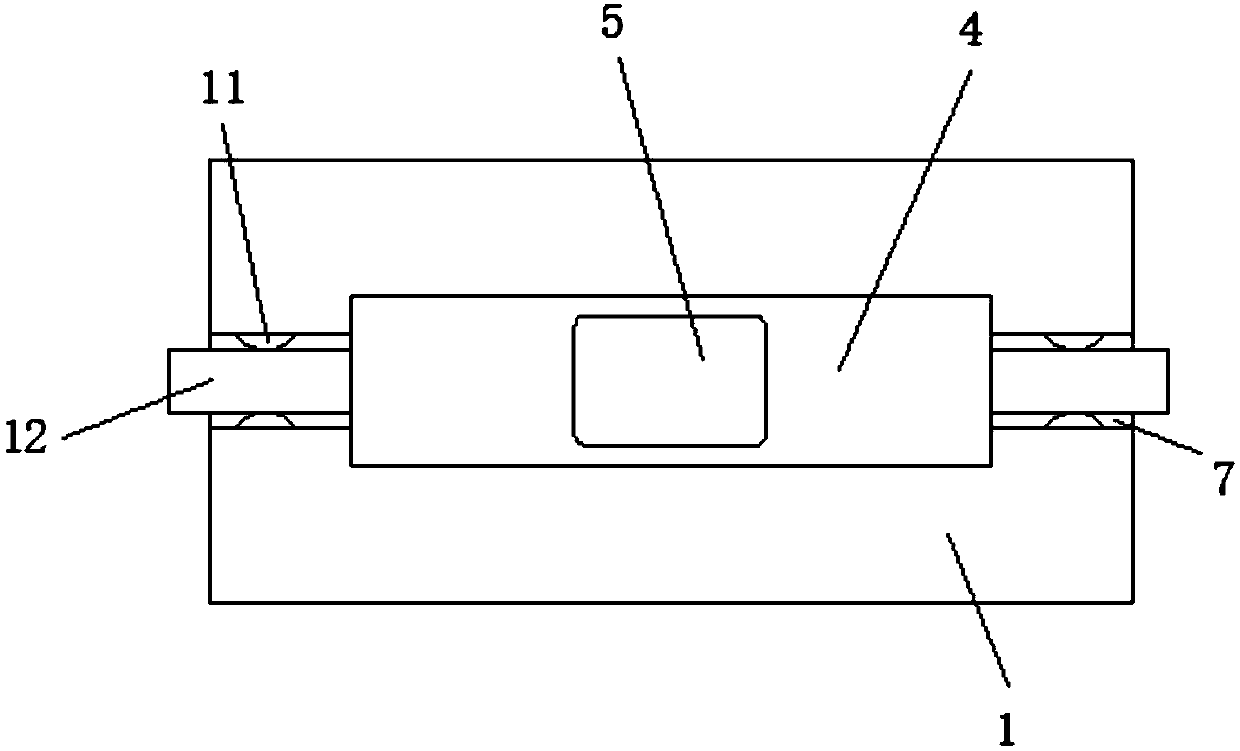

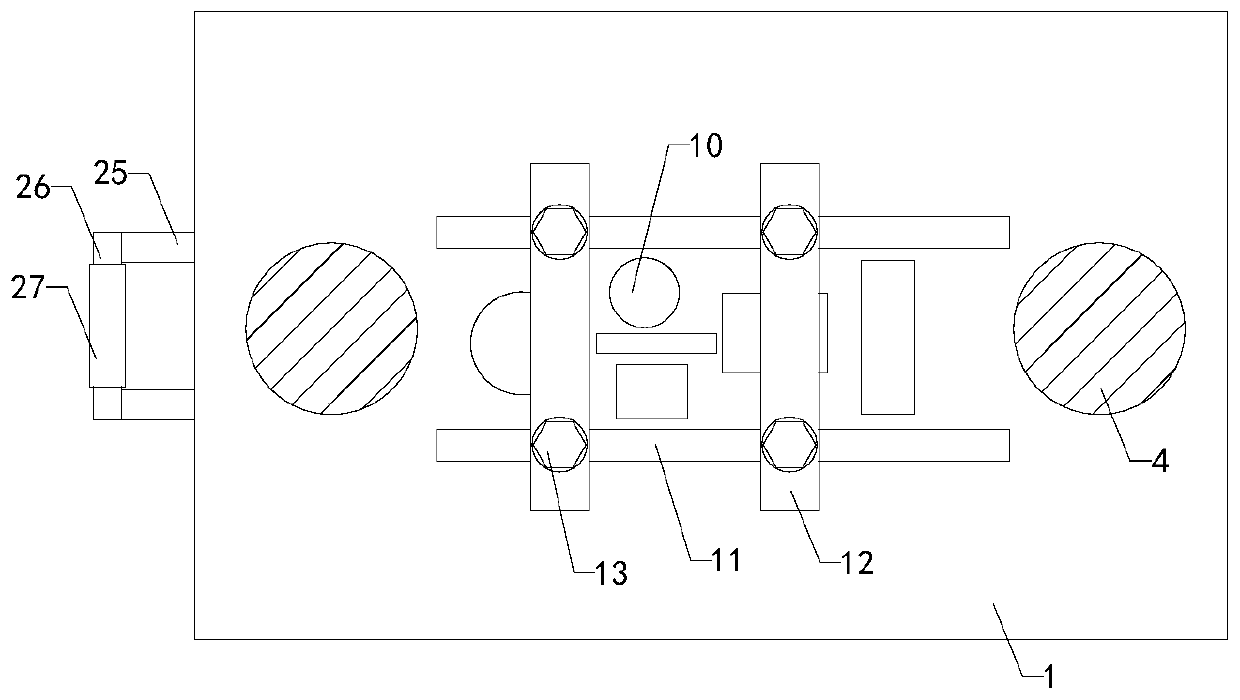

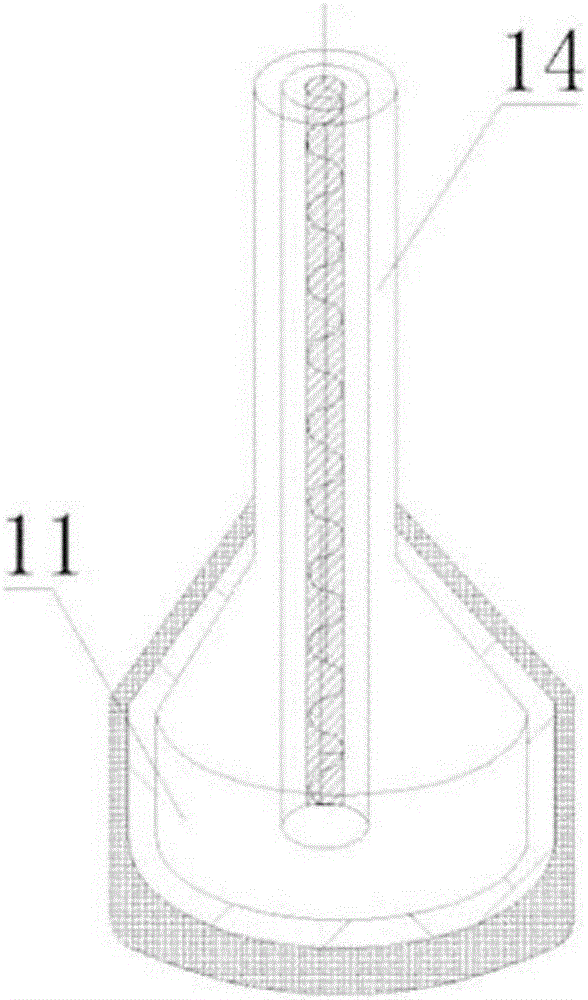

Automatic stamping system and method for cylinder part with automatic unloading function

InactiveCN107755474ARapid stampingReturn quicklyEjection devicesMechanical engineeringCylinder mould

The invention discloses an automatic stamping system and method for a cylinder part with an automatic unloading function. The automatic stamping system comprises a stamping base, stamping female mouldblocks and a stamping male mould rod, wherein two stamping limiting blocks are symmetrically arranged on the stamping base, and limiting arc-shaped surfaces are arranged on inner surfaces of the stamping limiting blocks; the two stamping female mould blocks are correspondingly arranged on the limiting arc-shaped surfaces of the two stamping limiting locks through limiting shafts; circular-arc shaped surfaces matched with outer-circle dimensions of stamped cylinder parts are arranged on the inner surfaces of the stamping female mould blocks; the stamping male mould rod is horizontally arrangedabove the stamping base and is connected with a stamping block; an unloading air cylinder is arranged at the rear side of the stamping block which corresponds to the stamping male mould rod; the unloading air cylinder is mounted on the stamping block through a mounting frame; a telescopic arm end head of the unloading air cylinder is equipped with a pushing frame; the stamping male mould rod is used for introducing the stamping plate into a cylinder mould formed by the two stamping female mould blocks; and under stamping action of the stamping male mould rod, the stamping female mould blocksrotate around the limiting shafts for stamping the stamping plate into the cylinder part.

Owner:巴中市新越不锈钢有限公司

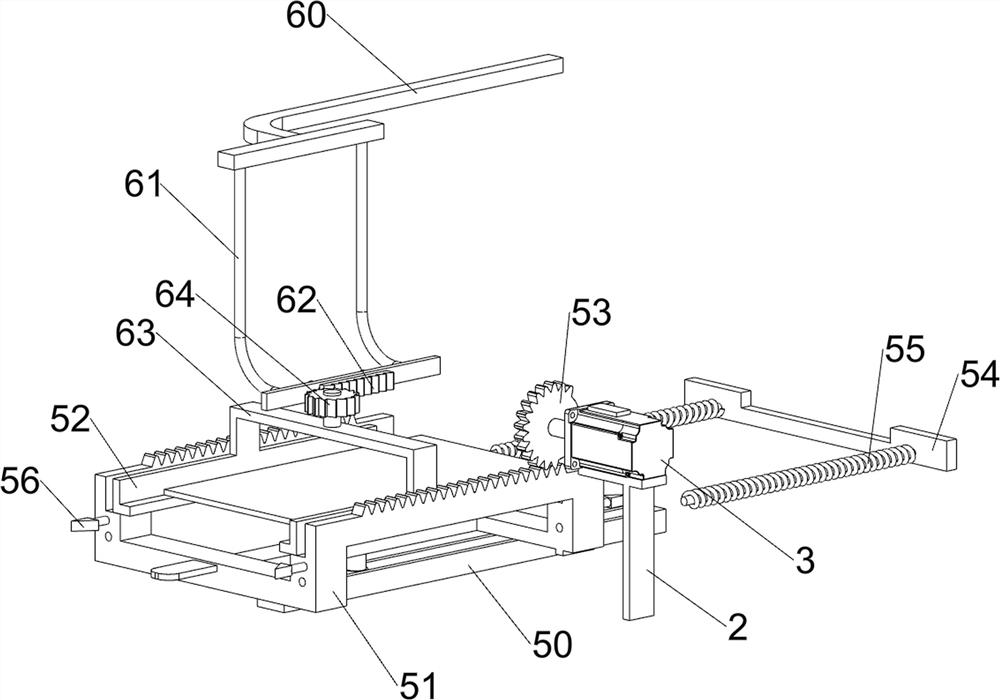

Mailbox Punching Device

InactiveUS20190105796A1Simple structureEasy to useLarge fixed membersMetal working apparatusPunchingGear wheel

The invention discloses a mailbox punching device, comprising a baseplate, two frames which are correspondingly arranged at the two ends of the top of the baseplate, and a box arranged between the two frames on the two ends through a lifting device. The inner bottom of the box is provided with a first steering cavity with a an opening facing downward, and a second steering cavity extends vertically is up and down extended in the box above the first steering cavity. A first sliding groove is connectedly set on the one inner wall of a the second steering cavity, and a steering platform, through bearings, is rotatably mounted in the first steering cavity. A first steering shaft which extends into the second steering cavity, is fixedly arranged on the top of the steering platform, and a first cone pulley bevel gear is fixedly mounted on the first steering shaft in the second steering cavity.

Owner:NANTONG WEIXING TEXTILE TECH CO LTD

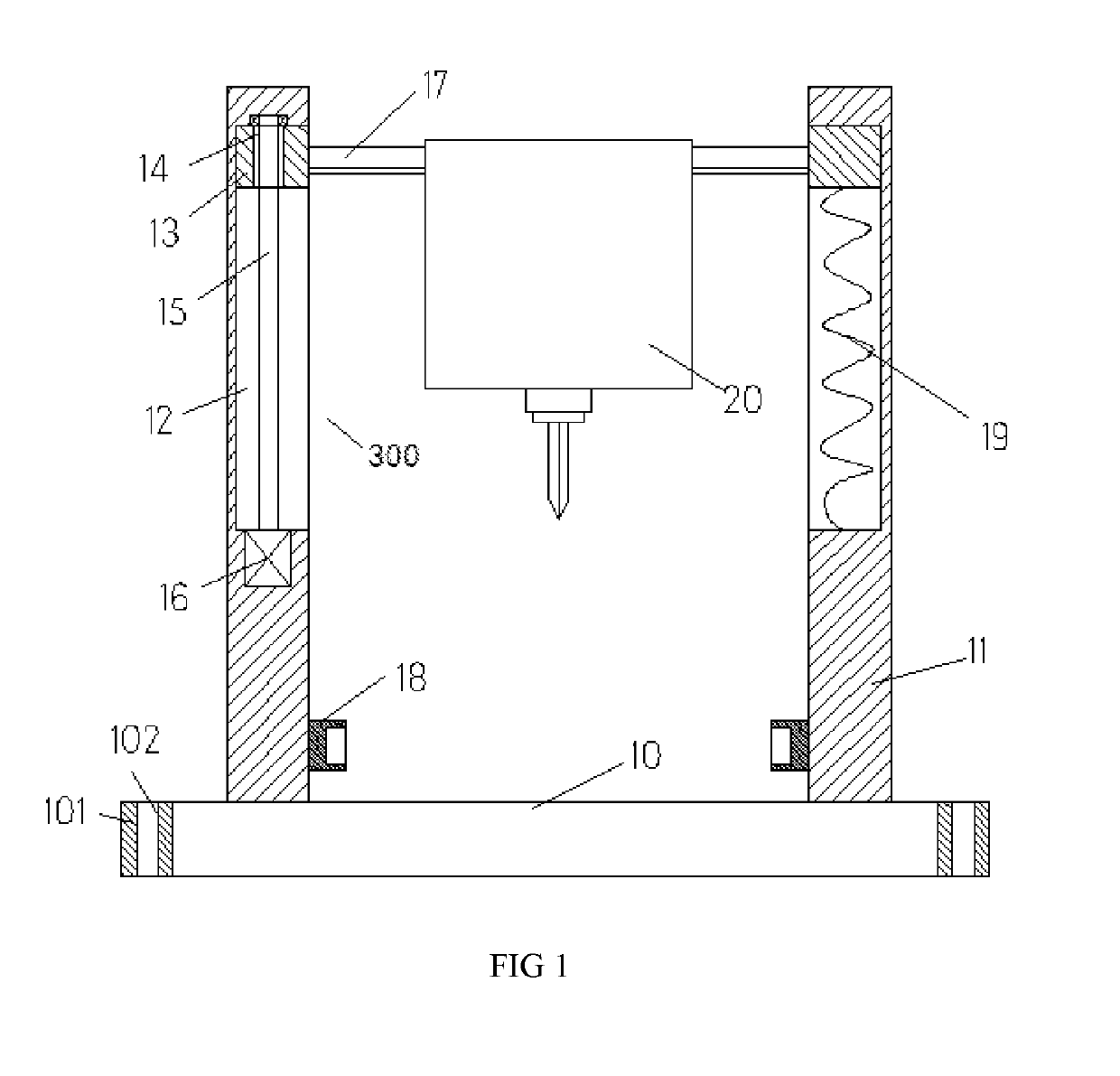

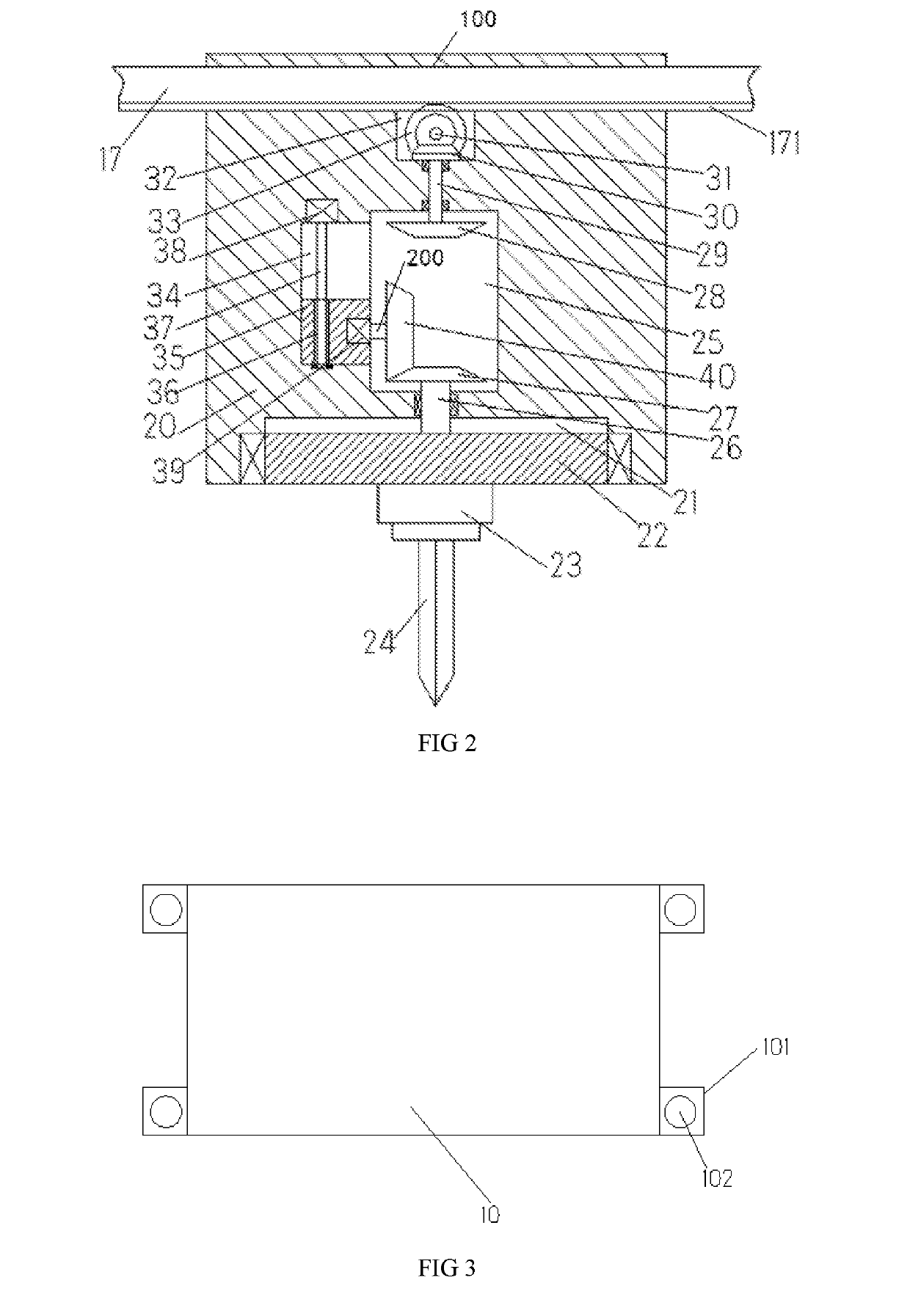

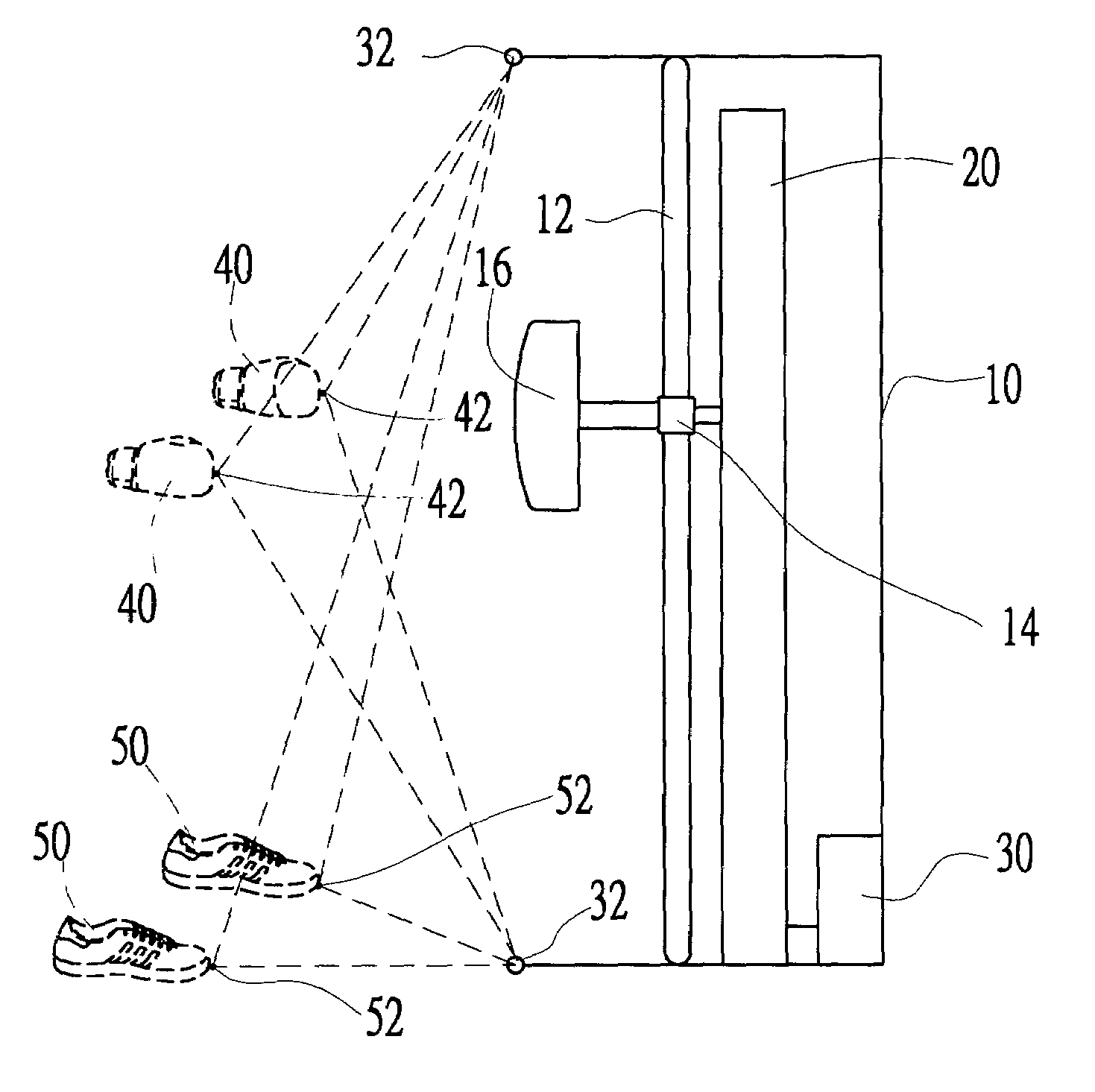

Interactive boxing trainer

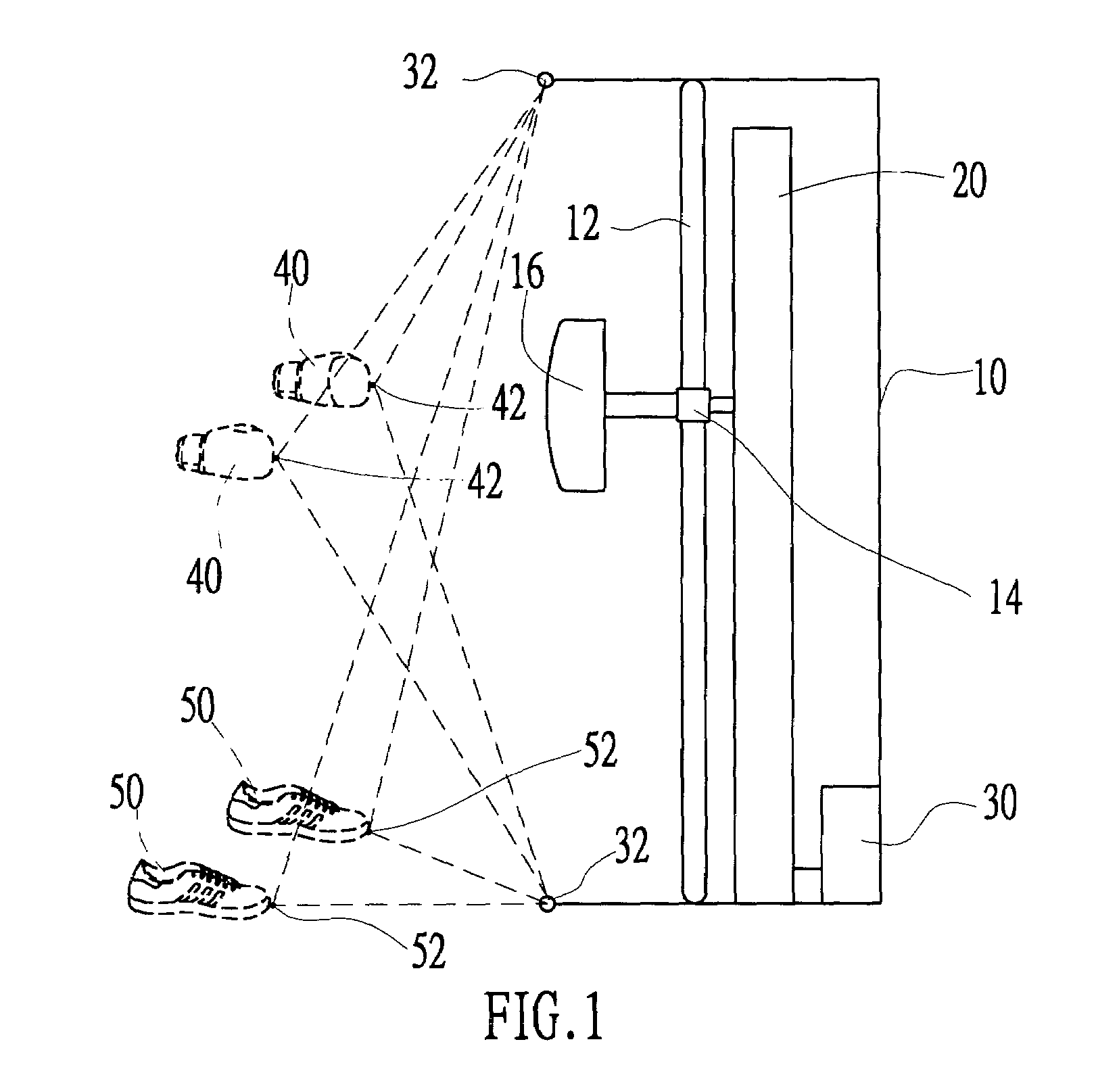

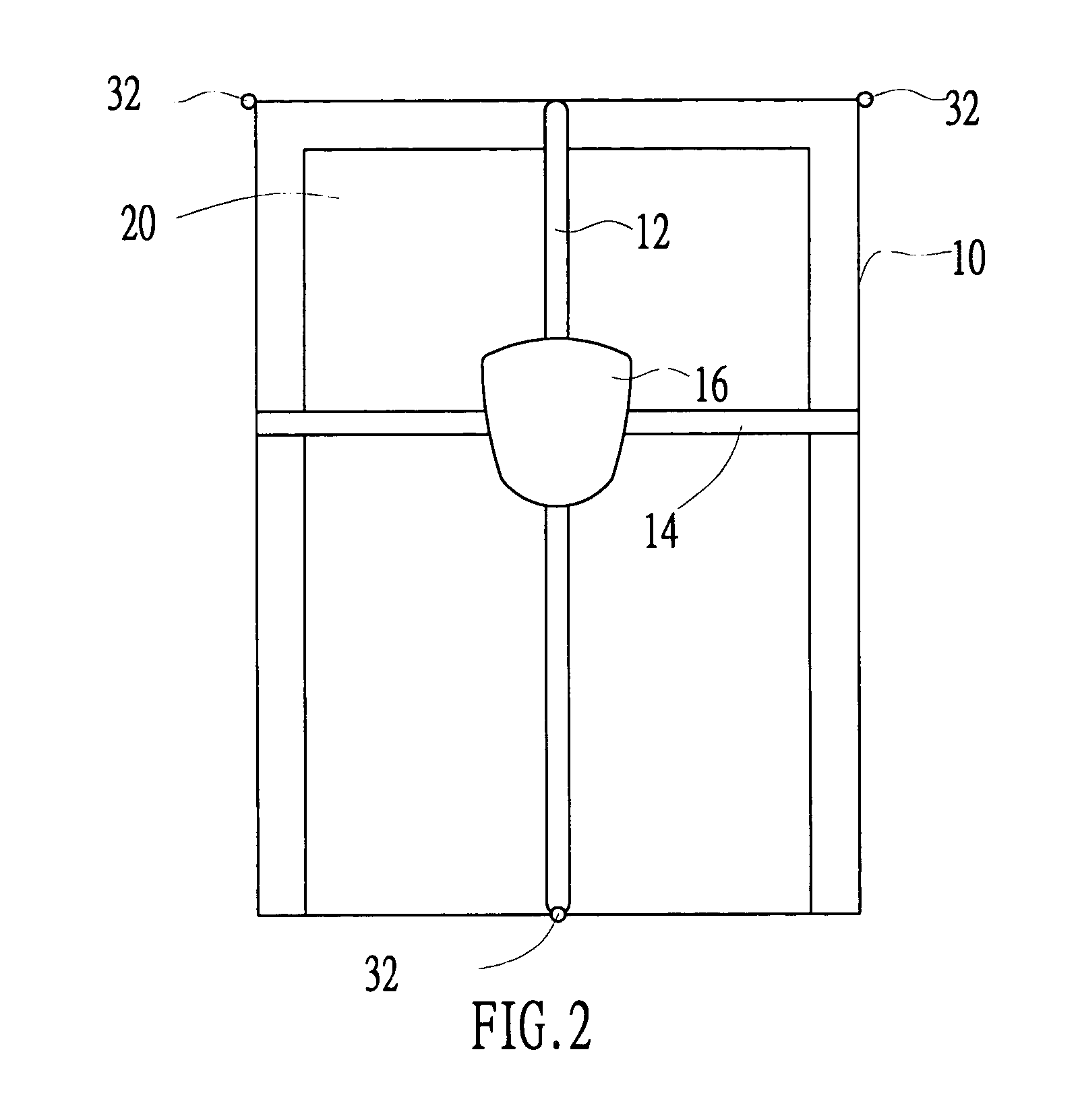

InactiveUS7041039B2Rapid movement of footRapid stampingMuscle exercising devicesEngineeringElectrical and Electronics engineering

The invention relates to an interactive boxing trainer which includes a main frame, a driving unit, a control unit, a pair of boxing gloves with a respective signal transmitter and a pair of shoes with a respective signal transmitter. The main frame contains a longitudinal slide rail, a lateral slide rail and a punched body. The driving unit moves the punched body on the longitudinal slide rail and the lateral slide rail. Moreover, the control unit is in connection with a plurality of signal receivers positioned at the upper and lower part of the main frame so as to receive signals sent by the signal transmitters on the boxing gloves and shoes. Therefore, the position, speed and travelling path of the boxing gloves can be detected and processed by the control unit which then commands the driving unit to move the punched body away from the approaching gloves and shoes.

Owner:WANG LEAO +1

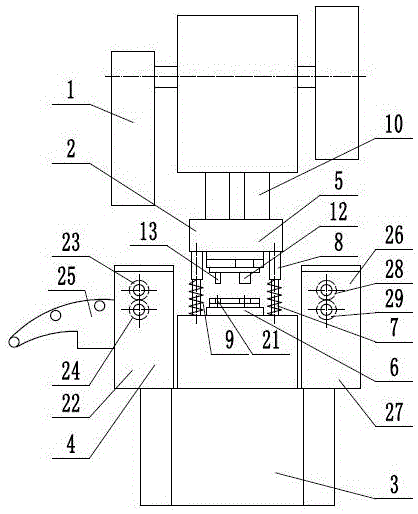

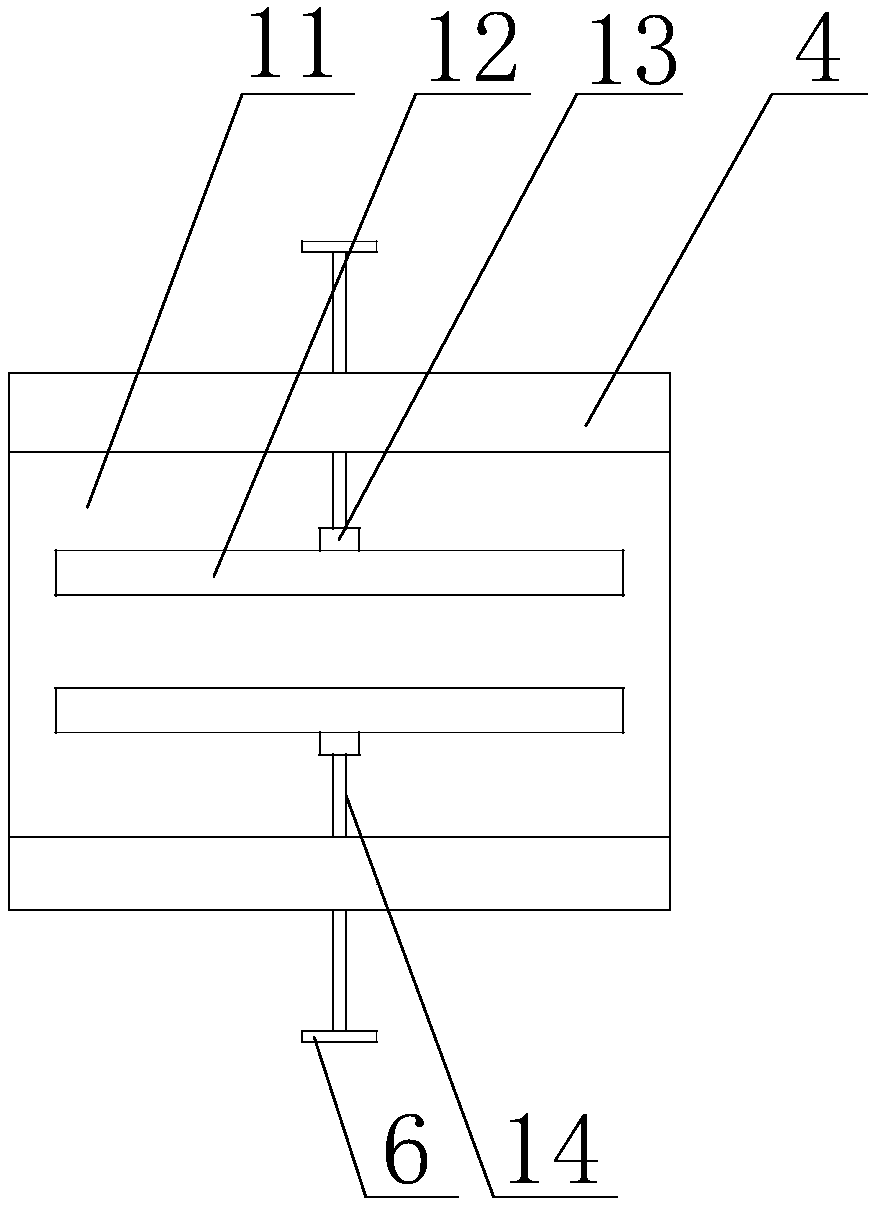

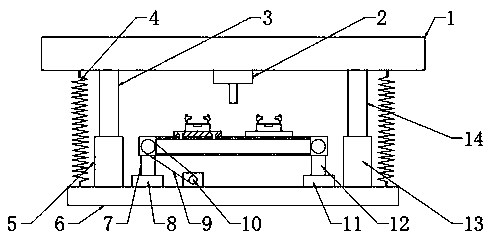

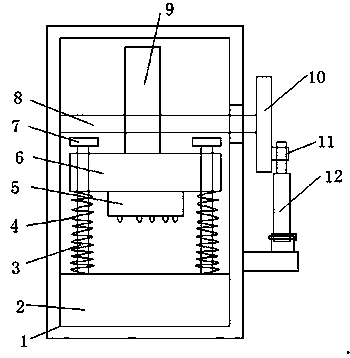

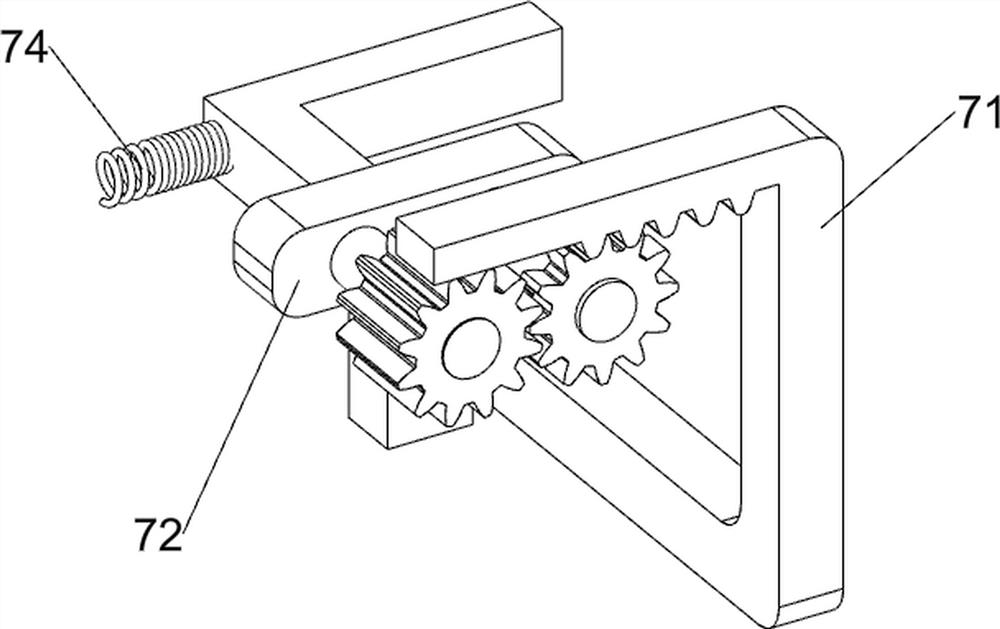

Single-power multi-mold punching machine

InactiveCN105013928ARealize feed orientationRapid stampingMetal-working feeding devicesStripping-off devicesPunchingMetal machining

The invention provides a single-power multi-mold punching machine, and belongs to the technical field of metal machining equipment. The single-power multi-mold punching machine comprises a punching mold and a feeding device, wherein an upper mold component of the punching mold is arranged at the lower end of a punching rod of the punching machine; a lower mold component is arranged at the upper end of a base; guide sleeves are concentrically arranged on a guide column in a vertical sliding manner; a support spring is arranged on the guide column; a fixed punching mold of the upper mold component is fixed at the lower side of an upper mold support plate; a movable punching mold is arranged at the lower side of the upper mold support plate in a vertical sliding manner; a slide plate is slidingly arranged on a slide groove; a feed device is arranged at one side of the punching mold; an upper feed roller and a lower feed roller of the feed device are both rotationally arranged on a feed bracket; and a feed guide plate is arranged at the front sides of the upper feed roller and the lower feed roller. The single-power multi-mold punching machine effectively guarantees opposite positions of punching holes, effectively controls the energy consumption, and reduces the cost.

Owner:ZHEJIANG WILLING TECH

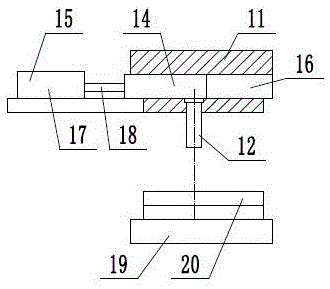

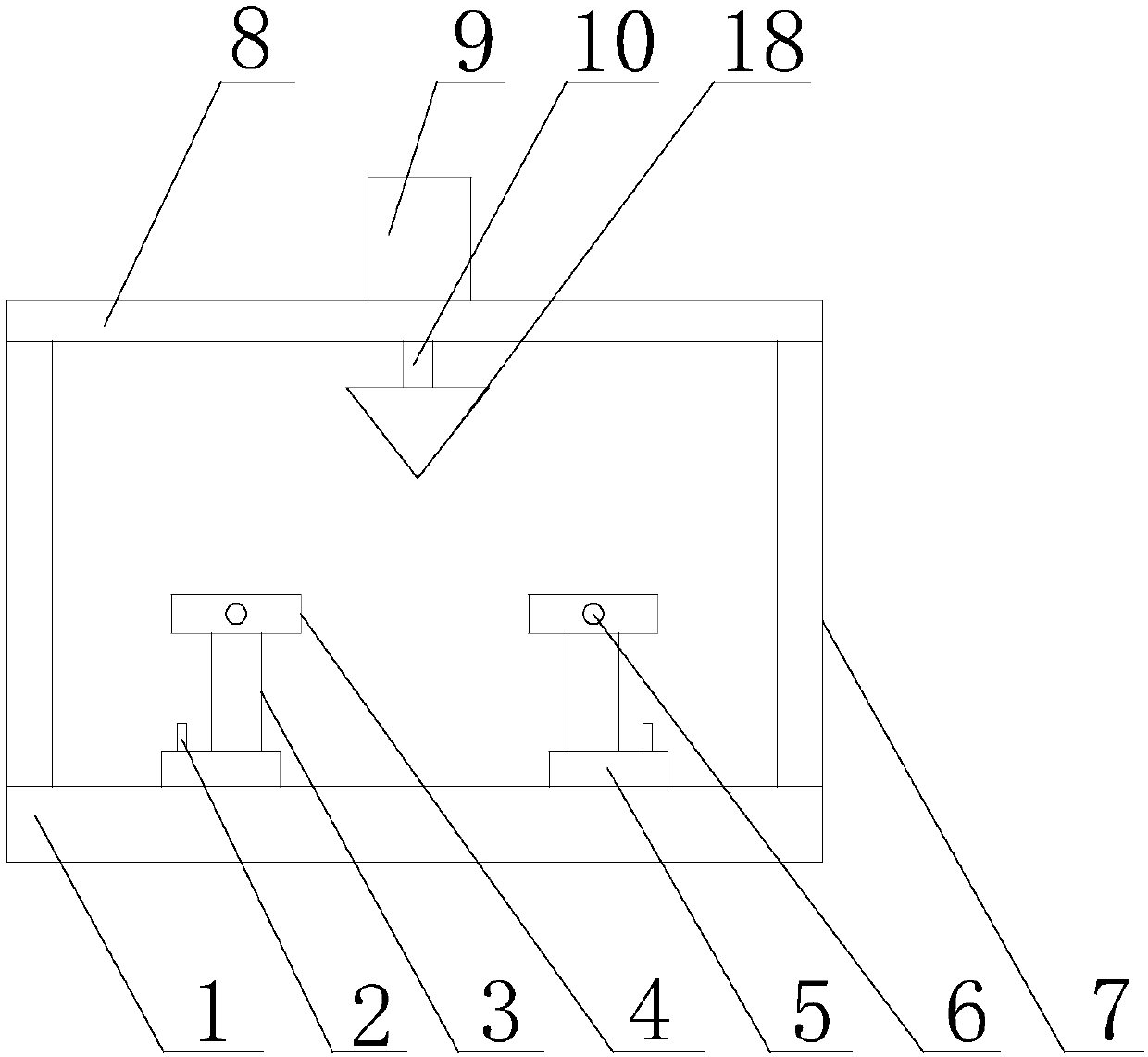

Bending and shaping device capable of absorbing bone plates

PendingCN108043914ARapid stampingApplicable useMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a bending and shaping device capable of absorbing bone plates. The bending and shaping device comprises a base, a driving mechanism and a punching head, two movable blocks arearranged at the top of the base, and the movable blocks can move on the base in the horizontal direction, supporting columns are arranged at the tops of the movable blocks; supporting tables are arranged at the top of the supporting columns, and grooves are formed in the top of the supporting tables; the two sides of the supporting tables are provided with movable rods, and the movable rods are horizontally connected with the supporting tables through threads; connecting blocks are arranged at the tail end, located in the grooves, of the movable rods, and the movable rods can rotate in the connecting block, and clamping plates are arranged on the connecting blocks, a plurality of supporting rods are further arranged at the top of the base, and a top plate is arranged at the top of the supporting rod; the bottom of the top plate is connected with the supporting rod, and the driving mechanism is located at the central position of the top plate; and the driving mechanism comprises an output shaft, the output shaft is vertically inserted into the top plate, and the bottom end of the output shaft is connected with the punching head.

Owner:CHENGDU MEDART MEDICAL SCI CO LTD

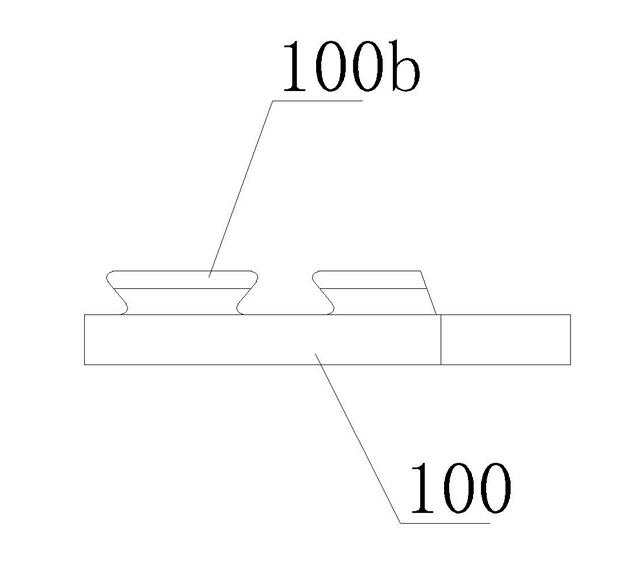

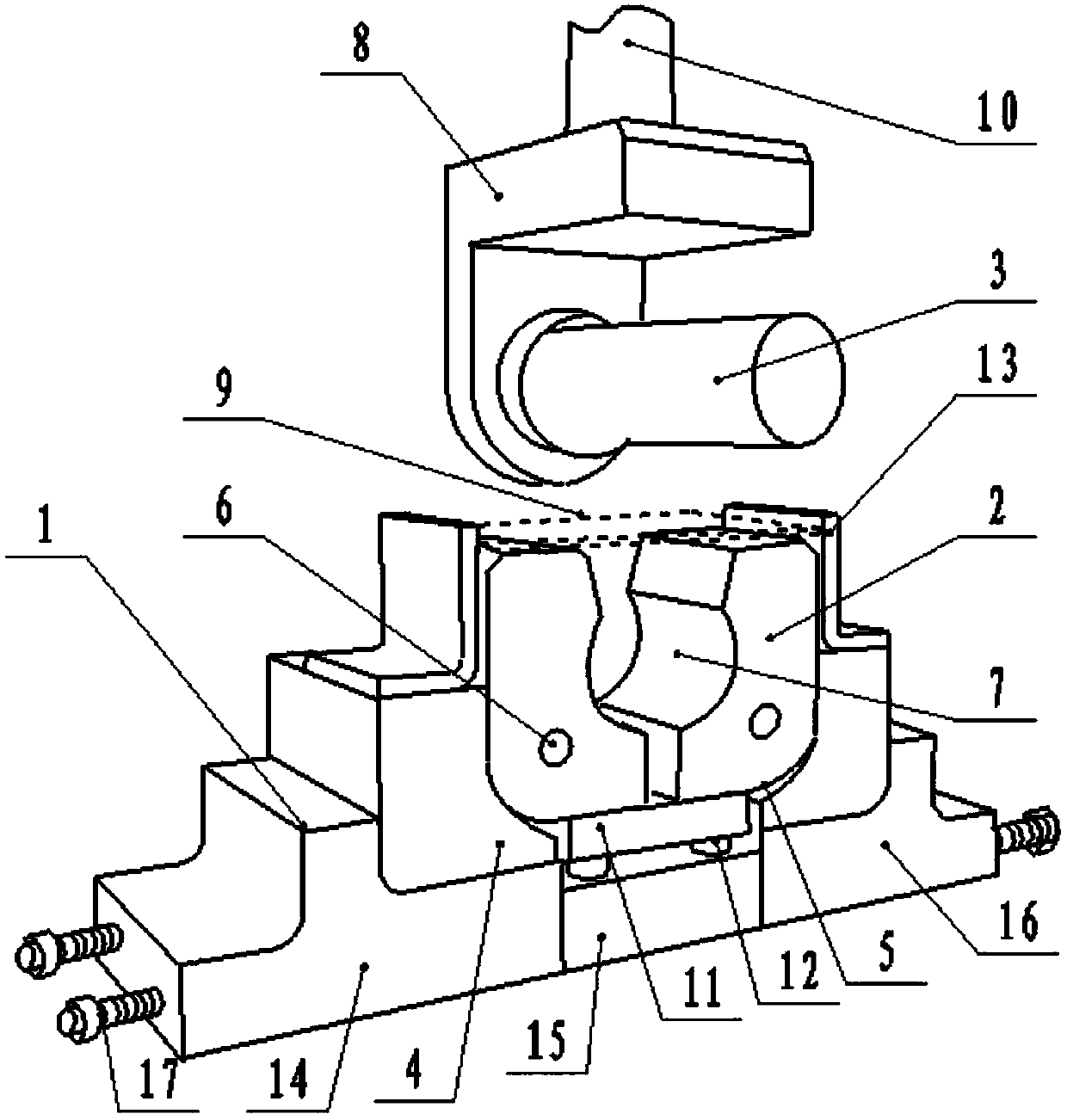

Punch die for commutator segment

The invention discloses a punch die for a commutator segment. The punch die comprises punches and punching openings, and is characterized in that: a bottom die of the punch die is provided with a transverse feeding channel; the shape of the vertical face of the transverse feeding channel is the same as the shape of the cross section of a drawn wire rod; the punching openings are formed on the bottom die, and comprise punching openings a, b and c; the punching openings a and b are formed in a vertical direction vertical to the feeding channel; the punching opening c is formed in a transverse direction vertical to the feeding channel; the punches corresponding to the punching openings are punches A, B and C; the punches A and B are vertically arranged; and the punch C is transversely arranged. The punch die realizes the rapid punch forming of the commutator segment, and is high in production efficiency and forming quality.

Owner:瑞安博宇科技股份有限公司

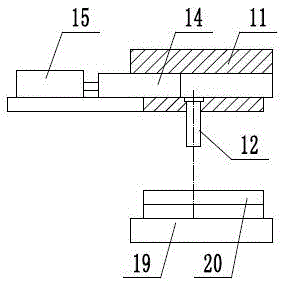

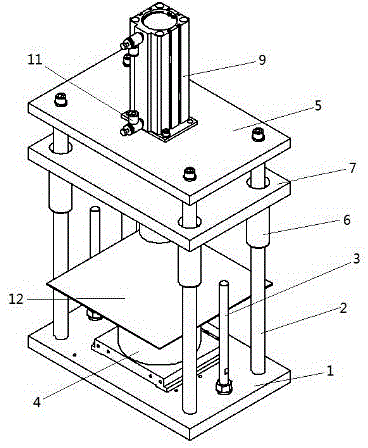

Direct-acting type panel punching mechanism

The invention relates to a direct-acting type panel punching mechanism. The direct-acting type panel punching mechanism comprises a fixing panel. A horizontal panel containing table is fixedly connected to the fixing panel. A plurality of vertical guiding shafts are arranged on the side face of the panel containing table. The lower ends of the guiding shafts are fixedly connected to the fixing panel. Limiting shafts lower than the guiding shafts are arranged between the guiding shafts. The lower ends of the limiting shafts are adjustably arranged on the fixing panel through threads. The upper ends of the guiding shafts are fixedly connected with a punching air cylinder fixing plate. A punching air cylinder is arranged on the punching air cylinder fixing plate. A punching head fixing plate is arranged between the punching air cylinder fixing plate and the panel containing table and arranged on the guiding shafts in a sliding manner. A punching head matched with the panel containing table at the lower portion is arranged on the punching head fixing plate. The punching head is connected with a cylinder rod of the punching air cylinder through a universal joint. According to the mechanism, plastic panels with the thickness smaller than 2 mm can be rapidly flattened, the structure is simple, the cost is low, and compared with a large punching mechanism, more electricity is saved during using of the direct-acting type panel punching mechanism.

Owner:SUZHOU INST OF TRADE & COMMERCE

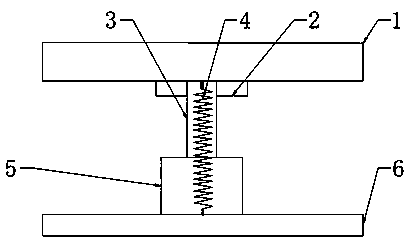

Multi-hole stamping die for hardware machining

InactiveCN110884203ARapid stampingSolve the problem of not being able to stamp quicklyShaping toolsPressesStampingConveyor belt

The invention relates to the technical field of stamping dies, and discloses a multi-hole stamping die for hardware machining. The multi-hole stamping die for hardware machining comprises an upper diebase. The bottom of the upper die base is fixedly connected with the top end of a male die, the bottom of the upper die base is fixedly connected with the top ends of springs, the bottom ends of thesprings are fixedly connected with the top of a lower die base, the top of the lower die base is fixedly connected with the bottom ends of first guide sleeves, the first guide sleeves are movably connected with first guide pillars, and the top ends of the first guide pillars are fixedly connected with the bottom of the upper die base. According to the multi-hole stamping die for hardware machining, by additionally arranging two female dies on a conveyor belt, the first female die is conveyed by the conveyor belt to move rightwards after completing stamping, the conveyor belt stops when the second female die arrives at a position below the male die, and the upper die base moves downwards to complete stamping of a second workpiece, so that the purpose of rapid stamping is achieved, and the problem that a traditional stamping die cannot perform rapid stamping is solved.

Owner:倪程凯

Automatic stamping system and method applicable to stainless steel cylinder parts of different sizes

InactiveCN107552609AAdjustable distanceRapid stampingMetal-working feeding devicesPositioning devicesEngineeringThreaded rod

The invention discloses an automatic stamping system and method applicable to stainless steel cylinder parts of different sizes. The automatic stamping system and method applicable to stainless steelcylinder parts of different sizes comprises a stamping base, stamping female die blocks and a stamping male die stick. The stamping base comprises a left side stamping base, a middle stamping base anda right side stamping base. The left side stamping base is connected with the middle stamping base through adjusting threaded rods. The right side stamping base is connected with the middle stampingbase through adjusting threaded rods. Two stamping limiting blocks are symmetrically arranged on the middle stamping base of the stamping base. A limiting cambered surface is arranged on the inner face of the left side stamping base. A limiting cambered surface is arranged on the inner face of the right side stamping base. The two stamping female die blocks are arranged on the limiting cambered surface of the left side stamping base and the limiting cambered surface of the right side stamping base correspondingly through limiting shafts. An arc surface matched with the excircle of a stamping cylinder part is arranged on the inner face of each stamping female die block. The stamping male die stick is horizontally arranged above corresponding to the stamping base and movably connected with astamping block. The stamping male die stick makes a plate to be stamped go into the cylinder die formed by the two stamping female die blocks, and under the stamping action of the stamping male die stick, the stamping female die blocks turn around the respective limiting shafts to make the plate to be stamped form a cylinder part in a stamping manner.

Owner:巴中市新越不锈钢有限公司

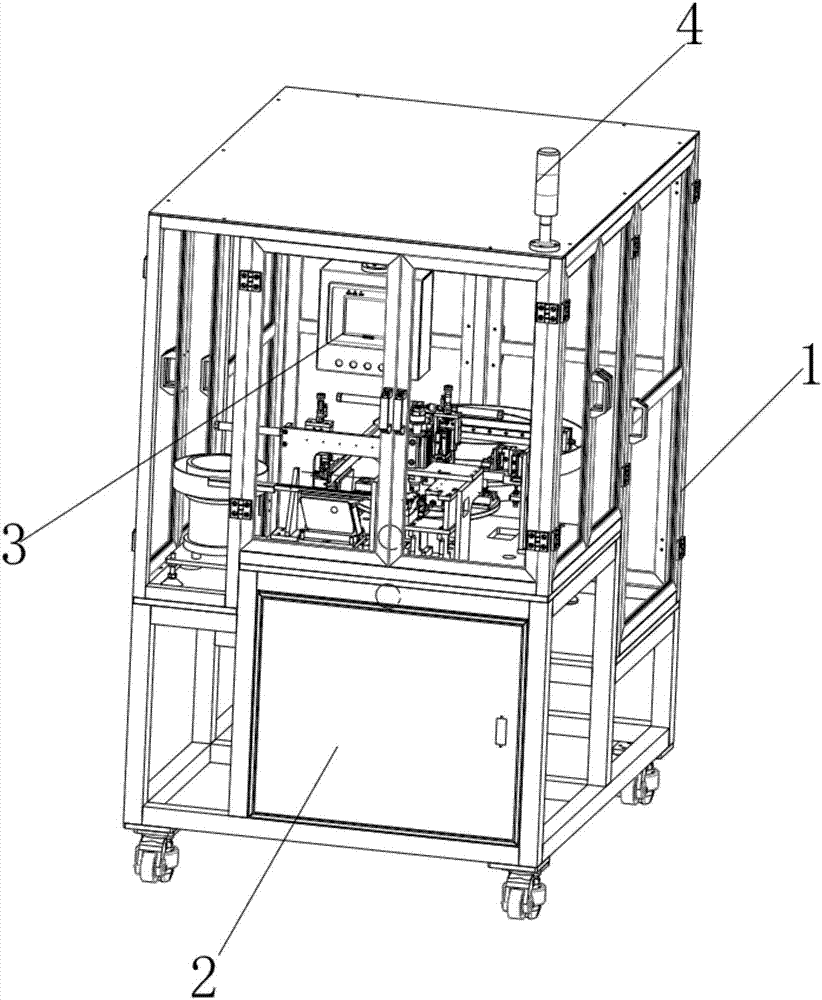

Punch forming technology and device for corrosion-resistant stainless steel seamless pipes

The invention provides a punch forming technology and device for corrosion-resistant stainless steel seamless pipes. The punch forming device for the corrosion-resistant stainless steel seamless pipesmainly comprises four stations, namely, a stainless steel pipe feeding mechanism, a plastic part feeding mechanism, a detection mechanism and a discharging mechanism. Compared with the prior art, thepunch forming technology and device for the corrosion-resistant stainless steel seamless pipes have the advantages that the stainless steel pipe feeding mechanism and the plastic part feeding mechanism are arranged so that stainless steel pipes and plastic parts can be automatically fed, and a rotating disc and clamps are arranged so that the circulating rotation of all the machining stations canbe realized; a punch head is arranged so that stainless steel pipe workpieces can be punched rapidly, and the detection mechanism is arranged so that the punching quality can be detected; and a manual assembling mode can be replaced, and the automation of feeding, punching, detecting and discharging can be realized.

Owner:浙江冠宇管业有限公司

Techniques for bonding substrates using dynamic alternating electric field

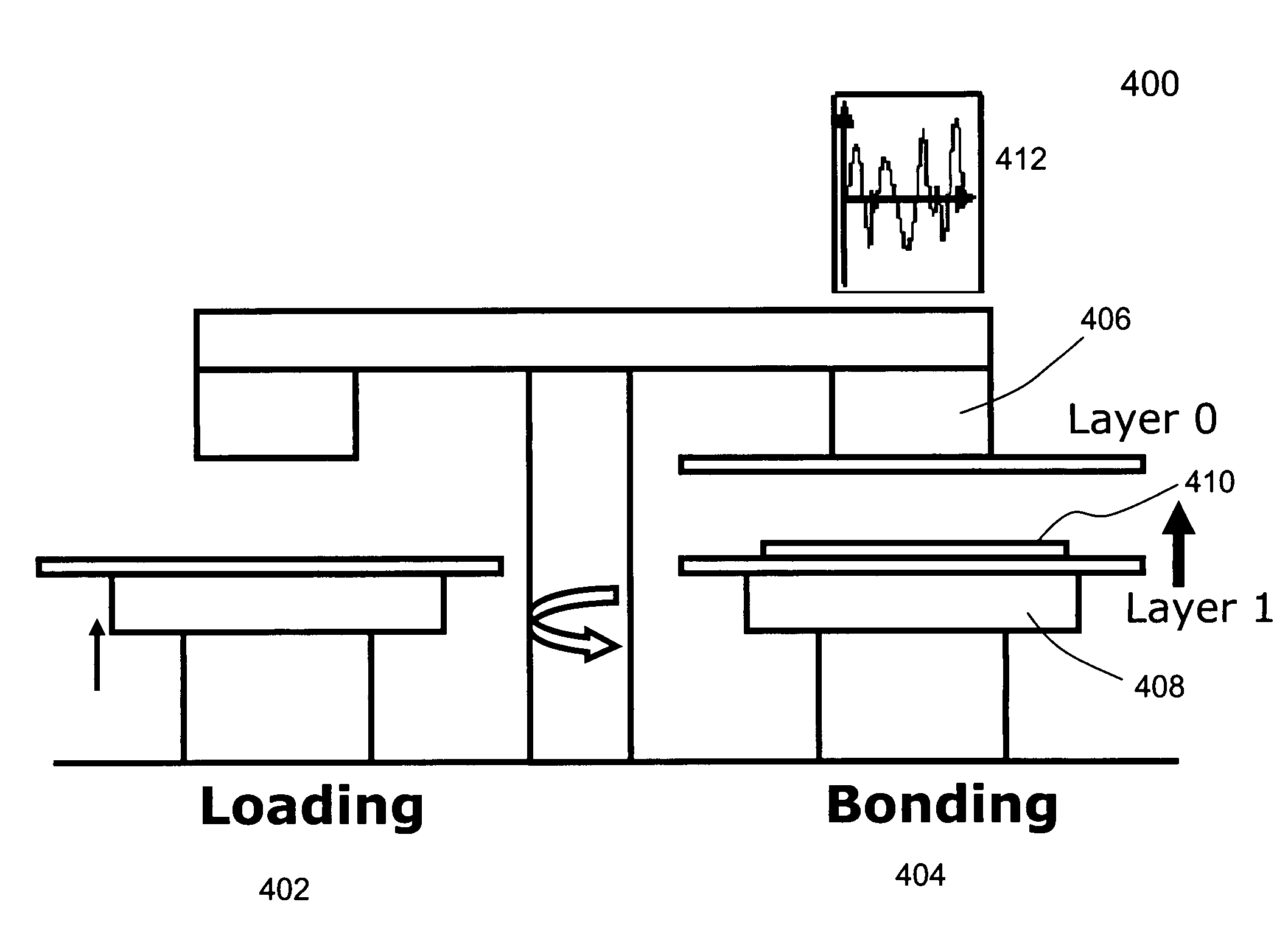

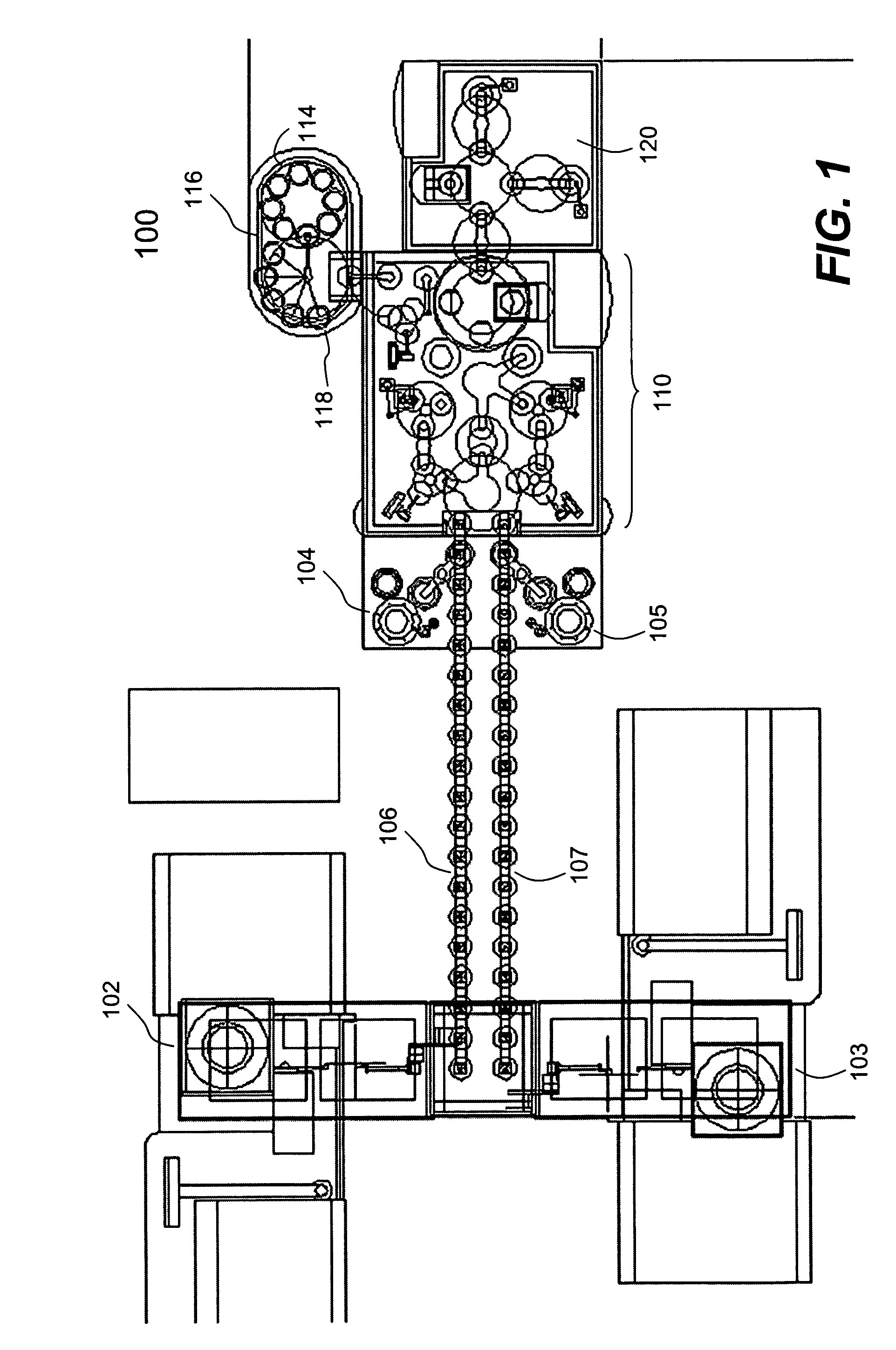

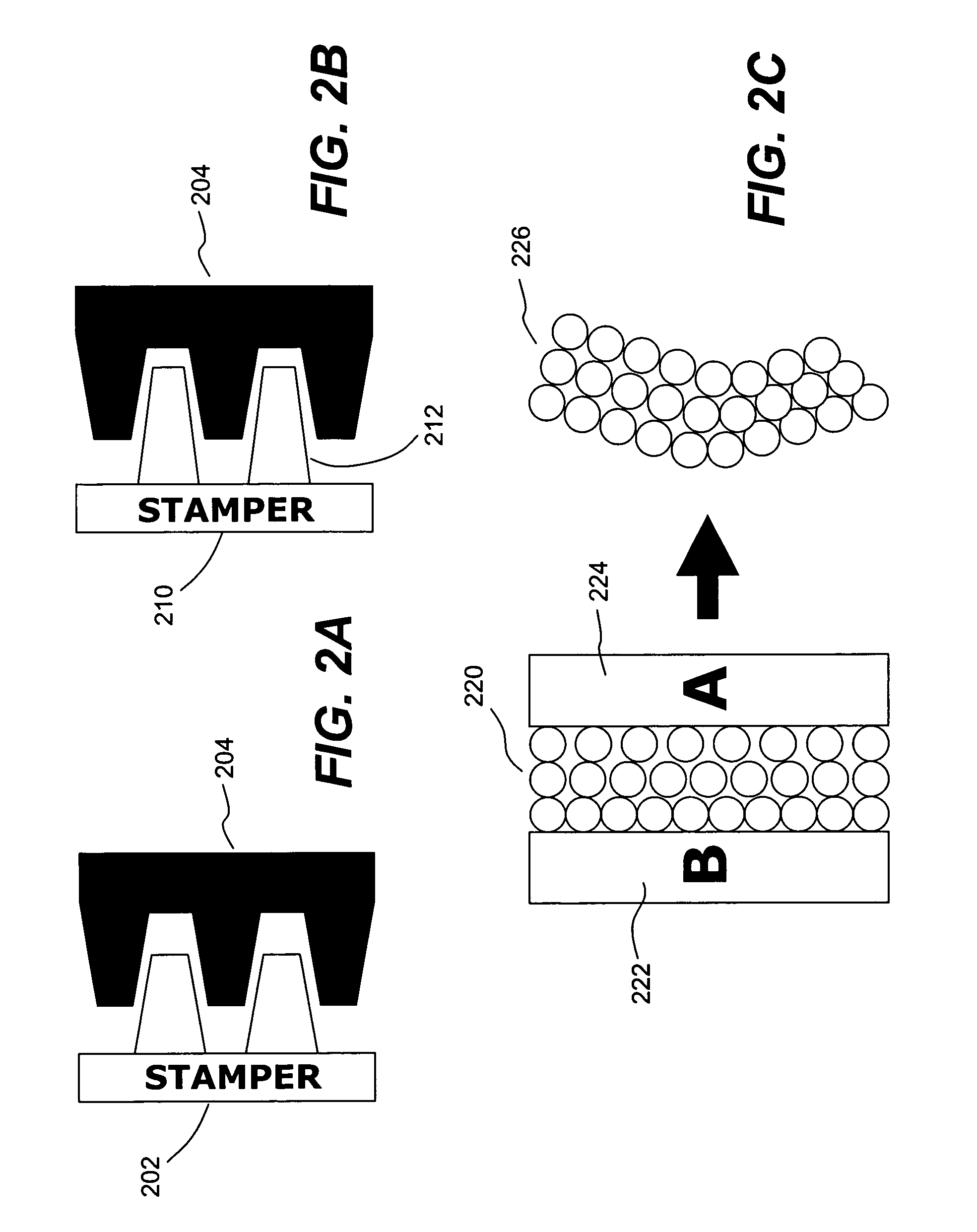

InactiveUS7591920B1Reduce surface tensionIncrease speedRecord carriersLamination ancillary operationsRefractive indexEngineering

Techniques for bonding substrates are disclosed. According to one aspect of the techniques, an index bonding is provided to ensure that non-flatness of substrates is compensated when two substrates are bonded together so as to minimize possible dynamic imbalance of a disc. According to another aspect of the techniques, a dynamic alternating electric field bonding is provided to eliminate bubbles from a type of glue used to bond two substrates, wherein a power source is used to generate a dynamic alternating electromagnetic field in accordance with the substrates and / or the characteristics of the glue.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

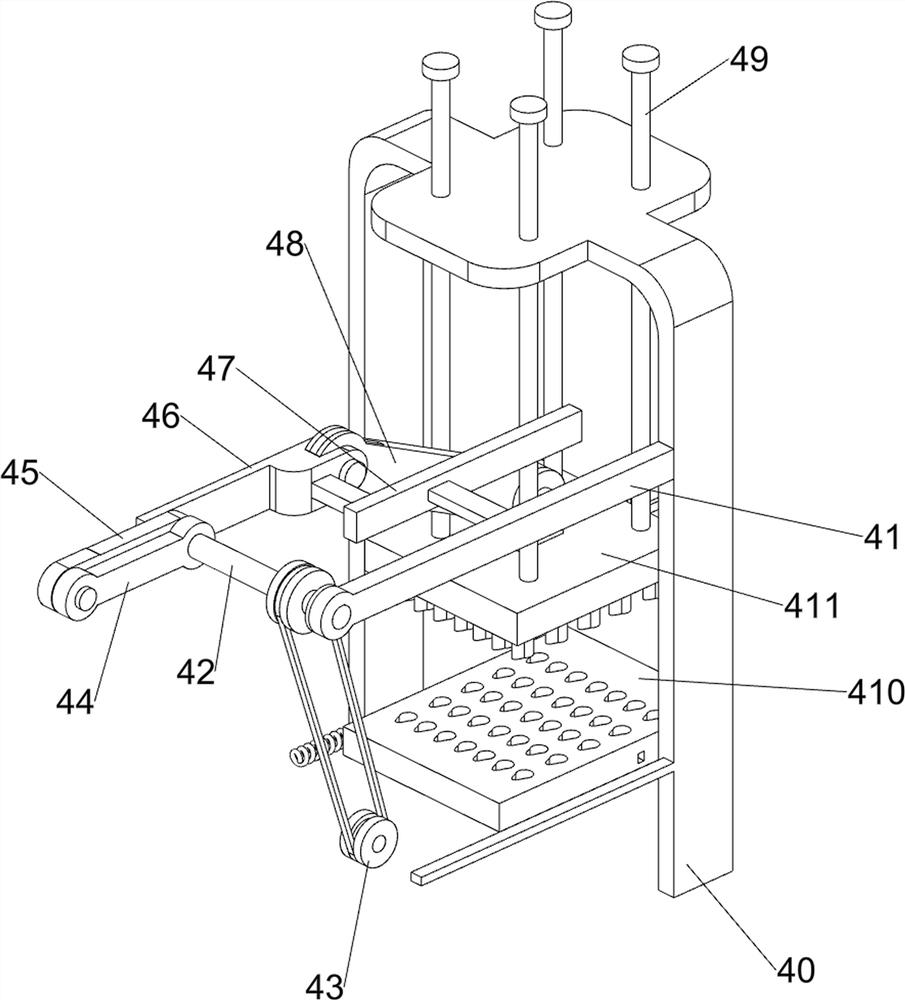

Positioning and grooving mechanism for pipe pile end square plate

ActiveCN110976589ARapid stampingFast and tight punchingMetal-working feeding devicesPositioning devicesStructural engineeringMachine

The invention discloses a positioning and grooving mechanism for a pipe pile end square plate. The mechanism comprises a bottom plate, wherein a face plate is arranged on the bottom plate, a pluralityof supporting legs are fixedly arranged below the bottom plate, square plate grooves are uniformly formed in the face plate, a punching machine is arranged on one of the square plate grooves, one ofthe square plate grooves is a discharging square plate groove, a discharging through hole formed in the bottom plate is formed below the discharging square plate groove, a material receiving mechanismis placed below the discharging through hole, a discharging mechanism is arranged on the plurality of square plate grooves, an intercepting mechanism is arranged on one side of the discharging mechanism, a transmission rod is fixedly arranged at the lower end of the middle of the face plate, the transmission rod movably penetrates through the bottom plate, a rotating disc is fixedly arranged at the end, far away from the face plate, of the transmission rod, and a plurality of static holes are uniformly formed in the rotating disc. The mechanism has the beneficial effects that rapid stamping is carried out, the grooving difficulty of manual stamping is relieved, and meanwhile, the grooving precision is increased, the situation that the construction is misaligned is reduced, and the construction efficiency is improved.

Owner:嘉兴晨坤金属制品有限公司

Refrigerator door inner container punching die positioning structure

PendingCN113751608AReduce tensile stressAvoid breakingShaping toolsMetal-working feeding devicesWheel driveCam

The invention relates to the technical field of refrigerator inner container forming, and discloses a refrigerator door inner container punching die positioning structure which comprises a feeding positioning mechanism. The feeding positioning mechanism comprises a base, and a lifting guide column is arranged at the top of the base. According to the refrigerator door inner container punching die positioning structure, a punching belt wheel drives a primary cam and a secondary cam to rotate, the primary cam drives a primary sliding plate to move downwards, the primary sliding plate drives a primary punching frame to move downwards, the primary punching frame drives a shaping die to move downwards, the shaping die conducts primary punching forming on a plate, the secondary cam drives a secondary sliding plate to move downwards, the secondary sliding plate drives a secondary punching frame to move downwards, the secondary punching frame drives a secondary die and a rotating sleeve to move downwards, and the rotating sleeve makes contact with a limiting rod, so that the effects that secondary stamping forming is achieved, the pulling stress of the plate is reduced, the plate is prevented from being broken, the plate can be rapidly stamped and formed, and a formed inner container is automatically separated from the die are achieved.

Owner:滁州佳诚模具制造有限公司

Device for machining accessories for track installation

InactiveCN107695162AMove quicklyFast processingMetal-working feeding devicesVehicle componentsFixed frameEngineering

The invention discloses a device for machining accessories for track installation. The device comprises a fixed frame, wherein the vertical section of the fixed frame is shaped like a rectangle, a base is installed on the inner wall of the bottom end of the fixed frame, and four vertically arranged guide columns are welded to the side wall of the top end of the base; a limiting block is welded tothe side wall of the top end of each guide column, a horizontally arranged stamping block is slidably connected to the guide columns, a stamping cutter head is installed on the side wall of the bottomend of the stamping block, and the stamping cutter head is located in a space defined by the four guide columns; each guide column is sleeved with a spring, the springs are located between the stamping block and the base, a horizontally arranged rotating shaft is arranged above the guide columns, the rotating shaft is rotationally connected inside the fixed frame, an eccentric block is fixedly installed on the rotating shaft, and the eccentric block is in sliding connection with the side wall of the top end of the stamping block; and a rotating disc is connected to one end of the rotating shaft, and the rotating disc is located outside the fixed frame. According to the device for machining the accessories for track installation, rapid moving of raw materials can be achieved, rapid stamping machining can be conducted on the accessories for track installation, and the machining efficiency is high.

Owner:安徽浦进轨道装备有限公司

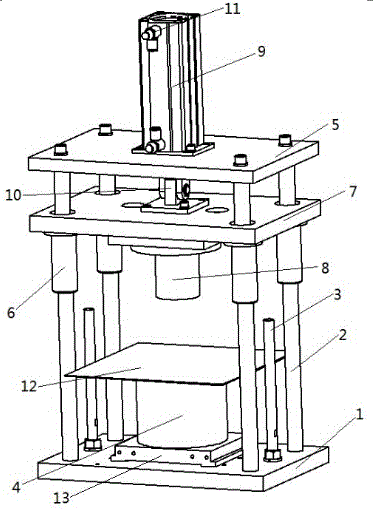

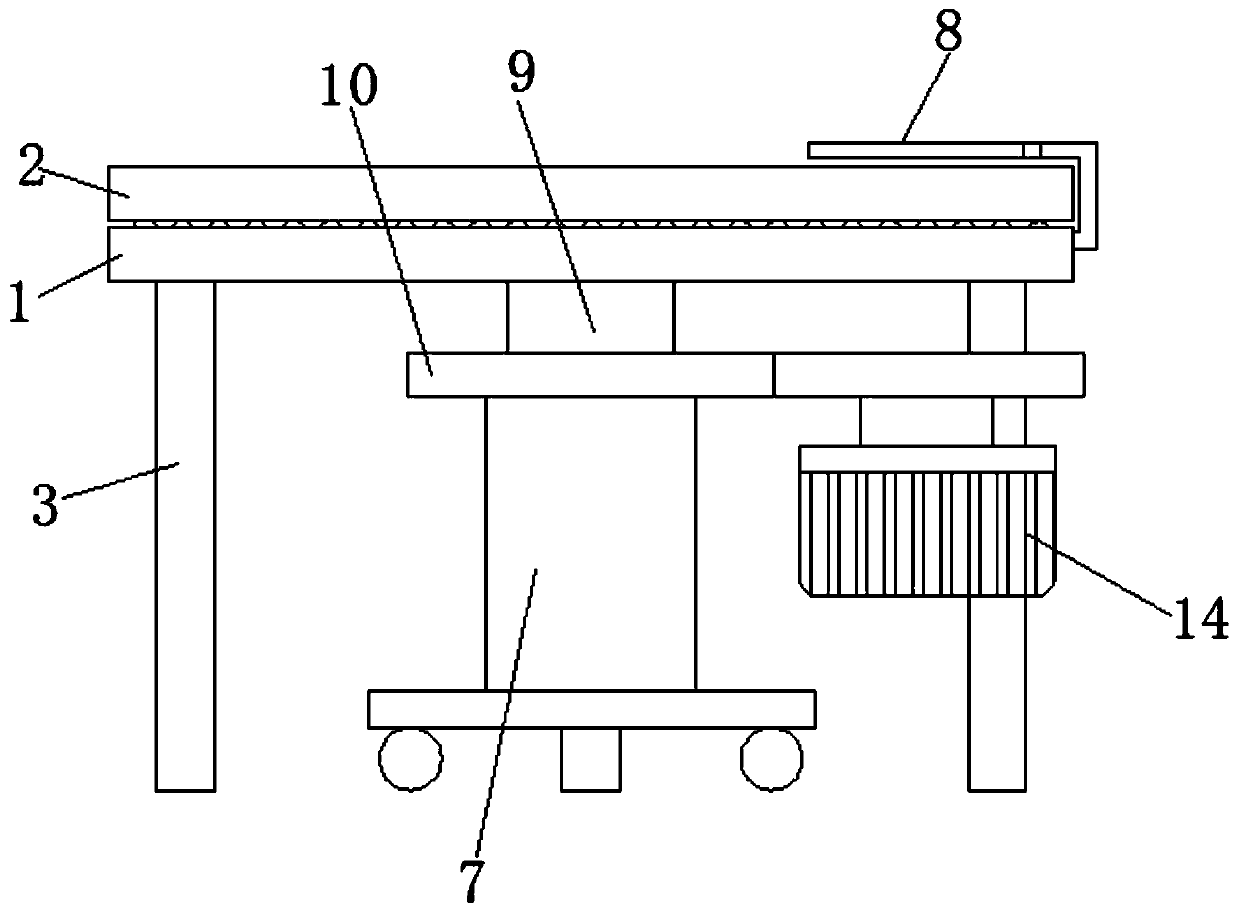

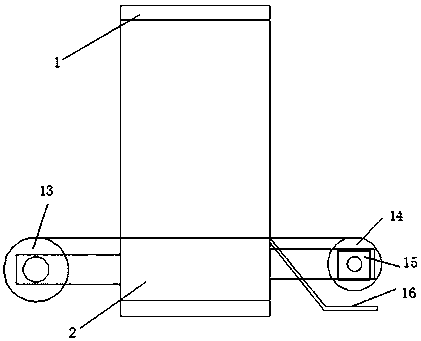

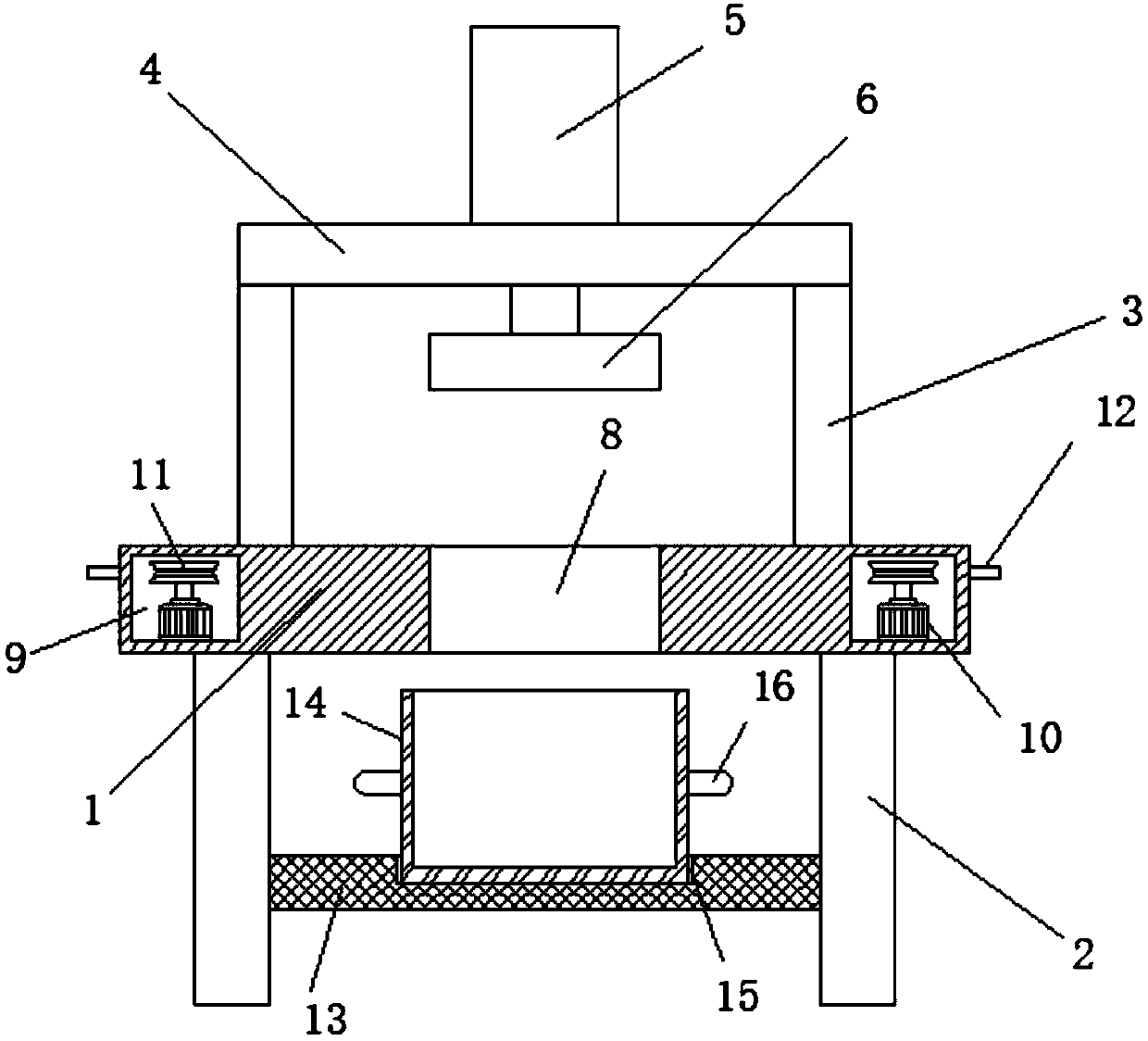

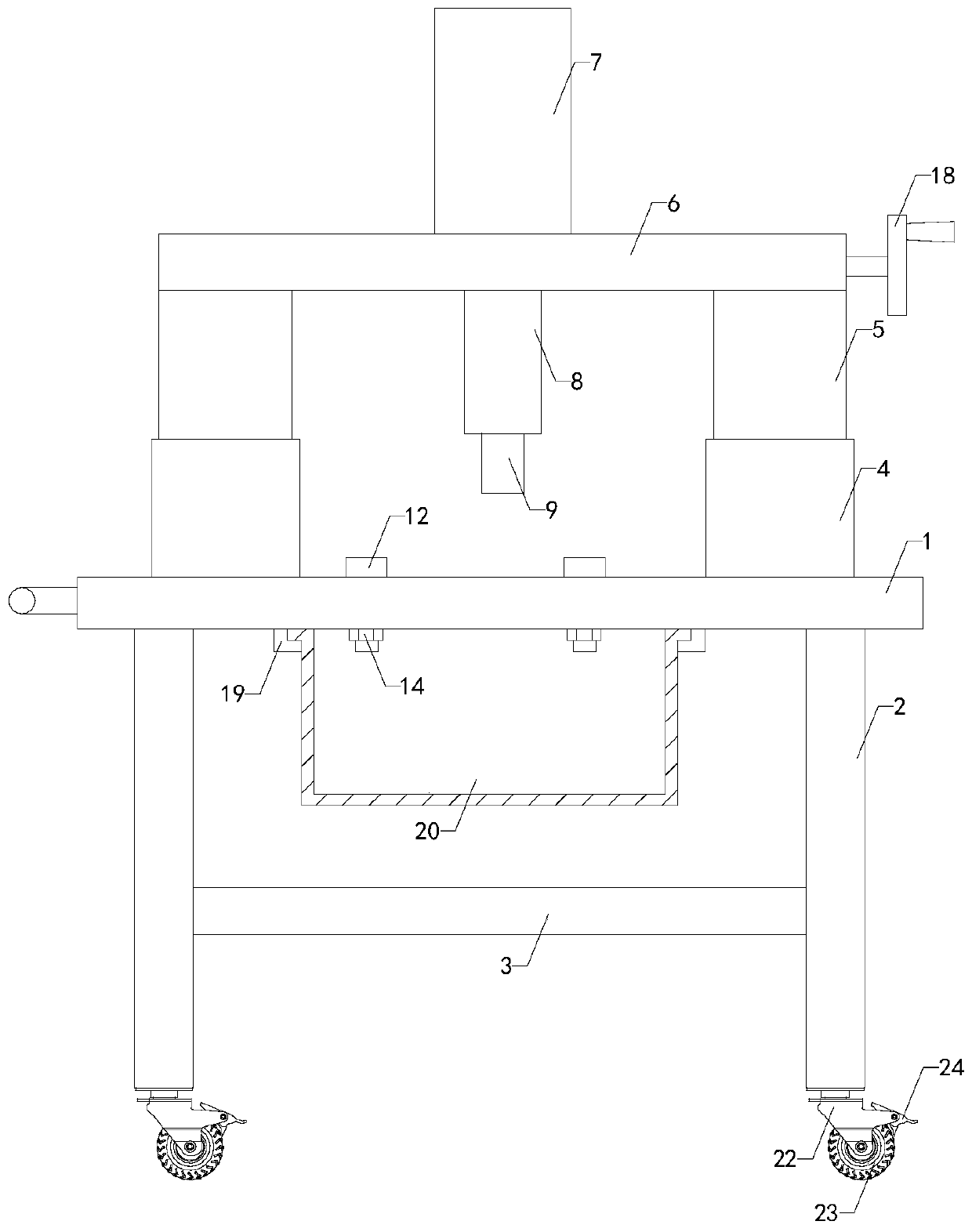

Rapid stamping forming equipment for metal stamping part

InactiveCN111375662AShorten the timeRapid stampingMetal-working feeding devicesPositioning devicesElectric machineryDrive motor

The invention discloses rapid stamping forming equipment for a metal stamping part. The rapid stamping forming equipment comprises a stamping base, wherein a plurality of supports are vertically fixedon the side wall of the lower end of the stamping base,two vertical rods are vertically fixed on the upper surface of the stamping base, a mounting plate is fixed between the upper ends of the two vertical rods, a stamping cylinder is vertically fixed on the side wall of the upper end of the mounting plate, a stamping die is fixed at the output end of the stamping cylinder, a strip-shaped grooveis formed in the upper surface of the stamping base, a stamping hole is vertically formed in the strip-shaped groove, and the stamping hole is arranged below the stamping die; and two sets of cavitiesare formed in the two ends of the stamping base separately, and driving motors are fixed in the cavities. Raw material plates are driven by transmission wheels to move in the strip-shaped groove, theair material plates are stamped by the stamping cylinder, thus the time of feeding and discharging can be saved, rapid stamping is realized, and the stamping speed is increased.

Owner:青岛益昕实业有限公司

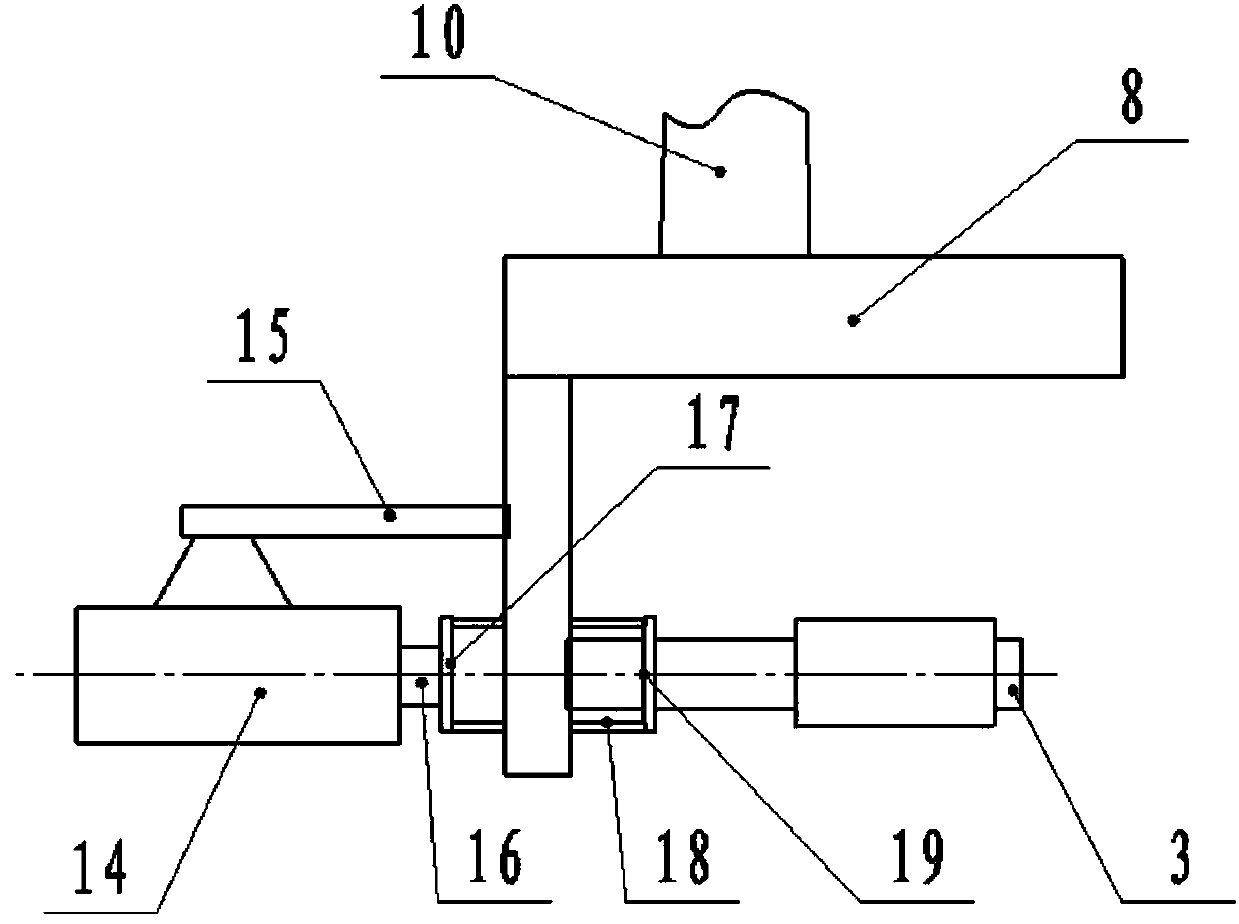

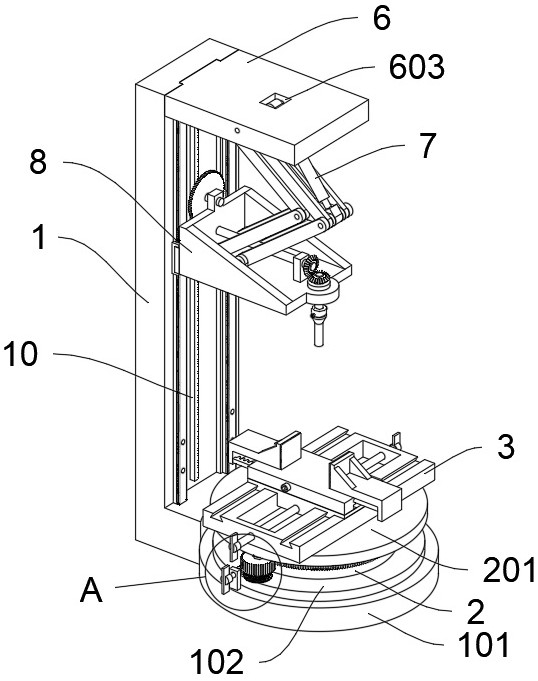

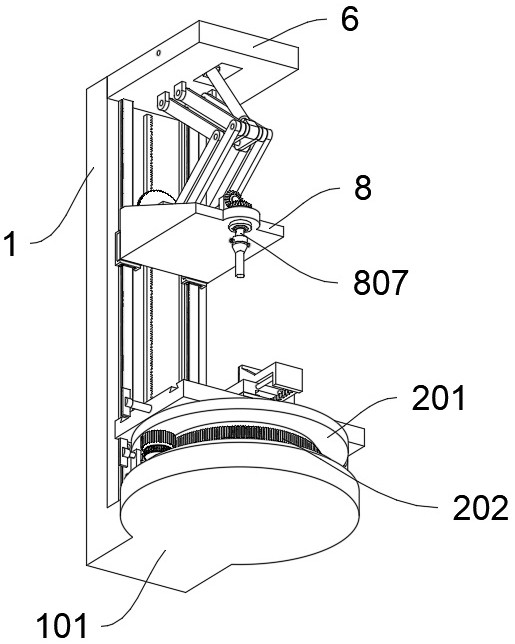

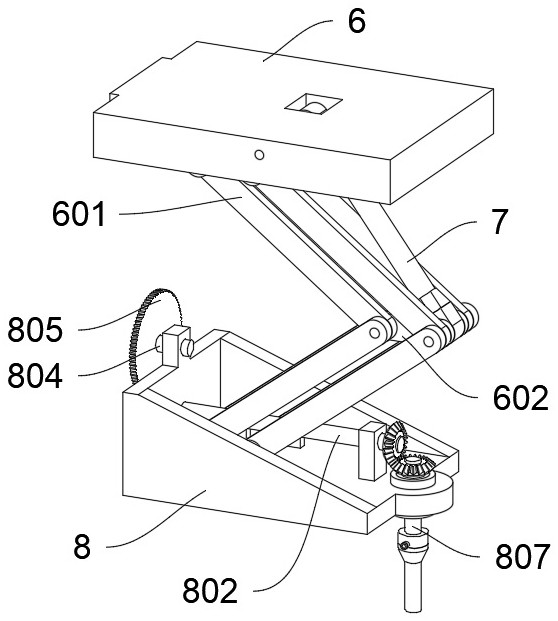

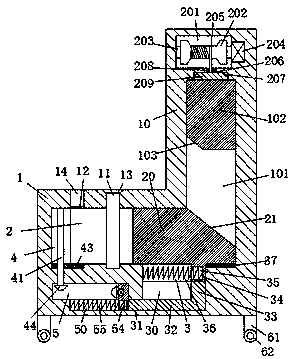

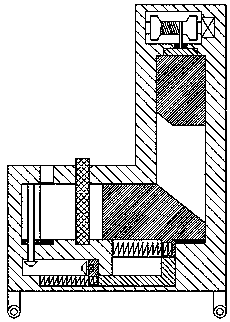

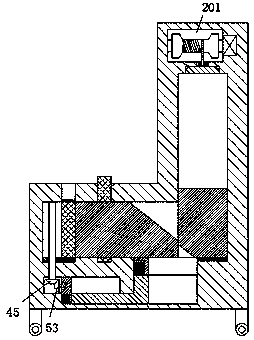

Three-dimensional automatic punching machine based on efficient precise numerical control

The invention discloses a three-dimensional automatic punching machine based on efficient precise numerical control, relates to the technical field of mechanical punching, and solves the problems that an existing punching machine is general in stability, low in stretching speed and not provided with a high-speed precise control mechanism, and the advancing mode of a punching assembly is fixed. The three-dimensional automatic punching machine based on efficient precise numerical control comprises: a main base, wherein a base is integrally arranged on the front side of the bottom of the main base, and an annular table is fixedly arranged at the top of the base; and a rotating table, wherein a main body of the rotating table is of a T-shaped structure, the bottom is rotationally arranged in the middle of the top of the base by matching with a bearing, and a pedestal is fixedly arranged at the top of the rotating table. A top base, a connecting rod A, a parallel connecting rod, an electric cylinder, a stamping base and a connecting rod B are arranged to form a parallel sliding block mechanism, a high-speed and more accurate control mechanism is provided, the connecting rod A and the connecting rod B can be unfolded by starting the electric cylinder to stretch, the stamping base vertically descends, a stamping pile and a stamping part move downwards for stamping, and rapid stamping is facilitated.

Owner:深圳市南旭精密五金制品有限公司

Stamping device for manufacturing electronic vacuum device

PendingCN114074142ARapid StampingQuick unloading operationShaping toolsMetal-working feeding devicesBall bearingStamping

The invention relates to the technical field of electronic vacuum device manufacturing, and discloses a stamping device for electronic vacuum device manufacturing, which comprises a base, a U-shaped fixing plate is fixedly arranged at the center of the upper end of the base, and a stand column is rotatably sleeved in the U-shaped fixing plate through a ball bearing; the upper end of the stand column penetrates through the upper end of the U-shaped fixing plate and is fixedly connected with a fixing block, the column wall of the lower end of the stand column is fixedly sleeved with a driven bevel gear, a rotating motor is fixedly arranged at the upper end of the base, an output shaft of the rotating motor is fixedly connected with a driving bevel gear meshed with the driven bevel gear, and grooves are formed in the two opposite sides of the fixing block. A rotating shaft is rotationally sleeved with the groove through the bearing, and one end of the rotating shaft extends out of the fixing block and is fixedly connected with stamping plates. The stamping device for manufacturing the electronic vacuum device has the advantages that rapid discharging operation can be achieved, relative continuous stamping operation can be achieved through the arrangement of the two stamping plates, and the stamping efficiency is greatly improved.

Owner:怀化华晨电子科技有限公司

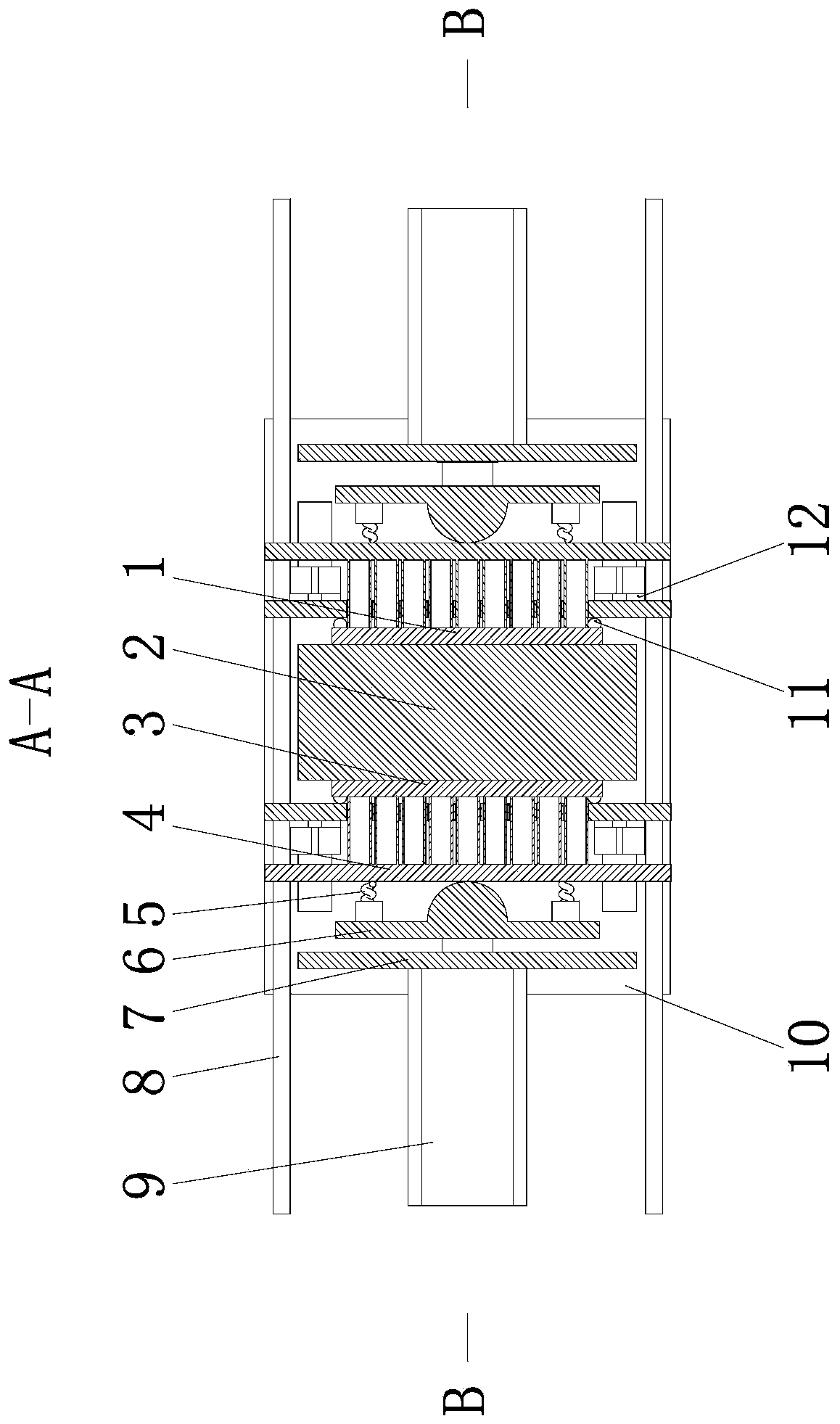

Rectangular pipe double-side multi-hole synchronous forming device

PendingCN110722055AGuarantee product qualityEven by forcePerforating toolsHydraulic cylinderPunching

The invention discloses a rectangular pipe double-side multi-hole synchronous forming device, and belongs to the technical field of machining equipment. The rectangular pipe double-side multi-hole synchronous forming device structurally comprises a mold core, material return plates, punching pin bases, springs, transition press plates, two-end fixing plates, guide rods, hydraulic cylinders, up-and-down fixing plates, locating pins and movable locating plates. The parts are symmetrical in the left-and-right mode. The same thrust is generated by the hydraulic cylinders under the action of a synchronizing valve and pushes the transition press plates on the left side and the right side to move forwards, the transition press plates combine the two parts of force transmitted by the hydraulic cylinders into one part of force by use of a semi-convex-circle and enable the force to act on the centers of the punching pin bases, the one-degree-of-freedom constraint is conducted on the force, and the springs at the periphery guarantee the force bearing uniformity. The punching pin bases move forwards under the guidance action of the guide rods, punching pins on the punching pin bases are stabilized and guided under the assistance action of punching pin holes of the material return plates, and the punching pins on the two sides synchronously punch a rectangular pipe together. The rapid efficient high-accuracy punching operation can be achieved through the low thrust, the large-batch production of parts is facilitated, and the product quality is also guaranteed.

Owner:YANGZHOU UNIV

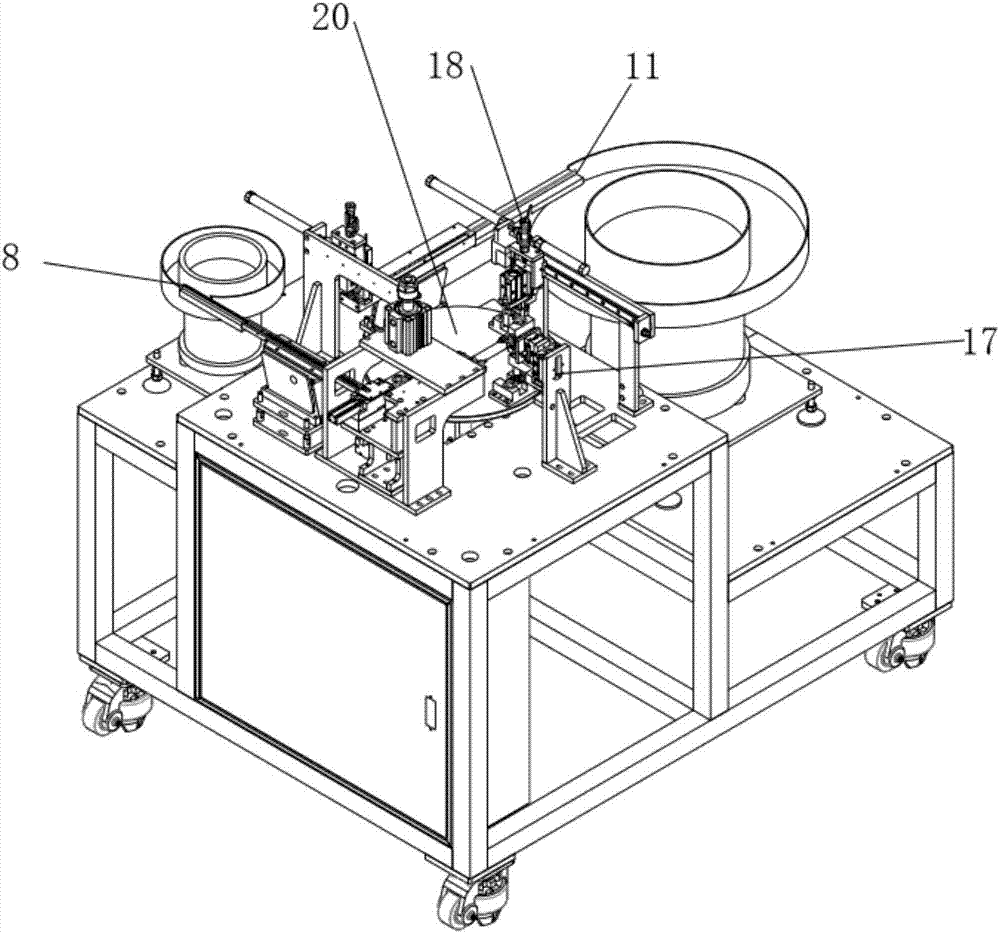

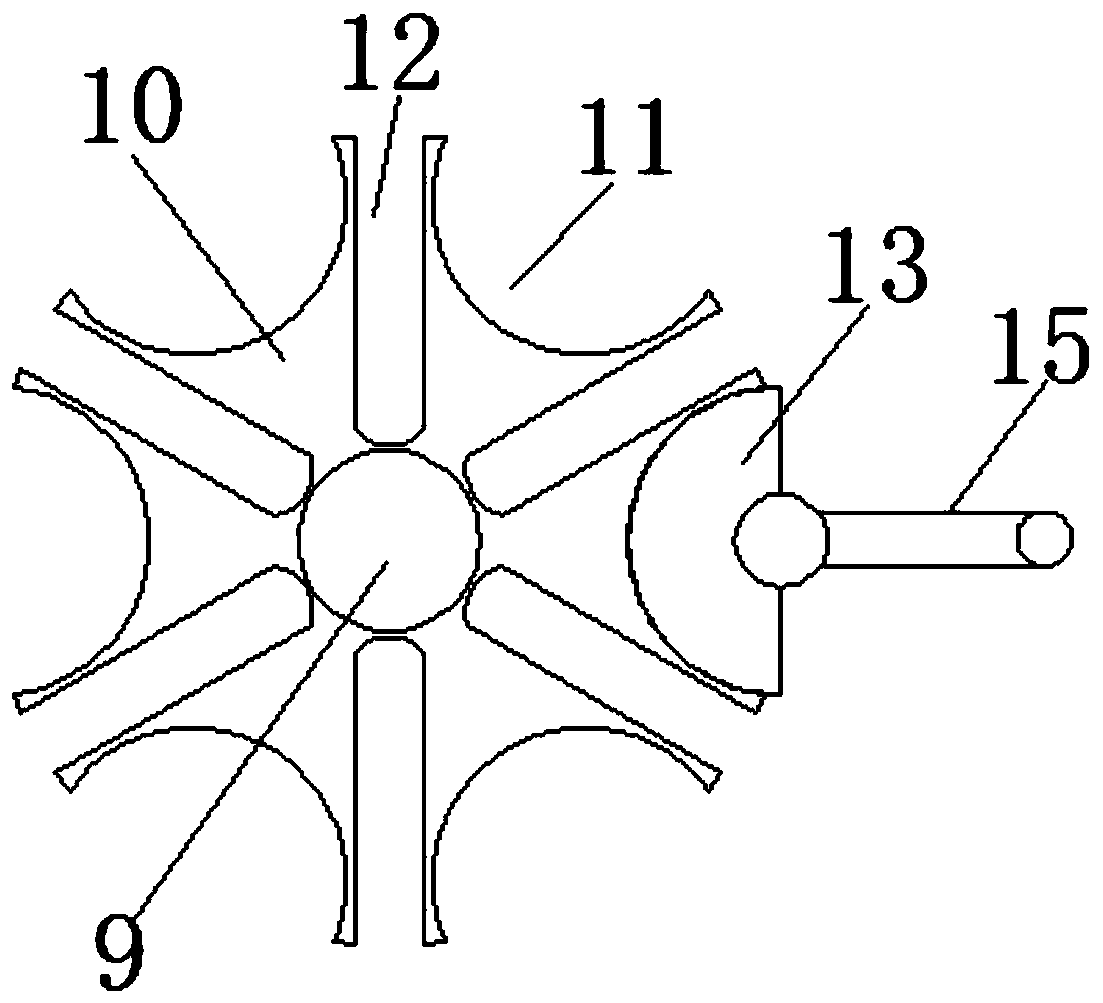

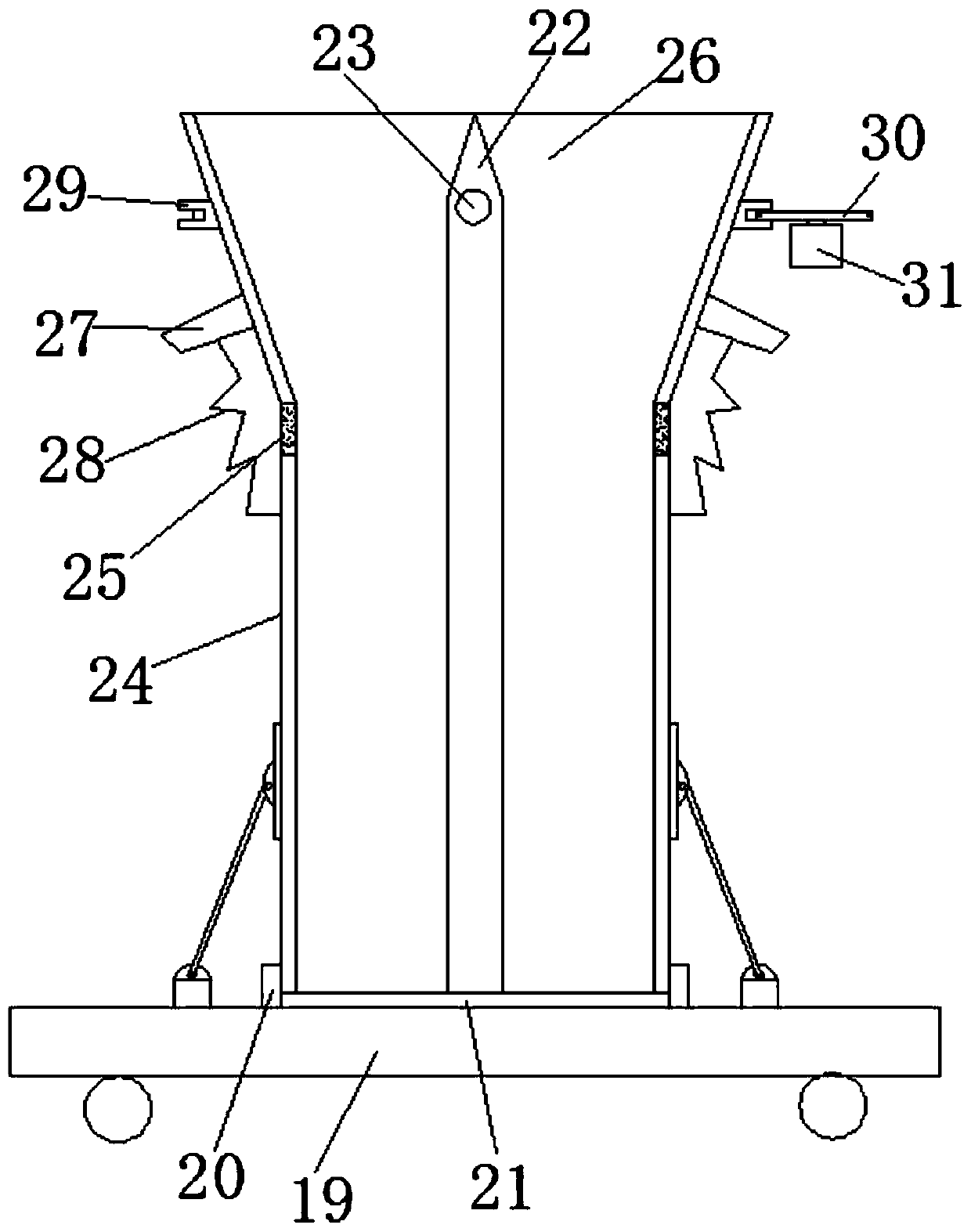

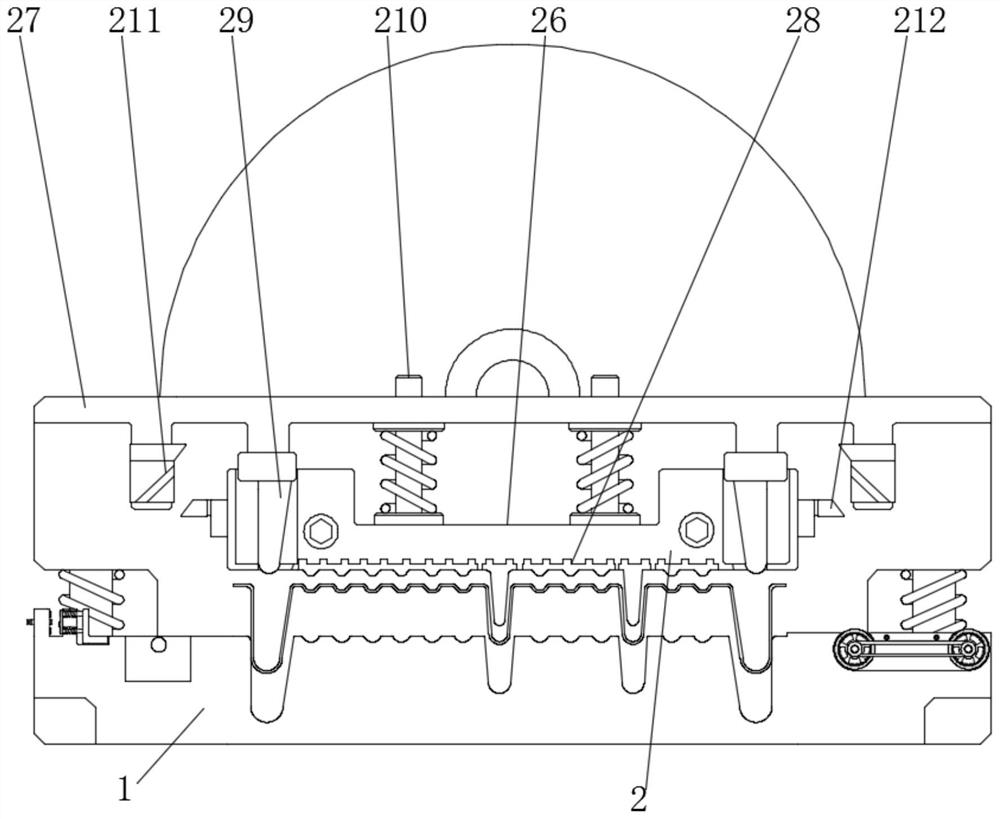

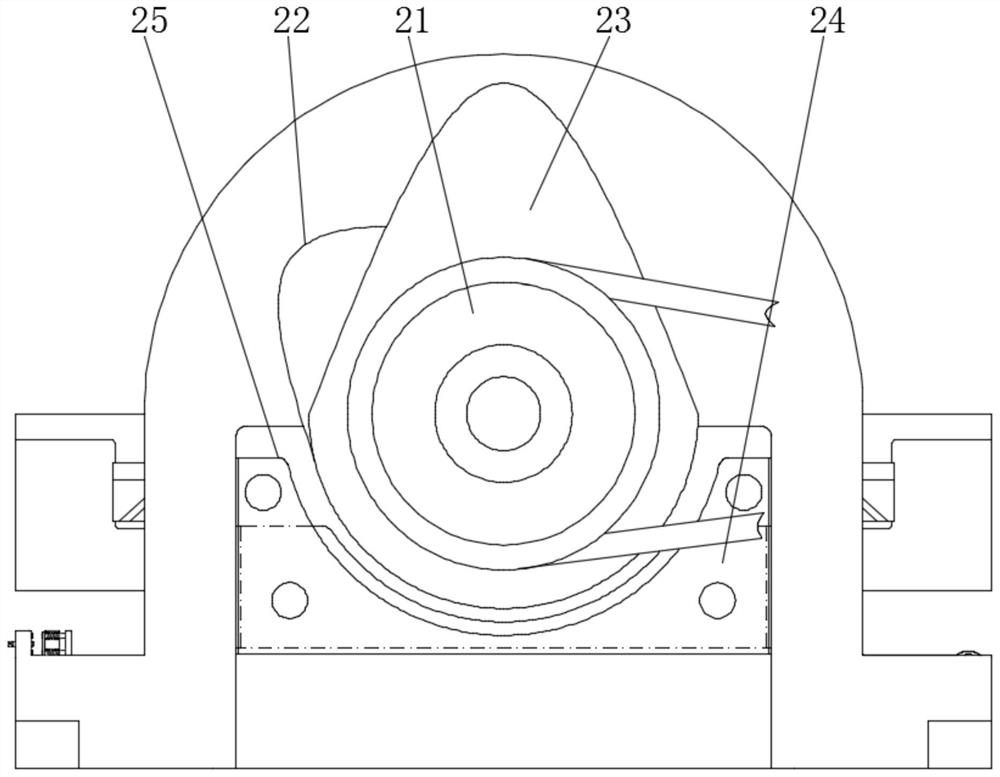

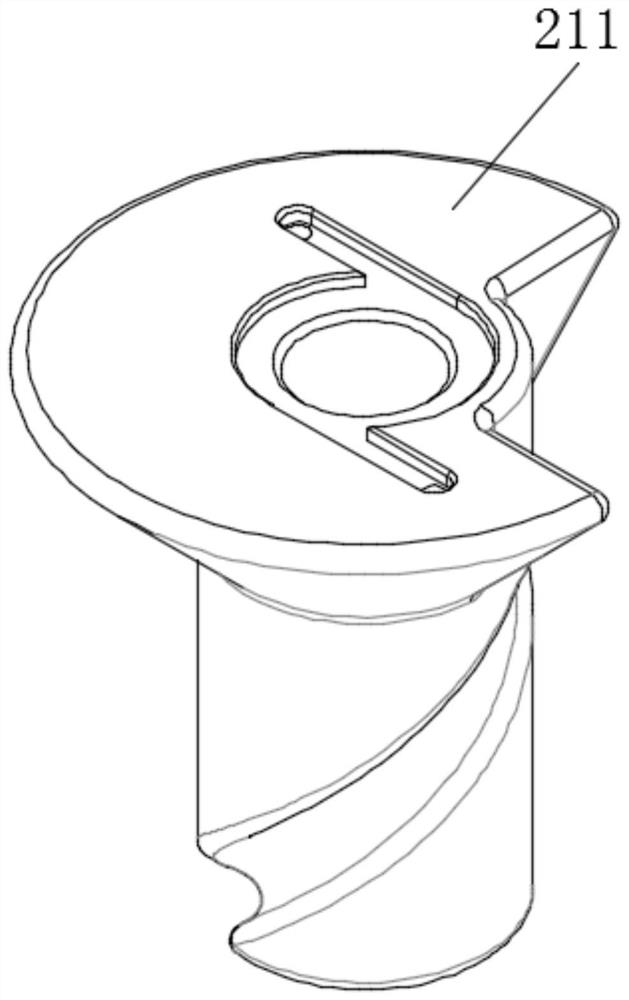

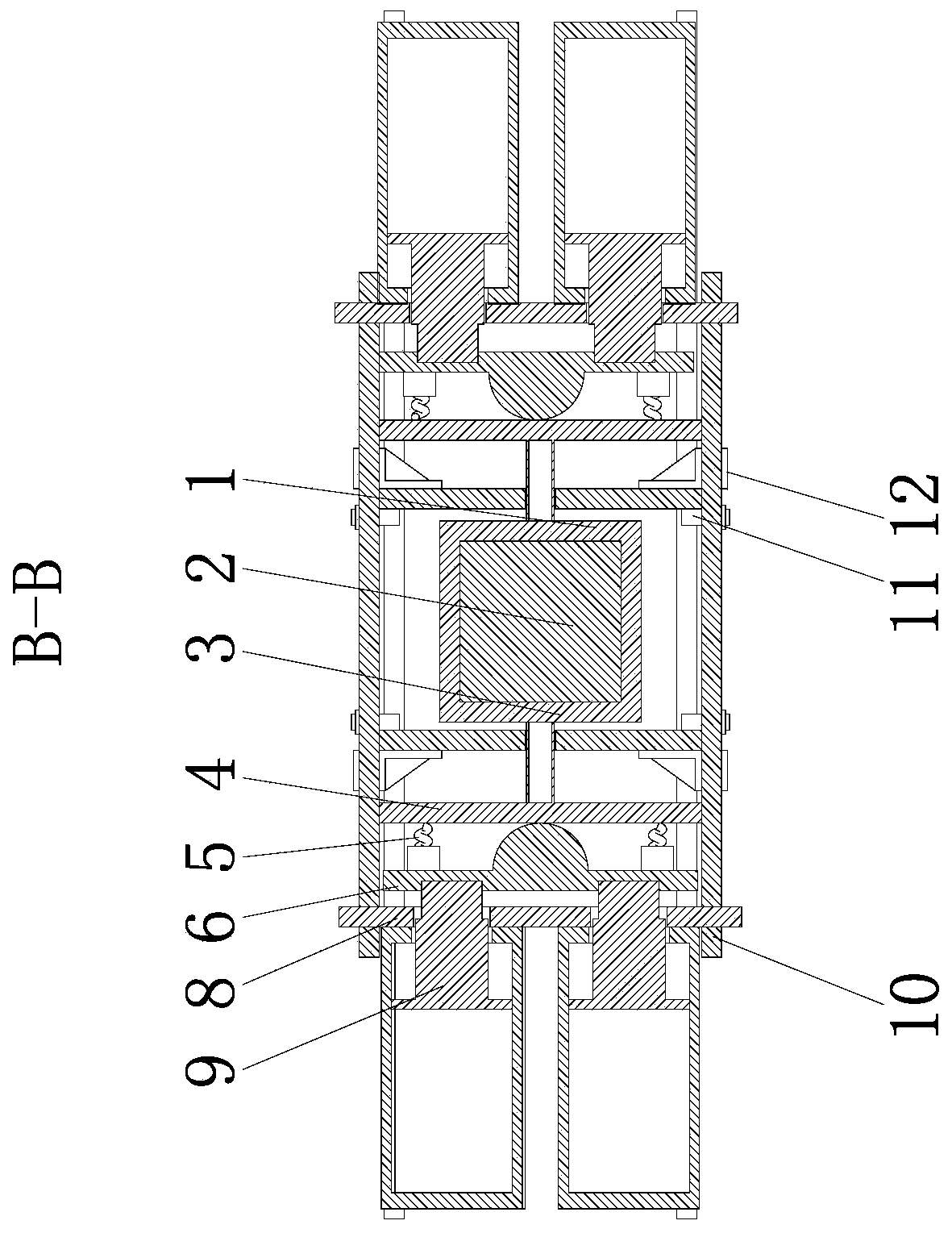

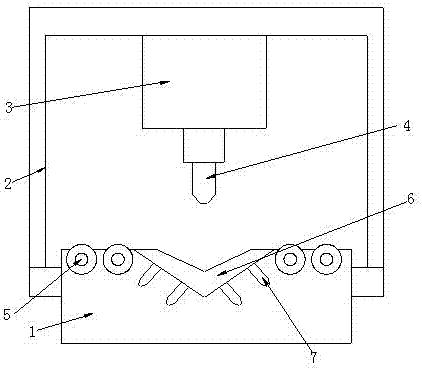

Pop-top can pull ring forming equipment

InactiveCN112191762ARapid stampingMetal-working feeding devicesPositioning devicesStructural engineeringIndustrial engineering

The invention relates to forming equipment, in particular to pop-top can pull ring forming equipment. According to the pop-top can pull ring forming equipment, an iron sheet does not need to be manually held by hand when being stamped, and the iron sheet can be rapidly stamped. The pop-top can pull ring forming equipment comprises a base used for installing the whole equipment, a supporting seat arranged in the middle of one side of the upper part of the base; a servo motor arranged at the upper part of the supporting seat; and a stamping mechanism arranged on one side of the upper part of thebase. According to the pop-top can pull ring forming equipment provided by the invention, the effects that the iron sheet does not need to be manually held by hand when being stamped, and the iron sheet can be rapidly stamped are achieved; and an iron sheet needing to be stamped is placed on fixing blocks on the two sides, and then the iron sheet is moved to the position below a lower pressing plate through the pushing mechanism so as to be stamped, so that the iron sheet does not need to be manually held by hand.

Owner:杨治宇

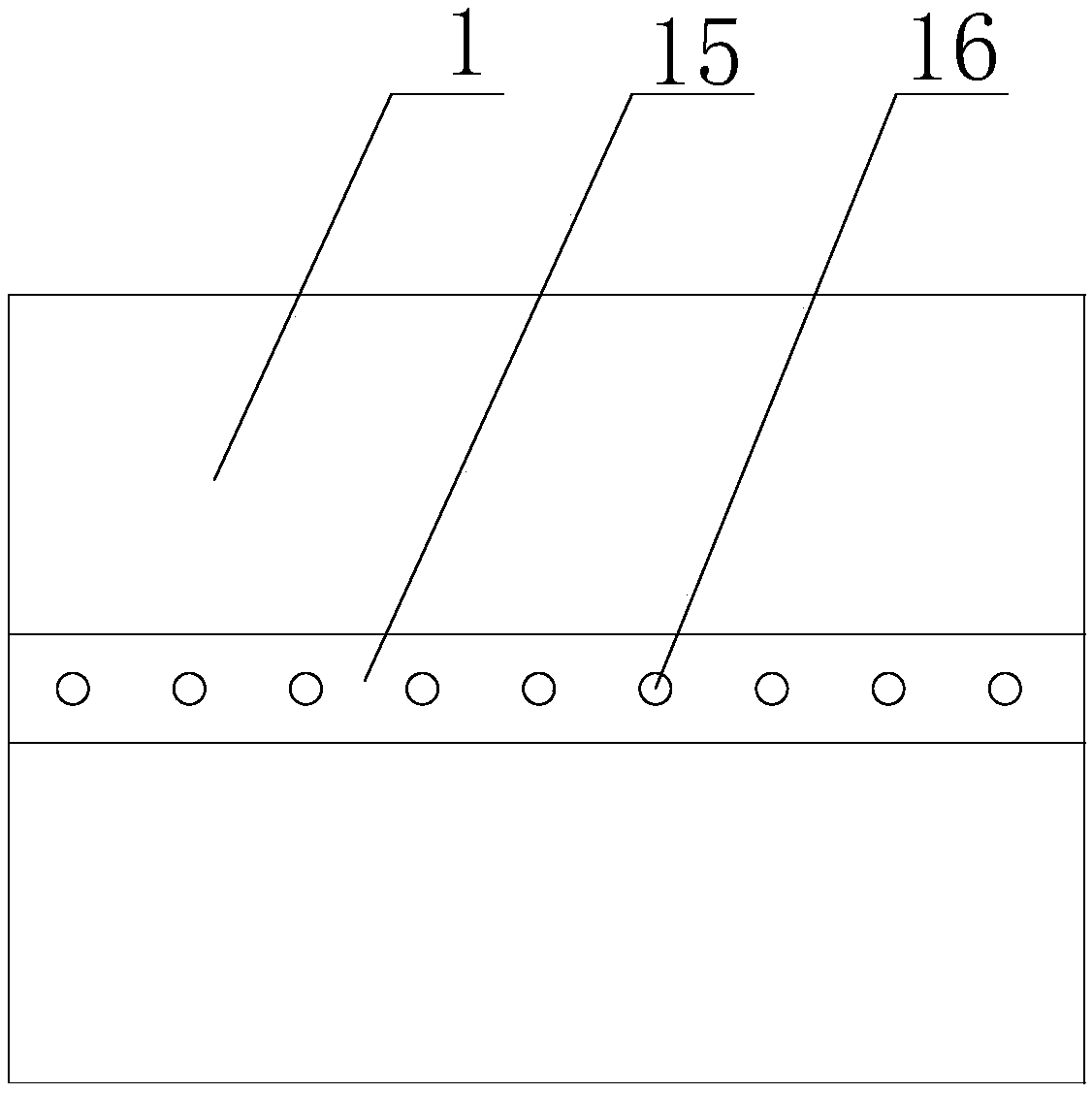

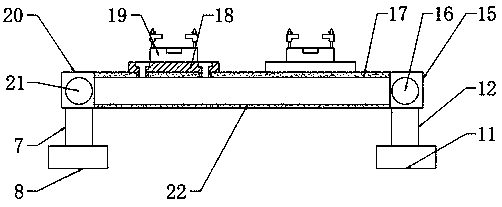

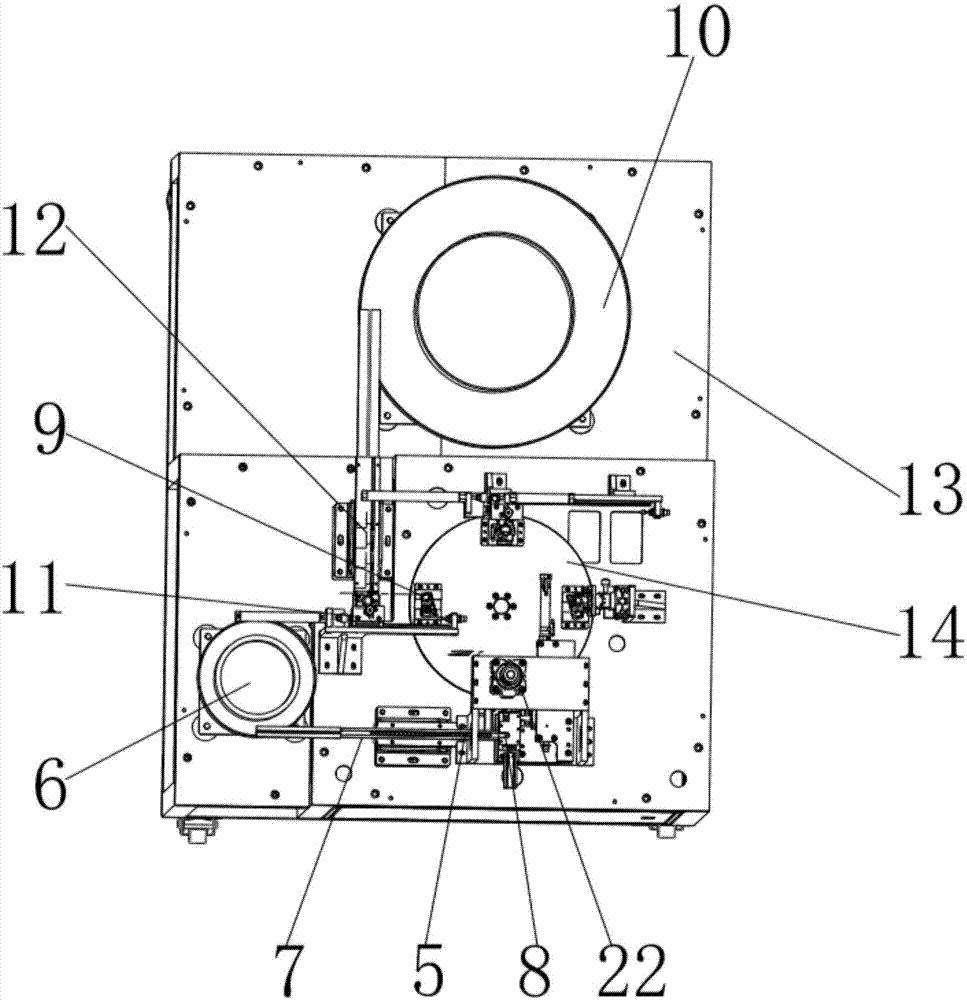

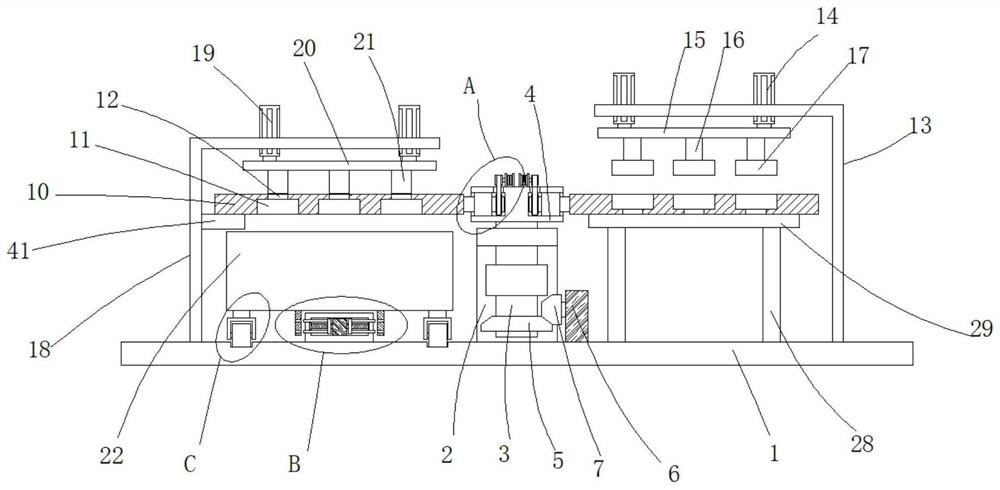

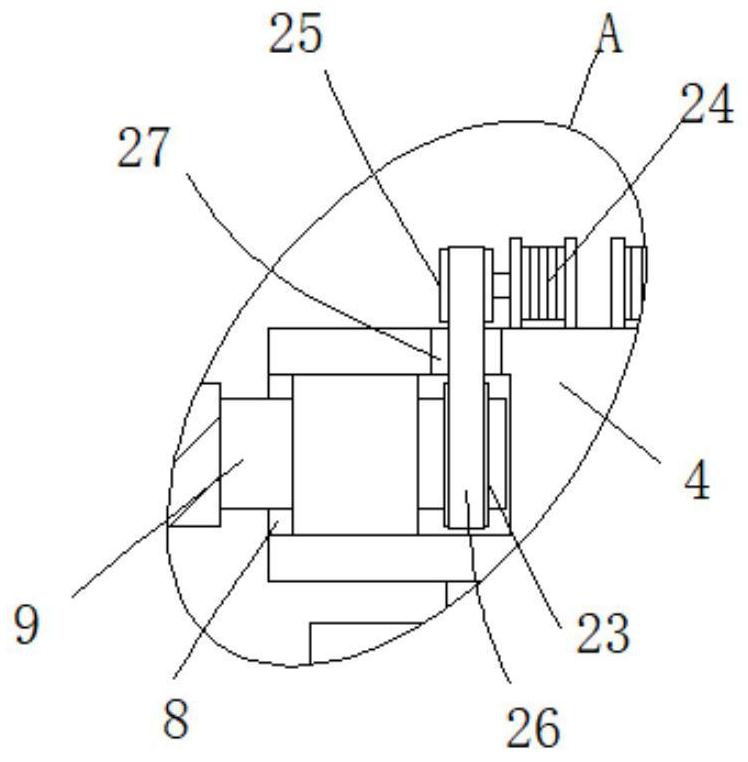

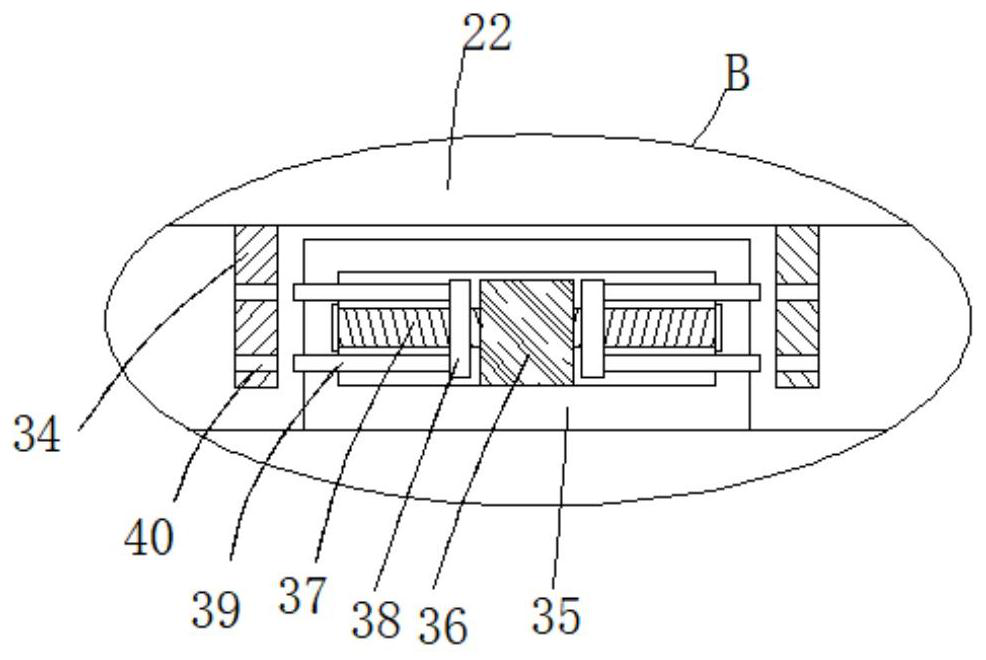

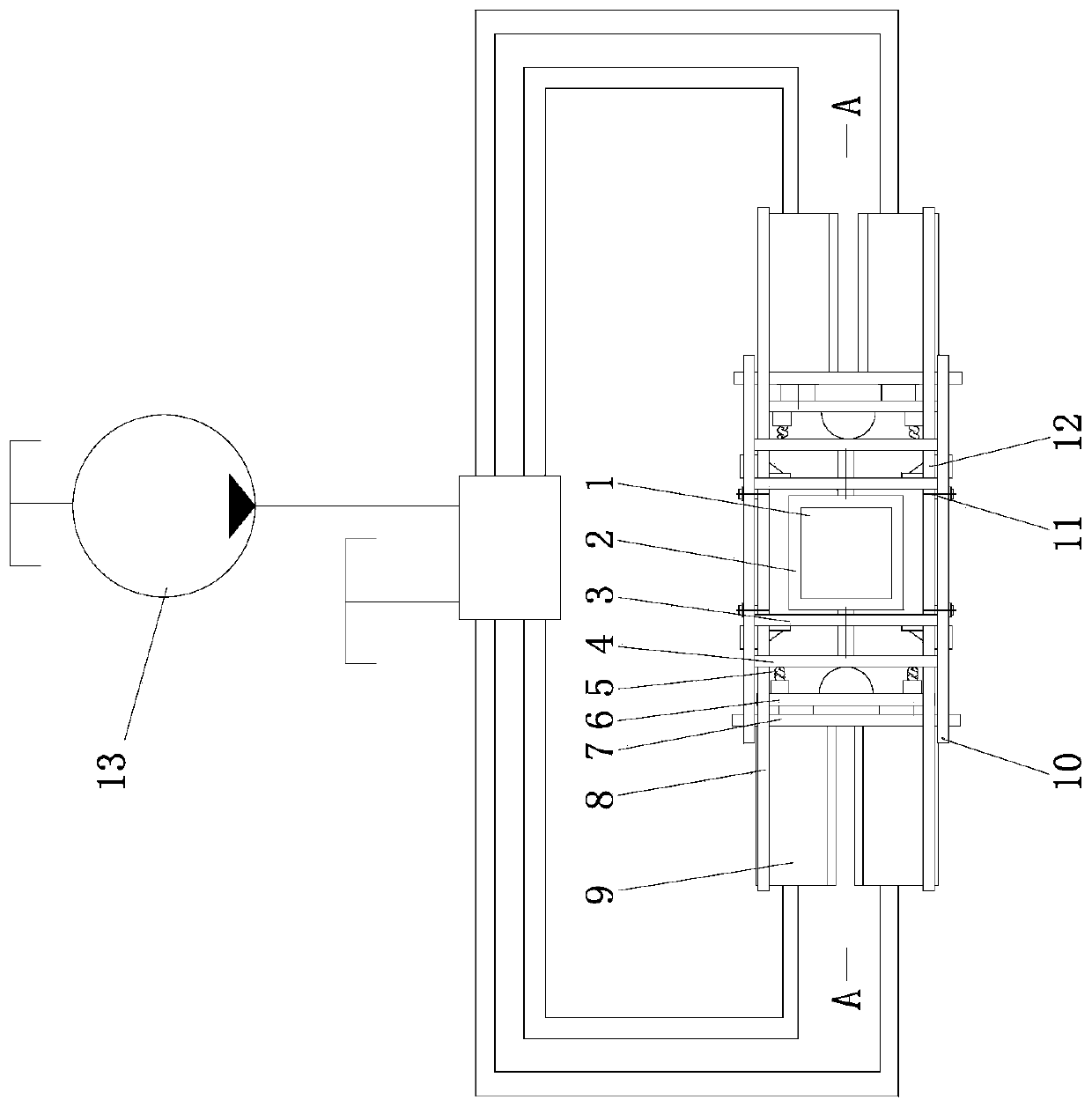

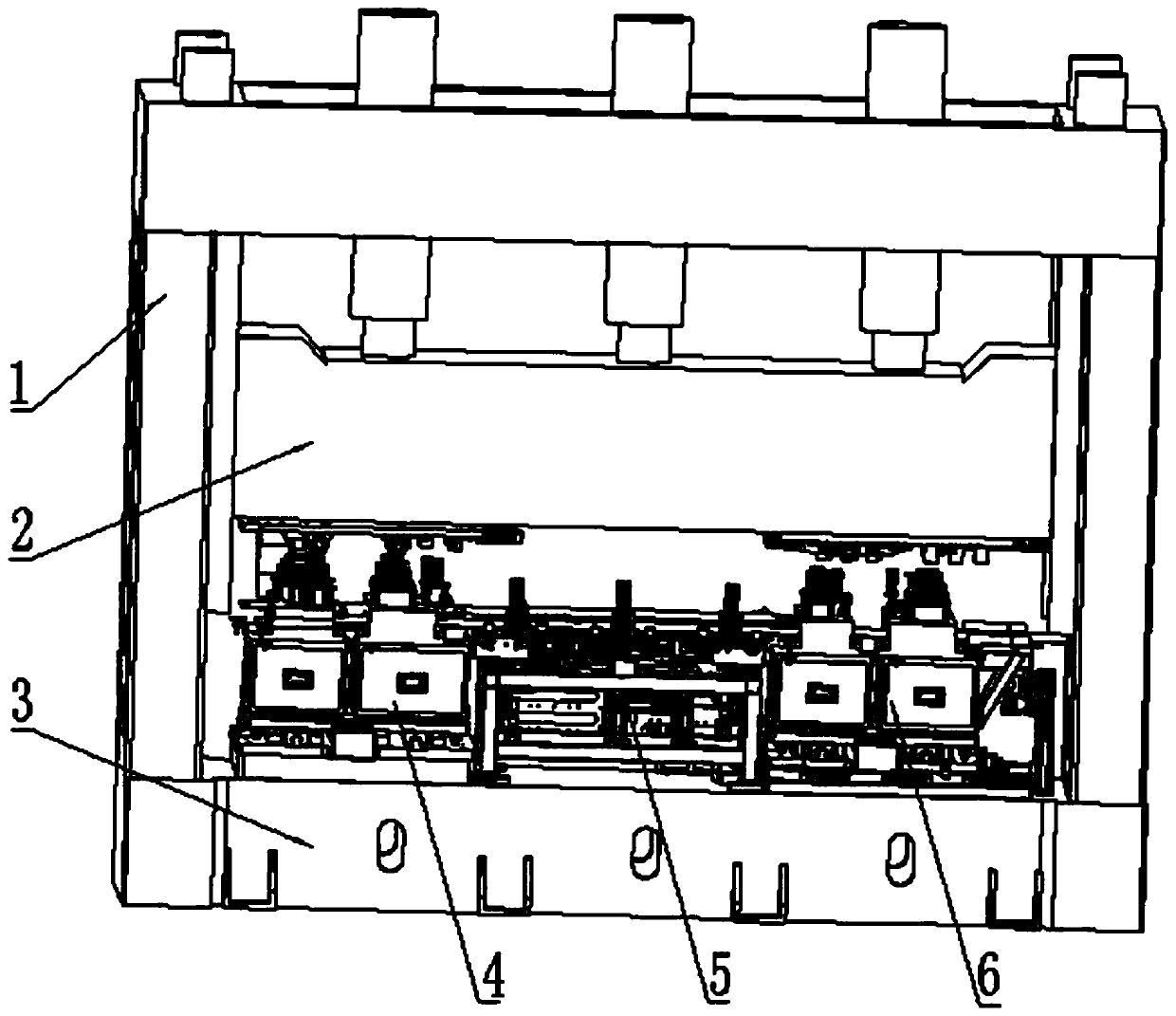

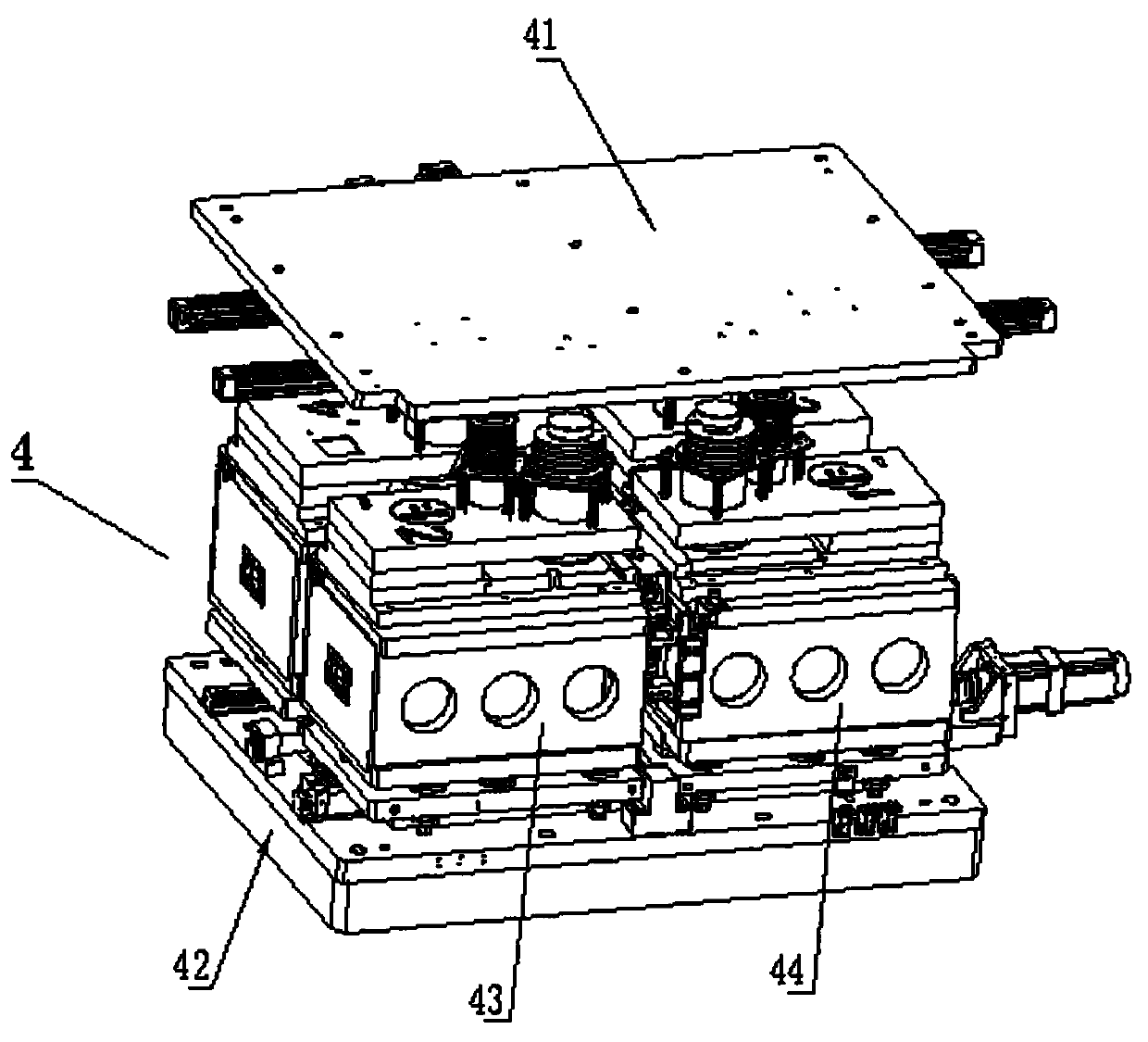

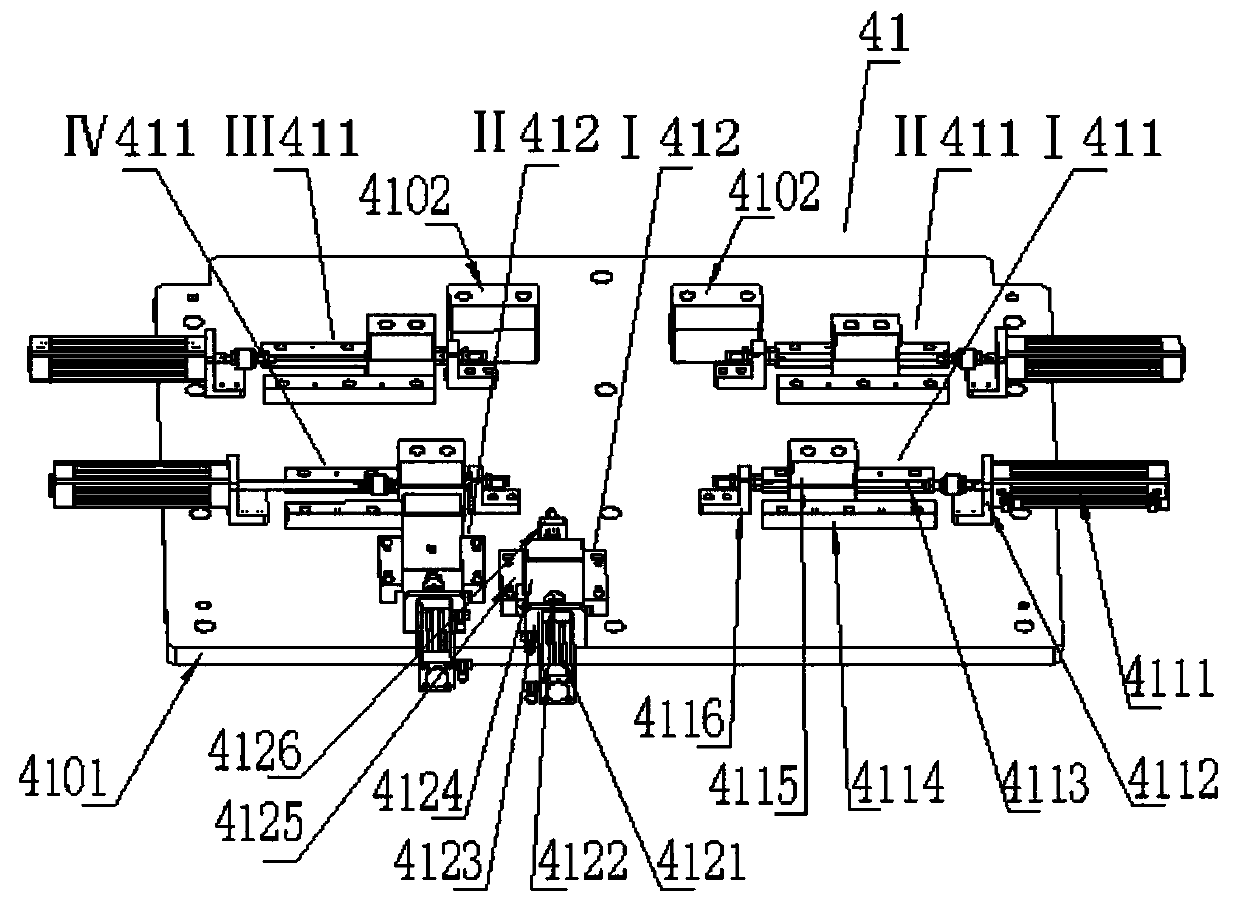

Efficient metal plate stamping equipment

ActiveCN111112449AIncrease productivityRapid stampingPerforating toolsMetal working apparatusEngineeringSheet metal stamping

The invention relates to efficient metal plate stamping equipment, which comprises a press bed. A press slide block is installed on the press bed, a front section stamping assembly, a conveying assembly and a rear section stamping assembly are arranged on the press table of the press bed, and the front section stamping assembly includes a front section pressure head assembly, a front section stamping die driving assembly and a front section stamping die assembly; the conveying assembly includes a conveying workbench assembly, a moving positioning assembly, a conveyor line and an auxiliary support; the rear section stamping assembly includes a rear section pressure head assembly, a rear section stamping die drive assembly and a rear section stamping die assembly component; the rear sectionpressure head assembly is connected with the end face, close to the press table of a press, of the press slide block; the rear section stamping die drive assembly is connected with the press table ofthe press and located under the rear section pressure head assembly; the rear section stamping die assembly component is located between the rear section pressure head assembly and the rear section stamping die drive assembly, and the conveying assembly is located between the front section stamping assembly and the rear section stamping assembly in the direction of the length of the press table.

Owner:SIASUN ROBOT & AUTOMATION LIMITED BY SHARE

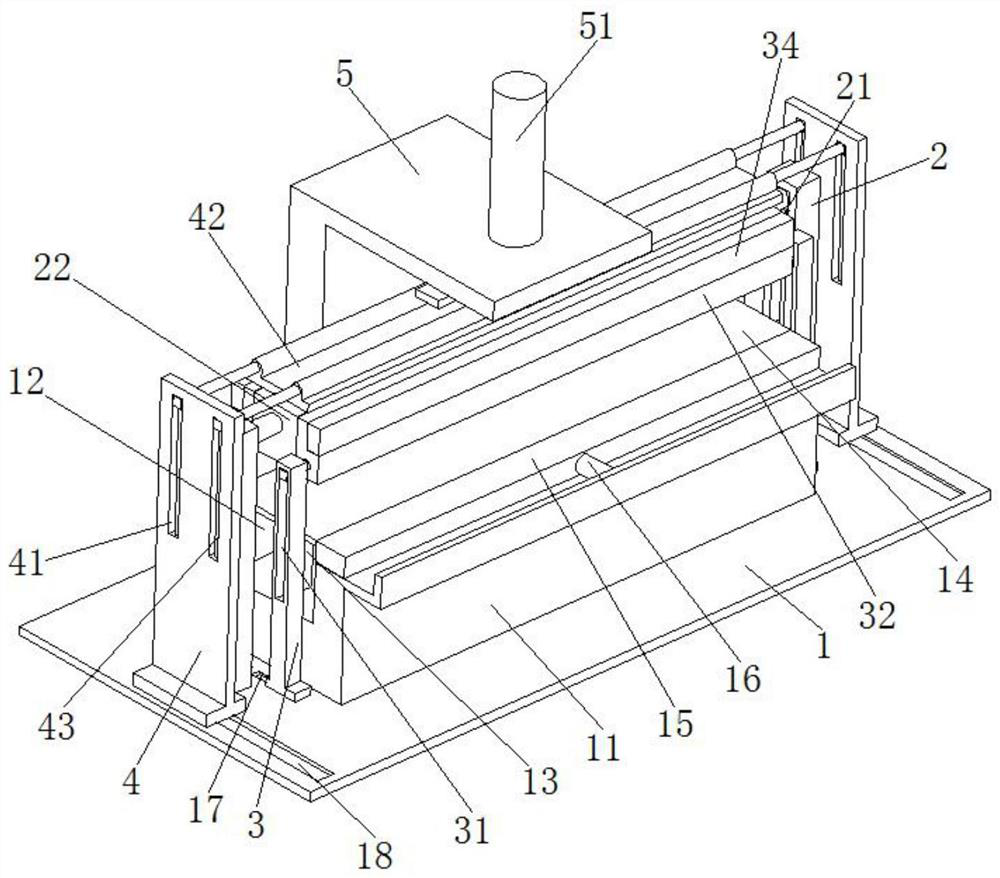

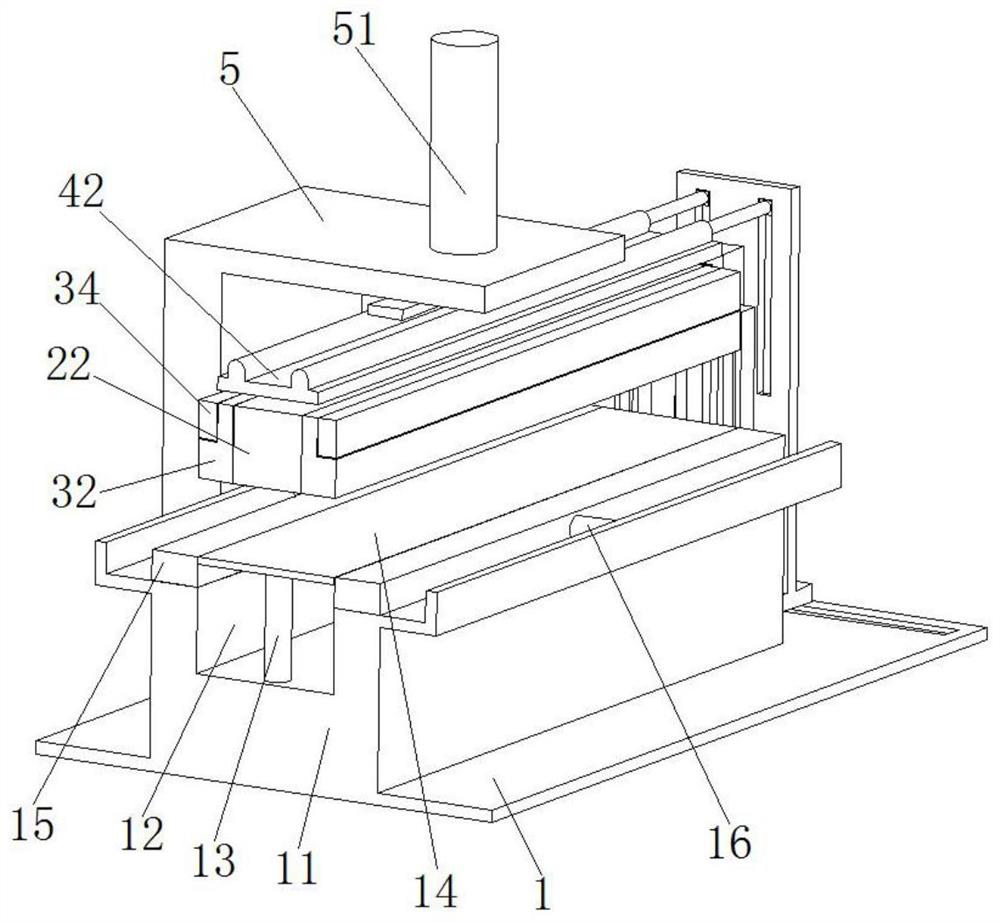

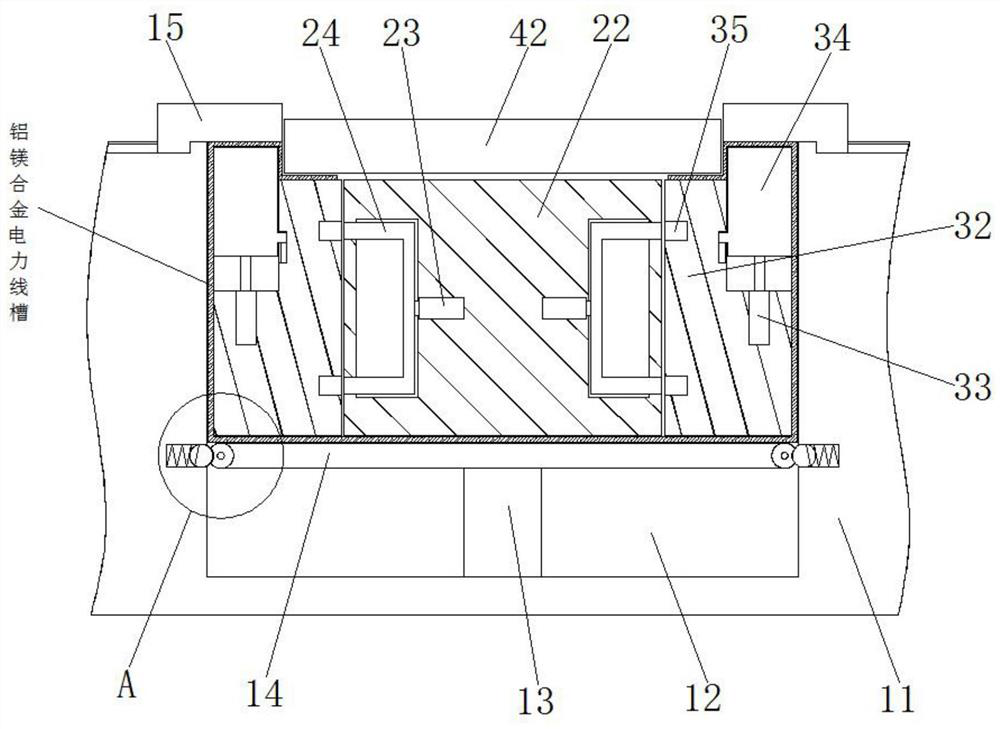

Aluminum magnesium alloy power line groove sheet metal machining equipment and machining method

ActiveCN113083977AFast and efficient compression moldingImprove processing efficiencyStripping-off devicesCompression moldingMetal machining

The invention relates to the field of electric power engineering, in particular to aluminum magnesium alloy power line groove sheet metal machining equipment and a machining method. The aluminum magnesium alloy power line groove sheet metal machining equipment comprises a base, a fixing table is arranged on the base, a die groove is formed in the top of the fixing table, a plurality of first spring rods are arranged in the die groove, and a supporting plate is arranged at the tops of the first spring rods. Pressing strips are arranged on the fixing table and located on the two sides of the die groove, the tops of the pressing strips are flush with the top of the supporting plate, first air cylinders are arranged on the two sides of the top of the fixing table correspondingly, and the output ends of the first air cylinders are fixedly installed on the correspondingly-arranged pressing strips correspondingly. First supports are symmetrically arranged on the base and located at the two ends of the fixing table, first sliding grooves are formed in the first supports, a first pressing block of a rectangular structure is arranged between the first supports, and the two ends of the first pressing block are connected into the first sliding grooves correspondingly in a sliding mode. According to the aluminum magnesium alloy power line groove sheet metal machining equipment and the machining method, compression molding of aluminum magnesium alloy power line grooves can be rapidly and efficiently achieved, and the aluminum magnesium alloy power line groove sheet metal machining equipment and the machining method are suitable for popularization.

Owner:广东海彬线槽有限公司

A kind of processing method of wheel spoke

Owner:CHONGQING FENGHUIDA METAL FORGING CO LTD

Method for machining spoke

The invention belongs to the technical field of machining, and particularly discloses a method for machining a spoke. The method comprises the following machining steps that (1) an upper punching dieis fixedly connected with an upper support, and an electromagnet is electrified; (2) a steel plate is placed on a lower punching die, electricity of the electromagnet is cut off, and the upper punching die is punched downwards by utilizing a press machine till a pre-formed spoke blank is punched; (3) a center hole and a mounting hole are punched while the steel plate is punched; (4) the upper punching die is dismantled from the upper support, a motor and an electric cutting saw are electrified, and waste materials on the periphery of the pre-formed spoke blank are cut away; (5) electricity ofthe motor and the electric cutting saw is cut off, the upper punching die is fixedly connected with the upper support, the electromagnet is electrified, and the spoke blank is taken out; and (6) finish machining is conducted on the spoke blank to manufacture the spoke. Compared with the prior art, the machining method mainly uses a machining device to machine the spoke, the machining process is simple in operation and convenient, and the machining efficiency and the precision of the spoke blank are greatly improved.

Owner:CHONGQING FENGHUIDA METAL FORGING CO LTD

Manufacturing method for automobile lamp light source

InactiveCN106764779AEasy to installImprove light effectLighting heating/cooling arrangementsOptical signallingEngineeringLight source

A manufacturing method for an automobile lamp light source comprises the heat dissipation base manufacturing step, the LED lamp panel manufacturing step and the LED lamp panel and heat dissipation base matching step. The LED lamp panel manufacturing step comprises the processes that a, an LED substrate is manufactured and composed of three substrate units, and each substrate unit is provided with an independent circuit layer and an independent LED chip; b, grooves are cut out along the edges of the substrate units; and c, a bending device is utilized for bending an LED lamp panel. In the LED lamp panel and heat dissipation base matching step, the bent LED lamp panel is attached to the installing face of a heat dissipation base, and each substrate unit is attached to a corresponding installing plane. The bent LED lamp panel is installed more conveniently and rapidly, and the light emitting effect of the bent LED lamp panel is higher.

Owner:GUANGDONG RAYTON INTELLIGENT OPTO CO LTD

High-automation board, belt and foil production technical equipment

The invention discloses high-automation board, belt and foil production technical equipment. The technical equipment comprises a first main machine and a second main machine located on the right sideof the top of the first main machine. The equipment is characterized in that supporting legs are fixedly arranged on the periphery of the bottom surface of the first main machine, travelling rolling wheels are correspondingly arranged at the bottoms of the supporting legs, a first execution cavity is arranged in the first main machine in a left-right extending mode, a second execution cavity communicating with the right side of the first execution cavity is vertically extended in the second main machine, a pushing and transporting block is arranged in the second executing cavity in a sliding mode, a first inclined surface is arranged on the left side of the bottom end surface of the pushing and transporting block, and a pushing and transporting block management and control device is arranged above the second execution cavity in the second main machine. According to the high-automation board, belt and foil production technical equipment, the structure is simple, the production cost is low, and the stamping operation of a workpiece is simple and rapid, so that the requirements of actual production are effectively met, the high-automation production of a board, a belt and a foil are realized, and the board, the belt and the foil are high in precision and high in quality.

Owner:广州市迪越网络科技有限公司

Anti-dazzling screen stamping device with die capable of being replaced

The invention discloses a shading sheet stamper capable of replacing moulds, which relates to the technical field of shading sheet production equipment; A stamping block is installed on the upper surface of the base, a conveying roller mechanism is arranged on the upper surface of the base, an installation groove is arranged in the middle of the base, an insertion hole is arranged on the groove wall of the installation groove, and an insertion column is arranged on the outer wall of the mold , the plugging column is plugged in the socket hole, the conveying roller mechanism includes several conveying roller bodies and a conveying motor, and the rotating shafts of several conveying roller bodies are connected with the pulley of the conveying motor after being connected by a belt; the present invention facilitates Replacement of molds and rapid stamping are easy to operate, and can realize rapid delivery of raw materials, making it easy to use.

Owner:苏州罗格特光电科技有限公司

Hardware punching device

InactiveCN110899466ASmall amount of deformationRapid stampingMetal-working feeding devicesPositioning devicesHydraulic cylinderPunching

The invention relates to the machining equipment technology field and especially relates to a hardware punching device. The device is used for fixing hardware firstly and then carrying out stamping secondary machining on the hardware through a stamping device. Compared with a traditional handheld stamping tool, the hardware punching device is more convenient to use, a stamping process is fast, a hardware deformation amount is small, and practicability is improved. The punching device comprises a workbench, a hydraulic cylinder piston, an air cylinder, an air cylinder piston, a punched hole, asliding pressing plate, a countersunk bolt and a nut. Supporting legs are arranged at four corners of a bottom end of the workbench. Top ends of the supporting legs are connected with a bottom end ofthe workbench. The bottom end of the countersunk bolt penetrates through a through hole in a bottom end of a sliding pressing plate to extend to the bottom end of the workbench so as to be connected with the nut in a matched mode, the sliding pressing plate can slide to the left and to the right in a sliding groove, the sliding pressing plate and the sliding groove can be fixed by rotating the countersunk bolt, the sliding pressing plate cannot slide on the sliding groove, and hardware can be placed at the top end of the workbench and is fixed through the sliding pressing plate.

Owner:盐城瑞嘉汽车服务有限公司

Cylindrical Cup Lid Fast Hot Pressing Equipment

InactiveCN105033091BHeating fastMeet the actual mass production requirementsHollow articlesEngineeringSoft materials

The invention discloses a rapid hot-pressing equipment for a cylindrical cup lid, which comprises a vertical fixed table with a positioning suction cup, a liftable self-positioning slide block, a cylindrical rapid heating pressure device, a controllable handle and a pedal control switch. Among them, the vertical fixed table with positioning suction cup includes positioning suction cup, horizontal fixed platform, and cylindrical vertical polished rod. The middle part of the rapid heating pressure device is connected with the inner wedge-shaped square slider, and moves up and down with the rotation and adjustment of the controllable handle. The cylindrical rapid heating pressure device consists of a hollow vertical cylinder, a thermocouple, a pneumatic pressure mechanism and a hot press The head is composed of a foot control switch to directly control the work of the pneumatic pressurization mechanism. This equipment is suitable for rapid hot-press forming of soft materials and steel materials for cups and lids. It has good stability, high production efficiency, and is safe and reliable.

Owner:HEFEI YIJIAHUAN HOUSEWARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com