Punch die for commutator segment

A commutator segment and punching die technology, applied in the field of stamping dies, can solve the problems of low production efficiency, easy bending and deformation of the commutator segment, and inability to effectively guarantee the forming quality of the commutator segment, so as to improve production efficiency and be less prone to bending. The effect of deformation and molding quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

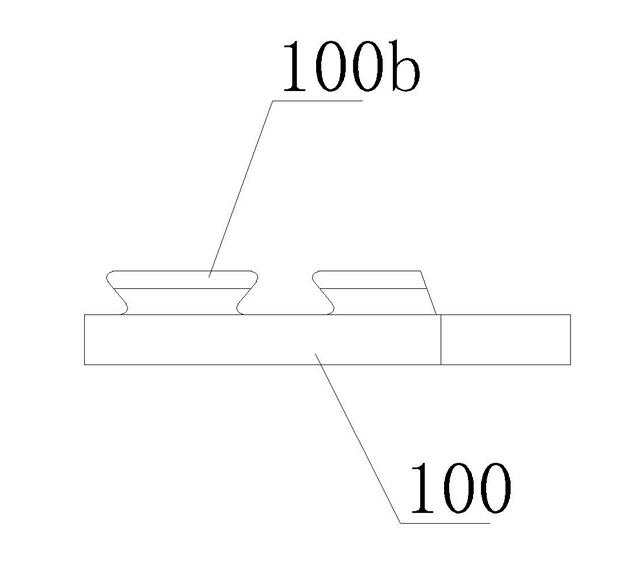

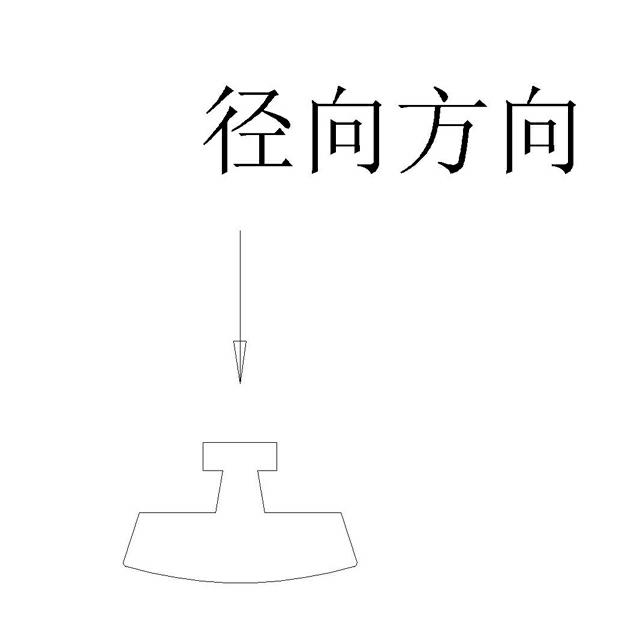

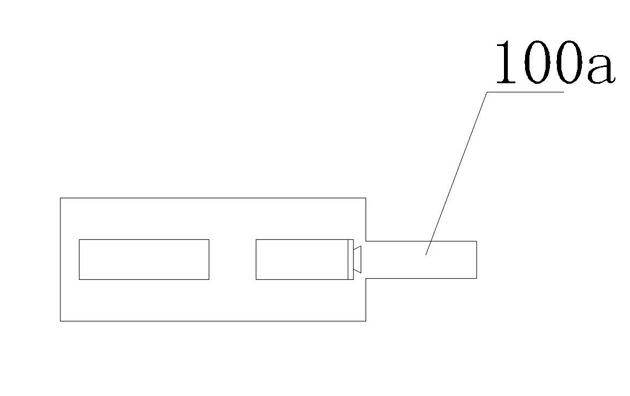

[0019] attached figure 1 , 2 , 3 shows the outline drawing of the stamped commutator piece product, and the vertical cross-sectional shape of the commutator piece 100 is as follows figure 2 As shown, the cross-sectional shape of the drawn wire of the commutator segment is the same as that of the head 100a of the commutator segment and the dovetail foot 100b of the commutator segment.

[0020] as attached Figure 4 , 5 , shown in 6 and 7, the commutator plate punching die of the present invention comprises punch head and punching mouth, and the bottom die 2 of punching die has a feed channel 1 that is arranged laterally, and the facade shape of feed channel 1 is in line with the wire changing plate pull The cross-sectional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com