Cylinder cover automatic detecting and spraying production line

An automatic detection and cylinder head technology, which is applied in spray booths, spraying devices, etc., can solve problems such as the inability to realize cylinder head air tightness detection and anti-rust oil spraying, low detection and spraying efficiency, and impact on personal health. And the improvement of spraying efficiency, avoiding environmental pollution and harm to human health, and the effect of improving spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

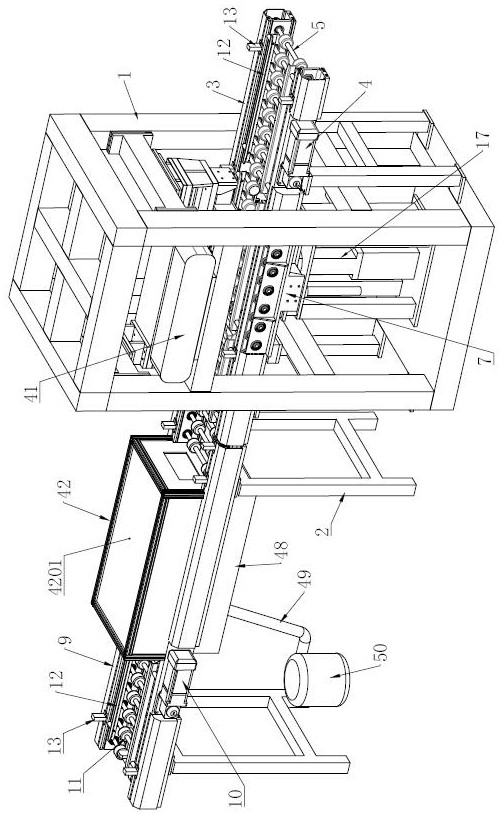

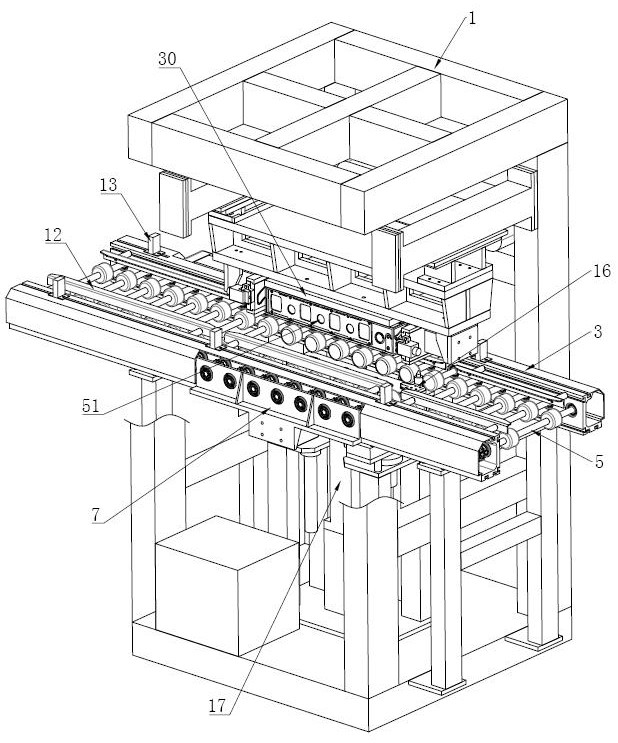

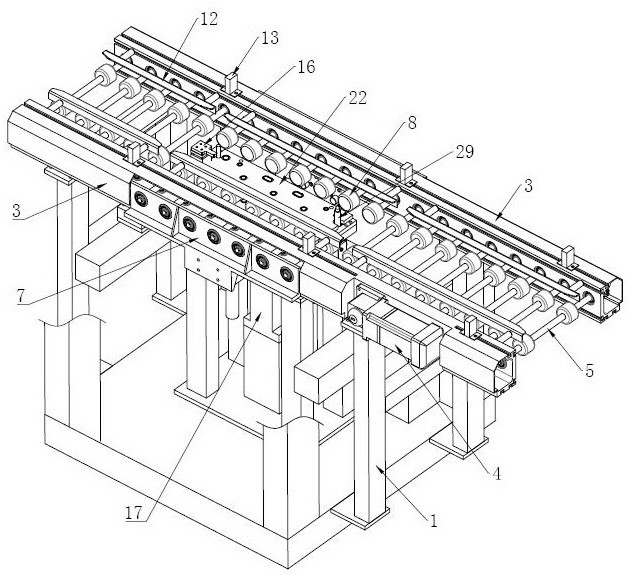

[0055] Such as figure 1 , figure 2 with Figure 9 Commonly shown, the present embodiment provides a cylinder head automatic inspection and spraying production line, including a detection frame 1 and a spraying frame 2, and the detection frame 1 and the spraying frame 2 are respectively provided with a first roller conveyor line and a second roller conveyor line. Two roller conveyor lines, one end of the first roller conveyor line and the second roller conveyor line are connected, and both the first roller conveyor line and the second roller conveyor line are equipped with cylinder head width matchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com