Soft and hard screen dual-purpose laminating machine and laminating process thereof

A gluing machine, soft and hard technology, applied in the direction of conveyor objects, lighting and heating equipment, furnace components, etc., can solve the problems of automatic feeding, single patch method, poor versatility, etc., and achieve auxiliary removal and easy tear-off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with accompanying drawing:

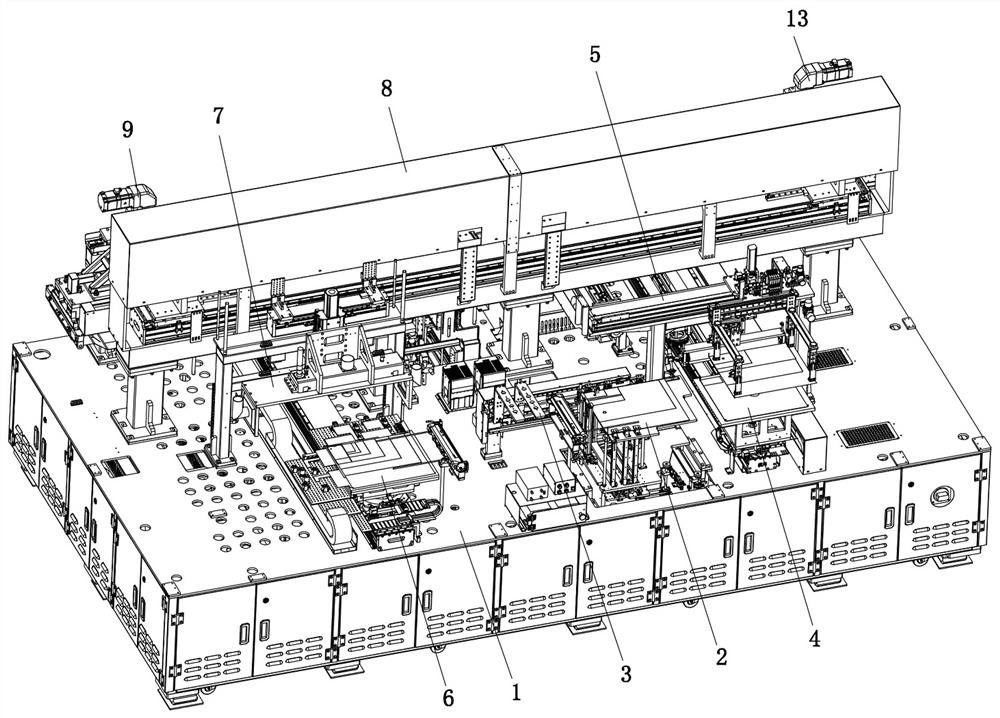

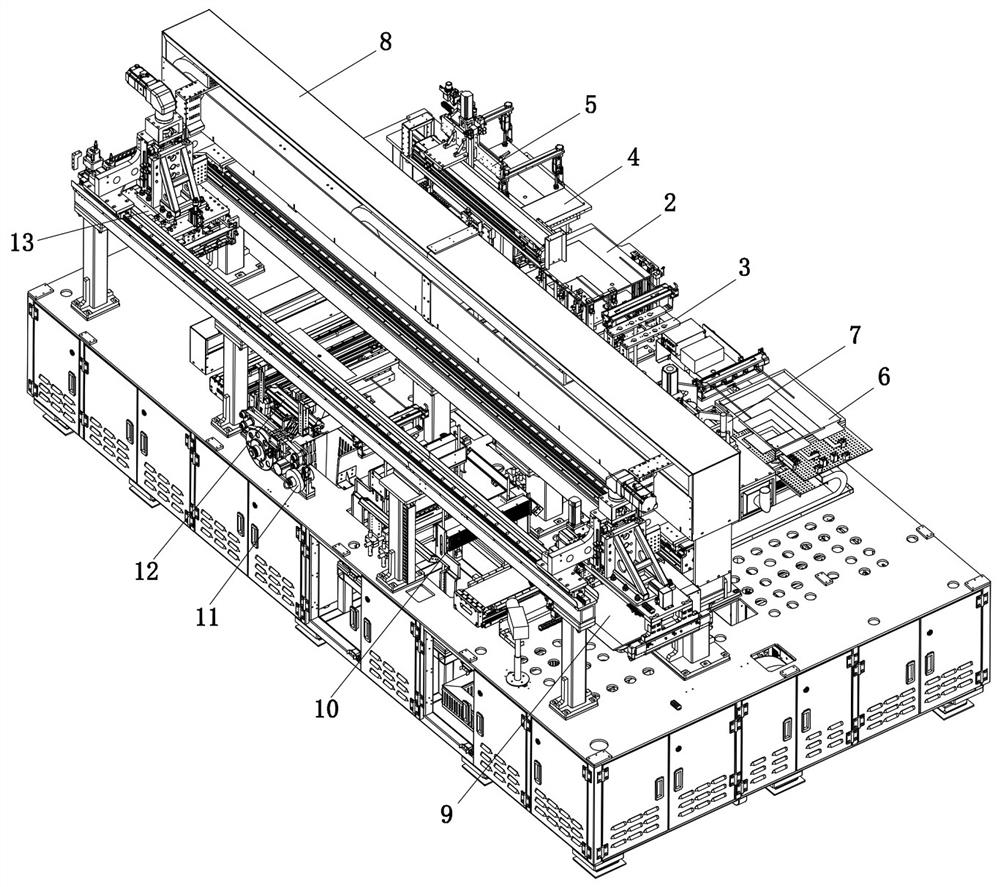

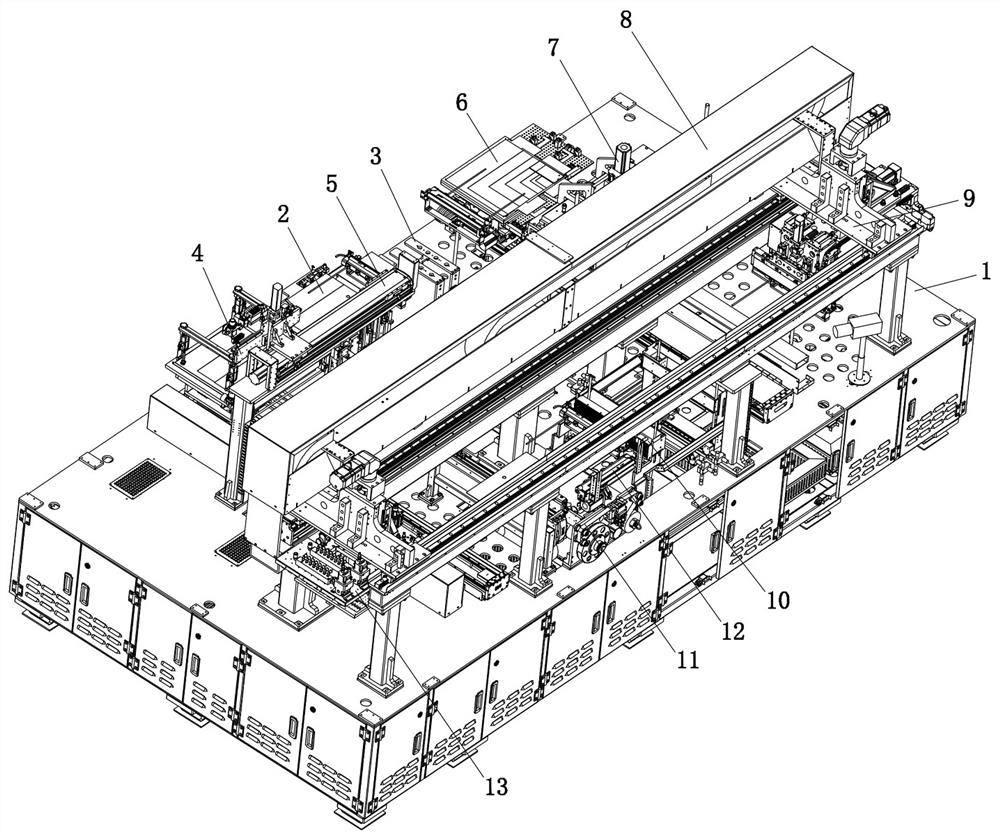

[0072] Such as Figure 1 to Figure 38 As shown, the technical solution adopted by the present invention is as follows: a laminating machine for both soft and hard screens, including a polarizer feeding mechanism, a retrieving mechanism 5, a patch platform 6, a detection and cleaning mechanism 7, a film tearing mechanism and a patch mechanism , wherein, the above-mentioned polarizer feeding mechanism is set on the machine 1, and the take-off mechanism 5 is set on one side of the polarizer feeding mechanism. Placement; the above-mentioned patching platform 6 is arranged at intervals on the side of the polarizer feeding mechanism, and the glass substrate to be patched is placed on the patching platform 6; the above-mentioned detection and cleaning mechanism 7 is erected above the patching platform 6, after loading The glass substrate is transported in a straight line by the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com