Patents

Literature

48results about How to "Realize automatic fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Turnover mechanism of film sticking machine for hook face member

ActiveCN105059593APrevent dust from stickingImprove work efficiencyPackagingMachine toolTectorial membrane

A turnover mechanism of a film sticking machine for a hook face member comprises a turnover shaft and a first drive driving the turnover shaft to rotate, a glass screen is disposed at a jig mechanism, the jig mechanism is installed at the turnover shaft, a turnover mechanism is fixed onto a machine tool, the jig mechanism comprises a jig, a jig installation member and a fifth drive, one end of the jig installation member is fixed to the turnover shaft, the jig is fixed to the jig installation member and is a curved-type member and provided with a hook face cavity for fixing a curved-type glass screen, the jig is installed onto the jig installation member through a rotating shaft, the turnover shaft is disposed at one end of the jig away from the turnover shaft, and the fifth drive acts between the jig and the jig installation member and enables the jig to rotate around the rotating shaft. Through the above structure, automatic attaching of a glass screen with a large-curvature hook face or a hook face with a variable curvature and a soft film, the soft film is automatically attached while a protective film is torn, adhesion of dust is prevented, and the working efficiency is raised.

Owner:广东韦达尔传媒有限公司

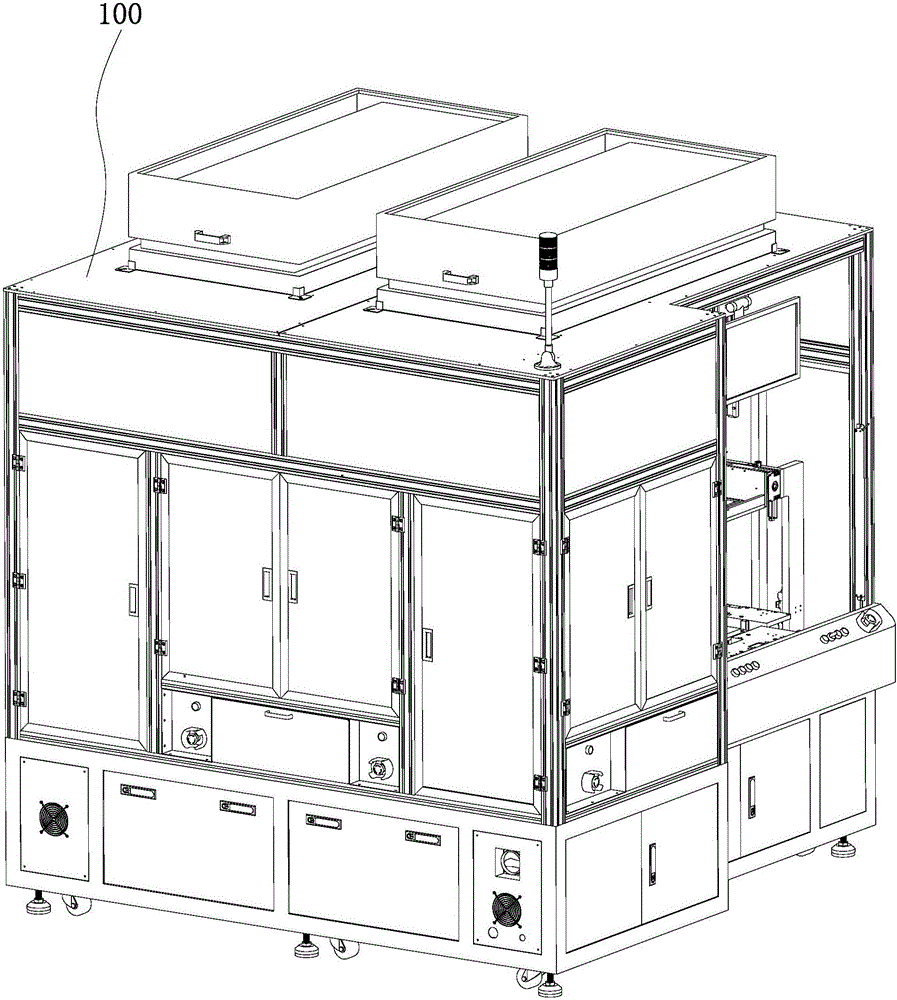

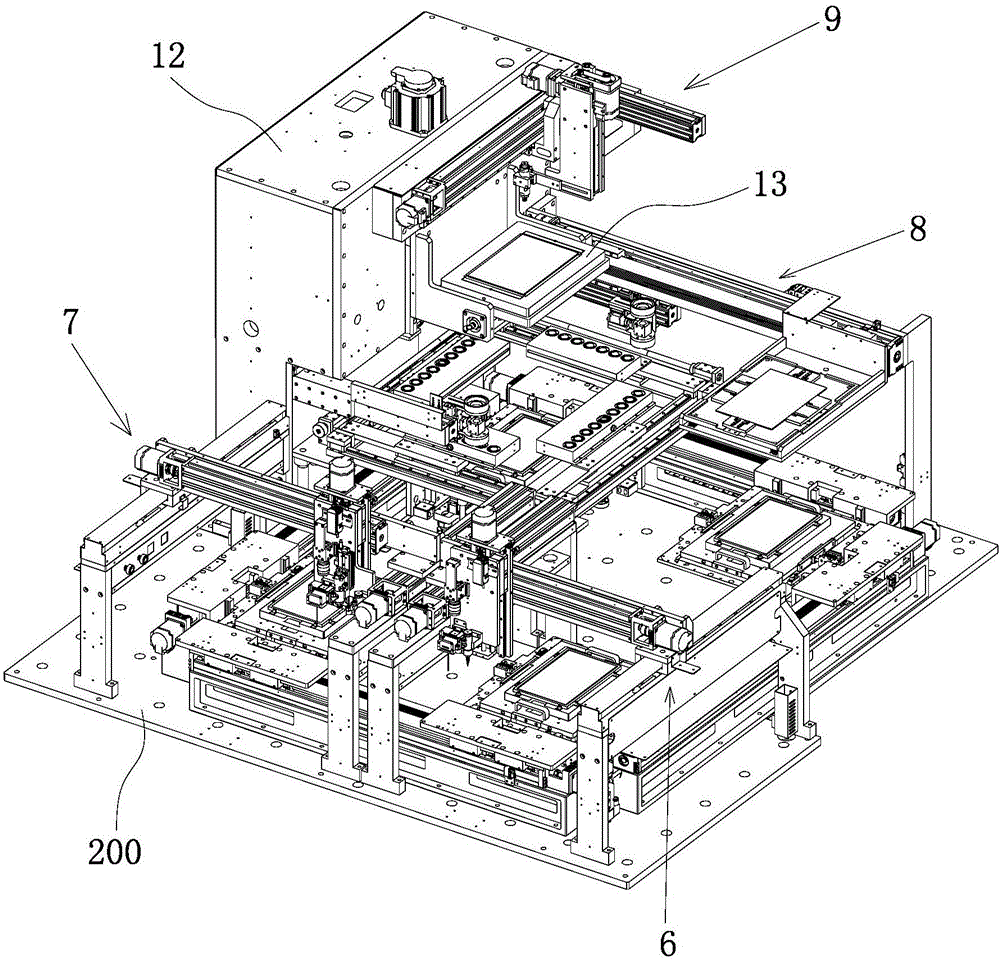

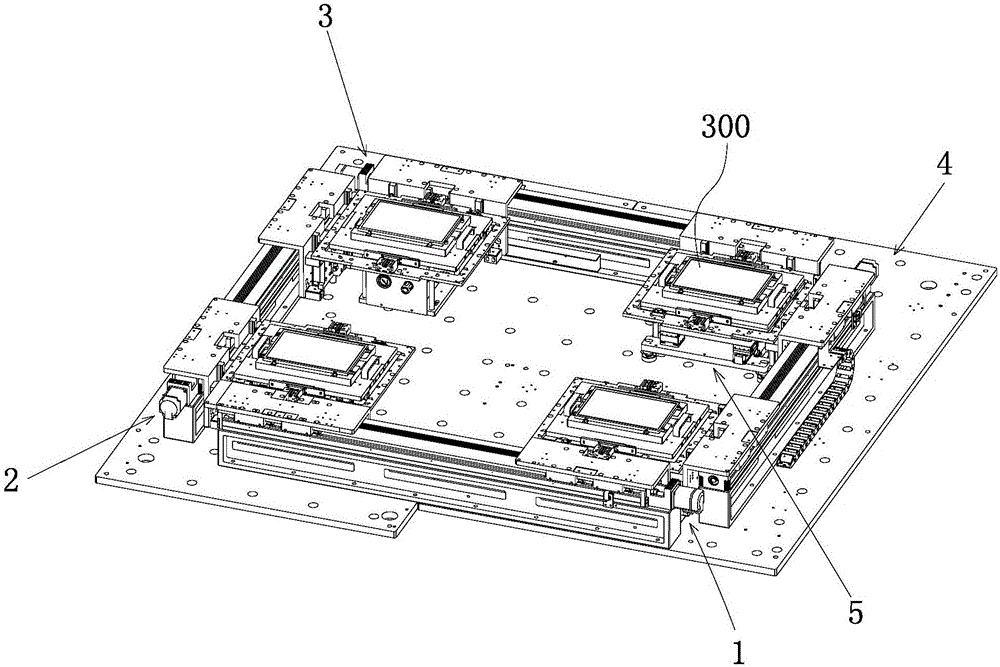

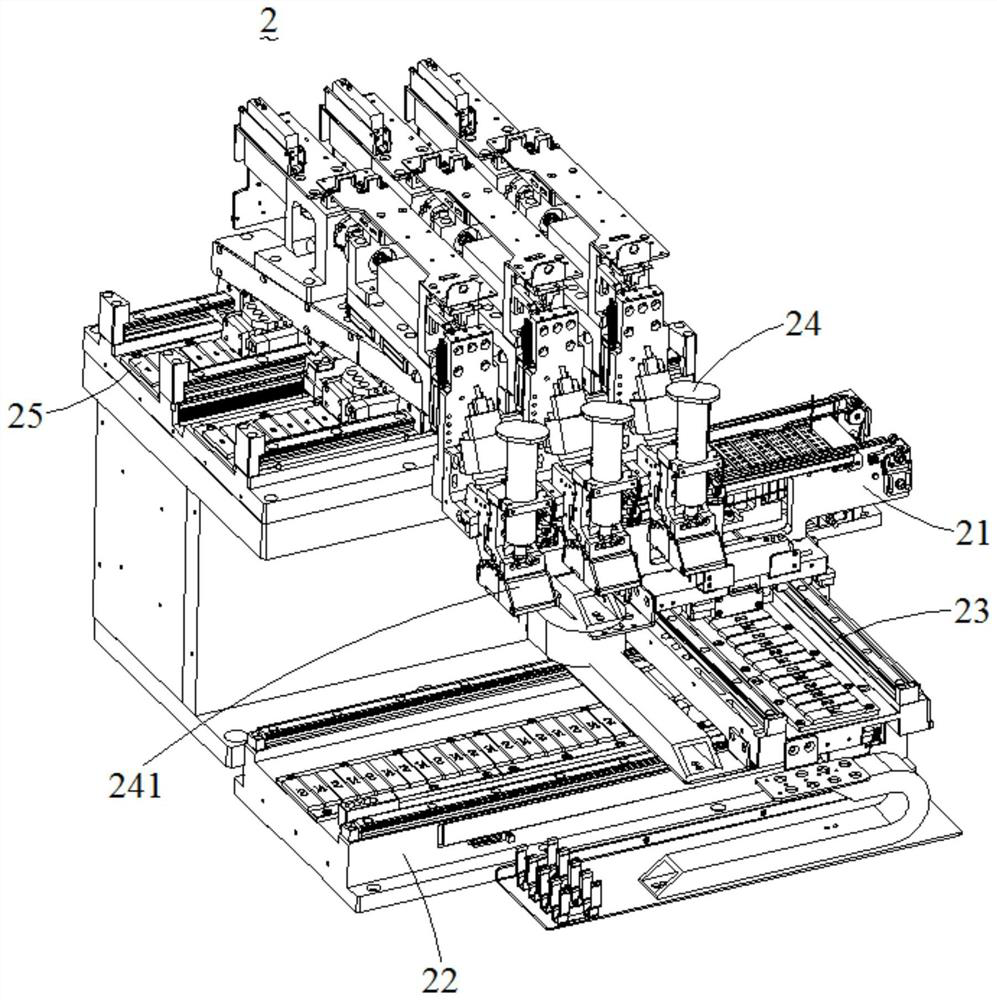

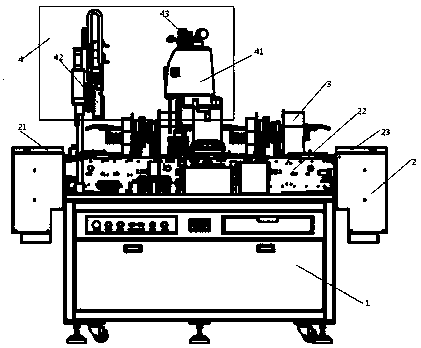

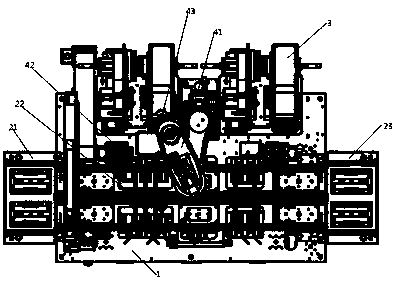

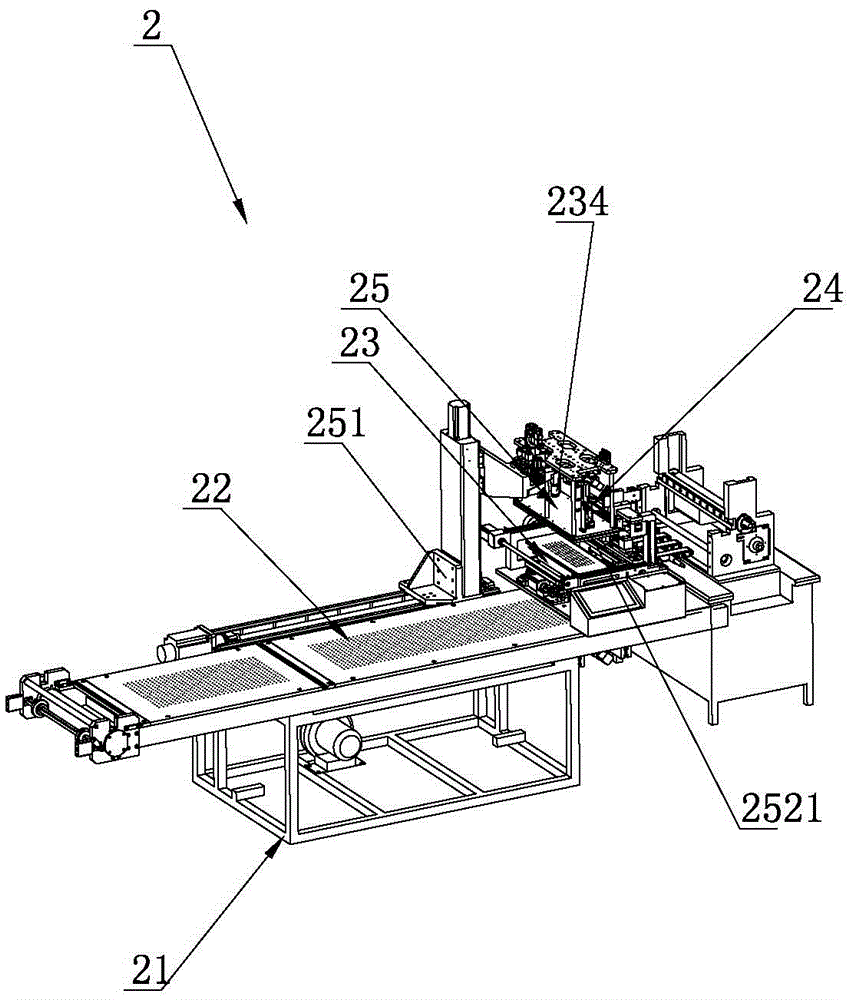

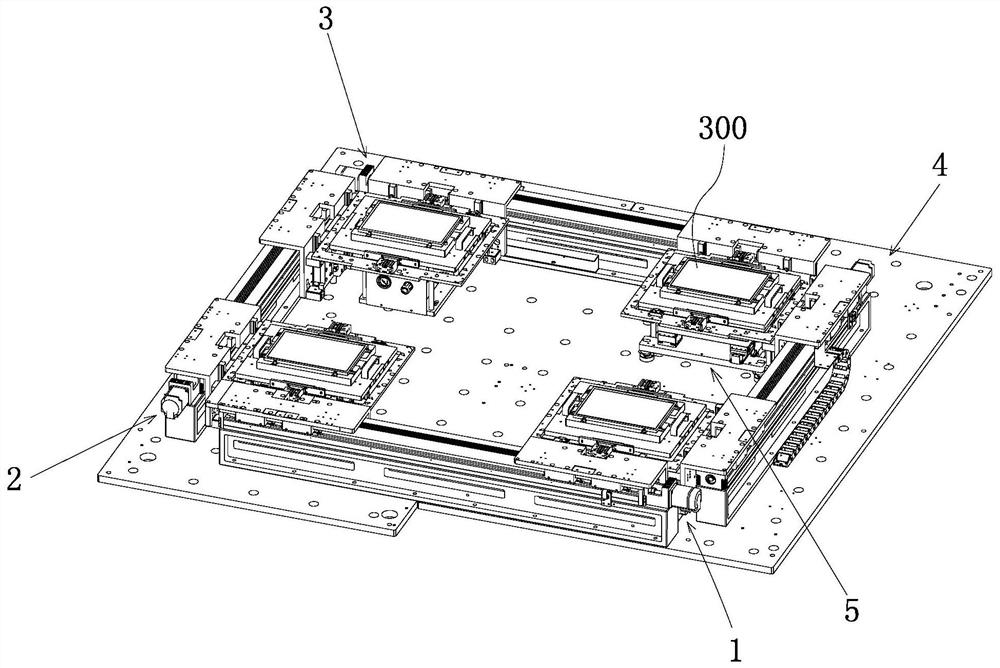

Adhesive dispensing attaching machine

ActiveCN106733429ARealize automatic dispensingRealize automatic fitMaterial gluingPretreated surfacesAdhesiveMechanical engineering

The invention discloses an adhesive dispensing attaching machine which is provided with a shell. The shell is internally and fixedly provided with a machine table, the machine table is provided with a conveying device, a first adhesive dispensing device, a second adhesive dispensing device, an attaching device for attaching mobile phone screens and cover plates and a third adhesive dispensing device. The conveying device of workpieces comprises a first conveying mechanism, a second conveying mechanism, a third conveying mechanism, a fourth conveying mechanism which are used for conveying the mobile phone screens and a fifth conveying mechanism used for conveying the cover plates. The output end of the third conveying mechanism is provided with a bearing table for storing mobile phone positioning jigs and an adjustment mechanism for adjusting the position of the bearing table, and the mobile phone screens are conveyed to the bearing table at the output end of the third conveying mechanism through the first conveying mechanism, the second conveying mechanism and the third conveying mechanism in sequence; and the fourth conveying mechanism can move the mobile phone screens and the cover plate obtained after adhesive dispensing attaching is performed on the bearing table to the output end of the fourth conveying mechanism from the input end of the fourth conveying mechanism. By means of the adhesive dispensing attaching machine, automatic adhesive dispensing attaching work can be achieved, and work efficiency is improved.

Owner:XIAMEN LIJU AUTOMATION TECH

Elastic Chicken Breast Appliance

Owner:李建华 +1

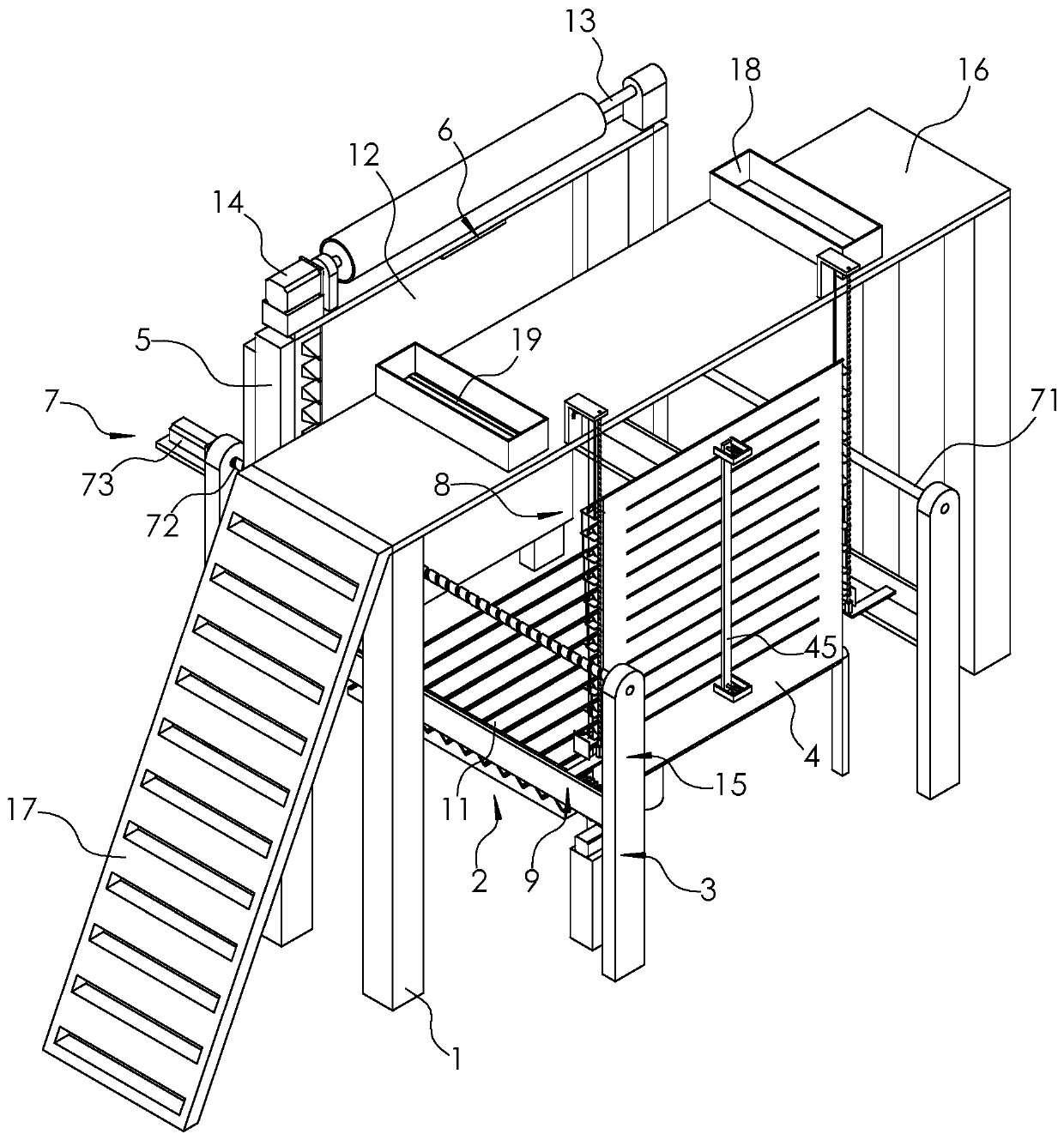

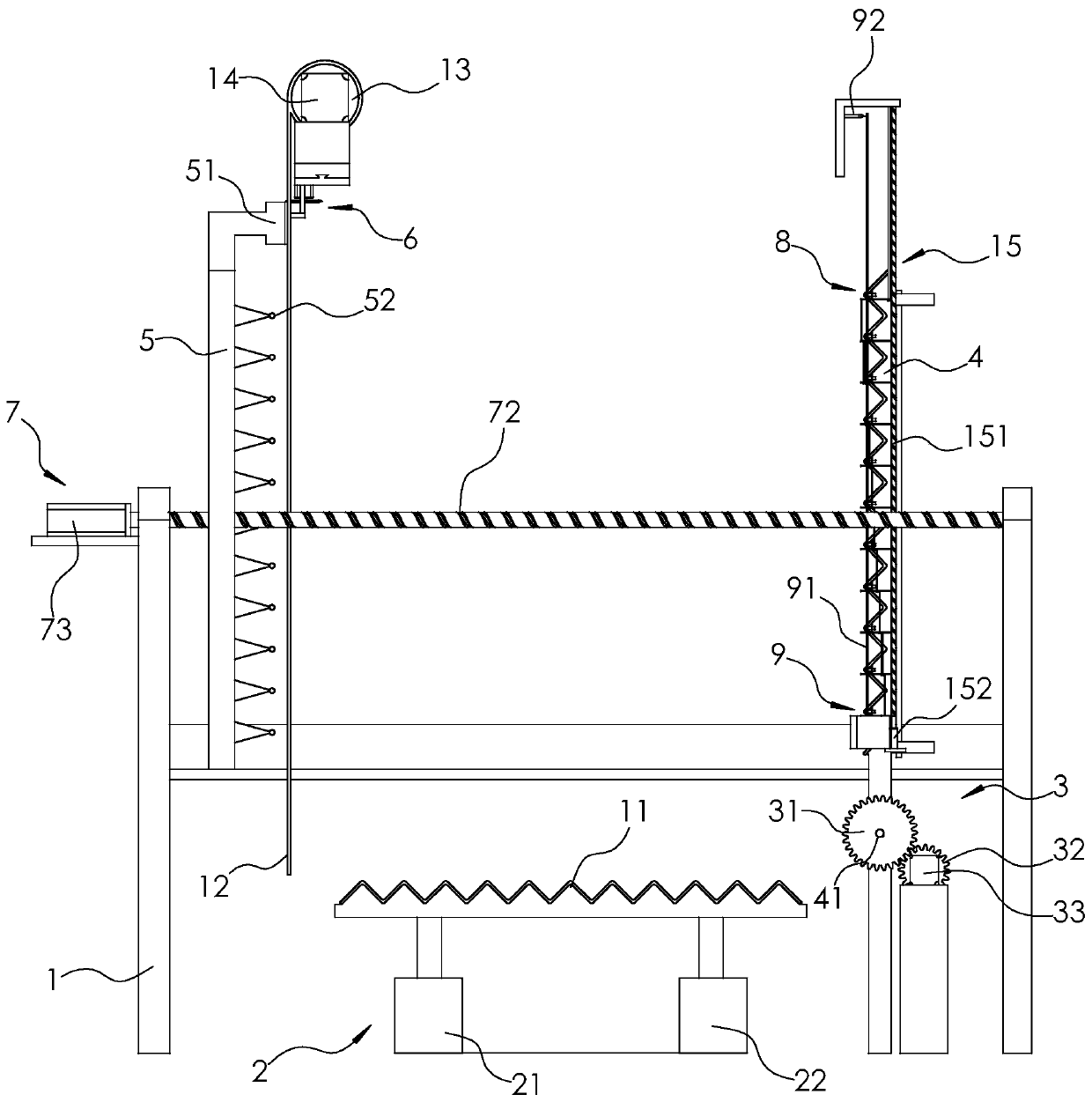

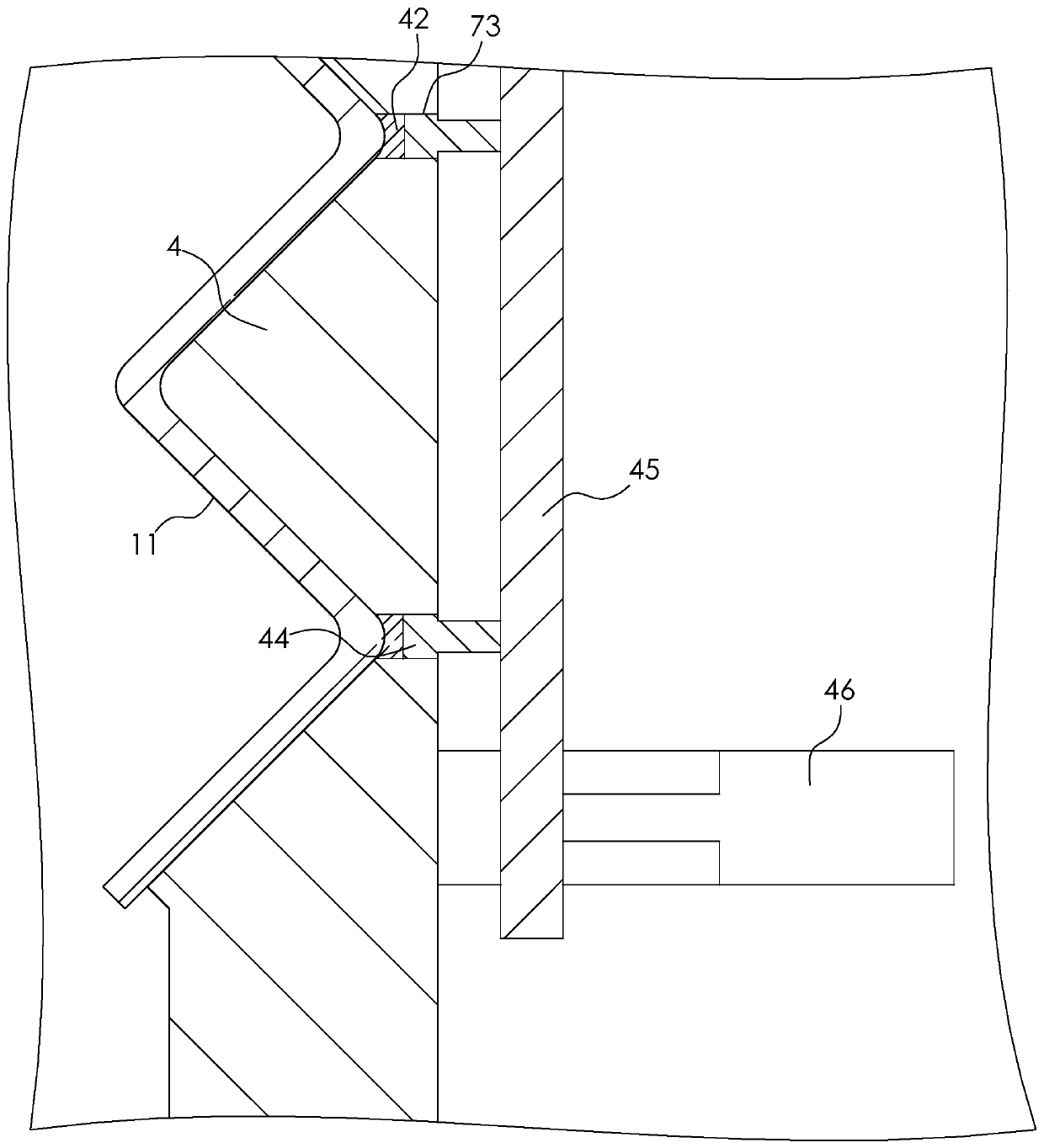

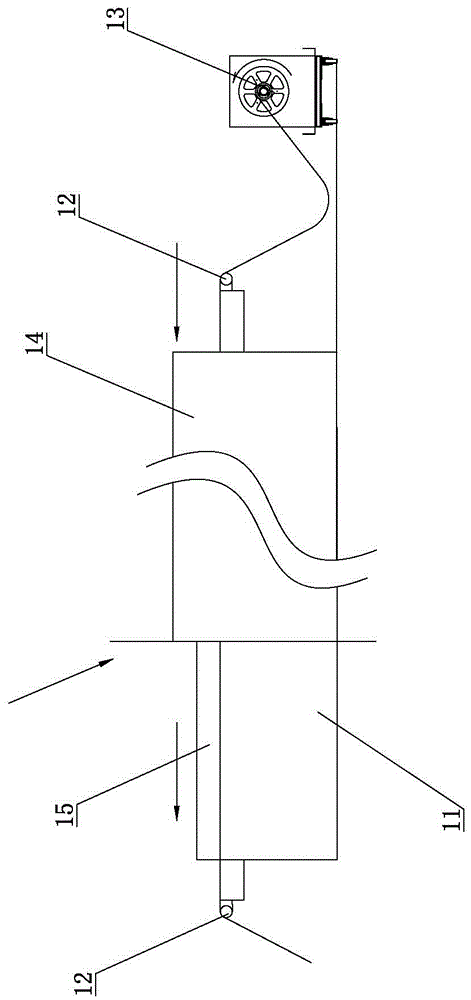

Feeding mechanism for shaping steam box

ActiveCN111485349ARealize automatic fitImprove feeding efficiencyTextile treatment containersSevering textilesPaperboardStructural engineering

The invention discloses a feeding mechanism for shaping steam box. The feeding mechanism comprises a support, a lifting table and a pushing frame; a plurality of thin paperboards are stacked on the lifting table, and a wavy surface is arranged on the upper side of the lifting table; a wavy plate and a rotating assembly are arranged on the support, the wavy plate is rotationally connected to the support through a horizontal shaft, and a plurality of first pasting strips are arranged on the wavy plate; a second pasting strip and a plurality of pressing rods are fixed to the pushing frame, a driving assembly is arranged on the support, and the moving direction of the pushing frame is parallel to the rotating plane of the wave plate; a plurality of clamping units are arranged at the two ends of the horizontal shaft, a penetrating column is fixed to each clamping unit, and the lower end of each penetrating column is fixedly sleeved with a baffle ring; and driving assemblies are arranged atthe two ends of the horizontal shaft. By means of the mechanism, automatic attaching of curtain cloth and a thin paper board, automatic clamping of the curtain cloth and the thin paper board and automatic folding of the curtain cloth and the thin paper board are achieved, and therefore the cloth feeding efficiency is improved; and the feeding efficiency of cloth is improved.

Owner:杭州富阳数马装饰工艺品有限公司

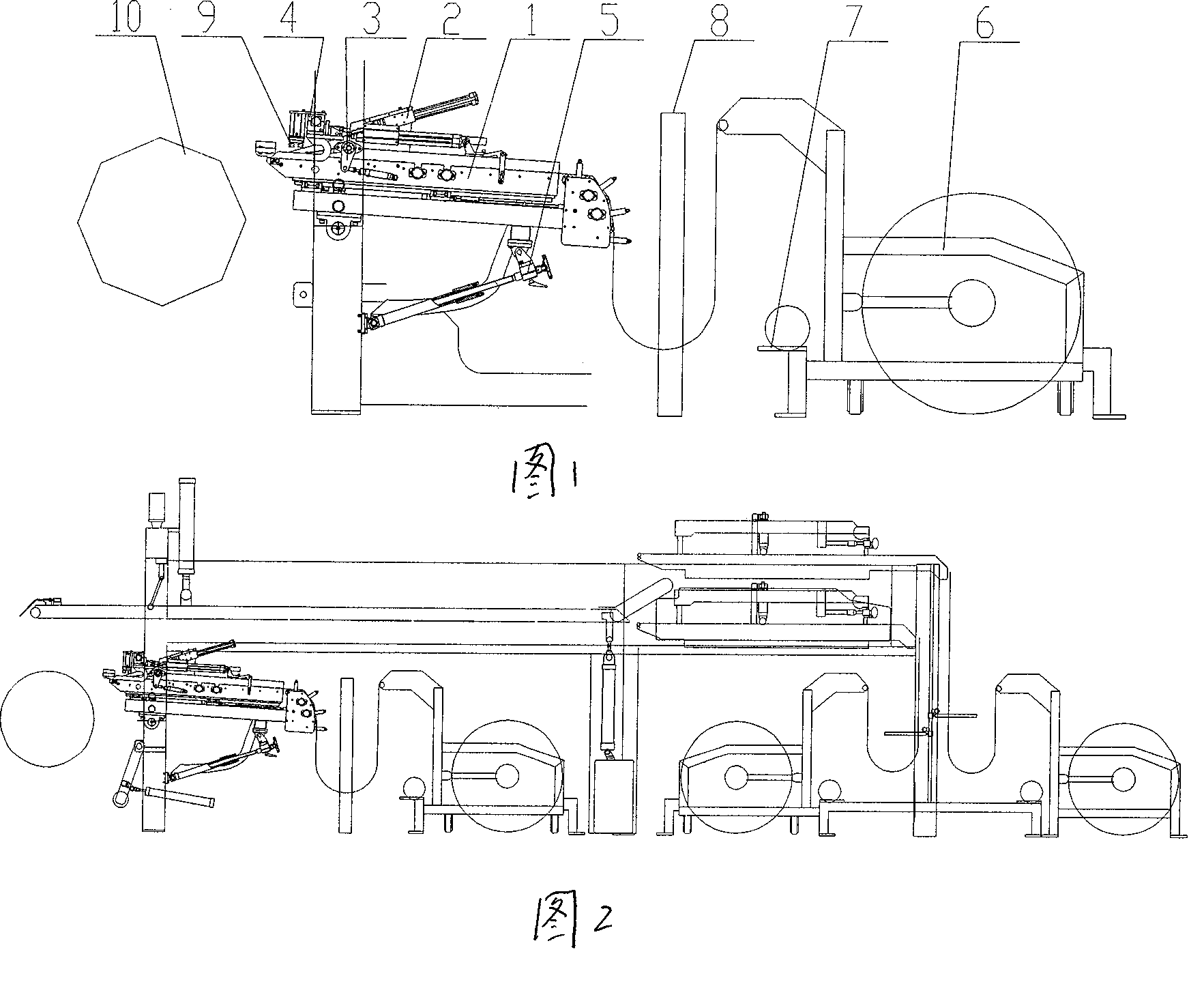

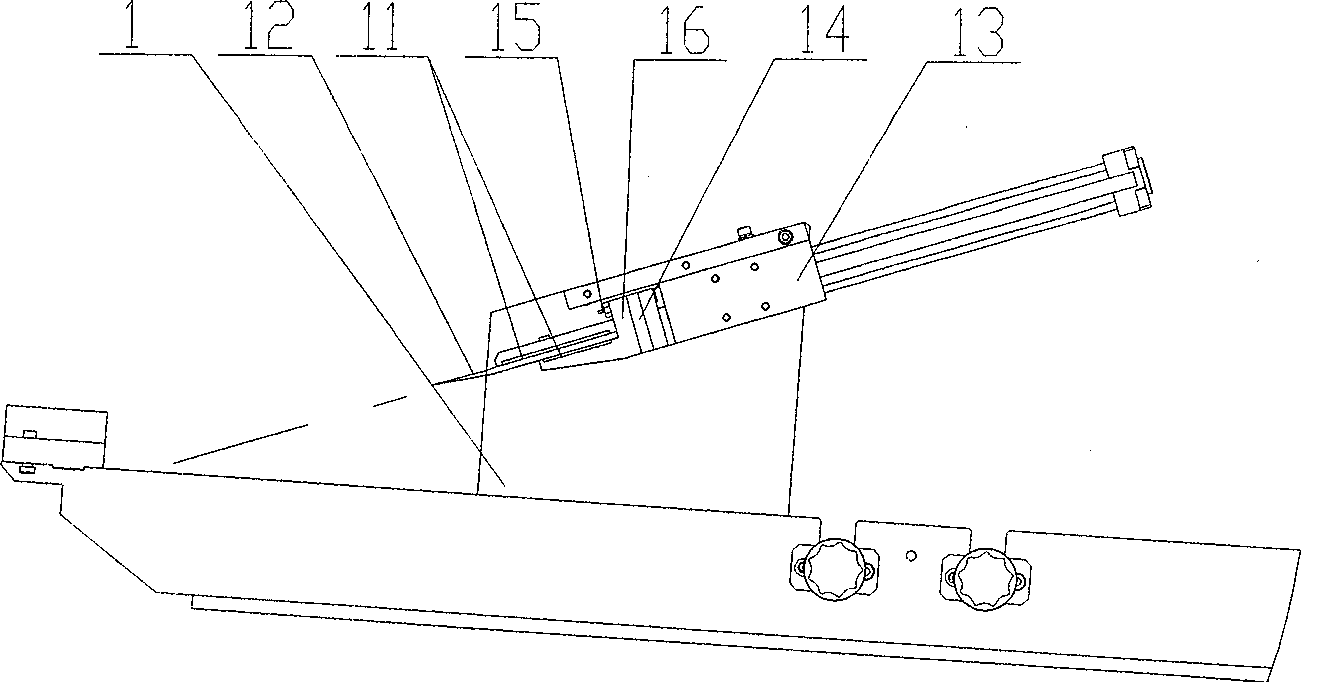

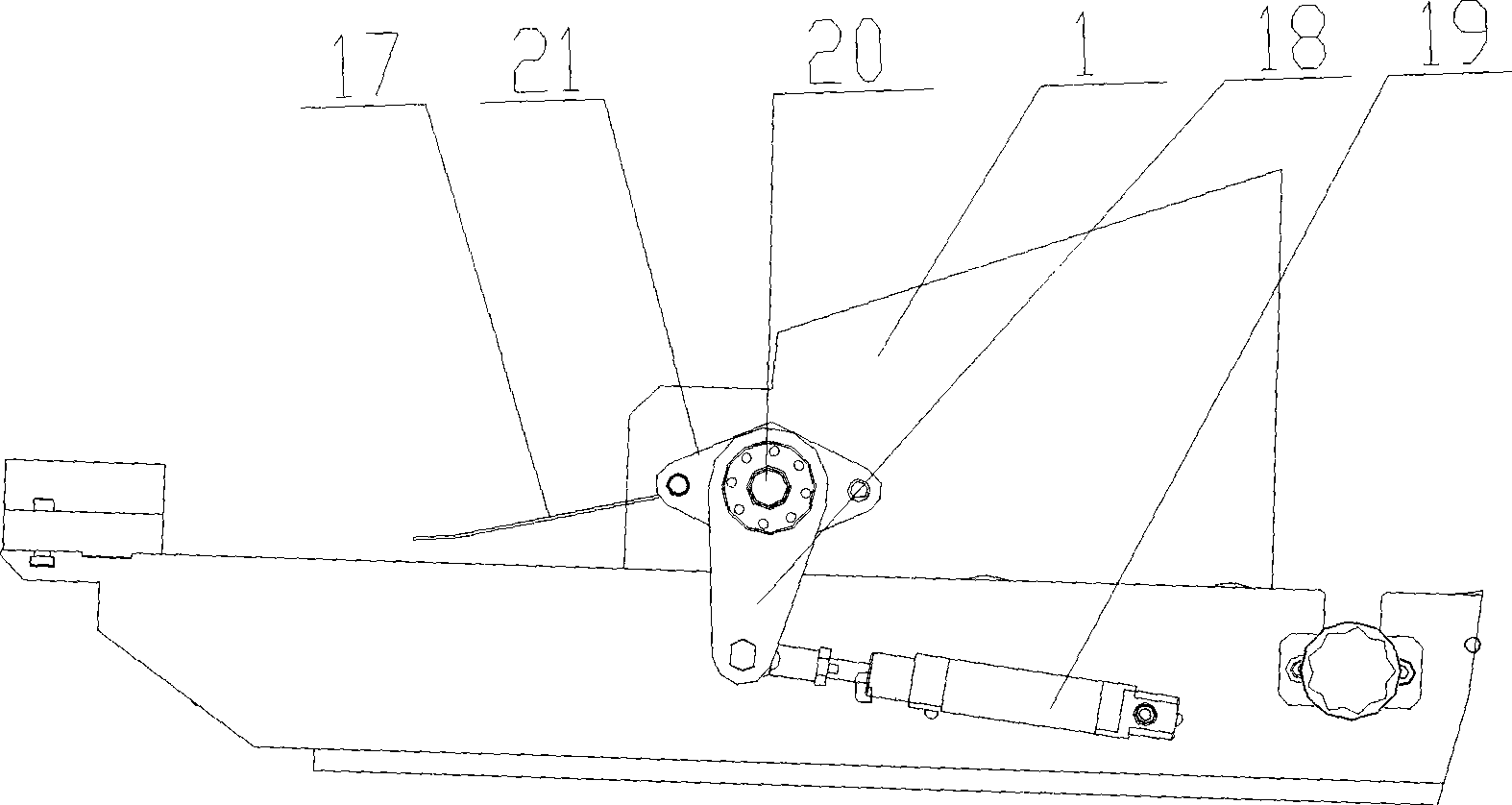

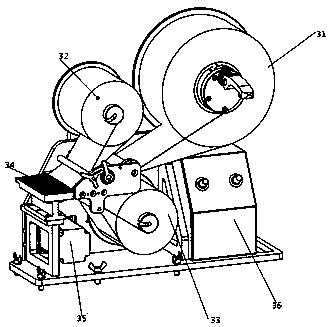

Automatic feeding device for belt filling adhesive of tyre building machine

InactiveCN101444966ARealize automatic separationRealize automatic fixed-length cuttingTyresInterliningMolding machine

The invention provides an automatic feeding device for belt filling adhesive of a tyre building machine, comprising a conveying frame, an angle adjusting device, a feeding trolley, unwinding equipment and a cloth storage mechanism, wherein, the feeding trolley, the unwinding equipment and the cloth storage mechanism are sequentially arranged at the back end of the conveying frame and feed for the conveying frame. The invention is characterized in that an electric knife cutting component for cutting semi-product material is arranged on the conveying frame, a flexible cutting platen component for cutting front press fit filling adhesive is arranged below the electric knife cutting component, and a vacuum absorbing component for automatically grasping and pasting the stub bar of the filling adhesive is arranged at the front of the electric knife cutting component 2. Compared with the prior art, the invention has the advantages that the device realizes the automatic separation, bonding and fixed-length cutting of the semi-product material interlining of the belt filling adhesive, reduces the labor intensity of the operator and effectively guarantees the bonding and positioning accuracy.

Owner:BEIJING BAMTRI DAIRUI TECH DEV

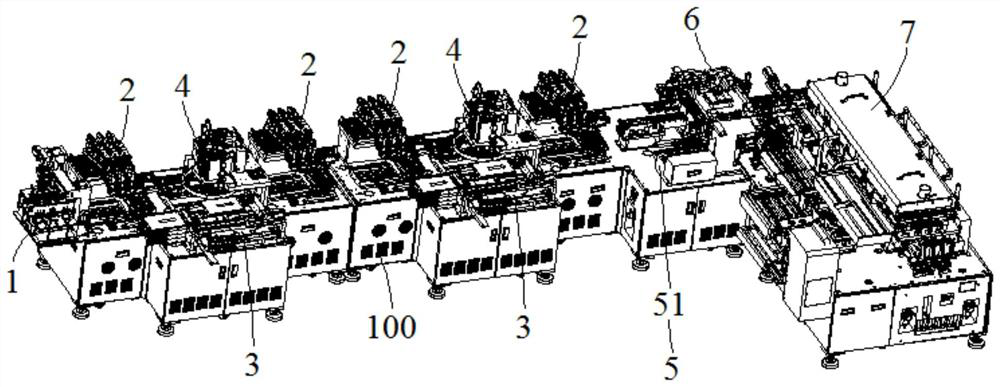

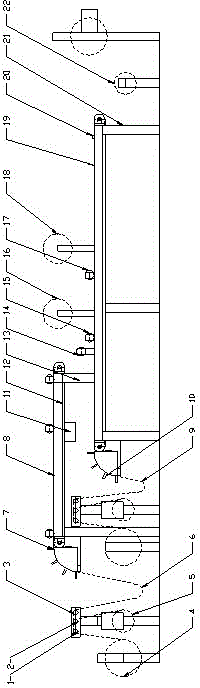

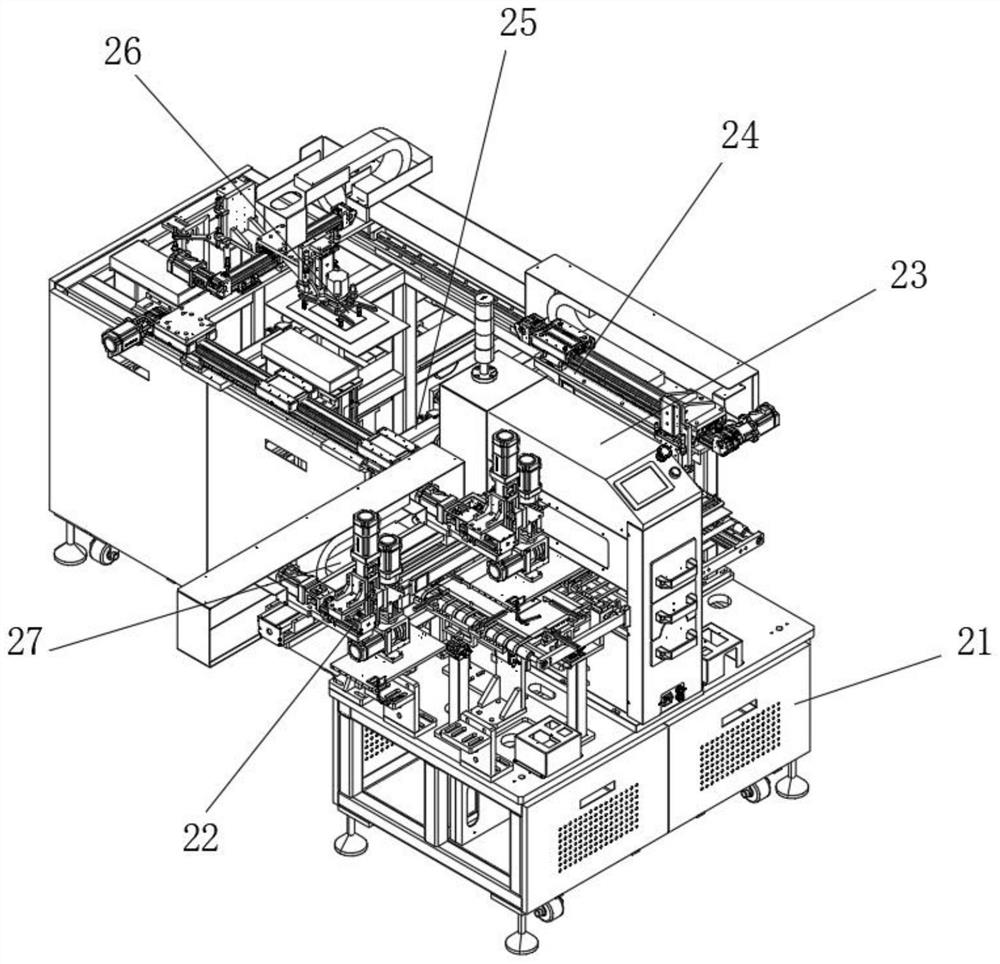

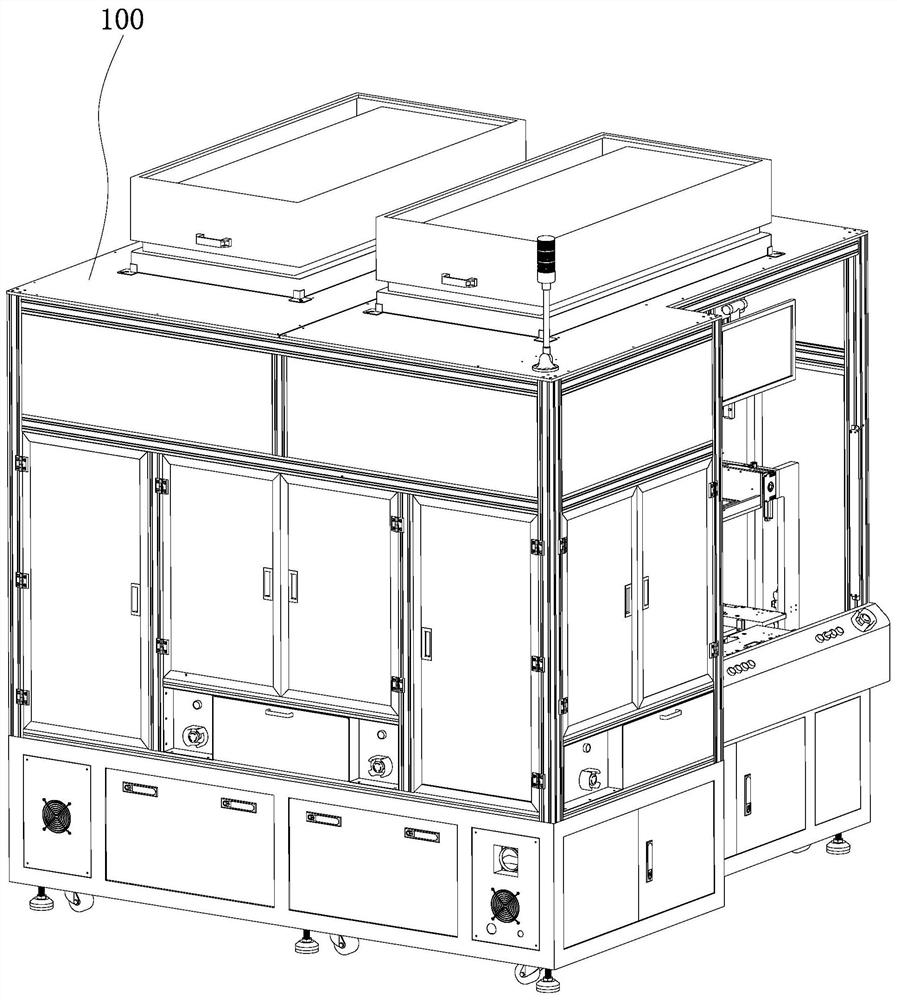

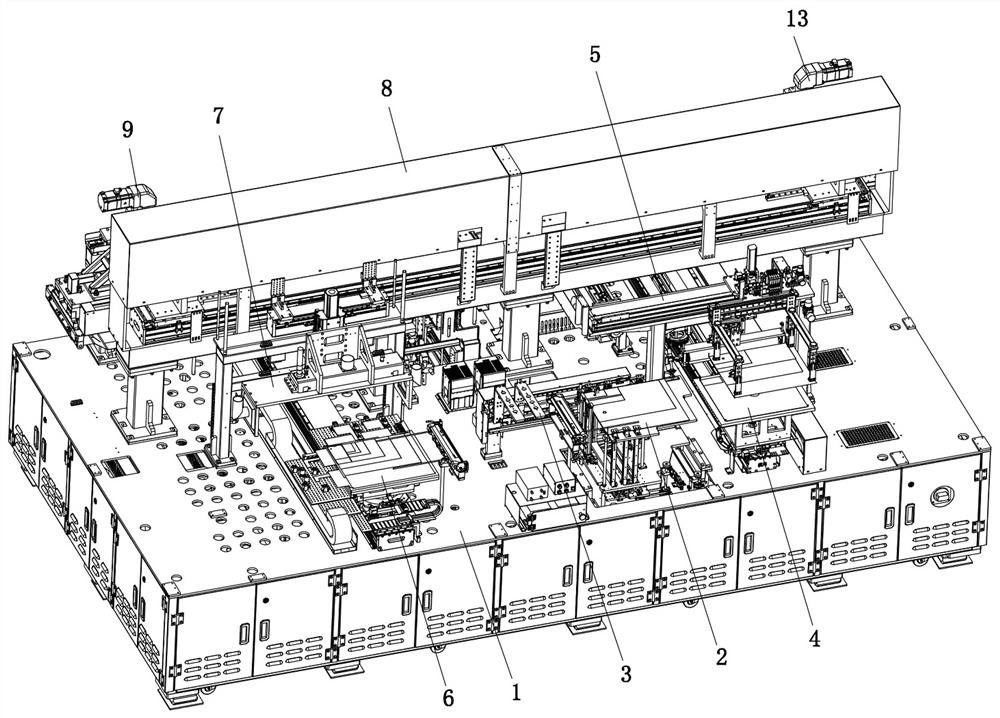

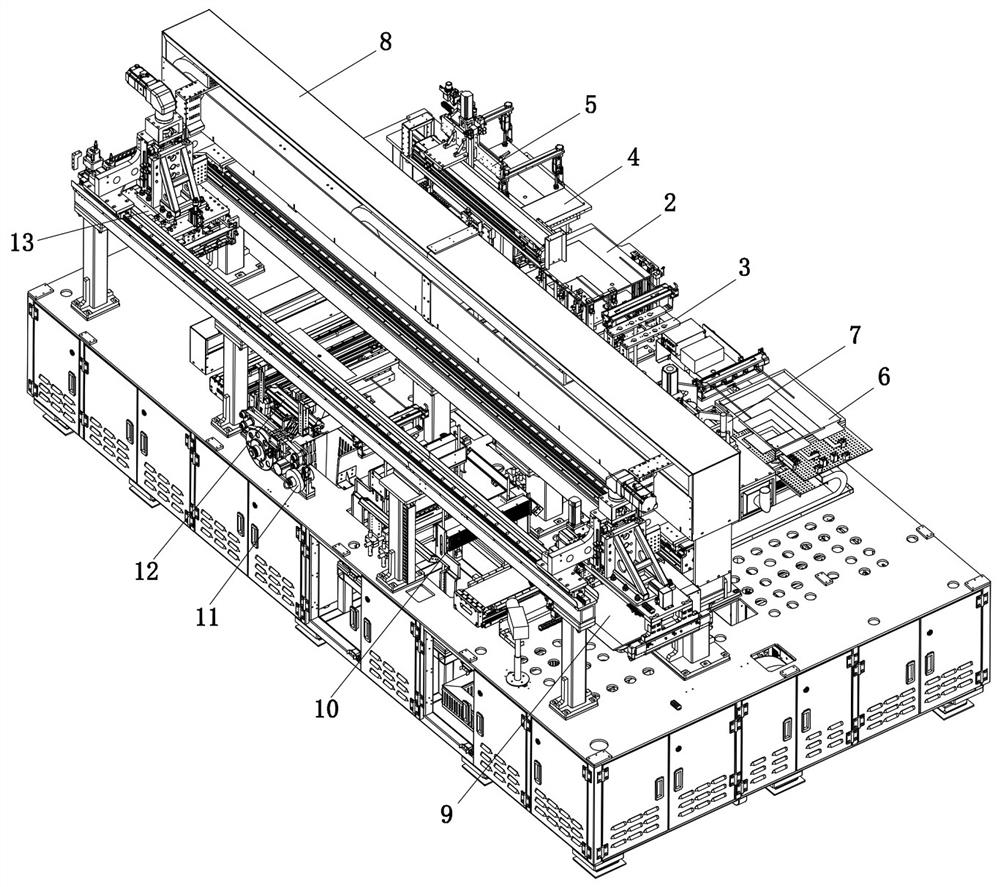

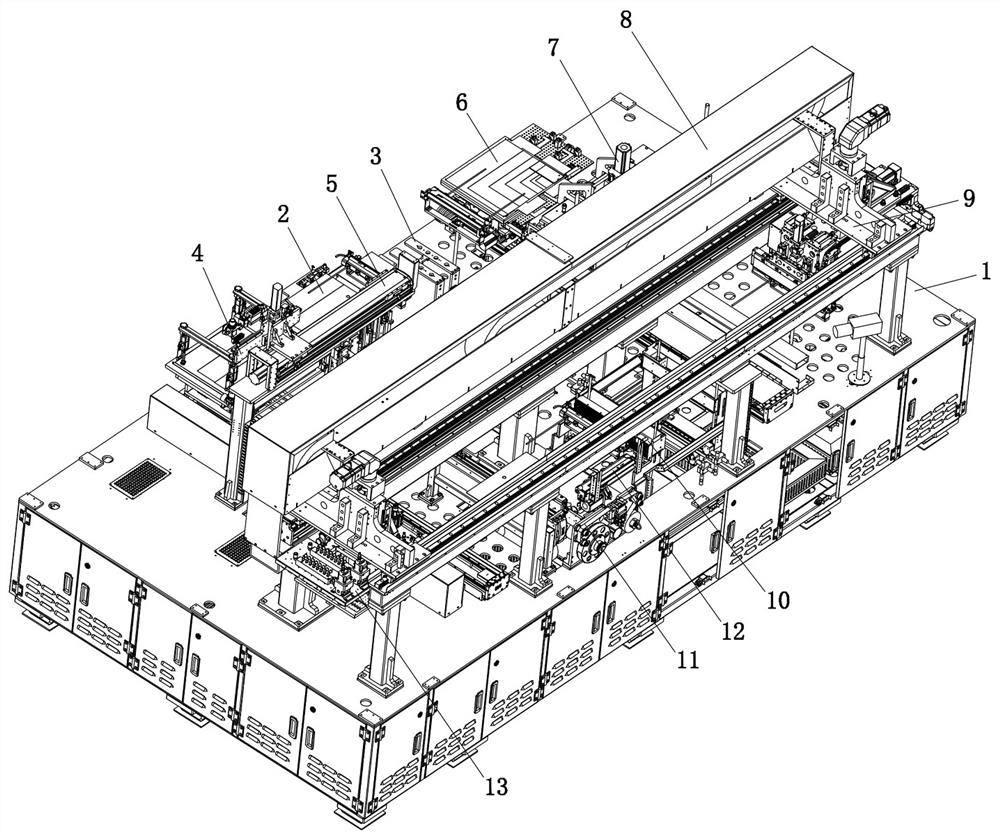

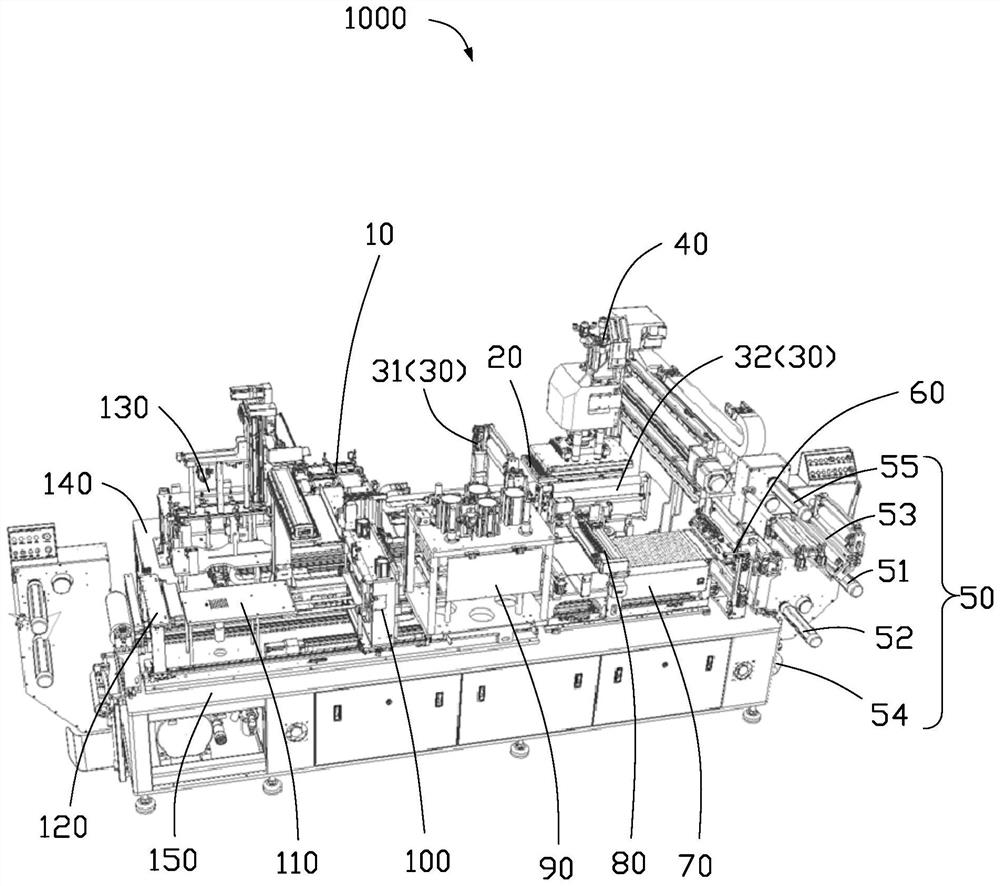

Semiconductor packaging all-in-one machine

ActiveCN112490160ARealize automatic fitHighly integratedSemiconductor/solid-state device manufacturingSemiconductor packageEngineering

The invention provides a semiconductor packaging all-in-one machine. The semiconductor packaging all-in-one machine comprises a rack, a first feeding mechanism used for supplying a first support, a dispensing mechanism used for dispensing the first support, a chip supply mechanism used for supplying a chip, a die bonding mechanism used for fixedly arranging the chip on the first support, a secondfeeding mechanism used for supplying a second support, a laminating mechanism used for laminating the second support and the first support to form a laminated body, and a reflow soldering mechanism used for carrying out reflow soldering treatment on the laminated body. The chip can be fixedly arranged on the first support through the dispensing mechanism, the chip supply mechanism and the die bonding mechanism, the second support can be attached to the first support through the laminating mechanism to form the laminated body, and the reflow soldering mechanism can conduct reflow soldering treatment on the laminated body. Therefore, the semiconductor packaging all-in-one machine can realize automatic lamination of the second support and the first support and automatic reflow soldering treatment of the laminated body, and has the advantages of high integration degree, high automation degree, high efficiency and the like.

Owner:SHENZHEN XINYICHANG TECH CO LTD

Automatic vertical fitting device for building wall bricks

The invention discloses an automatic vertical fitting device for building wall bricks. The automatic vertical fitting device comprises a working table top, a supporting frame and an air pump, wherein a cement smearing mechanism is installed on the right side of the upper portion of the working table top, a positioning mechanism is installed on the rear side of the supporting frame, and the air pump is provided with a clamping mechanism, wherein the lower side of the clamping mechanism is provided with a pushing and guiding mechanism, the cement smearing mechanism comprises positioning rods, a connecting plate, a cement storage box, a first hydraulic cylinder and a cement spray head, the positioning rods are installed on the right side of the upper portion of the working table top in a front-back and left-right symmetry mode, and the connecting plate is slidably connected to the outer sides of the positioning rods. According to the automatic vertical fitting device for the building wall bricks, cement is uniformly smeared through the cement smearing mechanism, so that cement smearing and wall brick fitting form process operation, the working efficiency is improved, the wall bricks are conveniently placed and taken, automatic fitting can be effectively achieved, limiting can be effectively achieved, and stability and safety performance can be improved.

Owner:郭桃会

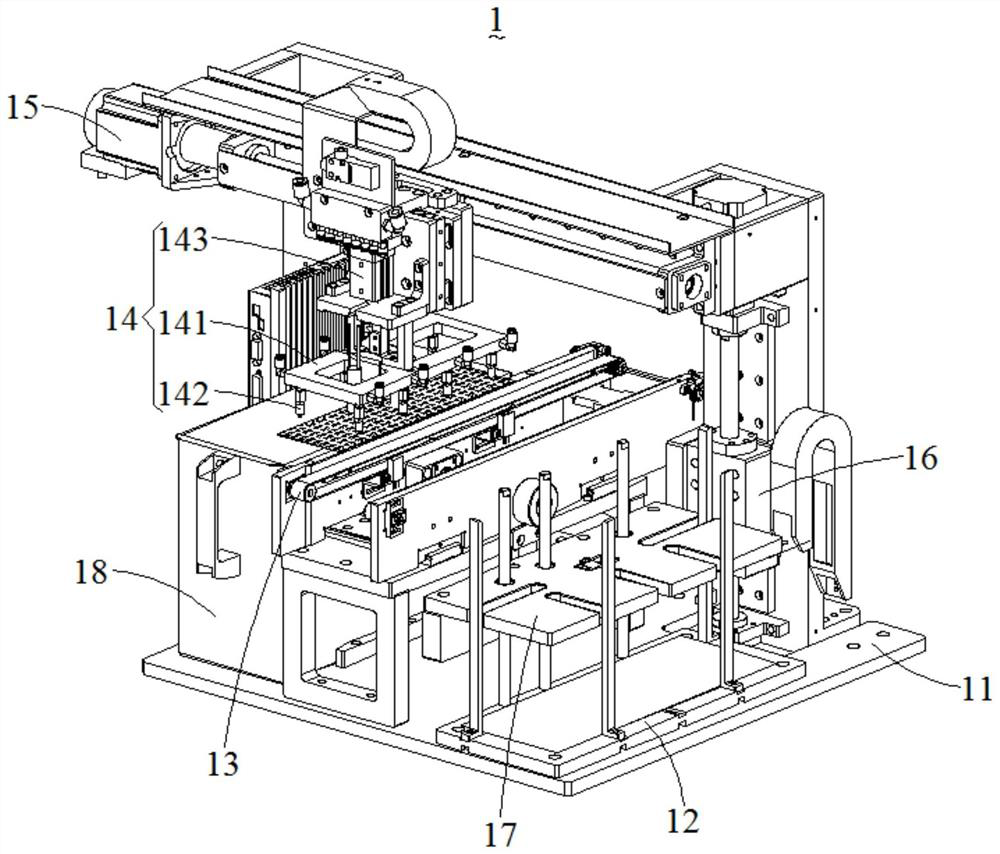

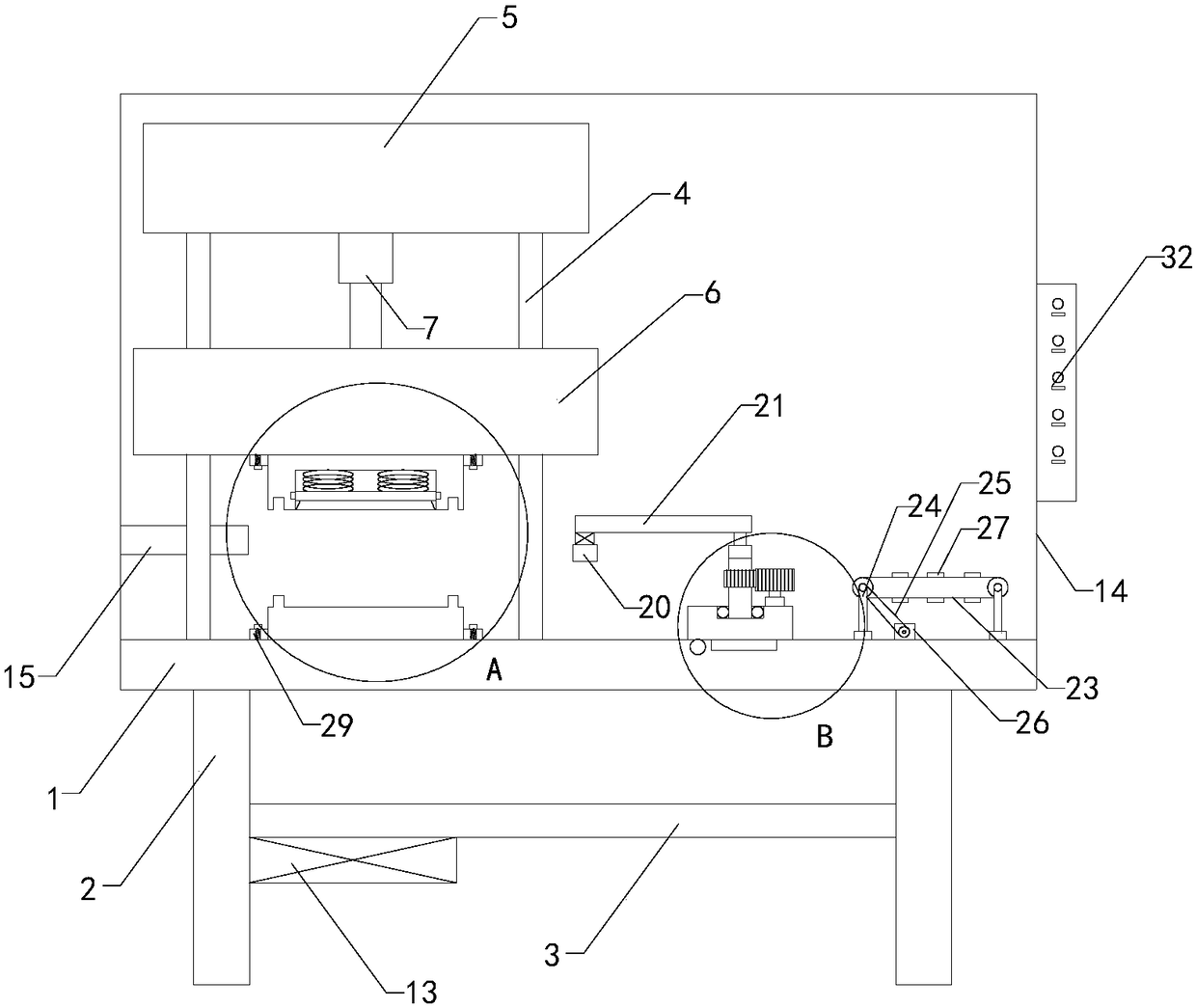

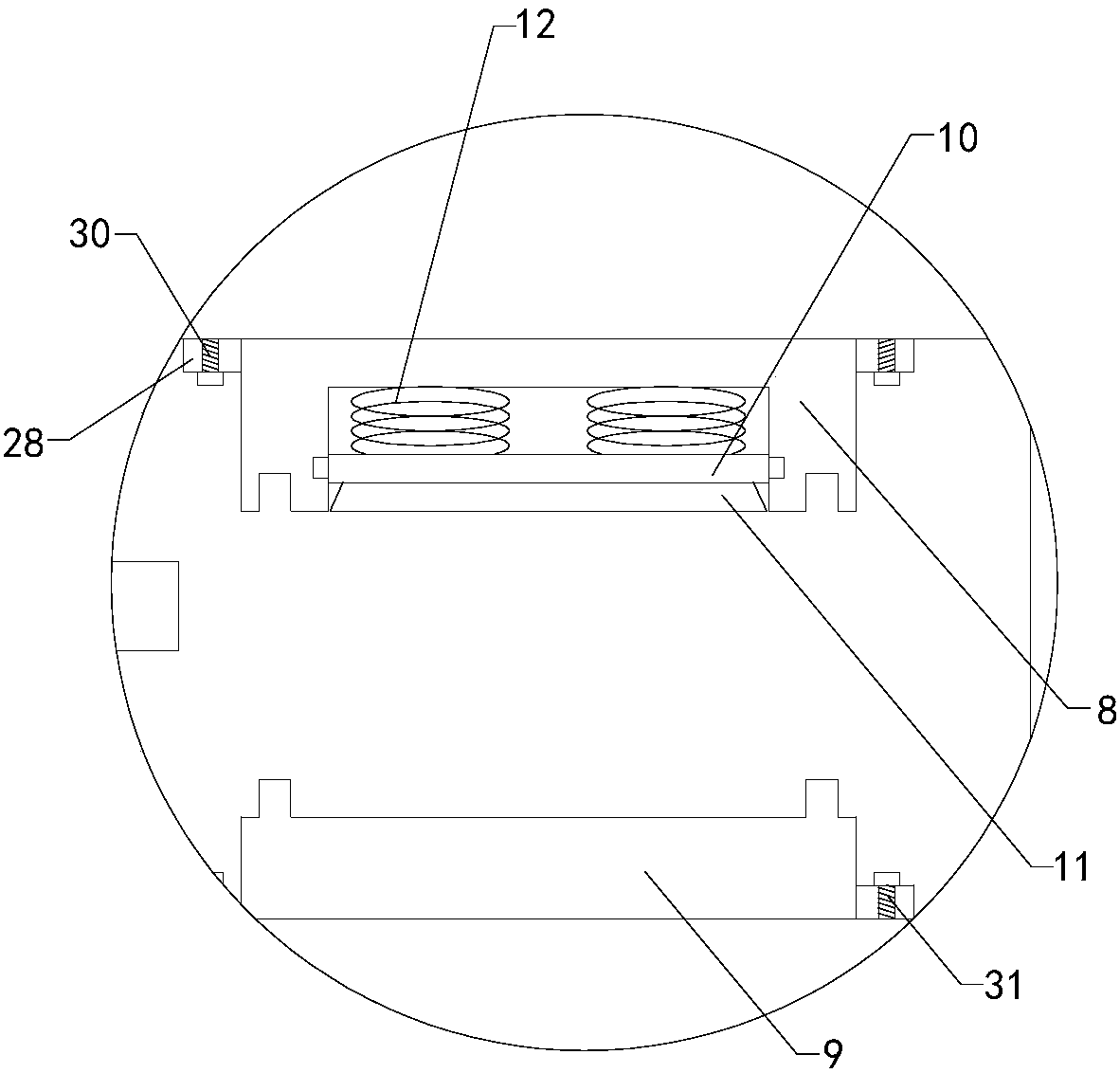

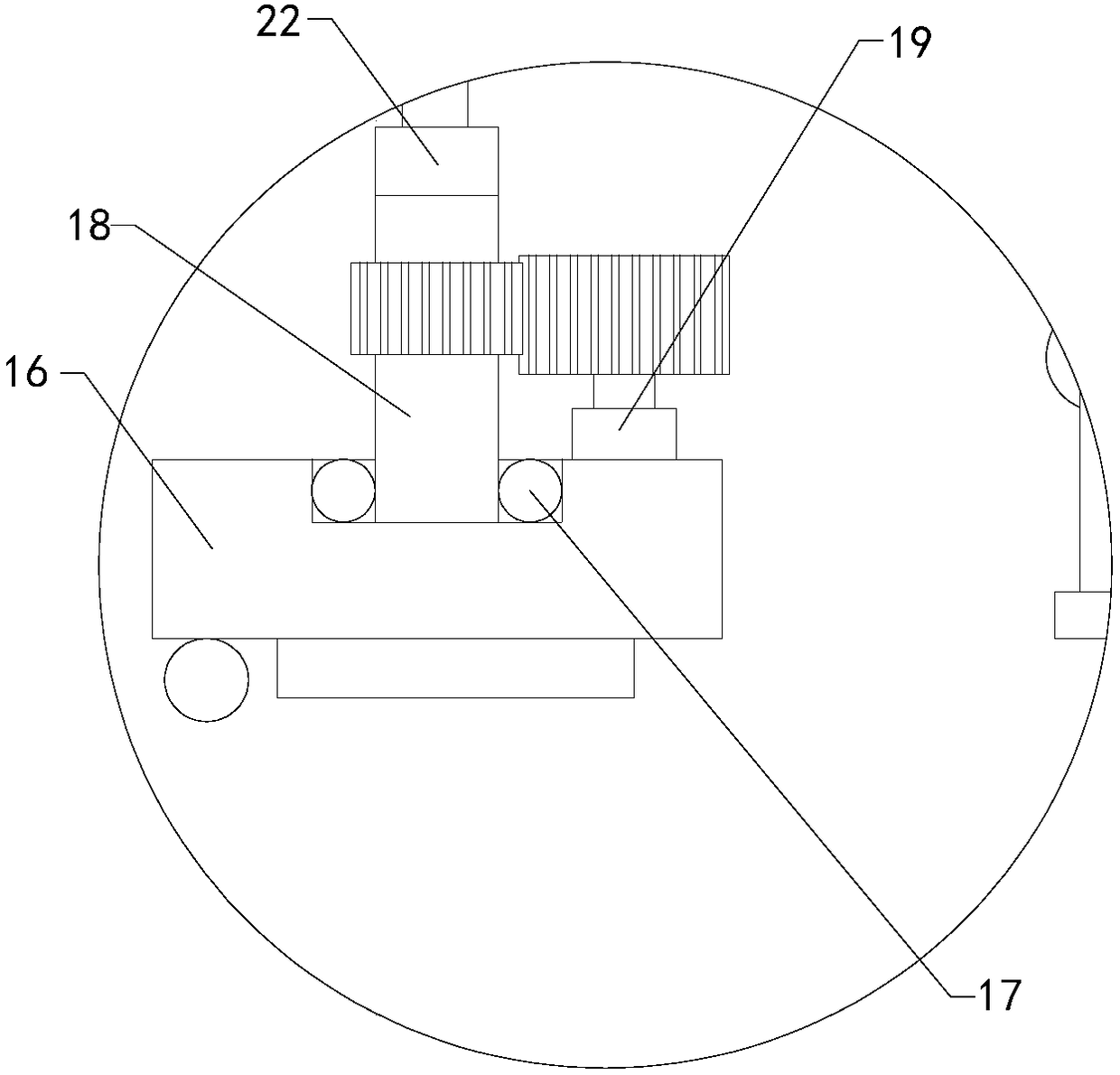

Steel disc reinforcement installation sticking machine of flexible circuit board in manufacture procedure

ActiveCN103096624ARealize automatic fitSkip the heating stepPrinted circuit manufactureAutomatic controlControl system

The invention relates to a steel disc reinforcement installation sticking machine of a flexible circuit board in a manufacture procedure. The steel disc reinforcement installation sticking machine of the flexible circuit board in the manufacture procedure comprises a machine body, wherein an operation cavity is arranged in the machine body. The steel disc reinforcement installation sticking machine of the flexible circuit board in the manufacture procedure is characterized in that a fixed groove is formed in the bottom of the operation cavity, and is used for placing jigs, the depth of the fixed groove is smaller than the height of the jigs, an air cylinder is arranged on the top of the operation cavity, a upper die template is arranged above the fixed groove, the upper end of the upper die template is connected with the air cylinder through a connecting plate, and can move along the air cylinder in a vertical mode, and a control system which is used for adjusting pressure, temperature and time is further arranged in the machine body. The steel disc reinforcement installation sticking machine of the flexible circuit board in the manufacture procedure can enable the jigs to be placed in the machine body to heat and pressurize, automatically controls the time, achieves automatic gluing between a steel disc and the flexible circuit board, saves steps of using electronic iron to carry out single disc heating, improves production efficiency, can generally use flexible circuit boards with different types in the manufacture procedure of flexible circuit boards, and can save resources. The steel disc reinforcement installation sticking machine of the flexible circuit board in the manufacture procedure is low in use cost, simple in operation, convenient to operate, and wide in applicability, and can greatly improve production efficiency.

Owner:NINGBO HUAYUAN ELECTRONICS TECH

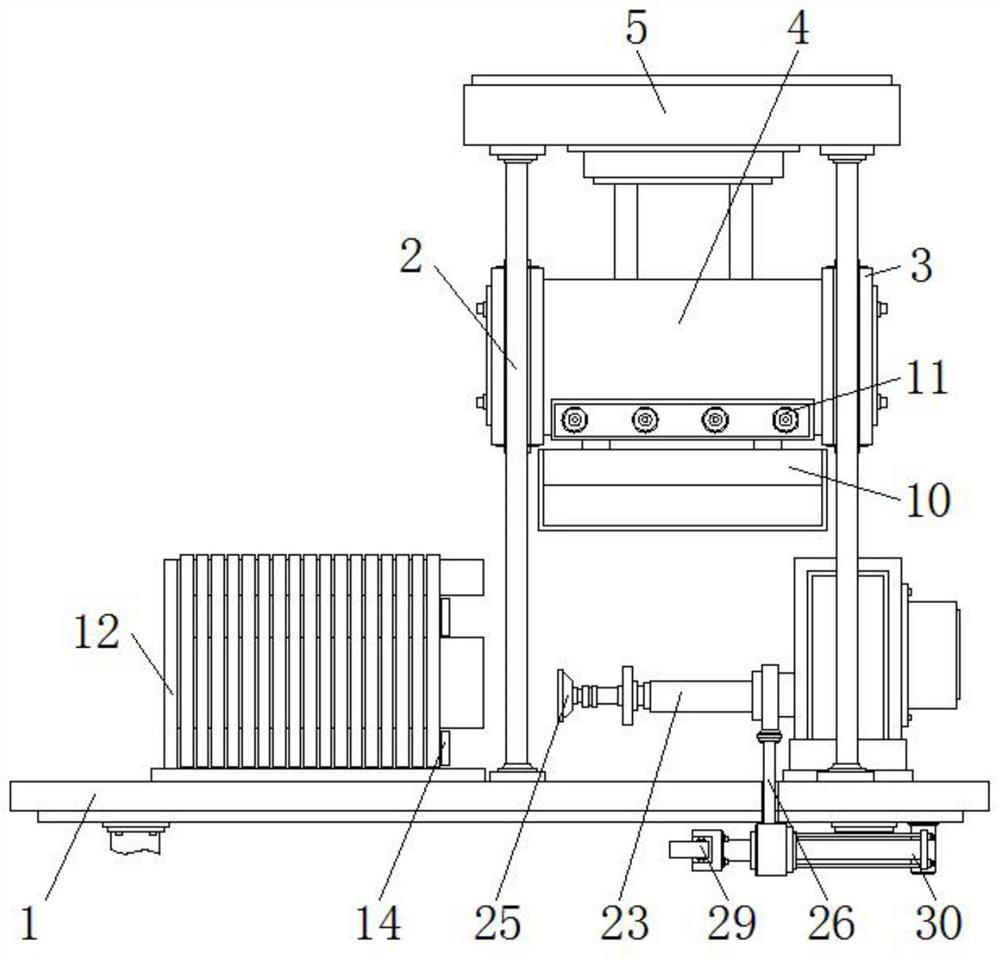

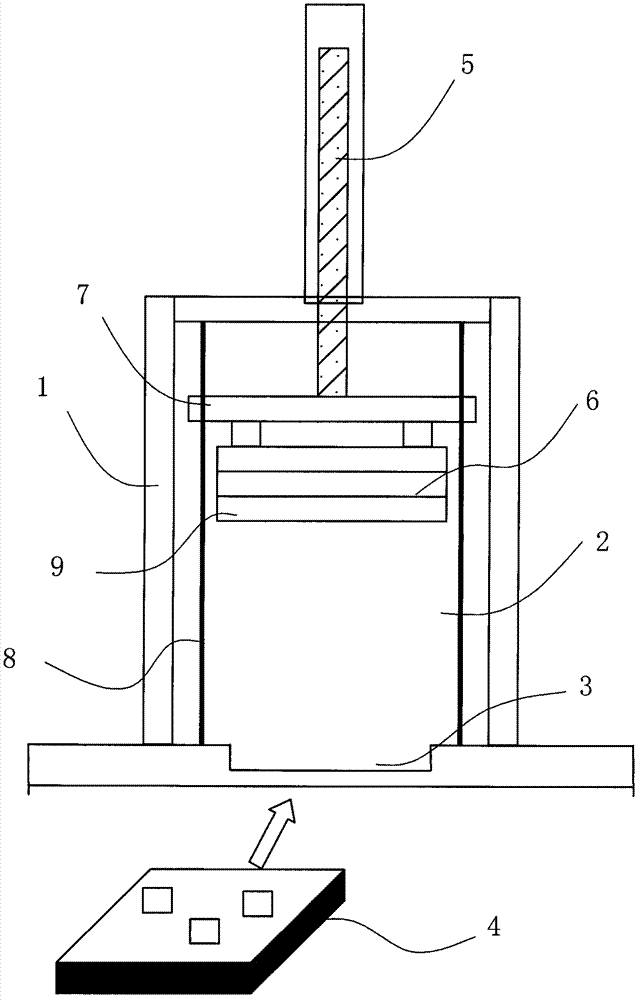

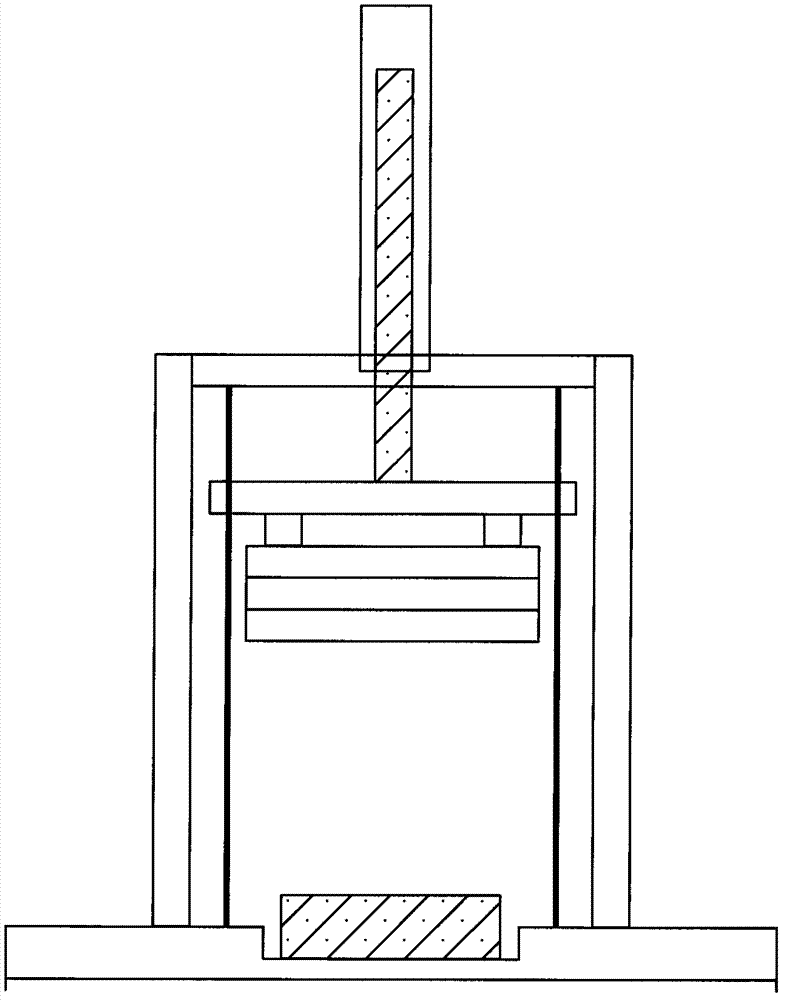

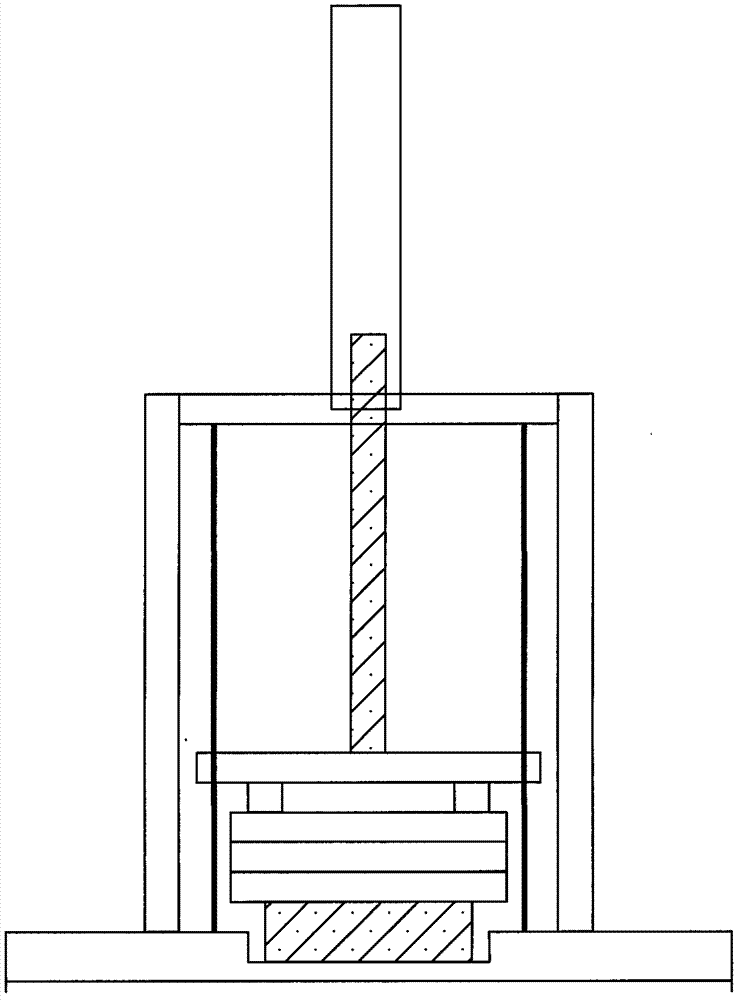

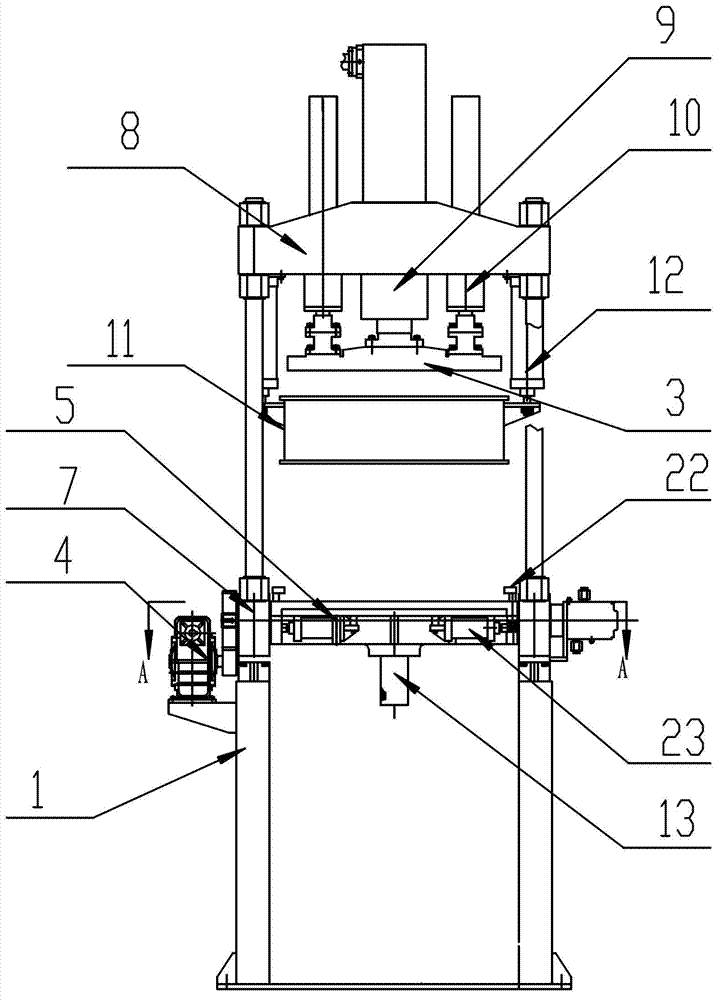

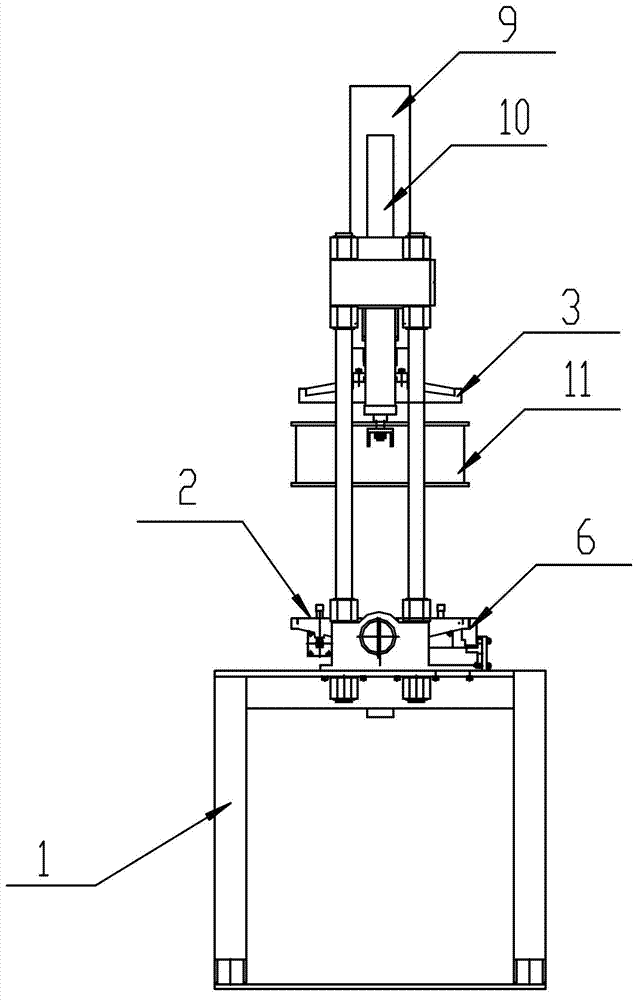

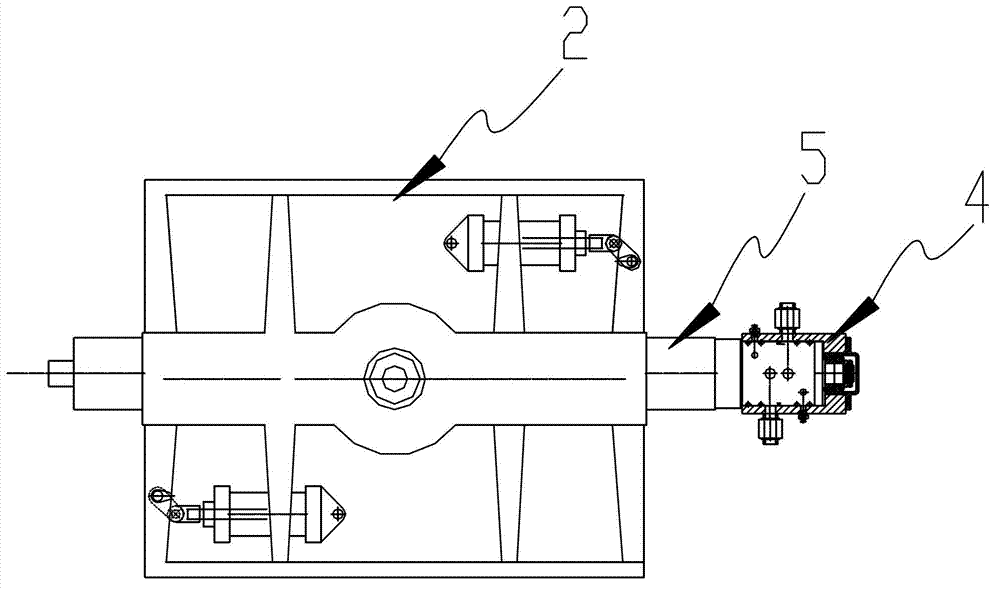

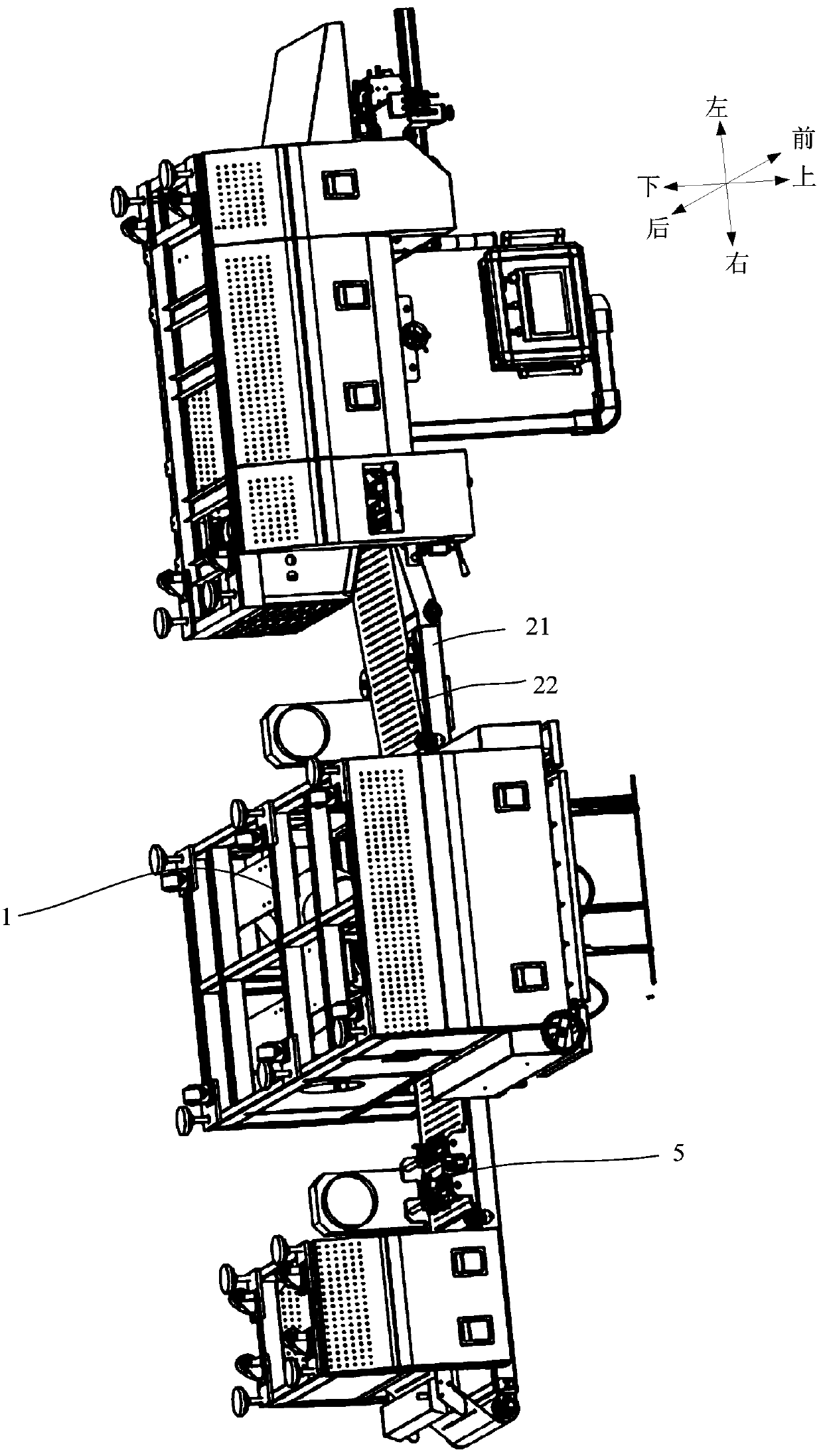

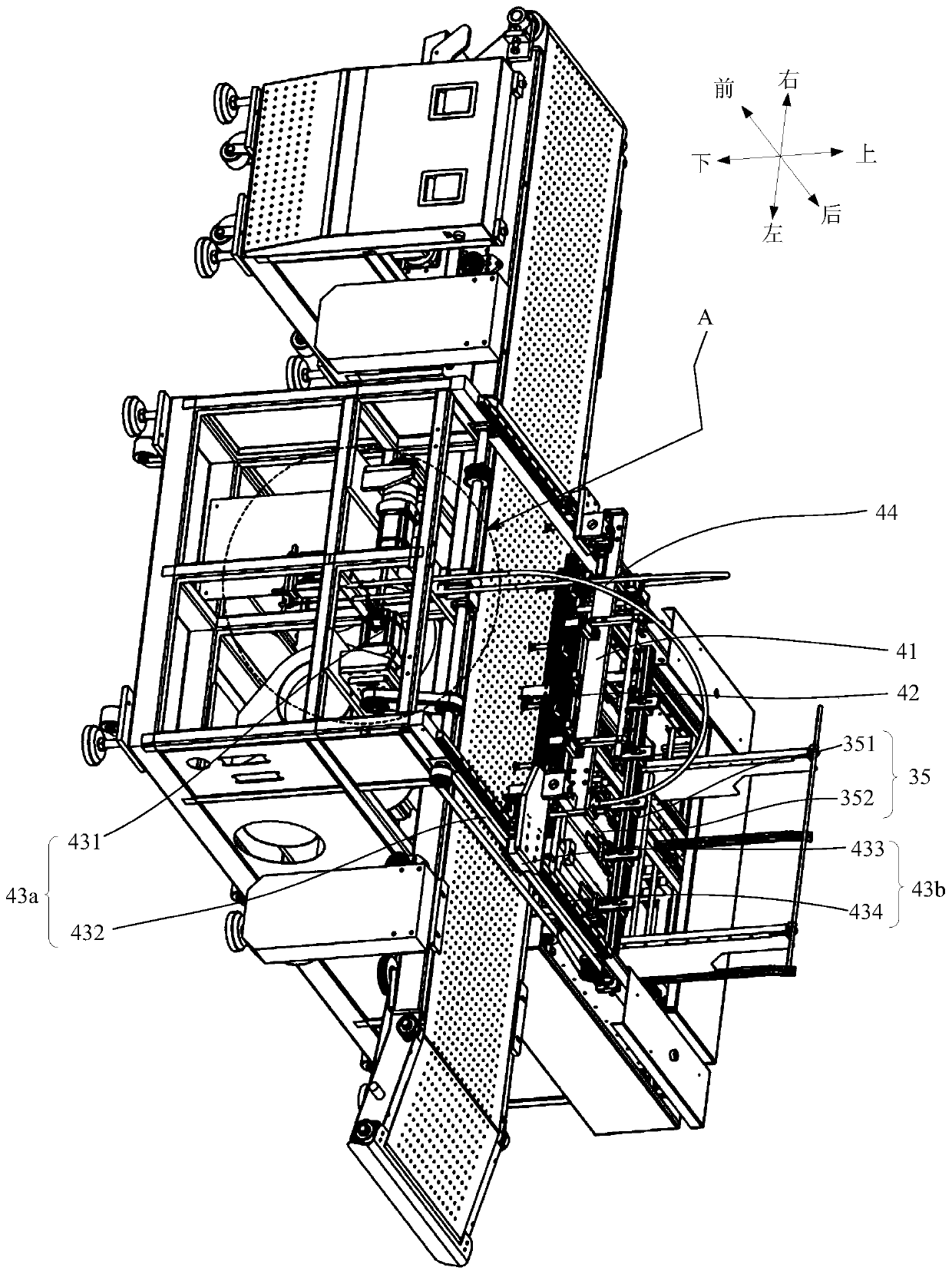

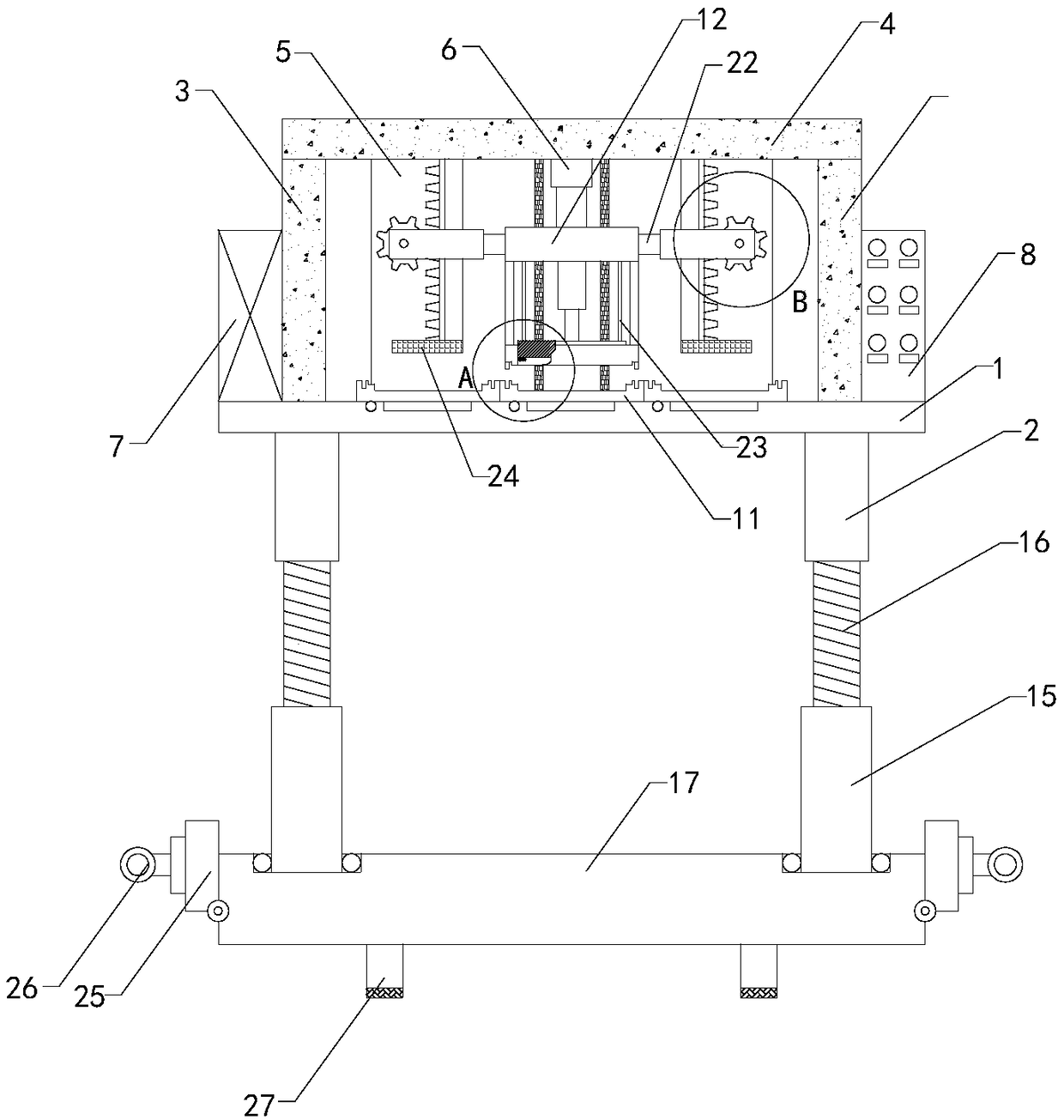

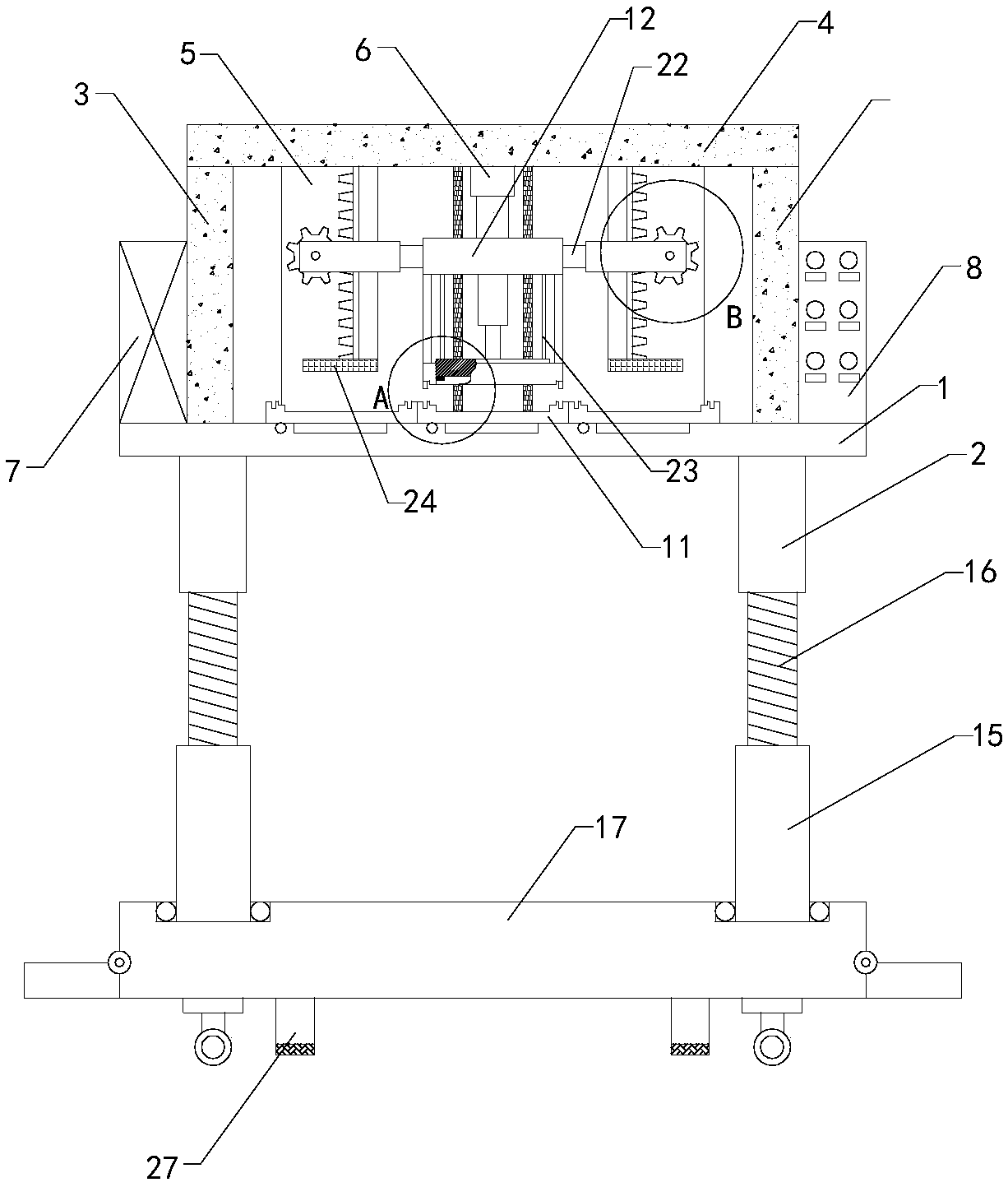

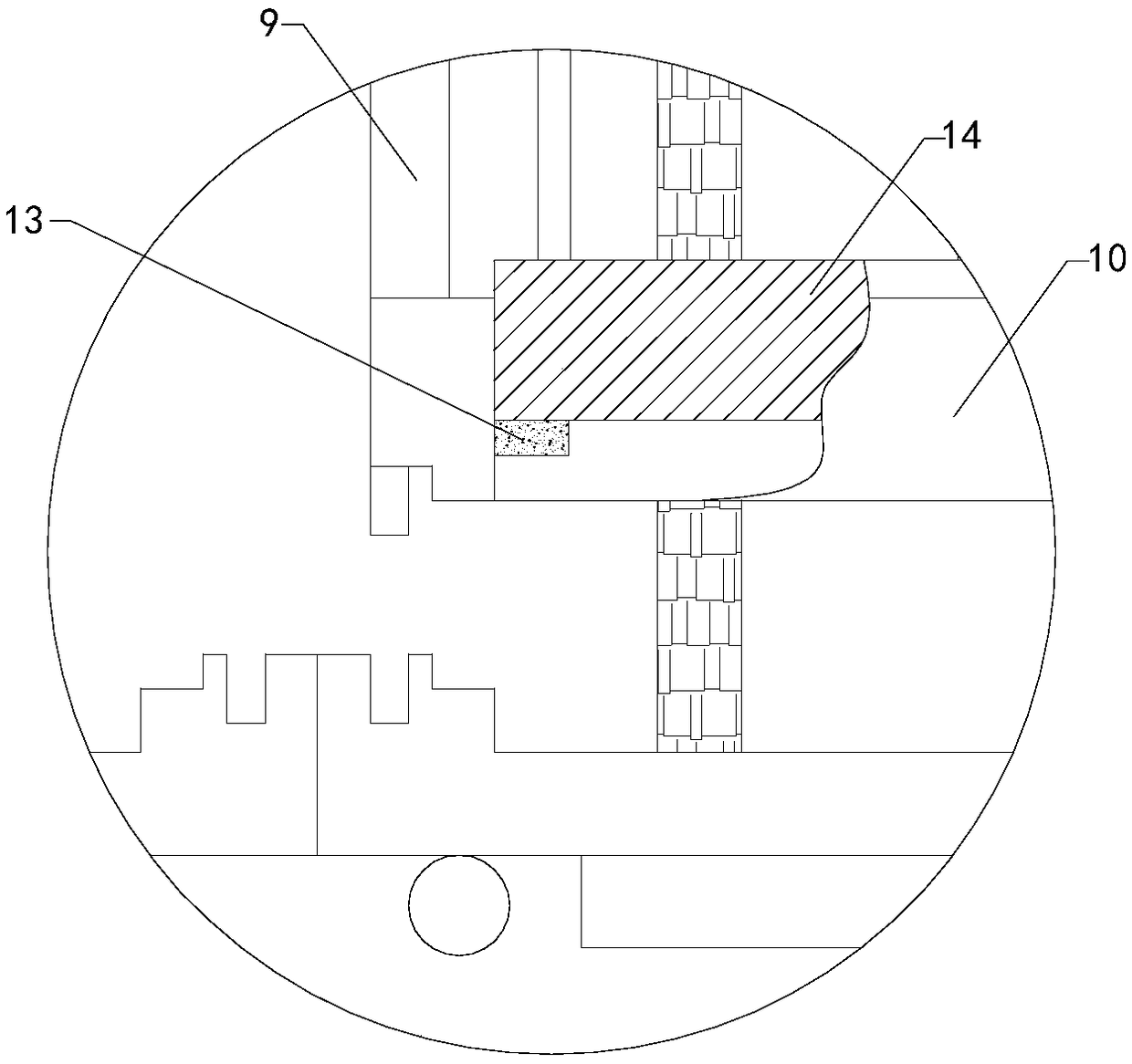

Horizontal mould parting static pressure molding machine and static pressure molding machine set capable of achieving automatic mould assembly

ActiveCN102847885ARealize automatic separationContinuous productionMoulding machinesMolding machineElectric control

The invention discloses a horizontal mould parting static pressure molding machine and a static pressure molding machine set capable of achieving automatic mould assembly. The machine set comprises a first horizontal mould parting static pressure molding machine used for manufacturing a sand discharging mould, a second horizontal mould parting static pressure molding machine used for manufacturing a sand feeding mould and a sand mould transporting device. Each molding machine comprises a machine frame, a horizontal working platform and an upper movable press plate, and the horizontal working platform is provided with an overturning mechanism capable of driving the horizontal working platform to overturn through 180 degrees. The sand mould transporting device passes through the below of the first horizontal mould parting static pressure molding machine and the below of the second horizontal mould parting static pressure molding machine and comprises a support frame, a sand mould support plate and a walking mechanism. A feeding mechanism capable of alternatively filling sand materials into sand boxes of the molding machines is arranged between the first horizontal mould parting static pressure molding machine and the second horizontal mould parting static pressure molding machine. The molding machines and the machine set are capable of achieving the aim of automatically and continuously producing sand moulds by means of the corresponding electric control systems and hydraulic systems.

Owner:孟昭贵

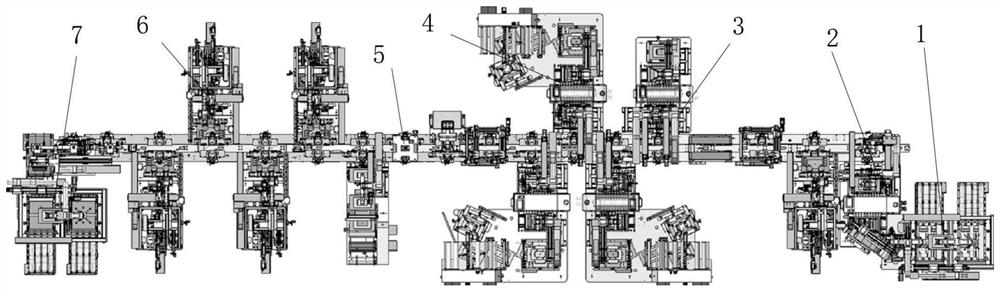

Automatic bonding forming machine for enclosing strip

PendingCN110641073ARealize automatic fitIncrease productivityBox making operationsPaper-makingAdhesiveMolding machine

The invention discloses an automatic bonding forming machine for an enclosing strip. The automatic bonding forming machine comprises a machine base, a surface paper conveying device, a grey board conveying device and a positioning transferring device, and a positioning pasting station and a grey board feeding station which are sequentially distributed in the front-back direction are formed on themachine base. According to the automatic bonding forming machine, the surface paper conveying device is used for conveying surface paper coated with an adhesive to the positioning pasting station, thegrey board conveying device is used for conveying a grey board to the grey board feeding station, the positioning transferring device is arranged on the machine base and is used for transferring thegrey board from the grey board feeding station to the positioning pasting station and adjusting the position of the grey board so as to enable the grey board and the surface paper to be bonded oppositely, and therefore the grey board and the surface paper are automatically bonded, and the production efficiency of products is improved.

Owner:SINOTECHO WUHAN INTELLIGENT TECH CO LTD

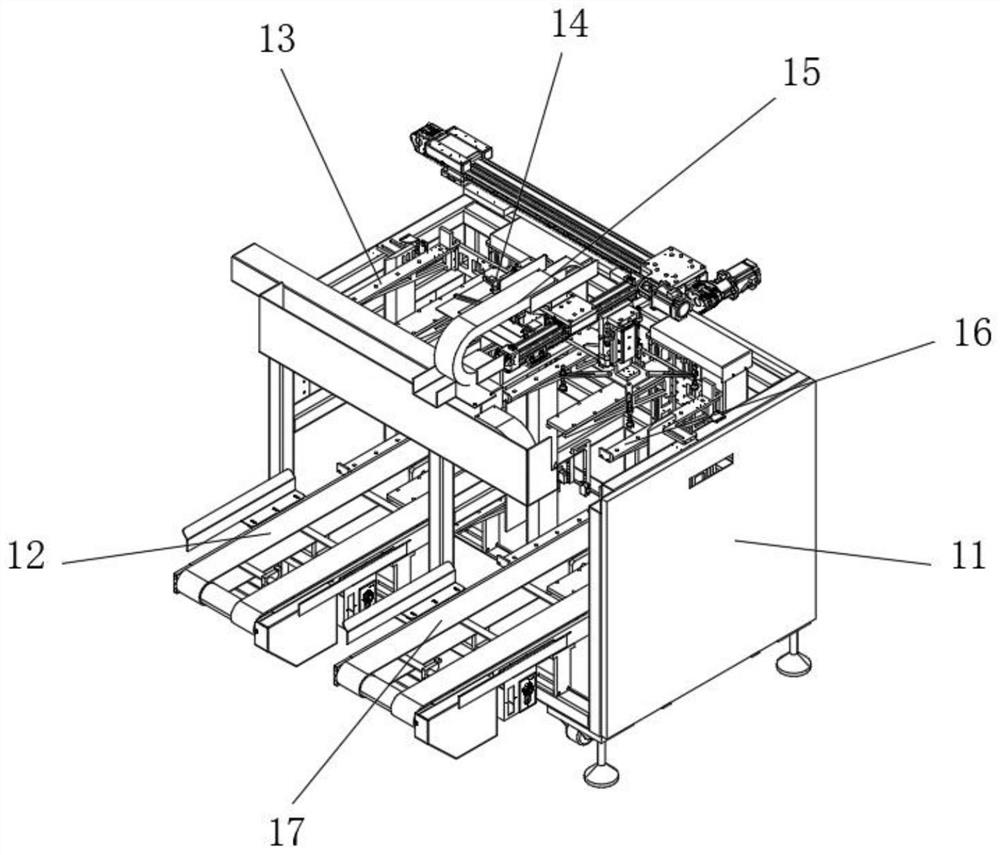

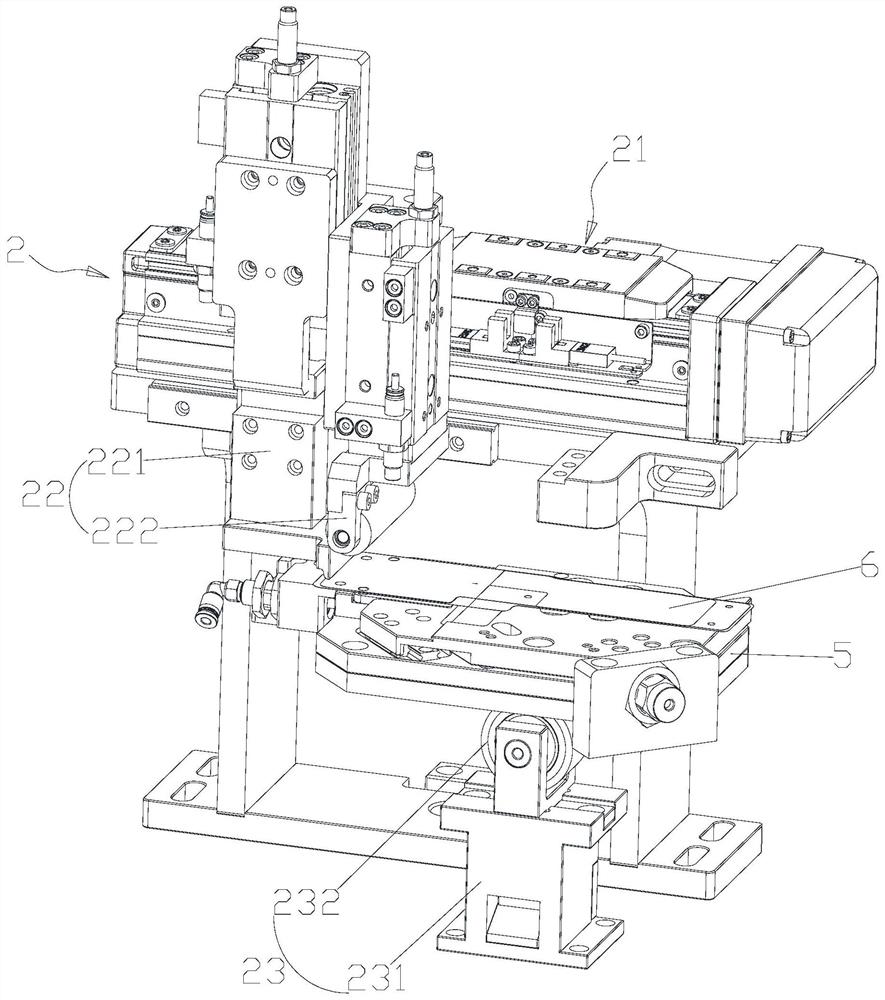

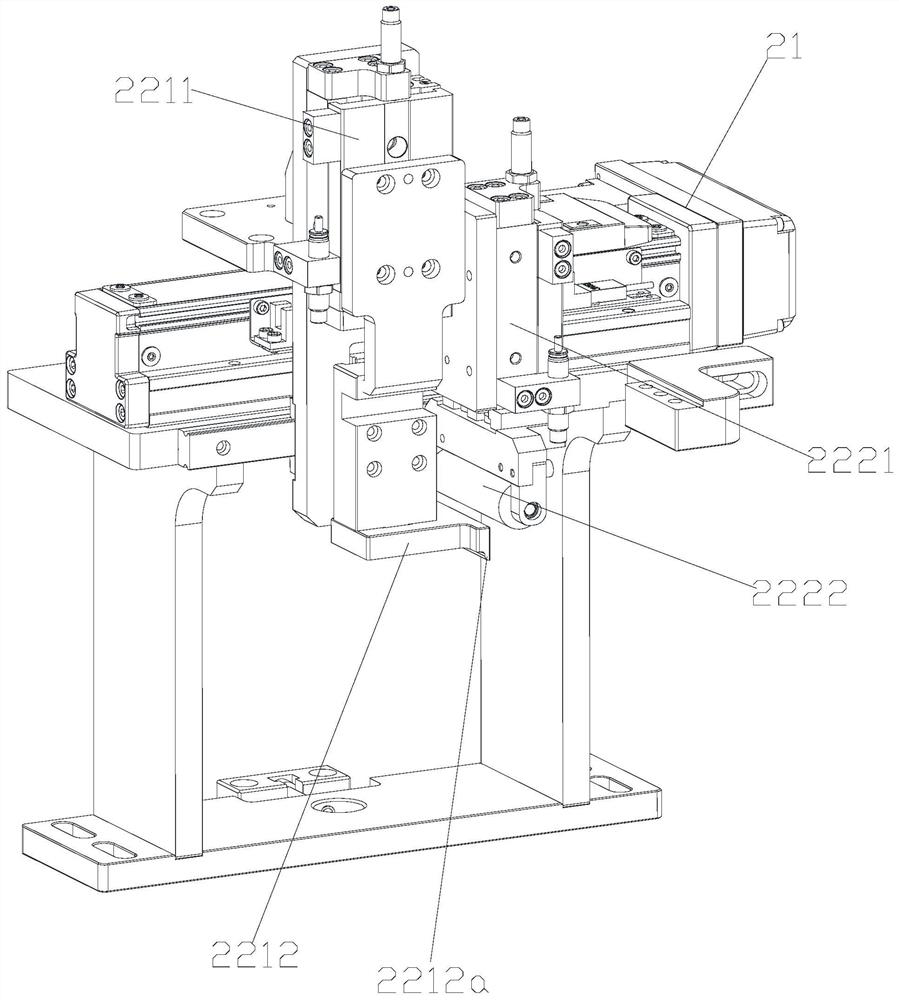

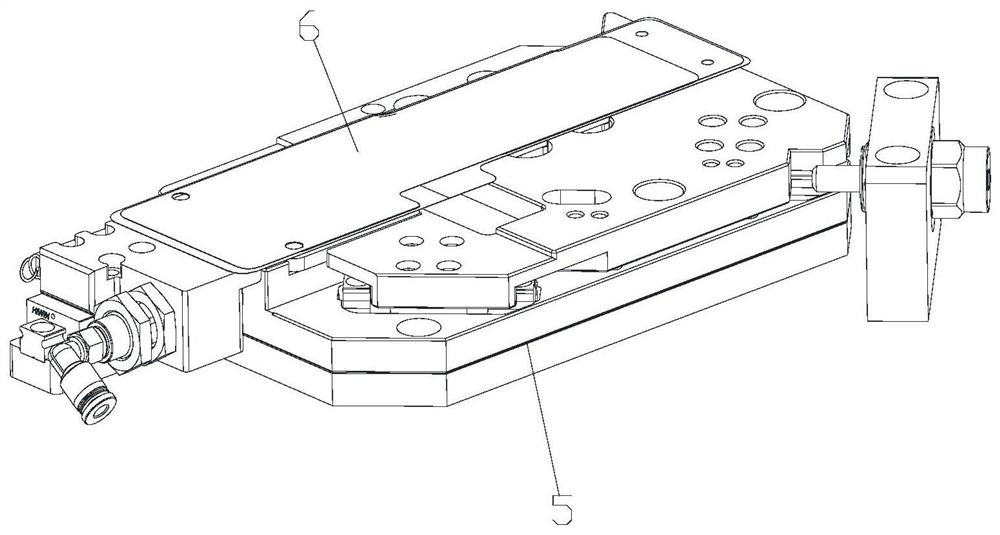

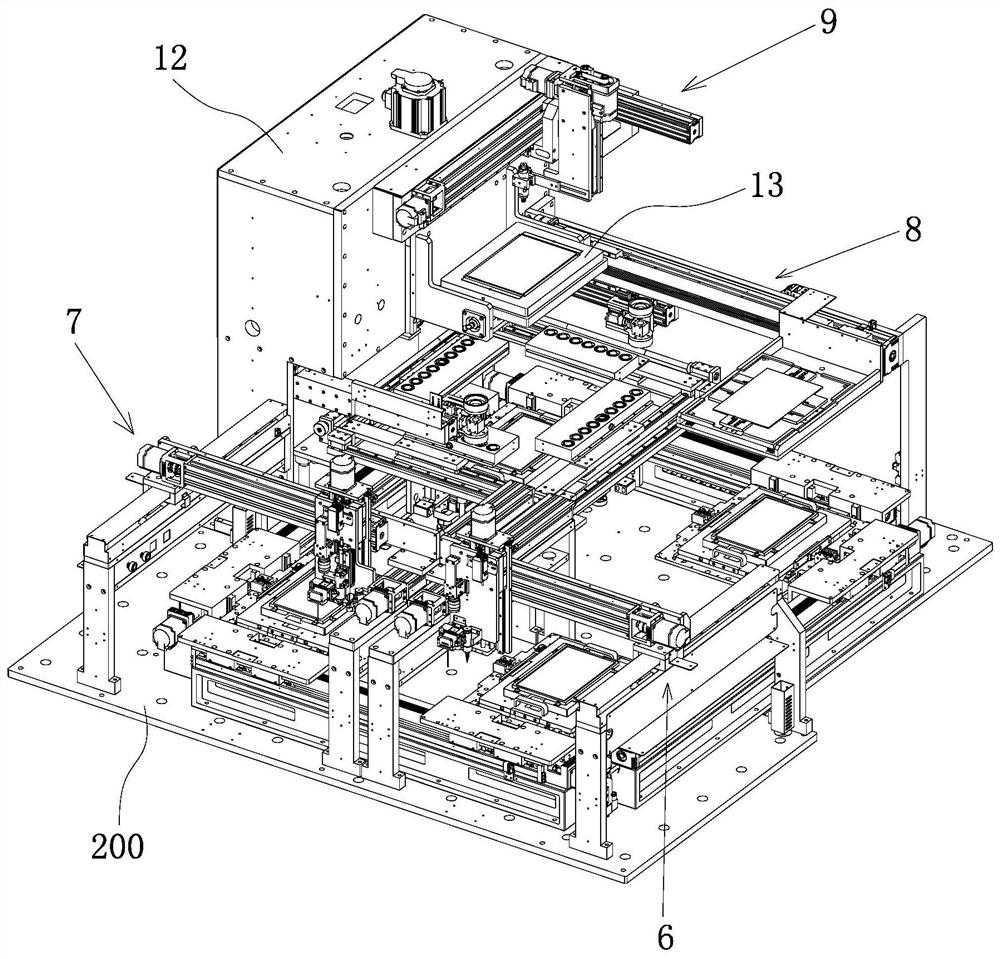

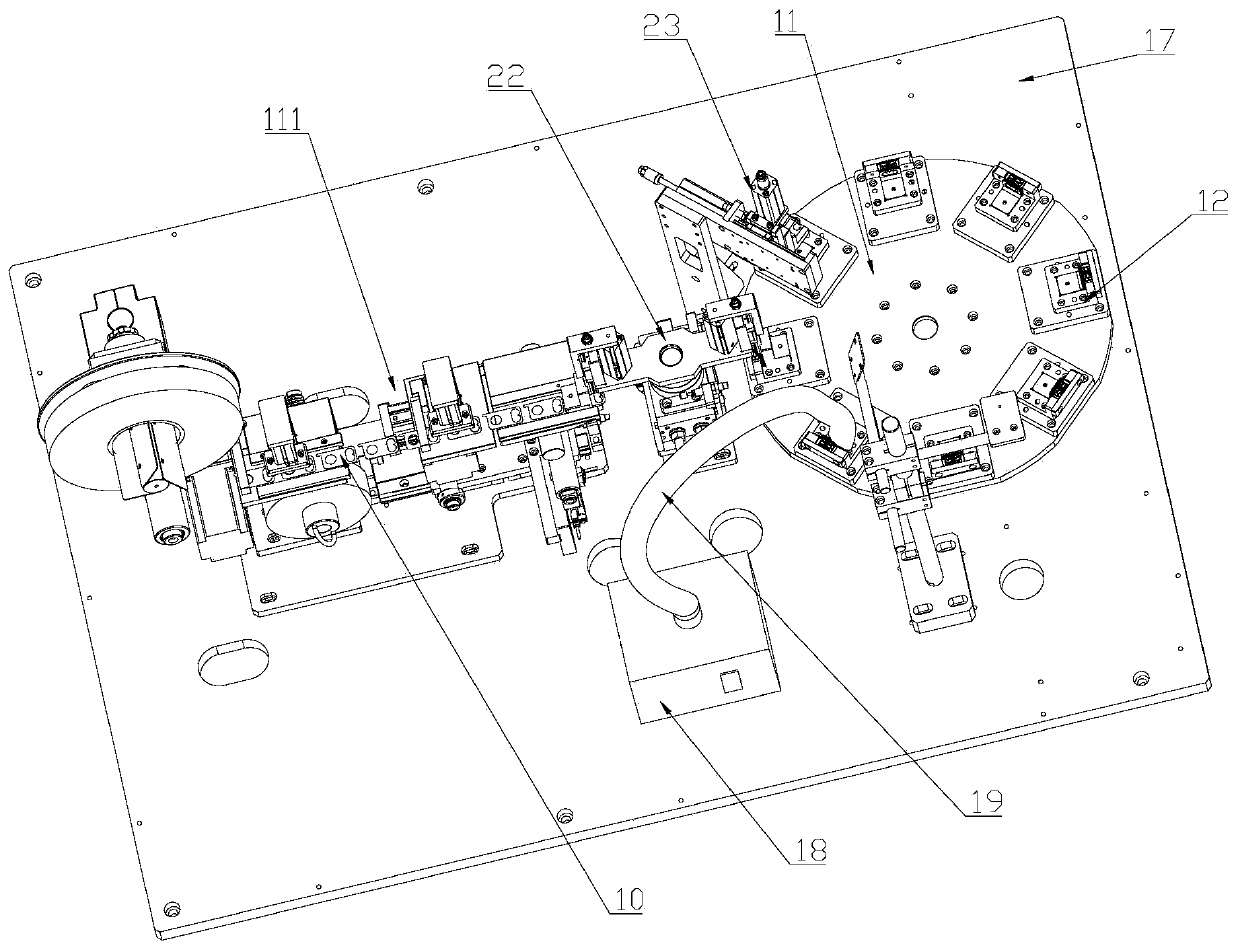

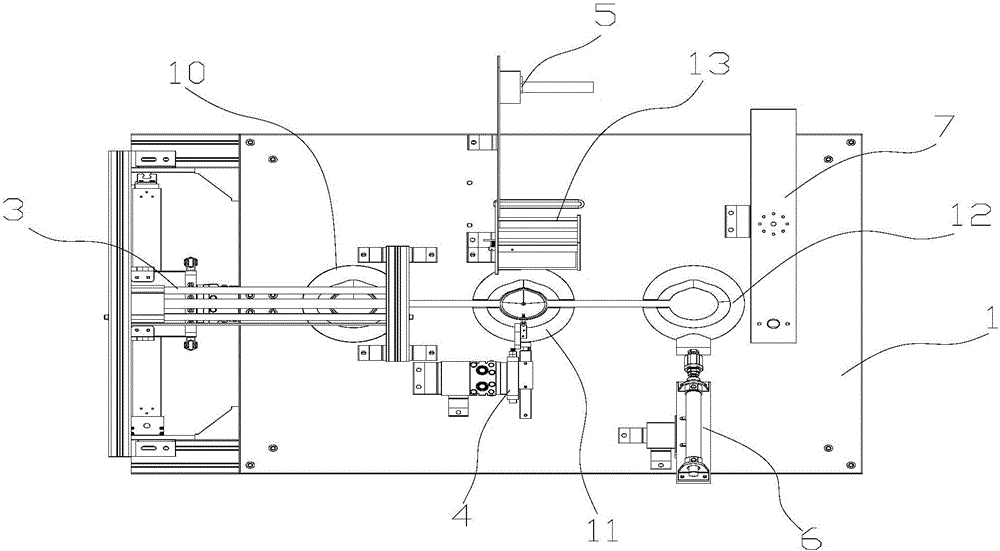

Automatic attaching machine for mobile phone auxiliary materials and operating method of automatic attaching machine

InactiveCN107725552AHigh precisionRealize automatic fitMaterial gluingEngineeringMechanical engineering

The invention discloses an automatic attaching machine for mobile phone auxiliary materials and an operating method of the automatic attaching machine. The automatic attaching machine comprises a machine frame, a feeding and discharging mechanism, an auxiliary material stripping mechanism and an auxiliary material attaching mechanism. The auxiliary material attaching mechanism comprises is fixedlymounted in the middle of the surface of the machine frame and used for attaching auxiliary materials of products and comprises an execution mechanism, a suction mechanism and a positioning mechanismwhich are matched mutually. The auxiliary material stripping mechanism is fixedly mounted on the rear portion of the surface of the machine frame and used for stripping auxiliary materials from an auxiliary material belt, and then the stripped auxiliary materials are sucked by the suction mechanism. The feeding and discharging mechanism is mounted on the front portion of the surface of the machineframe in a penetrating mode and used for conveying the to-be-attached auxiliary materials to an execution station of the execution mechanism and conveying the products attached with the auxiliary materials out of the machine frame. The auxiliary material attaching mechanism, the auxiliary material stripping mechanism and the feeding and discharging mechanism are all controlled through a program in a controller for processing, and thus the mobile phone auxiliary materials are automatically attached; and in this way, the mobile phone auxiliary materials can be attached automatically, labor is saved, and attaching is accurate.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

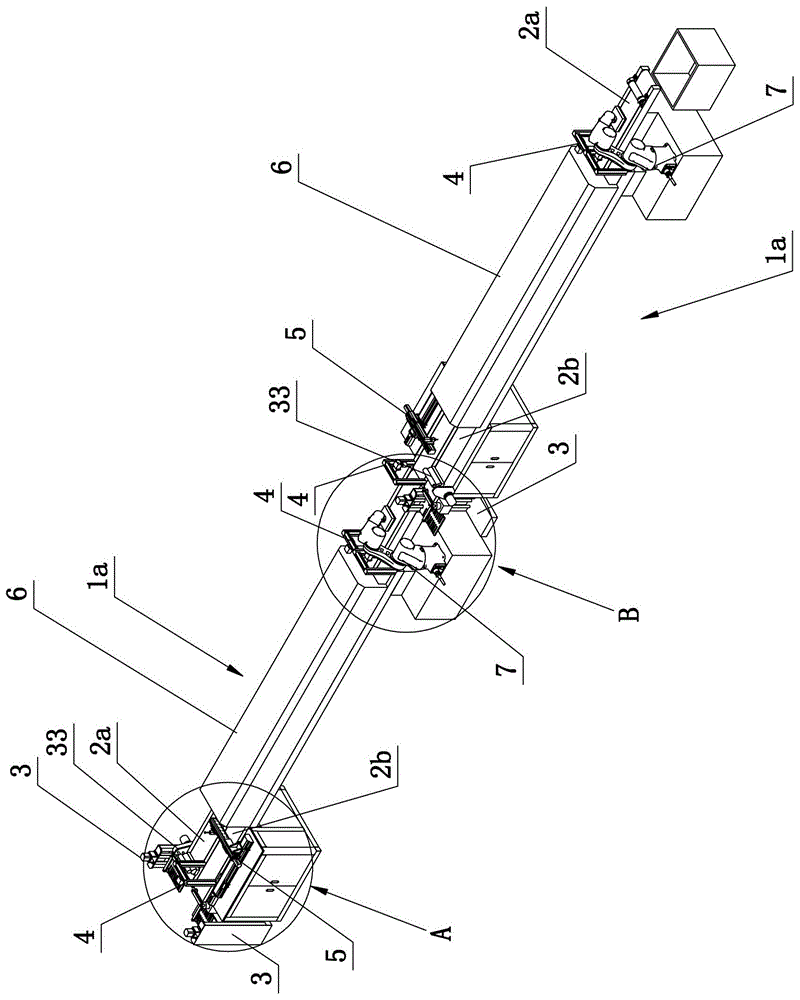

Automatic nylon fabric laminating system

The invention relates to an automatic nylon fabric laminating system. The system comprises two nylon fabric unwinding devices, two conveying devices, a laminating device, a rubber-clamping unwinding and taking device and a winding device, wherein the two nylon fabric unwinding devices comprise a nylon fabric unwinding device A and a nylon fabric unwinding device B, the two conveying devices comprise a conveying device A and a conveying device B, the nylon fabric unwinding device A, the nylon fabric unwinding device B, the conveying device B and the winding device are sequentially distributed, the conveying device B is located at the upper end of the nylon fabric unwinding device B, and the laminating device and the rubber-clamping unwinding and taking device are sequentially arranged at the upper end of the conveying device B in the material conveying direction. The system has the advantages as follows: by the aid of the system, automatic nylon fabric lamination can be realized, worker consumption is reduced, and labor intensity of workers is reduced.

Owner:DOUBLE COIN GRP JIANGSU TIRE

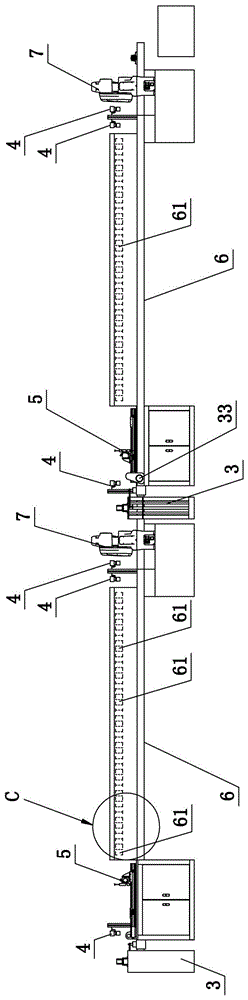

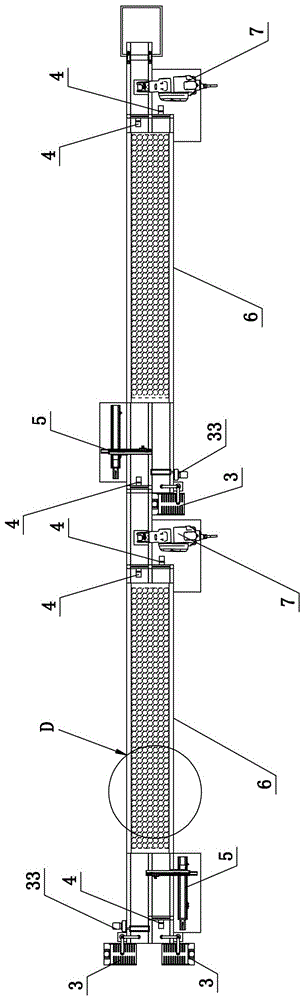

Vehicle-mounted integrated line complete equipment

The invention discloses vehicle-mounted integrated line complete equipment. A processing assembly line system comprises an automatic light guide plate feeding device, a light guide plate attaching device is arranged at one side of the automatic light guide plate feeding device, and a lower diffusion attaching device is arranged at the side, away from the automatic light guide plate feeding device, of the light guide plate attaching device. The side, away from the light guide plate attaching device, of the lower diffusion attaching device is provided with an upper brightness enhancement attaching device, the side, away from the lower diffusion attaching device, of the upper brightness enhancement attaching device is provided with a rubber frame pressing device, and the side, away from the upper brightness enhancement attaching device, of the rubber frame pressing device is provided with a black and white rubber attaching device. The light guide plate attaching device can detect whether the direction of a light guide plate meets the attaching requirement or not, if not, material discarding treatment is carried out, rapid feeding and oblique insertion attaching of the light guide plate are achieved, when materials need to be replaced through the lower diffusion attaching device, a baffle can be rapidly put down to supplement a sheet material box, the rapid material replacing requirement is met, and diffused lamination of a display screen is realized.

Owner:ANHUI ZHONGXIAN INTELLIGENT ROBOT CO LTD

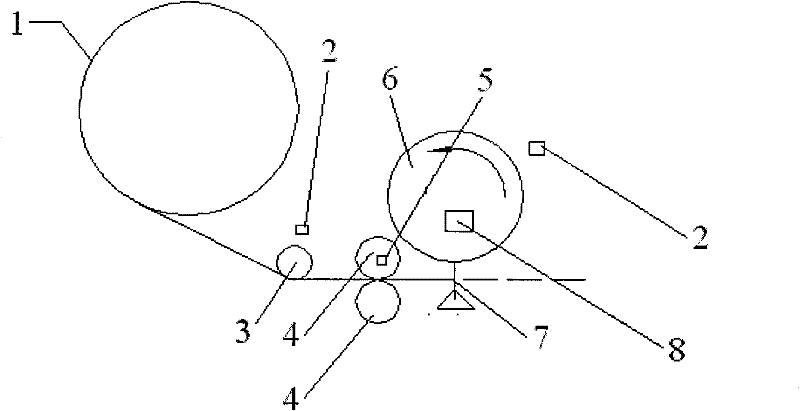

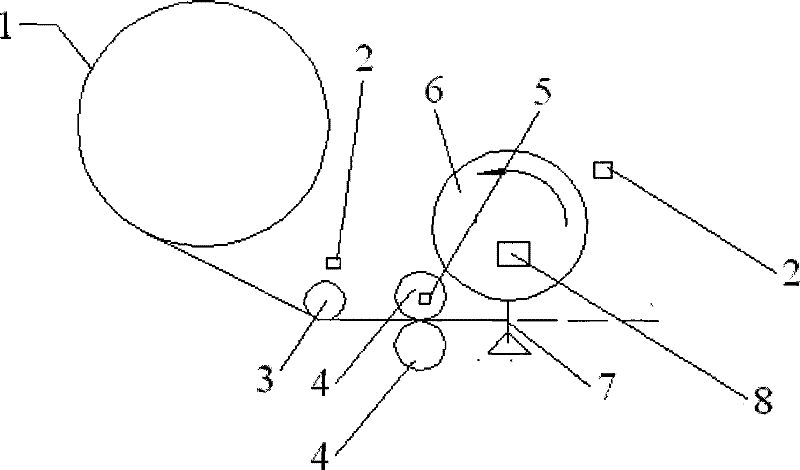

Method and device for manufacturing and locating window patching packaging material

InactiveCN102673021ADoes not affect production speedRealize automatic fitContainer making machinerySignal onServomotor

The invention relates to a method and a device for manufacturing and locating a window patching packaging material. A photoelectric sensor is used to detect a locating mark signal on a thin film, the rotation speed signal of a cutting-off roll is obtained by encoder detection, the photoelectric sensor is adopted to detect a cutter position signal, the signals are subjected to signal comparison and error calculation by an operation processor so as to control a servo motor, the servo motor controls a feed roll to deliver the thin film to the cutting-off roll, and the thin film is cut by a cutter on the cutting-off roll. The device comprises a guide roll, the photoelectric sensor, the feed roll, the servo motor, the operation processor, a touch screen, the cutting-off roll, the cutter and the encoder. Compared with prior arts, the invention realizes automatic bonding between a windowed film and a single-sheet windowed paper box, achieves accurate alignment, automatically corrects cutting-off position deviation without influencing the original production speed of the window patching machine, accurately locates and bonds the windowed film and the single-sheet windowed box, and keeps accurate locating of image / text positions on the windowed film.

Owner:SHANGHAI ZIDAN PRINTING

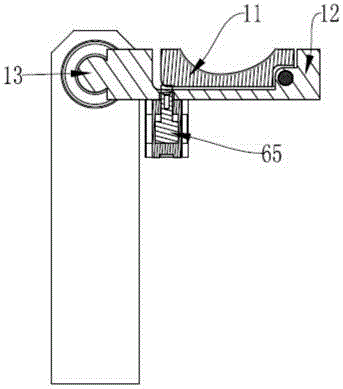

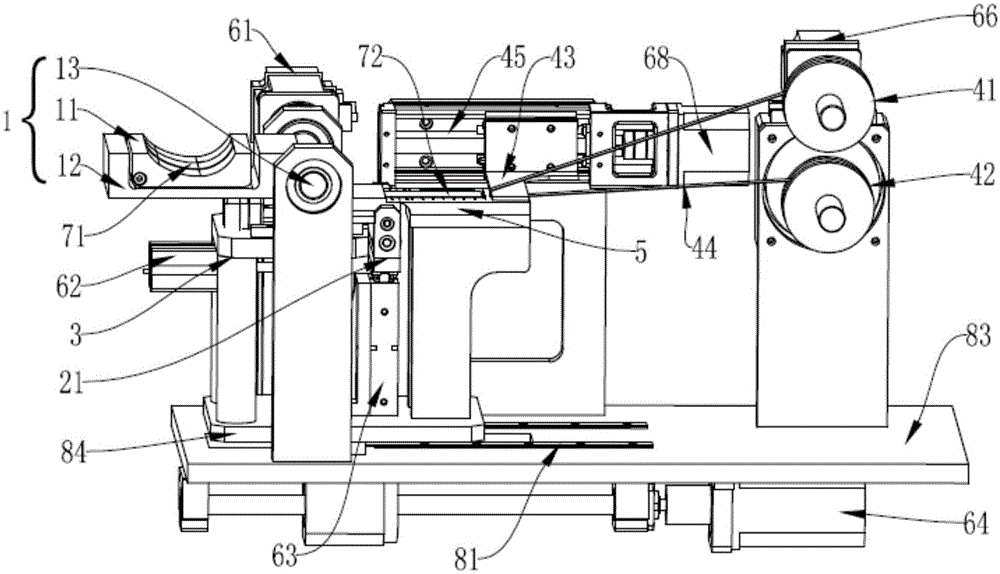

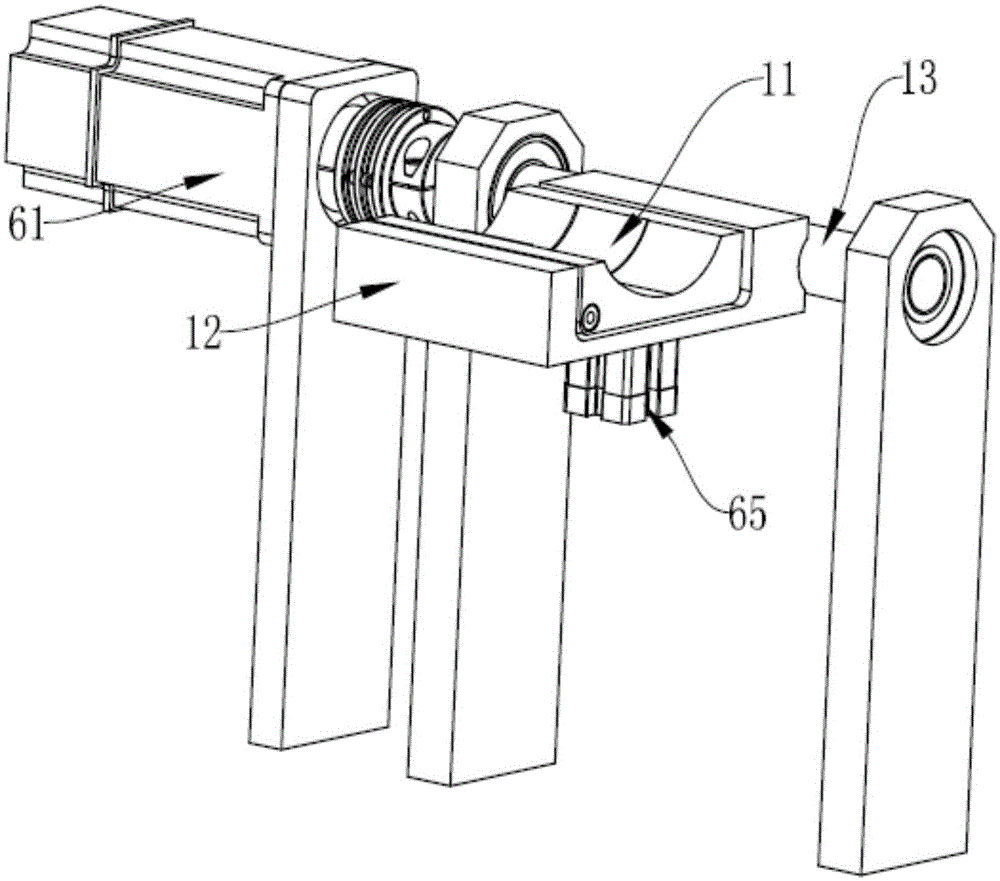

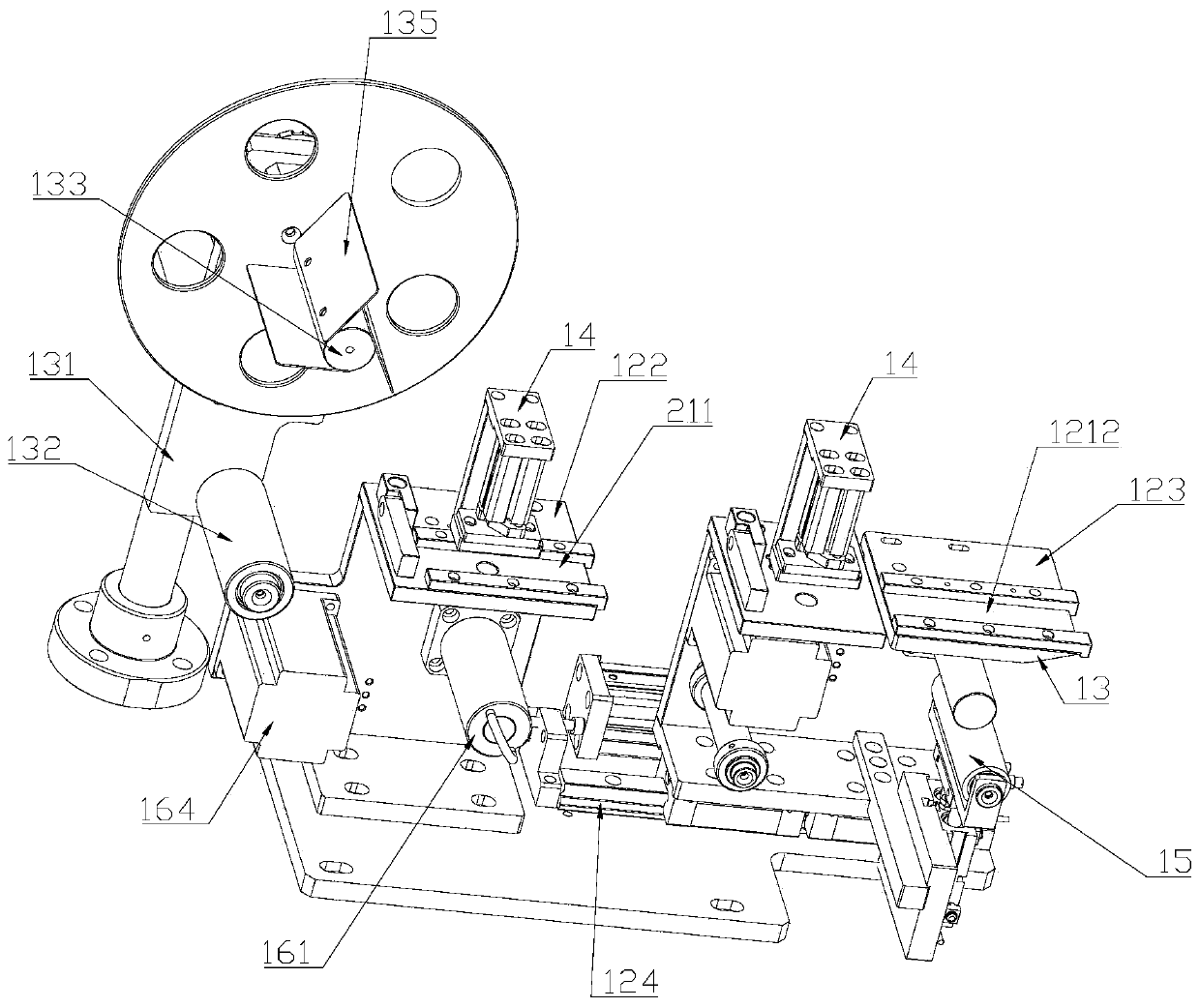

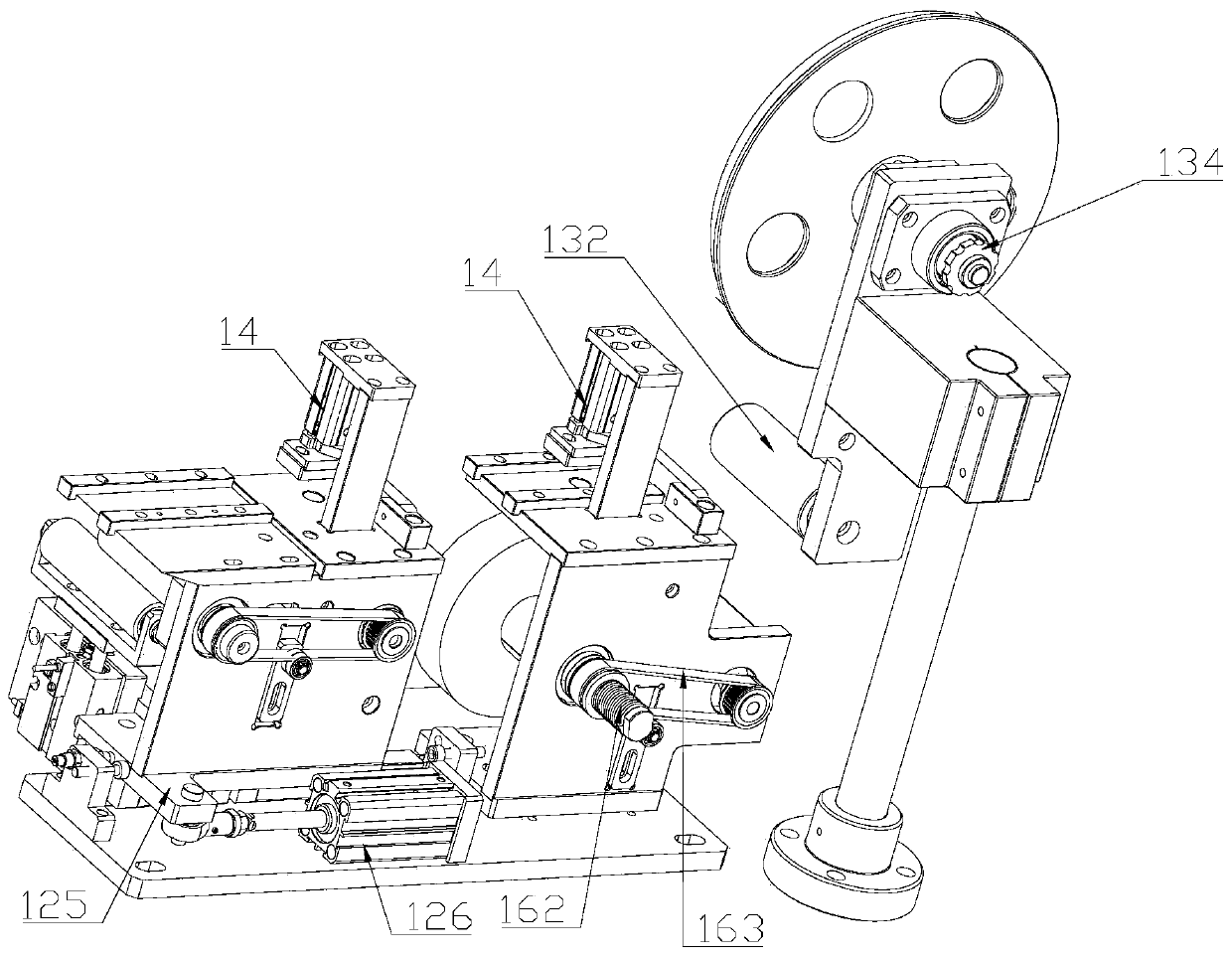

Rapid film pasting mechanism and automatic pasting all-in-one machine using same

InactiveCN112810882ARealize automatic fitSave human effortWrapping material feeding apparatusPhysicsFilm material

The invention discloses a rapid film pasting mechanism which comprises a linear driving module, a positioning jig, a pasting module and a supporting module. The pasting module is installed on the linear driving module, the supporting module is installed under the positioning jig, the positioning jig is configured to place and fix workpieces, and the workpieces comprise a film material and a metal part. The film material is arranged above the metal part in a covering mode, the pasting module is configured to press the workpieces placed on the positioning jig so that the film material can be pasted on the upper surface of the metal part, and the supporting module is matched with the pasting module and is configured to support the positioning jig when the pasting module performs film pasting work. And the linear driving module is configured to adjust the position of the pasting module. The invention further discloses an automatic pasting all-in-one machine which comprises the rapid film pasting mechanism and further comprises a rack, a feeding mechanism and a rotating disc mechanism. According to the rapid film pasting mechanism, automatic pasting of the film material and the metal part can be achieved, efficiency and precision are high, and the large-batch production requirements can be met.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

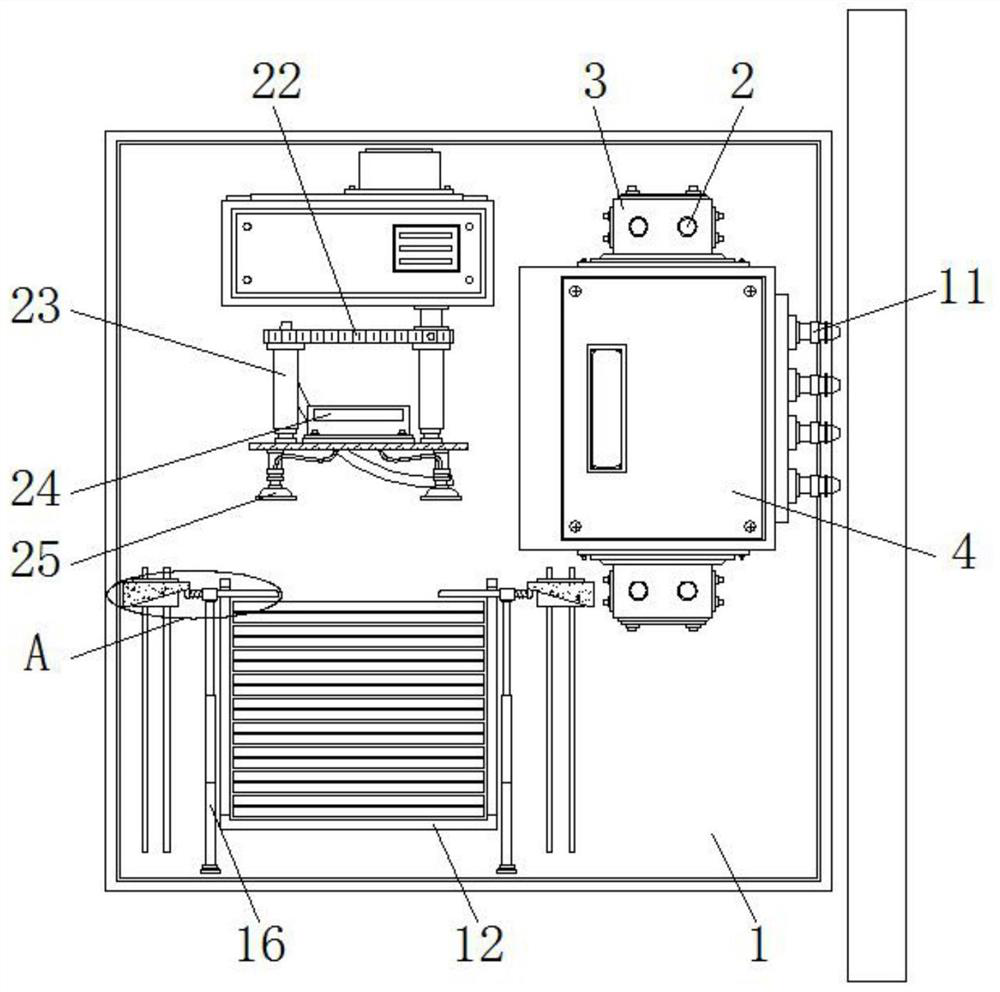

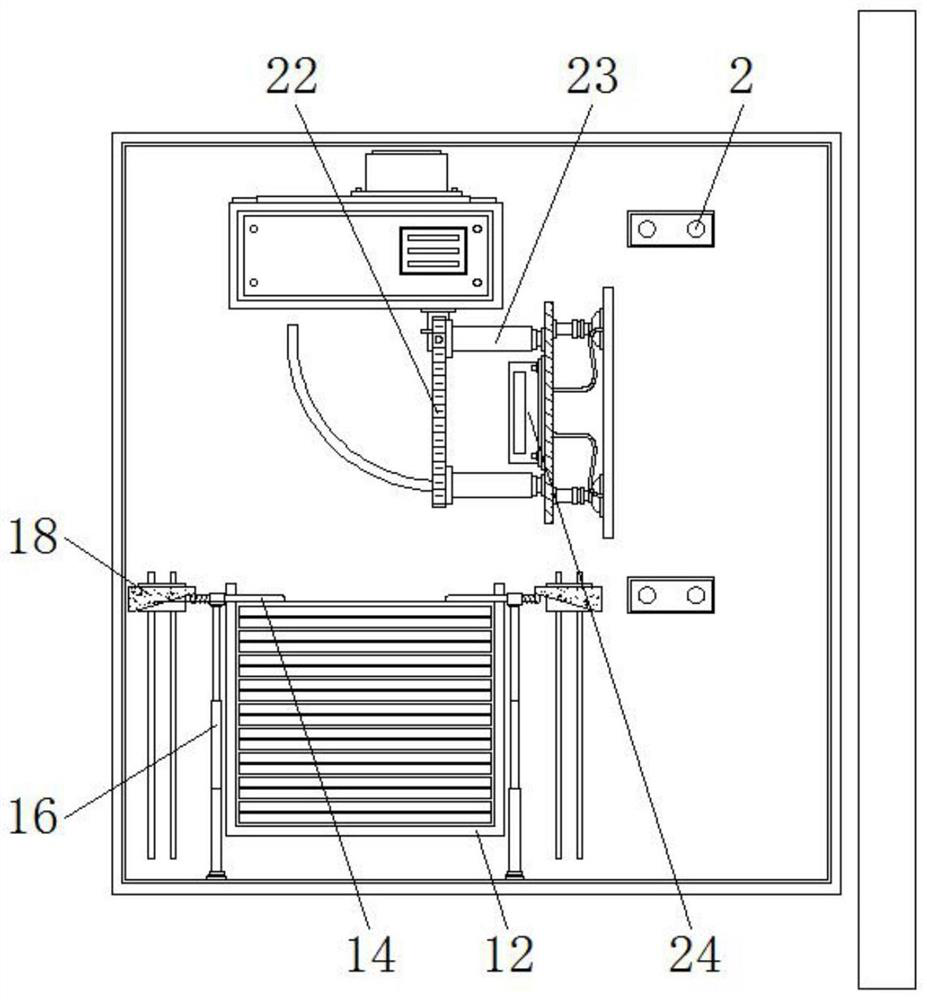

Carrier positioning method based on sensor technology and positioner

InactiveCN106092174APrecise positioningHigh precisionMeasurement apparatus componentsWheel-rims surveying/measuringThree-dimensional spaceEconomic benefits

The invention discloses a carrier positioning method based on sensor technology and a positioned. Compared with a conventional automatic probe carrier positioner, the positioner is characterized in that a probe carrier (flexible) automatically attaches to a tire tread, through sensors symmetrically installed on the two sides of a probe carrier and a high-precision servo rotary mechanism, and has the advantages that a wider wheel diameter application scope is ensured, and attaching pressure of the probe carrier is uniform and adjustable. A servo system is employed, automation level is higher, and the positioner can replace a manual positioning probe carrier to conduct wheel flaw detection work. Efficiency for flaw detection of various wheels can be improved, and the economic benefit is high. A high-precision servo motor is ensured, the positioning precision is high, repeatability is high, and flaw detection accuracy is ensured. A multi-shaft servo motor is employed to realize adjustment of any probe attitude in a three-dimensional space. Compared with a conventional automatic probe carrier positioner, the positioner is more suitable for complex underbody spatial environment of trains of various models to conduct probe positioning.

Owner:BEIJING LEAD TIME SCI & TECH

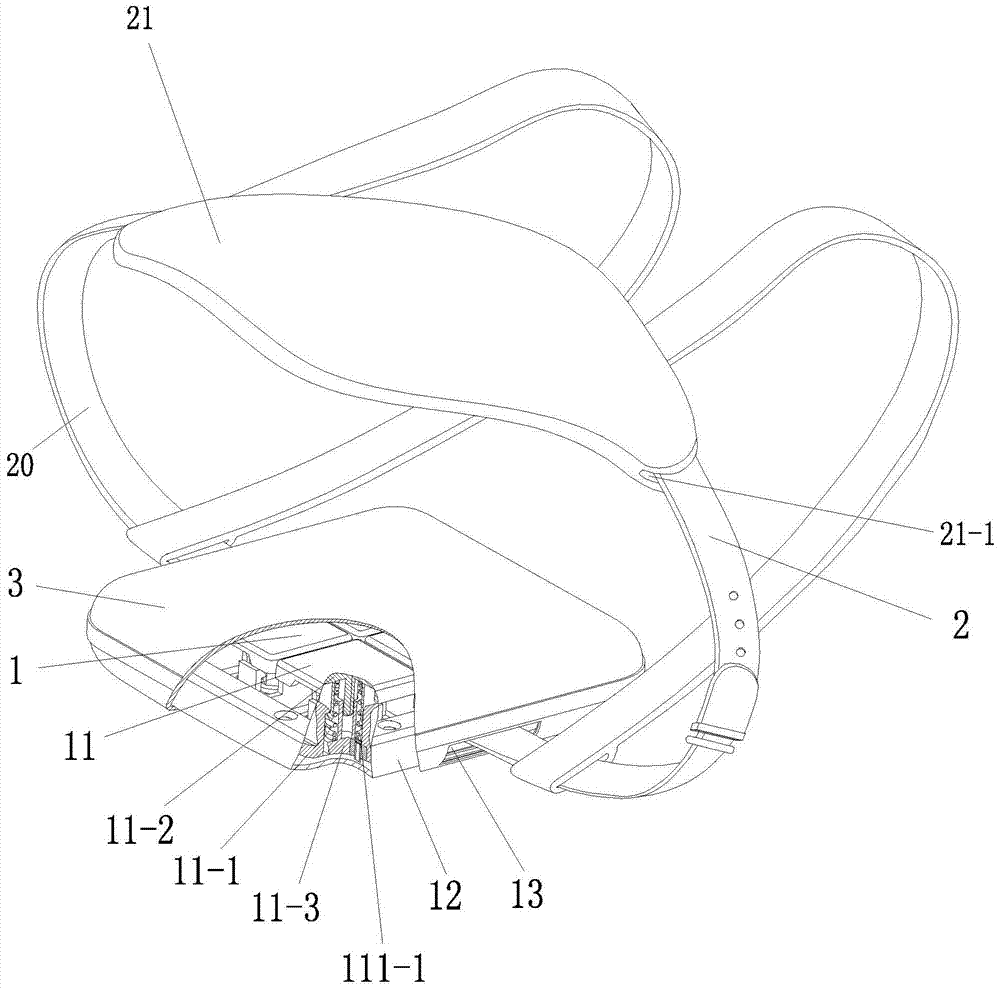

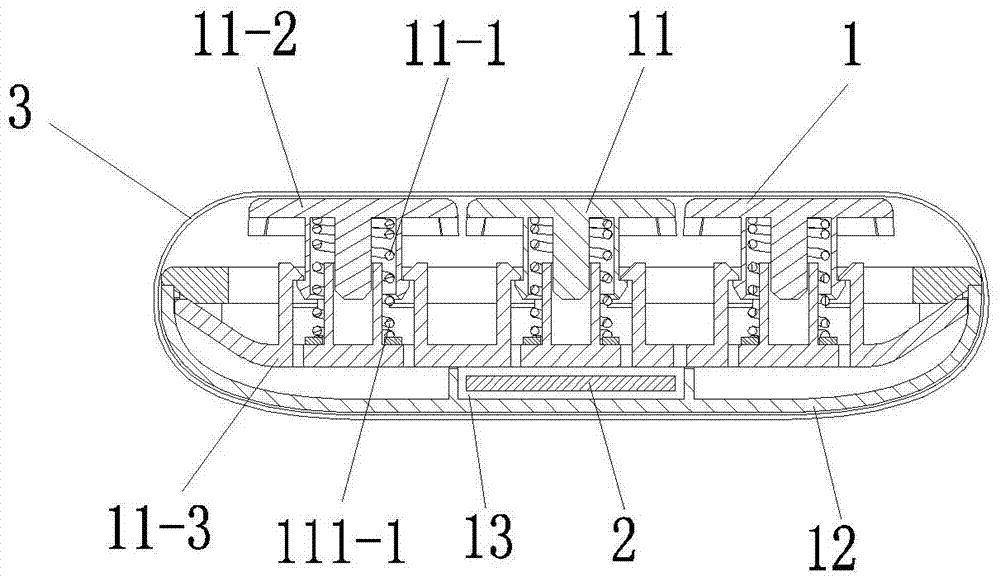

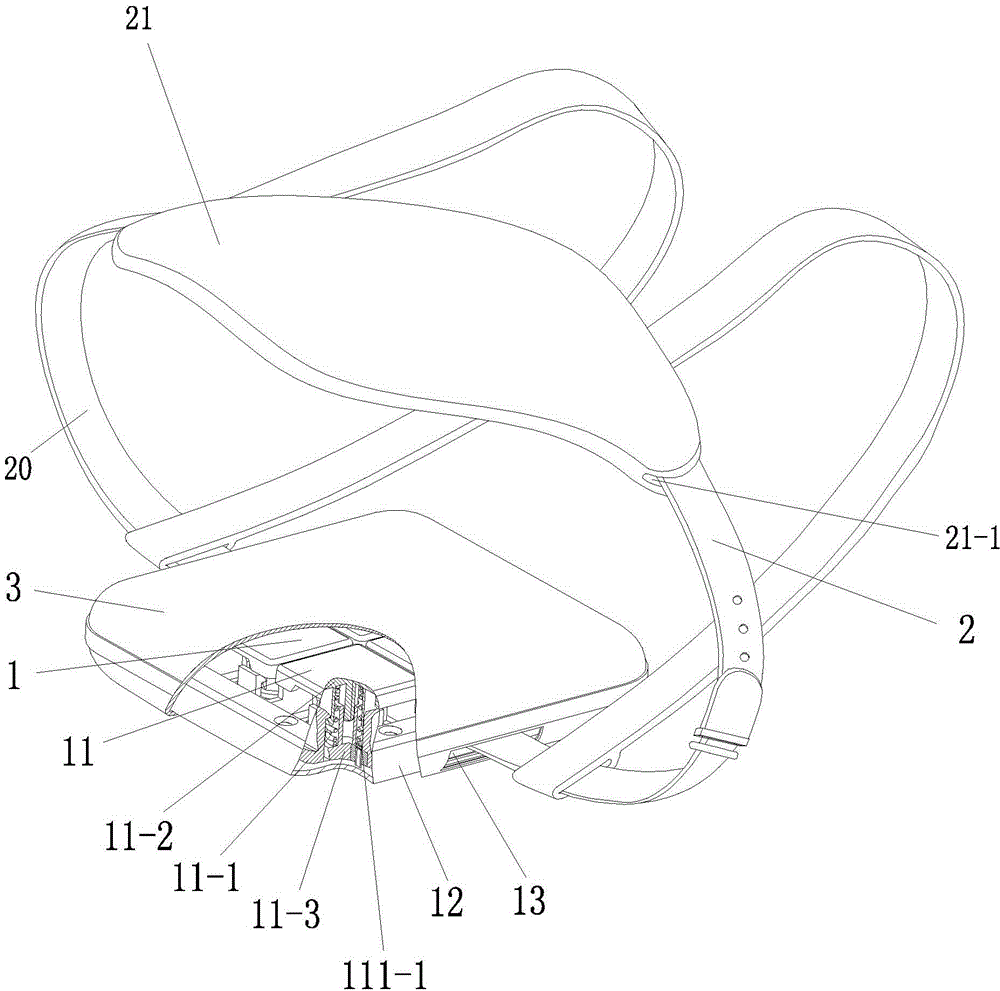

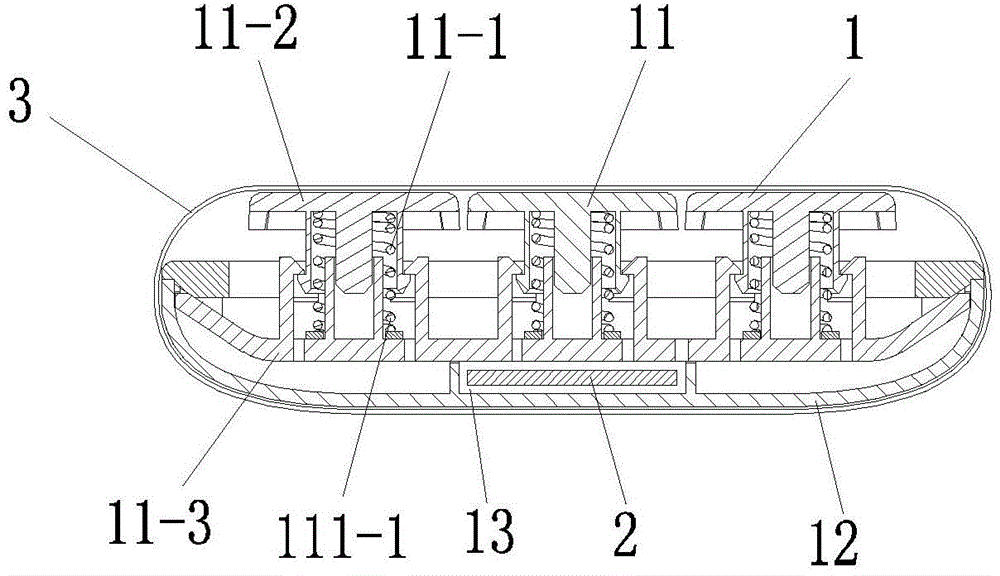

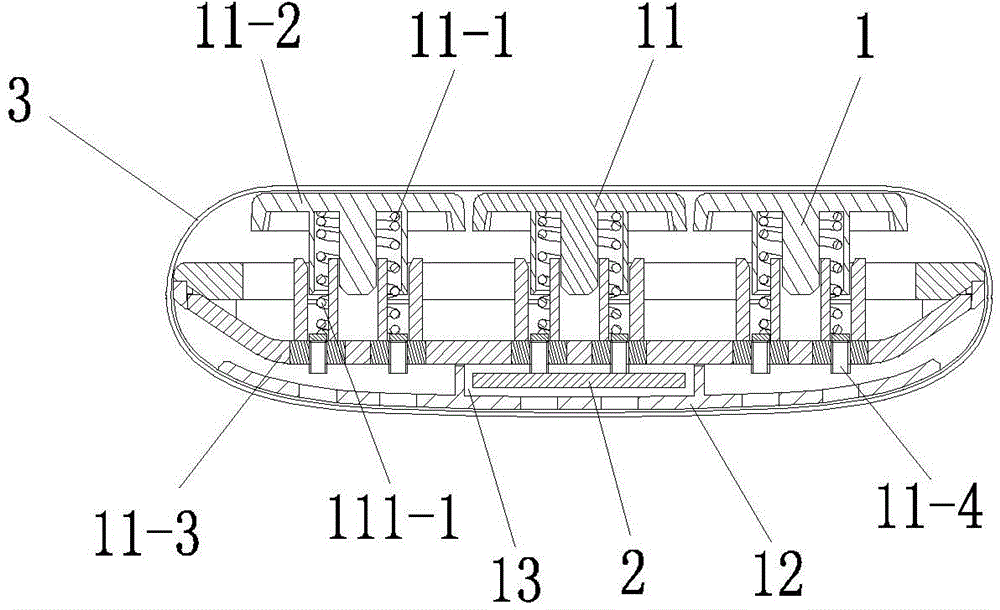

Elastic pigeon breast correction instrument

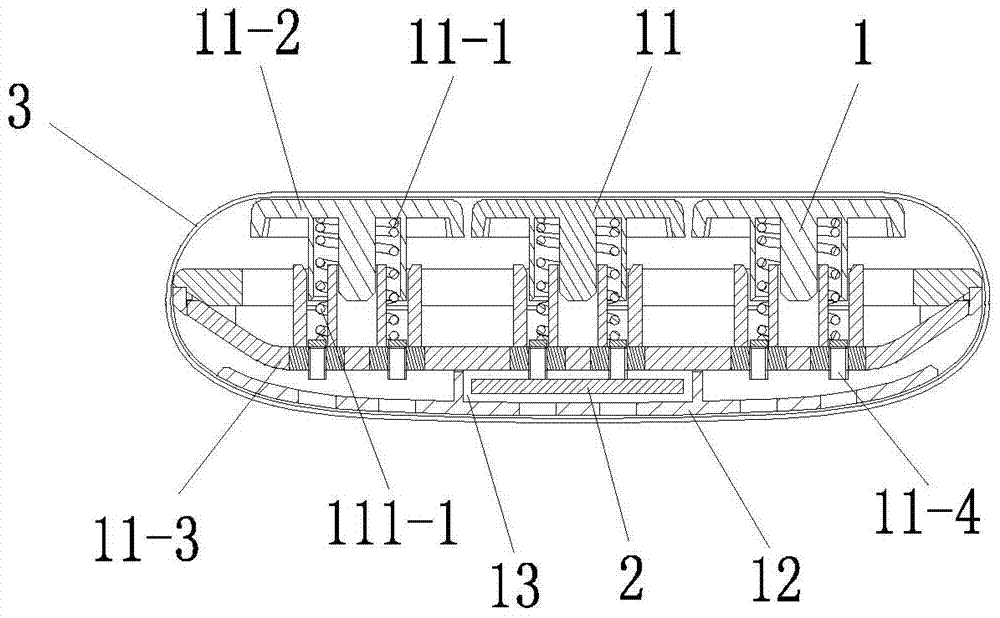

ActiveCN105434089ASafe Orthopedic TreatmentEffective orthopedic treatmentMedical scienceThoracic structureWorking pressure

The invention discloses an elastic pigeon breast correction instrument which comprises an elastic pressing plate and a fixing binding belt. The elastic pressing plate comprises a shell and at least one elastic mechanism, a binding belt through hole is formed in the shell, and the fixing binding belt can fix the elastic pressing plate to the pigeon breast protruding portion for in vitro correction after penetrating through the binding belt through hole. After the elastic pigeon breast correction instrument is worn, the elastic mechanisms can generate elastic deformation after being subjected to external force action, a dynamic fitting relationship is formed between the elastic pressing plate and the outline of a pigeon breast protrusion, therefore, it is guaranteed that the elastic pigeon breast correction instrument can continuously exert moderate working pressure in the exercise process, the correction pressure deficiency caused by contraction motion of the thoracic cavity cannot occur, and the excessive correction pressure caused by expansion motion of the thoracic cavity also cannot occur to cause tissue damage. In addition, due to the fact that the elastic mechanisms can generate elastic deformation, no matter what the outline shape of the pigeon breast protrusion is, the elastic pressing plate and the outline of the pigeon breast protrusion can achieve automatic fitting.

Owner:李建华 +1

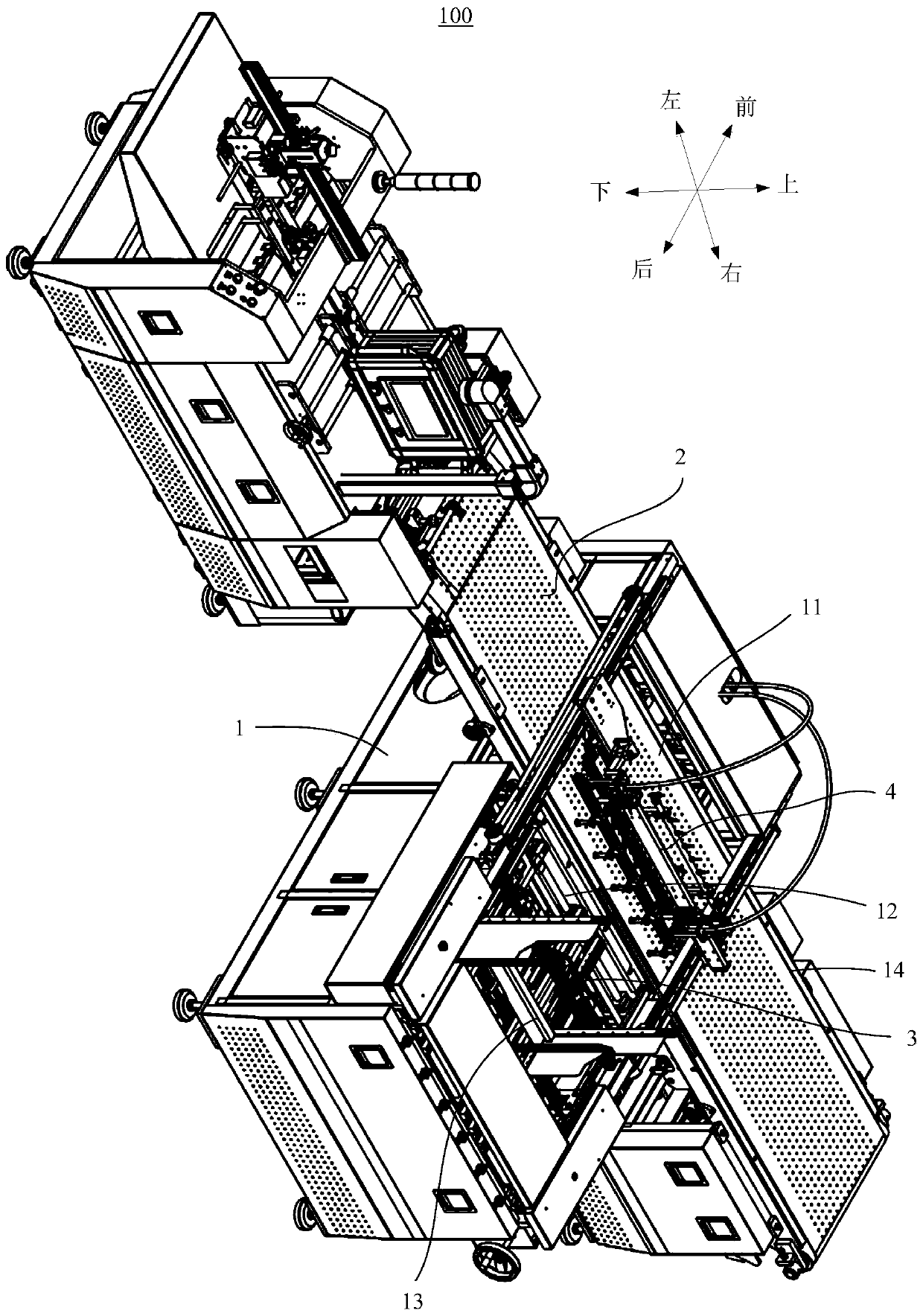

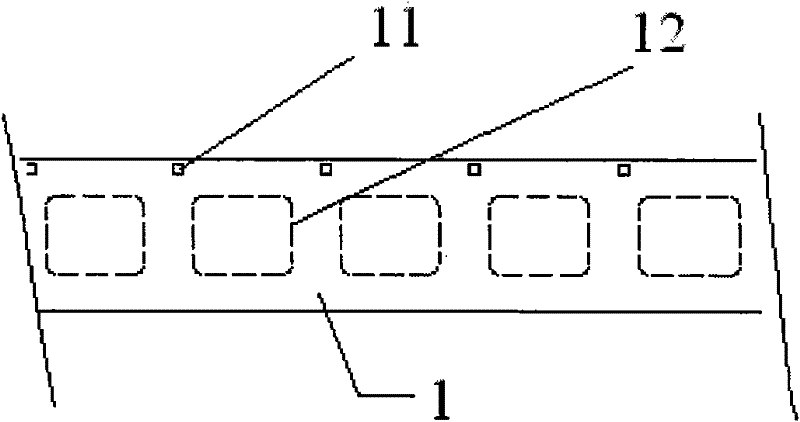

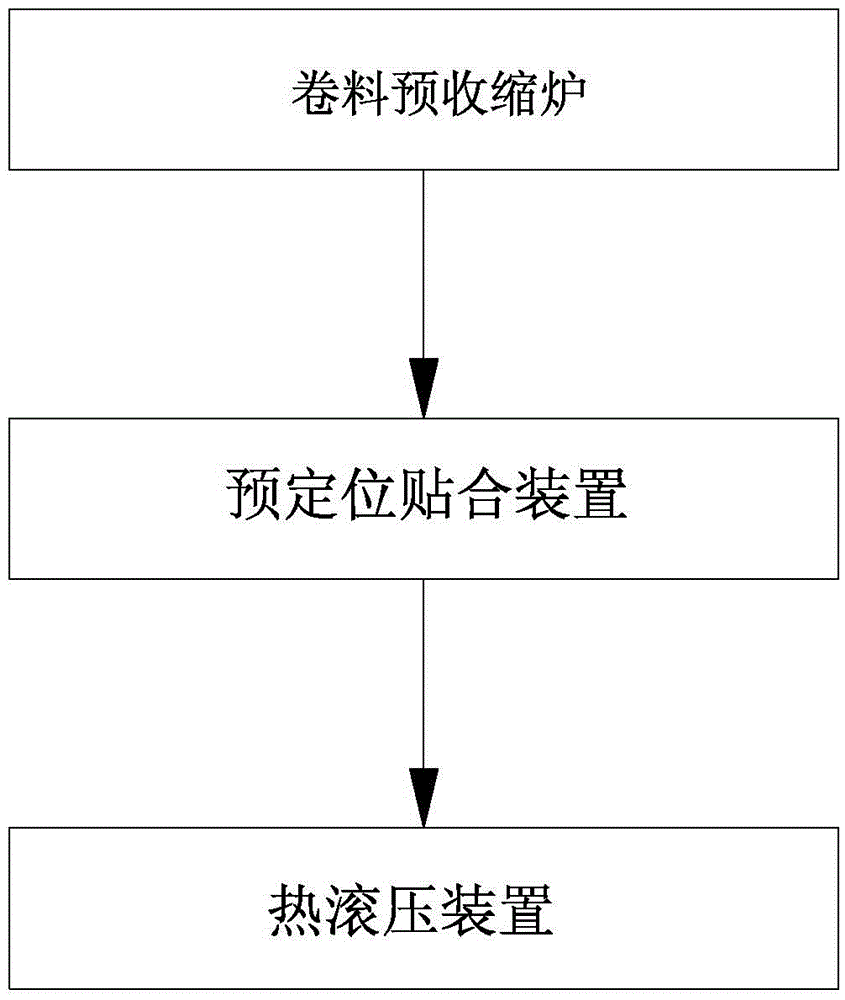

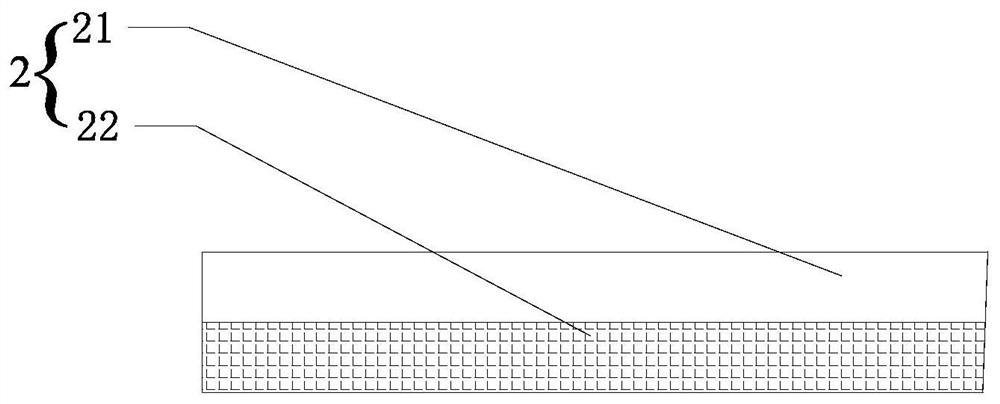

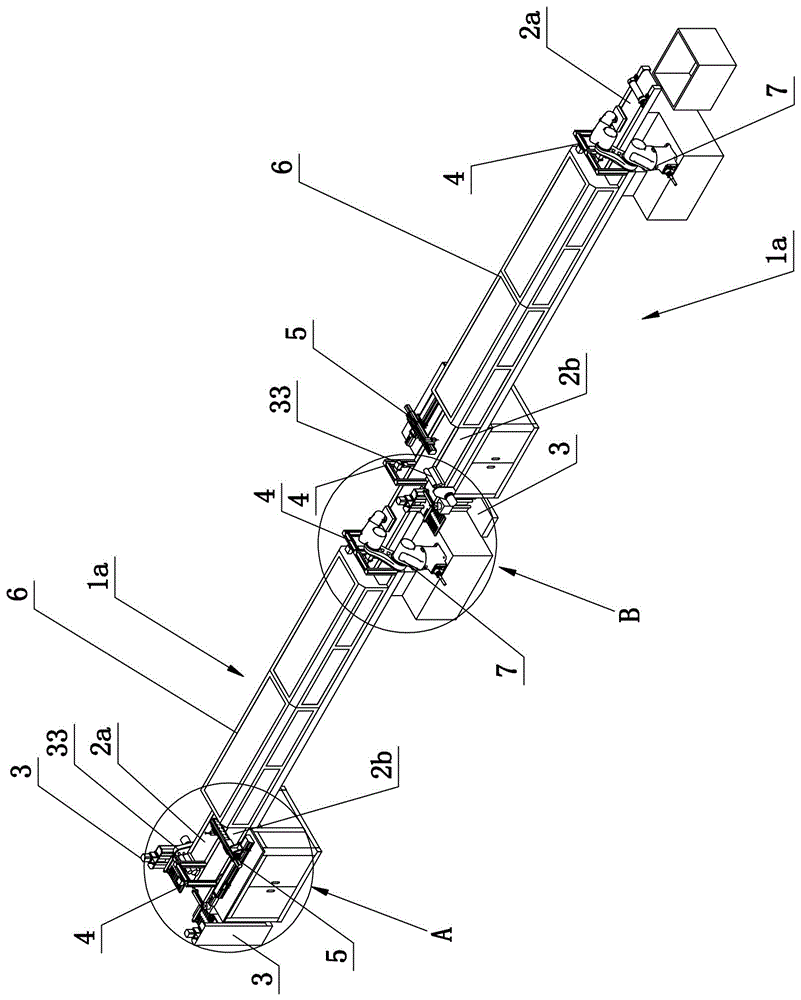

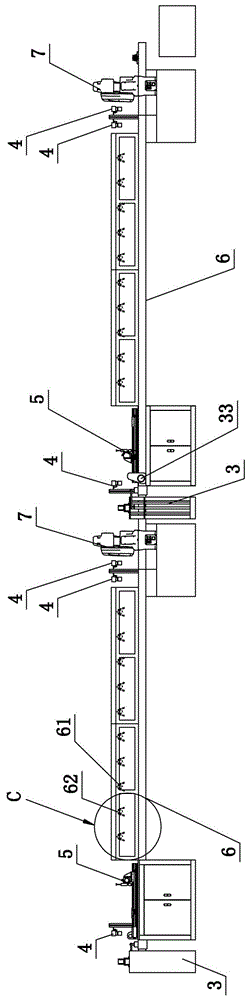

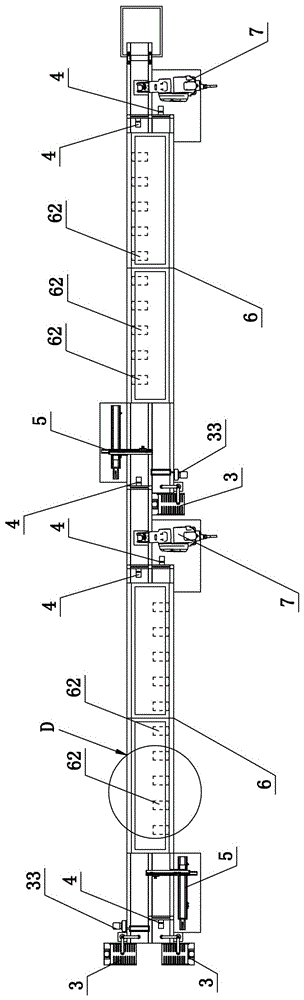

High-precision thin film circuit board production line

ActiveCN105704933AGuaranteed automated productionRealize automated productionLaminating printed circuit boardsProduction lineEngineering

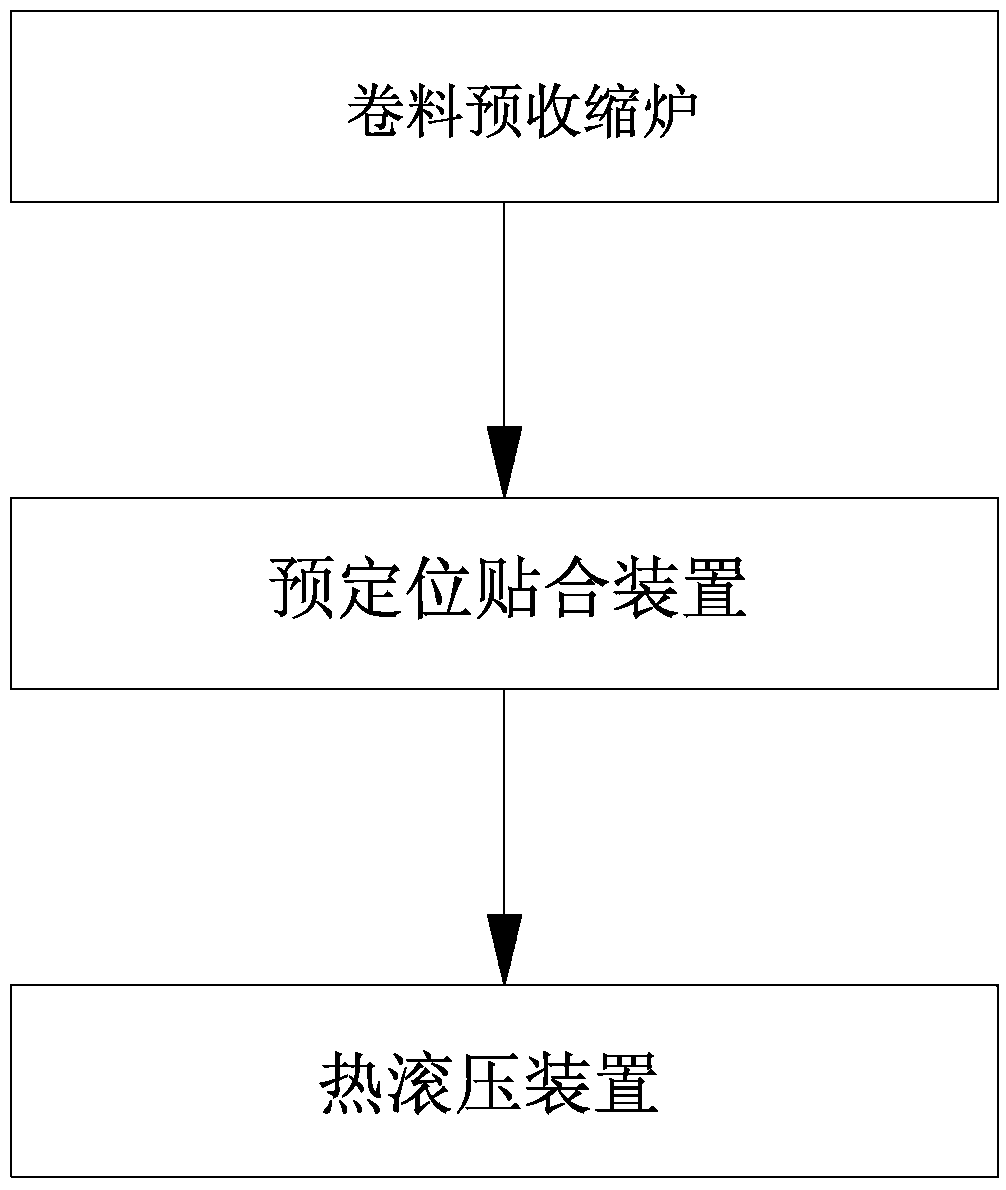

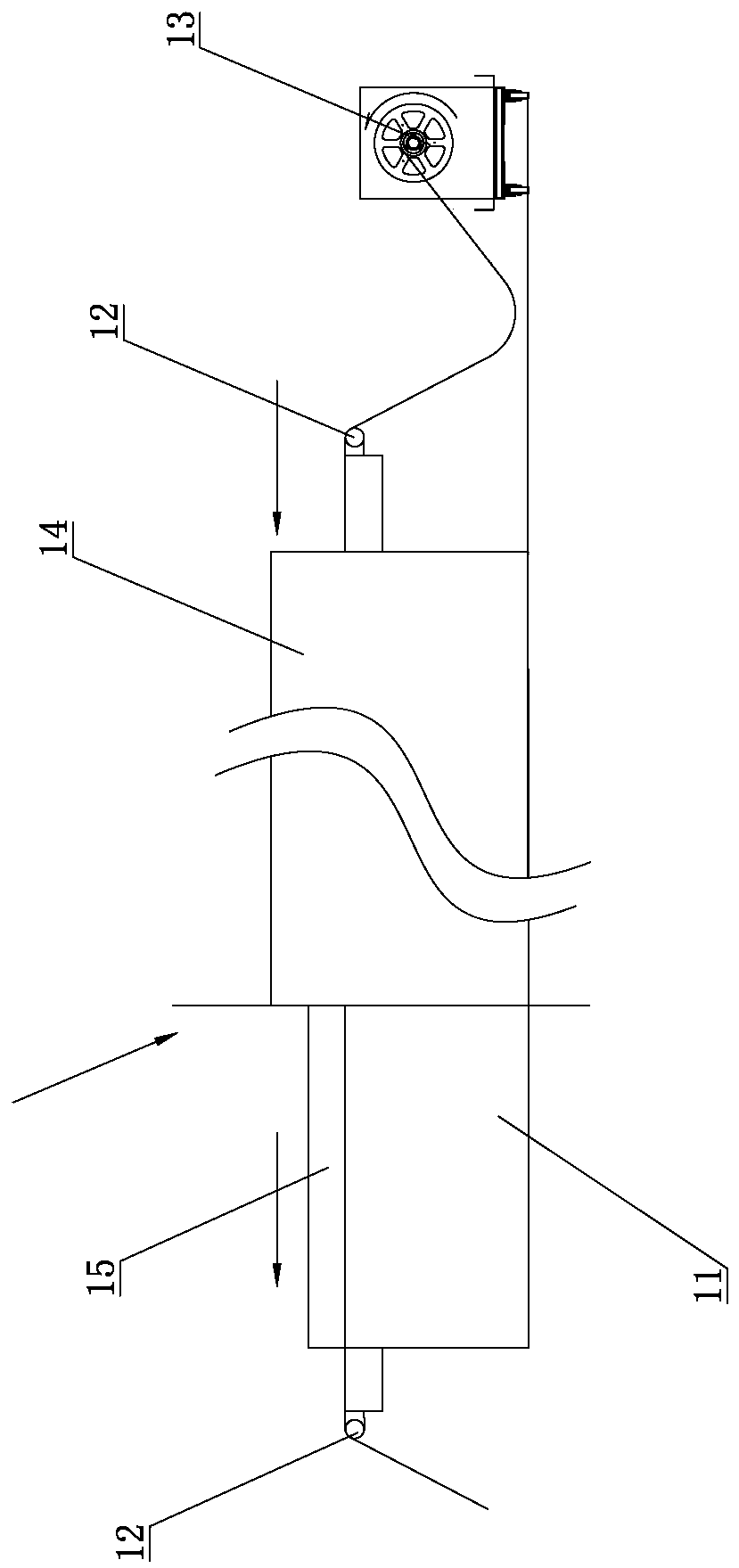

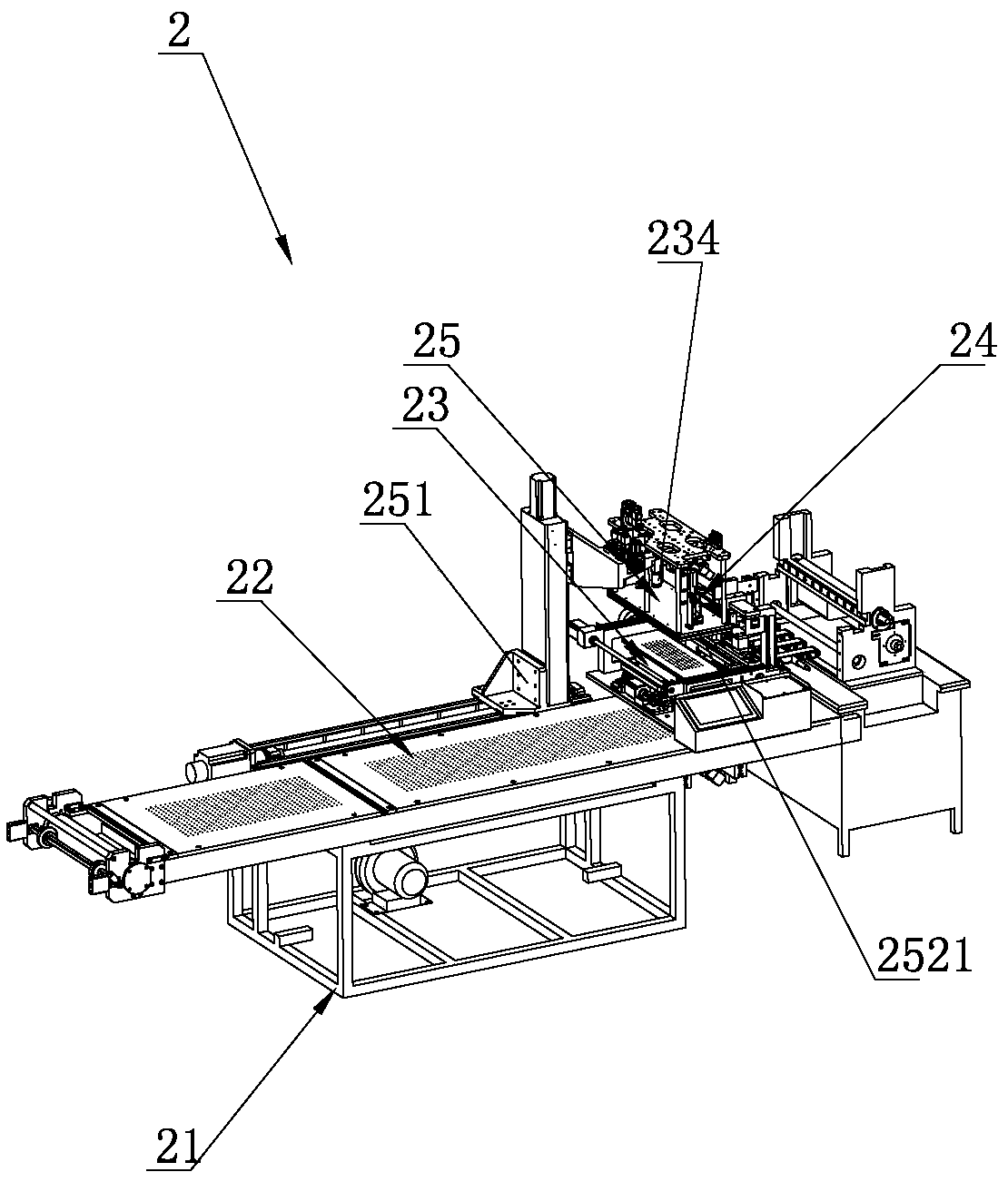

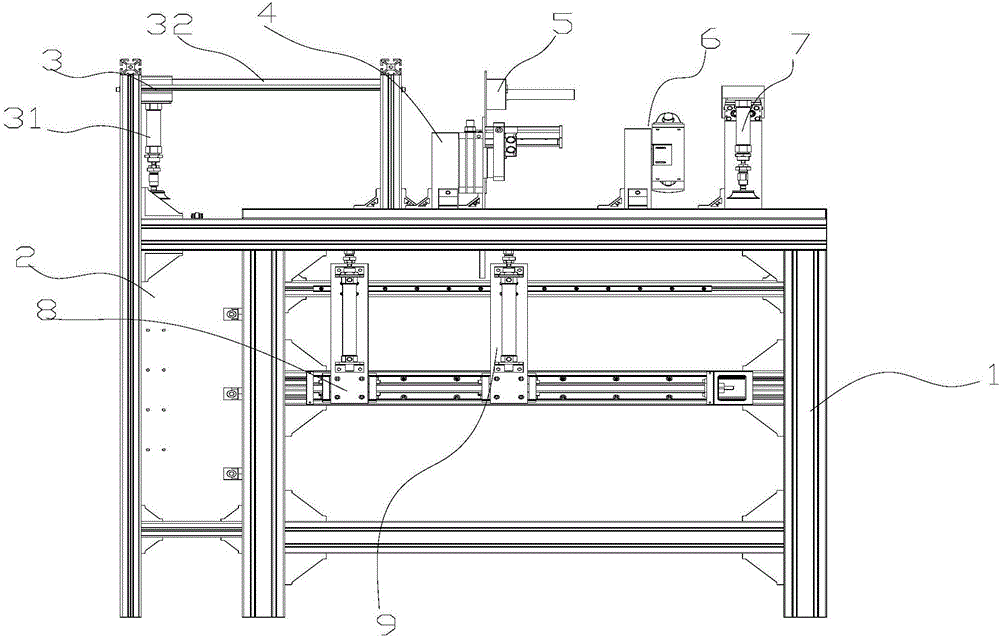

The invention relates to the technical field of automatic production equipment of thin film circuit boards, in particular to a high-precision thin film circuit board production line. The high-precision thin film circuit board production line comprises a coil preshrinking furnace, a pre-positioning lamination device and a hot roll-press device, wherein the coil preshrinking furnace is used for carrying out preshrinking on the coil; the pre-positioning lamination device is used for carrying out loading and pre-positioning lamination on the coil; the hot roll-press device is used for carrying out hot roll-press on the laminated coil; the coil preshrinking furnace, the pre-positioning lamination device and the hot roll-press device are sequentially connected with one another; the coil sequentially passes through coil preshrinking furnace, the pre-positioning lamination device and the hot roll-press device; the coil which passes through the coil preshrinking furnace in advance can ensure shrinkage of a product subjected to hot roll-press procedure; the pre-positioning lamination device accurately laminates a film sheet on the coil and achieves pre-positioning before lamination; the lamination and registration accuracy is improved when automatic lamination of the product is achieved; and the hot roll-press device carries out hot-press lamination on a multi-layer film material to form the high-precision thin film circuit board. The thin film circuit board can achieve automatic production, ensures the lamination accuracy, improves the yield and saves the production cost of an enterprise.

Owner:SHENZHEN VILITY AUTOMATION EQUIP

Dispensing and laminating machine

ActiveCN106733429BRealize automatic dispensingRealize automatic fitMaterial gluingPretreated surfacesProcess engineeringMechanical engineering

Owner:XIAMEN LIJU AUTOMATION TECH

Soft and hard screen dual-purpose laminating machine and laminating process thereof

PendingCN114132791AAuxiliary easy-to-tear stickersFunctionalPolarising elementsArticle unpackingFilm materialEngineering

The invention discloses a soft and hard screen dual-purpose laminating machine and a laminating process thereof.The soft and hard screen dual-purpose laminating machine comprises a polaroid feeding mechanism, a material taking mechanism, a laminating platform, a detecting and cleaning mechanism, a film tearing mechanism and a laminating mechanism, the polaroid feeding mechanism is arranged on a machine table, and the material taking mechanism is arranged on one side of the polaroid feeding mechanism; the surface mounting platforms are arranged on the side part of the polaroid feeding mechanism at intervals, and a glass substrate to be subjected to surface mounting is placed on the surface mounting platforms; the detecting and cleaning mechanism is erected above the surface mounting platform; the surface mounting mechanism stretches across the machine table and is erected between the surface mounting platform and the polaroid feeding mechanism; the film tearing mechanism is arranged on one side of the surface mounting mechanism and is used for tearing off a film material on the surface of the glass substrate placed on the surface mounting platform and a film material at the bottom of the polaroid. According to the polaroid laminating machine, automatic feeding and transferring, surface detecting and film tearing of polaroids are achieved, a roller belt type laminating mode and a pressing roller laminating mode are integrated, the hard screen and flexible screen compatible function is achieved, universality is high, and laminating bubbles are well reduced.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

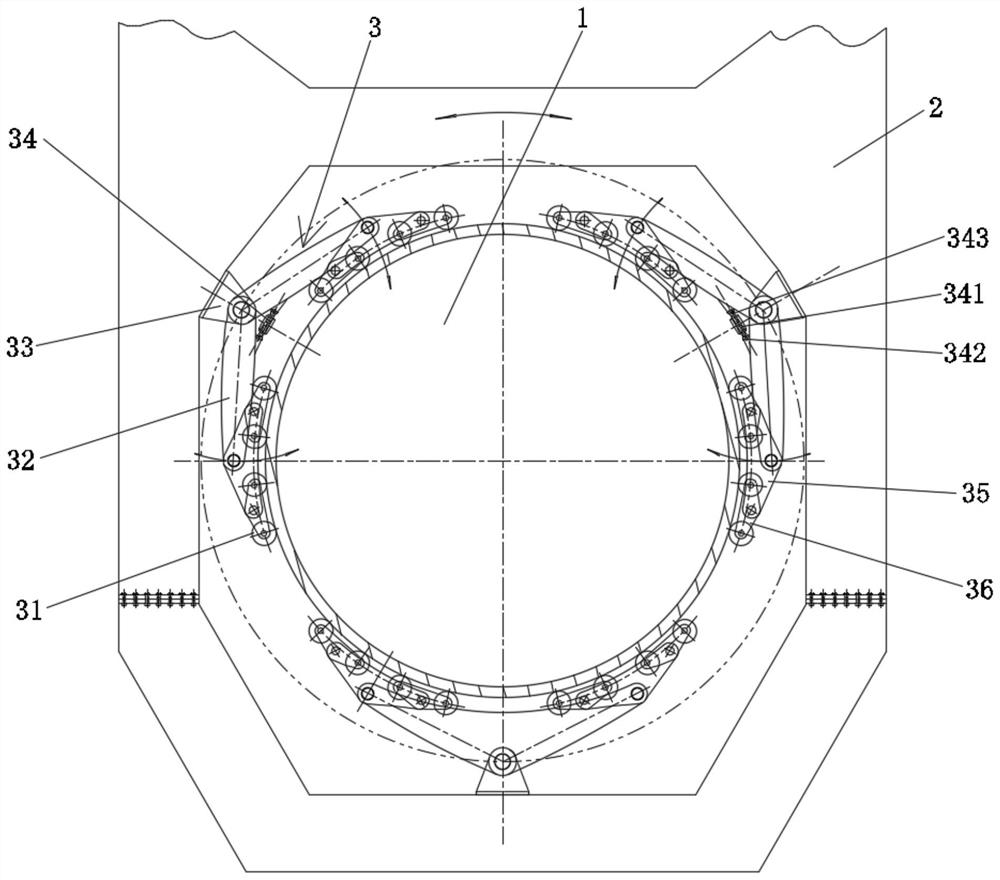

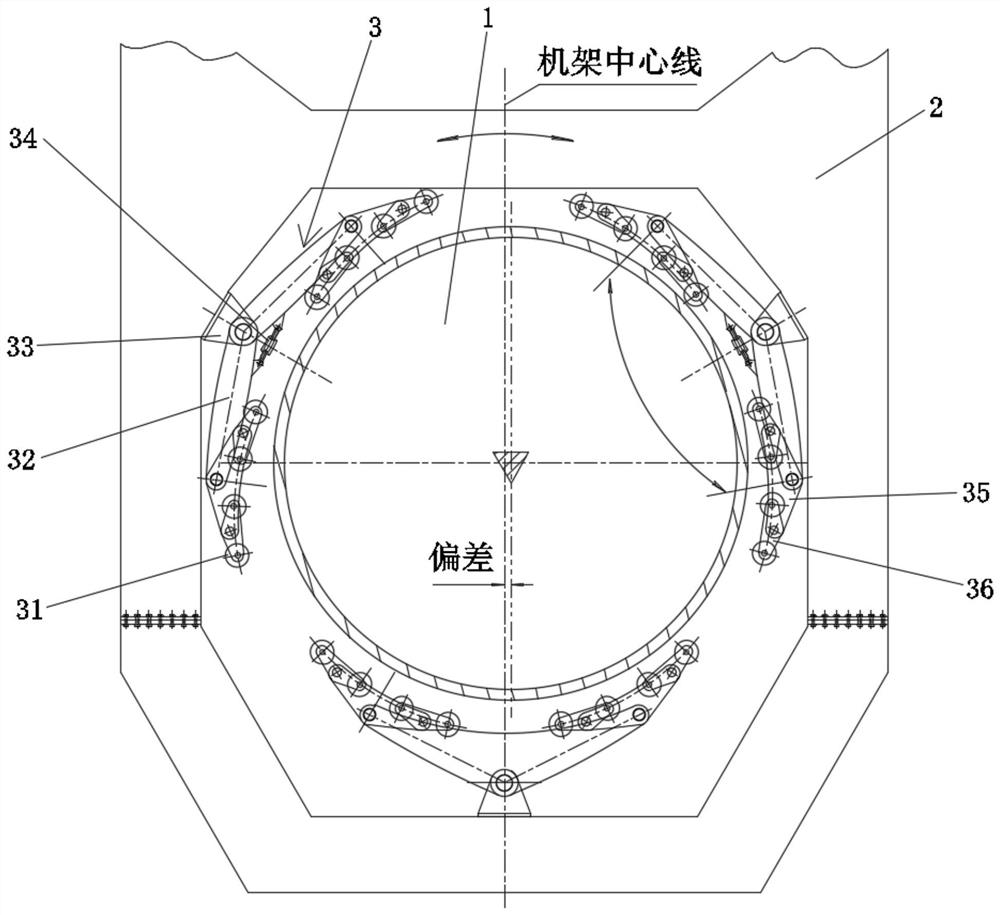

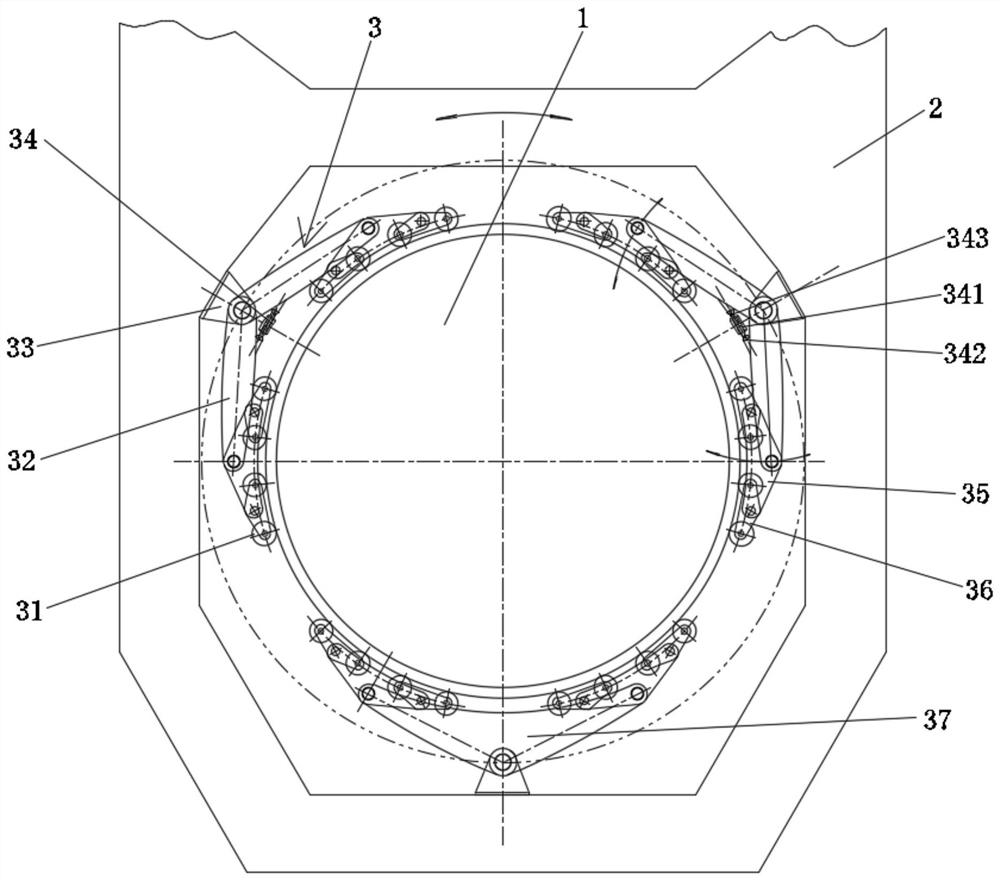

Self-centering mechanism for large-diameter centering rotary equipment

ActiveCN112664574AAchieve displacementPrecise positioningBearing unit rigid supportEngineeringStructural engineering

The invention discloses a self-centering mechanism for large-diameter centering rotary equipment. The rotary equipment comprises a fixed part and a rotating part, wherein the self-centering mechanism is arranged between the fixed part and the rotating part; one of the fixed part and the rotating part is cylindrical while the other one is provided with a corresponding inner cavity; the cylinder is located in the inner cavity; a roller path is arranged on the outer circumferential surface of the cylinder; the self-centering mechanism comprises at least two groups of rolling units, wherein at least one group of rolling units are adjusting units used for adjusting the position of the rotating part; at most one group of rolling units are positioning units, and the positioning units are arranged at the positioning reference of the fixed part; and the rotating part concentrically rotates relative to the fixed part through the adjusting units. According to the self-centering mechanism for the large-diameter centering rotary equipment, an aligning tool does not need to be additionally arranged, automatic centering is achieved, the assembly precision of a rolling pair is high, stress is balanced, and the self-centering mechanism is suitable for an inner centering outer rotation mechanism or an outer centering inner rotation mechanism.

Owner:TIDFORE HEAVY IND

Automatic laminating machine for circuit substrate and copper foil

InactiveCN113459633AAvoid warpingRealize automatic fitLamination ancillary operationsLaminationEngineeringCopper foil

An automatic laminating machine for a circuit substrate and a copper foil comprises: a copper foil cleaning device used for cleaning the copper foil; a false lamination platform used for false lamination of the substrate and the copper foil; a pre-pressing device used for pre-pressing the substrate and the copper foil; a clamping and pulling device used for fixing one end of the copper foil, pulling the copper foil after false lamination and pre-lamination, and moving the copper foil to a preset station; a roll type copper foil feeding device used for separating a copper foil and a release film in the roll type copper foil; a substrate transfer device used for transferring the substrate to a substrate to-be-sucked position; a substrate cleaning device positioned on one side of the substrate transfer device and used for cleaning the substrate on the transfer device; and a laminating suction cup device located between the substrate transfer device and the false attaching platform and used for sucking the substrate from the substrate transfer device, transferring the substrate to the position above the copper foil on the false attaching platform and enabling the substrate and the copper foil to be aligned and attached in a false mode. According to the automatic laminating machine for the circuit substrate and the copper foil, warping of the copper foil can be avoided, and bubbles and wrinkles are not prone to being generated.

Owner:HONGQISHENG PRECISION ELECTRONICS (QINHUANGDAO) CO LTD +1

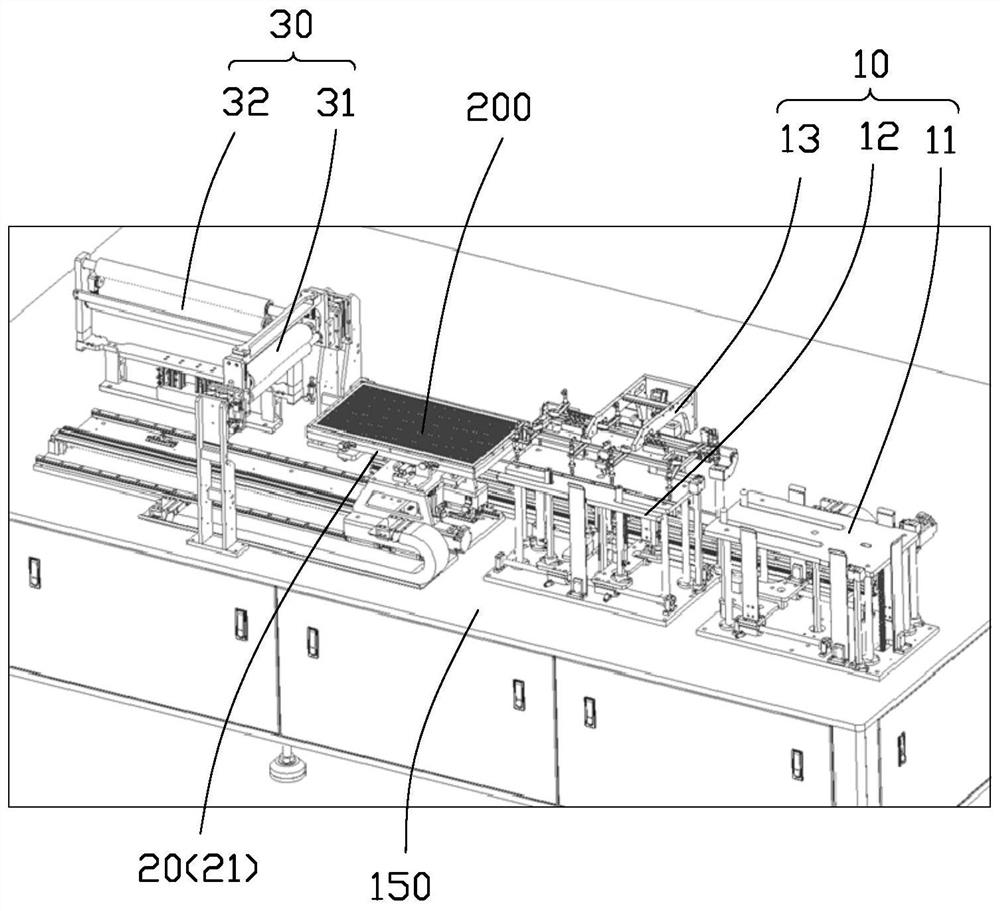

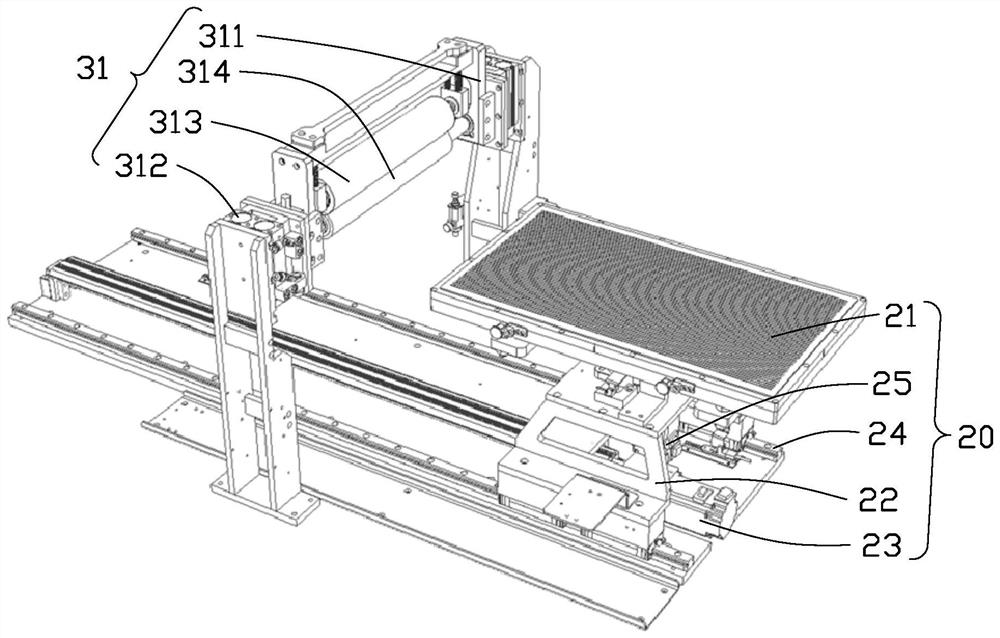

Processing method of super-thick special-shaped reinforcing sheet of flexible circuit

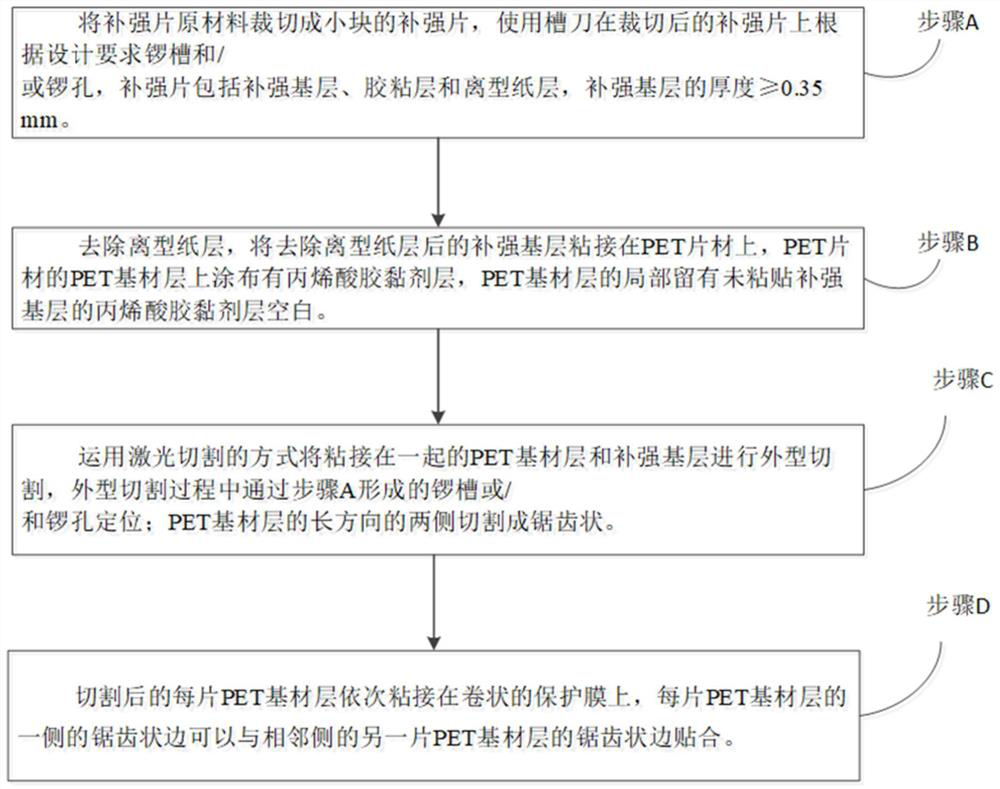

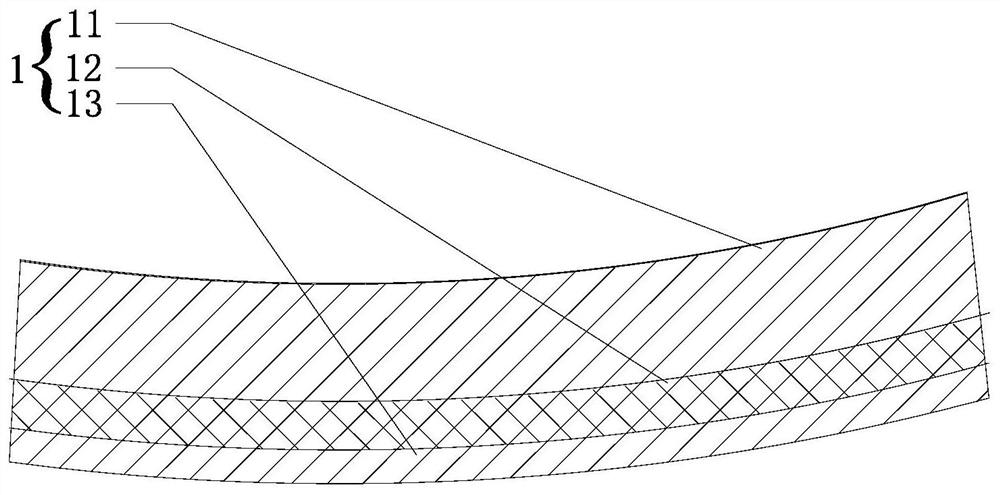

PendingCN112040630ARealize automatic fitCircuit bendability/stretchabilityLaminating printed circuit boardsFlexible circuitsManufactured material

The invention discloses a method for processing a super-thick special-shaped reinforcing sheet of a flexible circuit. The method comprises the following steps of: A, cutting a reinforcing sheet raw material into small reinforcing sheets, and milling grooves and / or milling holes including functional holes and positioning holes on the cut reinforcing sheets by using a slot cutter according to designrequirements, wherein the reinforcing sheet comprises a reinforcing base layer, an adhesive layer and a release paper layer, the thickness of the reinforcing base layer is greater than or equal to 0.35 mm, and the thickness is defined as an ultra-thick reinforcing sheet; B, removing the release paper layer, and adhering the reinforcing base layer with the release paper layer removed to a PET sheet, wherein the PET base material layer of the PET sheet is coated with an acrylic acid adhesive layer, and an acrylic acid adhesive layer blank which is not bonded with the reinforcing base layer is reserved on part of the PET base material layer; and D, bonding the PET sheets bonded with the reinforcing base layer to a rolled protective film one by one according to a set rule, wherein the protective film is bonded to the blank of the acrylic acid adhesive layer, and the adhesive PET bearing single sheet and the reinforcing sheet are combined in a crossed mode, so that the purpose of automaticroll material bonding is achieved.

Owner:深圳市鑫达辉软性电路科技有限公司

Sole attaching machine for insole

The invention relates to a sole attaching machine for an insole. The sole attaching machine for the insole comprises a plurality of sole attaching systems. Each sole attaching system comprises at least two conveying belts which are configured in a parallel manner and are further the same in the direction of transportation, a feeding device, a three-dimensional recognition device, an adhesive spraying device, a drying box and a sole attaching manipulator; the feeding devices are arranged adjacent to the head ends of the conveying belts; the feeding devices are used for transferring materials to the conveying belts; the conveying belts of each sole attaching system comprise a primary conveying belt and a secondary conveying belt; the main conveying belts of the adjacent sole attaching systems are arranged end to end; the head end of the primary conveying belt of a first sole attaching system located at the head end of the sole attaching machine for the insole is provided with one feeding device; the conveying belts are provided with the spraying devices, the drying boxes and the sole attaching manipulators in sequence from the head ends to tail ends. By using the sole attaching machine for the insole, the automatic attaching of the insole and an outsole which are in different shapes and are made from different materials and various cushioning pads and the like, which are additionally arranged between the insole and the outsole, is realized.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

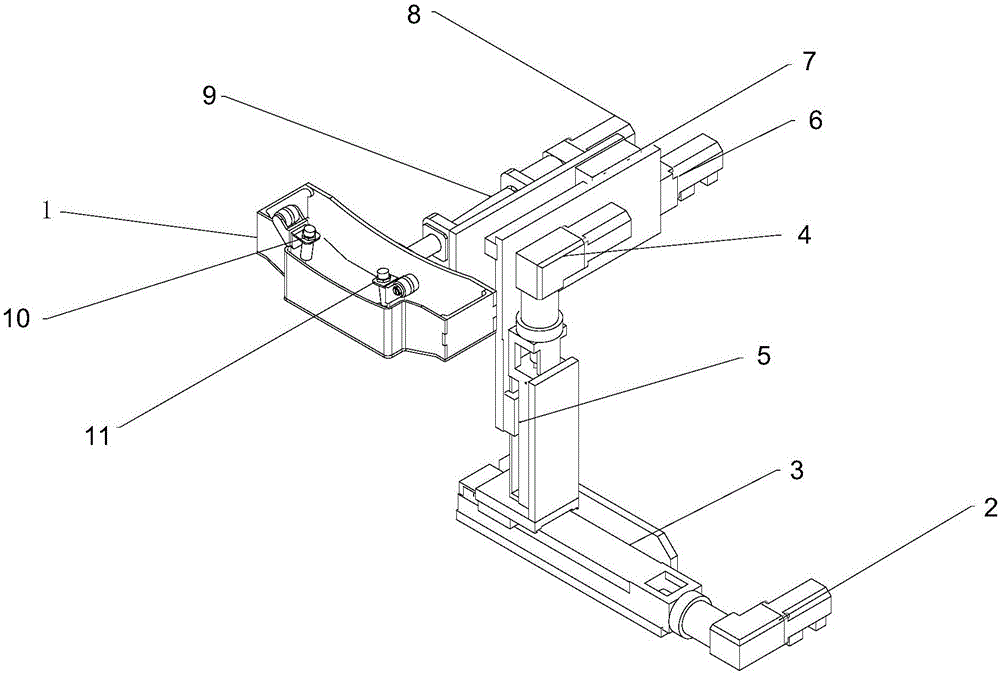

Positioning device for mobile phone touch screen and face shell

InactiveCN108581979AEven by forceAvoid pollutionWork holdersDirt cleaningHydraulic cylinderEngineering

The invention relates to the technical field of mobile phone touch screen accessory devices, in particular to a positioning device for a mobile phone touch screen and a face shell. The positioning device has the advantages that automatic attaching can be realized, accurate positioning can be realized, the product quality can be improved, the production efficiency can be improved, and the use limitation can be reduced; and in addition, adsorption of impurities such as dust can be reduced, the face shell can be prevented from being polluted, the attaching yield can be increased, and the use reliability can be improved. The positioning device comprises an operation table, a left front support leg, a left rear support leg, a right front support leg, a right rear support leg, a front cross beamand a rear cross beam, comprises four groups of limiting guide columns, a top plate, a pressing plate, a first hydraulic cylinder, an upper pressing block, a lower pressing block, a sliding plate, arubber acting plate, four groups of buffer springs and a hydraulic station, and further comprises a dust-free box and a dust remover, wherein the dust-free box sleeves the outer side of the top plateand the outer side of the top end of the operation table, and the dust remover is arranged on the inner wall of the left end of the dust-free box.

Owner:JIANGSU DIJIA ELECTRONICS CO LTD

Sole pasting machine for shoe manufacturing

The invention relates to a sole pasting machine for shoe manufacturing. The shoe pasting machine comprises a plurality of sole pasting systems, wherein the adjacent shoe pasting systems are connected end to end; each sole pasting system comprises at least two conveying belts which are arranged in parallel and used for conveying materials in the same direction, material supply devices, three-dimensional identification devices, a glue spraying device, a drying box and a sole pasting manipulator; the material supply devices are arranged near the head ends of the conveying belts and are used for transferring materials to the conveying belts; the glue spraying device, the drying box and the sole pasting manipulator are assembled on the conveying belts in sequence from the head ends to the tail ends; the glue spraying device is used for spraying glue onto the materials on the conveying belts; the sole pasting manipulator is used for turning the materials on one conveying belt to be attached with the materials on the other conveying belt; the three-dimensional identification devices are matched with the glue spraying device and the sole pasting manipulator respectively. The sole pasting machine for shoe manufacturing realizes automatic pasting of insoles and outer soles which have different shapes and are made of different materials, and various shock absorption gaskets additionally arranged between the insoles and the outer soles.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

Film pasting equipment

PendingCN110902070ARealize automatic fitTear off quicklyLabelling machinesEngineeringMechanical engineering

The invention relates to the technical field of film pasting equipment, in particular to film pasting equipment. The film pasting equipment comprises a machine table, a carrier used for placing a product, a material taking and placing device used for placing a transparent adhesive film on the product, a film feeding mechanism used for feeding the transparent adhesive film to an input end of the material taking and placing device, and a conveying assembly used for moving the carrier, wherein the film feeding mechanism, the material taking and placing device and the conveying assembly are all installed on the machine table. According to the film pasting equipment, the film can be automatically fed to a designated position, so that a user can quickly tear off the film from a material belt; and labels or transparent adhesive films from a material belt can be automatically attached to products, the film attaching efficiency is high, the transparent adhesive films can be flatly attached to the products, and the film attaching effect is good.

Owner:广东井岗智能精密有限公司

Foam attaching device for mobile phone touch screen

InactiveCN108688178ARealize automatic fitFitting position is accurateDomestic articlesHydraulic cylinderEngineering

The invention relates to the technical field of mobile phone touch screen accessory devices, in particular to a foam attaching device for a mobile phone touch screen. Automatic attaching can be achieved, the attaching position is precise, the finished product rate is increased, continuous operation is achieved, the automation degree is improved, manpower is reduced, the economic cost is reduced, the using limitation is reduced, and the using reliability is improved. The foam attaching device comprises a workbench, four groups of supporting legs, a left supporting plate, a right supporting plate and a top plate; the foam attaching device further comprises a back side plate, a first hydraulic cylinder, a second hydraulic cylinder, a hydraulic station, a control box, a left connecting plate,a right connecting plate, an upper pressing plate, a lower pressing plate, a supporting plate, four groups of foam attaching heads and an attaching plate; the top end of the back side plate is connected with the back side of the bottom end of the top plate, and the bottom end of the back side plate is connected with the back side of the top end of the workbench; and the supporting plates are located in front of the back side plate, two groups of first sliding blocks are longitudinally arranged at the back ends of the supporting plates, two groups of first sliding grooves are longitudinally formed in the front end of the back side plate correspondingly, and the two groups of first sliding blocks are in sliding fit with the two groups of first sliding grooves.

Owner:JIANGSU DIJIA ELECTRONICS CO LTD

A thin film circuit board production line

ActiveCN105704933BGuaranteed automated productionRealize automated productionLaminating printed circuit boardsProduction lineEngineering

The invention relates to the technical field of automatic production equipment of thin film circuit boards, in particular to a high-precision thin film circuit board production line. The high-precision thin film circuit board production line comprises a coil preshrinking furnace, a pre-positioning lamination device and a hot roll-press device, wherein the coil preshrinking furnace is used for carrying out preshrinking on the coil; the pre-positioning lamination device is used for carrying out loading and pre-positioning lamination on the coil; the hot roll-press device is used for carrying out hot roll-press on the laminated coil; the coil preshrinking furnace, the pre-positioning lamination device and the hot roll-press device are sequentially connected with one another; the coil sequentially passes through coil preshrinking furnace, the pre-positioning lamination device and the hot roll-press device; the coil which passes through the coil preshrinking furnace in advance can ensure shrinkage of a product subjected to hot roll-press procedure; the pre-positioning lamination device accurately laminates a film sheet on the coil and achieves pre-positioning before lamination; the lamination and registration accuracy is improved when automatic lamination of the product is achieved; and the hot roll-press device carries out hot-press lamination on a multi-layer film material to form the high-precision thin film circuit board. The thin film circuit board can achieve automatic production, ensures the lamination accuracy, improves the yield and saves the production cost of an enterprise.

Owner:SHENZHEN VILITY AUTOMATION EQUIP

Mask sponge bar laminating machine

The invention provides a mask sponge bar laminating machine. The mask sponge bar laminating machine comprises a machine frame, wherein a material supply unit, a location arrangement positioning station, a sponge bar laminating station, a sponge bar pressing station and a mask transfer system are arranged on the machine frame; a location arrangement positioning die is arranged on the location arrangement positioning station; a sponge bar laminating die, a sponge bar supply mechanism and a sponge bar fetching laminating mechanism are arranged on the sponge bar laminating station; a sponge bar pressing die and a sponge bar pressing mechanism are arranged on the sponge bar pressing station; the mask transfer system is used for sequentially transferring a mask fetched from the supply unit on the location arrangement positioning die, the sponge bar laminating die and the sponge bar pressing die. The mask sponge bar laminating machine has the advantages that the automatic laminating of sponge bars on the mask is realized, the working efficiency is effectively improved, the labor cost and production cost of enterprises are reduced, the laminating quality of sponge bars on the mask is effectively improved, and the protection effect of the mask is effectively improved.

Owner:苏州唯实机器人科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com