Sole pasting machine for shoe manufacturing

A bottom sticking machine and bottom sticking technology, which is applied in the direction of shoemaking machinery, footwear, shoe soles, etc., can solve the problems of high energy consumption and high labor cost, reduce energy consumption, realize automatic production, and increase market competitiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

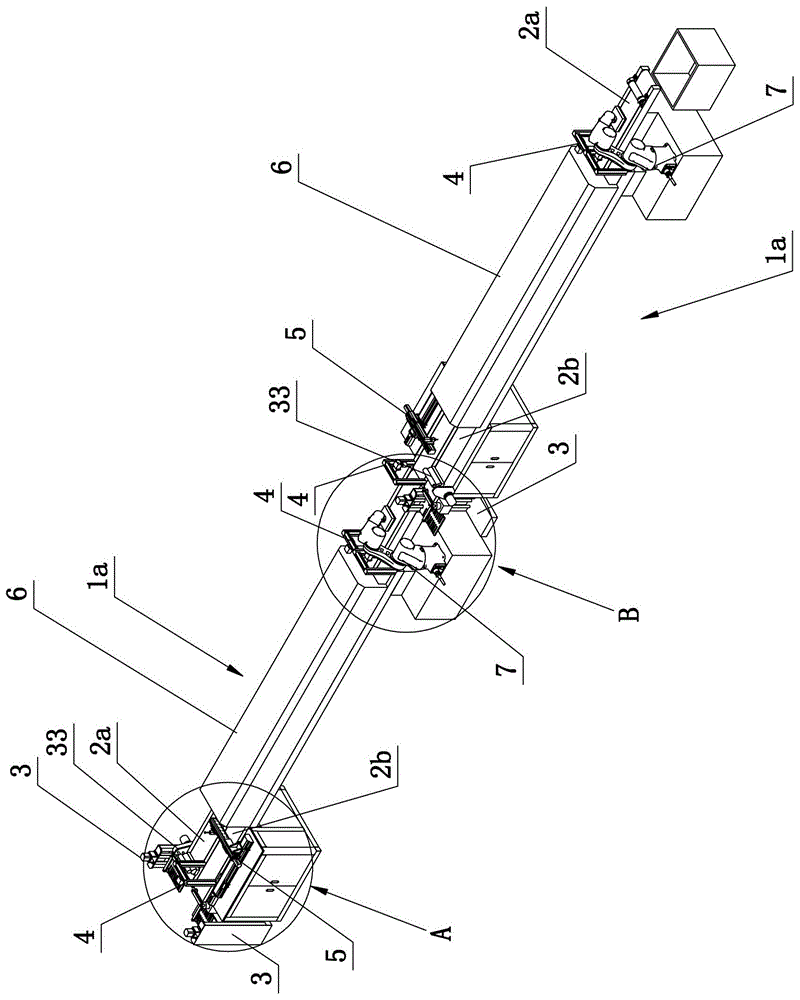

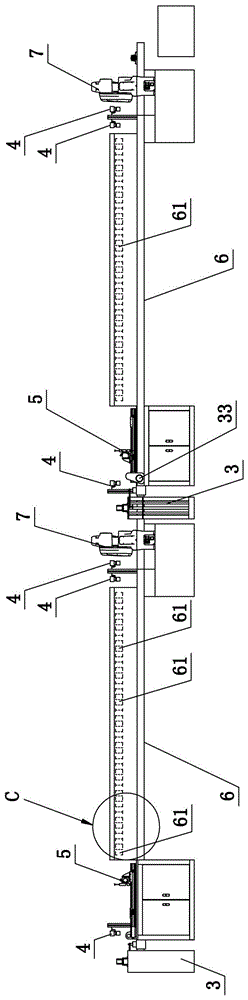

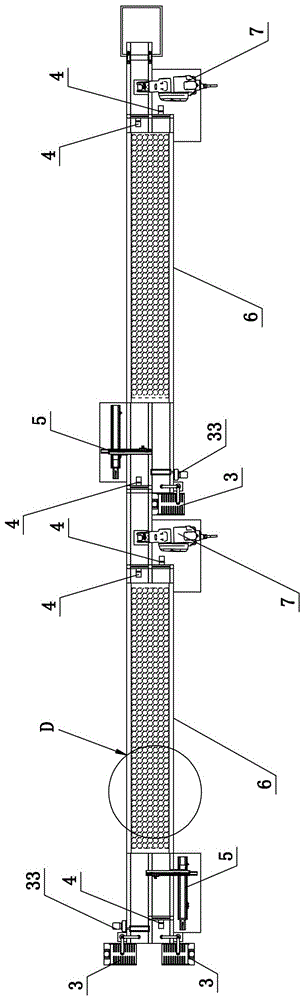

[0032] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0033] refer to figure 1 , Image 6 , Figure 7 , a bottom sticking machine for footwear manufacturing, comprising a plurality of bottom sticking systems, adjacent bottom sticking systems are arranged end to end. In this embodiment, there are preferably two bottoming systems, that is, the first bottoming system 1a and the second bottoming system 1b. Each of the above bottom sticking systems includes at least two conveyor belts arranged in parallel and conveying in the same direction, a feeding device 3, a three-dimensional recognition device 4, a glue spraying device 5, a drying box 6, a bottom sticking manipulator 7 and a control mechanism. In the present embodiment, each bottom sticking system preferably includes two conveyor belts, a main conveyor belt 2a and a secondary conveyor belt 2b. The main conveyor belt 2a and the secondary conveyor belt 2b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com