A thin film circuit board production line

A thin-film circuit board and production line technology, applied in the directions of laminated printed circuit board, printed circuit, printed circuit manufacturing, etc., can solve the problems of reduced fitting accuracy, misalignment of thin-film circuit board lines, easy to produce offset, etc. Save the production cost of the enterprise, improve the accuracy of the fit and set, and ensure the effect of the fit accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

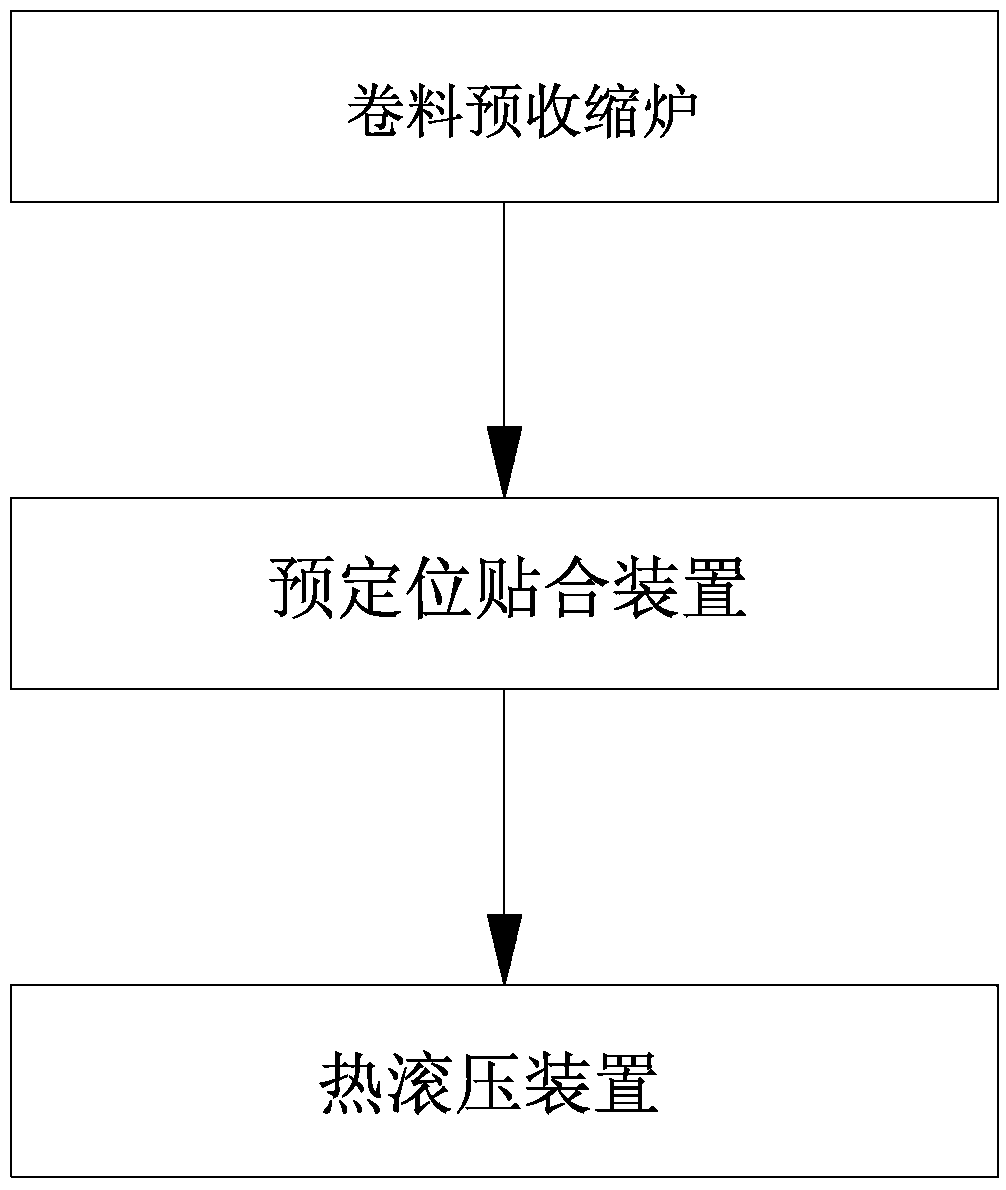

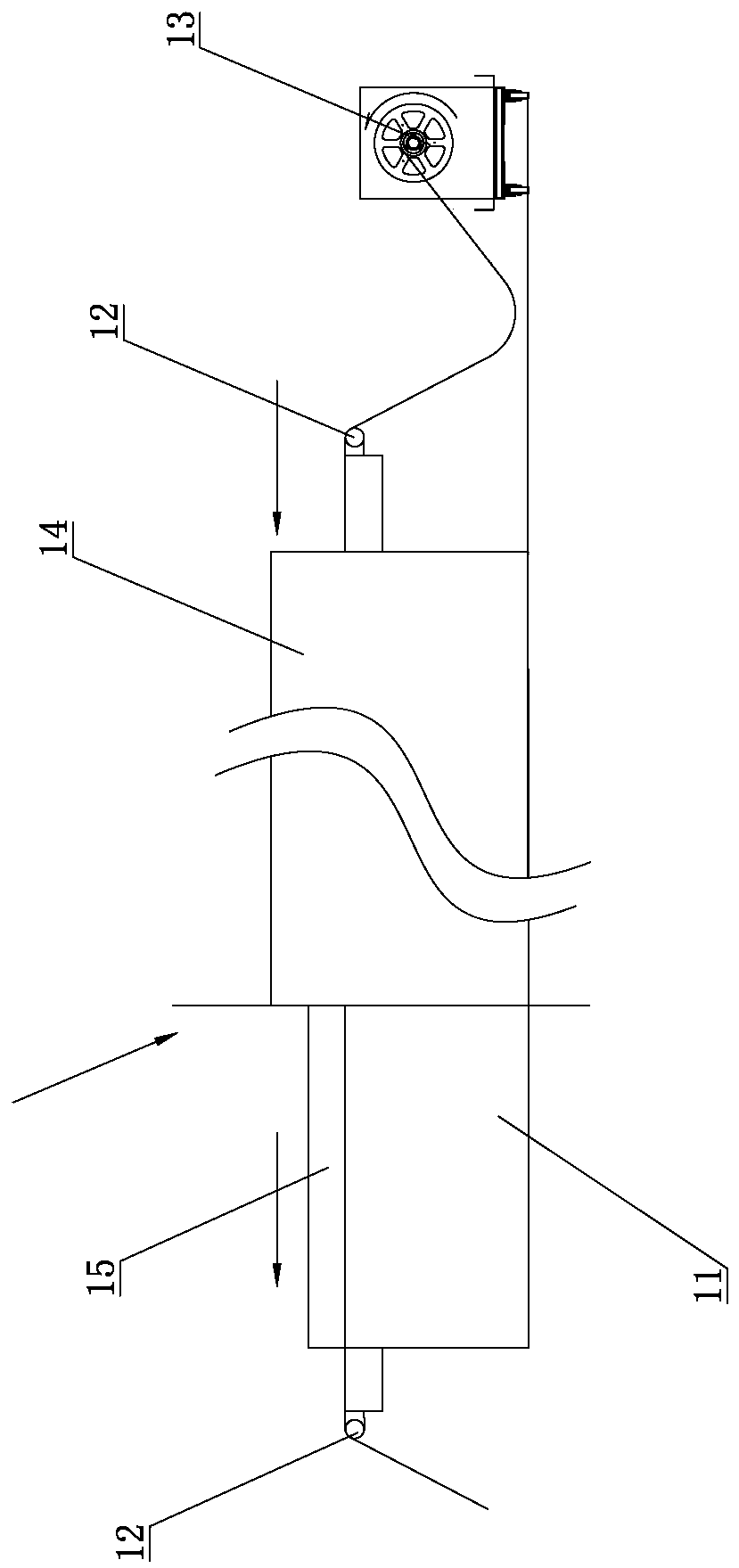

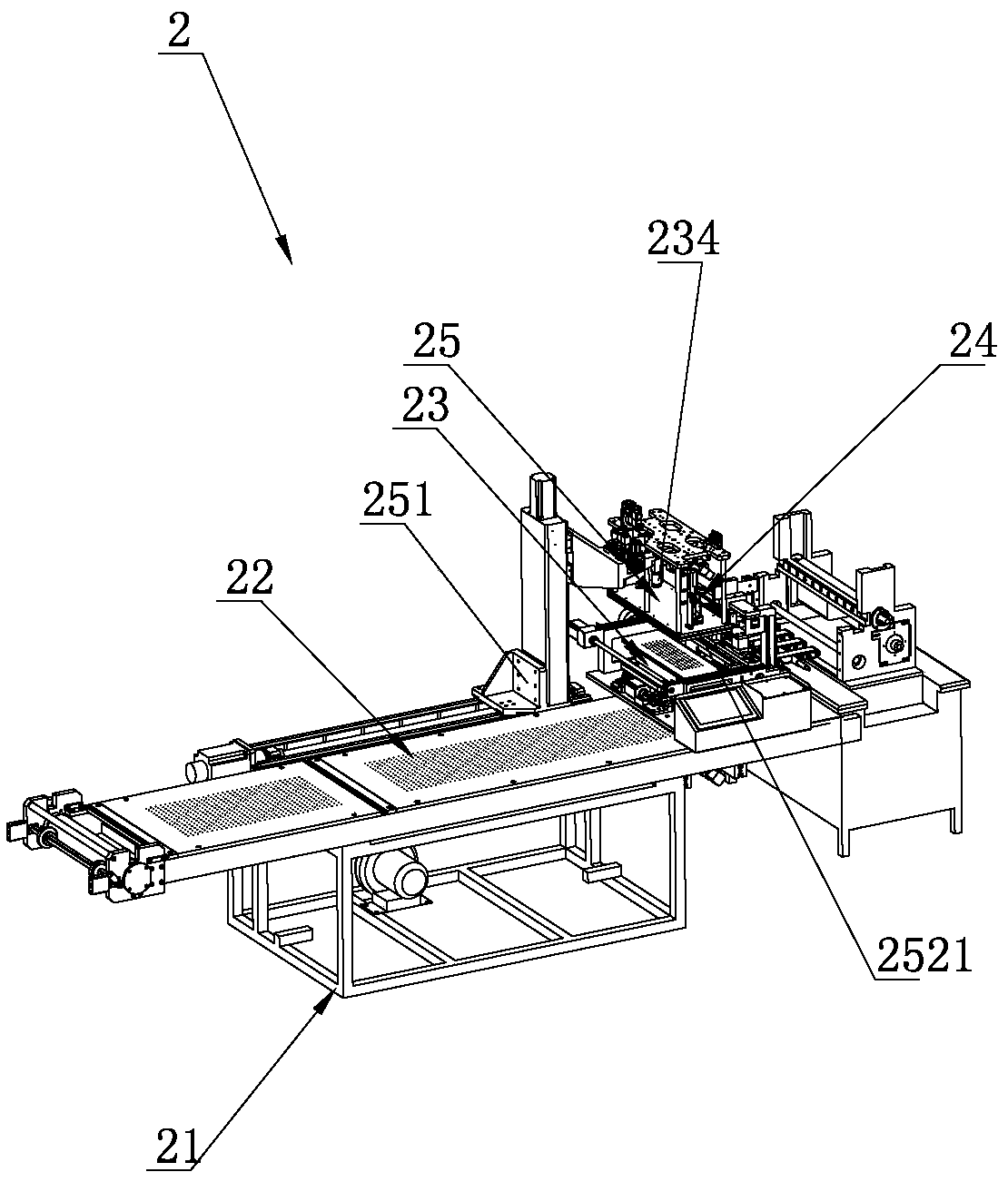

[0028] Such as Figure 1 to Figure 2 As shown, a kind of thin film circuit board production line of the present invention comprises the pre-shrinking coil furnace 1 that pre-shrinks the coil, the pre-positioning and laminating device 2 that loads and pre-positions the coil, and the lamination The hot rolling device 3 for hot rolling the final coil material; the coil material pre-shrinking furnace 1, the pre-positioning laminating device 2 and the hot rolling device 3 are connected in sequence. The coil material passes through the coil material pre-shrinking furnace 1, the pre-positioning laminating device 2 and the hot rolling device 3 in sequence. The coil material that has passed through the coil material pre-shrinking furnace 1 in advance can ensure that the product after the hot rolling process shrinks, and the pre-positioning lamination The laminating device 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com