A medical bottle cap assembly machine

A technology for assembly machines and bottle caps, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency and large footprint of the assembly line, and achieve increased production capacity, reduced labor costs, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

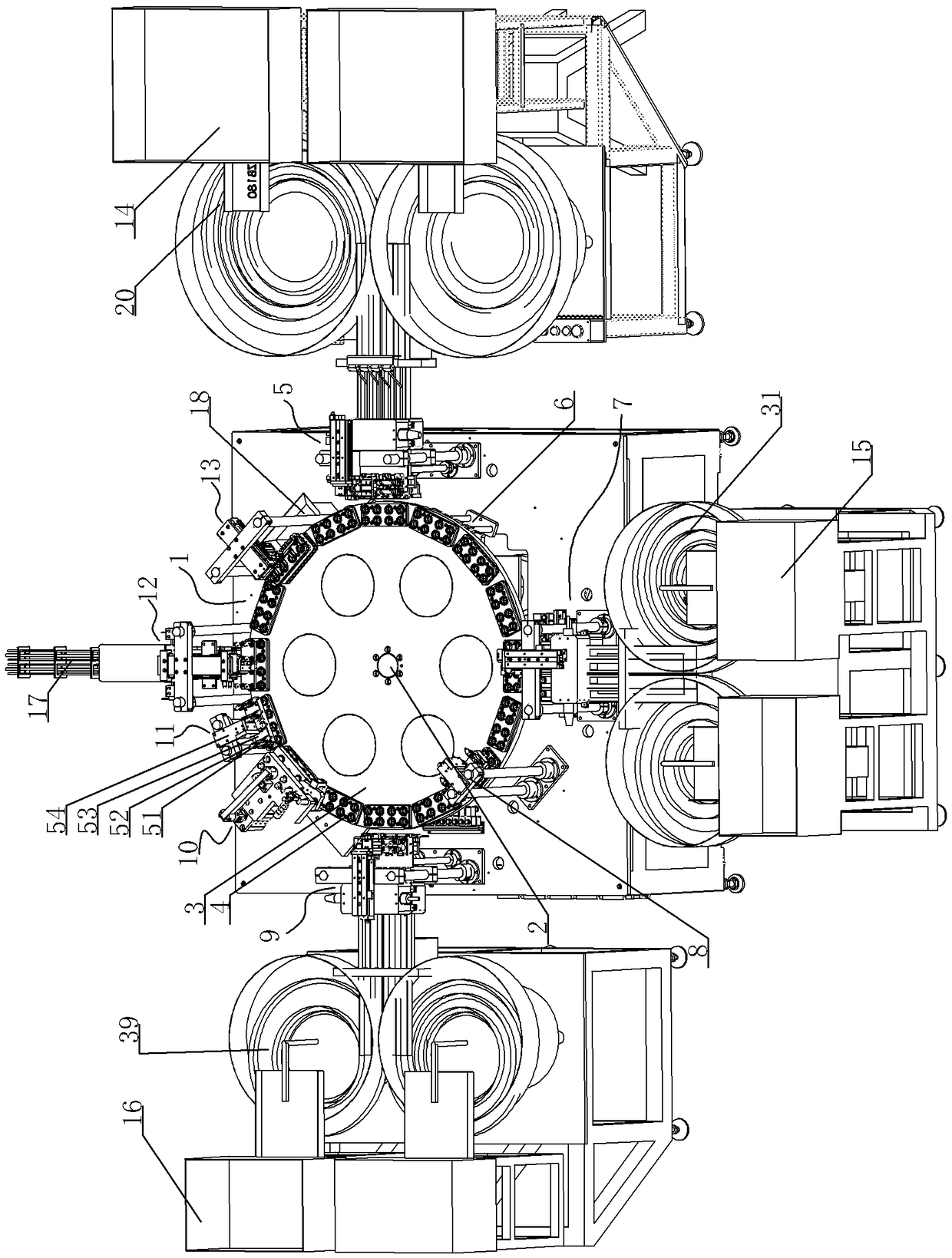

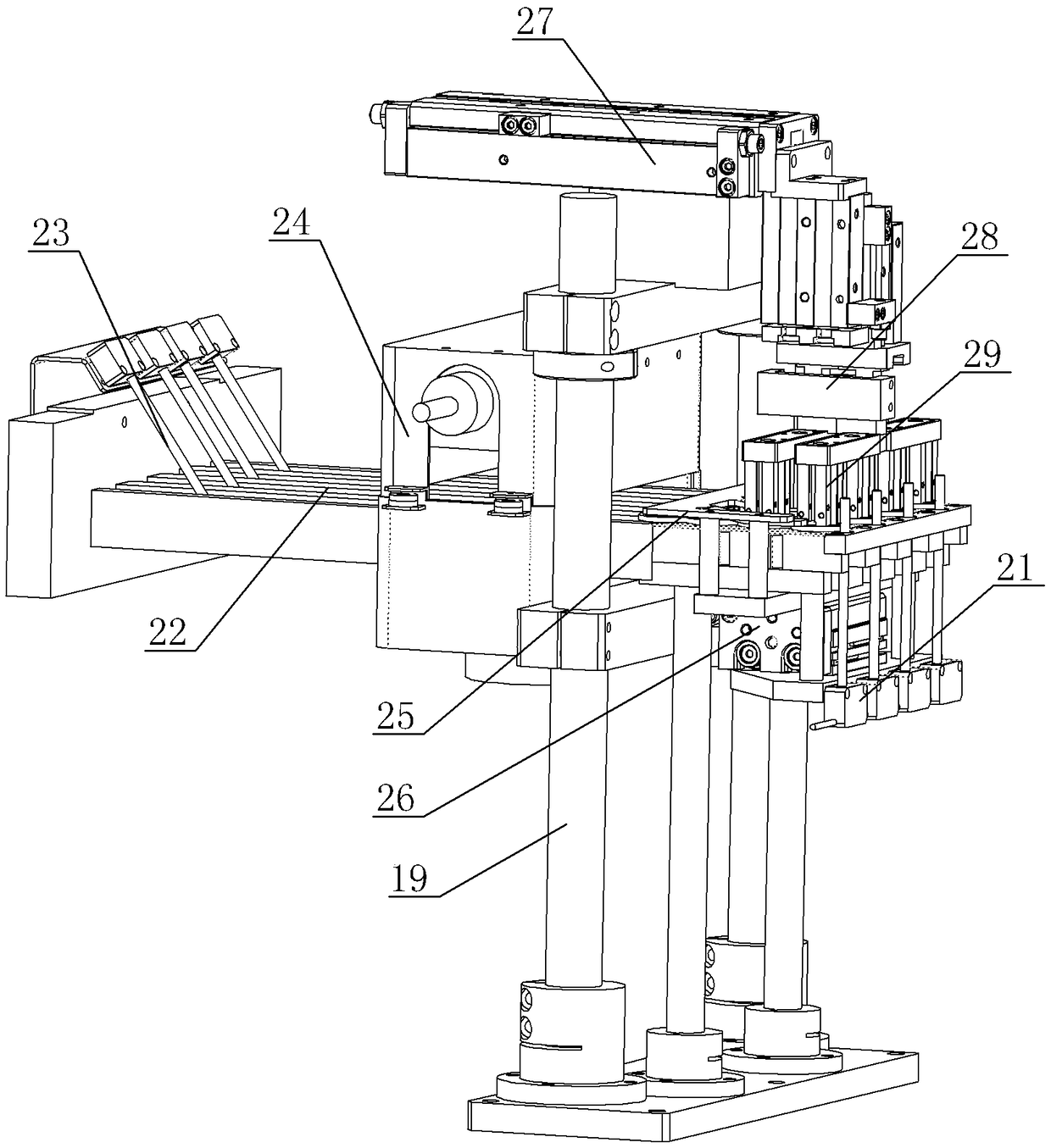

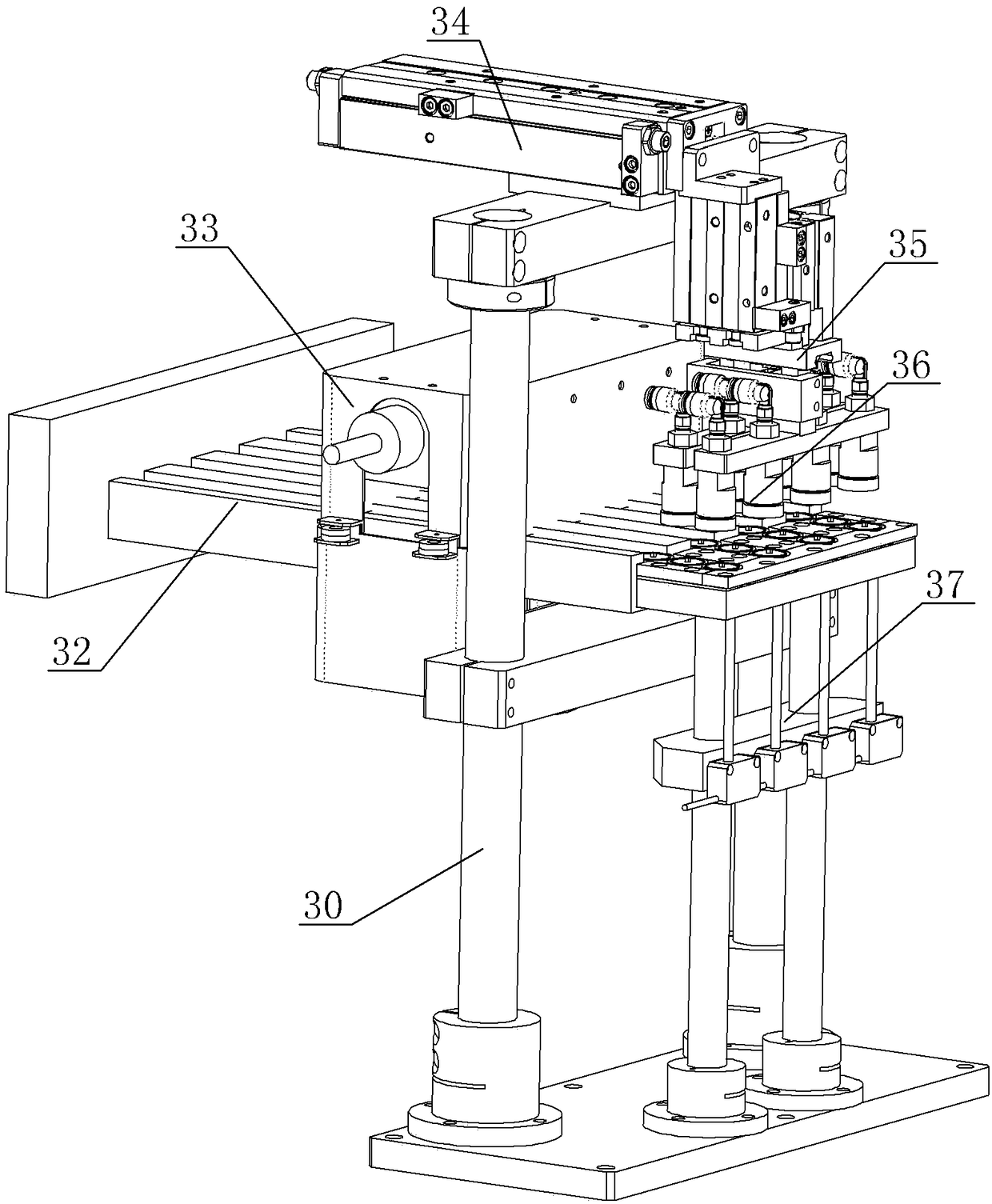

[0024] A kind of medical bottle cap assembly machine, see Figure 1 to Figure 5: It includes an indexing rotary table 1, and the indexing rotary table includes a central rotating shaft 2, an outer ring station 3, and the outer ring station 3 rotates around the central rotating shaft 2, and the upper ring of the outer ring station 3 A number of pin hole positioning structures are arranged, each pin hole positioning structure is provided with a carrier 4, and each carrier 4 is placed in a corresponding number of materials arranged in an array, and the ring direction of the outer ring station 3 is set in sequence With outer cover handling station 5, outer cover detection station 6, rubber pad handling station 7, rubber pad presence detection station 8, inner cover handling station 9, rolling pressing station 10, pressing Height detection station 11, finished product handling station 12, defective product handling station 13, outer cover handling station 5, rubber pad handling sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com