One-component anaerobic silicon chip bottom glue and preparation method thereof

An anaerobic silicon, one-component technology, applied in chemical instruments and methods, adhesives, transportation and packaging, etc., can solve the problem that can not meet the customer's 30min degumming time, is difficult to adapt to the industry trend of efficient diamond wire cutting, and is difficult to adapt to cutting Process high-speed flow and other problems, to achieve the effect of fast and efficient bonding, high shear strength, and reducing manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of one-component anaerobic silicon slice floor glue, wherein, comprise the raw material of following weight portion: take gram as unit, wherein:

[0039] Hydroxypropyl methacrylate 50, difunctional urethane acrylate 30, polymerization inhibitor p-hydroxyanisole 0.05, accelerator saccharin 1, complexing agent edetate disodium 0.02 and initiator cumene hydroperoxide 1. Methylpropylene glycol 1, polyethylene glycol (200) dimethacrylate 1 and microsphere blowing agent 1.

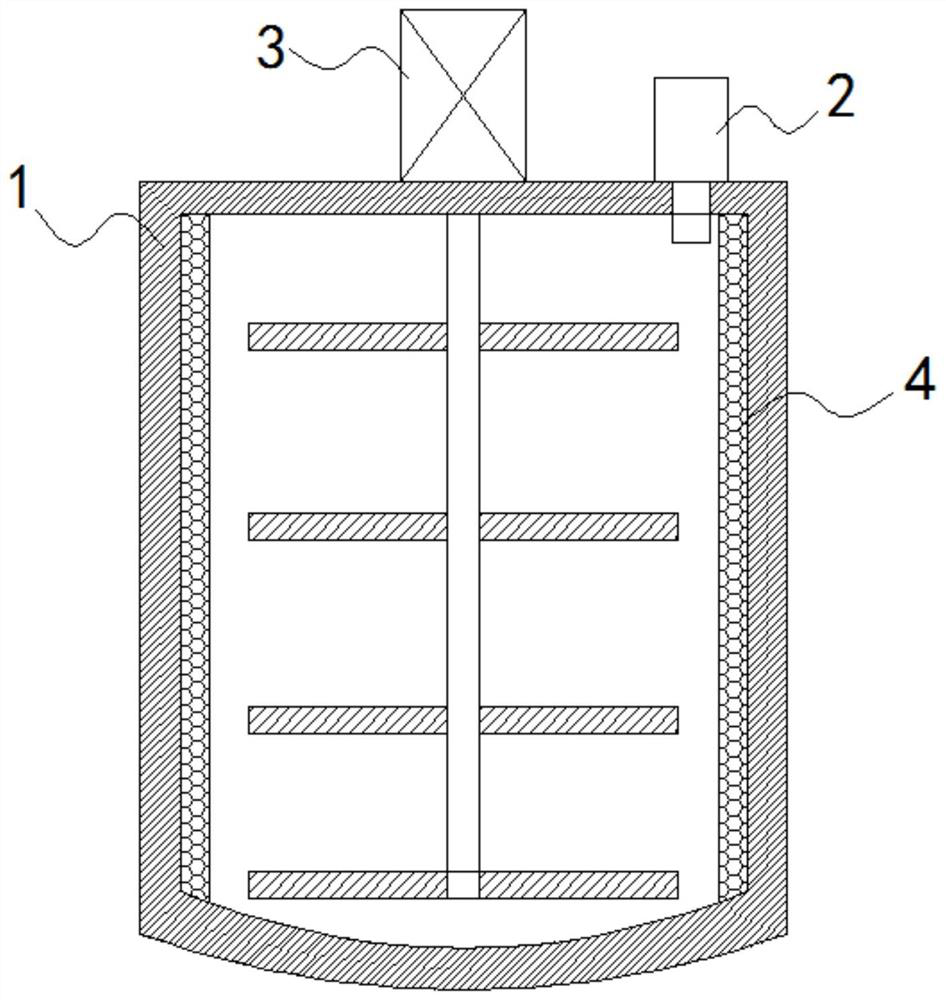

[0040] The preparation method of the one-component anaerobic silicon slice bottom plate adhesive is as follows: wipe the stirring tank clean to ensure that there are no impurities that affect the reaction; start the stirring tank, and turn on the temperature control device to control the temperature at 30°C, and add methacrylic acid to the reaction tank Hydroxypropyl ester, difunctional urethane acrylic resin, methyl propylene glycol, polyethylene glycol (200) dimethacrylate were stirred for 60 min...

Embodiment 2

[0042] A kind of one-component anaerobic silicon slice floor glue, wherein, comprise the raw material of following weight portion: take gram as unit, wherein:

[0043] Hydroxypropyl methacrylate 55, difunctional urethane acrylate 40, polymerization inhibitor p-hydroxyanisole 0.08, accelerator saccharin 1.5, complexing agent edetate disodium 0.06, initiator cumene hydroperoxide 3. Methylpropylene glycol 2, polyethylene glycol (200) dimethacrylate 2 and microsphere foaming agent 3.

[0044] The preparation method of the one-component anaerobic silicon slice bottom plate adhesive is as follows: wipe the stirring tank clean to ensure that there are no impurities that affect the reaction; start the stirring tank, and turn on the temperature control device to control the temperature at 30°C, and add methacrylic acid to the reaction tank Hydroxypropyl ester, difunctional urethane acrylic resin, methyl propylene glycol, polyethylene glycol (200) dimethacrylate were stirred for 60 minu...

Embodiment 3

[0046] A kind of one-component anaerobic silicon slice floor glue, wherein, comprise the raw material of following weight portion: take gram as unit, wherein:

[0047] Hydroxypropyl methacrylate 60, difunctional urethane acrylate 50, polymerization inhibitor p-hydroxyanisole 0.1, accelerator saccharin 2, complexing agent edetate disodium 0.1 and initiator cumene hydroperoxide 5. Methylpropylene glycol 3, polyethylene glycol (200) dimethacrylate 3 and microsphere blowing agent 5.

[0048]The preparation method of the one-component anaerobic silicon slice bottom plate adhesive is as follows: wipe the stirring tank clean to ensure that there are no impurities that affect the reaction; start the stirring tank, and turn on the temperature control device to control the temperature at 30°C, and add methacrylic acid to the reaction tank Hydroxypropyl ester, difunctional urethane acrylic resin, methyl propylene glycol, polyethylene glycol (200) dimethacrylate were stirred for 60 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com