Preparation method of antibacterial environment-friendly mulberry bark fiber

A technology of mulberry fiber and environmental protection, applied in the field of mulberry fiber, can solve problems such as microbial fiber modification, fiber damage, and environmental pollution, and achieve excellent performance, strength improvement, and good antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

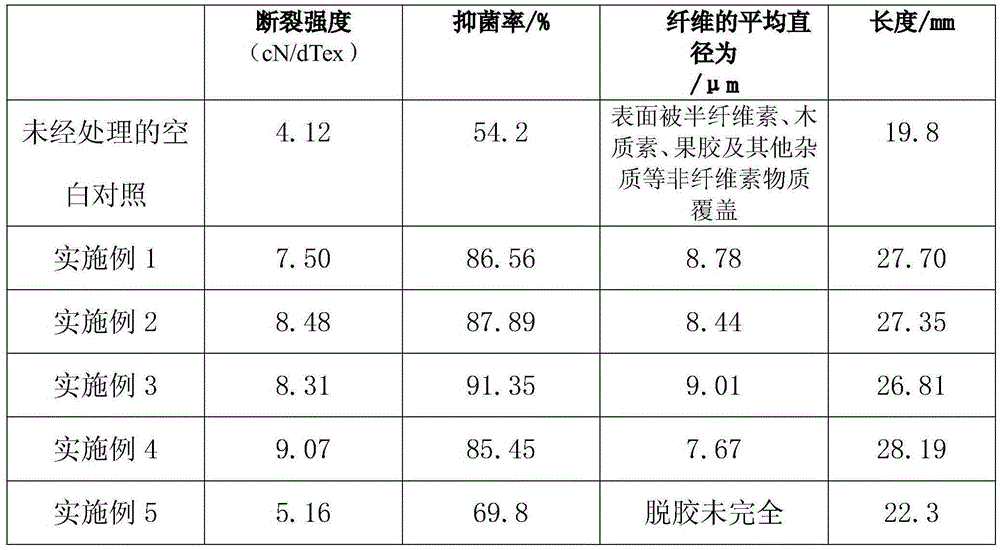

Examples

Embodiment 1

[0025] Mulberry fast biological degumming process, its steps are as follows:

[0026] (1) Preprocessing:

[0027] The mulberry bark picked is mechanically beaten to remove impurities, and then pretreated, the treatment process is: tea saponin 4g / L, time 3h, temperature 80°C, bath ratio 1:18;

[0028] (2) Microbial treatment:

[0029] Bacillus licheniformis, Bacillus subtilis, and EM bacteria are prepared according to the quantitative ratio of 1:0.2:0.5 to make a composite bacterial agent;

[0030] Spray the pretreated mulberry bark evenly with bacteria agent, ferment at 38°C for 8 hours, quickly raise the temperature to 45°C and maintain it for 2 seconds, then quickly cool down to 39°C and continue to ferment for 3 hours. After the fermentation is over, wash it with warm water;

[0031] (3) Enzyme treatment:

[0032] Equipped with enzyme solution: alkaline pectinase 1g / L, neutral protease 0.7g / L, cellulase 0.2g / L;

[0033] The enzyme activity of described alkaline pectinas...

Embodiment 2

[0039] Mulberry fast biological degumming process, its steps are as follows:

[0040] (1) Preprocessing:

[0041] The mulberry bark picked is mechanically beaten to remove impurities, and then pretreated, the treatment process is: tea saponin 5g / L, time 3h, temperature 80°C, bath ratio 1:18;

[0042] (2) Microbial treatment:

[0043] Bacillus licheniformis, Bacillus subtilis, and EM bacteria are prepared according to the quantitative ratio of 1:0.2:0.5 to make a composite bacterial agent;

[0044] Spray the pretreated mulberry bark evenly with bacteria agent, ferment at 38°C for 8 hours, quickly raise the temperature to 45°C and maintain it for 2 seconds, then quickly cool down to 39°C and continue to ferment for 2 hours. After the fermentation is over, wash it with warm water;

[0045] (3) Enzyme treatment:

[0046] Equipped with enzyme solution: alkaline pectinase 1.2g / L, neutral protease 0.6g / L, cellulase 0.2g / L;

[0047] The enzyme activity of described alkaline pectin...

Embodiment 3

[0053] Mulberry fast biological degumming process, its steps are as follows:

[0054] (1) Preprocessing:

[0055] The mulberry bark picked is mechanically beaten to remove impurities, and then pretreated, the treatment process is: tea saponin 4g / L, time 3h, temperature 80°C, bath ratio 1:18;

[0056] (2) Microbial treatment:

[0057] Bacillus licheniformis, Bacillus subtilis, and EM bacteria are prepared according to the quantitative ratio of 1:0.2:0.5 to make a composite bacterial agent;

[0058] Spray the pretreated mulberry bark evenly with bacteria agent, ferment at 38°C for 8 hours, quickly raise the temperature to 45°C and maintain it for 2 seconds, then quickly cool down to 39°C and continue to ferment for 3 hours. After the fermentation is over, wash it with warm water;

[0059] (3) Enzyme treatment:

[0060] Equipped with enzyme solution: alkaline pectinase 1.1g / L, neutral protease 0.7g / L, cellulase 0.2g / L;

[0061] The enzyme activity of described alkaline pectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com