Patents

Literature

43results about How to "Fast degumming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

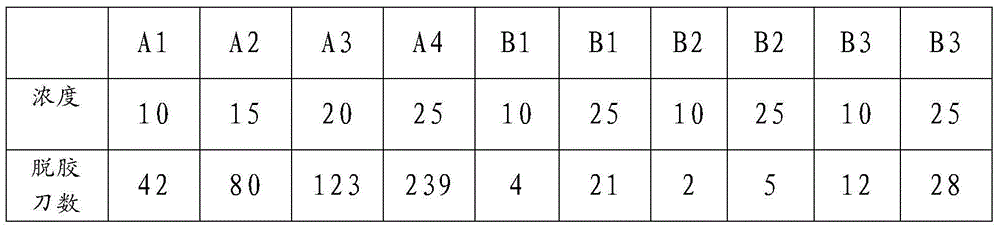

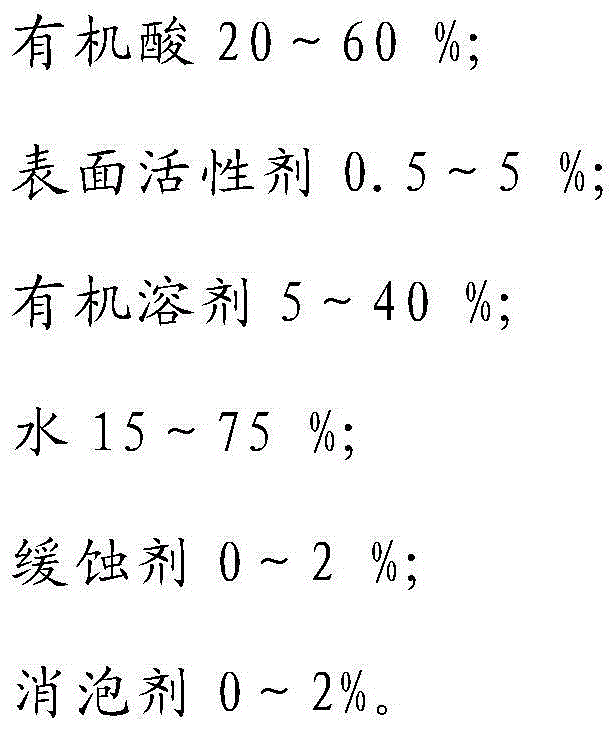

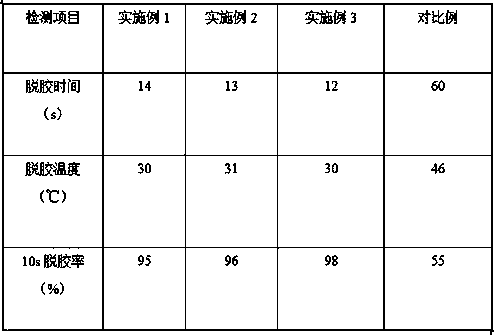

Silicon wafer degumming agent, manufacturing method and use method thereof

InactiveCN104862134AFast degummingNo irritating smellSurface-active non-soap compounds and soap mixture detergentsOrganic acidOrganic solvent

The invention relates to a silicon wafer degumming agent, which comprises, by weight, 20-60% of an organic acid, 0.5-5% of a surfactant, 5-40% of an organic solvent, 15-75% of water, 0-2% of a corrosion inhibitor, and 0-2% of an antifoaming agent. The present invention provides the silicon wafer degumming agent with characteristics of rapid degumming, no irritating odor, low cost, weak corrosion, effective reduction of wafer and edge breaking rate, and provision of excellent pre-washing effect for the next washing step so as to solve defects of poor degumming effect, high degumming cost, and strong corrosion of the existing degumming agent.

Owner:武汉宜田科技发展有限公司

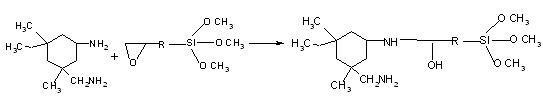

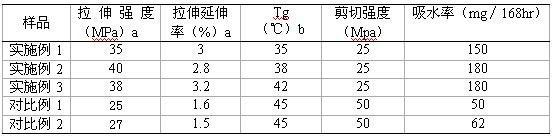

Modified epoxy resin of monocrystalline silicon rod cutting glue and preparation method thereof

InactiveCN102120925AGood degumming performanceReduce chip drop rateNon-macromolecular adhesive additivesMacromolecular adhesive additivesDefoaming AgentsMonocrystalline silicon

The invention relates to a modified epoxy resin of monocrystalline silicon rod cutting glue. The modified epoxy resin of the monocrystalline silicon rod cutting glue comprises the following raw materials comprising a component A and a component B, wherein the component A comprises 35 to 78 percent of epoxy resin, 20 to 60 percent of toughening agent, 0.5 to 2 percent of defoaming agent and 0.5 to 3 percent of coupling agent; and the component B comprises 48 to 69 percent of polymerized mercaptan, 30 to 50 percent of alicyclic modified amine and 1 to 5 percent of accelerator. The modified epoxy resin has a high degumming property and can reduce sheet-falling rate. According to epoxy silane, toughness and temperature resistance of an alicyclic amine material are achieved and low surface tension of the whole system is achieved, so that the whole levelling property of the system is improved in the whole gluing process. A hydrolysis reaction can be performing on a silane bond and the hydroxy on the surface of glass and the surface of a silicon wafer, so that the adhesion to the surface of the glass and the surface of the silicon wafer is improved. In addition, the system is toughened, the water-absorbing rate of the system after the alicyclic amine is modified is increased and the heat-resistant temperature TG is reduced, so that a sheet-falling phenomenon does not exist in the cutting and spraying processes, and the resin can be degummed quickly in the process of heating to 40 to 50 DEG C in the state of high water absorbability and softening after heating. The modified epoxy resin is applied to monocrystalline silicon rod cutting and has an extremely important effect on the monocrystalline silicon wafer industry.

Owner:康达新材料(集团)股份有限公司

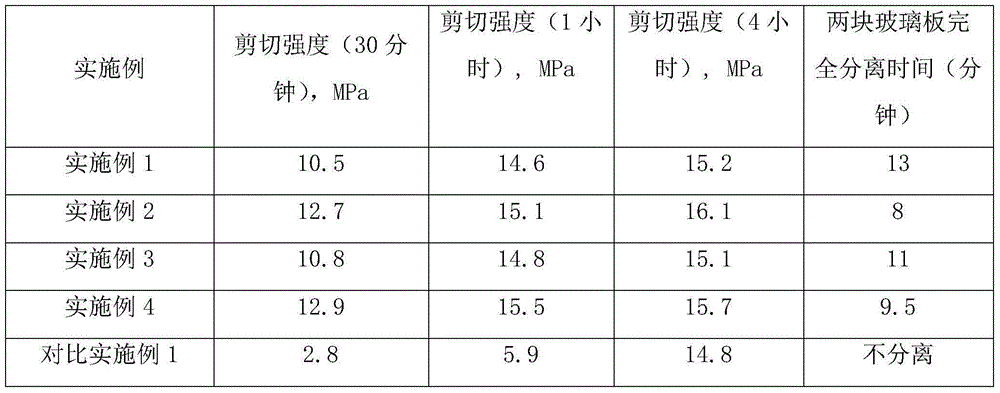

Adhesive able to realize rapid bonding and rapid separation and preparation method thereof

ActiveCN105062393AFast curingQuick breakNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesEpoxyAdhesive

The invention relates to an adhesive able to realize rapid bonding and rapid separation. The adhesive is composed of a component A and a component B in a weight ratio of 1:1. The component A comprises: 40-65 parts of special epoxy resin, 6-19 parts of thermoplastic phenolic resin, 5-20 parts of a diluent, 1-6 parts of a thermal expansion agent, 1-10 parts of a water decomposition additive, 5-20 parts of a desiccant, and 0.5-5 parts of a thixotropic agent. The component B comprises: 40-70 parts of a curing agent, 6-12 parts of a diluents, 0.5-5 parts of a degumming accelerator, 1-15 parts of a water decomposition additive, 15-35 parts of a desiccant, and 0.5-5 parts of a thixotropic agent. As a crystal holder-glass temporary bonding glue, the product provided by the invention has fast bonding speed, and at the end of wafer cutting, the crystal holder and glass plate can be immersed in hot water to realize rapid degumming and separation. No harmful gas is generated, the adhesive is energy saving and environment-friendly, and the production efficiency of solar crystal silicon slices is significantly enhanced.

Owner:YANTAI DARBOND TECH

Ramee rapid glue-removing production process

InactiveCN1629367AFast degummingReduce cooking timeFibre treatment to obtain bast fibreAqueous solutionRamie

Disclosed is a method for removing glue from ramee rapidly, which comprises the steps of, steeping raw ramee with aqueous solution of sulfuric acid, flushing immersed raw ramee with clean water, steeping the ramee with aqueous solution of NaOH, charging adjuvant, sodium tripolyphosphate, boiling in water.

Owner:张利中

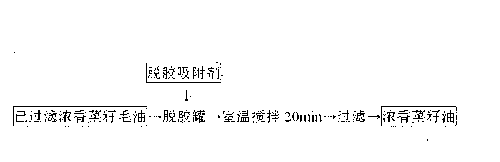

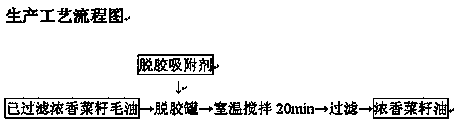

Simple degumming method of concentrated-fragrance colza oil

ActiveCN103215123AThe supporting facilities are simpleShort degumming timeOther chemical processesFatty-oils/fats refiningSlagPhospholipid

The invention relates to a simple degumming method of concentrated-fragrance colza oil. The degumming method comprises the following steps of: (1) pumping squeezed concentrated-fragrance colza crude oil with slag removed into a degumming tank, wherein the concentrated-fragrance colza crude oil does not need to be heated or cooled and just is operated at normal temperature; (2) adding a degumming absorption agent into the degumming tank; (3) stirring for 15-20min at room temperature; and (4) filtering and separating the absorption agent by using a plate frame filtering machine of which the filtering aperture is 5mu m, so as to obtain the refined concentrated-fragrance colza oil. The degumming absorption agent is prepared from montmorillonoid, silicate, modified bentonite and filter aids with different apertures which are mixed and stirred. According to the simple degumming method, the gum impurities such as phospholipids and protein in the concentrated-fragrance colza oil are absorbed by using the degumming absorption agent and then filtered and separated, thus degumming the concentrated-fragrance colza oil; and the conventional process that the concentrated-fragrance colza oil stands for a long time or is subjected to hydration degumming firstly and then dried and dehydrated is replaced, both the gum impurities can be simply and rapidly eliminated, and the concentrated fragrance of the oil is not lost, so that colza oil which is fragrant, pure in quality, nutritive and sanitary is obtained.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Degumming technology added nono-powder of apocynum by ultrasonic and microwave

InactiveCN1920126AAvoid damageLow costFibre treatment to obtain bast fibreMicrowaveVolumetric Mass Density

The invention relates to a method for using ultrasonic wave and microwave to degelatinize apocynum, used in one additional nanometer material, wherein it is characterized in that: putting the apocynum into sealed container with diluted alkali liquid of stannic oxide nanometer powder; heating with microwave; washing with water; washing with acid, and putting it into the washing liquid whose alkali density is 1.0-2.0% with stannic oxide nanometer powder; treating with utlrasonic wave with low frequency; treating with ultrasonic wave with high frquency; washing it with acid and water, then drying. The inveniton has lower cost and high speed, without pollution.

Owner:LANYAN GROUP

A kind of m-xylenediamine prepolymer and preparation method thereof

Owner:广西珀源新材料有限公司

Novel high-pressure refining process for silk folded cone yarn

InactiveCN106120310AFast degummingUniform degummingSucessive textile treatmentsDry-cleaning apparatus for textilesYarnSurface layer

The invention discloses a novel high-pressure refining process for a silk folded cone yarn, wherein the high-pressure refining process is characterized by comprising the following steps: injecting water to raise the temperature, adding a refining agent, boosting the pressure, raising the temperature, refining continuously, reducing the pressure, draining liquid, and washing with water. A special processing process is adopted, so that a silk gum wrapped in the center of a silk folded yarn is removed more rapidly and efficiently, and gums of a raw silk in both the outer layer and a central core of the whole silk folded yarn are removed evenly and cleanly. Due to the reasonable processing process, the refining time of the silk folded cone yarn is shorter, the refining efficiency is higher, so that the damage of a fibroin of the raw silk on a surface layer of the silk folded yarn is reduced, and the quality of the silk folded yarn is further improved.

Owner:DONGTAI SUMENG KNITTING FASHION

Production method of elastic puffed silk quilt

ActiveCN106757384AGood elasticityPrevent excessive fiber damageAnimal materialSilk filament obtainingEngineeringTextile

The invention discloses a production method of an elastic puffed silk quilt, relating to the technical field of home textile preparation. The method comprises cocoon selecting, cocoon cooking, degumming, pupae removing, ring sleeving, thread insertion and wire drawing, and is characterized by also comprising the steps of (A) firstly soaking cocoons into purified water before cooking the cocoons, wherein the water temperature is 50-70 DEG C and the soaking time is 3-5 minutes, putting the cocoons and the purified water into a vacuum container after soaking is completed, adding an alkaline swelling agent of which the pH is 9-10 for cooking, wherein the cooking temperature is 90-100 DEG C and the cooking time is 5-10 minutes; and (B) soaking natural silk into the purified water after wire drawing is completed, wherein the water temperature is 70-80 DEG C and the soaking time is 3-5 minutes, soaking the natural silk into the purified water containing an acid swelling agent, wherein the water temperature is 20-30 DEG C and the soaking time is 2-4 minutes, and finally drying and arranging the natural silk. Compared with the prior art, the production method has the advantage that the problem that the elasticity of an existing silk quilt is easily reduced can be solved.

Owner:广西江缘茧丝绸有限公司

Clean jute fiber degumming method

The invention relates to a clean jute fiber degumming method and belongs to the fields of textiles, biology and environmental protection. The clean jute fiber degumming method comprises a degumming step, wherein in the degumming step, the used cooking liquor is at least one of diluents of a cellulose extracting agent, residual liquor with the solid content of less than or equal to 10% and wastewater in which residues and lignin are removed; the extracting agent is prepared by mixing a solution A and a solution B; the solution A is alkali liquor; the solution B is prepared from crude enzyme fluid and an enzyme stabilizer; and the crude enzyme fluid is clarified crude enzyme fluid prepared by fermenting bacillus subtillis and separating the thallus. According to the method disclosed by the invention, jute fibers are treated in a bath by adopting the crude enzyme fluid and dilute alkali, so that the molecular structure of colloid in the original hemp is greatly changed, the stability of the colloidal complex is severely damaged, alternation and cycle of swelling-modification-colloid removing can be formed, and the aim of rapidly degumming the jute fibers is rapidly achieved under normal temperature conditions.

Owner:晟颐天祥天然纤维科技有限公司

Method for high-temperature and high-pressure acid degumming of tussah silk

The invention discloses a method for high-temperature and high-pressure acid degumming of tussah silk. Firstly, acid, a penetrant and water are mixed, degumming liquid is obtained, silk is soaked with the degumming liquid, and degumming is carried out under the conditions that the pressure is 1.0-3.0 MPa and the temperature is 100-140 DEG C. The tussah silk is treated through the high-temperature and high-pressure acid degumming method, the hydrolysis speed of sericin and the breaking speed of protein peptide bonds are increased, degumming time is short, the degumming rate can reach 13%, the breaking strength of the silk obtained after degumming can be kept at about 620 N, the strength losses of the silk are small, and rapid degumming of the tussah silk is achieved.

Owner:EASTERN LIAONING UNIV

Clean plant cellulose extraction agent, preparation method and applications thereof

ActiveCN107699596AFast degummingFast pulpingMicroorganism based processesFermentationHemp fiberProduct processing

The present invention relates to a clean plant cellulose extraction agent, a preparation method and applications thereof, and belongs to the field of biotechnology and agricultural product processingand production. The clean plant cellulose extraction agent is formed by mixing a liquid A and a liquid B, wherein a volume ratio of the liquid A to the liquid B is 3:1-5:1, the liquid A is an alkalineliquid, the liquid B comprises a crude enzyme liquid and an enzyme stabilizer, and Bacillus subtilis CGMCC1.836 is fermented, and bacterial separation is performed to obtain the clarified crude enzyme liquid. According to the present invention, the molecular structure of the colloid in the raw fiber is greatly changed by mainly using the alkaline pectin lyase, the alkaline polygalacturonase and the dilute alkali liquid, such that the stability of the colloid complex is severely damaged, and the alternating and circulating of swelling-modifying-colloid removing can be formed so as to achieve rapid hemp fiber degumming, reed pulping, cotton straw pulping and other purposes at the normal temperature.

Owner:晟颐天祥天然纤维科技有限公司

Simple degumming method of concentrated-fragrance colza oil

ActiveCN103215123BThe supporting facilities are simpleShort degumming timeOther chemical processesFatty-oils/fats refiningSlagPhospholipid

The invention relates to a simple degumming method of concentrated-fragrance colza oil. The degumming method comprises the following steps of: (1) pumping squeezed concentrated-fragrance colza crude oil with slag removed into a degumming tank, wherein the concentrated-fragrance colza crude oil does not need to be heated or cooled and just is operated at normal temperature; (2) adding a degumming absorption agent into the degumming tank; (3) stirring for 15-20min at room temperature; and (4) filtering and separating the absorption agent by using a plate frame filtering machine of which the filtering aperture is 5mu m, so as to obtain the refined concentrated-fragrance colza oil. The degumming absorption agent is prepared from montmorillonoid, silicate, modified bentonite and filter aids with different apertures which are mixed and stirred. According to the simple degumming method, the gum impurities such as phospholipids and protein in the concentrated-fragrance colza oil are absorbed by using the degumming absorption agent and then filtered and separated, thus degumming the concentrated-fragrance colza oil; and the conventional process that the concentrated-fragrance colza oil stands for a long time or is subjected to hydration degumming firstly and then dried and dehydrated is replaced, both the gum impurities can be simply and rapidly eliminated, and the concentrated fragrance of the oil is not lost, so that colza oil which is fragrant, pure in quality, nutritive and sanitary is obtained.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

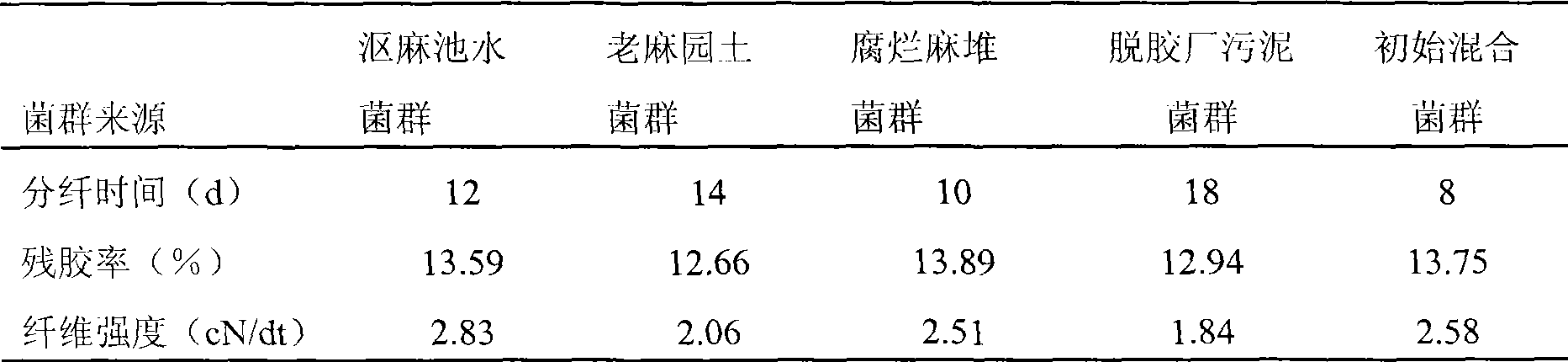

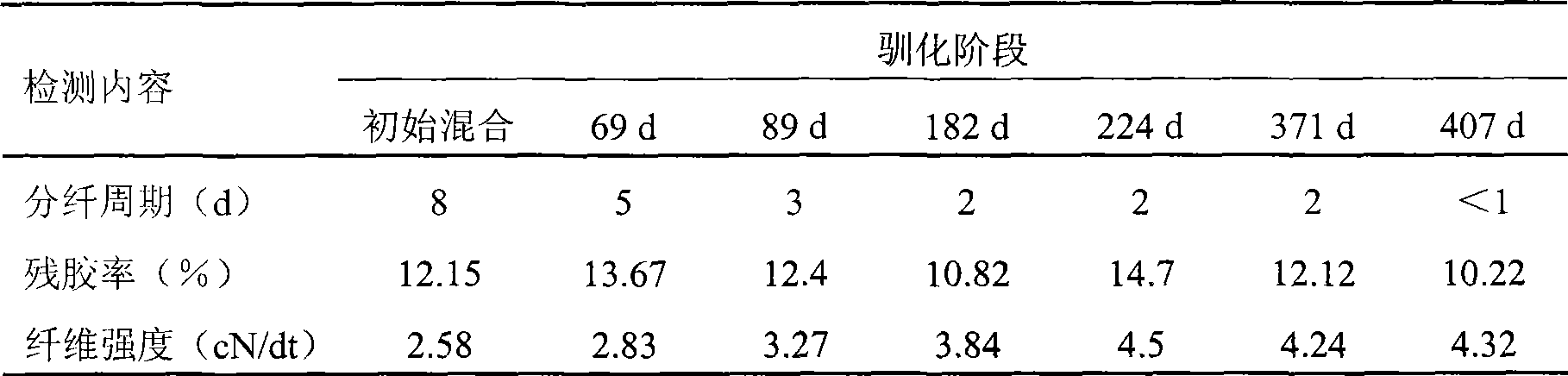

Construction method of microecosystem for microbial retting of ramie phloem

The invention relates to a method for establishing a ramie phloem fiber biological degumming microecosystem, which comprises the following steps: bacterial sources are collected from a plurality of rotten ramie habitats; and ramie phloem is taken as a single carbon source and a single energy, subjected to enrichment culture for a short period and mixed with the bacterial sources in equal proportion; the ramie phloem is taken as the single carbon source and the single energy and subjected to directional acclimatization at a temperature of between 40 and 43 DEG C and at an initial pH value of 7.5; the ramie phloem is subjected to refueling and repeated inoculation when being separated into the shape of cotton, wherein the inoculum size is 10 percent of the total volume of a culture solution, and the accumulated acclimatization time is between 1 and 2 years; the degumming microecosystem is established after gradual removal of mixed bacteria; floras are subjected to cross-feeding in the system, and secrete extracellular enzymes to highly efficiently degrade the colloids; and the flora structure and the functional stability in the system are maintained by means of transfer of living bodies. The method has the advantages of quick speed of acquisition of high-efficiency degumming strains, extensive varieties of degumming enzymes, high appetency of the enzymes and ramie colloid substrates, strong mixed bacteria resistance of the floras, difficulty of causing degeneration of the degumming capacity, etc.

Owner:WUHAN TEXTILE UNIV

A kind of rapid biological degumming process of mulberry bark

ActiveCN105420821BWill not cause pollutionFast degummingBacteriological rettingFibre treatment to obtain bast fibreBacillus licheniformisBiotechnology

The invention discloses a rapid mulberry bark biological degumming process. Picked mulberry bark is pretreated. The treatment process includes the steps that tea saponin ranges from 4 g / L to 5 g / L, time is 3 h, temperature is 80 DEG C, and the bath ratio is 1:18; bacillus licheniformis, bacillus subtilis and EM bacteria are prepared into a complex microbial inoculant according to the quantity ratio of 1:0.2:0.5; the microbial inoculant is evenly sprayed to the pretreated mulberry bark, and after being fermented for 8 h at the temperature of 38 DEG C, the mulberry bark is rapidly heated to 45 DEG C, the temperature is kept for 2 s and then rapidly cooled to 39 DEG C, continues to be fermented for 2-3 h, and is completely washed with warm water after fermentation is finished; an enzyme solution is prepared, wherein the treatment parameters are characterized in that the bath ratio is 1:15, time ranges from 100 min to 120 min, and temperature is 45 DEG C. The biological fermentation process and bio-enzyme treatment are fully utilized, especially unique heat shock treatment is used in the fermentation process, the mulberry bark can be rapidly degummed, and the gum content of the treated mulberry bark can be controlled to be 40% or below.

Owner:桐乡市立明喷织股份有限公司

Preparation method of degumming agent

InactiveCN111100765ADegumming completelyImprove degumming efficiencyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsActive agentCatalytic effect

The invention relates to a preparation method of a degumming agent, and belongs to the technical field of glue cleaning. The bio-enzyme and the citric acid-sodium citrate buffer solution are mixed, the inorganic solvent sodium peroxide, the organic solvent ethylene glycol carbonate, the auxiliary sodium tripolyphosphate and the surfactant are combined to prepare the environment-friendly degummingagent, the degumming efficiency is high, and degumming is thorough; the bio-enzyme is an organic matter which is generated by living cells and has a catalytic effect, most of the bio-enzyme is protein, a small part of the bio-enzyme is RNA, degumming by a bio-enzyme method is to catalyze and hydrolyze colloid by directly utilizing a bio-enzyme preparation or extracted degumming enzyme liquid, degumming is realized, the process is simple, and the operation is flexible; and the organic solvent in the degumming agent is used for dissolving and dispersing the glue, reducing the molecular weight and viscosity, dispersing the glue into microparticles and stripping the residual glue.

Owner:张艳

Clean and environment-friendly flax degumming method

InactiveCN110983449AFast degummingImprove degumming problemMechanical fibre separationFibre treatment to obtain bast fibreWastewaterProcess engineering

The invention discloses a clean and environment-friendly flax degumming method. The method comprises the following steps of: 1, pretreating flax raw stems; 2, carrying out water bath soaking; 3, carrying out hemicellulase soaking; 4, carrying out water bath soaking again; and 5, carrying out mixed enzyme liquid retting and degumming. Generated wastewater is little, the smell is light, and the pollution to the surrounding environment is little.

Owner:沈金标

Gluewater for bonding with rubber plate in rhinestone grinding process and preparation method thereof

InactiveCN106634735AConvenient ironing drill cleaningNo irritating smellNon-macromolecular adhesive additivesGraft polymer adhesivesSodium bicarbonatePolyvinyl alcohol

The invention relates to an auxiliary article for a rhinestone grinding process, in particular to gluewater for bonding with a rubber plate in a rhinestone grinding process. The gluewater is prepared from the following ingredients in percentage by mass: 40 to 45 percent of water, 6.5 to 7 percent of polyvinyl alcohol, 1 to 1.4 percent of emulsifiers, 0.8 to 1.0 percent of ammonium persulfate, 0.8 to 1.2 percent of acrylic acid, 2 to 4 percent of methacrylic acid, 35 to 40 percent of vinyl acetate, 2 to 4 percent of butyl acrylate, 3.0 to 3.4 percent of dibutyl phthalate and 0.6 to 1.0 percent of sodium bicarbonate. After rhinestones are pasted on the rubber plate and are dried, no smoke and no pungent smell are generated; the environment is protected; no pollution is caused; the firmness is high; the stability is high; meanwhile, after the grinding is completed, the glue can be fast removed only through water soaking; the cleaning of the rhinestone can be convenient; the manufacturing is convenient; the manufacturing cost is low.

Owner:建德市鑫辉水晶工艺品有限公司

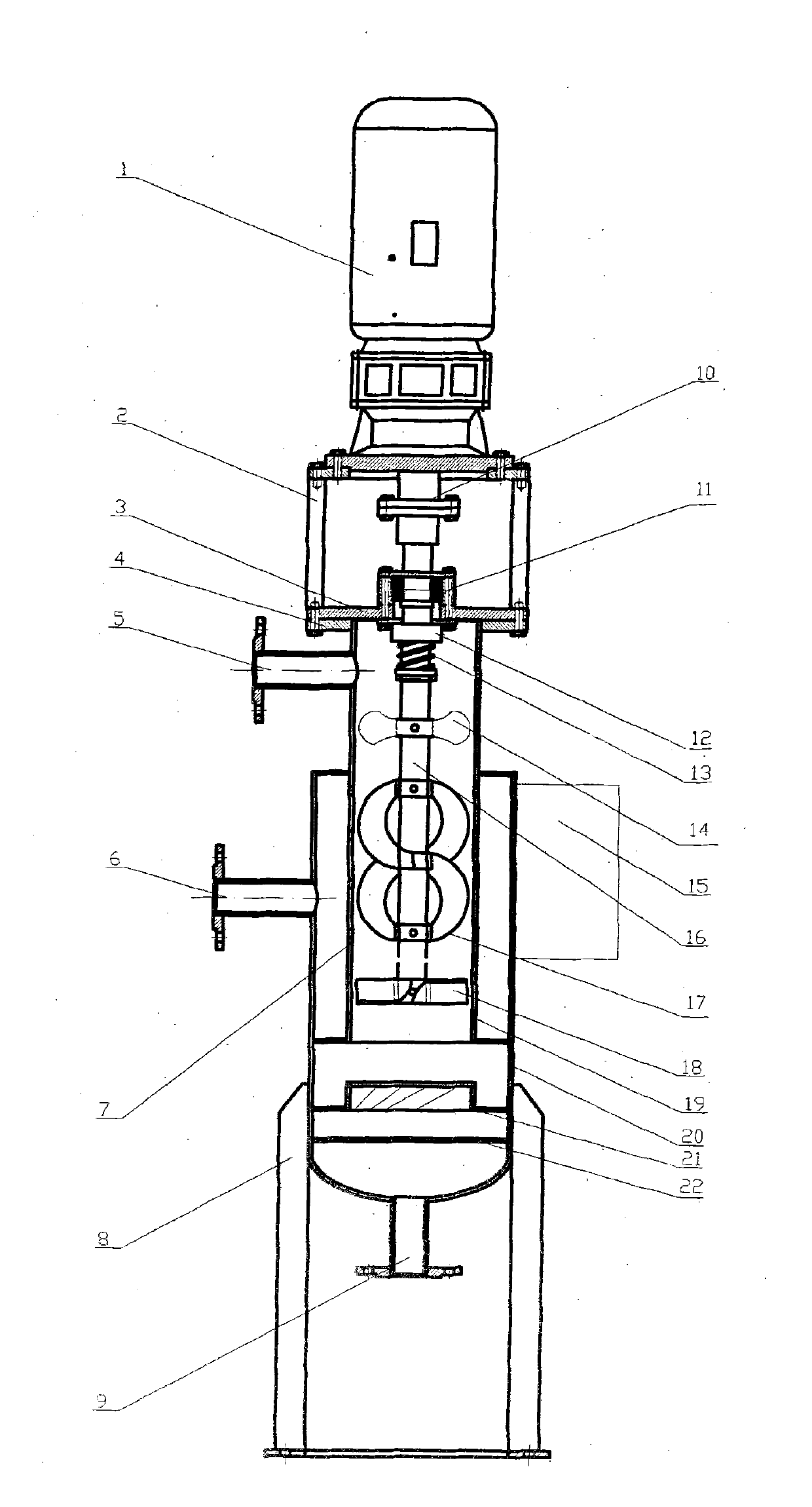

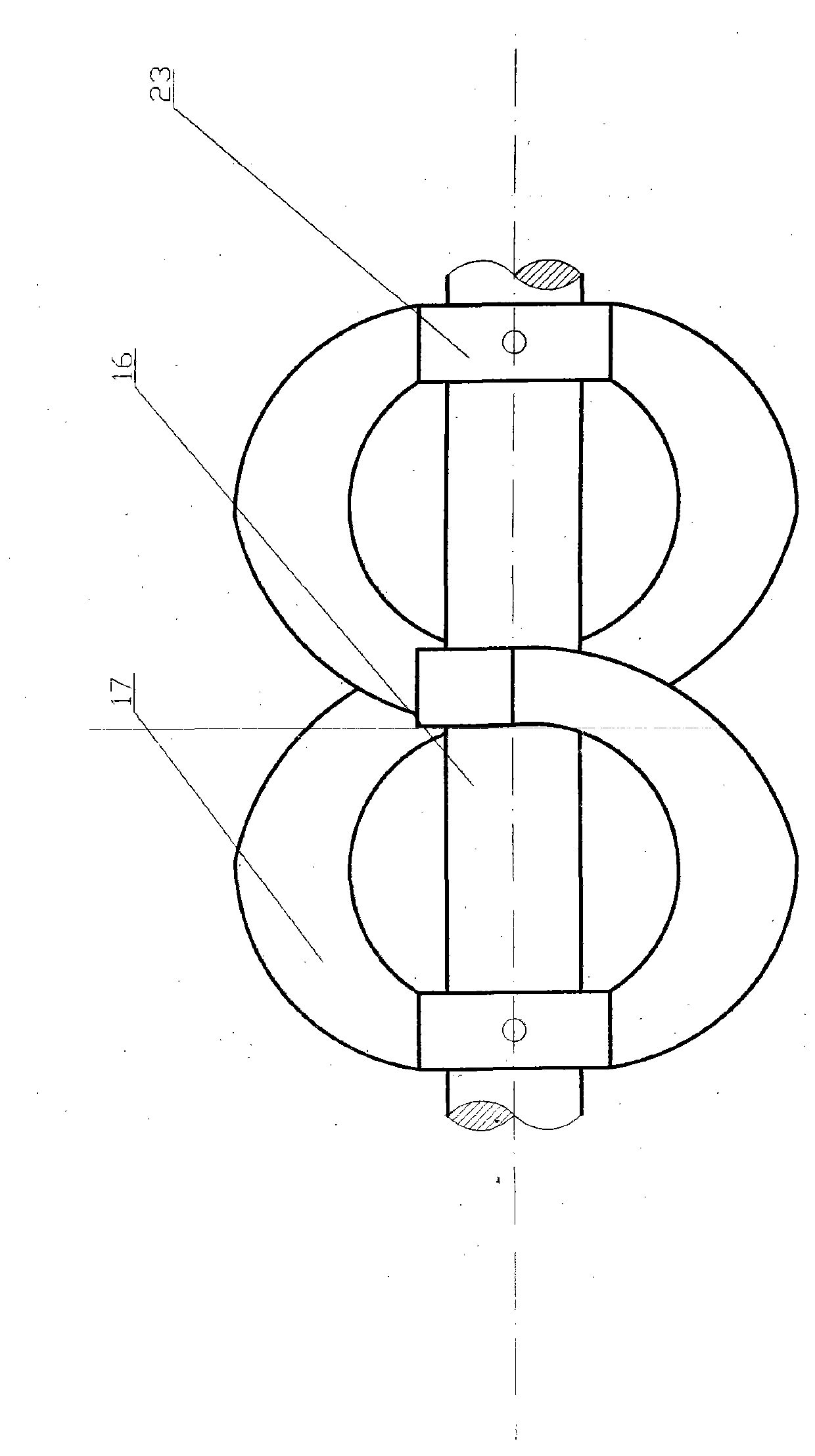

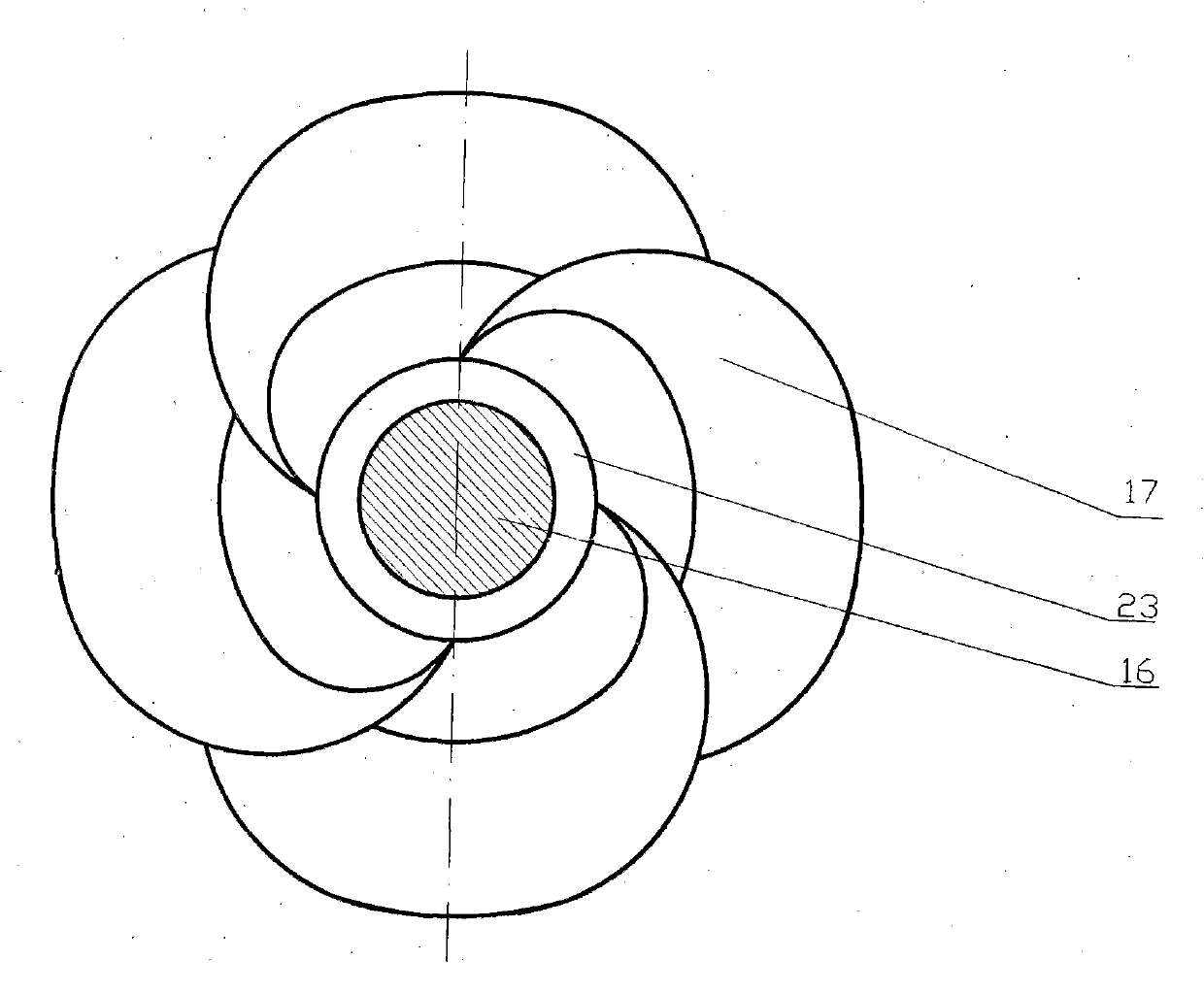

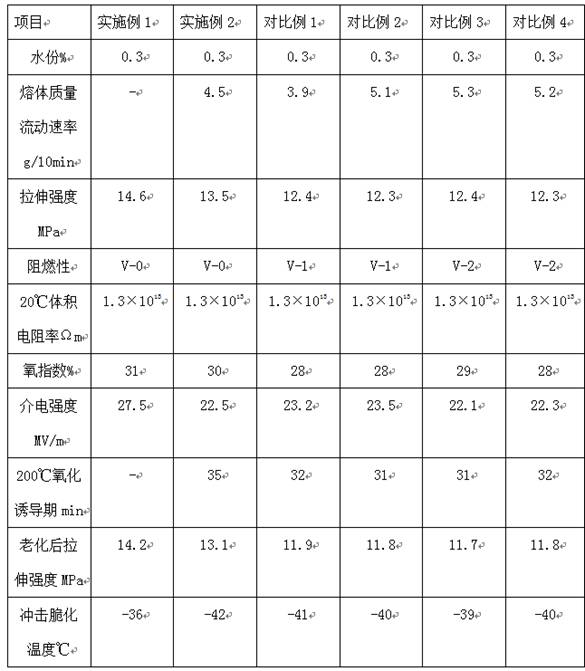

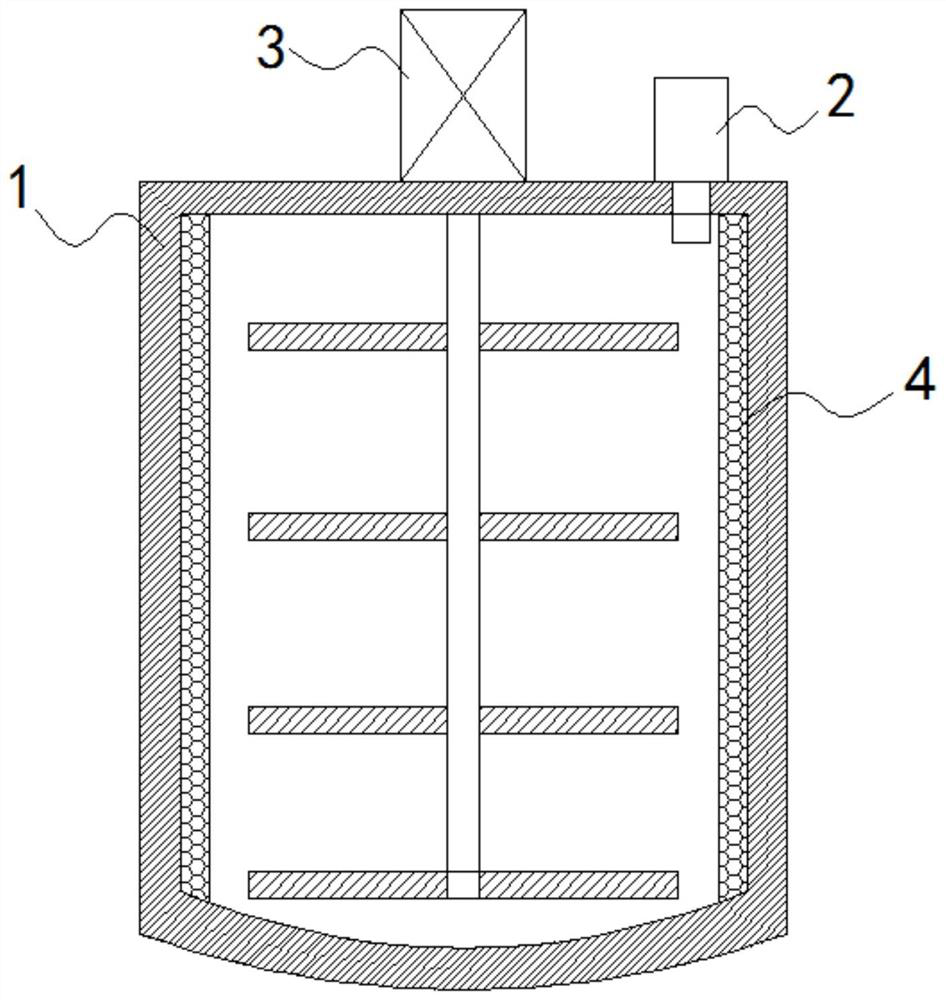

Ultrasonic multi-effect mixer for edible oil

InactiveCN103861510AFully dispersedIncreased diffusion rateMixersFatty-oils/fats refiningTreatment effectBiochemical engineering

The invention discloses an ultrasonic multi-effect mixer for edible oil, which adopts the design of an upper cavity and a lower cavity, wherein the upper one is a dispersing cavity, and the lower one is a mixing cavity. The mixed solution entering in the dispersing cavity performs radial and axial circulation under the reverse pushing of a stirring blade, and with the influence action of a baffle in the cavity, the treatment effect of dispersing and mixing is completely achieved, and the requirement of micromixing is achieved. The ultrasonic wave generated by an ultrasonic generator arranged in a barrel body can be used for assisting in degumming, when an ultrasonic field passes through a uniform gum dispersion system, gum grains move towards the direction of the crest or the trough of the ultrasonic wave, and then perform breakage and collapse to demulsify, and the cavatition effect of the ultrasonic wave causes the changes of a medium, a substrate, and the generation structure and properties of an enzyme in an enzyme reaction system, and then causes the exposure of the action centre of the enzyme; effective binding between the substrate and the enzyme is promoted, thus improving the catalytic activity of the enzyme; and via the arrangements of multi-stage mixing and the ultrasonic generator, edible crude oil achieves the effect of a high degumming speed.

Owner:BEIJING ZHONGTIAN JINGU GRAIN OIL ENG TECH

Process method for regenerating flame-retardant plastic particles by using waste powder coating

The invention discloses a process method for regenerating flame-retardant plastic particles from waste powder coating. The invention belongs to the technical field of recycled plastics. The prepared recycled plastic particles have obvious cost advantages; particularly, the price of plastic raw materials rises greatly recently; the requirements of the market on reclaimed materials are further improved; according to the invention, the requirements can be greatly met; the conversion and metabolism rules of material energy in the recycling process of the waste powder coating are utilized; the regeneration process does not comprise the melting extrusion molding granulation of the conventional regenerated plastic particles, so that the high manufacturing cost and complex process procedures of equipment such as an extruder are reduced, the labor is saved, the labor and the cost are greatly reduced, and the prepared regenerated plastic particles have extremely high economic added value.

Owner:蒋娜

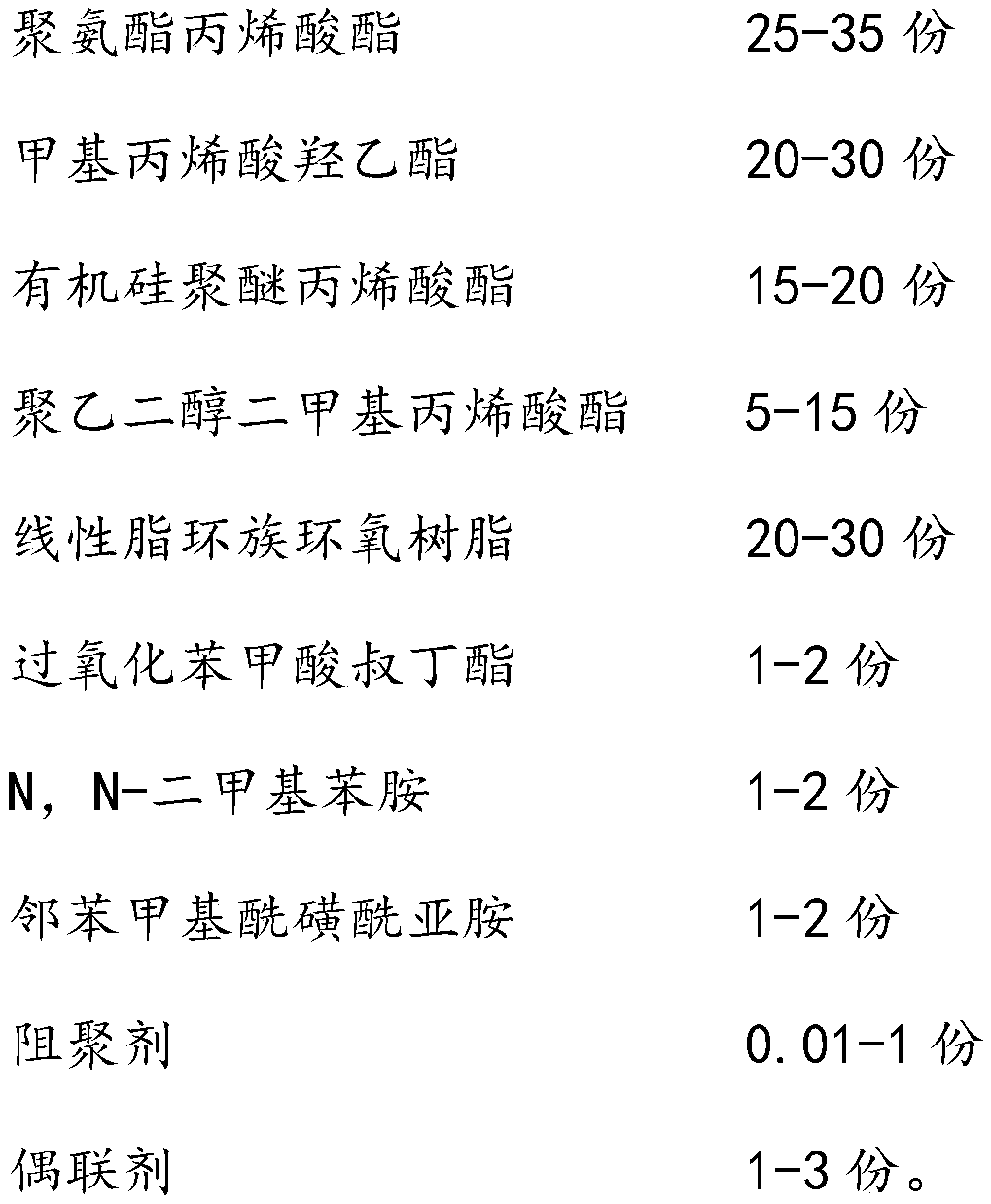

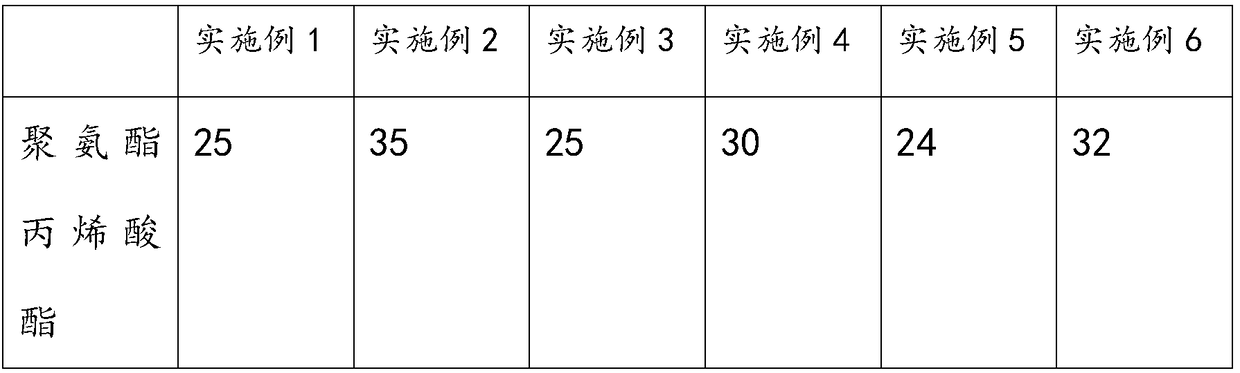

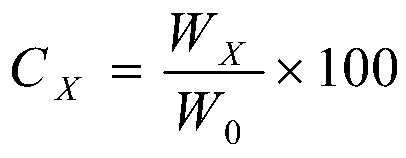

Fixing glue for cutting silicon crystal as well as preparation method and application thereof

InactiveCN109054722APhysical stabilityChemically stableAdhesive processesNon-macromolecular adhesive additivesOxygenSilicon dioxide

The invention relates to fixing glue for cutting a silicon crystal as well as a preparation method and application thereof. The fixing glue is prepared form anaerobic glue and a surface accelerator, wherein the anaerobic glue is a single-component sealing adhesive prepared by utilizing an oxygen free radical polymerization inhibition principle; the anaerobic glue has the advantages of good curingspeed, storage stability, bonding strength, chemical medium resistance, easy for degumming and the like, so that the anaerobic glue is used for cutting and fixing various gemstones and crystals in recent years; the anaerobic glue prepared in the scheme has high bonding strength, a rapid curing speed and rapid and complete degumming, and damages to cut gemstones and adhesion strength are not easy to cause; the dosage of organic silicon polyether acrylate, linear cycloaliphatic epoxy resin and tert-butyl peroxybenzoate is increased and part of organic silicon groups are introduced, so that the flowability of the anaerobic glue is reduced, rapid degumming is convenient to realize and adhesion between the anaerobic glue and the crystal is reduced; compared with free silicon including silicon dioxide and the like, the organic silicon groups do not easily form other silicon impurities on the surface of the crystal in a curing and adhesion or degumming process.

Owner:江苏乐美新材料科技有限公司

A kind of method for cleaning hemp fiber degumming

The invention relates to a clean jute fiber degumming method and belongs to the fields of textiles, biology and environmental protection. The clean jute fiber degumming method comprises a degumming step, wherein in the degumming step, the used cooking liquor is at least one of diluents of a cellulose extracting agent, residual liquor with the solid content of less than or equal to 10% and wastewater in which residues and lignin are removed; the extracting agent is prepared by mixing a solution A and a solution B; the solution A is alkali liquor; the solution B is prepared from crude enzyme fluid and an enzyme stabilizer; and the crude enzyme fluid is clarified crude enzyme fluid prepared by fermenting bacillus subtillis and separating the thallus. According to the method disclosed by the invention, jute fibers are treated in a bath by adopting the crude enzyme fluid and dilute alkali, so that the molecular structure of colloid in the original hemp is greatly changed, the stability of the colloidal complex is severely damaged, alternation and cycle of swelling-modification-colloid removing can be formed, and the aim of rapidly degumming the jute fibers is rapidly achieved under normal temperature conditions.

Owner:晟颐天祥天然纤维科技有限公司

Production method of elastic bulked silk quilt

ActiveCN106757384BBest puffed stateIncrease elasticityAnimal materialSilk filament obtainingEngineeringWater temperature

The invention discloses a production method of an elastic puffed silk quilt, relating to the technical field of home textile preparation. The method comprises cocoon selecting, cocoon cooking, degumming, pupae removing, ring sleeving, thread insertion and wire drawing, and is characterized by also comprising the steps of (A) firstly soaking cocoons into purified water before cooking the cocoons, wherein the water temperature is 50-70 DEG C and the soaking time is 3-5 minutes, putting the cocoons and the purified water into a vacuum container after soaking is completed, adding an alkaline swelling agent of which the pH is 9-10 for cooking, wherein the cooking temperature is 90-100 DEG C and the cooking time is 5-10 minutes; and (B) soaking natural silk into the purified water after wire drawing is completed, wherein the water temperature is 70-80 DEG C and the soaking time is 3-5 minutes, soaking the natural silk into the purified water containing an acid swelling agent, wherein the water temperature is 20-30 DEG C and the soaking time is 2-4 minutes, and finally drying and arranging the natural silk. Compared with the prior art, the production method has the advantage that the problem that the elasticity of an existing silk quilt is easily reduced can be solved.

Owner:广西江缘茧丝绸有限公司

A kind of microbial composite bacteria agent for ramie biological degumming pretreatment and preparation method thereof

The invention relates to the technical field of biological degumming, in particular to a microbial composite bacterial agent for ramie biological degumming pretreatment and a preparation method thereof. The preparation method comprises the following steps: respectively inoculating Bipedia, Rhizopus chrysporus, Erwinia, and Pantoea disperse into culture medium to obtain Bipedia bacterium liquid, Rhizopus chlamesporum liquid, Erwinia spp. Bacillus bacteria liquid and dispersed Pantoea bacteria liquid, these four kinds of bacterial liquids are mixed to obtain compound bacterial agent seed liquid; the compound bacterial agent seed liquid is inoculated into compound bacterial agent medium for mixed fermentation to obtain microbial compound bacteria agent. The preparation method provided by the invention is simple and low in cost, and can effectively realize biological degumming of ramie.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI +1

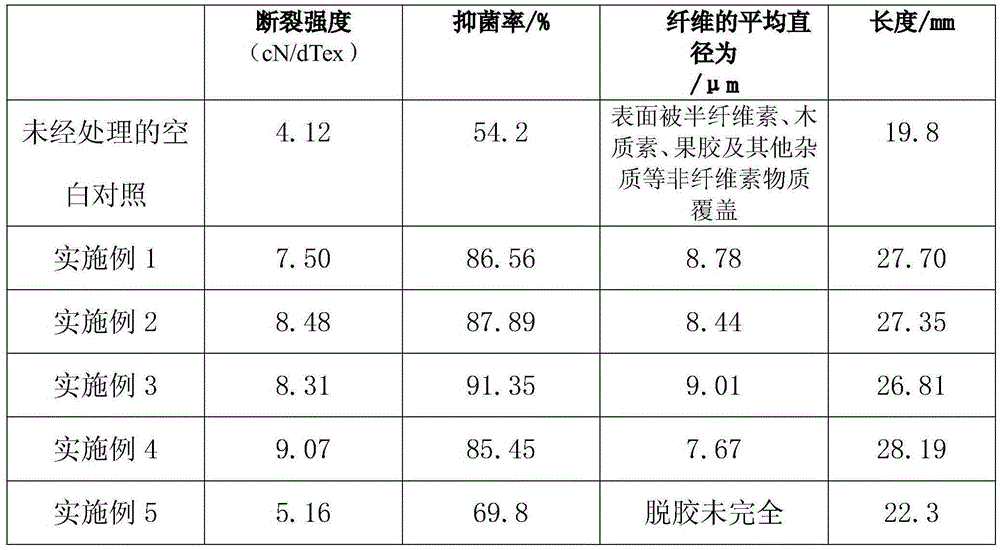

An antibacterial and environmentally friendly mulberry fiber

ActiveCN105239168BFast degummingImprove performanceMicroorganismsVegetable materialBacillus licheniformisFiber

The invention discloses a preparation method of antibacterial environment-friendly mulberry bark fiber. The method is as below: conducting mechanical beating on the mulberry bark to remove impurities; then conducting pretreatment with the process of tea saponin 4-5 g / L, 3h, temperature of 80 DEG C, and bath ratio of 1:18; preparing Bacillus licheniformis, Bacillus subtilis, and EM bacteria in the ratio of 1:0.2:0.5 into a compound inoculant; uniformly spraying the inoculant on the pretreated mulberry bark, fermenting at 38 DEG C for 8 h, rapidly heating to 45 DEG C and maintaining for 2 s; then rapidly cooling to 39 DEG C, continuing fermentation for 2-3 h, and washing with warm water after fermentation; preparing an enzyme solution under the parameters of bath ratio of 1:15, 100-120 min, and temperature of 45 DEG C; and rinsing, carrying out routine soaping, loosing and drying.

Owner:韩建华

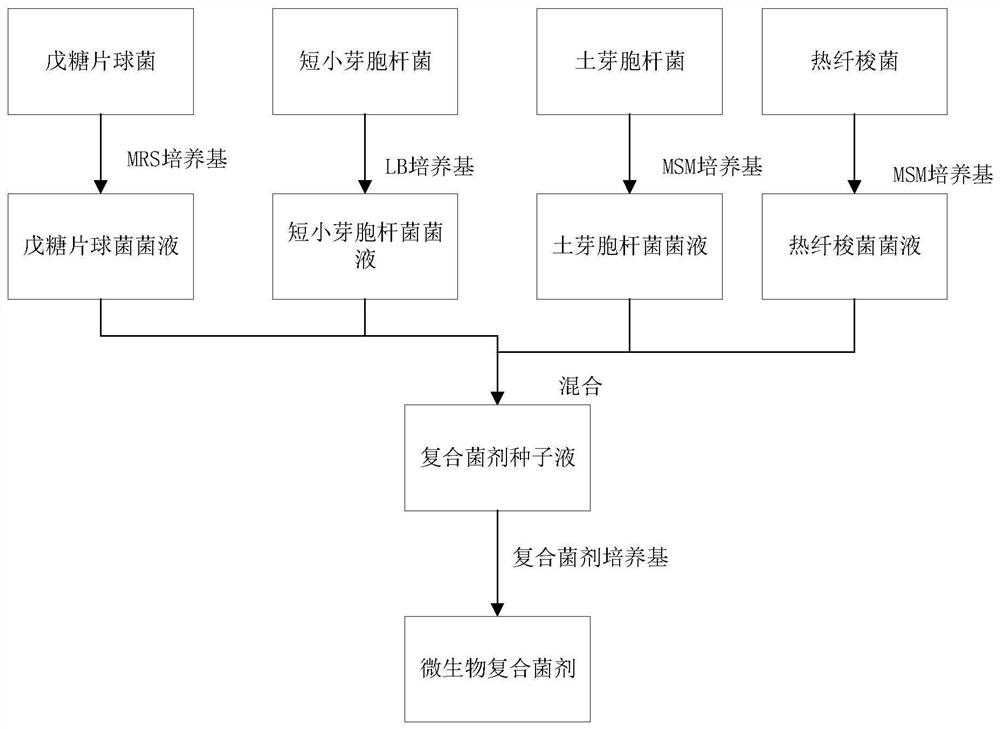

A kind of high-temperature microbial composite bacterial agent for ramie biological degumming pretreatment and preparation method thereof

ActiveCN111763640BEfficient decompositionFast degummingBacteriaMicroorganism based processesBiotechnologyBiology

The invention relates to the technical field of biological degumming, in particular to a preparation method of a high-temperature microbial composite bacterial agent used for pretreatment of ramie biological degumming. The preparation method comprises the following steps: respectively culturing Pediococcus pentosaceae, Bacillus pumilus, Geobacillus and Clostridium thermocellum in the culture medium to obtain the bacterial liquid of Pediococcus pentosaceae, the bacterial liquid of Bacillus pumilus and the bacterial liquid of Geobacillus pumilus Bacterial solution, Clostridium thermocellum bacterial solution, these four kinds of bacterial solutions are mixed to obtain a composite bacterial agent seed solution, and the composite bacterial agent seed solution is inserted into a composite bacterial agent medium for mixed fermentation to obtain a microbial composite bacterium agent. The preparation method provided by the invention is simple and low in cost, and can effectively realize biological degumming of ramie.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

A kind of clean plant cellulose extractant and its preparation method and application

The present invention relates to a clean plant cellulose extraction agent, a preparation method and applications thereof, and belongs to the field of biotechnology and agricultural product processingand production. The clean plant cellulose extraction agent is formed by mixing a liquid A and a liquid B, wherein a volume ratio of the liquid A to the liquid B is 3:1-5:1, the liquid A is an alkalineliquid, the liquid B comprises a crude enzyme liquid and an enzyme stabilizer, and Bacillus subtilis CGMCC1.836 is fermented, and bacterial separation is performed to obtain the clarified crude enzyme liquid. According to the present invention, the molecular structure of the colloid in the raw fiber is greatly changed by mainly using the alkaline pectin lyase, the alkaline polygalacturonase and the dilute alkali liquid, such that the stability of the colloid complex is severely damaged, and the alternating and circulating of swelling-modifying-colloid removing can be formed so as to achieve rapid hemp fiber degumming, reed pulping, cotton straw pulping and other purposes at the normal temperature.

Owner:晟颐天祥天然纤维科技有限公司

A kind of high temperature and high pressure acid degumming method of tussah silk

The invention discloses a method for high-temperature and high-pressure acid degumming of tussah silk. Firstly, acid, a penetrant and water are mixed, degumming liquid is obtained, silk is soaked with the degumming liquid, and degumming is carried out under the conditions that the pressure is 1.0-3.0 MPa and the temperature is 100-140 DEG C. The tussah silk is treated through the high-temperature and high-pressure acid degumming method, the hydrolysis speed of sericin and the breaking speed of protein peptide bonds are increased, degumming time is short, the degumming rate can reach 13%, the breaking strength of the silk obtained after degumming can be kept at about 620 N, the strength losses of the silk are small, and rapid degumming of the tussah silk is achieved.

Owner:EASTERN LIAONING UNIV

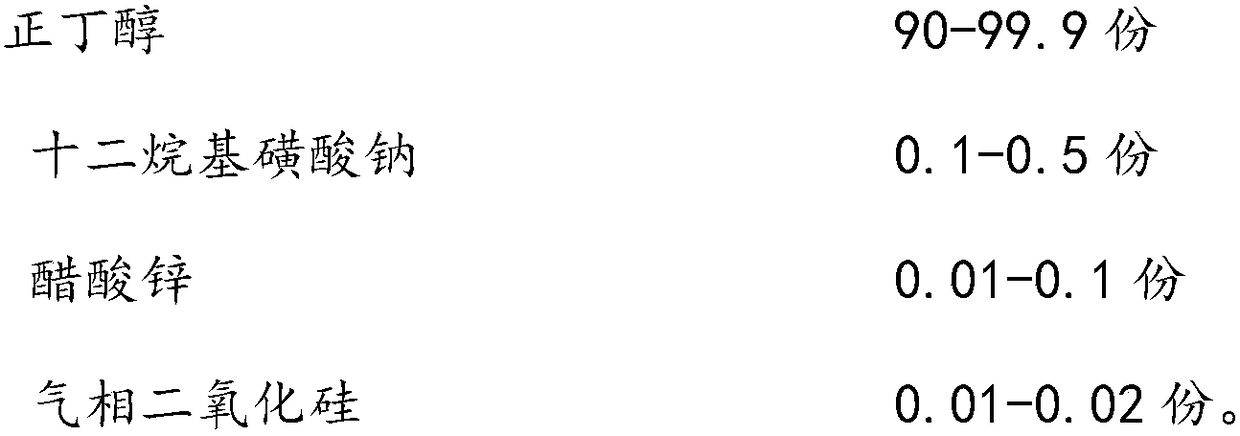

One-component anaerobic silicon chip bottom glue and preparation method thereof

ActiveCN110437793BFast degummingSave manpower and material resourcesNon-macromolecular adhesive additivesRotary stirring mixersMeth-Ethyleneglycol dimethacrylate

The invention discloses a single-component anaerobic silicon slice bottom plate adhesive, which comprises the following raw materials in parts by weight: 50-60 parts of hydroxypropyl methacrylate, 30-50 parts of polyurethane acrylate, 0.05-0.1 parts of polymerization inhibitor, and accelerator 1-2, complexing agent 0.02-0.1 and initiator 1-5; also include: methyl propylene glycol 1-3, polyethylene glycol dimethacrylate 1-3 and foaming agent 1-5. The one-component anaerobic silicon slice floor adhesive of the present invention, compared with the conventional two-component adhesive, does not require glue mixing time, and the initial curing time is about 40s. Degumming is convenient and fast, reduces manpower and material resources, greatly speeds up the production rhythm, and meets the needs of rapid and efficient industry development.

Owner:广西珀源新材料有限公司

Preparation method of antibacterial environment-friendly mulberry bark fiber

The invention discloses a preparation method of antibacterial environment-friendly mulberry bark fiber. The method is as below: conducting mechanical beating on the mulberry bark to remove impurities; then conducting pretreatment with the process of tea saponin 4-5 g / L, 3h, temperature of 80 DEG C, and bath ratio of 1:18; preparing Bacillus licheniformis, Bacillus subtilis, and EM bacteria in the ratio of 1:0.2:0.5 into a compound inoculant; uniformly spraying the inoculant on the pretreated mulberry bark, fermenting at 38 DEG C for 8 h, rapidly heating to 45 DEG C and maintaining for 2 s; then rapidly cooling to 39 DEG C, continuing fermentation for 2-3 h, and washing with warm water after fermentation; preparing an enzyme solution under the parameters of bath ratio of 1:15, 100-120 min, and temperature of 45 DEG C; and rinsing, carrying out routine soaping, loosing and drying.

Owner:韩建华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com