Process method for regenerating flame-retardant plastic particles by using waste powder coating

A technology of powder coatings and flame-retardant plastics, applied in the field of recycled plastics, can solve the problems of high baking temperature of powder coatings, achieve high economic added value, save labor, and reduce labor and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

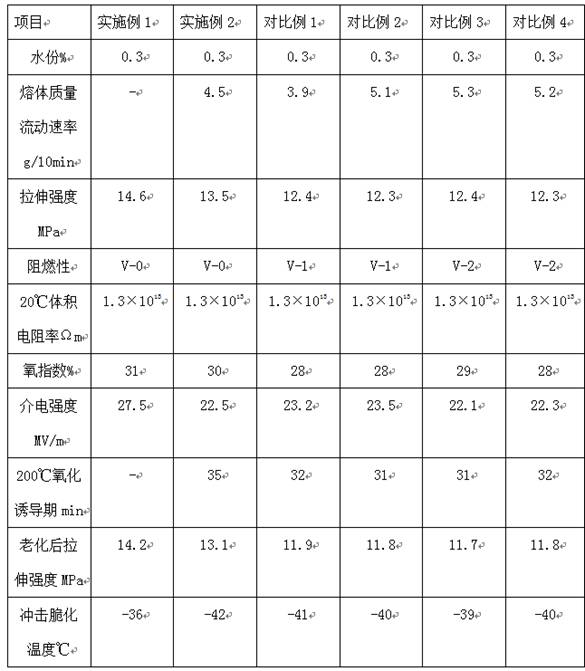

Embodiment 1

[0017] A process for regenerating flame-retardant plastic particles from waste powder coatings, comprising the following steps:

[0018](1) Modified treatment of waste powder coatings: peel off the waste powder coatings on the coating surface; use dispersant to break and disperse, and then use electromagnetic iron remover to remove iron to obtain clean waste powder coatings; the waste powder coatings It is a polyester powder coating; (2) the waste powder coating in step (1) is subjected to sedimentation, impurity removal and dispersion modification to obtain a modified mixture; wherein, the specific process of modification is to process the obtained mixture in step (1) The clean waste powder coating sinks into a settling tank containing water 1.3 times the weight of the clean waste powder coating, and settles together with the water. Add an inorganic dispersing agent calcium oxide 0.1 times the weight of the clean waste powder coating to the settling tank and stir evenly for 20...

Embodiment 2

[0020] A process for regenerating flame-retardant plastic particles from waste powder coatings, comprising the following steps:

[0021] (1) Modified treatment of waste powder coatings: peel off the waste powder coatings on the coating surface; use dispersant to break and disperse, and then use electromagnetic iron remover to remove iron to obtain clean waste powder coatings; the waste powder coatings It is a polyethylene powder coating; (2) the waste powder coating in step (1) is subjected to sedimentation, impurity removal and dispersion modification to obtain a modified mixture; wherein, the specific process of modification is to process the obtained product in step (1) The clean waste powder coating sinks into a settling tank containing water 1 times the weight of the clean waste powder coating, and settles together with the water, and adds an inorganic dispersing agent aluminum trichloride 0.1 times the weight of the clean waste powder coating to the settling tank to evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com