Patents

Literature

34results about How to "Fast pulping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

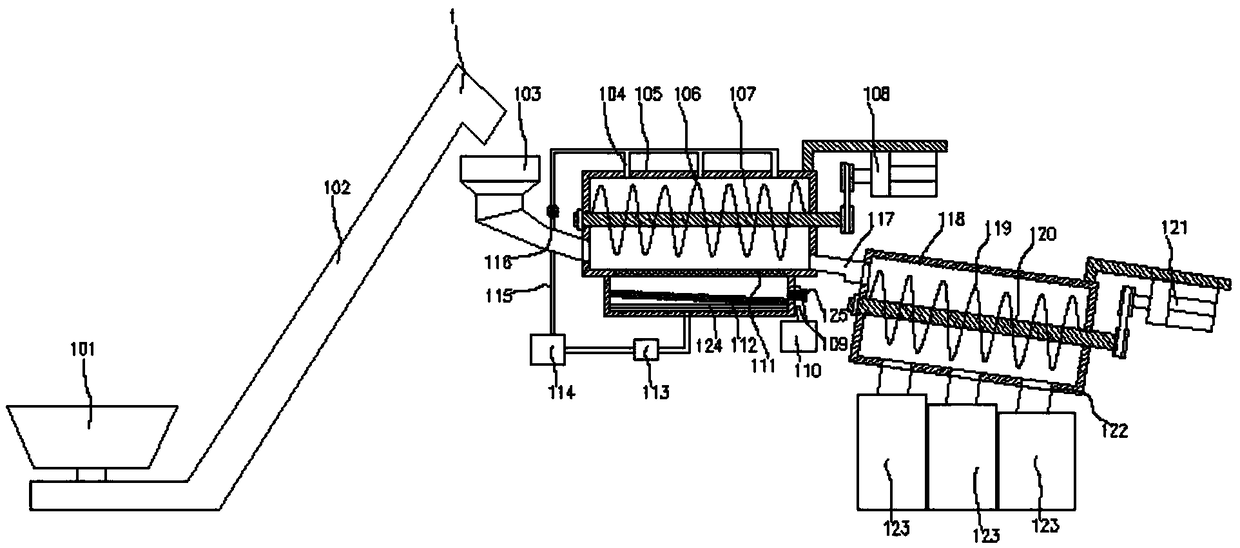

Quick pulping method of soymilk maker

ActiveCN101715835AMeet needsFully heatedBeverage vesselsMilk substitutesPulp and paper industryMouthfeel

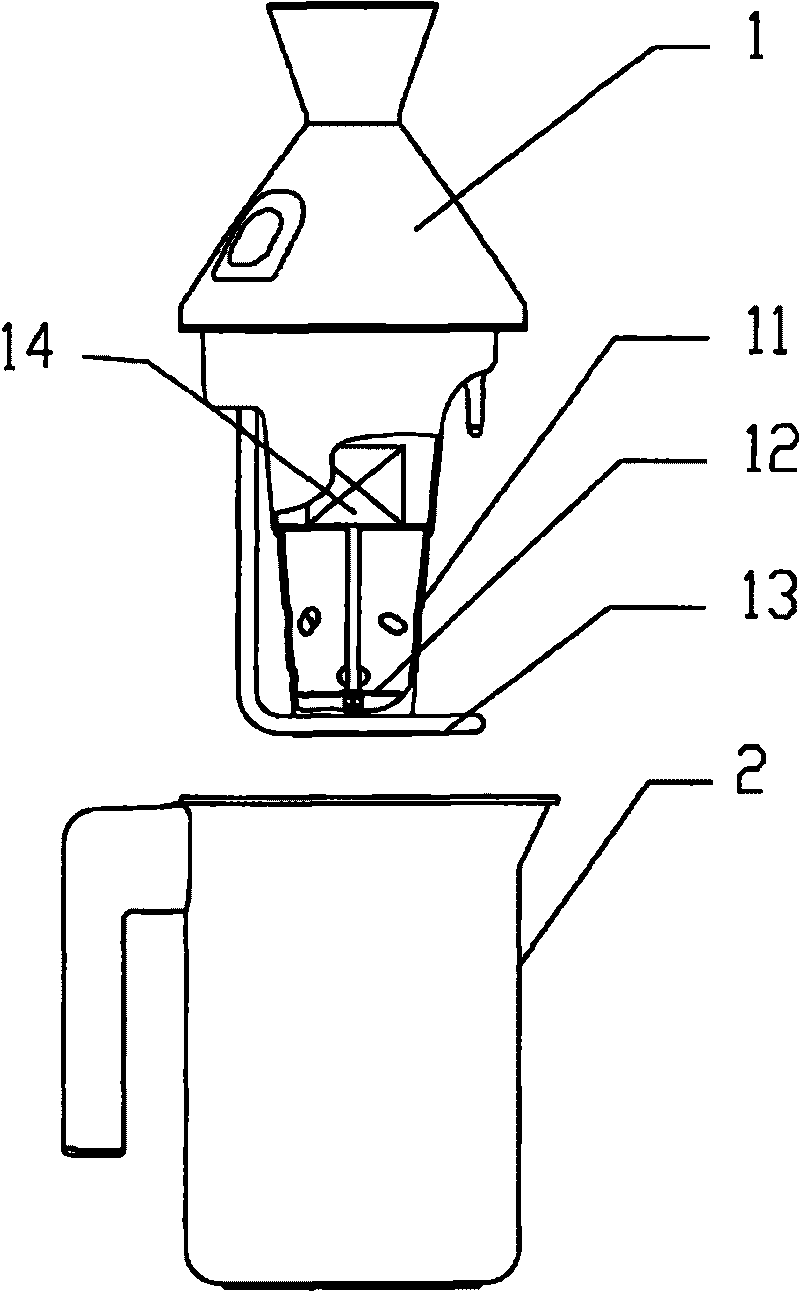

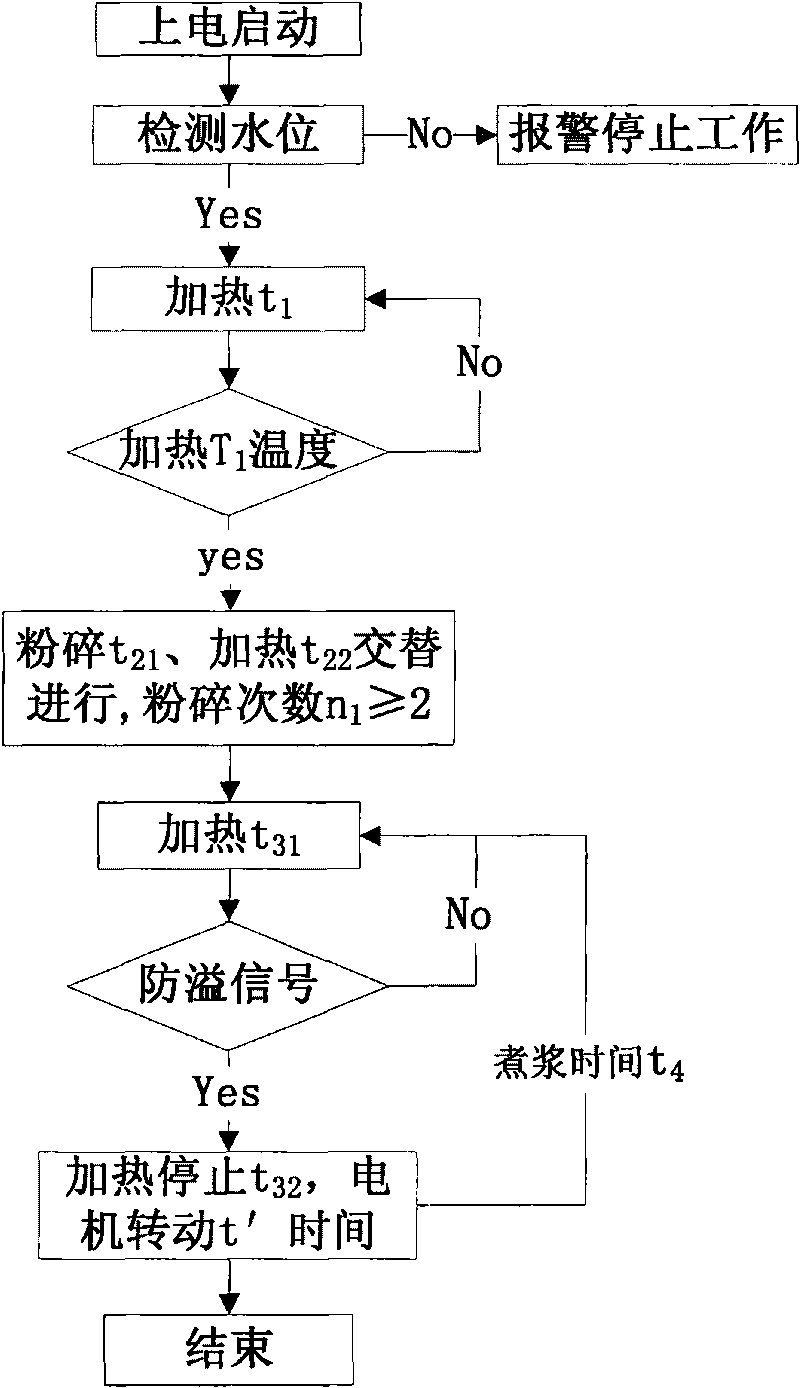

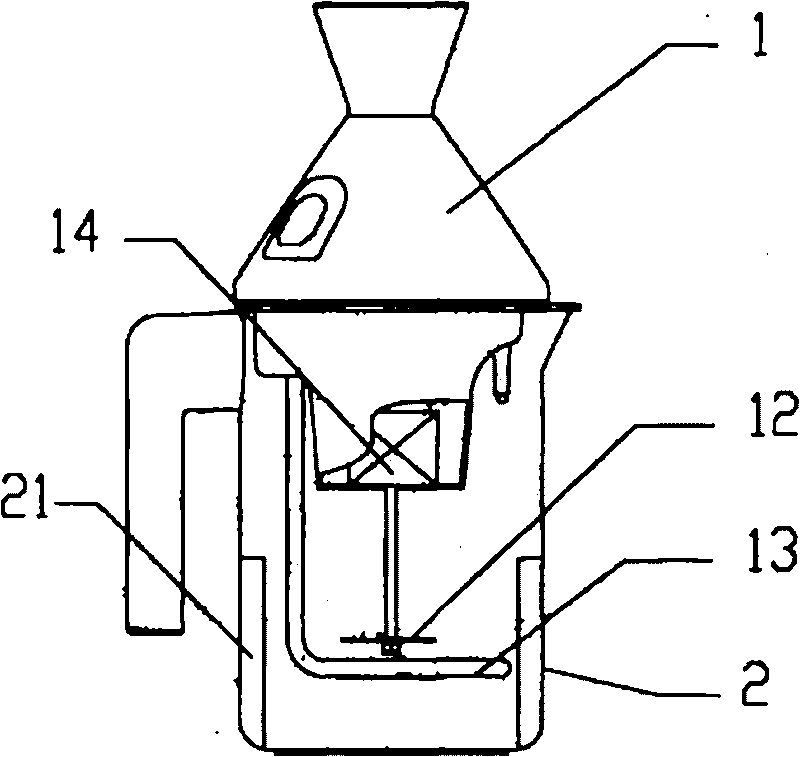

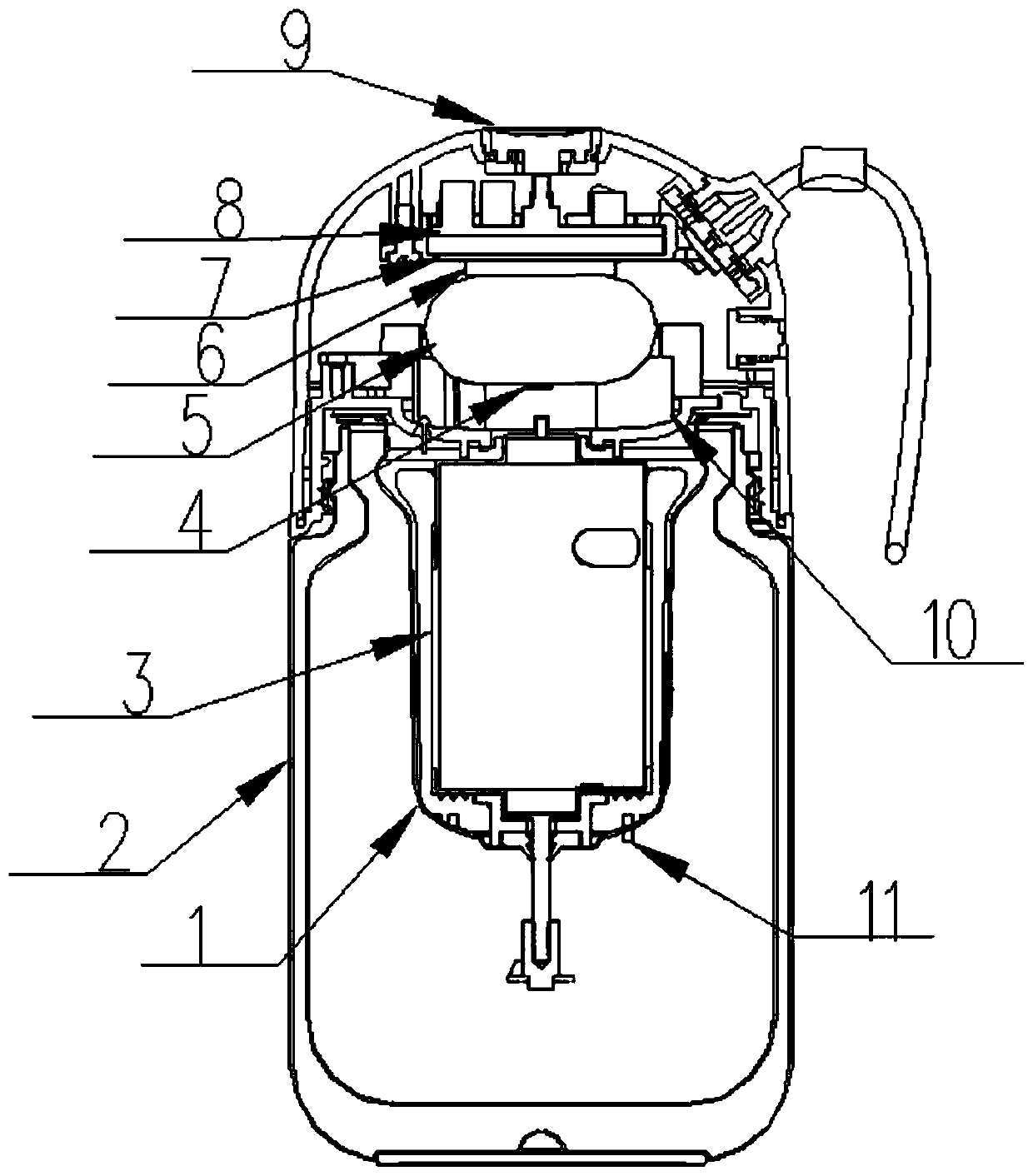

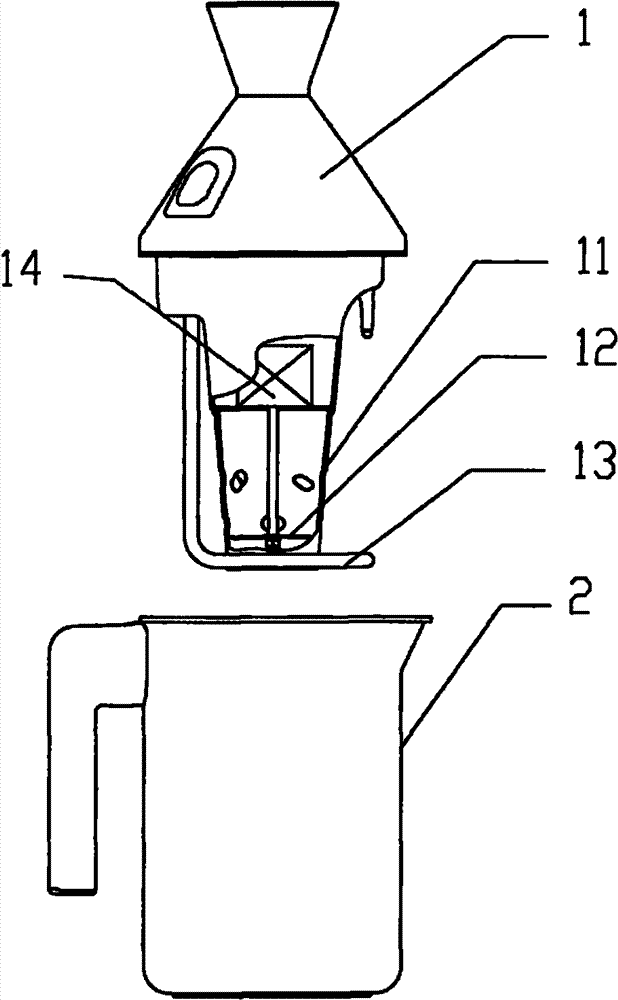

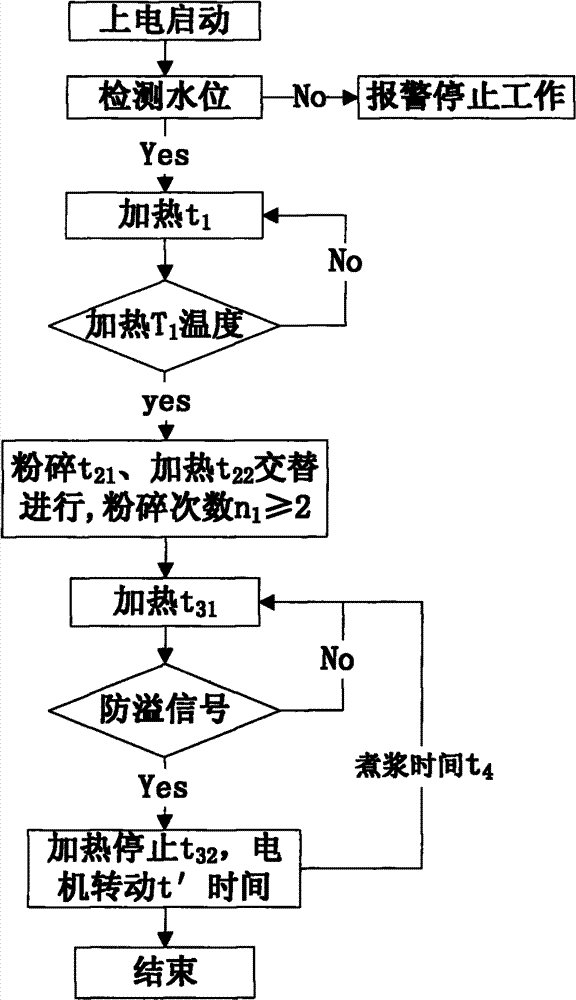

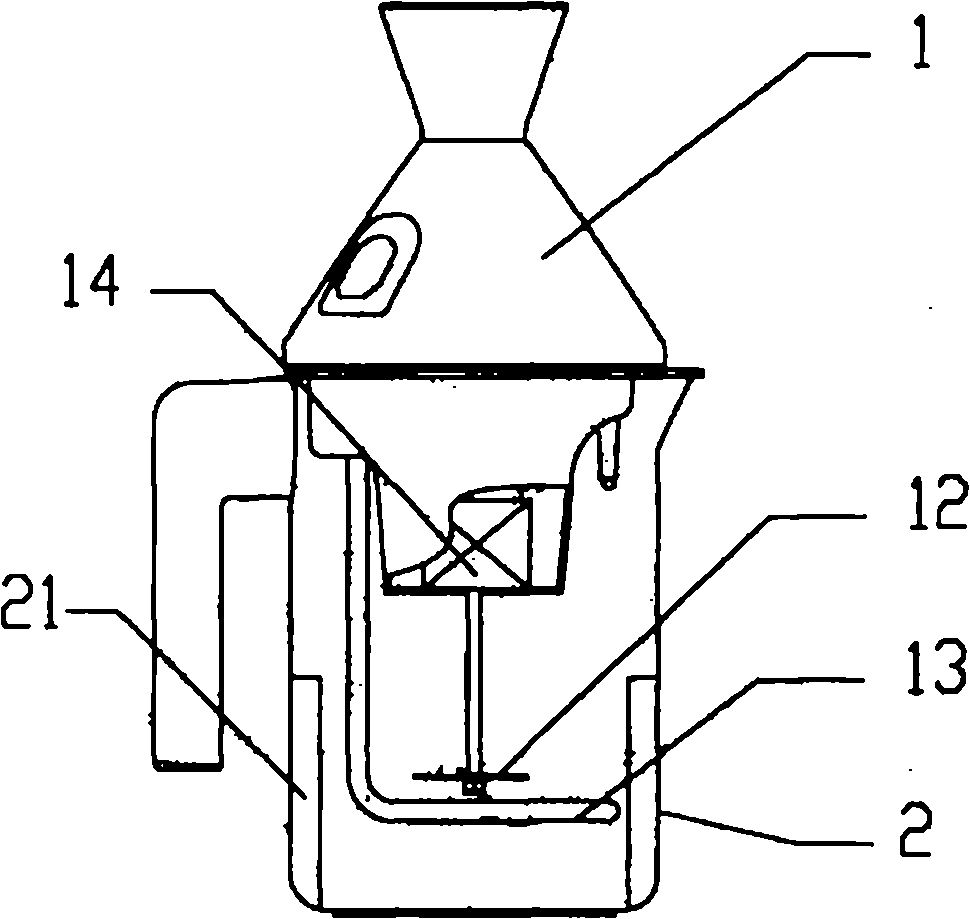

The invention relates to a method for preparing soymilk, in particular to a quick pulping method of a soymilk maker, which comprises a heating process, a pulverization process and a boilout process, wherein the pulverization process comprises a stage that a pulverization cutter is driven by a motor to pulverize materials and a stage of motor stop; the boilout process comprises a stage of heating the materials and water by a heating device and a stage of stopping heating; and the time of the heating process is t1, the time of the pulverization process is t2, the time of the boilout process is t3, the total time of pulping is T, and T is less than 900 seconds and is more than t1+t2+t3. The soymilk maker realizing the quick pulping method comprises a maker head, a cup body, the motor, a pulverization device and the heating device, wherein the pulverization device comprises the pulverization cutter. The pulping working procedure of the soymilk maker comprises the quick pulping method of the soymilk maker in any item from 1 to 9 of patent claim. The invention provides a pulping method capable of preparing the soymilk with good mouthfeel quickly and efficiently.

Owner:JOYOUNG CO LTD

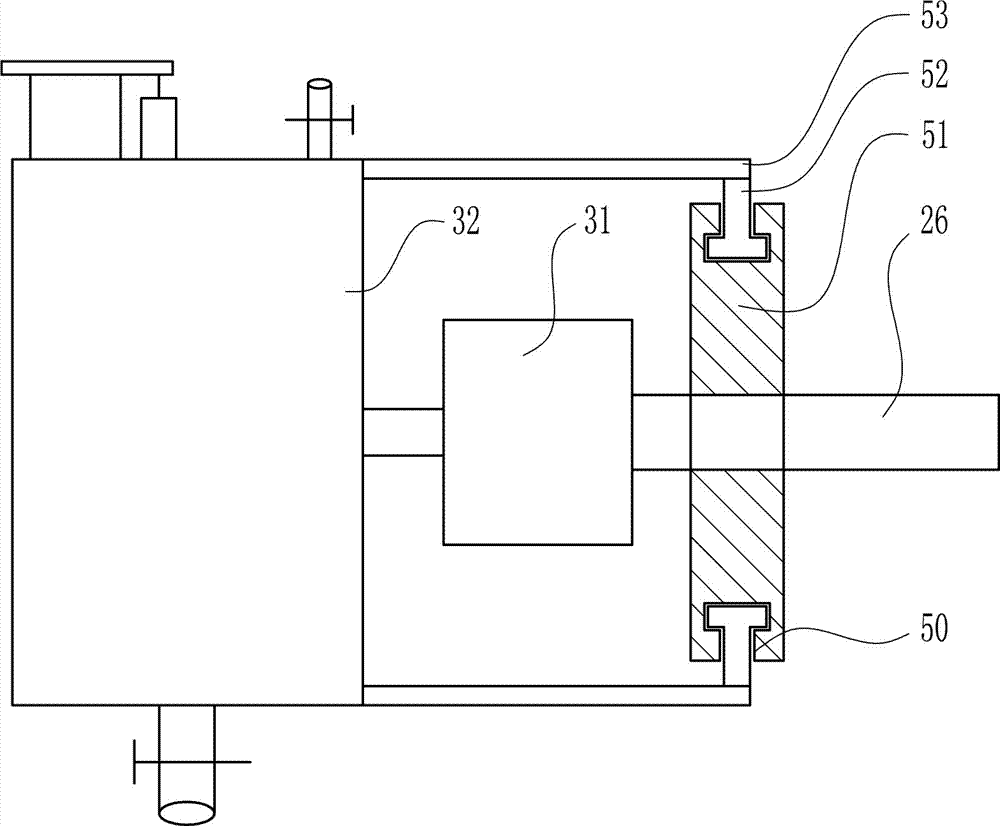

Mortar mixer for fast slurry forming

InactiveCN106808594AAdjust densityFast pulping speedDischarging apparatusCement mixing apparatusSlurryMaterials science

The invention discloses a mortar mixer for fast slurry forming, which comprises a base and a dry powder stirrer and a mortar stirrer arranged on the base; the dry powder stirrer comprises a dry powder stirring cylinder and a first stirring shaft arranged in the dry powder stirring cylinder; the first stirring shaft is provided with first stirring blades; a feeding port is arranged on the top of the dry powder stirring cylinder; a powder outlet is arranged at the bottom of the dry powder stirring cylinder; the powder outlet is externally connected with a powder conveying pipe which communicates with the mortar stirrer; the mortar stirrer comprises a mortar stirring cylinder, a second stirring shaft arranged in the mortar stirring cylinder, and second stirring blades arranged on the second stirring shaft; a water filling pipe is arranged on the mortar stirring cylinder; and a slurry outlet is arranged at the bottom of the mortar stirring cylinder. The invention has the advantages of dry-wet stirring separation and fast slurry forming speed.

Owner:HENGYANG SHUANGYAN TRANSPORTATION MACHINERY

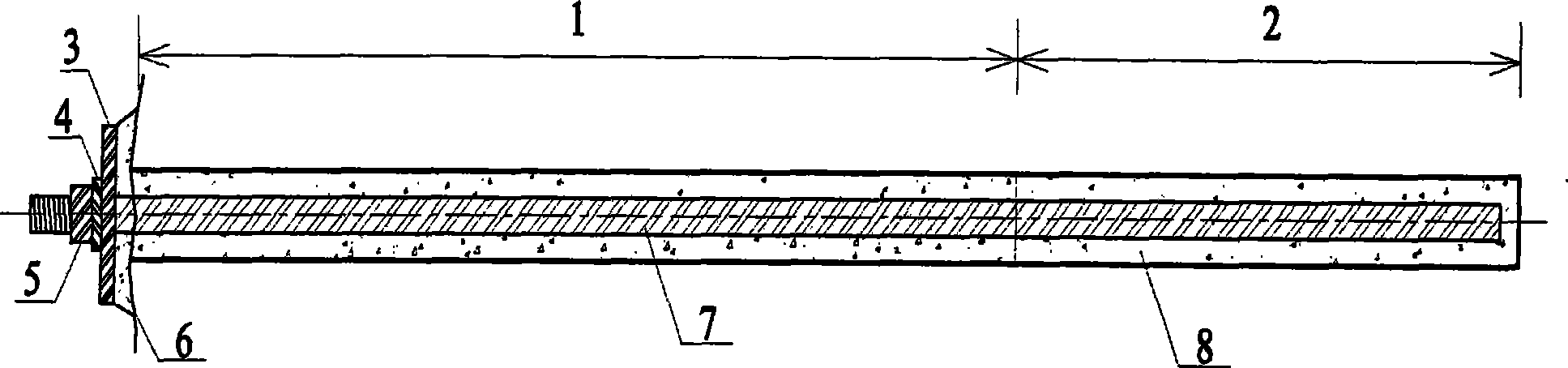

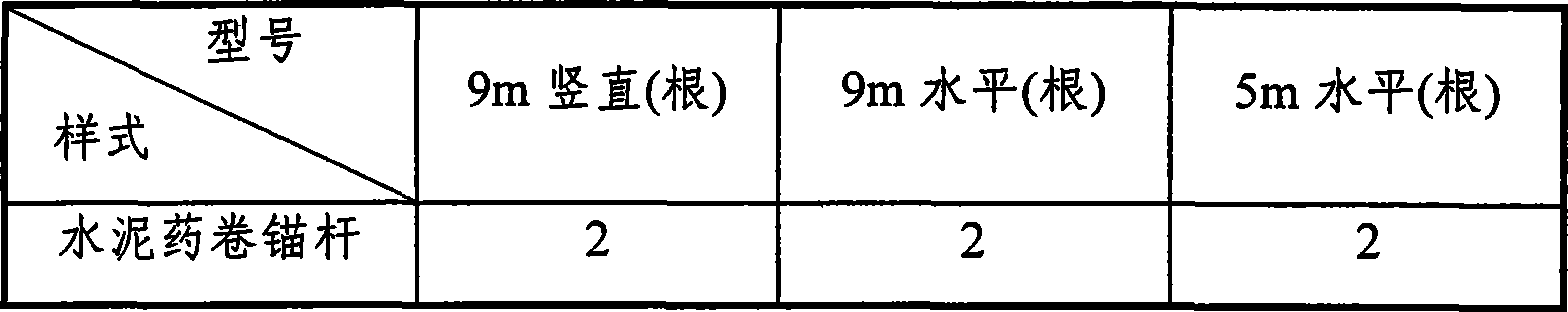

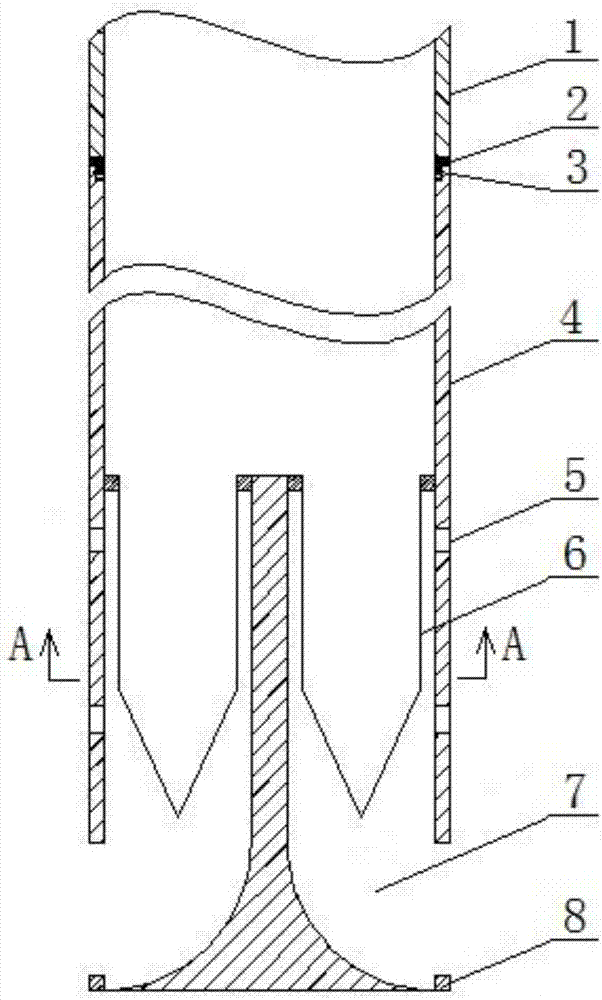

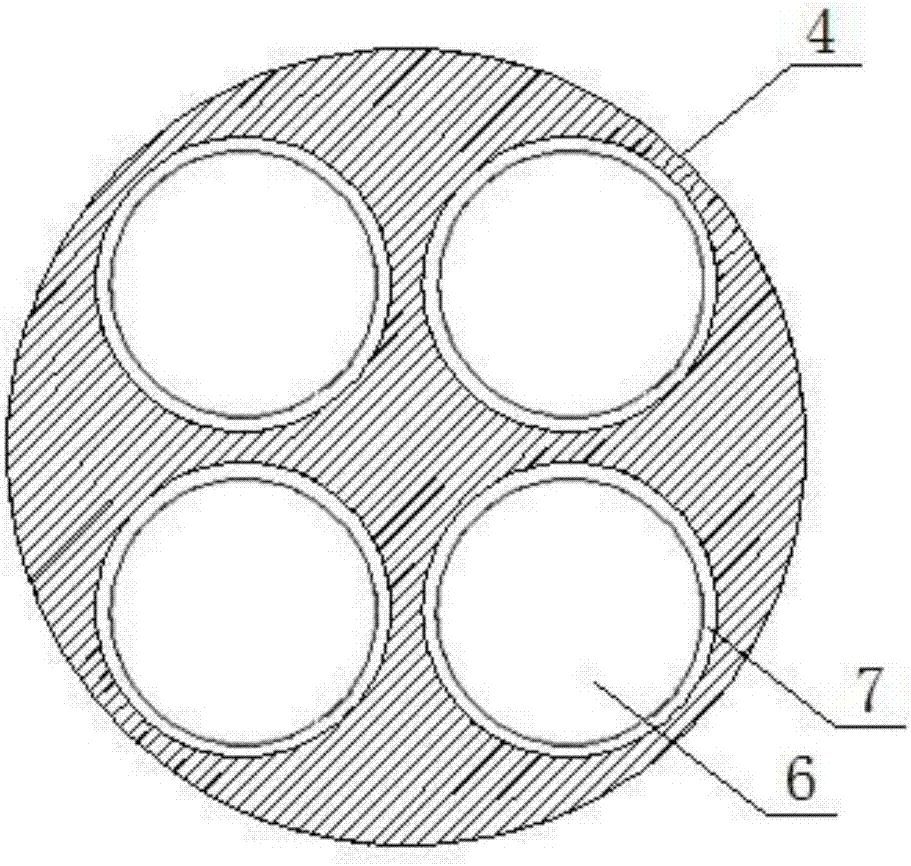

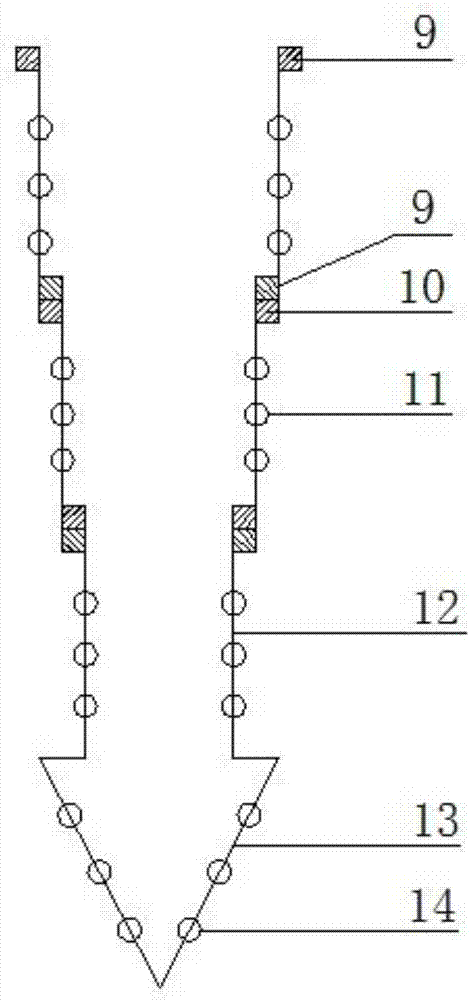

Injecting and mounting method of stretching anchor rod

The invention discloses a grouting method for a stretch-draw anchor rod, wherein a fast-setting anchoring agent and a slow-setting anchoring agent are grouted into an anchor rod hole respectively by adoption of an extruding grouter by means of fast setting first and slow setting subsequently; a grout pipe is extruded by grouting pressure and smoothly withdrawn until the anchor rod hole is filled with serum; and stretch-draw locking of the anchor rod is performed before initial setting of the slow-setting anchoring agent and after final setting of the fast-setting anchoring agent when the anchor rod is arranged in place and the strength required is reached. The grouting is uniform and continuous, the grout pipe is slowly extruded by the serum and is not influenced by artificial influence, so that no gap can occur and the compactness can be fully guaranteed; grouting equipment only needs power supply, so that a complex blast pipe line is saved; and the grouting method has the advantages of simple and convenient technology, high construction efficiency and good application prospect, and safety and reliability.

Owner:SINOHYDRO BUREAU 14 CO LTD

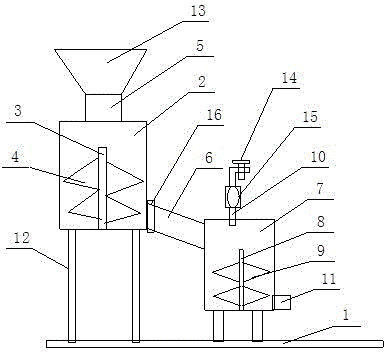

Rapid soybean milk making method of soybean milk machine

The invention provides a rapid soybean milk making method of a soybean milk machine. Before a soybean milk discharging stage is performed, water corresponding to soybean milk to be made in amount is filled into a soybean milk receiving cup; soybean milk liquid / paste generated in the dense soybean milk making stage is made to be mixed with the water in the soybean milk receiving cup, and therefore problem that time is wasted due to the facts that soybean milk discharging is performed firstly and then blending is performed is solved. During soybean milk discharging, when the water of the soybean milk receiving cup fluctuates upwards and downwards, the soybean milk liquid / paste and the water can be fully mixed in the soybean milk receiving cup, and therefore the quality of the made soybean milk is improved.

Owner:JOYOUNG CO LTD

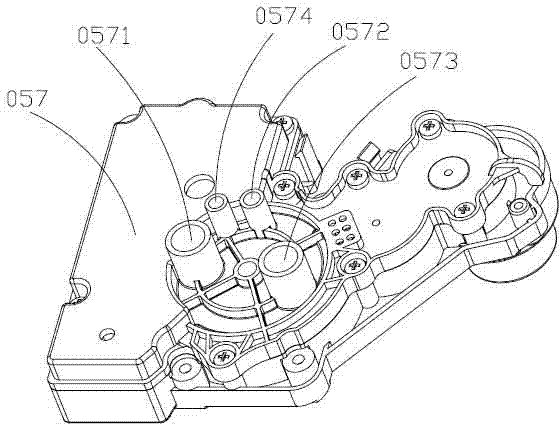

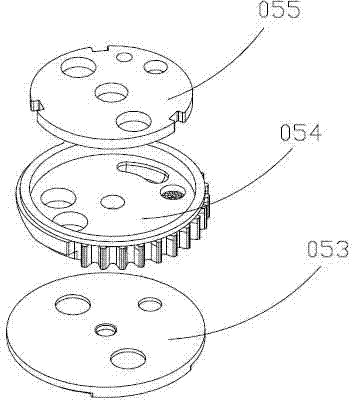

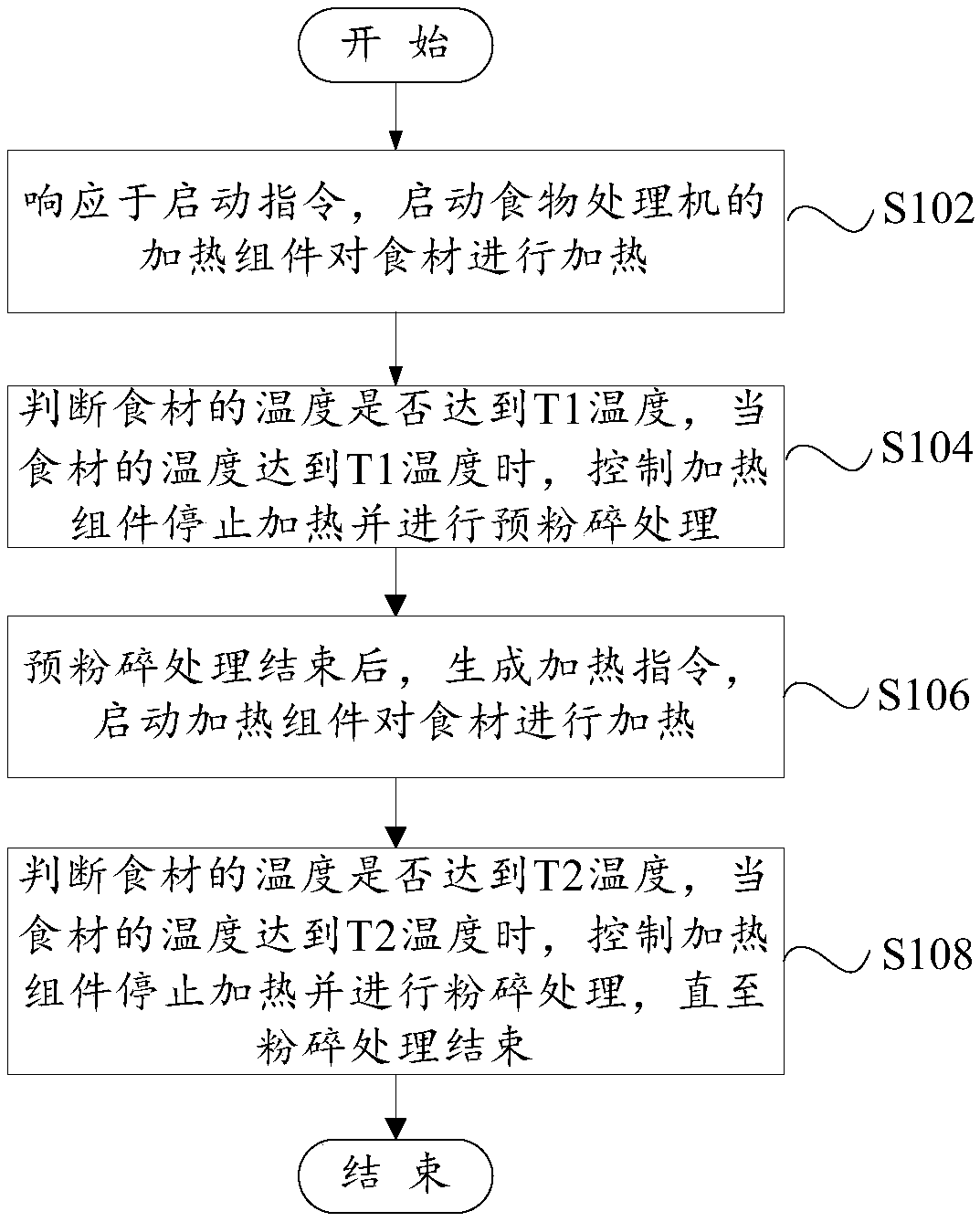

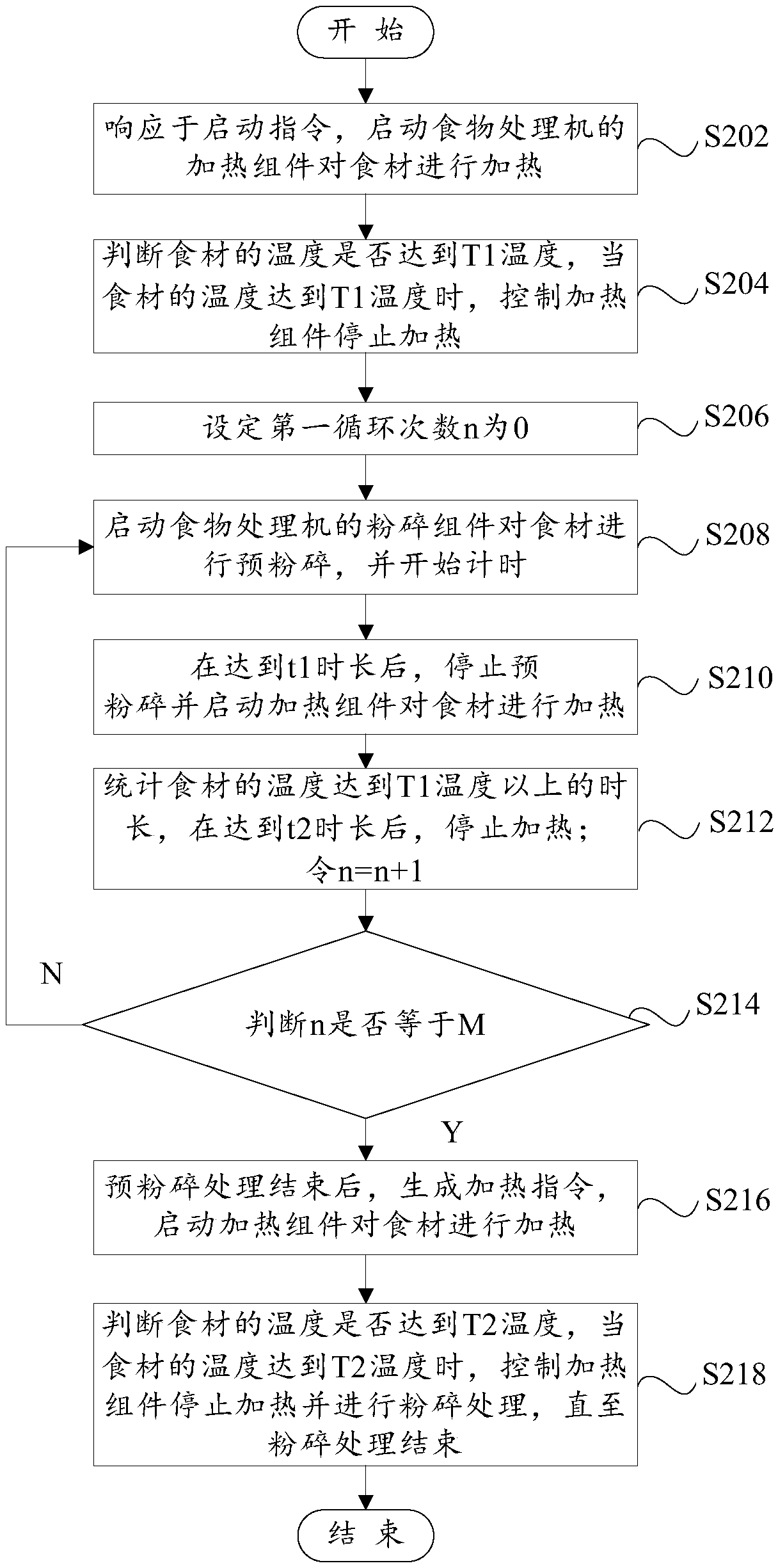

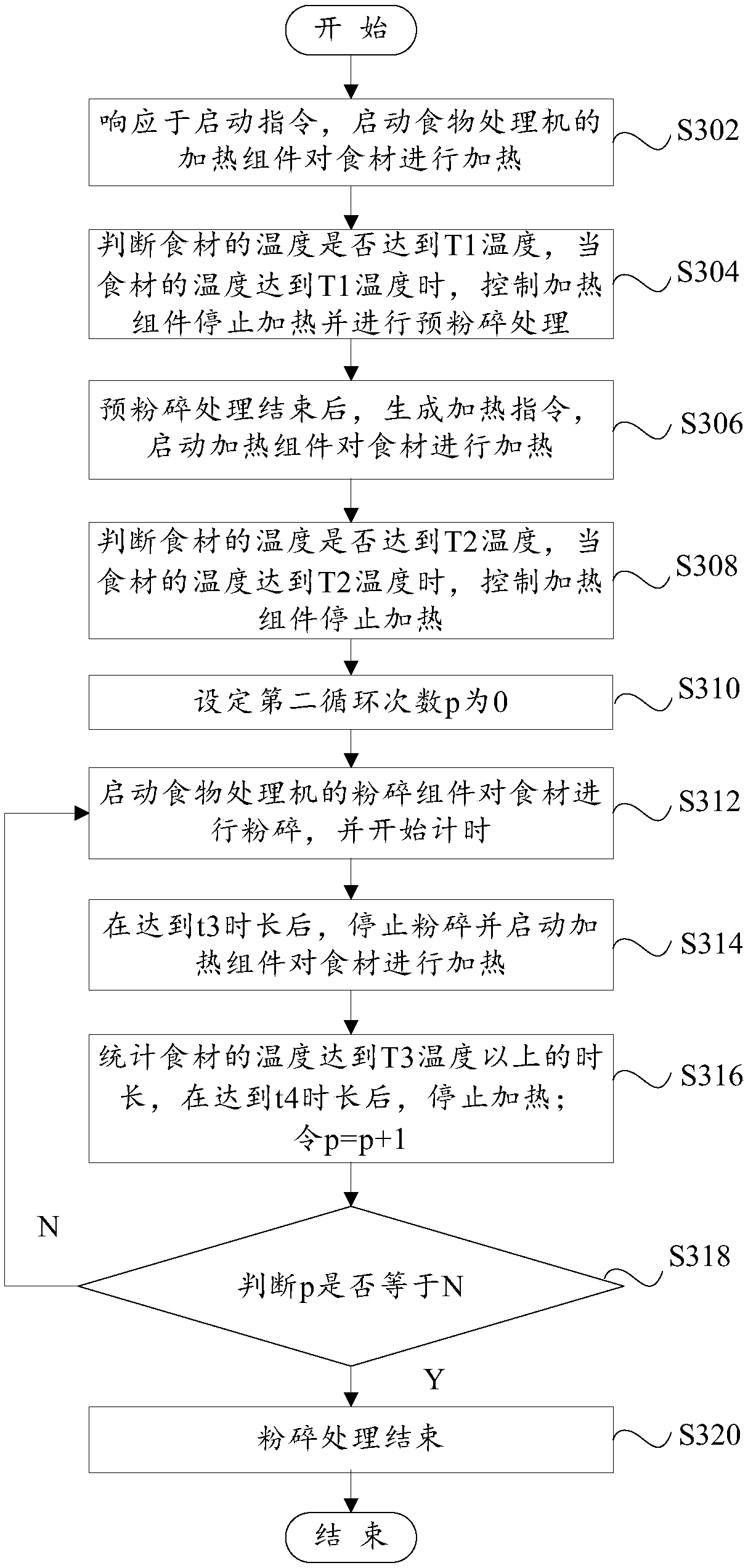

Food processor and pulping method thereof and computer readable storage medium

ActiveCN111084534AImprove crushing effectIncrease whipping timeStrainersVessels with intergral heatingProcess engineeringFood material

The invention provides a pulping method of a food processor, the food processor and a computer readable storage medium, wherein the pulping method of the food processor comprises the following steps:in response to a starting instruction, starting a heating assembly of the food processor to heat food materials; judging whether the temperature of the food materials reaches T1 or not, and when the temperature of the food materials reaches T1, controlling the heating assembly to stop heating and conduct pre-smashing treatment; after the pre-crushing treatment is finished, generating a heating instruction, and starting the heating assembly to heat the food materials; and judging whether the temperature of the food materials reaches T2 or not, and when the temperature of the food materials reaches T2, controlling the heating assembly to stop heating and carrying out crushing treatment until the crushing treatment is finished. By adopting the pulping method provided by the invention, the pulping time is greatly shortened, and rapid pulping is realized.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

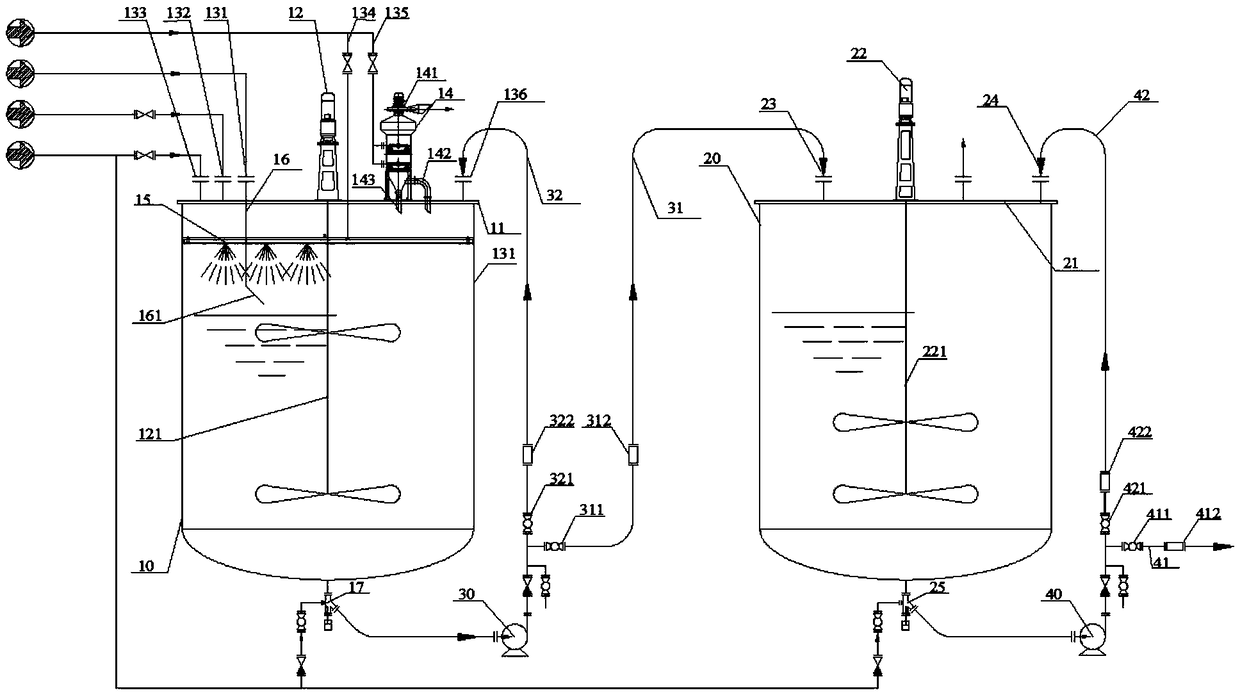

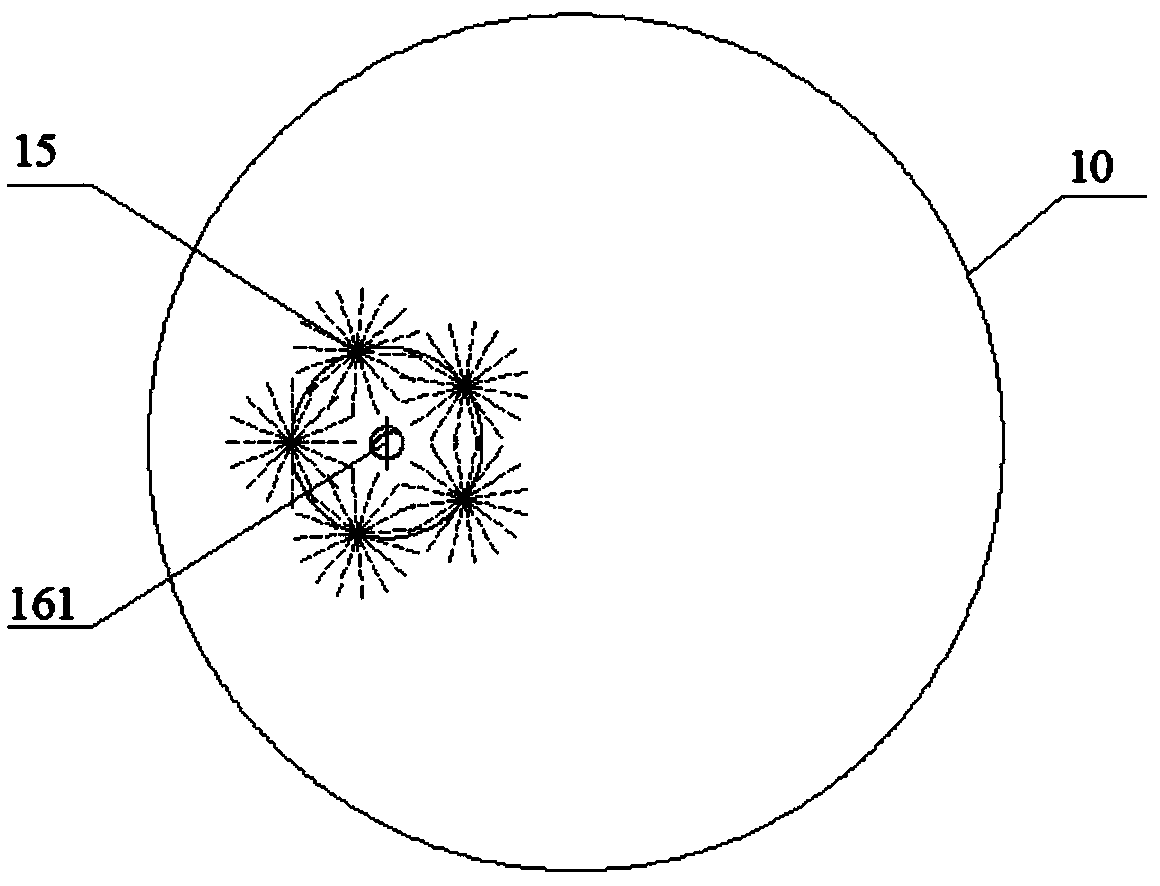

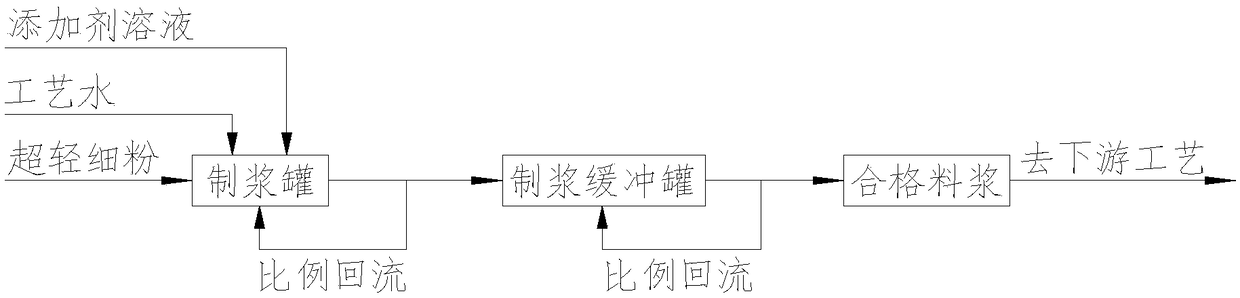

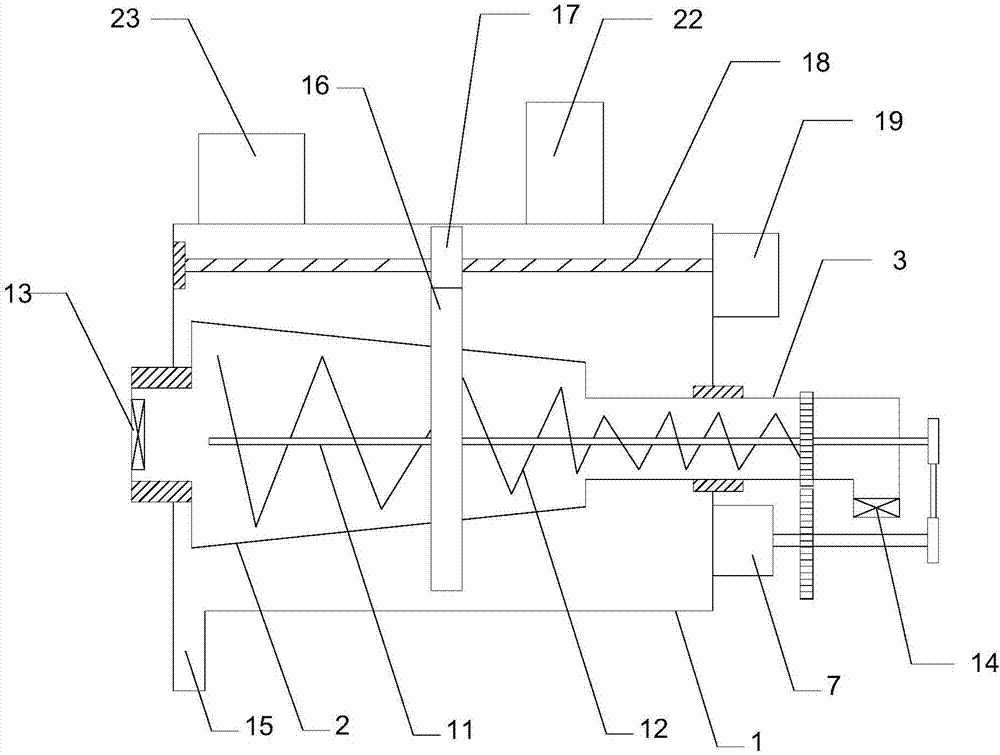

Ultra-light fine material continuous pulping equipment and pulping method

ActiveCN108854641AContinuous pulping processGuaranteed uniformityFlow mixersRotary stirring mixersWater pipeBuffer tank

The invention particularly relates to ultra-light fine material continuous pulping equipment and a pulping method. The pulping equipment comprises a pulping tank, wherein a first top cover is arrangedon the top of the pulping tank; a first stirring motor and a first feeding opening are arranged on the first top cover; a first stirring paddle is arranged on an output shaft of the first stirring motor; the first stirring paddle is positioned in the pulping tank; the first stirring opening comprises an ultra-light fine material inlet, an adhesive inlet, a process water inlet and a first materialreturn opening; a first water pipe, a second water pipe and a water film dust remover are also arranged on the first top cover; an atomization spray head and a material falling pipe are also arrangedinside the pulping tank; the ultra-light fine material continuous pulping equipment also comprises a buffer tank connected in series with the pulping tank. The continuous pulping method is used; thepartial backflow operation is added on the existing ultra-light fine material pulping process, so that the pulping process is continuous; the problem of instable pulp quality due to long pulping time,personnel error and accumulated error of the conventional intermittent pulping process can be effectively solved; in addition, the secondary stirring of the pulping material is uniform; the pulping material composition uniformity can be ensured.

Owner:EAST CHINA ENG SCI & TECH

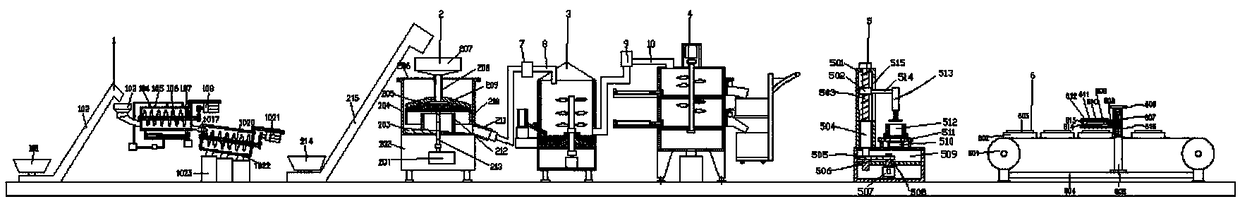

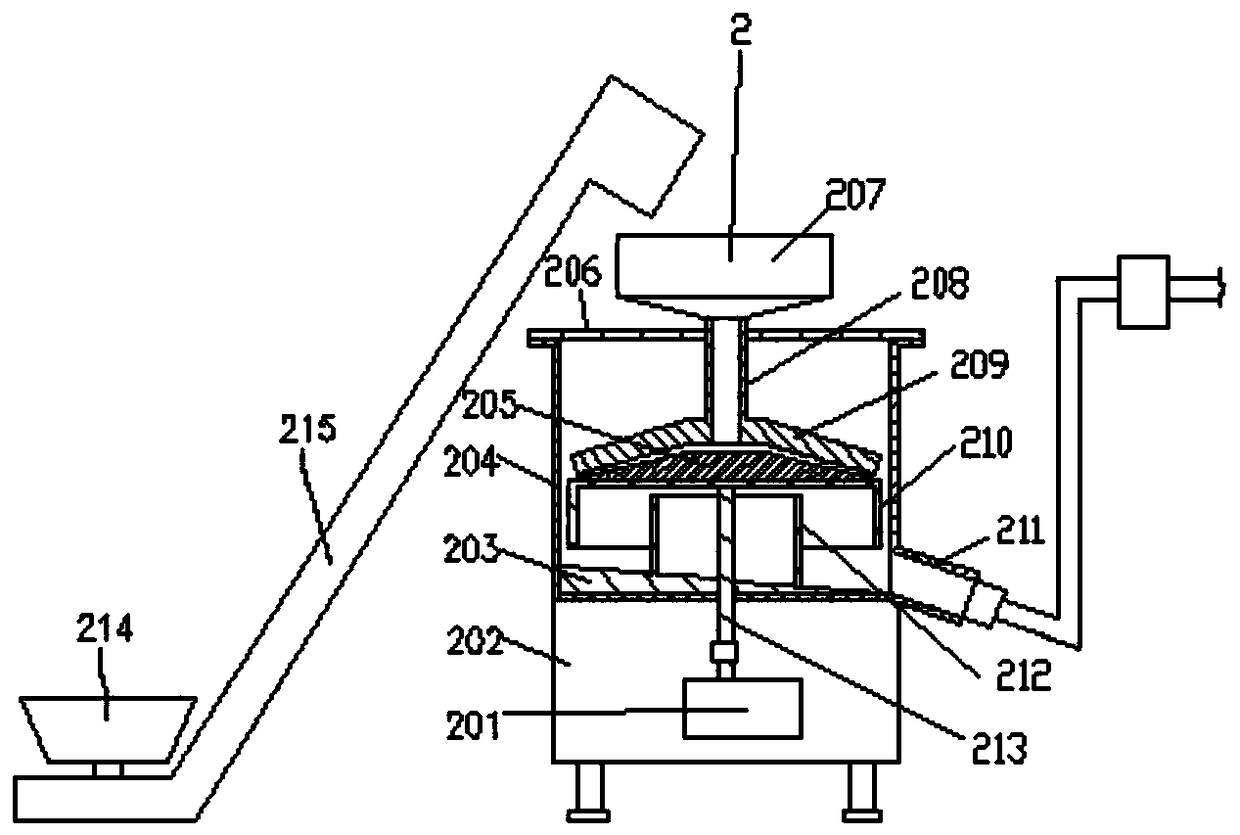

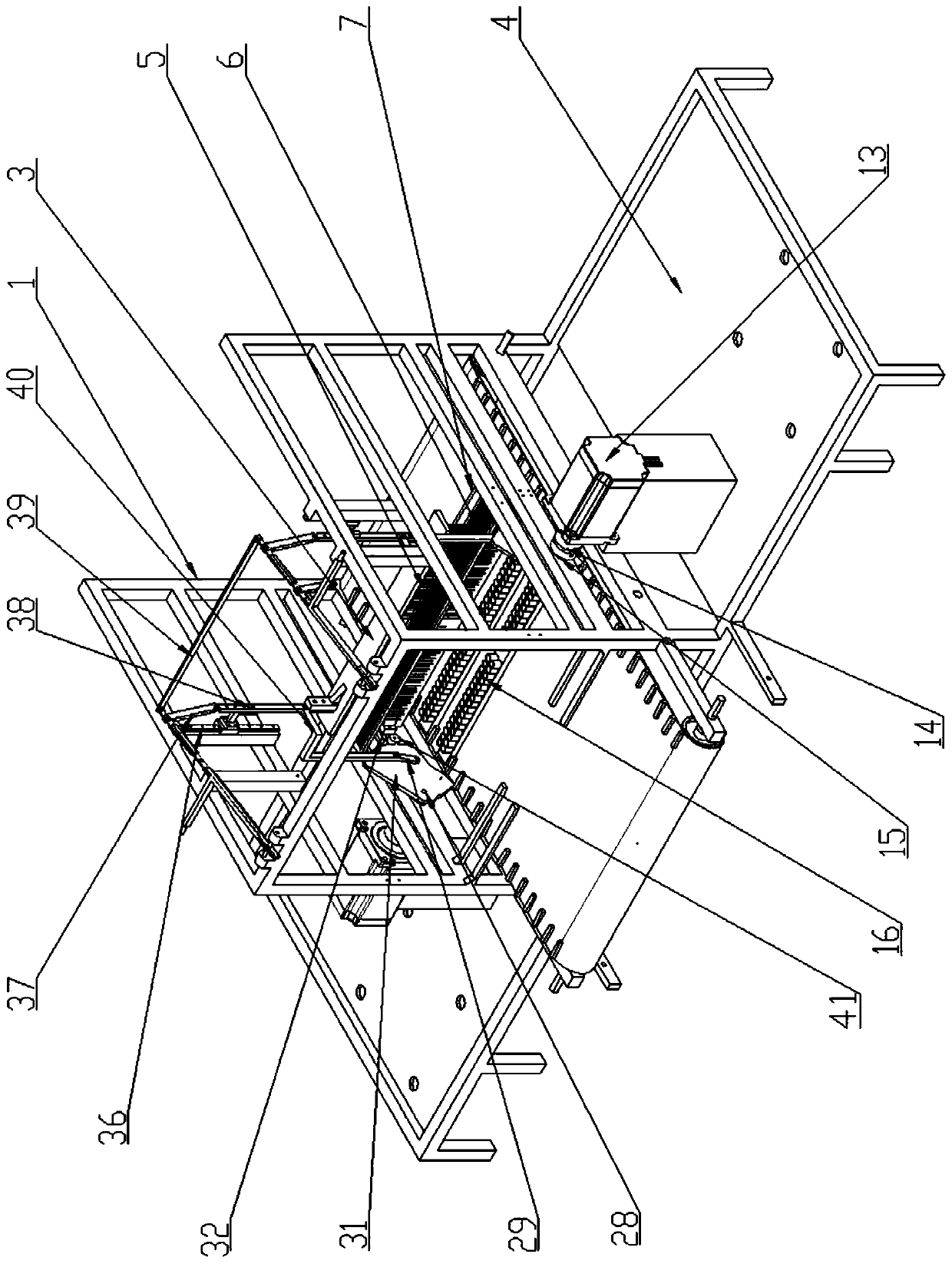

Manufacturing process and production line of dried tofu

InactiveCN109169952AFull of nutritionIncrease elasticityCheese manufactureFood sciencePulp and paper industryGypsum

The invention discloses a manufacturing process and a production line of dried tofu. The production line comprises a clearing and soaking device, a pulping device, a pulping boiling and curding device, a pulp filtering device, a pressing device and a slicing device; and the pulping device communicates with the pulping boiling and curding device by a first pipe, a first pump is arranged on the first pipe, the pulping boiling and curding device communicates with the pulp filtering device by a second pipe, and a second pump is arranged on the second pipe. The invention provides the manufacturingprocess and the production line of the dried tofu. The dried tofu is rich in nutrients, has a tender, smooth and elastic mouth feel, has a long shelf life, does not contain gypsum, and is good for thebody.

Owner:湖南省富田桥游浆豆制品发展有限公司

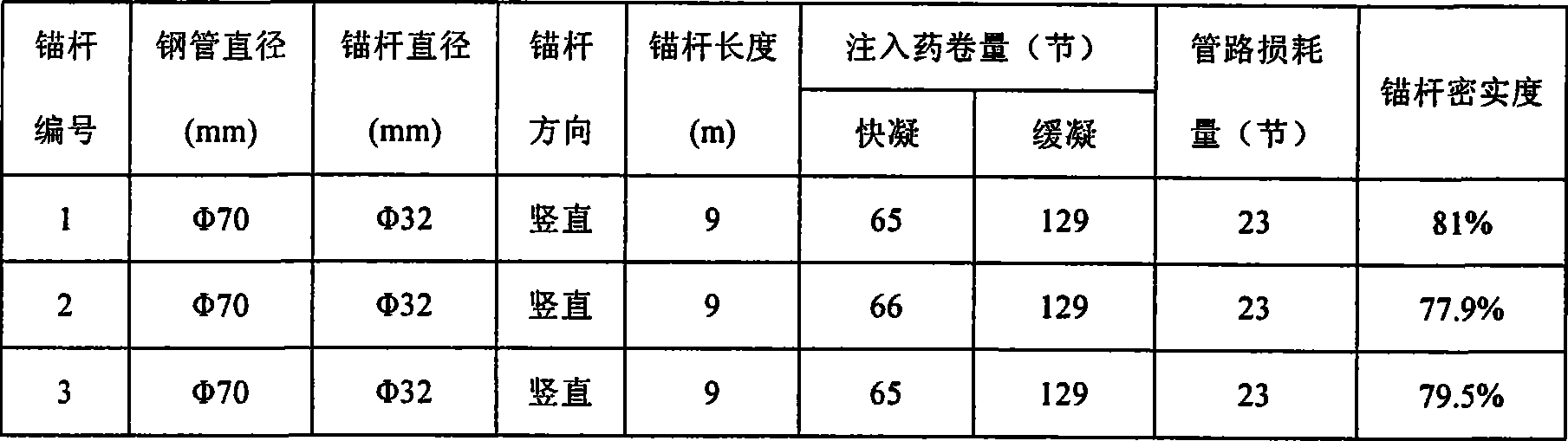

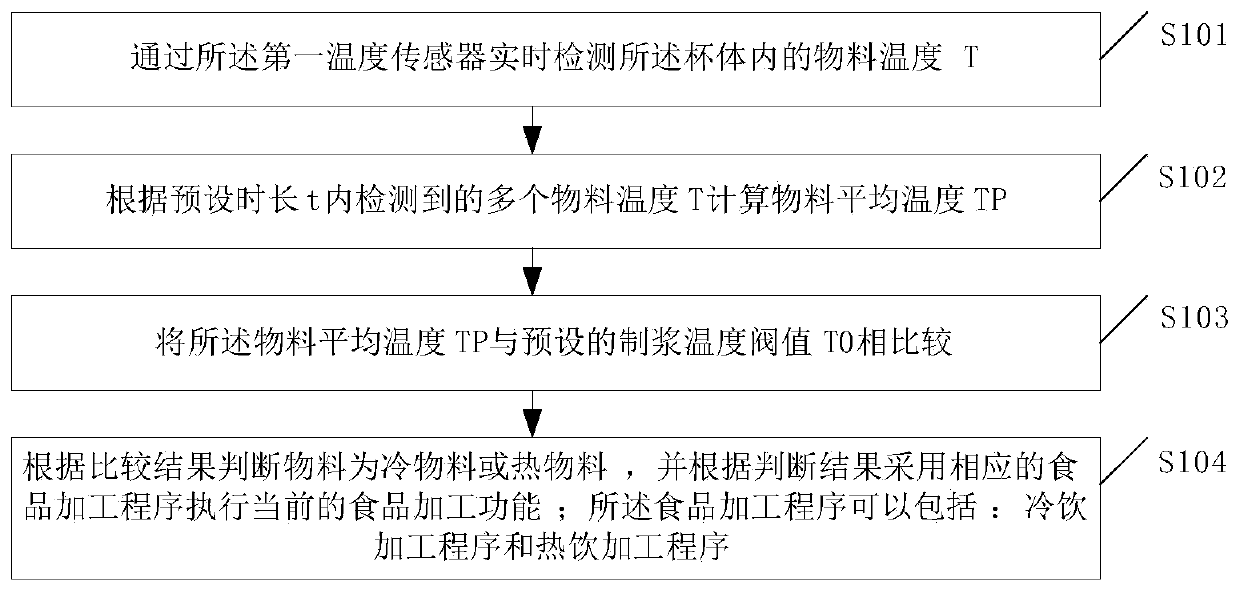

Control method of food processor

ActiveCN111000463AImprove experienceFast pulpingElectric motor controlKitchen equipmentProcess engineeringCold drinks

The embodiment of the invention discloses a control method of a food processor. The food processor comprises an electric power storage device and a first temperature sensor which are arranged on a machine head, and power is supplied to the food processor through the power storage device. The method comprises the steps of detecting the temperature T of materials in a cup body in real time through afirst temperature sensor; calculating a material average temperature TP according to a plurality of material temperatures T detected within a preset time length t; comparing the average temperature TP of the materials with a pulping temperature threshold value T0; judging whether the materials are cold materials or hot materials according to a comparison result, and executing a current food processing function by adopting a corresponding food processing procedure according to a judgment result, wherein the food processing procedure comprises a cold drink processing procedure and a hot drink processing procedure. According to the scheme of the embodiment, the corresponding food processing flow is matched by distinguishing cold drink from hot drink, it is guaranteed that the cold drink function rapidly makes milk, the hot drink function is good in smashing effect, the overflow risk is avoided, and the intelligence of the whole machine is improved.

Owner:JOYOUNG CO LTD

Portable type vegetable sampling device

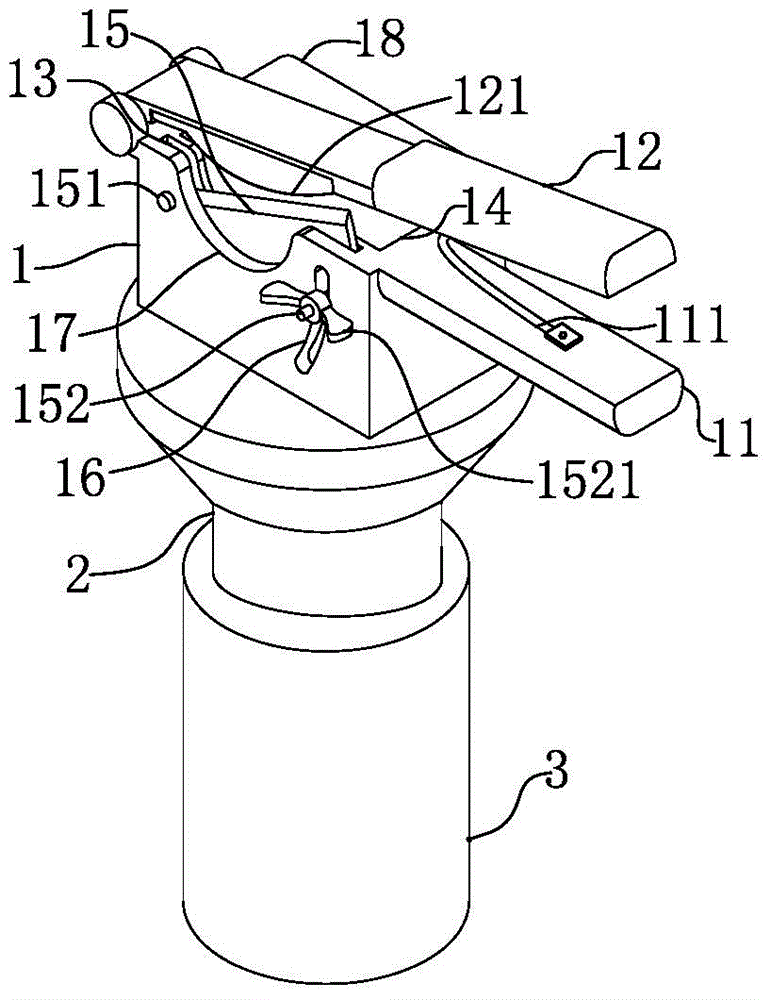

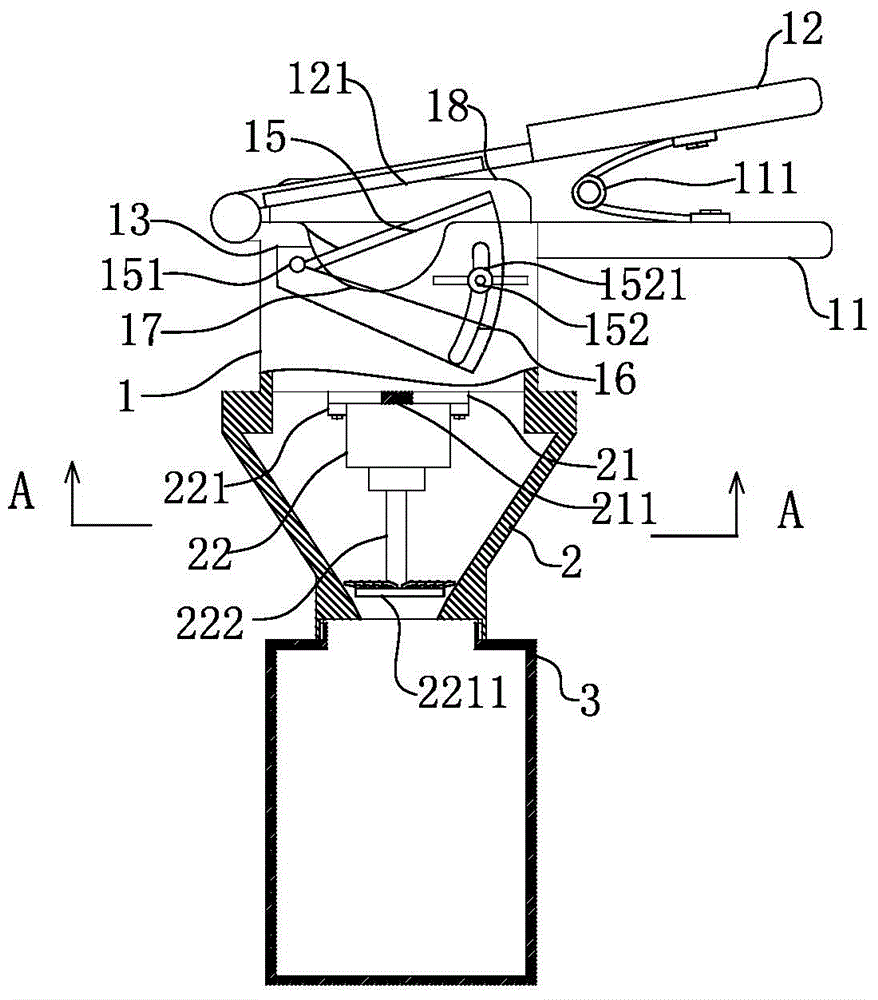

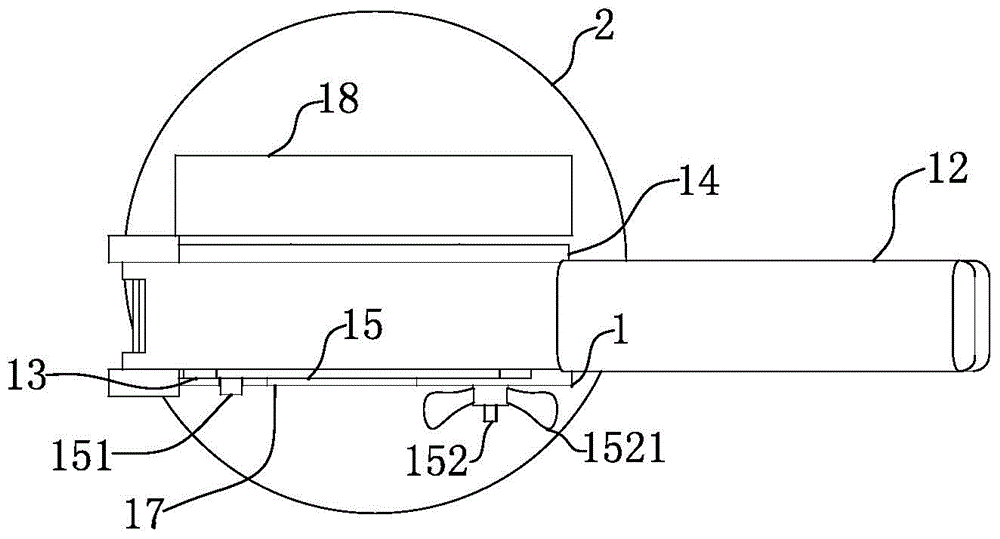

InactiveCN104913947ASimple structureEasy to operateWithdrawing sample devicesPreparing sample for investigationElectric machineryAllium schoenoprasum

The invention provides a portable type vegetable sampling device, aiming at mainly solving the problems in the prior art that a homogenizing machine is relatively troublesome to operate and the rapid development of casual inspection work is not facilitated. The portable type vegetable sampling device mainly comprises a crushing box, a material cutting box and a material collection bottle, wherein the material cutting box is provided with a first cutter and a second cutter which are similar with scissors; the size of an opening between the two cutters is adjusted and changed by the second cutter so that a plurality of types of vegetables are rapidly chopped; the chopped vegetables fall into the crushing box; a motor driving cutter disc arranged in the crushing box is used for crushing and pulping the vegetables; and the material collection bottle is arranged at the opening of the lower end of the crushing box and is mainly used for recycling the prepared vegetable pulp. The portable type vegetable sampling device has a simple structure and is convenient to use, and is suitable for rapidly sampling the vegetables with a lot of branches and leaves, such as celery, Chinese chives, green Chinese onions and caraway, and long-strip-shaped vegetables, such as cucumbers and towel gourds, so that the rapid development of the casual inspection work is facilitated.

Owner:INST OF QUALITY STANDARDS & TESTING TECH FOR AGRO PROD OF SHANDONG ACADEMY OF AGRI SCI

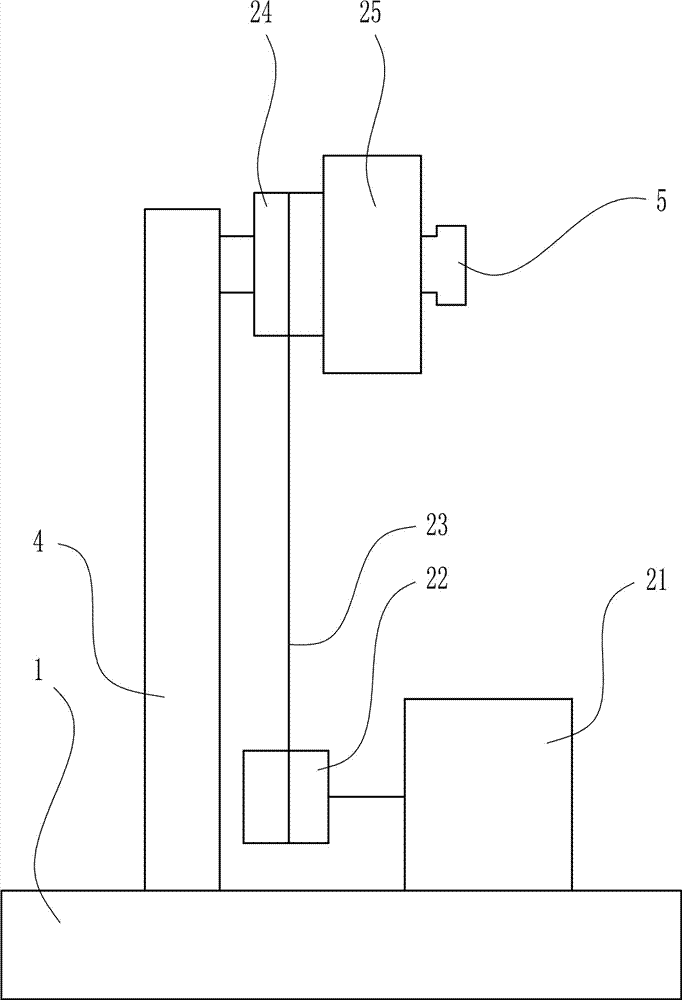

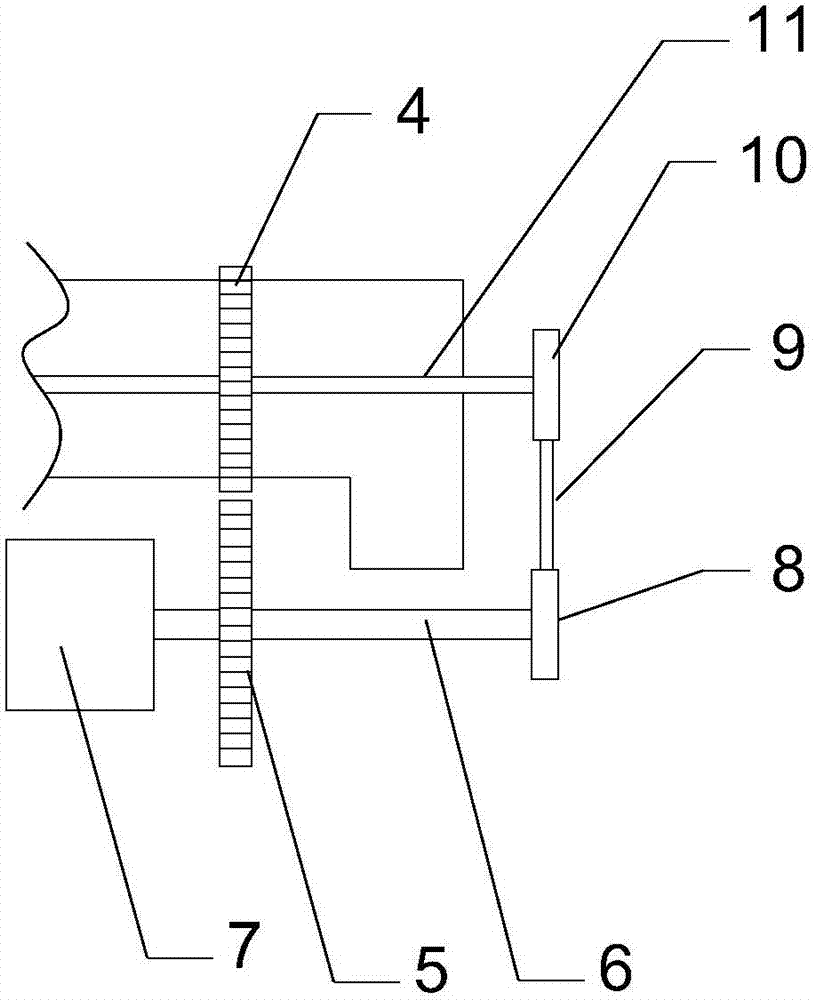

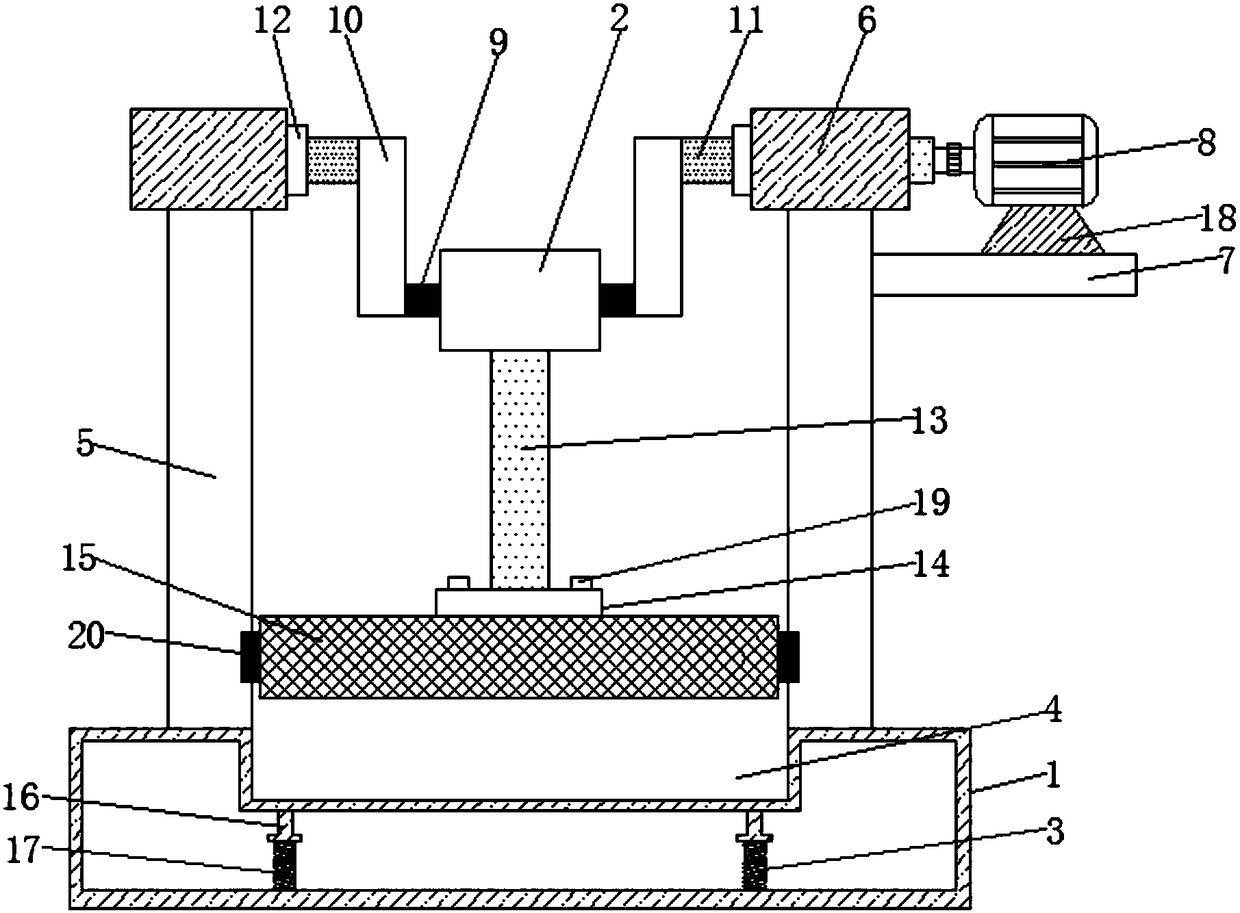

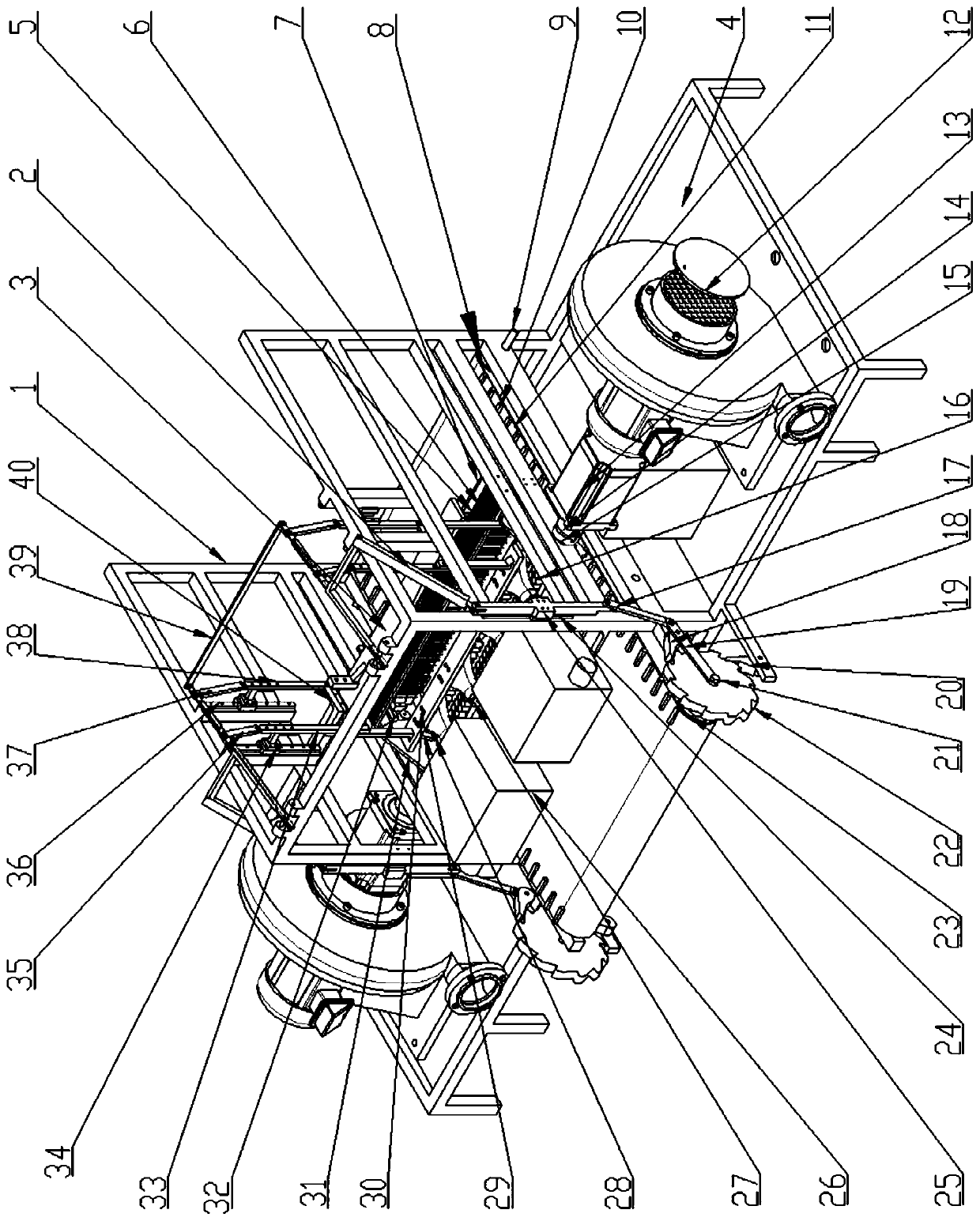

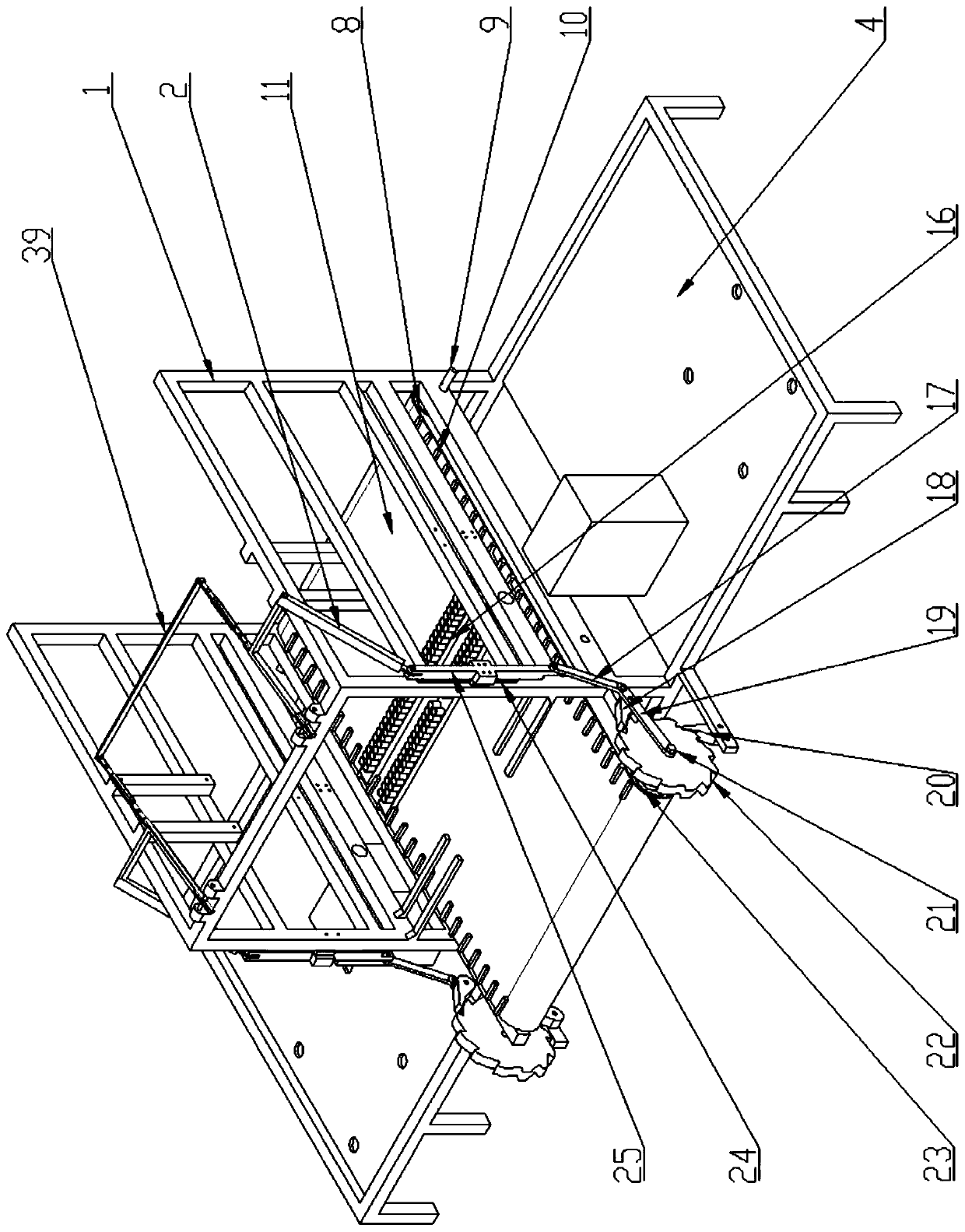

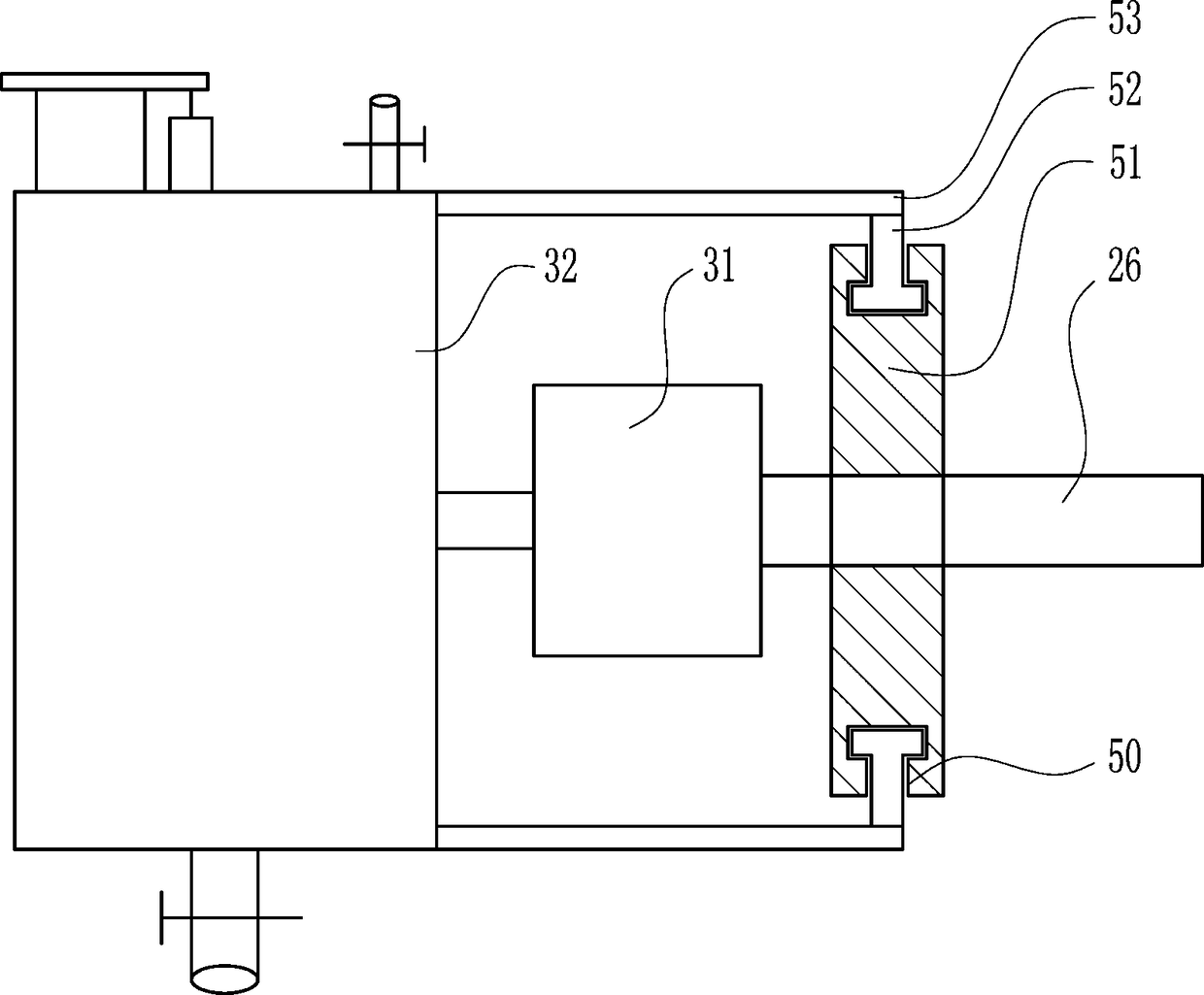

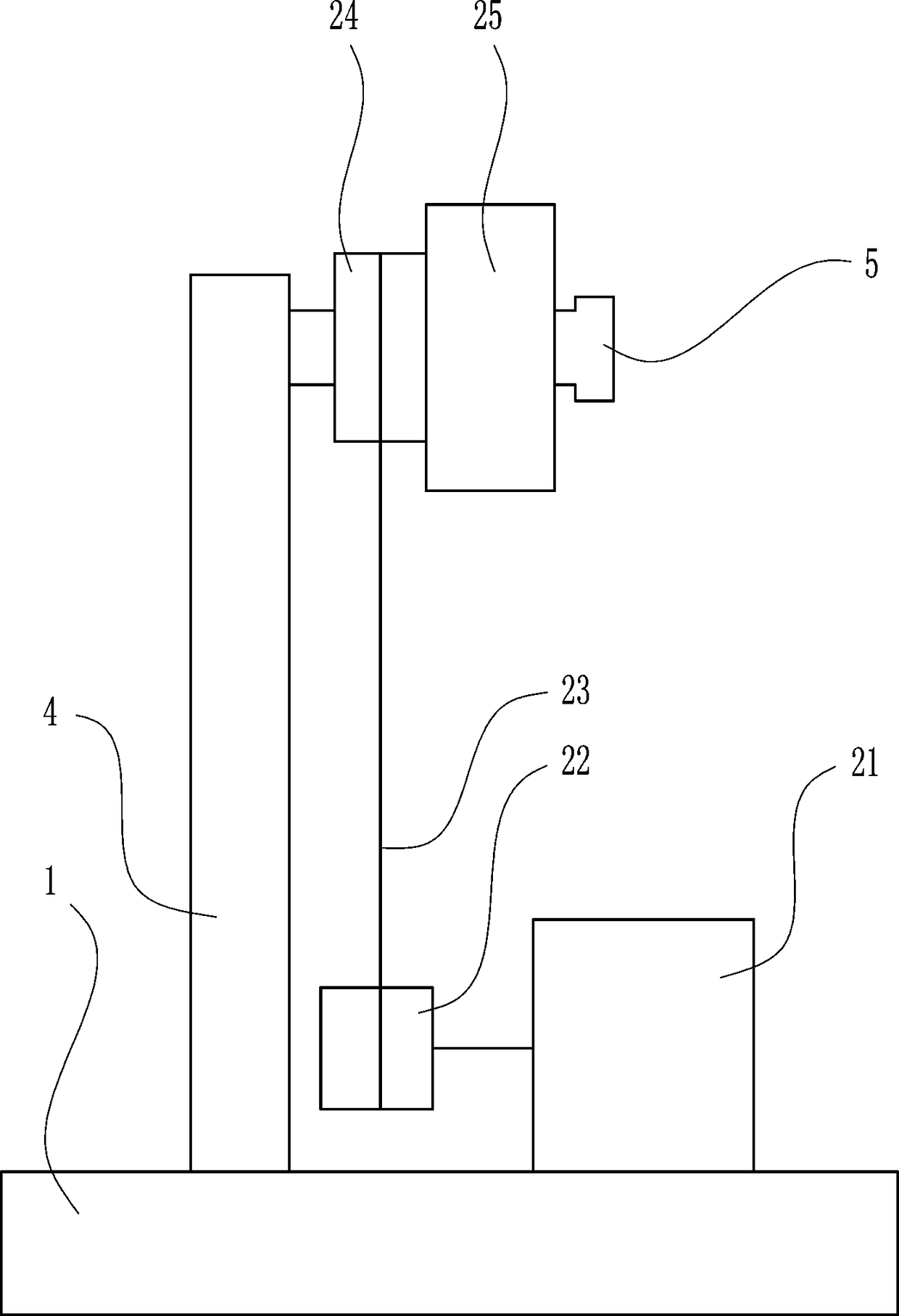

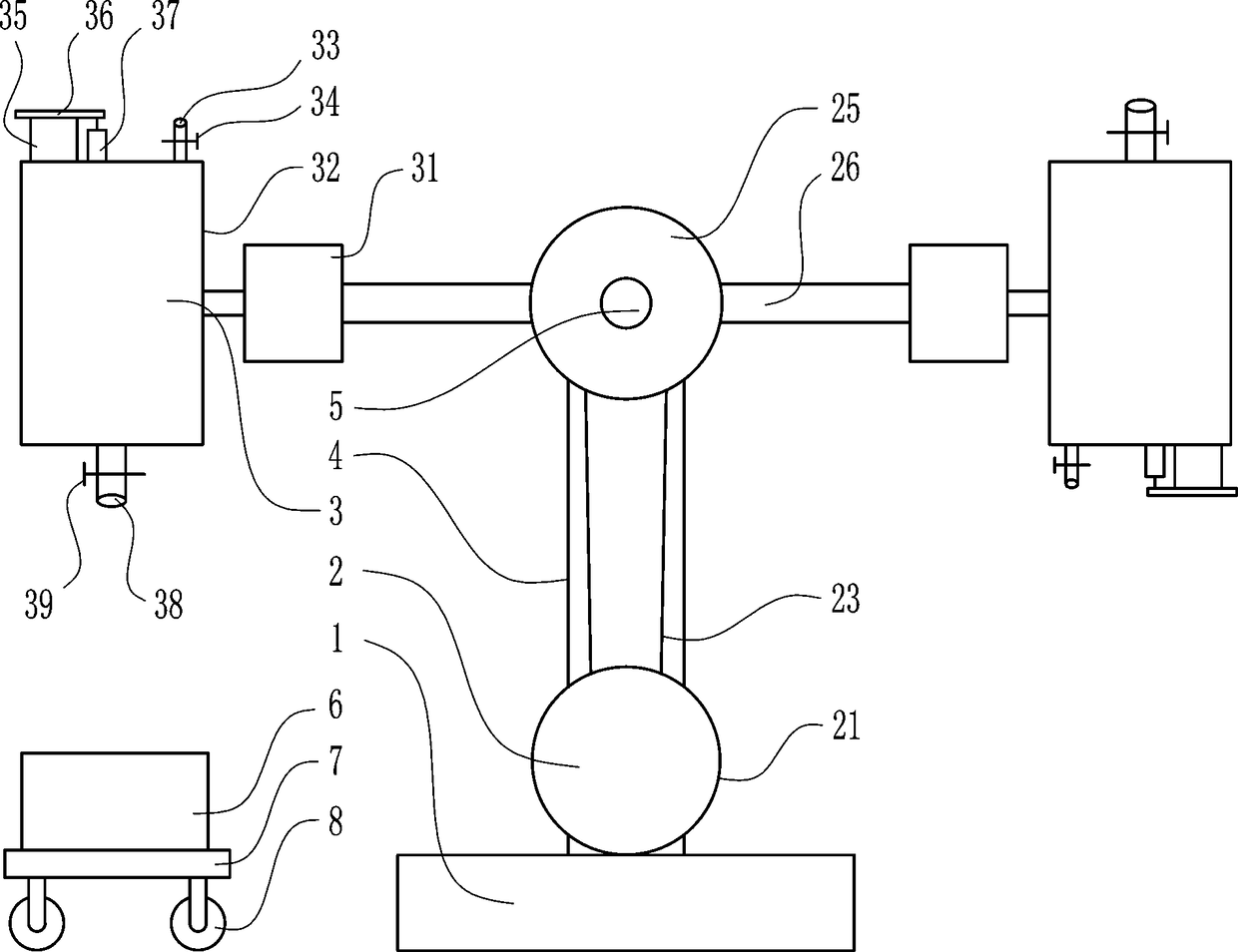

Quick pulping device for rare earth ore

InactiveCN106985276AImprove uniformityImprove pulping efficiencyMixing operation control apparatusClay mixing apparatusRare earthEngineering

The invention relates to a pulping device, and in particular relates to a quick pulping device for rare earth ore. The device comprises a base, an up-down rotating device, a front-back rotating device, a bracket, a connecting shaft, a receiving cylinder, etc., wherein the front-back rotating device is connected with the up-down rotating device; the lower end of the bracket is connected to the top part of the base by welding; the connecting shaft which forwards extends is welded at the upper end of the front sidewall of the bracket; the receiving cylinder is arranged at the left side of the base and is positioned on a supporting plate; a plurality of universal wheels are welded at the bottom part of the supporting plate. According to the quick pulping device for the rare earth ore, the up-down rotating device and the front-back rotating device are provided, so that the rare earth ore can be quickly pulped, the pulping efficiency is high, and the pulping effect is good.

Owner:绍兴柯桥嘉好钰定型股份有限公司

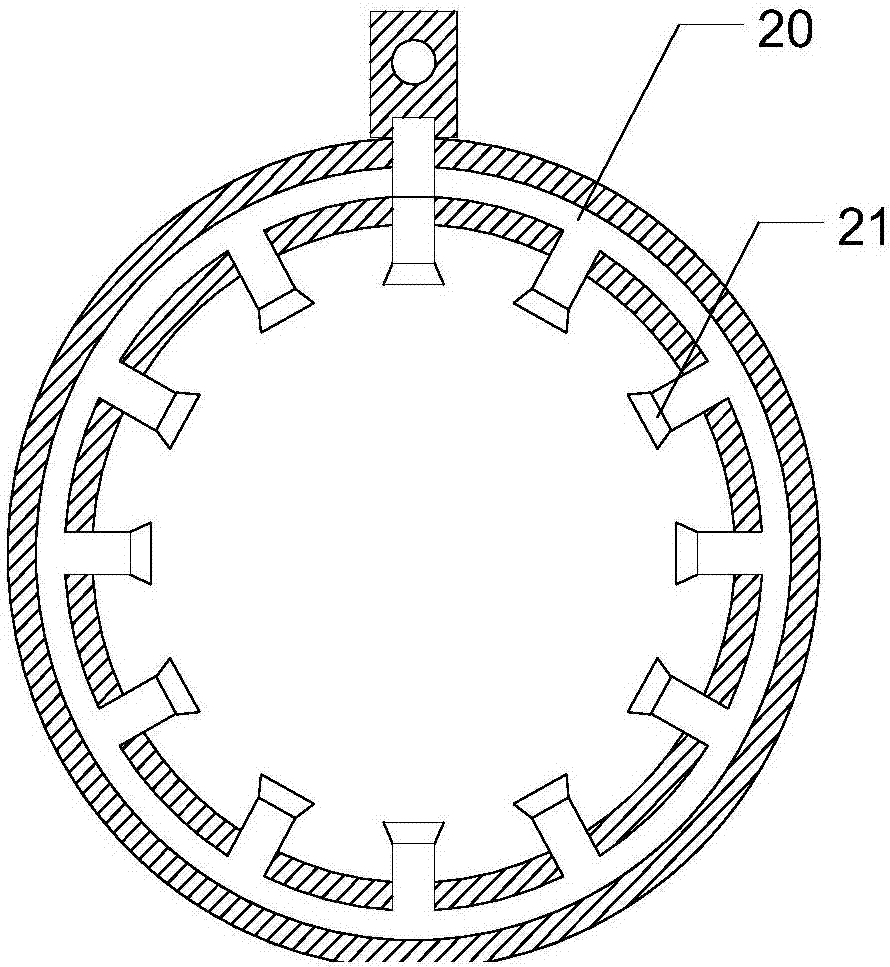

Rotary drum type efficient pulp washer

InactiveCN107034713ADehydration fastFast pulpingWashing/displacing pulp-treating liquorsElectric machineryAgricultural engineering

The invention discloses a rotary drum type efficient pulp washer which comprises a housing and a first variable frequency motor. A rotary drum is arranged in the body and is rotatably connected to the housing through a bearing; the inner diameter of the rotary drum is gradually reduced from left to right, a spiral blade is arranged in the rotary drum, a discharge pipe communicates with the right side of the rotary drum, the discharge pipe is horizontally arranged, and meshes are uniformly formed in the side wall of the discharge pipe. By arranging spiral blades which are different in spacing distance and size, pulp slurry is quickly dehydrated and collected, a scraper which damages a filter screen is not used, and the service life of the device is prolonged; the filter holes are prevented from being blocked through the rotary drum and the rotary spiral blades, so that continuous production is guaranteed, and the production efficiency is increased.

Owner:合肥九州龙腾科技成果转化有限公司

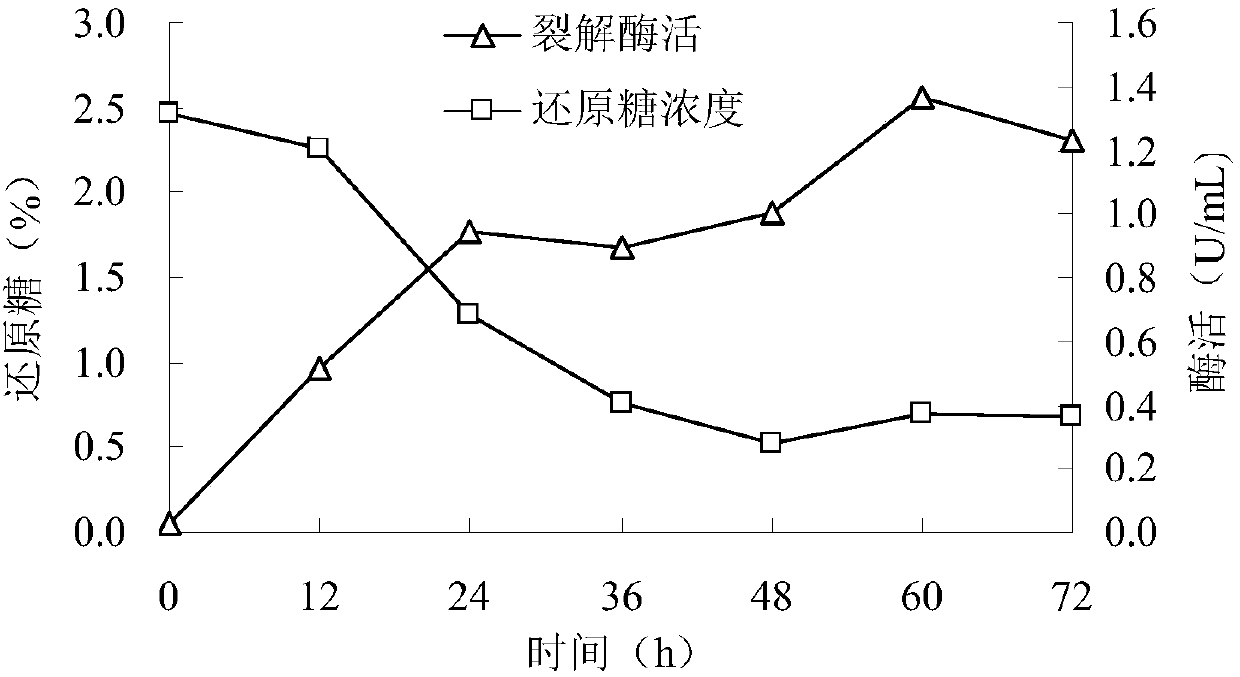

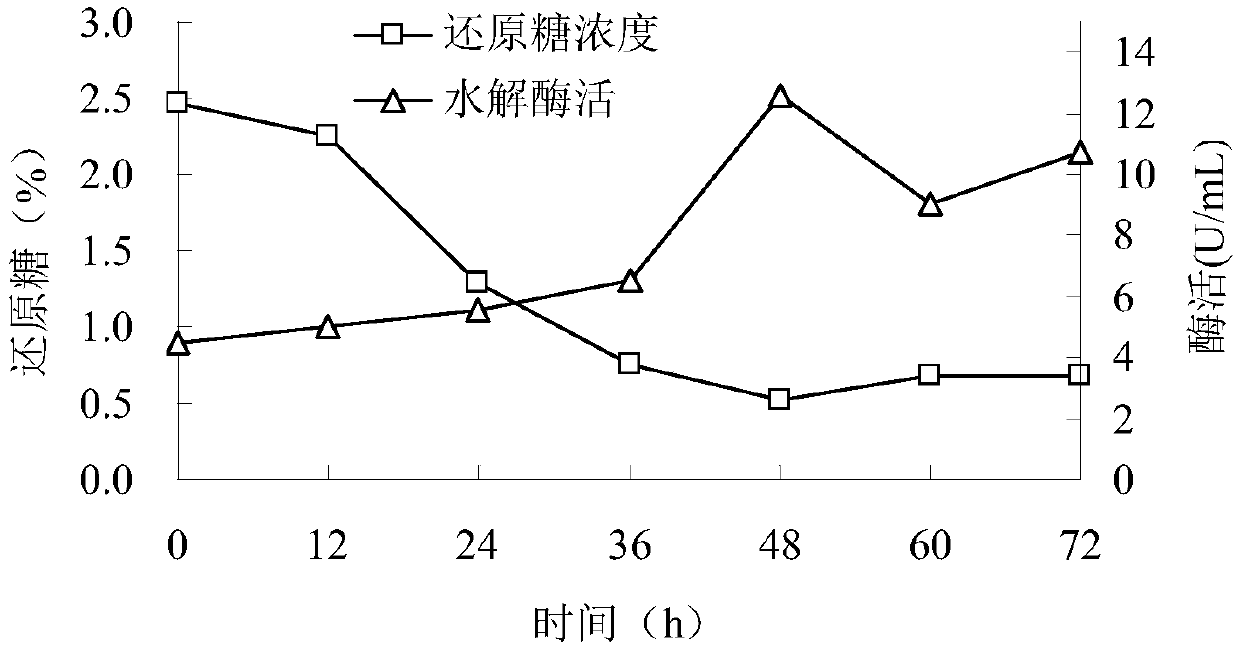

Clean plant cellulose extraction agent, preparation method and applications thereof

ActiveCN107699596AFast degummingFast pulpingMicroorganism based processesFermentationHemp fiberProduct processing

The present invention relates to a clean plant cellulose extraction agent, a preparation method and applications thereof, and belongs to the field of biotechnology and agricultural product processingand production. The clean plant cellulose extraction agent is formed by mixing a liquid A and a liquid B, wherein a volume ratio of the liquid A to the liquid B is 3:1-5:1, the liquid A is an alkalineliquid, the liquid B comprises a crude enzyme liquid and an enzyme stabilizer, and Bacillus subtilis CGMCC1.836 is fermented, and bacterial separation is performed to obtain the clarified crude enzyme liquid. According to the present invention, the molecular structure of the colloid in the raw fiber is greatly changed by mainly using the alkaline pectin lyase, the alkaline polygalacturonase and the dilute alkali liquid, such that the stability of the colloid complex is severely damaged, and the alternating and circulating of swelling-modifying-colloid removing can be formed so as to achieve rapid hemp fiber degumming, reed pulping, cotton straw pulping and other purposes at the normal temperature.

Owner:晟颐天祥天然纤维科技有限公司

Production method of degradable straw pulp molded tableware

The invention discloses a production method of degradable straw pulp molded tableware, and the production method comprises the following steps: 1) the pulping process step: taking bagasse and wheat straw or rice straw as raw materials, screening, cutting roots, crushing, diluting, adding a strong oxidant and preparing plant fiber pulp under the pressurization condition; 2) the pulp mixing process step: adding water in the plant fiber pulp for dilution till the weight ratio of raw material to water is 1: 150-200, sequentially adding a food-grade water-proofing agent and a food-grade oil-proofing agent, stirring and obtaining pulp liquid for production; 3) the molding process step: spirally injecting the pulp into a mold of a molding machine along the inner wall, uniformly stirring the pulp by relying on the recoil force formed by fluid, carrying out vacuum removal of part of the water, and completing the production of a wet green; and 4) the product sizing: transferring the wet green into the mold of the molding machine and preparing a finished product under high temperature and high pressure. The production method is pollution-free and can reduce the production energy consumption, reduce the failure rate of the product and significantly improve the product quality.

Owner:浙江金晟环保股份有限公司

Fast pulper for paper making

InactiveCN108221426AFast pulpingReduce work intensityRaw material divisionElectric machineryPulp and paper industry

Owner:上海多木实业有限公司

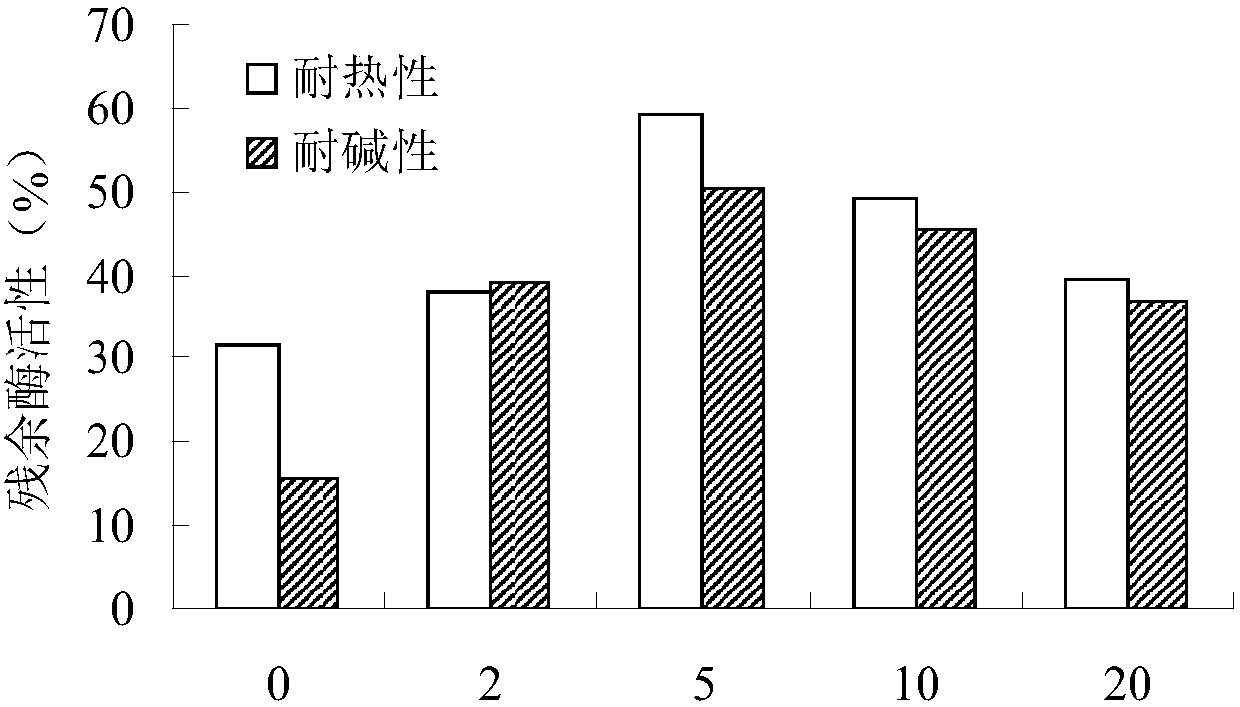

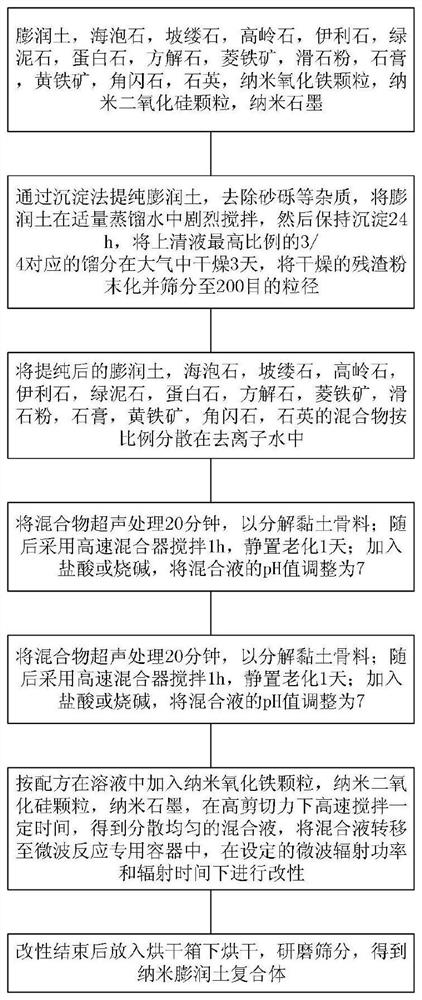

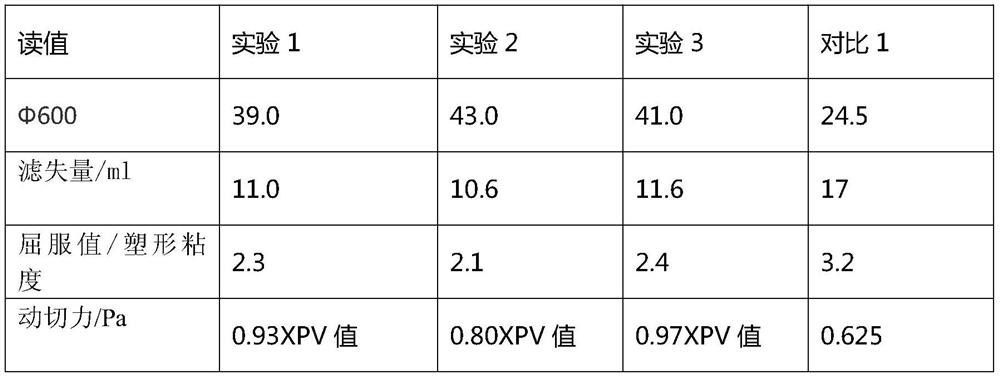

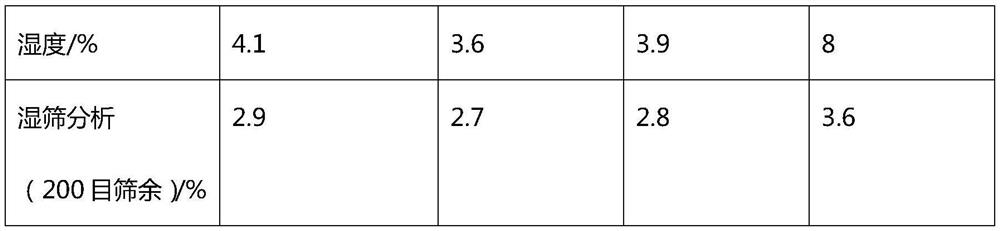

Modified bentonite for seawater drilling and preparation method thereof, and drilling fluid

PendingCN112011320AFast pulpingReduce sand contentDrilling compositionSilicon compoundsPalygorskiteSlurry

The invention provides modified bentonite for seawater drilling and a preparation method thereof, and a drilling fluid. The modified bentonite for seawater drilling comprises the following components:bentonite, sepiolite, palygorskite, kaolinite, illite, chlorite, opal, calcite, siderite, talcum powder, gypsum, pyrite, hornblende, quartz, nanometer iron oxide particles, nanometer silicon dioxideparticles and nanometer graphite. The bentonite prepared from the components is high in slurrying speed, low in sand content, good in slurry making rate, high in sand carrying capacity, low in filterloss and high in stability.

Owner:WUHU FEISHANG NONMETAL MATERIAL

A kind of grouting reinforcement method for highway foundation or base course and building weak foundation

The invention discloses a road foundation or base and building soft foundation grouting reinforcement method. The method comprises the following steps: setting a reinforcement position, and drilling to form a grouting hole; making a grouting pipe with the length being greater than the depth of the grouting hole according to the depth of the grouting hole, and connecting the grouting pipe to a grouting pump; arranging the grouting pipe and starting the grouting pump to make a slurry flow into the grouting pipe, and allowing the slurry to be shunted when the slurry flows to the tail end of the casting pipe in order to make the slurry flow to a flow guiding pipe, and allowing the flow guiding tube to downward slide along a flow guiding slot under the pressure action of the slurry and to outward extend in a cruciform manner in order to make the nested flow guiding tube extend step by step; allowing the slurry to be discharged from slurry outlet holes arranged on the grouting pipe and the flow guiding pipe and to diffuse to a predetermined grouting reinforcement position and range; and stopping grouting, and pulling out the grouting pipe. The method has the advantages of wide diffusion range of the slurry, uniform distribution in the soft foundation, fast slurry discharging speed, good grouting reinforcement effect, and avoiding of secondary grouting.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

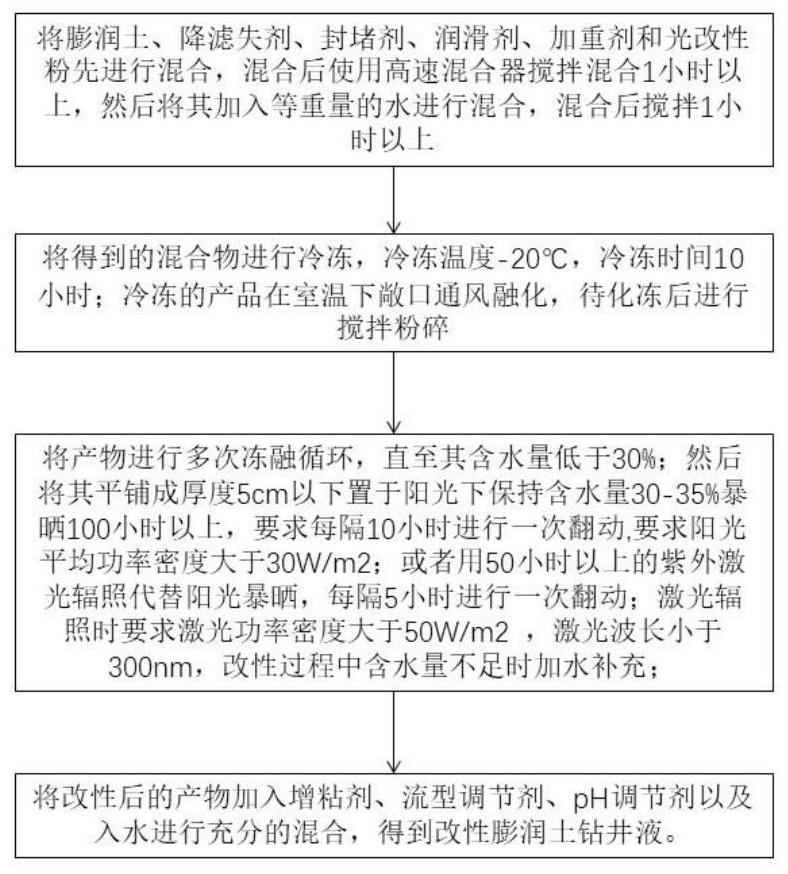

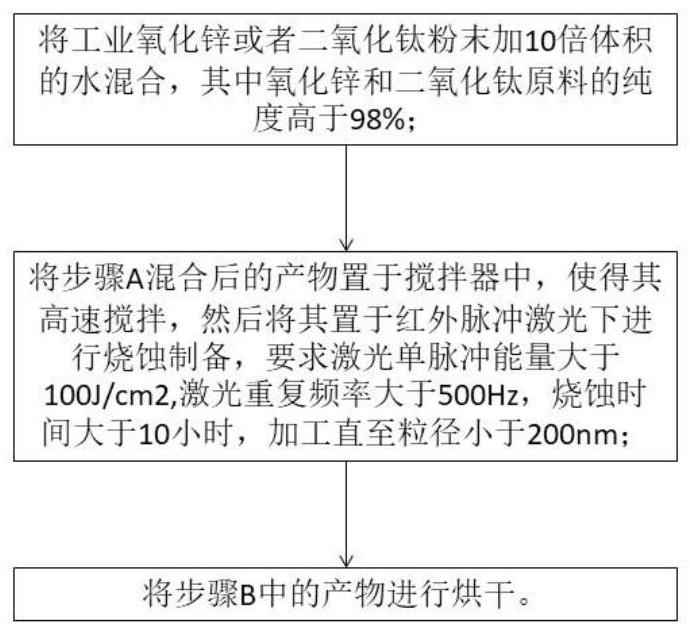

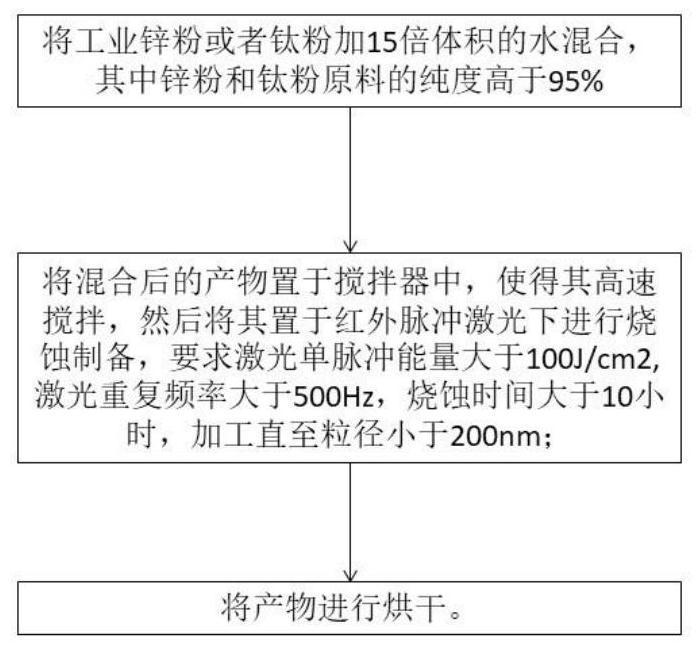

Modified bentonite drilling fluid for well drilling and preparation method thereof

The invention relates to a modified bentonite drilling fluid for well drilling and a preparation method thereof. According to the preparation method, raw materials containing bentonite and light modified powder are subjected to freeze-thaw cycle stirring for multiple times, water loss is carried out at a low temperature, so that the connection strength of molecules in the raw materials is furtherreduced, the light modified powder and the bentonite raw materials are mixed more fully after water loss, nanoscale contact is achieved, and the adjusting effect can be improved during tackifying andother adjustment; the surface charge property of the raw materials can be adjusted by further modifying in a sunlight exposure or ultraviolet irradiation manner, so that after a surfactant tackifier,a flow pattern regulator, a pH regulator and the like are added later, the slurry forming speed is high, the slurry forming rate is high, the sand wrapping capability is high, the filter loss is low,and the stability is better; the preparation method of the used light modified powder is a laser ablation method, no other raw material is introduced in the preparation process, metal or oxide thereofcan be directly ablated to obtain a product, and the light modified powder is high in yield, safe, free of pollution, free of influence on modification of bentonite and suitable for other industrialapplications.

Owner:WUHU FEISHANG NONMETAL MATERIAL

Pulping auxiliary added in normal-pressure low-temperature clean pulping process

ActiveCN102926254AIncrease profitEmission reductionCellulose material pulpingDust controlPulp and paper industry

The invention discloses a pulping auxiliary added in a normal-pressure low-temperature clean pulping process. The puling process comprises five steps including cutting straws and removing dust, placing in a reaction kettle, screening and grinding into pulp, bleaching and squeezing out the finished pulp. The pulping auxiliary is characterized by comprising sodium hydroxide, green oxygen, sodium silicate, hydrogen peroxide, DTPA (diethylene triamine pentaacetic acid) and low concentration acid. By means of the technical characteristics during the pulping process, the mechanical device such as the reaction kettle is organically combined with the pulping auxiliary to pulp quickly and effectively during the pulping process in a low-temperature and normal-pressure work environment. The pulping auxiliary is environment-friendly in process, green and clean, improves the utilization ratio of the raw materials, and reduces emission load of pollutants.

Owner:TIANJIN RONGYEDA TECH DEV

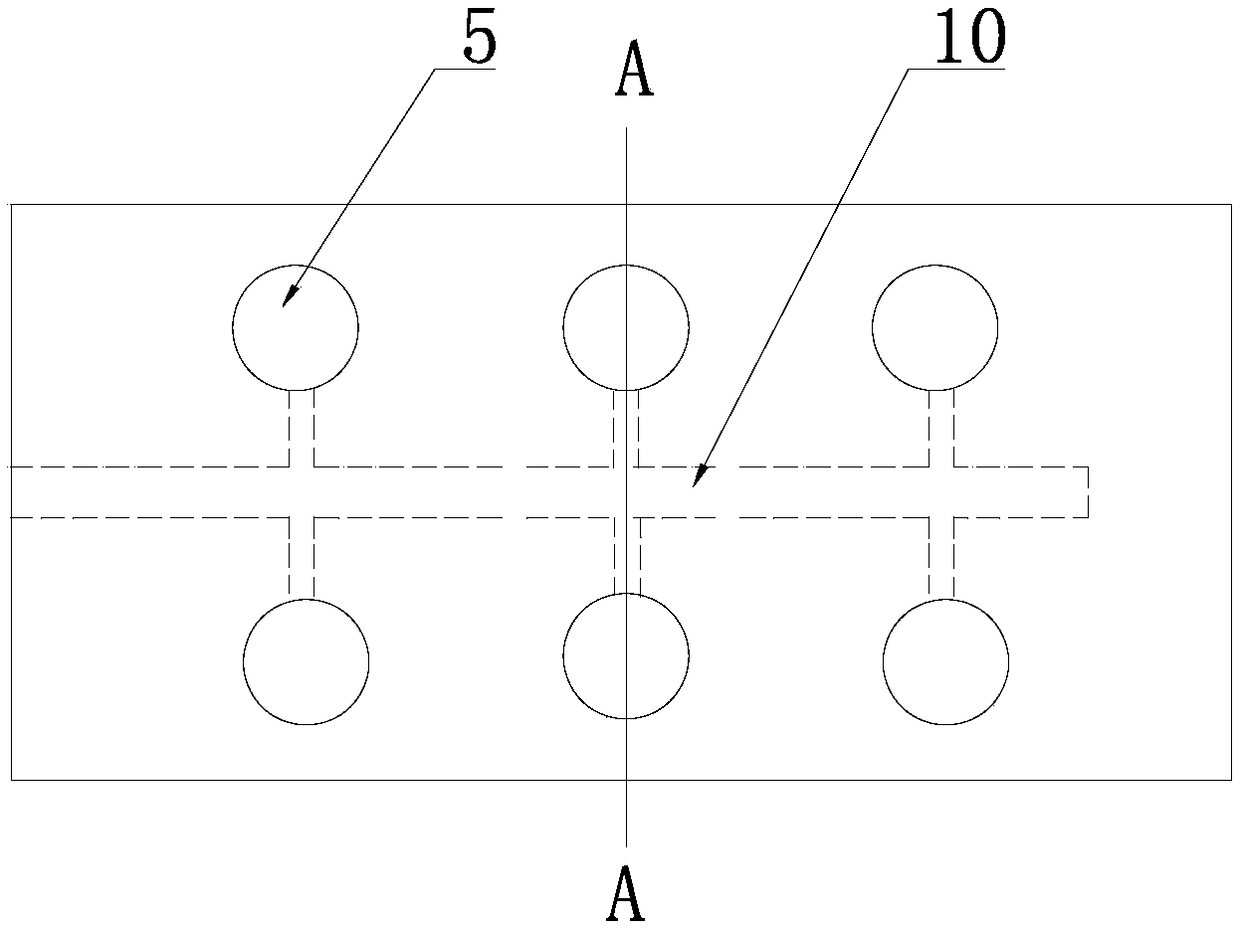

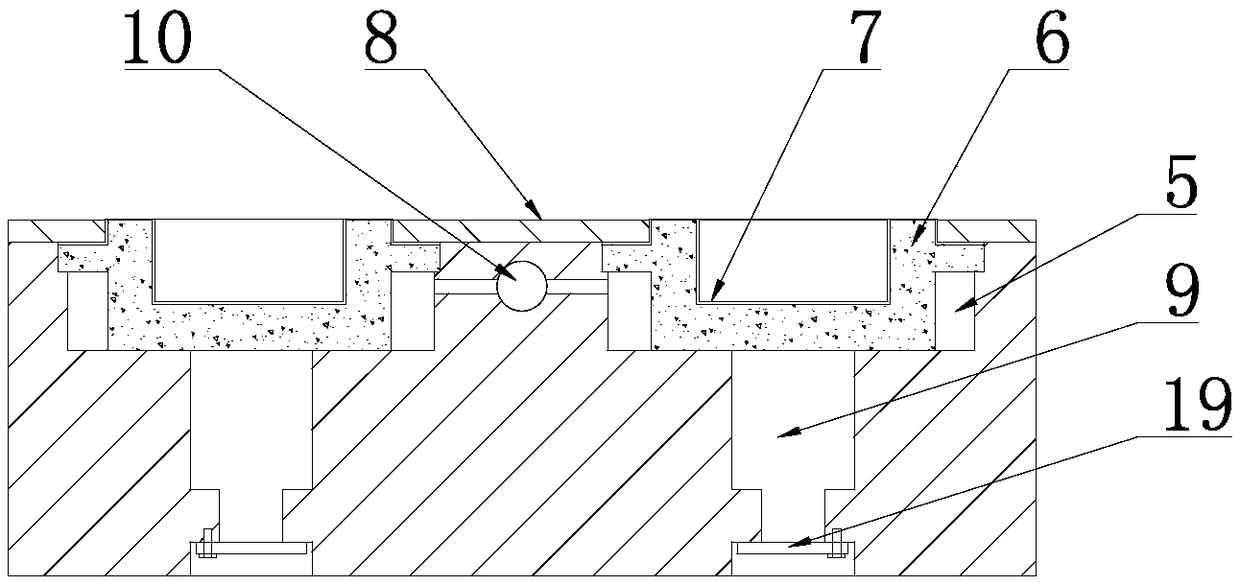

Pulp catching device and method in disposable fiber tableware molding equipment

PendingCN108824095AThe pulping process is simpleFast pulpingTextiles and paperFiberPulp and paper industry

The invention discloses a pulp catching device in disposable fiber tableware molding equipment, and aims to provide the pulp catching device with short time of a pulp catching process, pre-forming anda good drying effect in the disposable fiber tableware molding equipment. A technical scheme key point of the invention is that the device comprises a machine body, a pulp tank, an upper mold and a lower mold; the lower mold is provided with a plurality of chambers, the interior of each chamber is provided with one chamber forming mold prepared from one porous metal, and each chamber forming moldis covered with one mesh cloth; the upper surface of the lower mold is provided with pressure plates for fixing the chamber forming molds, the bottom of each chamber forming mold is in contact with the bottom of one corresponding chamber, one hollow cavity is arranged between the side wall of each chamber forming mold and the side wall of one corresponding chamber, and the bottom of each chamberis provided with one water passing hole; the lower mold is further provided with air suction holes communicating with the hollow cavities, and the air suction holes are connected with a first vacuum suction device; the upper mold is provided with mold cores matched with the chamber forming molds, each mold core is provided with adsorption holes, and the adsorption holes are connected with a secondvacuum suction device; and the upper mold is provided with a heating device. The device disclosed by the invention is suitable for the technical field of fiber tableware molding equipment.

Owner:TAIZHOU JIADEBAO TECH

Glass kiln-used dry type micro-expansion heat preservation coating

ActiveCN103011861AReduce trapped material defoaming static linkReduce crackingGlass furnace apparatusHollow fibreFiber

The invention discloses a glass kiln-used dry type micro-expansion heat preservation coating which is characterized by comprising the following ingredients in part by weight: 30-60 parts of expanded perlite, 20-40 parts of superfine surface active ground calcium carbonate, 5-10 parts of alumina silicate fiber, 2-5 parts of siliceous fine powder, 2-5 parts of hollow fiber, 5-13 parts of composite binding agent, and 1-4 parts of chemical additives. When being prepared, the expanded perlite, the superfine surface active ground calcium carbonate, the alumina silicate fiber, the alumina silicate fiber and the hollow fiber are put into a stirring machine in sequence to be uniformly stirred and mixed up; the reset composite binding agent and the chemical additives are added into the stirring machine to be stirred and sufficiently mixed so as to prepare the coating. According to the coating, the raw materials are prepared into the dry type heat preservation coating, so that not only are the procedures of mixture ageing, defoaming and standing after foaming reduced, but also the problem that a traditional coating is deteriorated and dehydrated caused by long distance transportation is avoided; and meanwhile the coating has the characteristics of rapid curing strength, remarkable heat preservation and energy conservation effect, convenience for construction and the like.

Owner:山西高科耐火材料股份有限公司

A kind of royal jelly automatic insect suction device

InactiveCN110432185BEliminate the need for manual worm extraction and pulpingImprove work efficiencyHoney collectionRatchetAnimal science

The invention provides a royal jelly automatic insect taking and jelly sucking device which comprises a rack, a working platform, a transmission device, an insect taking device and a jelly sucking device. Each conveying belt is used to cooperate with a ratchet mechanism, each ratchet wheel, a corresponding ratchet and a corresponding ratchet rod are in intermittent motion, the intermittent motionis transmitted to the insect taking device and the jelly sucking device through a rocker and a connection rod mechanism to enable a jelly generating strip, the insect taking device and the jelly sucking device to correspondingly act, and insect taking and jelly sucking can be performed at the same time; a filtering interception net is arranged above an insect clamp, so that the problem that too much royal jelly is left in the filtering interception net. The royal jelly automatic insect taking and jelly sucking device is high in jelly taking speed and low in residual rate, condition of the royal jelly is well ensured, and jelly generating quality is fully guaranteed.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

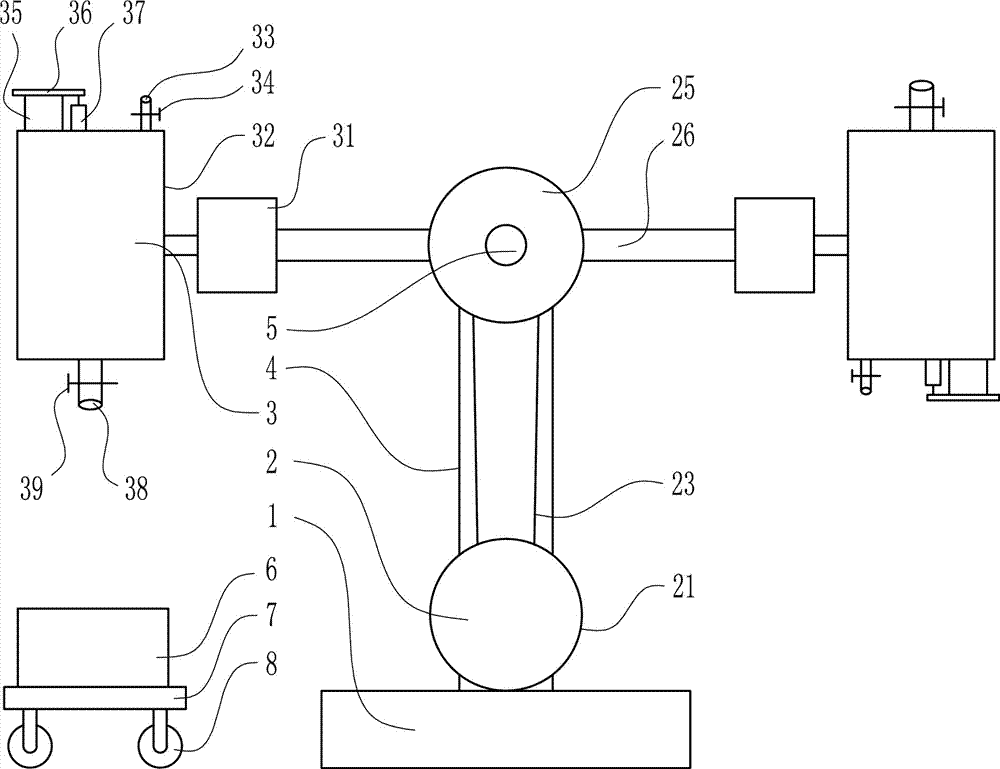

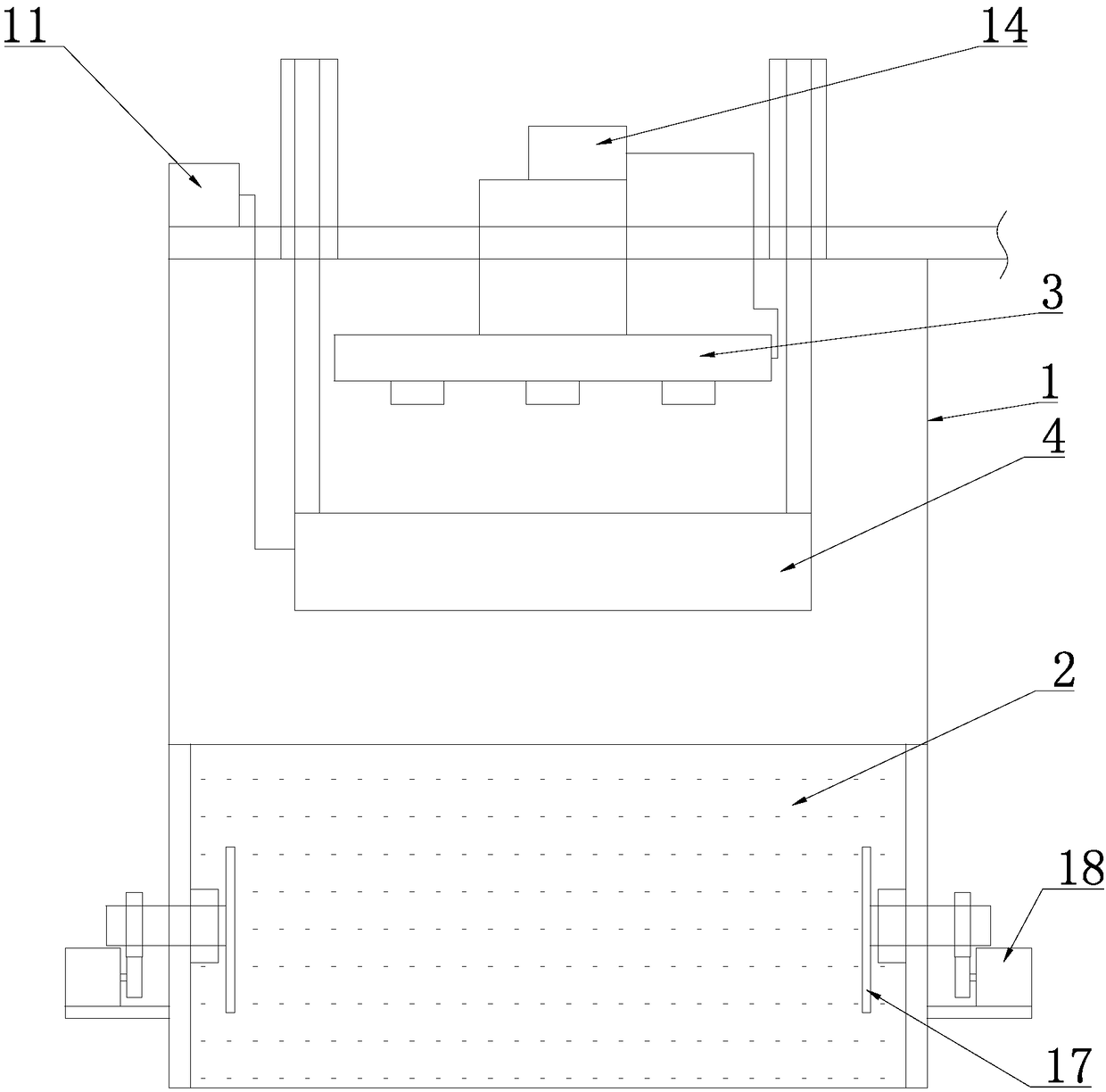

Rapid pulper for papermaking

InactiveCN109680527ASimple device structureEasy to operateRaw material divisionElectric machineryPapermaking

The invention discloses a rapid pulper for papermaking. The rapid pulper for papermaking comprises a base and a sleeve, the sleeve is located right above the base, a buffering device is arranged in the base, a groove is formed in the center of the top of the base, and brackets are separately mounted on two sides of the top of the base. The top ends of the two brackets are separately and fixedly connected with the bottom of a bearing seat, a supporting block is fixedly mounted on one side of one of the brackets, a motor is arranged at the top of the supporting block, a connecting rod is arranged in the sleeve, two ends of the connecting rod separately penetrate through the two sides of the sleeve and extend to the outside of the sleeve and are movably connected with the bottom end of one side of a driving rod, and the top end of the other side of the driving rod is movably connected with one end of a rotary rod. The rapid pulper for papermaking is simple in structure and convenient to operate, can rapidly pulp raw materials, reduces the working strength of working personnel, and improves the working efficiency.

Owner:上海多木实业有限公司

Glass kiln-used dry type micro-expansion heat preservation coating

ActiveCN103011861BReduce trapped material defoaming static linkReduce crackingGlass furnace apparatusHollow fibreFiber

The invention discloses a dry-type micro-expansion thermal insulation coating for a glass kiln, which is characterized in that it contains the following raw materials in parts by weight: 30-60 parts of expanded perlite, 20-40 parts of superfine surface-active heavy calcium carbonate, silicon 5-10 parts of aluminum acid fiber, 2-5 parts of siliceous fine powder, 2-5 parts of hollow fiber, 5-13 parts of composite binder, 1-4 parts of chemical additives; Active ground calcium carbonate, aluminum silicate fiber, siliceous fine powder, and hollow fiber are put into the mixer in turn and mixed evenly, and then the remaining composite binder and chemical additives are added into the mixer and stirred until they are fully mixed. The dry thermal insulation coating made from the above-mentioned raw materials in the present invention not only reduces the stagnant material defoaming and standing link after foaming, but also avoids the problems of deterioration and dehydration caused by long-distance transportation of traditional slurry coatings. It has the characteristics of remarkable heat preservation and energy saving effect, convenient construction and so on.

Owner:山西高科耐火材料股份有限公司

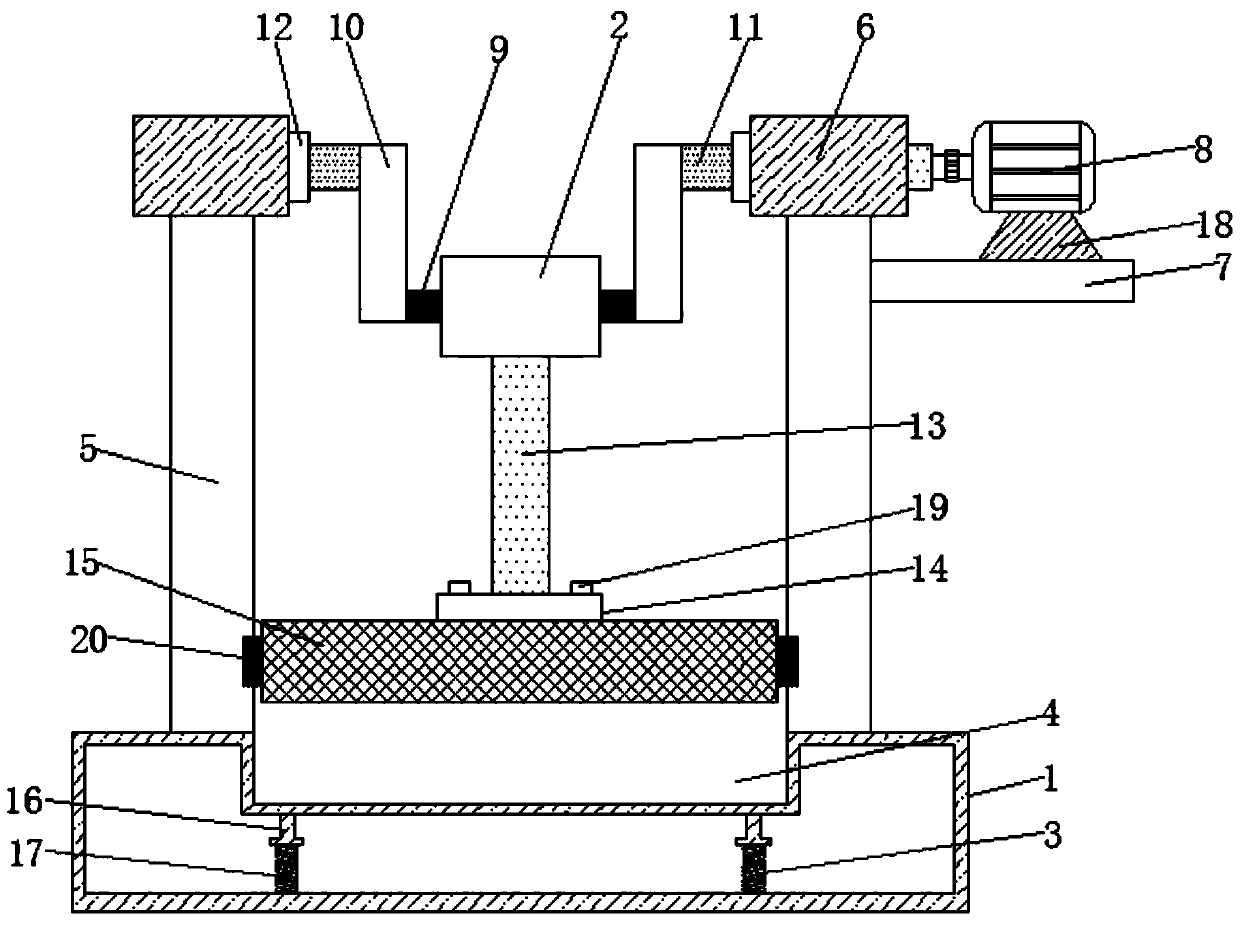

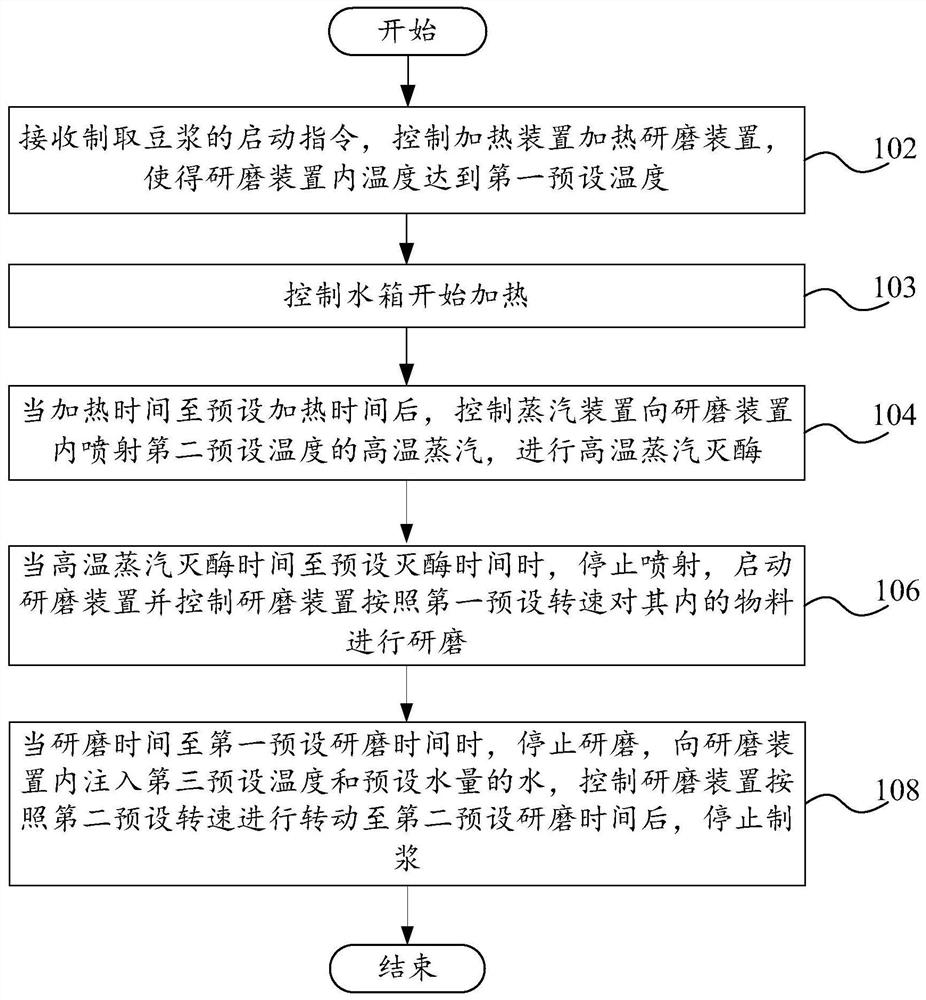

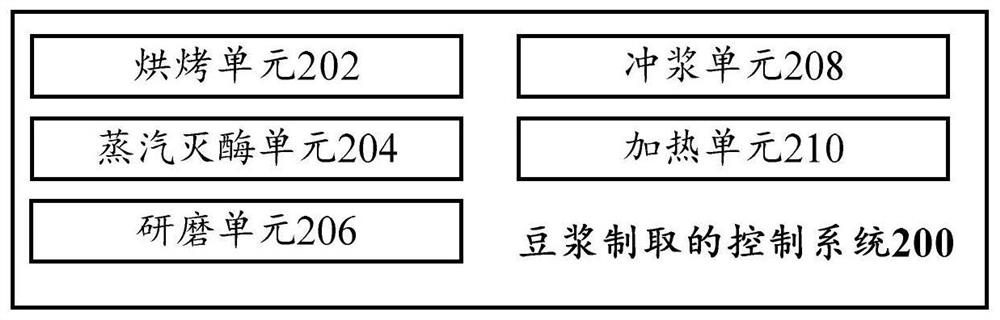

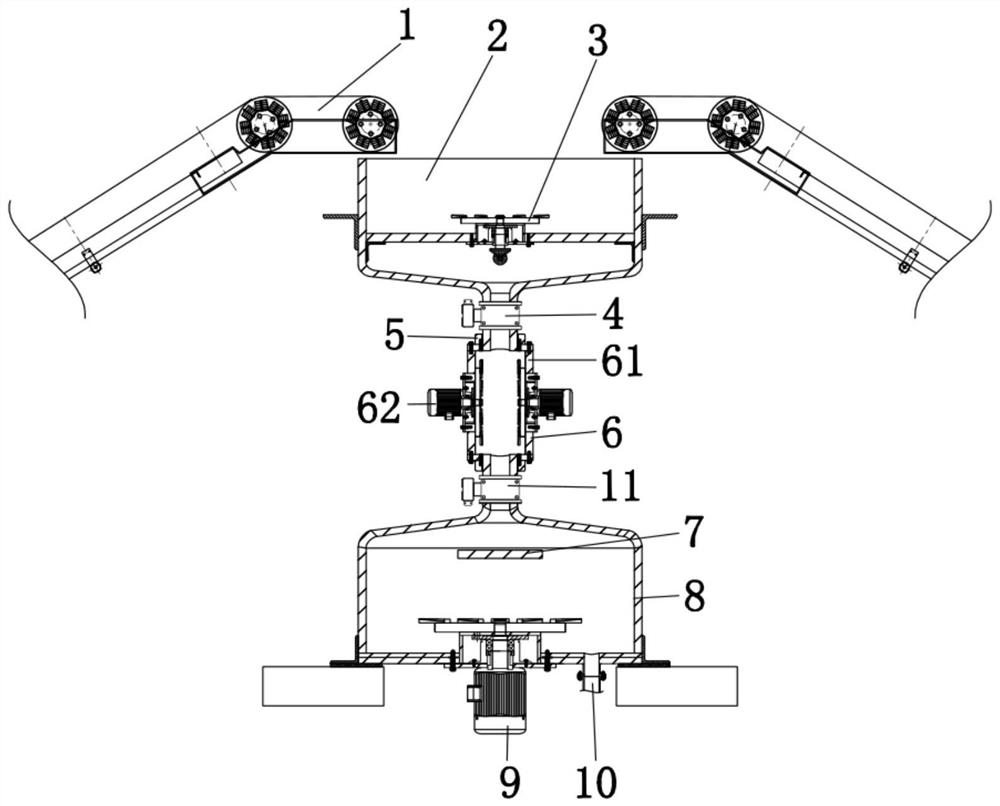

Method for preparing soybean milk, control system for preparation, soybean milk machine and computer device

ActiveCN109419301BSlow down passivationReduced nutritional valueWarming devicesFood scienceControl systemProcess engineering

The invention provides a method for preparing soybean milk, a control system for preparing soybean milk, a soybean milk machine, a computer device and a computer-readable storage medium. The grinding device reaches the first preset temperature; when the heating time reaches the preset heating time, the steam device injects high-temperature steam of the second preset temperature into the grinding device; when the high-temperature steam deactivation time reaches the preset deactivation time, the injection is stopped , control the grinding device to grind the material according to the first preset speed; stop grinding when the grinding time reaches the first preset grinding time, inject water with the third preset temperature and preset water volume into the grinding device, and control the grinding device according to the second The pulping is stopped after the preset rotation speed rotates to the second preset grinding time. The method for preparing soybean milk provided by the invention effectively shortens the pulping time, improves the quality of soybean milk, expands the application range of the soybean milk machine and improves user satisfaction.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Efficient pulping system for dry and wet broken paper

PendingCN114134745AFast pulpingSpeed up pulpingPaper recyclingRaw material divisionPapermakingManufacturing engineering

The invention discloses an efficient dry and wet broken paper pulping system which comprises a pulping cylinder and a conveyor used for feeding, the pulping cylinder comprises an upper pulping cylinder and a lower pulping cylinder, a pulping device A and a pulping device C are arranged in the upper pulping cylinder and the lower pulping cylinder respectively, a discharging pipe is arranged at the bottom of the lower pulping cylinder, and a feeding pipe is arranged at the bottom of the lower pulping cylinder. And the bottom of the upper repulping cylinder is communicated with the top of the lower repulping cylinder through the central repulping cylinder. The invention relates to the technical field of papermaking. According to the efficient repulping system for the dry and wet broken paper, the dry broken paper can be conveyed into the upper repulping cylinder through the conveyor to be repulped for the first time, then the repulped dry broken paper and wet pulp which is added later are put into the central repulping cylinder at the same time, and pulp in the shell is rapidly repulped in a narrow space through the repulping devices B which are oppositely arranged; and after passing through the shell, the pulp flows into the lower pulping cylinder for third-time pulping work. The oppositely arranged repulping device B is used for quickly grinding the pulp, so that the repulping speed is increased.

Owner:辽宁兴东科技有限公司

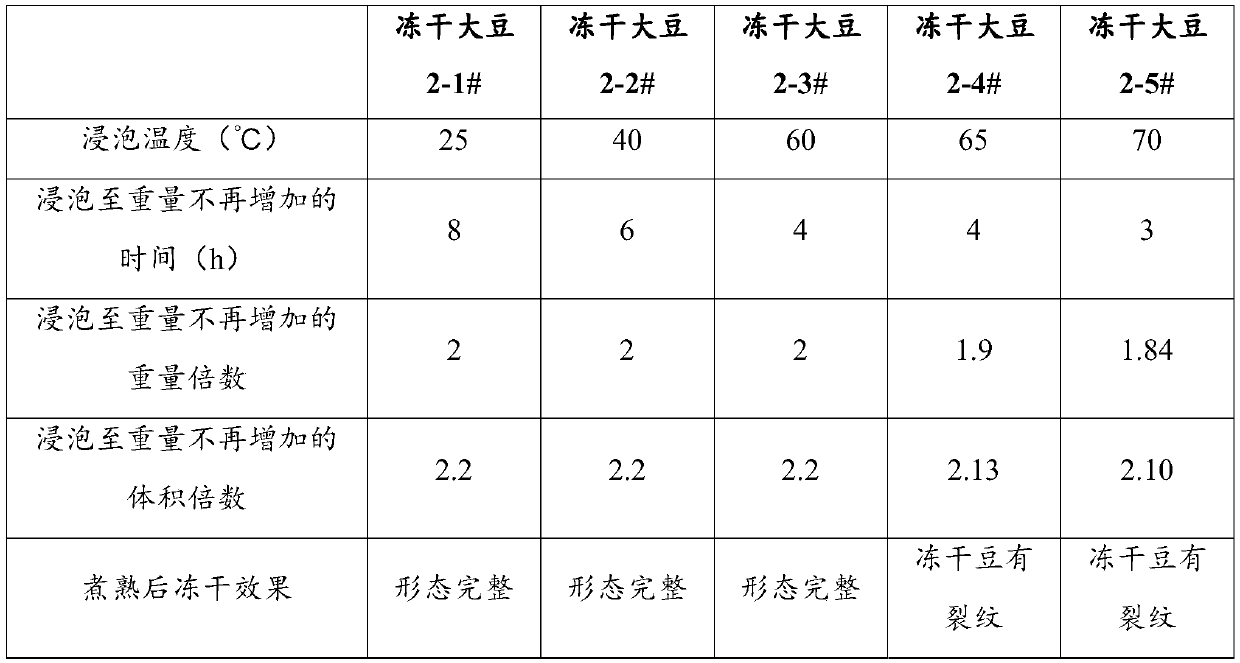

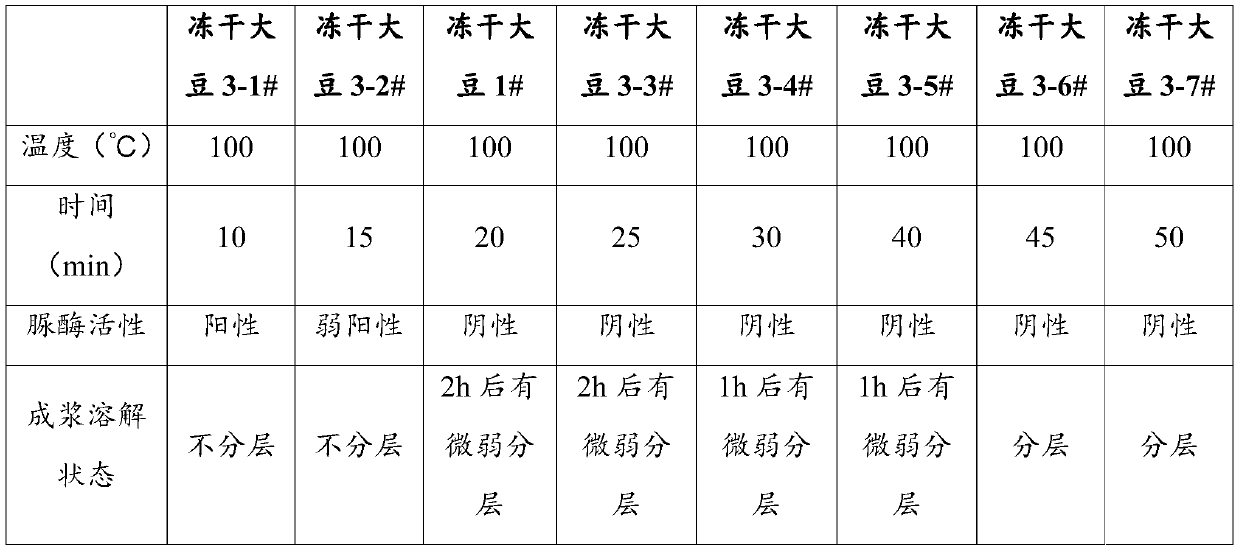

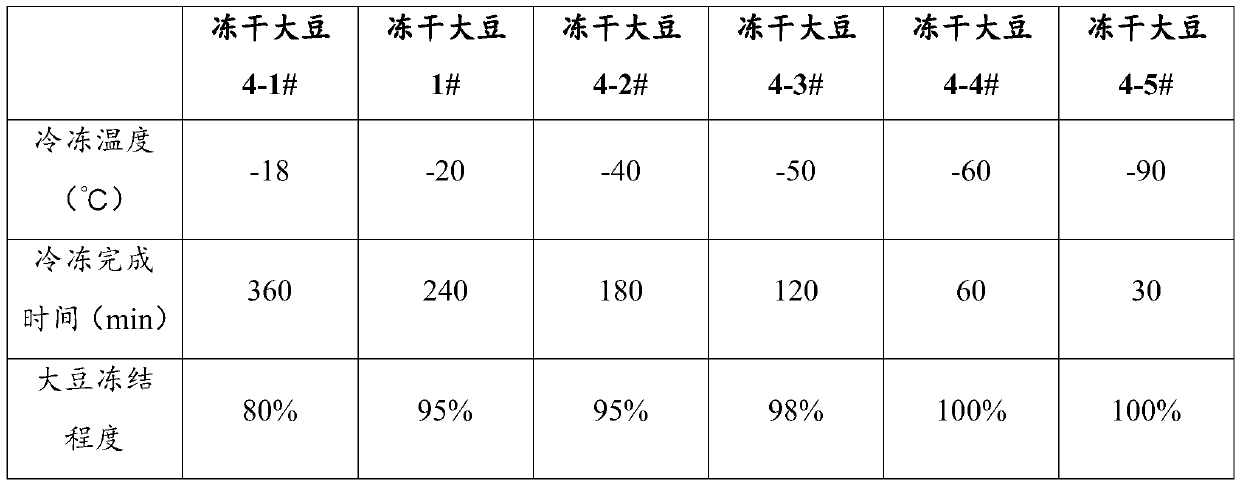

Raw material bag applied to food processor and preparation method and application thereof

The invention discloses a raw material bag applied to a food processor and a preparation method and application thereof, and belongs to the field of food processing. The raw material bag suitable forthe food processor comprises that: the food processor mixes and crushes the raw material bag and water into slurry, and the raw material bag comprises, in parts by weight, 15-50 parts of freeze-driedsoybeans and 40-50 parts of oat. The raw material bag adopts a soybean milk raw material matching scheme taking the freeze-dried soybeans as a main raw material, realizes no beany flavor and comprehensive nutrition, and can meet the requirements of consumers on flavor, health and convenience through a formula and process of soybean milk food raw materials which are rapidly self-made by a householdfood processing machine.

Owner:JOYOUNG CO LTD

Quick pulping method of soymilk maker

ActiveCN101715835BMeet needsFully heatedBeverage vesselsMilk substitutesPulp and paper industryMouthfeel

The invention relates to a method for preparing soymilk, in particular to a quick pulping method of a soymilk maker, which comprises a heating process, a pulverization process and a boilout process, wherein the pulverization process comprises a stage that a pulverization cutter is driven by a motor to pulverize materials and a stage of motor stop; the boilout process comprises a stage of heating the materials and water by a heating device and a stage of stopping heating; and the time of the heating process is t1, the time of the pulverization process is t2, the time of the boilout process is t3, the total time of pulping is T, and T is less than 900 seconds and is more than t1+t2+t3. The soymilk maker realizing the quick pulping method comprises a maker head, a cup body, the motor, a pulverization device and the heating device, wherein the pulverization device comprises the pulverization cutter. The pulping working procedure of the soymilk maker comprises the quick pulping method of the soymilk maker in any item from 1 to 9 of patent claim. The invention provides a pulping method capable of preparing the soymilk with good mouthfeel quickly and efficiently.

Owner:JOYOUNG CO LTD

A rapid pulping device for rare earth ore

InactiveCN106985276BFast pulpingSave resourcesMixing operation control apparatusClay mixing apparatusRare earthEngineering

The invention relates to a pulping device, and in particular relates to a quick pulping device for rare earth ore. The device comprises a base, an up-down rotating device, a front-back rotating device, a bracket, a connecting shaft, a receiving cylinder, etc., wherein the front-back rotating device is connected with the up-down rotating device; the lower end of the bracket is connected to the top part of the base by welding; the connecting shaft which forwards extends is welded at the upper end of the front sidewall of the bracket; the receiving cylinder is arranged at the left side of the base and is positioned on a supporting plate; a plurality of universal wheels are welded at the bottom part of the supporting plate. According to the quick pulping device for the rare earth ore, the up-down rotating device and the front-back rotating device are provided, so that the rare earth ore can be quickly pulped, the pulping efficiency is high, and the pulping effect is good.

Owner:绍兴柯桥嘉好钰定型股份有限公司

Pulping Auxiliaries Added During Atmospheric Pressure Low Temperature Clean Pulping Process

ActiveCN102926254BIncrease profitEmission reductionCellulose material pulpingPollutant emissionsOxygen

The invention discloses a pulping auxiliary agent added in the normal-pressure low-temperature clean pulping process. The pulping process includes five steps of cutting grass and removing dust, putting into a reaction kettle, screening and refining pulp, bleaching and extruding finished pulp , characterized in that the pulping aids include sodium hydroxide, green oxygen, sodium silicate, hydrogen peroxide, DTPA and low-concentration acid; the present invention utilizes the technological characteristics in the pulping process to combine mechanical devices such as reactors with pulping The organic combination of additives enables the overall pulping process to achieve rapid and efficient pulping under low temperature and normal pressure working environment. The process is environmentally friendly, green and clean, which improves the utilization rate of raw materials and reduces the emission of pollutants.

Owner:TIANJIN RONGYEDA TECH DEV

Production method of degradable straw pulp molded tableware

ActiveCN101869380BNo pollution in the processNo hazardous solid waste dischargeOther accessoriesPlatesFiberFood grade

The invention discloses a production method of degradable straw pulp molded tableware, and the production method comprises the following steps: 1) the pulping process step: taking bagasse and wheat straw or rice straw as raw materials, screening, cutting roots, crushing, diluting, adding a strong oxidant and preparing plant fiber pulp under the pressurization condition; 2) the pulp mixing processstep: adding water in the plant fiber pulp for dilution till the weight ratio of raw material to water is 1: 150-200, sequentially adding a food-grade water-proofing agent and a food-grade oil-proofing agent, stirring and obtaining pulp liquid for production; 3) the molding process step: spirally injecting the pulp into a mold of a molding machine along the inner wall, uniformly stirring the pulpby relying on the recoil force formed by fluid, carrying out vacuum removal of part of the water, and completing the production of a wet green; and 4) the product sizing: transferring the wet green into the mold of the molding machine and preparing a finished product under high temperature and high pressure. The production method is pollution-free and can reduce the production energy consumption,reduce the failure rate of the product and significantly improve the product quality.

Owner:浙江金晟环保股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com