Mortar mixer for fast slurry forming

A mortar mixing and mixer technology, which is applied to cement mixing devices, liquid batching supply devices, clay preparation devices, etc., can solve the problems of waste of resources, inconvenient adjustment, excessive mortar, etc., and achieves high speed of slurry formation, simple structure, The effect of adjusting the mortar concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

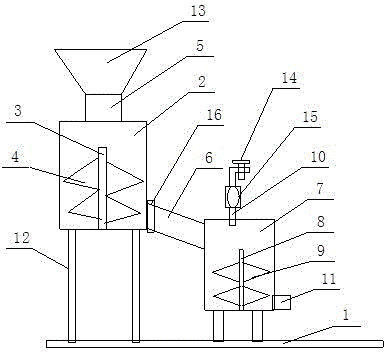

[0021] combine figure 1 A kind of mortar mixer of fast slurrying shown, comprises base 1 and the dry powder mixer and the mortar mixer that are arranged on base 1, and dry powder mixer includes dry powder mixing drum 2 and is arranged on the first stirring drum 2 in dry powder mixing drum Shaft 3, the first stirring shaft 3 is provided with a first stirring blade 4, the top of the dry powder mixing drum 2 is provided with a feeding port 5, the bottom of the dry powder mixing drum 2 is provided with a powder outlet, and a powder delivery pipe 6 is connected outside the powder outlet. The powder pipe 6 communicates with the mortar mixer, and the mortar mixer includes a mortar mixing drum 7 and a second stirring shaft 8 arranged in the mortar mixing drum 7 and a second stirring blade 9 arranged on the second stirring shaft 8, and the mortar mixing drum 7 A water feeding pipe 10 is arranged on the top, and a slurry outlet 11 is arranged at the bottom of the mortar mixing drum 7 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com