Patents

Literature

70results about How to "Reduce sand content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

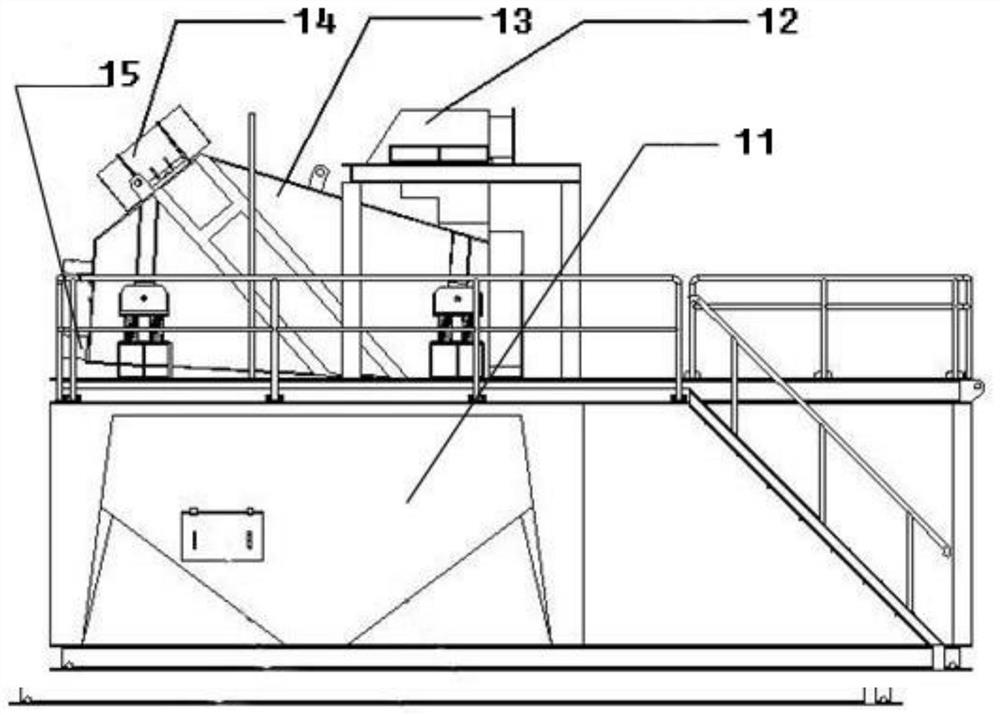

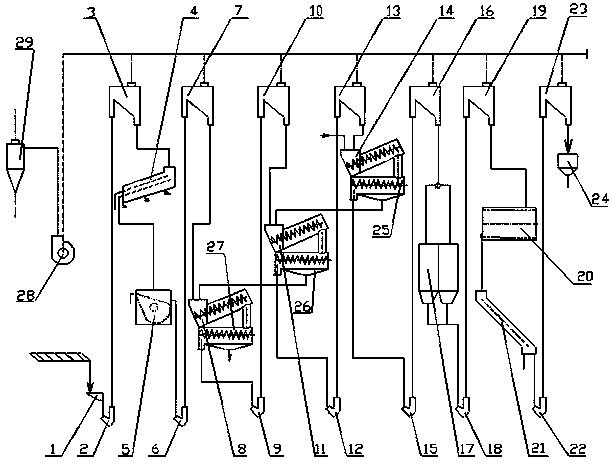

Plaster multi-step treatment device for underground engineering construction

InactiveCN101177325AReduce sand contentLight weightWater/sewage treatment by centrifugal separationSludge treatmentSlurryMud weight

The invention discloses a multilevel treatment equipment for slurry in underground construction, which comprises a prescreening device, a desander and a desilter; wherein, through a pipeline the dredge pump is connected with the prescreening device the prescreening device is connected with the desander through a pipeline; the outlet of the middle storage tank of the desander is respectively connected with a slurry-storing tank and a slurry-adjusting pool of the desilter through a conversion valve and a pipeline; the middle storage tank of the desilter is connected with the slurry-adjusting pool. The invention can process the slurry in complex strata stage by stage, meeting the requirements of processing slurry under different construction condition. The invention has the advantages of strong adaptability for strata, high precision of solid phase separation, low mud weight ratio for processed clean mud and low sand content rate.

Owner:三川德青工程机械有限公司

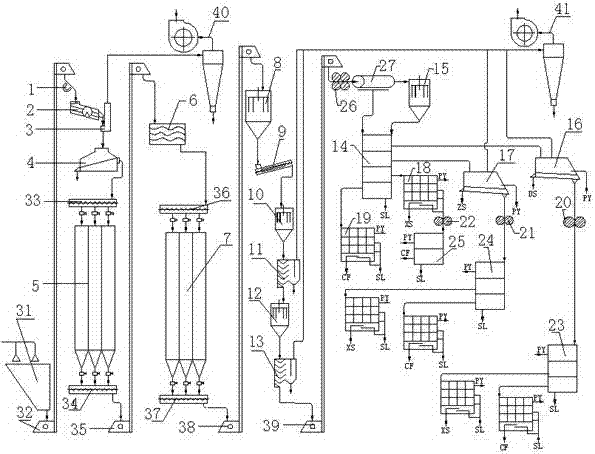

Dry method processing process and device for corn

InactiveCN102500446ASolve the problem of difficult germinationEasy to separateGrain treatmentsFood scienceBiotechnologyBLENDER/MIXER

The invention relates to a dry method processing process for corn, which is mainly composed of processes of clearing, hardening and tempering, peeling, degerming, hominy chop breaking, embryo choosing and hominy chop extraction. The peeling process is sequentially composed of primary stirring peeling, water addition and secondary stirring peeling. The water addition process comprises adding water with the weight to be 0.5-5% of the weight of the corn to the corn by utilizing a water addition machine and enabling the water temperature to be 10-60 DEG C. After water addition, the corn is sent to the stirring peeling process within 10min to be processed, the height of the corn is controlled within 0.5-3m during the stirring peeling process, a blender is adopted during stirring, and the speed of a stirring rod line of the blender is controlled to be at 1-6m / S. The dry method processing process for the corn can remarkably improve yield rates of hominy chop with fat content below 1%, corn starch and embryos with purity to be over 80%, particularly embryo extracting rate and purity of the extracted embryos, and is remarkable in economic and social benefits.

Owner:王洪福

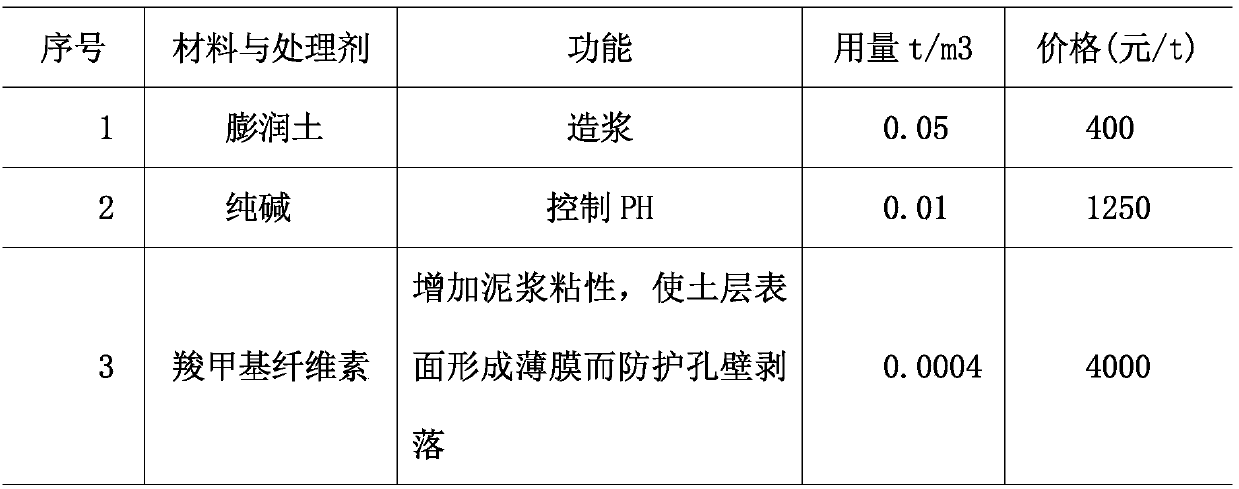

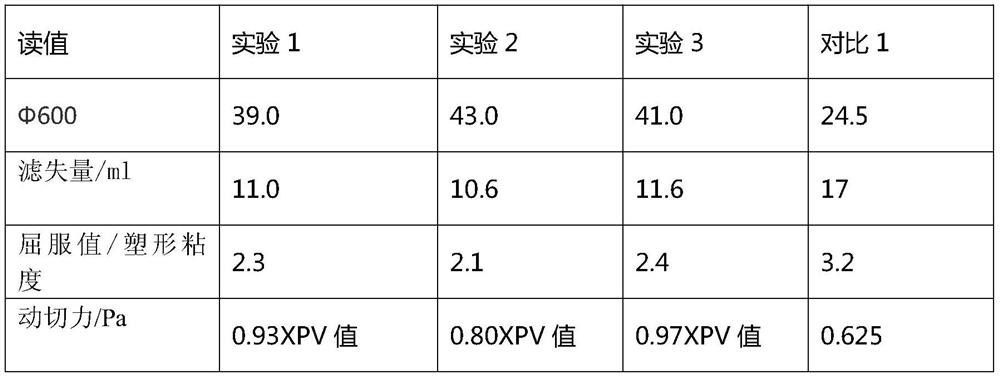

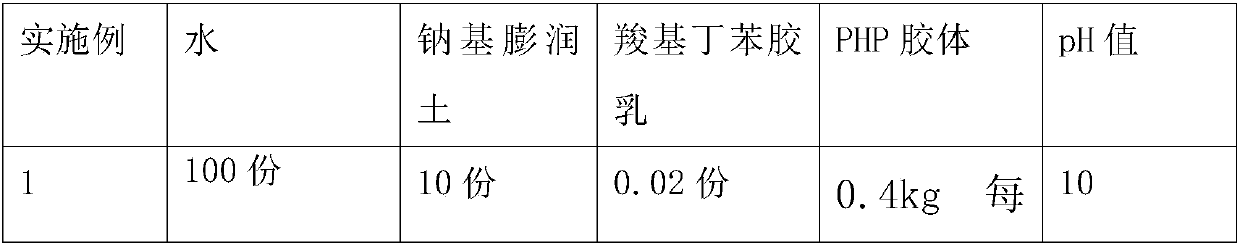

PHP mud manufacturing method and applications of PHP mud

InactiveCN105236832APrevent sinkingReduce resistanceFlushingBulkheads/pilesMaterials preparationSodium Bentonite

The invention discloses a PHP mud manufacturing method and applications of PHP mud, and belongs to the reconstruction technology field of cast-in-situ bored pile manufacturing method and applications thereof. According to the PHP mud manufacturing method, bentonite, sodium carbonate, hydroxymethyl cellulose, and polyacrylamide are taken as main raw materials, barite powder is taken as an additive. The PHP mud manufacturing method comprises following steps: a, material preparation; b, stirring of a base slurry; c, material adjusting; and d, additive adding. The invention also discloses applications of PHP mud, and PHP mud can be applied to construction of cast-in-situ bored piles. Beneficial effects are that: thixotropy is excellent; specific gravity is low, and solid phase content is low; viscosity is high; mud cover is thin; water loss is low; dispersion is not caused; and environmental protection performance is excellent.

Owner:JSTI GRP CO LTD

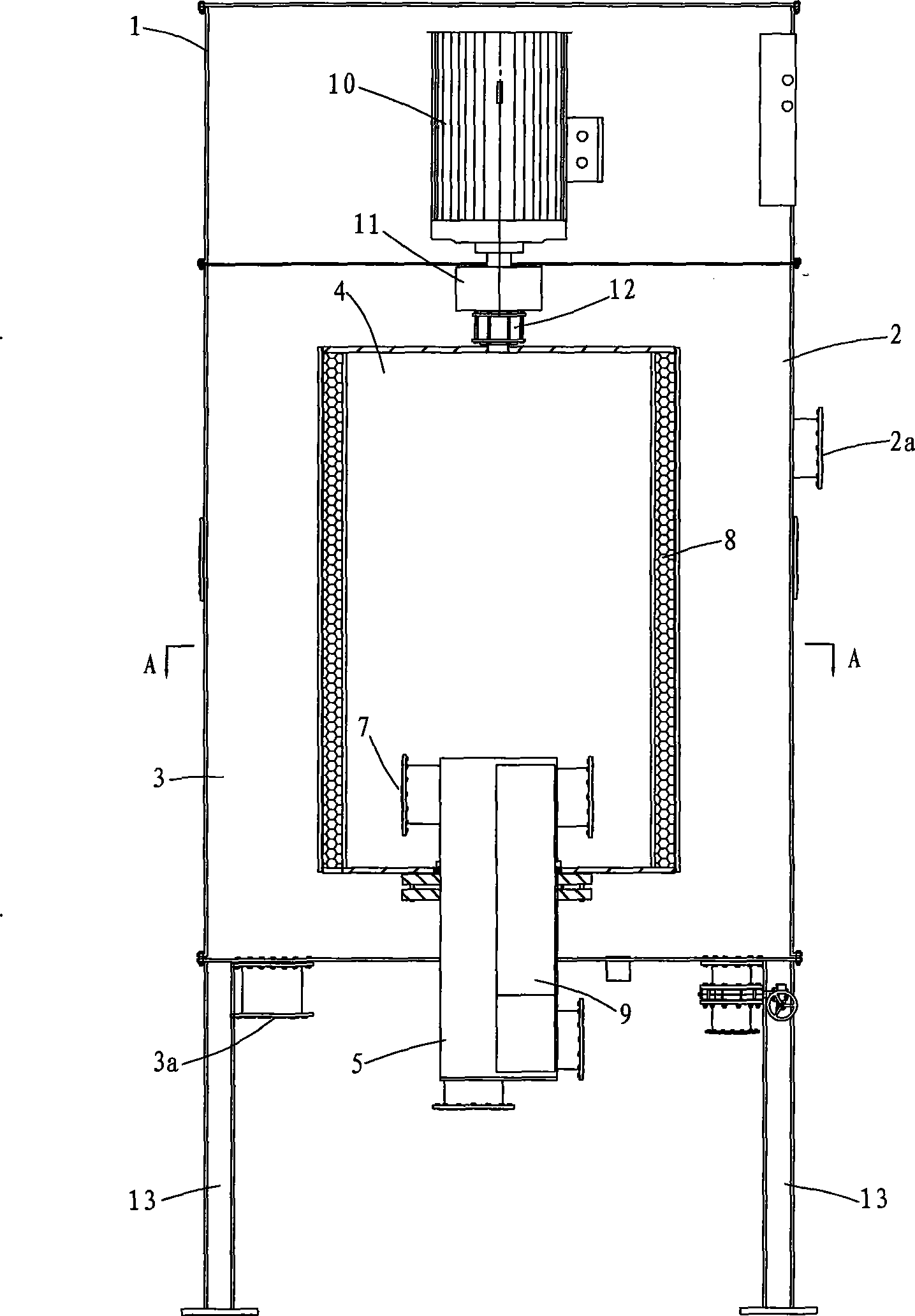

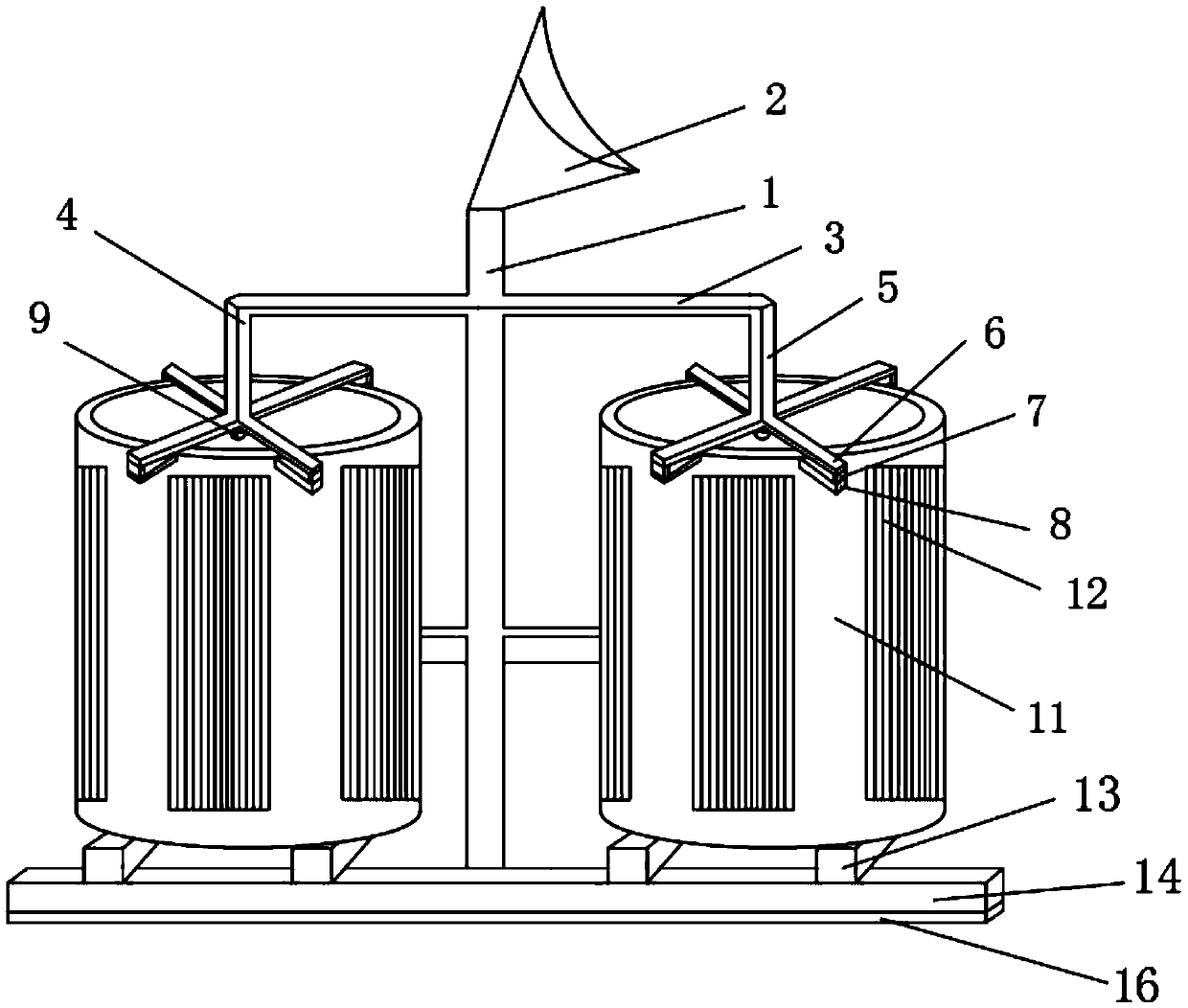

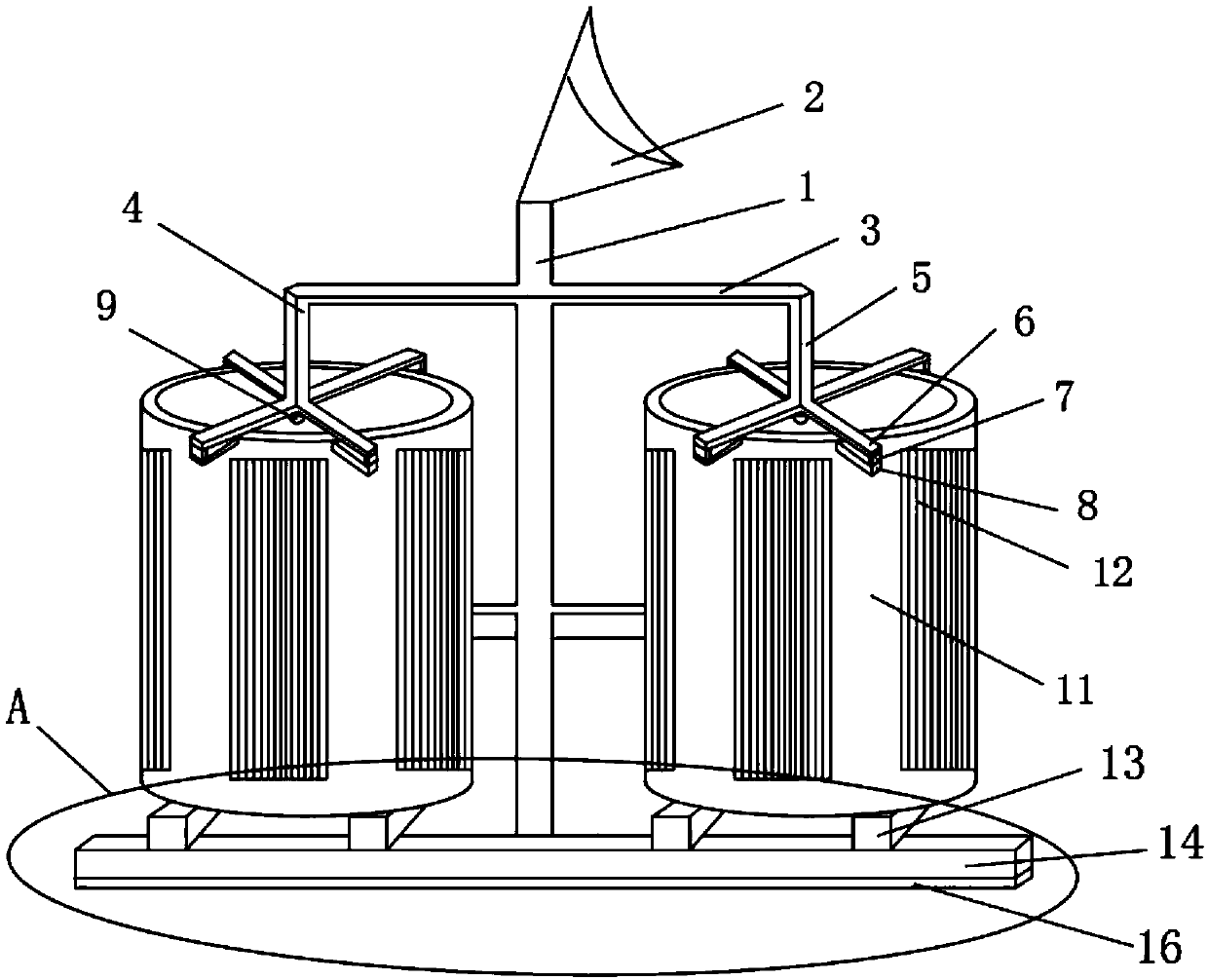

Water filter special for water source heat pump system

ActiveCN101485944AMeet the needs of useFiltering continuesMoving filtering element filtersFiltrationWater source

The invention discloses a water purifier special for a water resource heat pump system. A driving device is arranged at the top of a barrel body (1), the bottom of the barrel body (1) is supported by a stander (10), the barrel body (1) is provided with a rotational cartridge filter (4), and washing and filtering are performed simultaneously through a filtration piloting device and a washing device of the rotational cartridge filter (4). The device is searched and developed for the water resource heat pump system, and is mainly used for the water resource heat pump system to filter silt, floater, particles, and the like in river, lake, sewage, and other water quality. The filter surface of the water purifier rotates, and part of the filter surface is positioned in the back washing area at any time with constant filter function. The sand-carrying capacity after filtration of the device is less than one in 200,000, and the use of a water resource heat pump assembly is satisfied. The water purifier back washed by used purified water is not blocked and scaled. The water purifier has small occupied area and does not need a person to specially manage.

Owner:零碳未来(重庆)能源发展有限公司

Compound fertilizer for improving coastal sandy saline and alkaline land and preparation method thereof

InactiveCN107973640AGood moisture absorptionImprove dehumidification effectCalcareous fertilisersMagnesium fertilisersLand improvementMicroorganism

The invention discloses compound fertilizer for improving a coastal sandy saline and alkaline land and a preparation method thereof. The compound fertilizer for improving the coastal sandy saline andalkaline land is prepared from attapulgite clay, desulphurization gypsum, organic fertilizer, fulvic acid, citric acid, a sandy soil binding agent, a compound water retaining agent, a saline and alkaline land improvement agent, expanded vermiculite and microorganism powder at the weight ratio of (24 to 30) to (8 to 12) to (20 to 22) to (12 to 16) to (6 to 8) to (5 to 7) to (5 to 7) to (4 to 6) to(2 to 4) to (0.5 to 1.5). The compound fertilizer for improving the coastal sandy saline and alkaline land can be used for effectively improving a soil structure of the sandy saline and alkaline land,reducing the saline and alkaline degree, reducing the sand content in soil, improving the content of nutrient components in the soil and improving the compacting degree of the soil; the compound fertilizer is matched with plant cultivation and the sandy saline and alkaline land can be continuously and effectively improved.

Owner:WEIFANG YOURONG IND

Application method of composite sodium-based bentonite on construction of underground continuous wall

The invention provides an application method of composite sodium-based bentonite on construction of an underground continuous wall, which takes the composite sodium-based bentonite as a material for preparing a wall-protection slurry and comprises the following process steps of: (1) preparing the wall-protection slurry by using the composite sodium-based bentonite, calcined soda and water and sufficiently mixing and storing the wall-protection slurry for standby; (2) during the trough-forming process of the underground continuous wall, filling the wall-protection slurry to be used into the trough section so as to carry out wall protection by slurry; (3) cleaning the hole after forming the trough; (4) repeatedly separating, purifying and detecting the slurry pumped out of the trough bottom during the cleaning-hole process; and (5) adjusting the qualified sands after separating the sand; subsequently repeatedly using the slurry; and abandoning the recycled slurry exceeding the index range. The wall-protection slurry prepared by the method has excellent wall-protection performance, slag-carrying capability and anti-pollution capability, can overcome the quality problems of the underground continuous wall such as collapse, settlement, exposed reinforcement, water leakage, and the like, thereby being suitable for all enclosure structures of the underground continuous walls, particularly the ultra-deep underground wall engineering with thicker sandy silts.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

Compound fertilizer for improving sandy saline-alkali soil and preparation method thereof

InactiveCN108129227AGood physical propertiesEnhance water and soil retention capacityCalcareous fertilisersExcrement fertilisersAlkali soilSludge

The invention discloses a compound fertilizer for improving sandy saline-alkali soil and a preparation method thereof. The compound fertilizer for improving sandy saline-alkali soil is prepared from the following components of desulfurized gypsum, fly ash, sludge of sewage plant, peat, organic fertilizer, sand adhesive, a composite water retention agent, an improvement agent of the saline-alkali soil, and a microorganism powder according to a weight ratio of (22 to 30):(8 to 12):(14 to 16):(12 to 16):(18 to 22):(6 to 8):(3 to 5):(2 to 4):(0.5 to 1.5). The compound fertilizer for improving thesandy saline-alkali soil has the advantages that the soil structure of the sandy saline-alkali soil can be effectively improved, the saline-alkali degree is reduced, the content of sand in soil is reduced, the content of nutritional components in soil is increased, and the soil density is increased; the compound fertilizer is matched with plant cultivation, so as to lastingly and effectively improve the sandy saline-alkali soil.

Owner:WEIFANG YOURONG IND

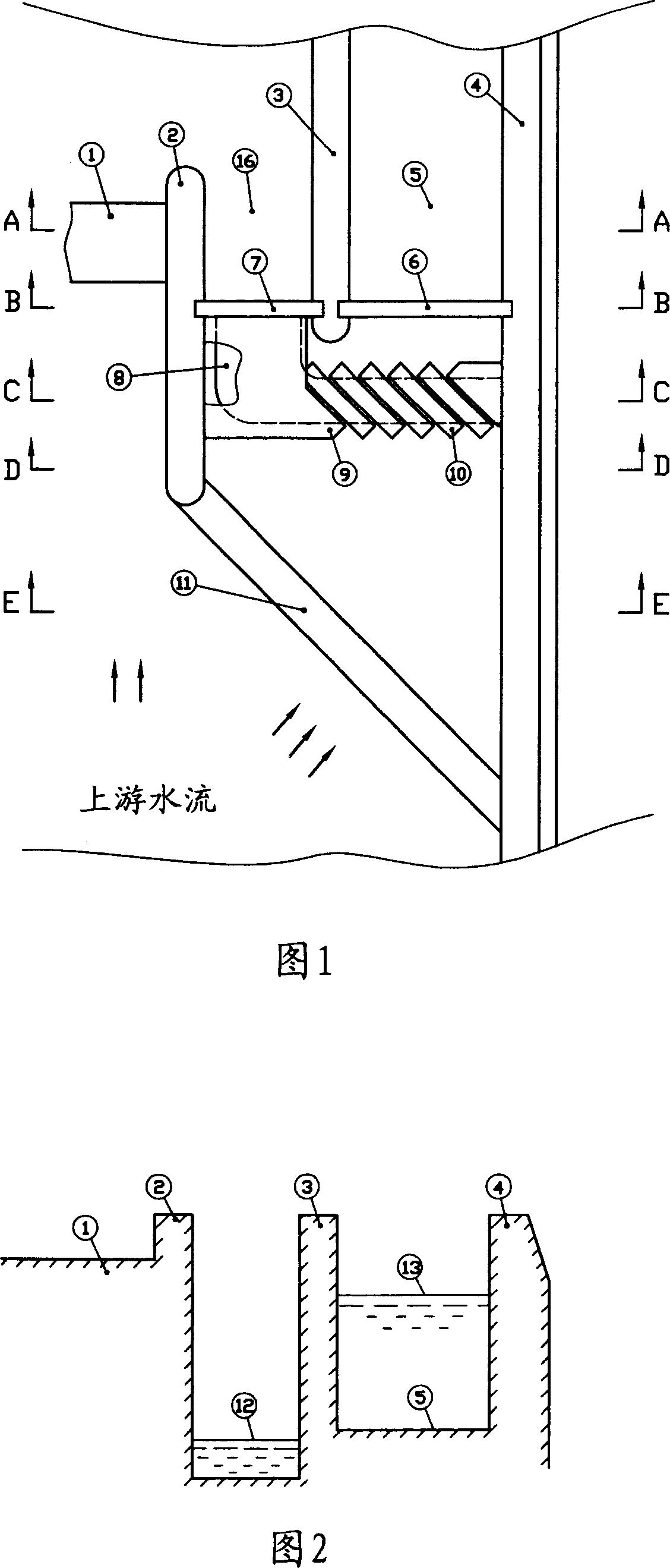

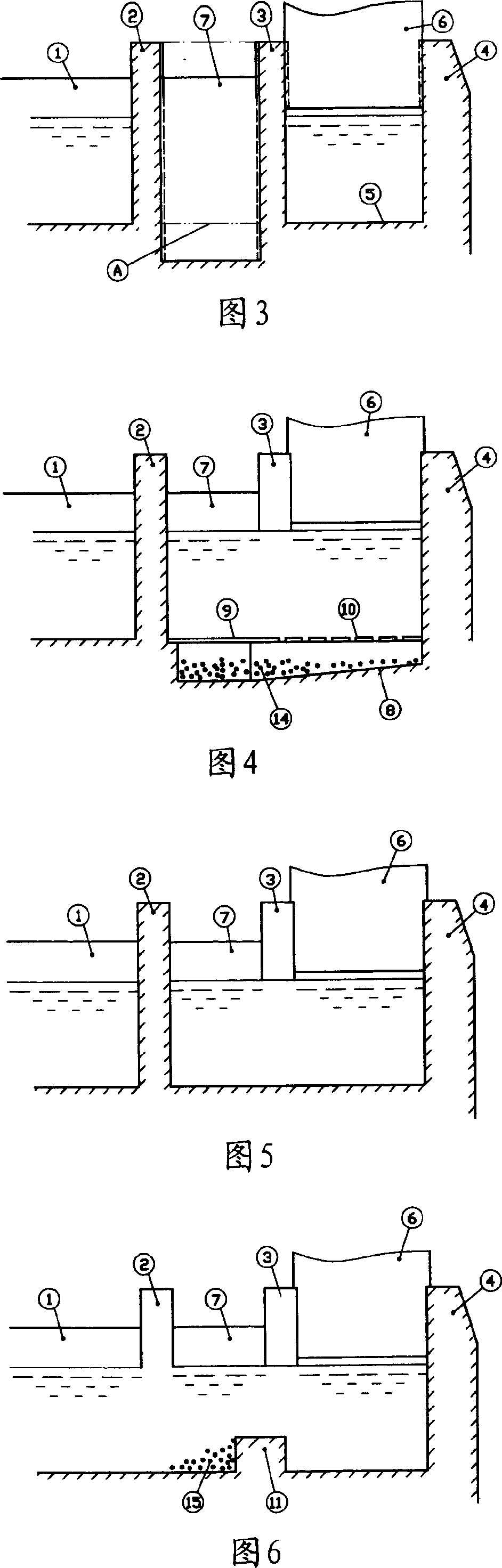

Sand-drainage construction system for diversion channel

ActiveCN1952269AReduce sand contentExtend your lifeBarrages/weirsWater-power plantsWater storageWater channel

The invention discloses a structural system for excluding sand in diversion canal of hydraulic station, comprising waste water storage dam of draining line, diversion bank, guide bank, right bank, conduit, diversion gate, sand flushing channel, sand flushing gate, waste sand storage weir of draining line, sand slot, cover of sand flushing and cover of sand guiding. Riverway is divided into draining line, sand flushing channel and conduit by diversion and guide banks. There is L-shape sand slot on the one side of the upper of sand guiding and flushing channels, of which one end is started from right bank and parallel to the direction of diversion gate, and the bottom is inclined to deepen from starting end of right bank to left end. Cover of sand guiding is fixed on the sand slot parallel with diversion gate in certain distance. The left end of sand slot ends to the position of diversion bank and gate of sand flushing and is shaped L, of which the bottom is inclined to deepen to gate of sand flushing. Cover of sand flushing is set on the sand slot to gate of sand flushing. The system can exclude sand thoroughly and automatically.

Owner:四川希望深蓝能源化工有限公司

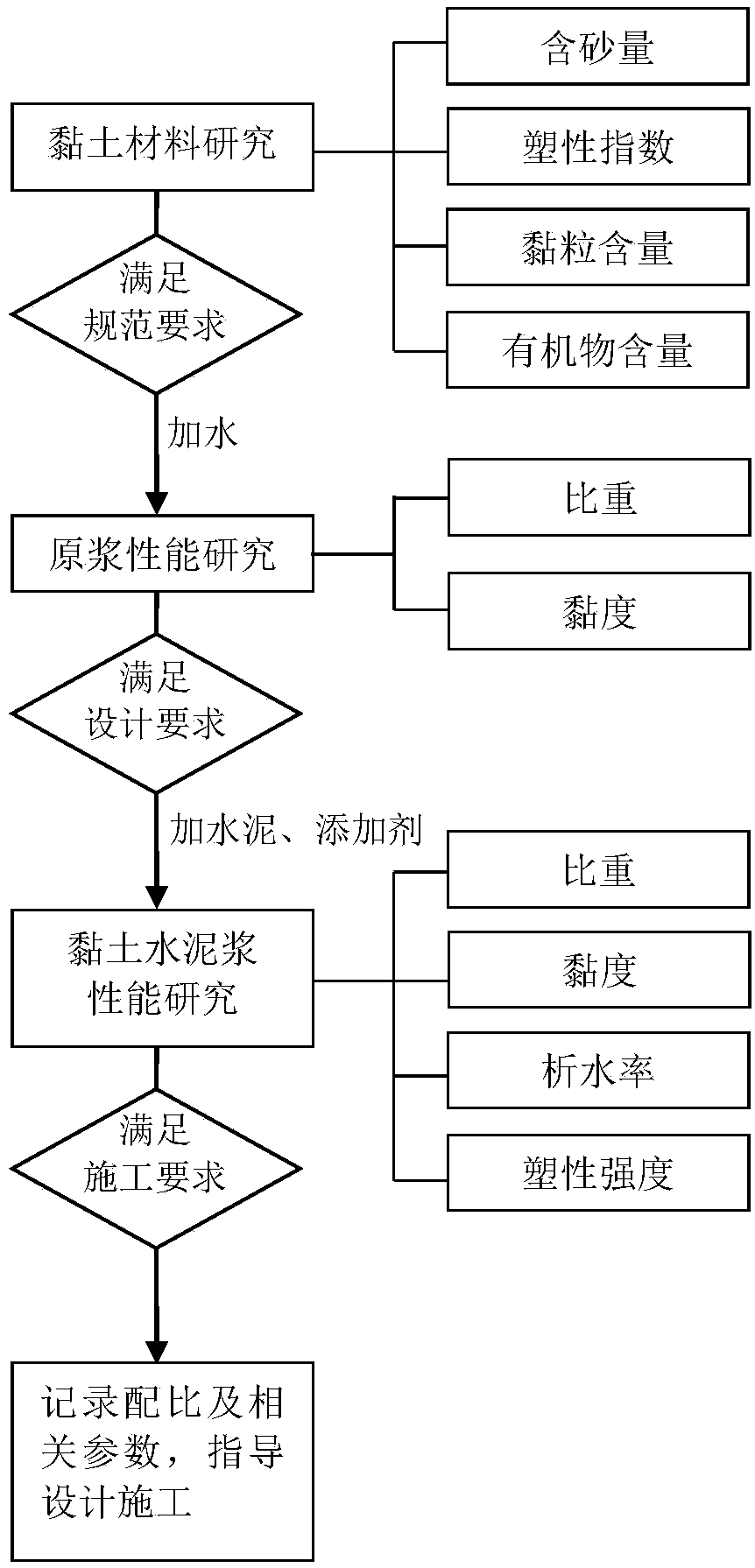

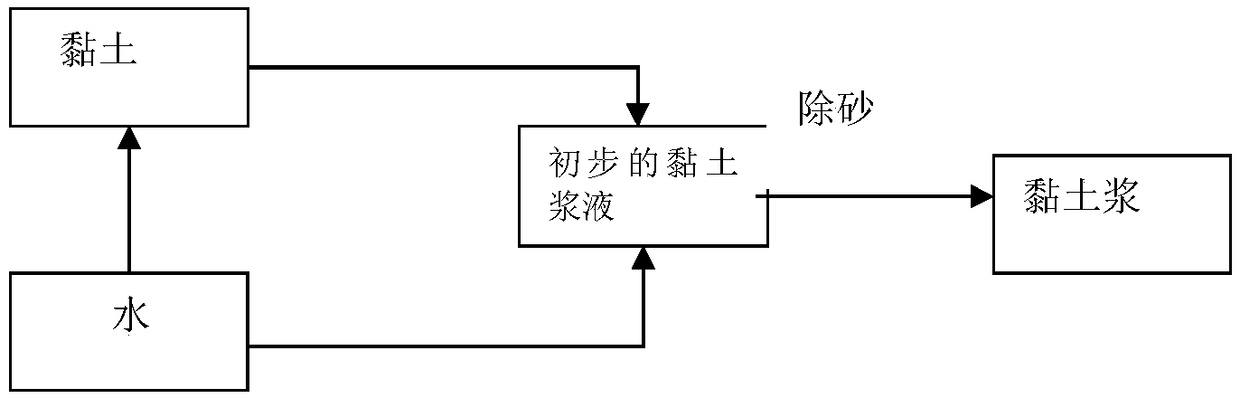

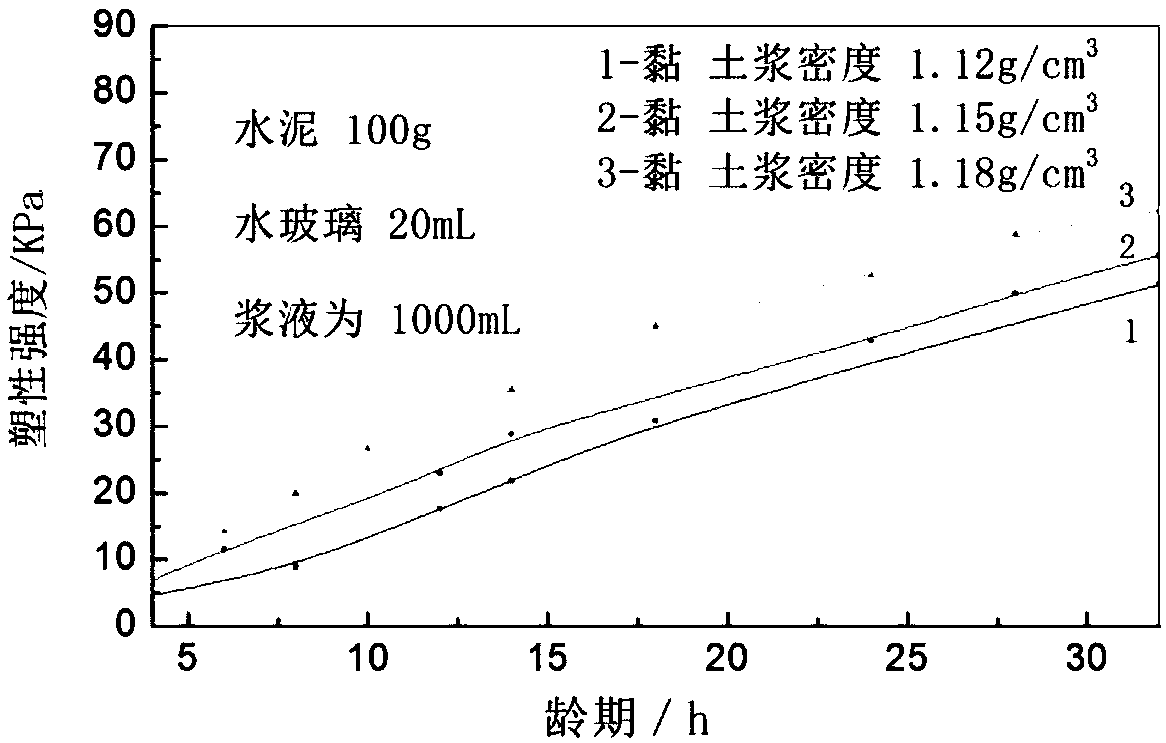

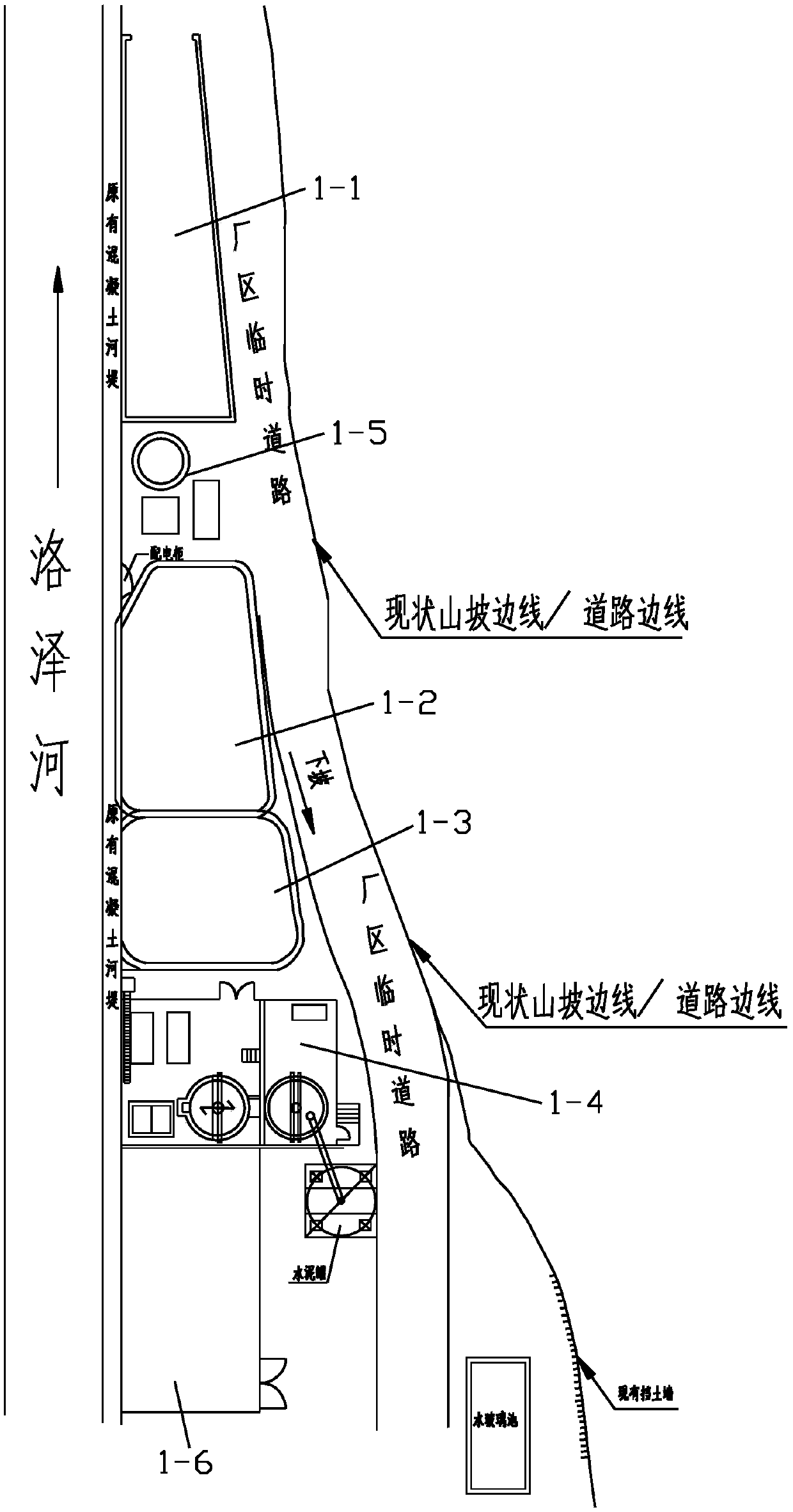

Environment-friendly grouting material based on red soil in Wumeng Mountain area

The invention discloses an environment-friendly grouting material based on red soil in a Wumeng Mountain area. The environment-friendly grouting material based on the red soil in the Wumeng Mountain area is CL-C type clay cement paste, and the CL-C type clay cement paste is composed of clay paste, cement and additives. The environment-friendly grouting material based on the red soil in the WumengMountain area is good in past stability, the paste is not separated or precipitated in pumping and diffusion processes, and in a solidification process, the water bleeding is little, the concretion rate is high, and the anti-permeability performance is good. Clay particles in the clay paste are fine, are low in sand content, and have a high dispersion degree, so that the environment-friendly grouting material based on the red soil in the Wumeng Mountain area is good in fluidity and easily permeates into fine cracks of rock stratums. In a Maoping lead-zinc ore 112-line vertical shaft pre-grouting water-plugging engineering of the Yiliang Chihong mining limited company, 15189.132 m<3> of clay cement paste prepared from the environment-friendly grouting material provided by the invention is injected, and the residual water burst amount of the well shaft after grouting is about 4.83 m<3> / h and meets the qualified standard of a construction contract.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

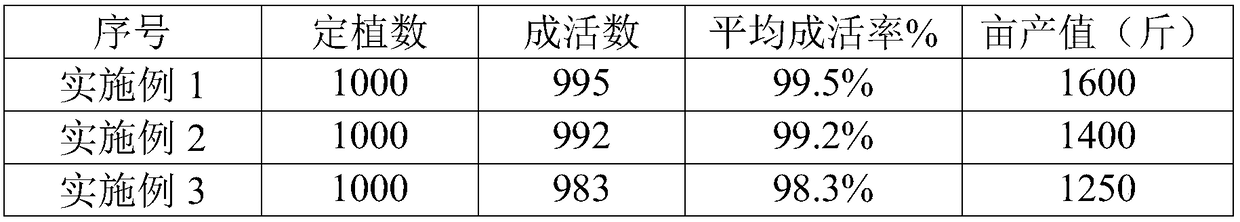

Comprehensive treatment method for planting peanuts on saline-alkali land

InactiveCN109168400ASimple structureReduce sand contentFabaceae cultivationAmmonium salt fertilisersBacillus licheniformisAlkali soil

The invention relates to the crop soil comprehensive treatment field and particularly relates to a comprehensive treatment method for planting peanuts on the saline-alkali land. The treatment fertilizer and the biological bacterial fertilizer substrate are mixed according to 3-5:1 to form a treatment agent, and the treatment agent is then mixed into the soil; the input amount of the treatment agent is 50 kg / ha. soil; the treatment fertilizer for treatment includes 10-20 parts of ammonium ferrous sulfate, 10-20 parts of potassium sulphate, 40-50 parts of ferrous sulfate and 30-40 parts of cornstalk biochar, the biological bacterial fertilizer includes bacillus subtilis, bacillus licheniformis, peanut rhizobium, bacillus megatherium, bacillus mucilaginosus, bacillus azotobacter, lactobacillus plantarum, and the like. The treatment method is advantaged in that the idea is novel, the saline-alkali land is improved, the peanuts can be grown, the yield per mu can not only reach the output value of the fertile soil, but also the yield can be increased by 60-75%.

Owner:BAICHENG NORMAL COLLEGE

Sandy alkaline-saline soil improving fertilizer prepared with thermal power plant wastes and preparation method thereof

InactiveCN107915522AImprove soil physical propertiesEnhance water and soil retention capacityCalcareous fertilisersAlkali orthophosphate fertiliserFertilizerUrea

The invention discloses a sandy alkaline-saline soil improving fertilizer prepared with thermal power plant wastes and a preparation method thereof, wherein the improving fertilizer is made with desulfurization gypsum, flyash, urban domestic waste sludge, fulvic acid, plant straw particles, sodium lignin sulfonate, urea resin, an inorganic fertilizer and microbial powder according to the weight ratio of (20-30):(10-14):(11-15):(18-22):(16-20):(4-6):(3-5):(3-5):(0.5-1.5). The improving fertilizer herein is effective in improving soil structure of sandy alkaline-saline soil, lowering alkalinityand salinity, reducing sand content of the soil, increasing nutrient content of the soil and improving soil compactness and can be applied with plant cultivation to constantly and effectively improvethe sandy alkaline-saline soil.

Owner:WEIFANG YOURONG IND

Mixture fertilizer for improving sandy saline-alkali soil and preparation method of the fertilizer

InactiveCN107963944AGood physical propertiesEnhance water and soil retention capacityCalcareous fertilisersMagnesium fertilisersAlkali soilPlant cultivation

The invention discloses a mixture fertilizer for improving sandy saline-alkali soil and a preparation method of the fertilizer. The fertilizer includes desulfurization gypsum, fly ash, organic fertilizer, fulvic acid, clay, sand binder, a composite water retaining agent, a saline-alkali soil improver, expanded vermiculite, and a microbial powder agent according to weight ratio of 22-30:8-12:18-22:12-16:6-10:6-8:4-8:4-6:2-4:0.5-1.5. The mixture fertilizer can effectively improve the soil structure of the sandy saline-alkali soil, reduces saline alkali degree and content of sand in the soil, andcan improve content of nutrients in soil and increase compactness of the soil. With combination of plant cultivation, the mixture fertilizer can durably and effectively improve the sandy saline-alkali soil.

Owner:WEIFANG YOURONG IND

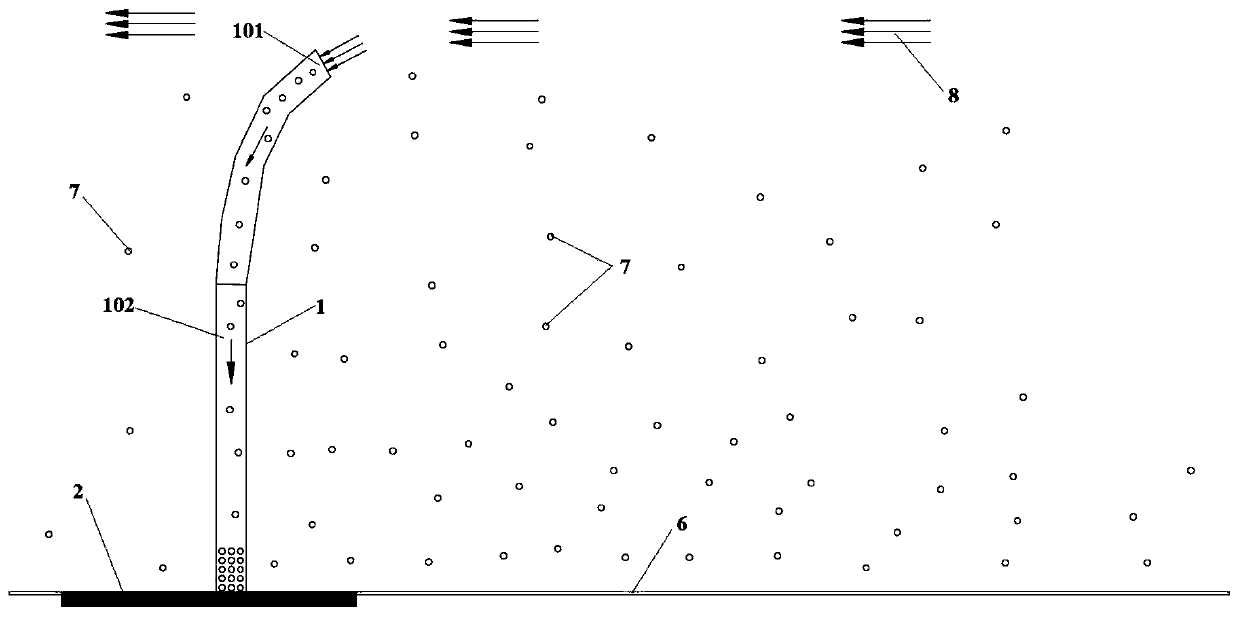

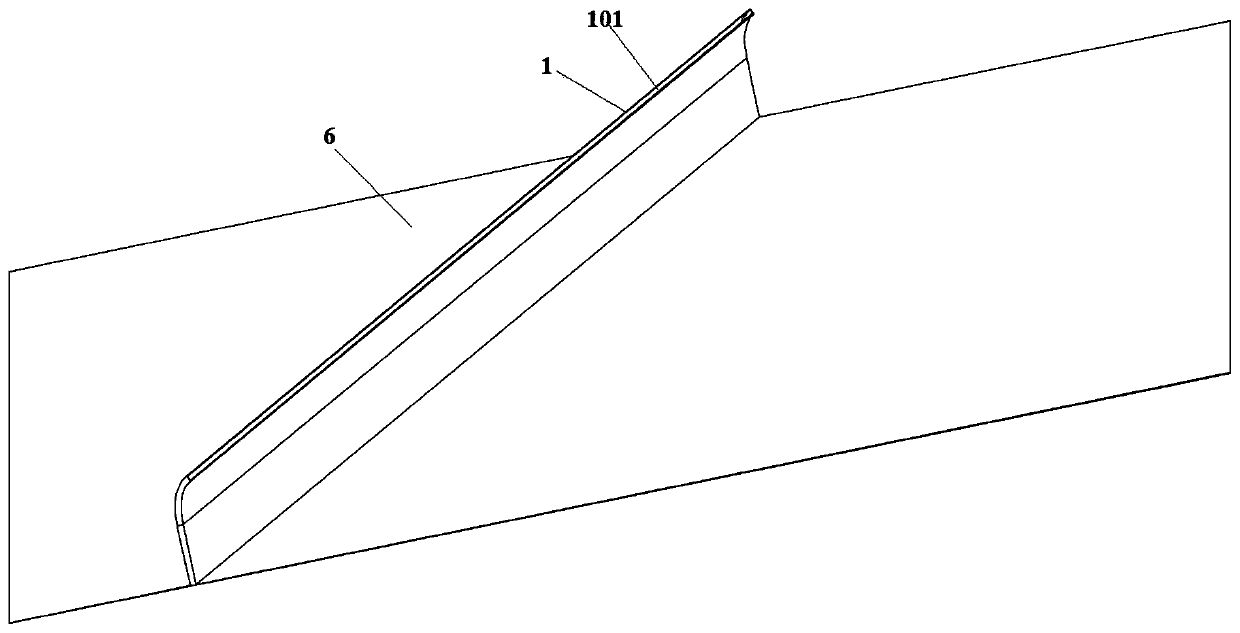

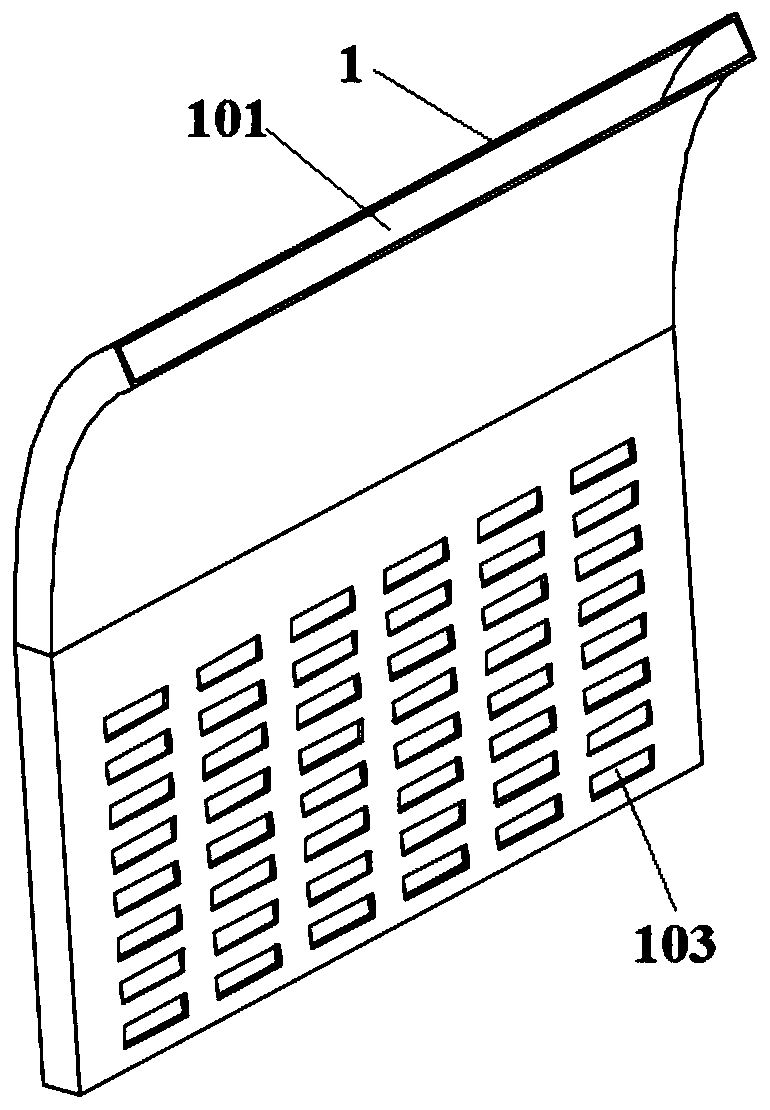

Windproof sand-reducing wall for environment protection

InactiveCN110847067AReduce sand contentImprove the living environmentProtective constructionStructural engineeringMechanical engineering

The invention discloses a windproof sand-reducing wall for environment protection, and relates to the technical field of wind-sand-resistant walls. The windproof sand-reducing wall for environment protection comprises a wind-resistant sand-reducing wall, wherein a cavity for reducing sand is arranged in the wind-resistant sand-reducing wall; a wall base fixing seat for fixing is fixedly arranged on the bottom part of the wind-resistant sand-reducing wall; air inlet holes are uniformly arrayed on the surface of the inner side of the wind-resistant sand-reducing wall; curved plates for reducingsand are fixed to the surfaces of the inner sides of the air inlet holes; a sand reducing device for collecting sand and discharging air is in through connection to the bottom part of the wind-resistant sand-reducing wall, and is of a circular pipe structure; a rectangular groove is formed in the bottom part of the sand reducing device; arc-shaped sand blocking plates are arranged on the inner surface of the sand reducing device; and an air outlet is formed at the position, located above the part between the two arc-shaped sand blocking plates, on the inner surface of the sand reducing device.According to the windproof sand-reducing wall for environment protection provided by the invention, through the functions of the wind-resistant sand-reducing wall, the sand reducing device and an airpurification device, the wind sand content on the other side of the wind-resistant sand-reducing wall is greatly reduced, the living environment is improved to a certain extent, and the problems suchas the destructive power and the intrusiveness of wind sand are retarded.

Owner:界首市利能环保技术开发有限公司

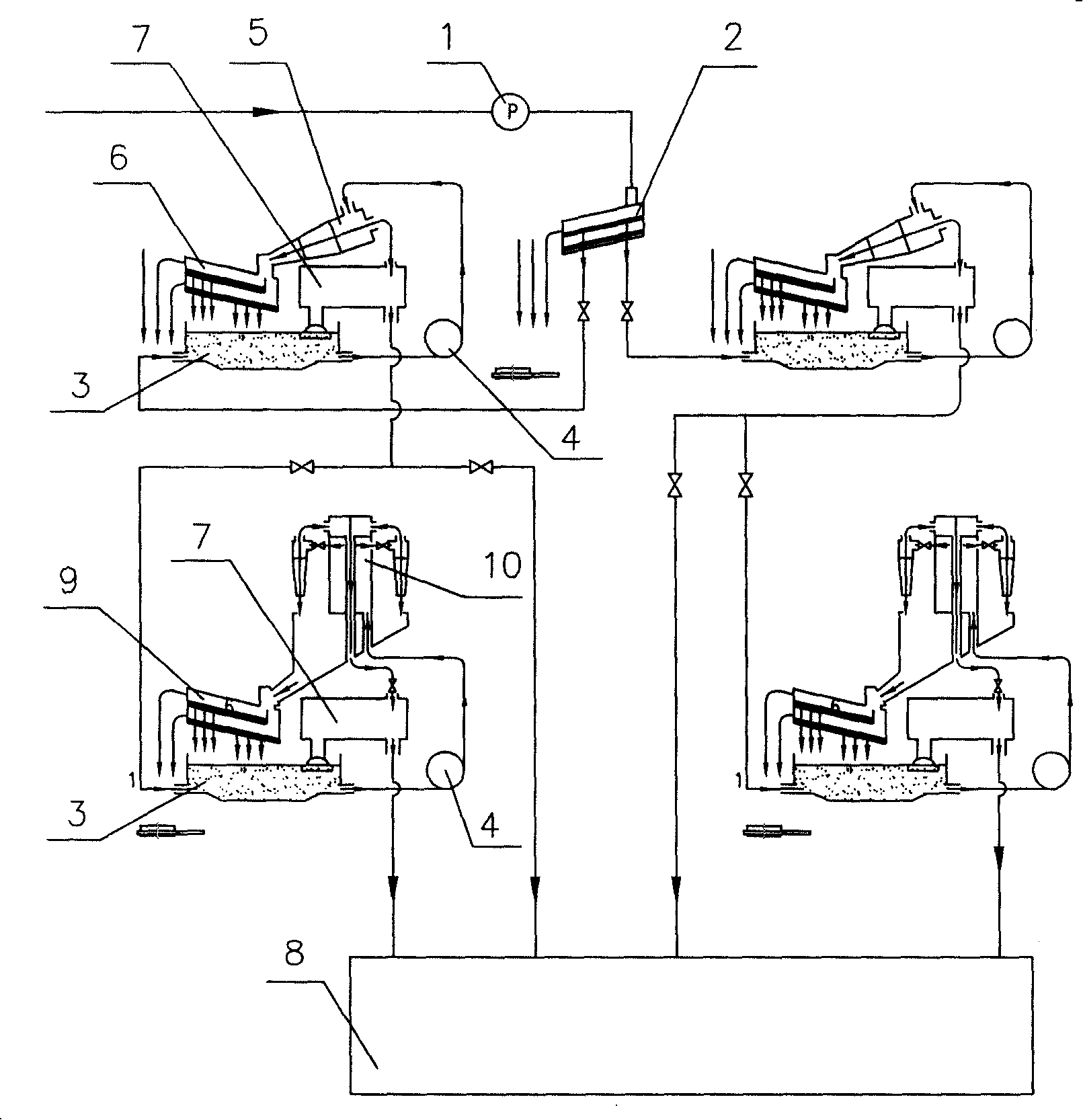

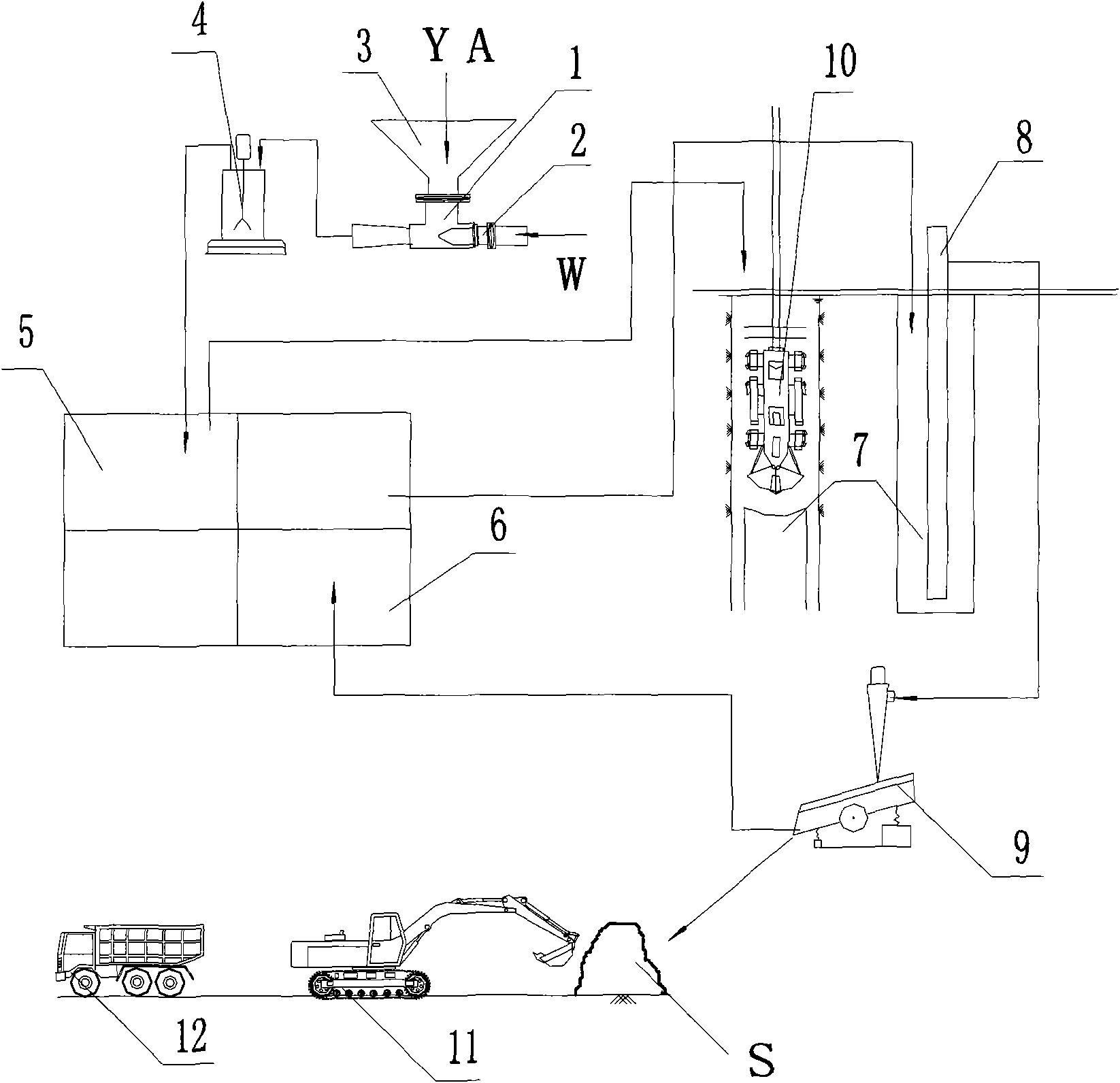

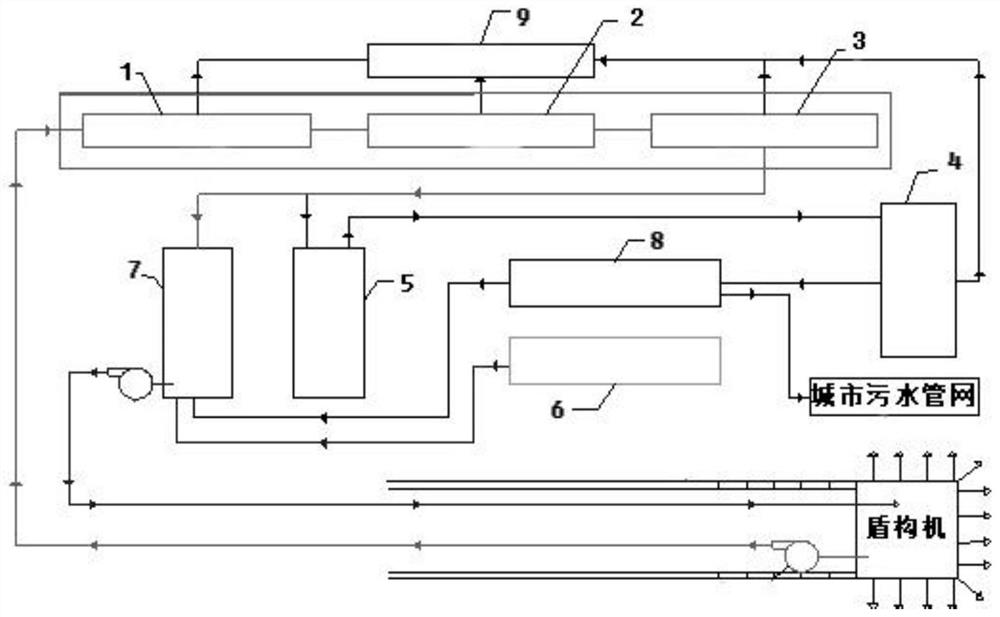

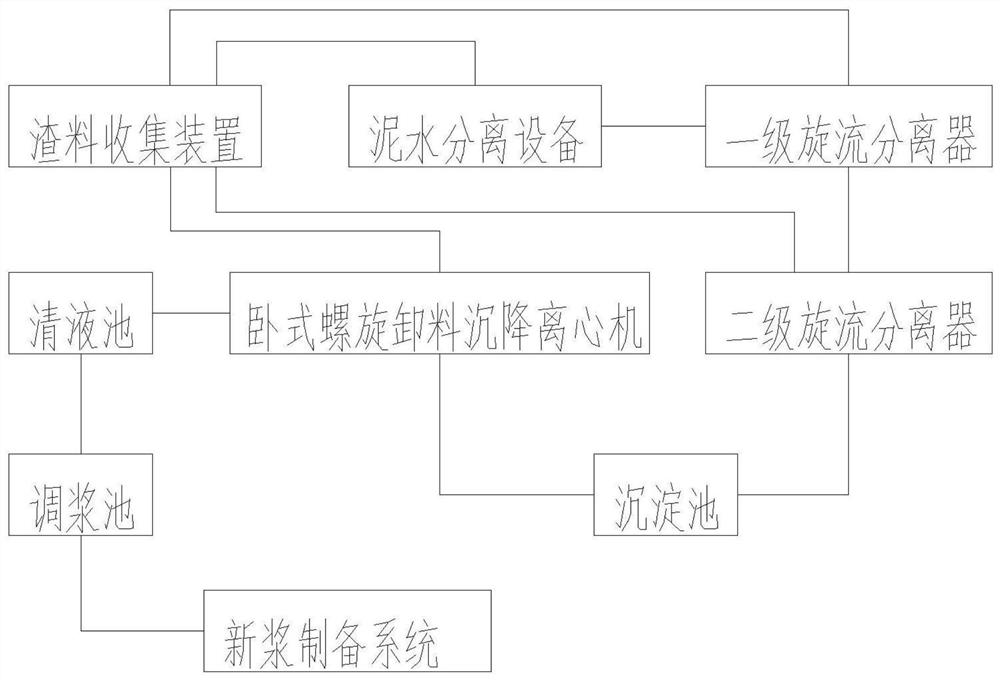

Waste slurry circulating method and system for shield in weathered argillaceous siltstone stratum tunneling

PendingCN111606431AHigh precision of solid phase separationLight weightWaste water treatment from quariesWater/sewage treatment by centrifugal separationSlurryShield tunneling

The invention discloses a waste slurry circulation method and system for shield in weathered argillaceous siltstone stratum tunneling. The method comprises the following steps of: 1, primary selectionof waste slurry: discharging the waste slurry to slurry-water separation equipment through a slurry discharging pump station and by means of the slurry discharging pipeline of a shield tunneling machine so as to subject the waste slurry to separation treatment; step 2, separation and dehydration by a primary cyclone separator; step 3, separation and dehydration by a secondary cyclone separator; step 4, dewatering by a horizontal spiral discharging sedimentation centrifuge; and 5, transferring treated usable slurry to a slurry pool of the shield tunneling machine by the horizontal spiral discharging sedimentation centrifuge to reuse the treated usable slurry. The system comprises slurry-water separation equipment, a primary cyclone separator, a secondary cyclone separator, a sedimentationtank, a horizontal spiral discharging sedimentation centrifuge, a clear liquid pool and a size mixing tank. Muck soil and muddy water are effectively separated through muddy water system equipment, separated mud indexes meet shield tunneling slurry indexes again, and therefore the purpose of recycling waste slurry is achieved.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP +1

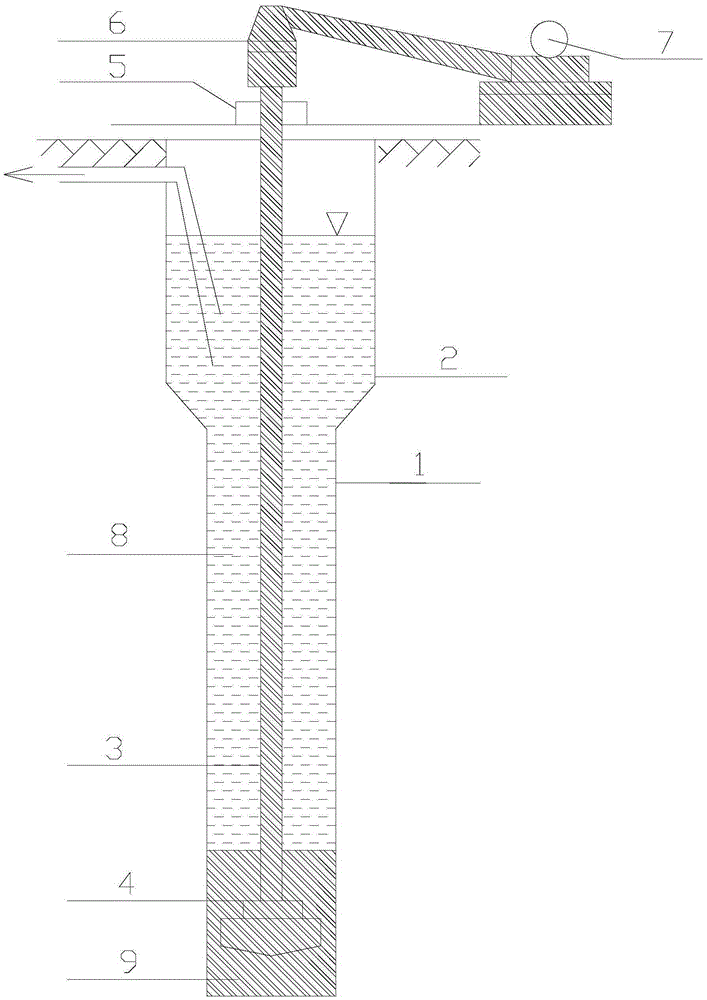

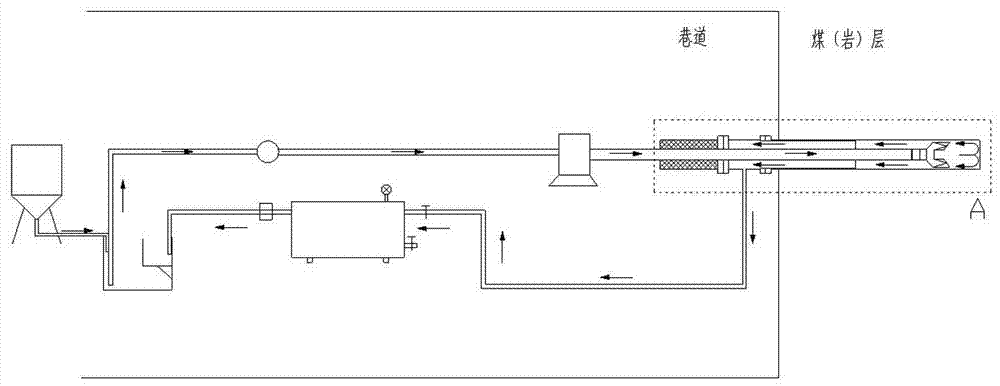

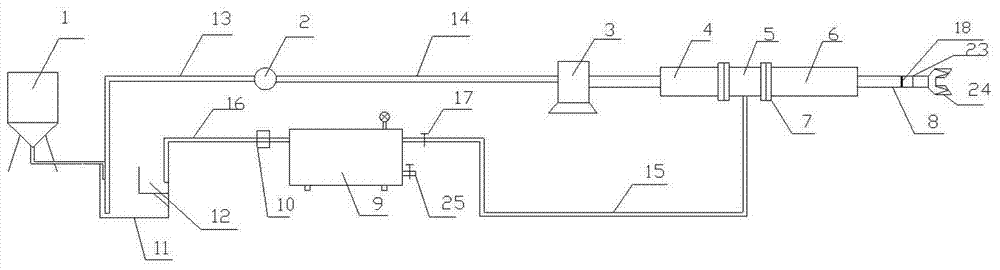

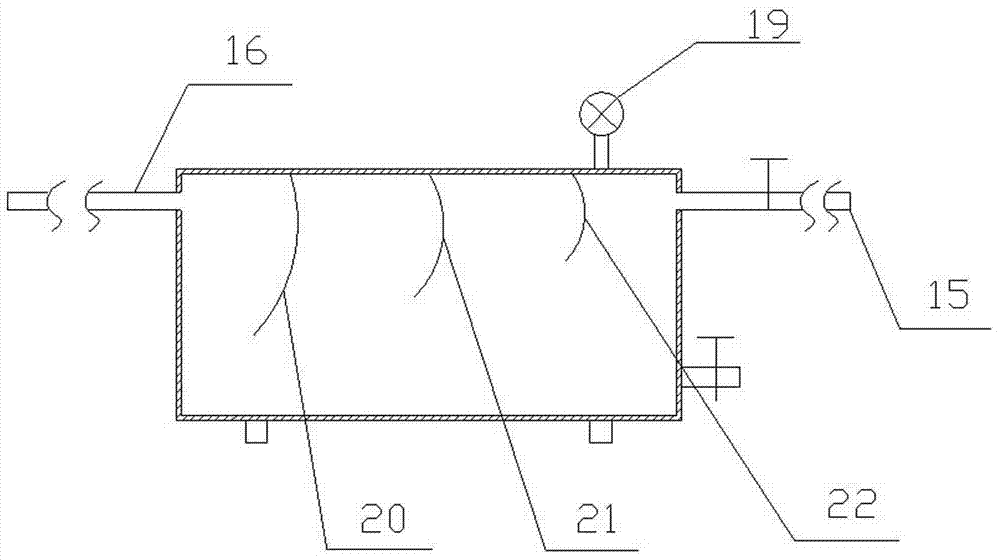

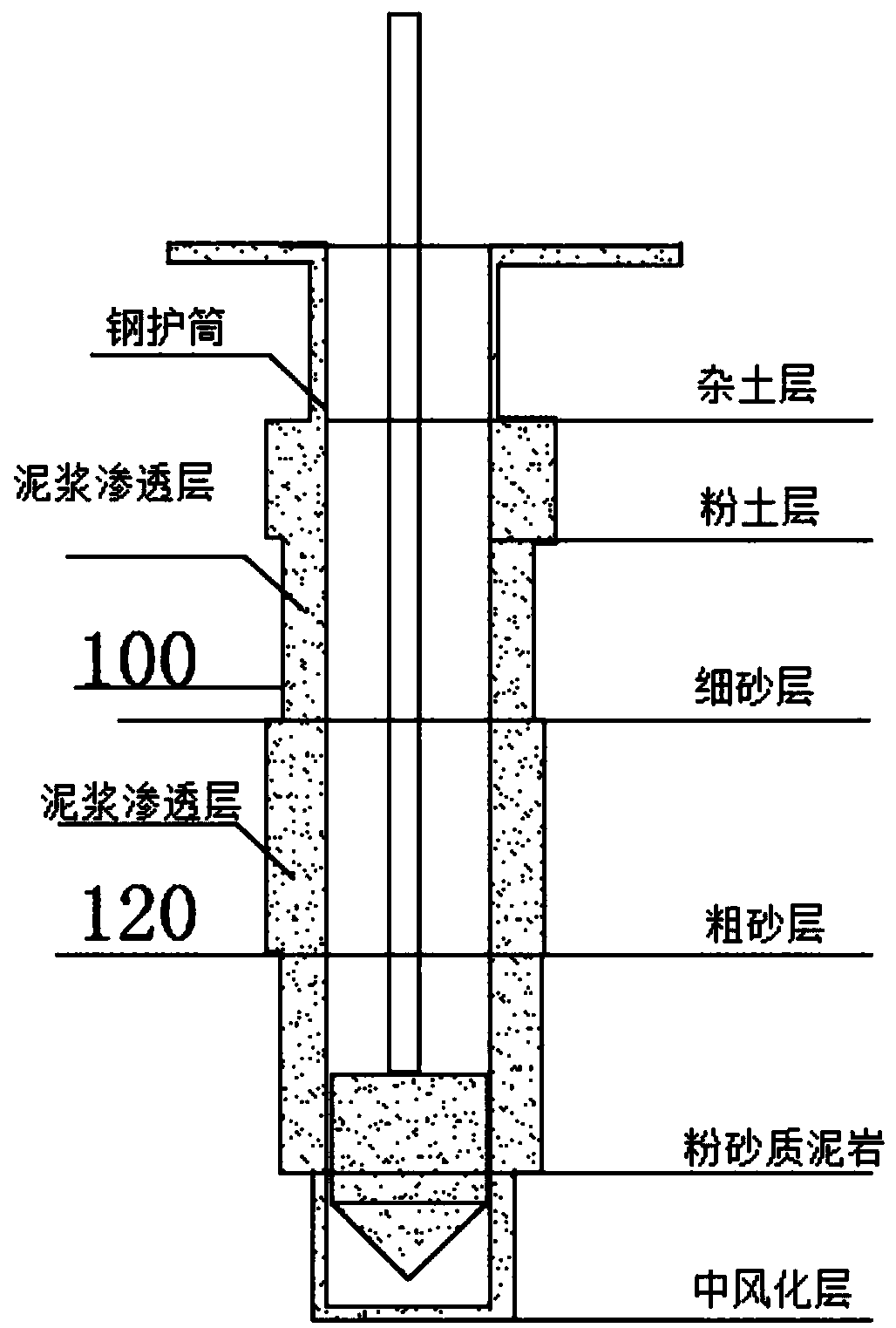

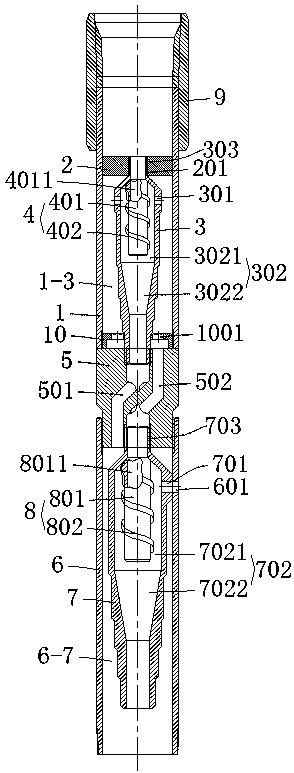

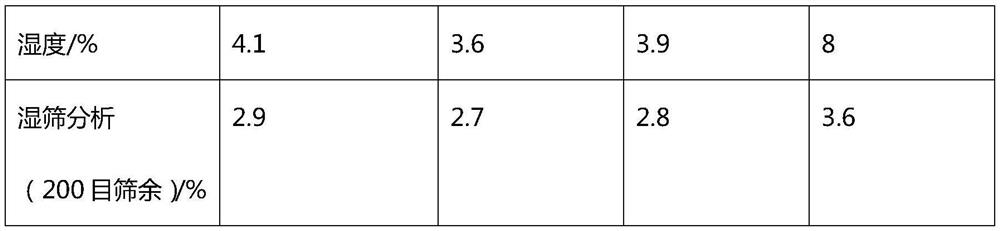

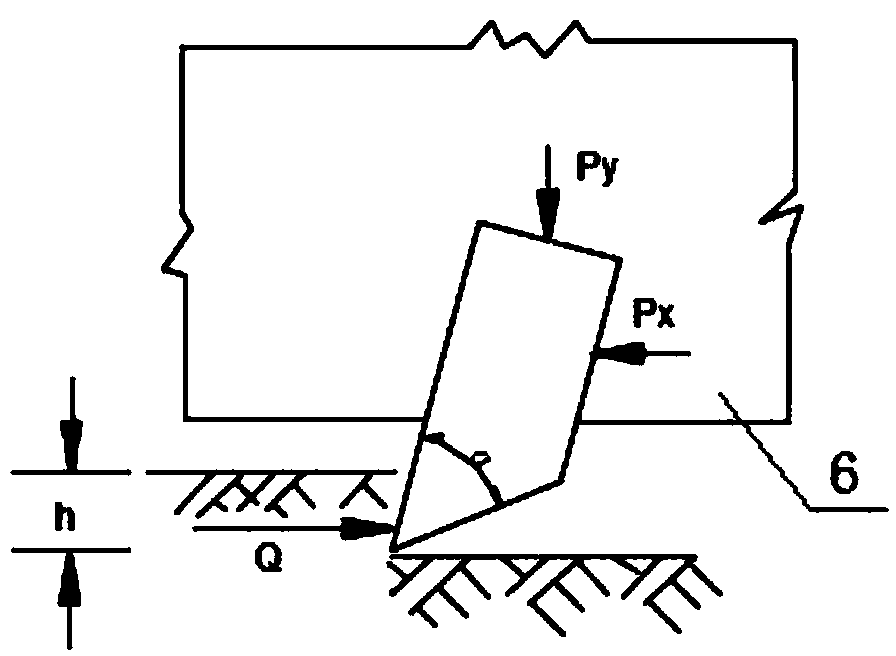

High-pressure slurry wall-protection method and device

ActiveCN107575249AIncrease pressureReduce sand contentUnderground chambersTunnel liningSlurry wallPositive pressure

The invention belongs to the field of mine drilling and relates to a high-pressure slurry wall-protection method and device. In order to solve the technical problems in the prior art, the downhole high-pressure slurry wall-protection method is designed, and the method is conducted based on utilizing the downhole high-pressure slurry wall-protection device. The downhole high-pressure slurry wall-protection comprises a slurry circulation system formed by a slurry making machine, a slurry pump, a drilling machine, a hollow drill rod, a drill rod check valve, a blowout preventer, a three-way joint, a hole opening pipe, a slurry depositing tank, an overflow valve, a steel plate slurry pool, a filter net and the like. Slurry can be supplied circularly through the downhole high-pressure slurry wall-protection device, and thus water is saved. The content of sand in the slurry can be decreased by 98% or above through settlement of the slurry depositing tank. According to the downhole high-pressure slurry wall-protection method, positive pressure can be generated on the hole wall of a drilled hole, and a layer of slurry film is formed on the hole wall, so that hole collapse and hole shrinkage of the drilled hole are prevented, and normal drilling is guaranteed.

Owner:HENAN POLYTECHNIC UNIV

Construction process of underwater churning-driven cast-in-place bored pile by adopting chemical slurry powder to make slurry and protect wall

The invention discloses a construction process for an underwater churning-driven cast-in-place bored pile by adopting a chemical slurry powder to make slurry and protect a wall, comprising the following specific operation steps of: 1, making construction preparation, specifically, fully preparing equipment, tools and objects required by construction, flattening and compacting a construction site,cleaning impurities, removing soft soil, measuring and labeling the center of a pile position, and embedding a pile casing; 2, putting a drilling machine in place, moving the drilling machine to the pile casing, conducting installation and adjusting on the drilling machine, making a drill bit to be aligned with the center of the pile position, integrally checking the drilling machine, and removingfaults in time; and 3, conducting wall protection by slurry, specifically, arranging a slurry pool in a construction site. A double-bottom sand bailing drill is used for bailing slag, and through combination with a pump suction reverse circulation hole-cleaning construction process, the hole cleaning speed is high, hole bottom sediment can be effectively controlled, chemical slurry is prepared according to a proportion determined based on the construction site geology and actual conditions, complex geological conditions in water are considered, the wall protecting capacity of the slurry is improved, the hole forming quality is guaranteed, and the construction progress is accelerated.

Owner:CCCC TIANJIN DREDGING

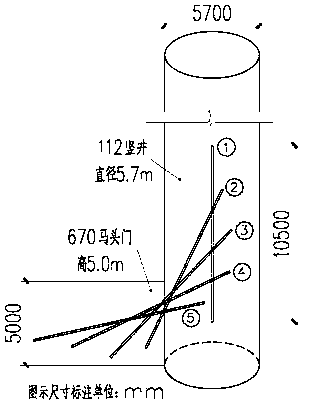

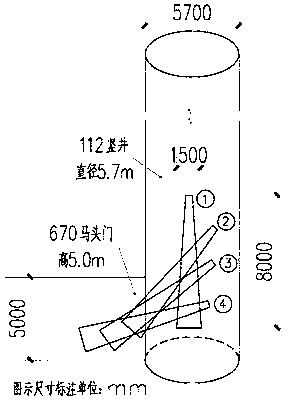

Technical method for controlling water in kilometer-level internal shaft in metal mine

The invention discloses a technical method for controlling water in a kilometer-level internal shaft in a metal mine. The technical method comprises the steps of (A) grouting hole drilling and (B) grouting hole grouting. A feasibility test is carried out on a 112-line internal-shaft shaft pre-grouting project in MaoPing lead zinc mine of the YiLiang ChiHong Mining Limited Company on December 30, 2016, and the feasibility test is completed on September 14, 2017 and lasted 258 days. During the grouting hole drilling grouting construction process, the preparation work of a metal rock internal-inclined-shaft shaft is not delayed by adopting the technical method for controlling the water in the kilometer-level internal shaft in the metal mine, and since a drilling chamber is arranged at the position 14m away from an internal inclined shaft, the preparation work of the metal rock internal-inclined-shaft shaft is not affected, so that the grouting hole drilling grouting construction and the preparation work of the metal rock internal-inclined-shaft shaft are carried out at the same time.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Two-stage cyclone separator

InactiveCN111396024AImprove separation efficiencyReduce sand contentFluid removalMechanical engineeringMechanics

The invention provides a two-stage cyclone separator. The separator comprises an upper outer cylinder, a sealing partition plate, an upper cyclone cover, an upper cyclone separation assembly, a reversing block, a lower outer cylinder, a lower cyclone cover and a lower cyclone separation assembly, wherein the sealing partition plate is arranged in the upper outer cylinder, and is provided with a mounting hole; the upper cyclone cover is fixed to the sealing partition plate, an upper annular cavity is formed between the upper cyclone cover and the upper outer cylinder, and the side wall of the upper cyclone cover is provided with an upper side directional liquid inlet hole; the upper cyclone separation assembly is contained in the upper cyclone cover, and comprises an upper main body piece inserted into the mounting hole, and an upper spiral sheet arranged outside the upper main body piece; the reversing block is connected to the lower end of the upper outer cylinder, and is provided with first and second reversing channels, and the lower end of the upper cyclone cover is inserted into the first reversing channel; the lower outer cylinder is connected to the lower end of the reversing block, and the side wall of the lower outer cylinder is provided with an outer side directional liquid inlet hole; the lower cyclone cover is fixed at the lower end of the reversing block and is contained in the lower outer cylinder, and the side wall of the lower cyclone cover is provided with a lower side directional liquid inlet hole; and the lower cyclone separation assembly is contained inthe lower cyclone cover, and comprises a lower main body piece inserted in the second reversing channel and a lower spiral sheet arranged outside the lower body piece. According to the embodiment of the separator, the separation effect on a high-sand-content well liquid can be improved, and the efficient production of oil recovery can be effectively realized.

Owner:沿海石油技术(辽宁)有限公司

Method for removing grit from chicken dung

InactiveCN104386890AReduce sand contentGuaranteed uptimeWaste water treatment from animal husbandryBiological sludge treatmentDiluentMacromolecular Substances

The invention belongs to the field of biogas projects and in particular relates to a method for removing grit from chicken dung. The method is characterized by comprising the following steps: pouring chicken dung into a stirred grit chamber, adding water for stirring, diluting and removing grit, removing grit with the particle size of larger than 0.6mm in the dung, overflowing the upper chicken dung diluent subjected to stirring and grit removing into a hydrolysis acidification pool, and separating to remove grit with the particle size of smaller than 0.6mm in the hydrolysis acidification process, wherein the hydrolysis acidification pool comprises a primary hydrolysis acidification pool and a secondary hydrolysis acidification pool from a higher part to a lower part. The method disclosed by the invention has the advantages that the grit of various particle sizes in the dung can be completely removed due to the grit removal method, so that the grit content of feed liquid entering a fermentation tank is reduced to 2 percent or below, the influence of the grit on various subsequent links is greatly reduced, and stable operation of the biogas project by taking the chicken dung as a raw material is realized. Meanwhile, due to two-stage hydrolysis, insoluble macromolecular substances in the feed liquid are degraded into soluble small molecular substances, which are conveniently utilized by the methane bacteria, so that the gas production efficiency is improved.

Owner:GUIZHOU LIUJIANG ANIMAL & POULTRY

Two-stage sand removal process for livestock manure

The invention belongs to the field of biogas engineering, and particularly relates to a sand removal process for livestock manure. The sand removal process is characterized in that the livestock manure is poured into a stirring settling tank, water is added into the livestock manure to stir and dilute the livestock manure and remove sand in the livestock manure, the sand with the size larger than 0.5mm in the manure is removed, an upper layer of livestock manure diluent overflows to a hydrolytic acidification tank after stirring and sand removal, sand with the size smaller than 0.5mm is separated and removed during hydrolytic acidification, and the hydrolytic acidification tank sequentially consists of a primary hydrolytic acidification tank and a secondary hydrolytic acidification tank from a high position to a low position. The sand removal process has the advantages that by the aid of the two-stage sand removal process, the sand with various sizes in the manure are thoroughly removed, sand content in liquid entering a fermentation tank is reduced to be lower than 2%, influences of the sand to various follow-up links are greatly reduced, and stable running of biogas engineering with the livestock manure as a raw material is guaranteed. In addition, insoluble macromolecular substances in the liquid are degraded into soluble micro-molecule substances which can be easily utilized by methane bacteria, and gas yield efficiency is improved.

Owner:SHANDONG MINHE BIOTECHNOLOGY CO LTD

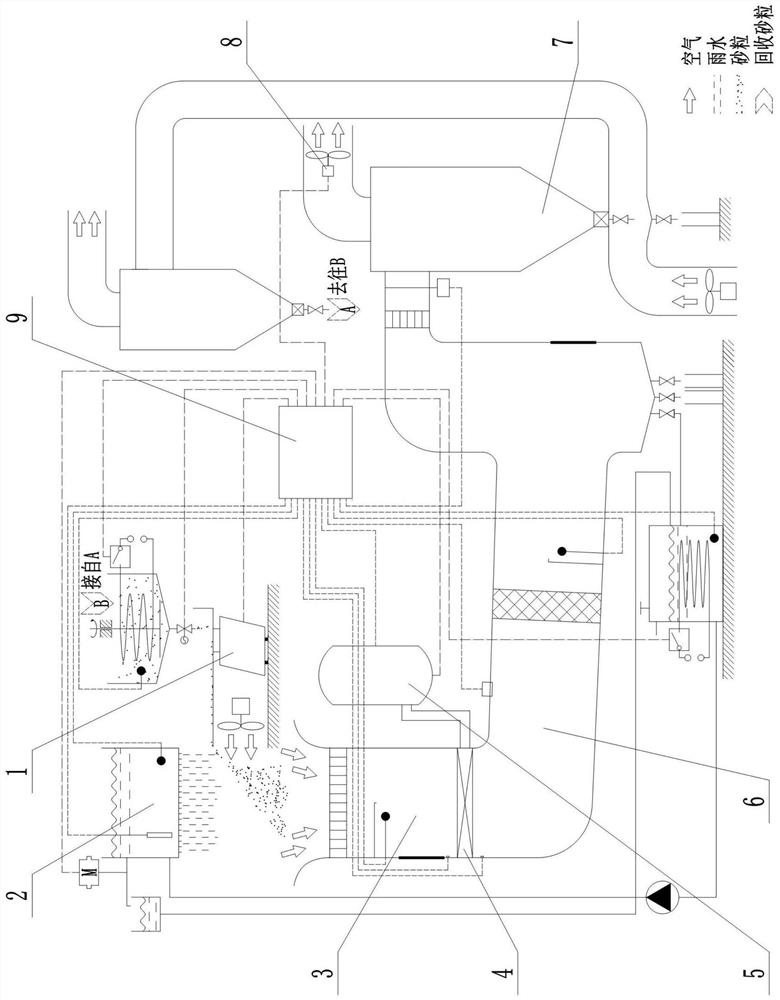

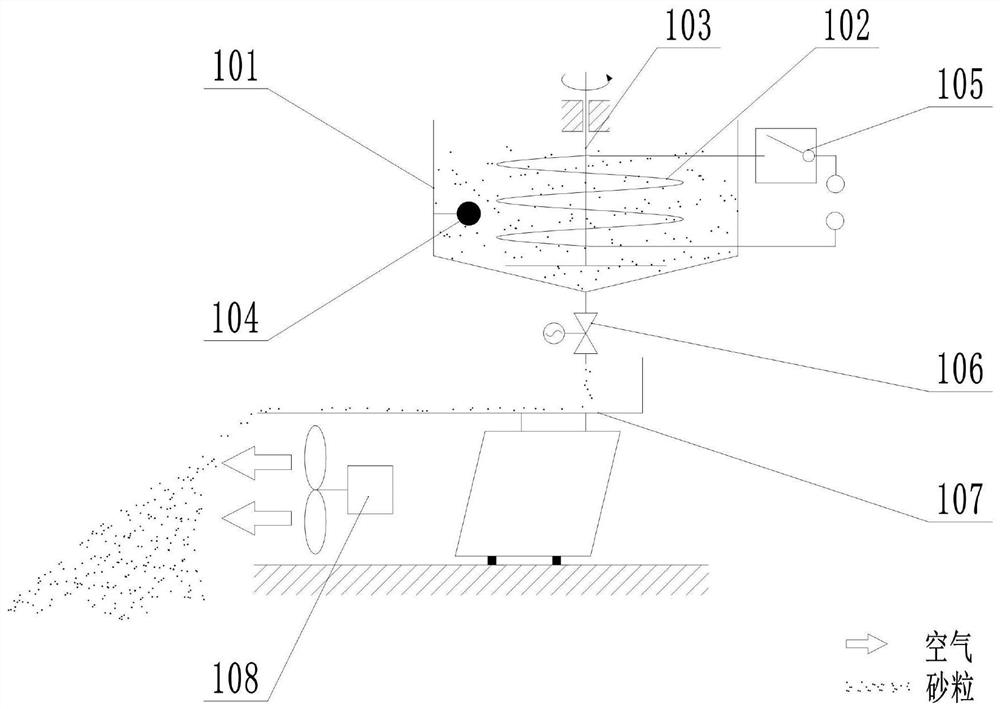

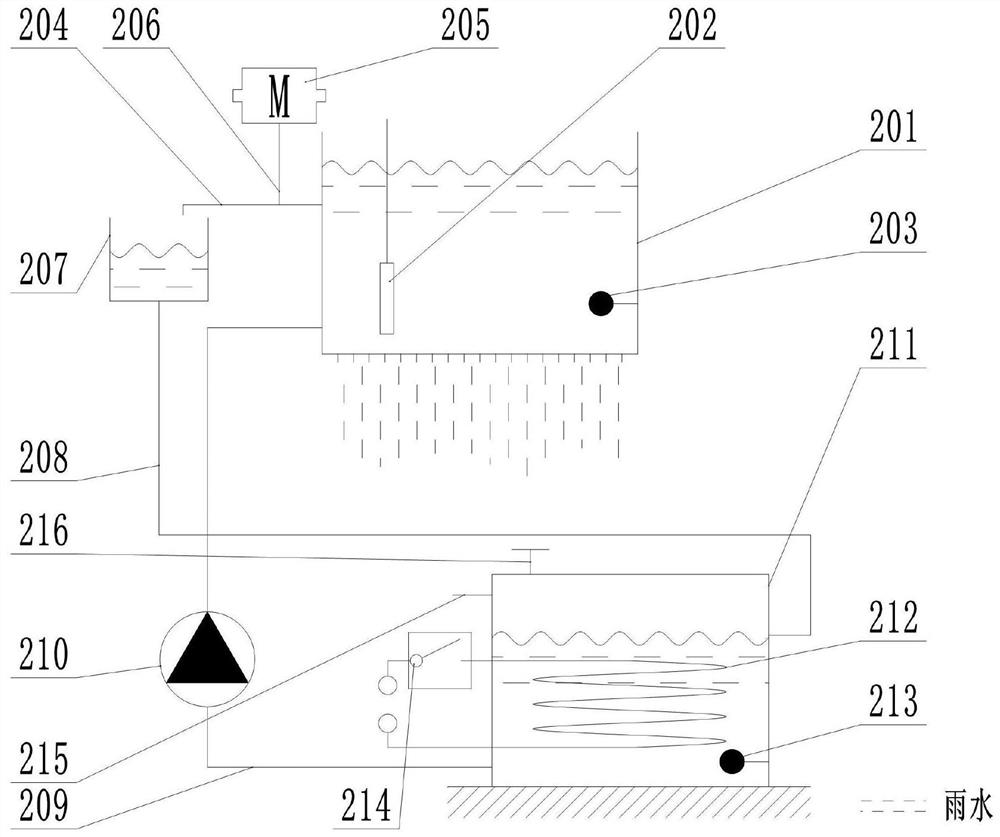

Radiator performance wind tunnel test device capable of simulating multiphase flow air inlet environment

ActiveCN112067234AVarious working conditionsWide applicabilityAerodynamic testingEngineeringAtmospheric sciences

The invention discloses a radiator performance wind tunnel test device capable of simulating a multiphase flow air inlet environment, which belongs to the technical field of radiator performance testdevices. The test device provided by the invention comprises a sand and dust generation device, a rain generation device, an upstream section, a radiator, a hot side circulation system, a downstream section, a separation and recovery section, an induced draft fan and a measurement controller. Performance wind tunnel tests of radiators in sand and dust environments with different sand and dust concentrations and different sand grain temperatures, performance wind tunnel tests of radiators in rain environments with different rainfall amounts and different raindrop temperatures and performance wind tunnel tests of radiators in sand and dust and rain composite environments can be carried out, and meanwhile, performance wind tunnel tests of radiators in conventional natural environments can becarried out, so that the applicability is wide; the parameter range of test conditions is large, and the test function is broadened; sand grains and water can be recycled, and the economical efficiency is high; air exhaust is thorough, and feasibility is high; the structure is compact, and the occupied area is saved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

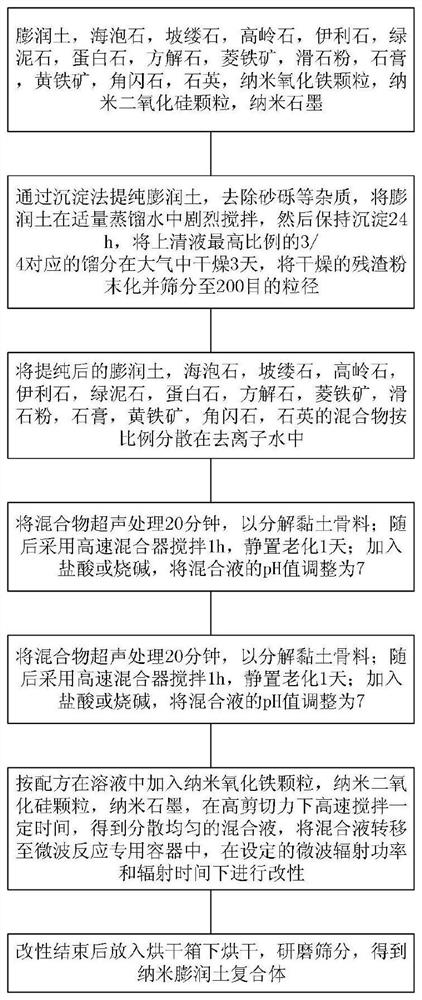

Modified bentonite for seawater drilling and preparation method thereof, and drilling fluid

PendingCN112011320AFast pulpingReduce sand contentDrilling compositionSilicon compoundsPalygorskiteSlurry

The invention provides modified bentonite for seawater drilling and a preparation method thereof, and a drilling fluid. The modified bentonite for seawater drilling comprises the following components:bentonite, sepiolite, palygorskite, kaolinite, illite, chlorite, opal, calcite, siderite, talcum powder, gypsum, pyrite, hornblende, quartz, nanometer iron oxide particles, nanometer silicon dioxideparticles and nanometer graphite. The bentonite prepared from the components is high in slurrying speed, low in sand content, good in slurry making rate, high in sand carrying capacity, low in filterloss and high in stability.

Owner:WUHU FEISHANG NONMETAL MATERIAL

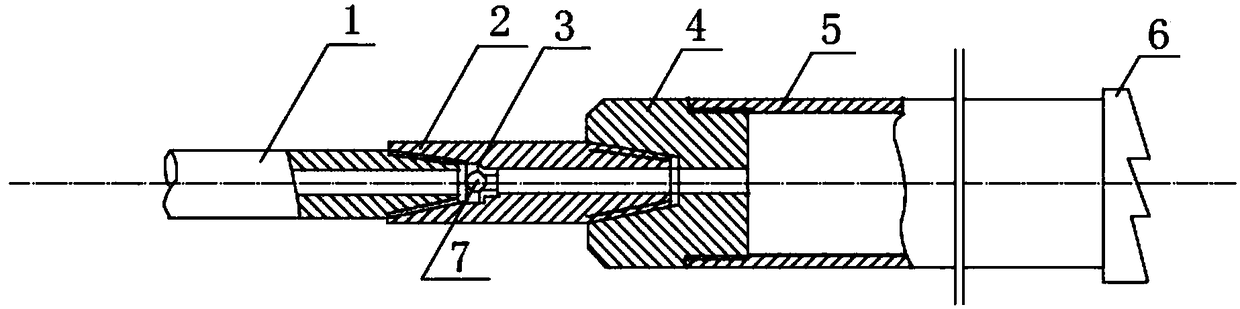

Drilling coring equipment by adopting natural composite slurry to drill to achieve effect of rock core coated with mud

The invention discloses drilling coring equipment by adopting natural composite slurry to drill to achieve the effect of a rock core coated with mud. The drilling coring equipment comprises a drill pipe and a rock core pipe. A drill pipe joint located on the upper portion of the rock core pipe is a joint with a marble seat, the marble seat is arranged in the drill pipe joint, and when a water stopping marble is arranged in the marble seat, the upper portion of the rock core pipe is sealed; and the two ends of the rock core pipe are connected with a rock core pipe joint and an alloy drill bit,one end of the drill pipe is connected to the interior of the drill pipe joint, and the drill pipe joint is connected with the rock core pipe joint. The defects that in the prior art, the sandy soil rock core sample recovery is lower than 70%, and the undisturbed grain composition and structure of sandy soil cannot be maintained are overcome. The drilling coring equipment has the advantages that the sandy soil rock core sample recovery is sharply improved and can be as high as 100%, and the sampled sandy soil rock core sample is coated with mud, so that the undisturbed grain composition and structure of the sandy soil of the sandy soil rock core sample are maintained.

Owner:长江岩土工程有限公司 +1

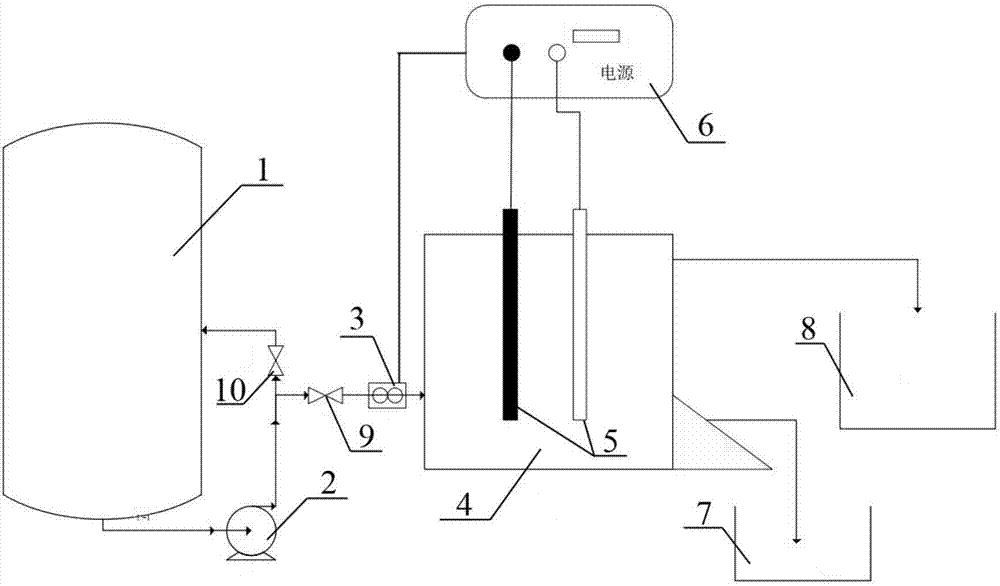

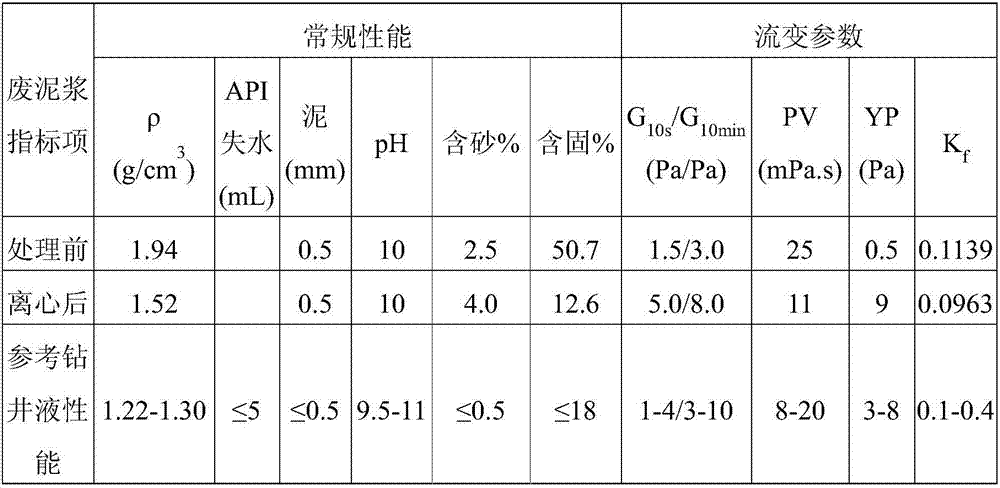

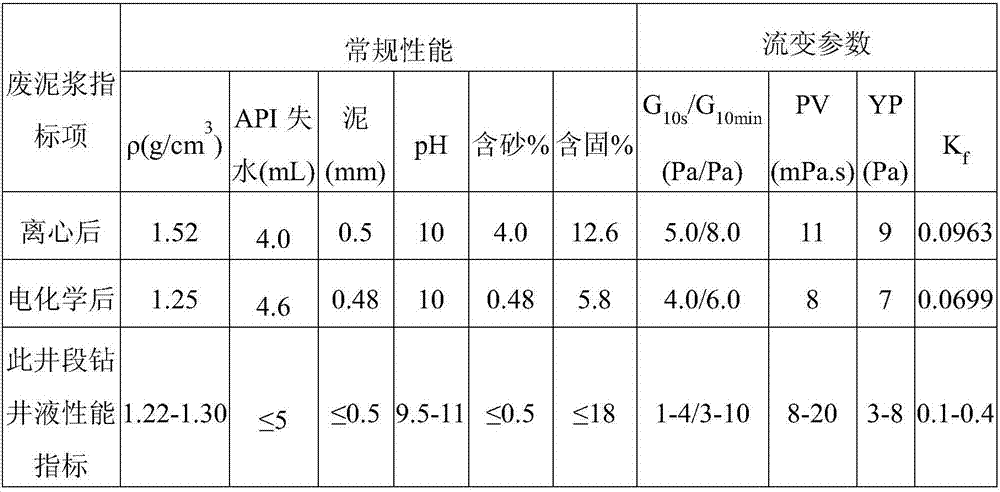

Electrochemical adsorption treatment device and process for water-based waste drilling fluid

ActiveCN107445258AAchieve removalImprove performanceWaste water treatment from quariesDispersed particle separationChemical treatmentWater based

The invention provides an electrochemical adsorption treatment device and process for water-based waste drilling fluid. The electrochemical adsorption treatment device for the water-based waste drilling fluid comprises a mud tank, a mud pump, a flow meter, an electrolytic bath, an electrode and an automatic control system, wherein the mud tank is circularly communicated with the mud pump; the mud pump is communicated with the flow meter; the mud tank is communicated with the flow meter; the flow meter is communicated with the electrolytic bath; the electrode comprise an anode and a cathode; the electrode is arranged in the electrolytic bath; the automatic control system is electrically connected with the electrode; the automatic control system is electrically connected with the flow meter. According to the electrochemical adsorption treatment device and process for the water-based waste drilling fluid, which are provided by the invention, a chemical treating agent is not added; an effective component in drilling fluid is not destroyed; inferior solid phases of a superfine micro-particle and the like in waste drilling fluid can be effectively removed; thus, main performance indexes of the density, the silt content, the solid content and the like of the waste drilling fluid are decreased; the rheological characteristic of the waste drilling fluid is improved, and the recycling performance index requirement of waste-based drilling fluid is met.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Drilling mud

InactiveCN108034414AQuality improvementImprove performance indicatorsDrilling compositionMining engineeringPetroleum engineering

The invention relates to drilling mud. Basic mud is firstly prepared, and then new mud is prepared, to obtain the drilling mud. The preparation method is simple; component and performance indexes arecontrolled accurately; various performance indexes of wall-protecting mud in a cast-in-situ bored pile construction process are improved favorably, and the quality of the mud is improved; a drill is relatively low in initial gel strength, so that the mud can discharge included gas easily, and the sand factor is reduced.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

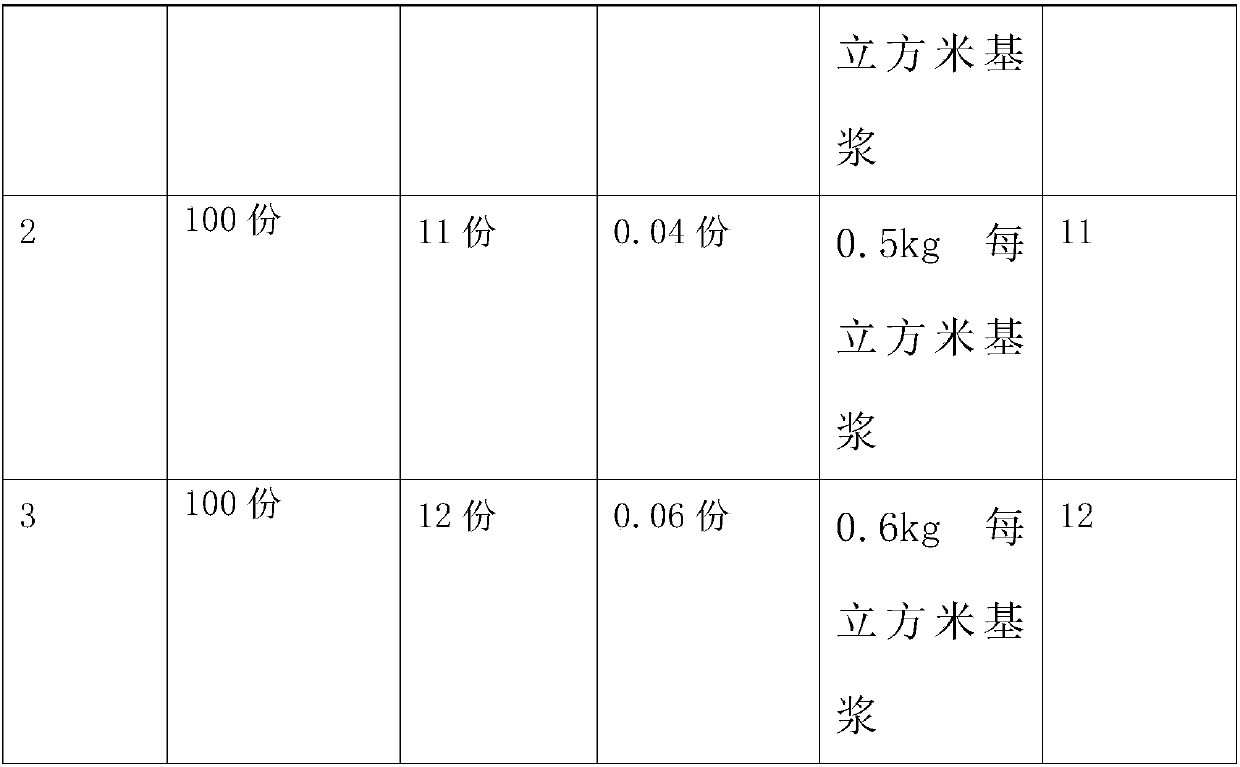

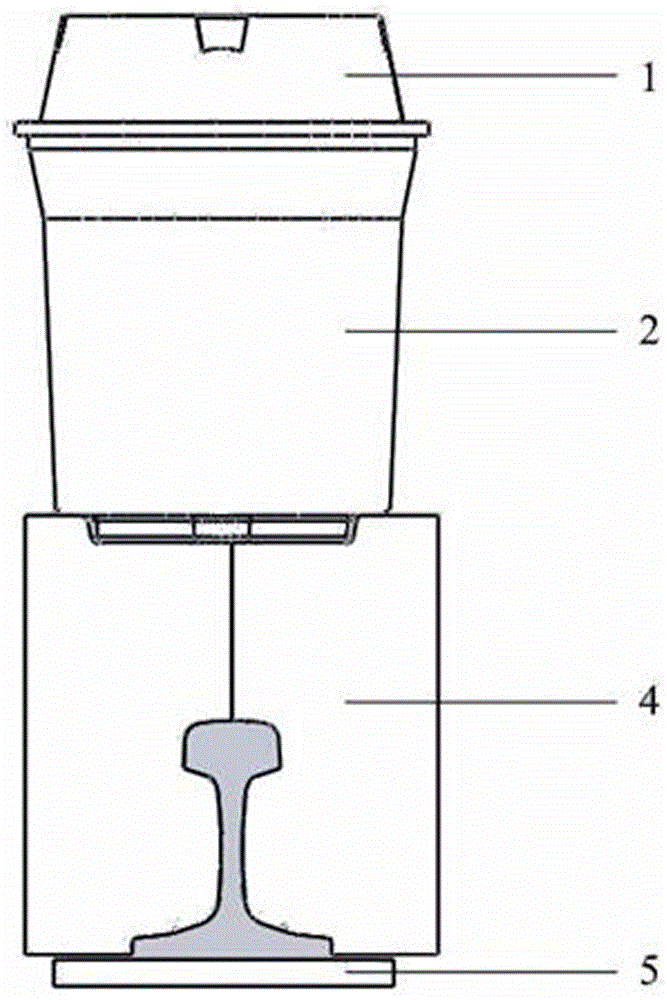

Steel rail thermite welding gating system

The invention relates to a steel rail thermite welding gating system. The system comprises a sand mold, a crucible body arranged above the sand mold, a crucible cover matched with the crucible body, a shunting plug arranged inside the sand mold, and a base plate arranged at the bottom of the sand mold. According to the system, a reaction crucible and a pouring gate system are both designed to be of a liquid deslagging structure, and the purity of molten steel in a purifying cavity is fully considered. The crucible top cover of the system is in a pneumatic layout mode, reaction high-temperature gas can be dredged and high-temperature liquid-solid splash can be blocked. Two risers at the bottom of the sand mold in the system communicate with each other, and thus the casting feeding capacity is enhanced.

Owner:洛阳双瑞橡塑科技有限公司

Lost foam casting mould with positioning accuracy for electromotor shell

InactiveCN111250657AIncrease frictional resistanceImprove success efficiencyFoundry mouldsFoundry coresDry sandMolten steel

The invention discloses a lost foam casting mould with the positioning accuracy for an electromotor shell. The lost foam casting mould with the positioning accuracy for the electromotor shell comprises a main casting pipe and an electromotor shell body, wherein a casting funnel device is fixedly arranged at the upper end of the main casting pipe; a No.1 branched casting pipe is fixedly arrangedat one end of a horizontal casting pipe; a fixed rod is fixedly arranged at the lower end of a No.2 branched casting pipe; a casting port is arranged under the fixed rod; and a sand residue filter screen is arranged above the casting port. According to the lost foam casting mould with the positioning accuracy for the electromotor shell provided by the invention, through arranging a rubber spacer,a positioning main rod and the sand residue filter screen, the frictional resistance between the equipment and the ground can be increased, so that the overall stability of the equipment is improved,and a buffer effect can be further achieved; and the accuracy of a product casting position can be effectively improved through the positioning main rod, and dry sand impurities in molten steel can be effectively cleaned and filtered through the sand residue filter screen, so that the lost foam casting mould with the positioning accuracy for the electromotor shell brings a better use prospect.

Owner:嘉兴镇宇物联网科技有限公司

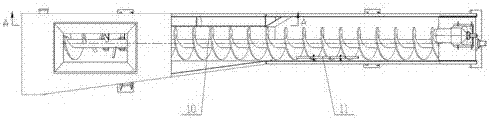

Small-scale combined wheat washing equipment and small-scale combined wheat washing method

InactiveCN103816955AImprove cleanlinessImprove cleaning rateGrain millingWater circulationProcess engineering

The invention discloses small-scale combined wheat washing equipment and a wheat washing method thereof. The wheat washing method mainly comprises the following steps: plane rotary sieving, stone removing, coarse wheat washing, secondary wheat washing, final wheat washing, wheat wetting and wheat wiping. Through the adoption of the method, the problems of large water consumption, serious pollution, low washing quality and the like of washing via a wet method of the current small and medium flour processing enterprises can be effectively solved. Through the adoption of the small-scale combined wheat washing equipment, the movement route of wheat flows in the washing is changed, a traditional single-stage rinsing technology is replaced with classified washing technology, so that the wheat flows are subjected to multiple-stage rinsing in sequence, the washing is more thorough, and recycling water effectively is realized via water circulation. Compared with the traditional washing technology, water is saved by about 70%, environmental pollution can be reduced from sources, at the same time, the production cost of the enterprises can be reduced, and the application range is wide.

Owner:YANCHENG INST OF TECH

Silt brick

The invention provides a more economical and energy-saving silt brick. River silt, coal slag and flyash are used as main raw materials, and after the raw materials are sintered, polystyrene foam plastic added with a flame retardant or polyurethane is used for foaming. The brick is of a right-angled hexahedron in appearance, and the brick has an outline the specification of which is basically consistent with the specification of a conventional brick. Compared with the prior ordinary bricks, the silt brick has the characteristics of less sand content, high plasticity, strong bonding force, gooddrying sensitivity, large shrinkage, and the like.

Owner:苏州同济材料科技股份有限公司

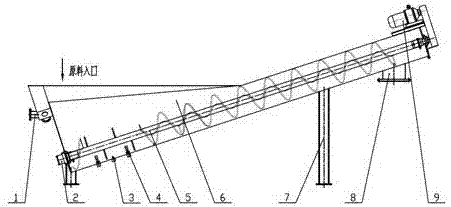

Sand removal method and sand removal device of excrement

The invention relates to a sand removal method and a sand removal device of excrement. The sand removal method mainly comprises the steps of performing impact grinding on the excrement and a sand cake with water and gas, allowing the excrement with smaller density to be located at the upper part of a mixed liquid, forming a gas flotation phenomenon by the combined action of the water and the gas, allowing bubbles to exert a support effect on ground cattle manure, and allowing sand to deposit at the bottom to be discharged by a conveying screw shaft. The sand removal device comprises a body placed obliquely; a reducer motor and a bearing are arranged on the outer sides of the high end and the low end of the body respectively; the conveying screw shaft is arranged in a groove of the body; the low end of the conveying screw shaft is mounted on the bearing; the high end of the conveying screw shaft is driven by the reducer motor to rotate; a raw material inlet is formed at the upper part of the low end of the body; a manure water overflow port is formed above the side part of the low end of the body; air nozzles and hydrojet nozzles are sequentially arranged at the bottom of the low end of the body; and a sand discharge port is formed at the bottom of the high end of the body. The method and the device effectively solve the sand removal problem of the excrement in the modern breeding industry, and the device is simple in structure, low in cost and easy to maintain.

Owner:GANSU LANPEC TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com