Waste slurry circulating method and system for shield in weathered argillaceous siltstone stratum tunneling

A siltstone and weathering technology, applied in chemical instruments and methods, earthwork drilling, mining wastewater treatment, etc., can solve problems such as incomplete separation of slag and soil, and achieve lower pulping costs, high separation accuracy, and low sand content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

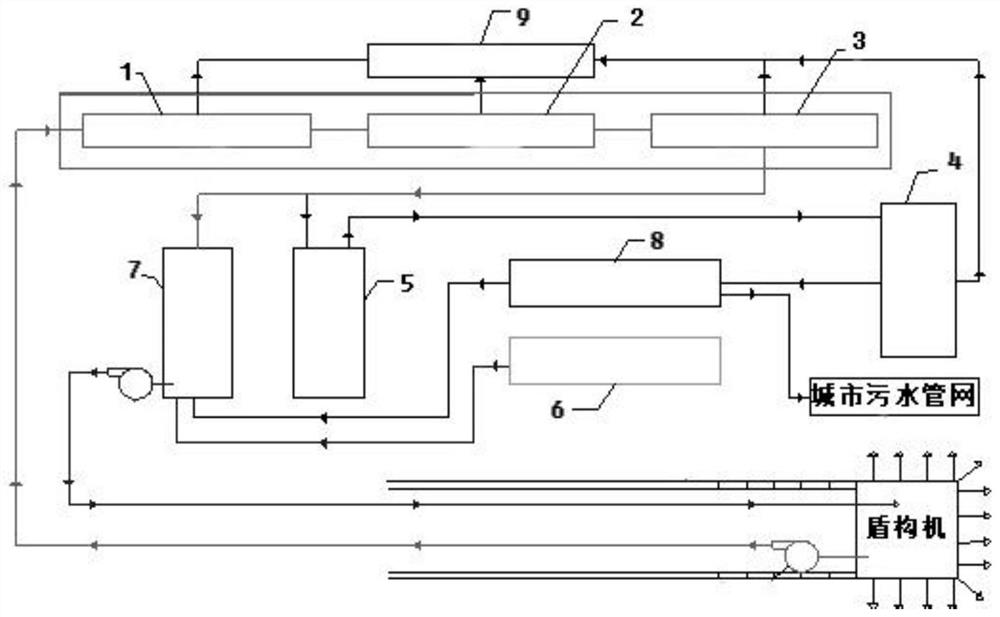

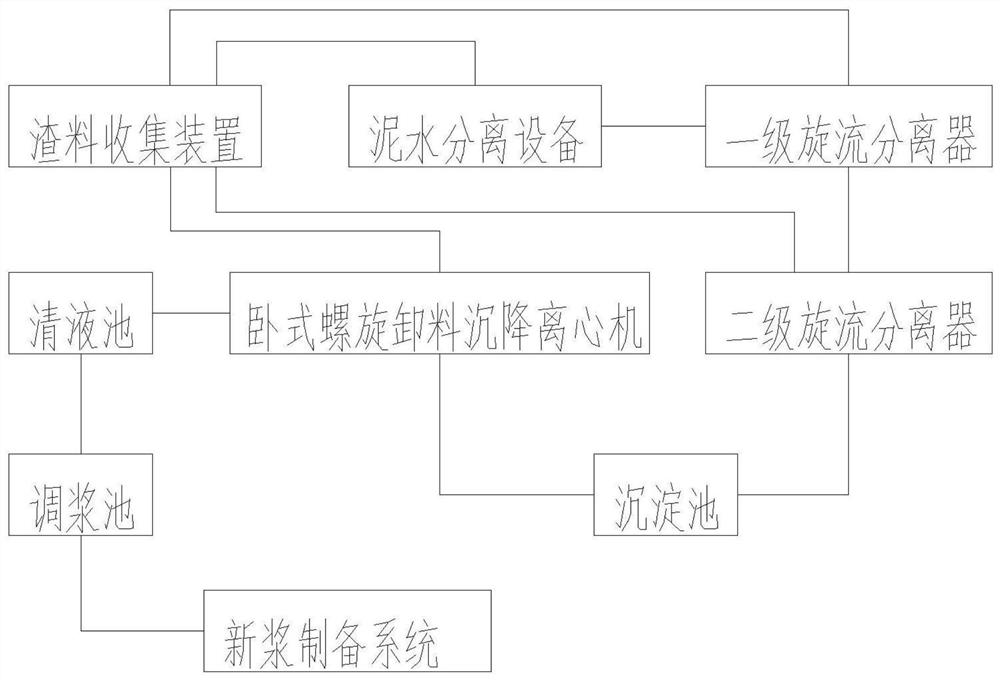

[0039] like figure 1 Shown, method of the present invention comprises the steps:

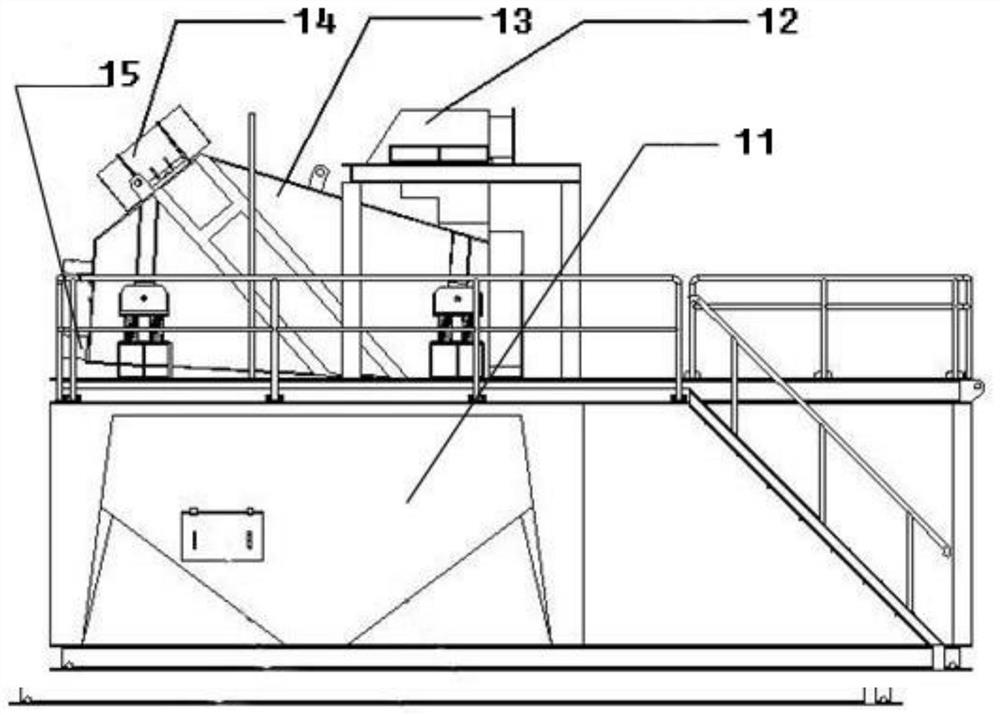

[0040] Step 1, primary selection of waste slurry, use the shield machine slurry discharge pipeline and the slurry discharge pump station to discharge the waste slurry to the mud-water separation equipment 1 for separation treatment, and the large pieces of material on the screen ≥ 4 ~ 250mm fall to the slag Collecting device 9, the underscreen mud enters the primary slurry storage tank 11 of the mud-water separation equipment 1;

[0041] Step 2, the primary cyclone separator 2 is separated and dehydrated, the primary slurry storage tank 11 of the mud-water separation equipment 1 is connected to the primary cyclone separator 2, and the primary cyclone separator 2 is 0.074 ~ 4mm The sand material is screened out and the sand material is delivered to the slag collection device 9;

[0042] Step 3, the secondary cyclone separator 3 is separated and dehydrated, the secondary cyclone separator 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com