High-pressure slurry wall-protection method and device

A kind of mud retaining wall and mud technology, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc. It can solve problems such as locking, affecting the progress of drilling construction, and stuck drill, so as to prevent hole collapse and shrinkage, and save the supply of clean water and sewage discharge, to ensure the effect of normal drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

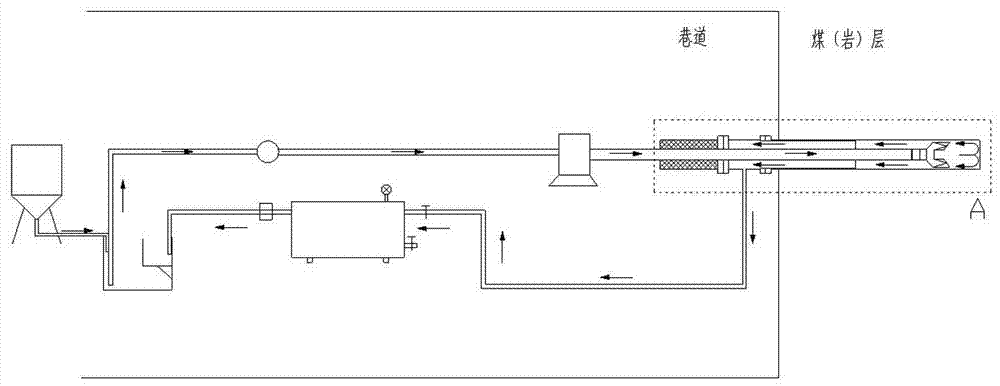

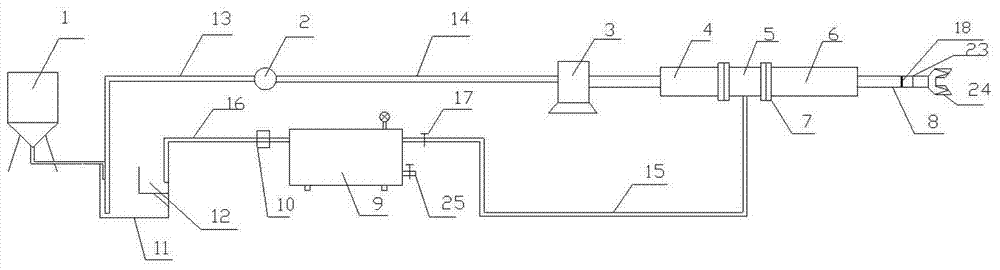

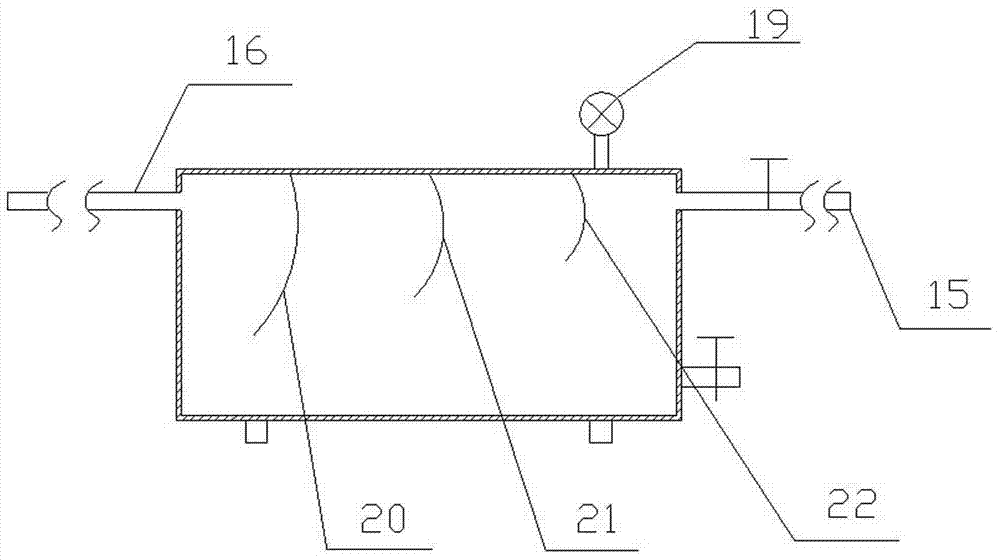

[0017] Such as figure 1 with figure 2 As shown, a high-pressure mud wall protection device includes a pulping machine 1, a mud pump 2, a drilling rig 3, a hollow drill pipe 8, a drill pipe check valve 18, a screw motor 23, a drill bit 24, a blowout preventer 4, and a tee 5 , orifice pipe 6, mud settling tank 9, overflow valve 10, steel plate mud pool 11, filter screen 12; described pulp machine 1 is connected with described steel plate mud pool 11 by pipeline, is used for mud is transported to steel plate mud pool The mud pump 2 is connected to the steel plate mud pool 11 through the first pipeline 13, and one end of the first pipeline 13 is connected to the mud pump 2, and the other end is connected to the bottom of the steel plate mud pool 11. The mud is supplied through the first pipeline through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com