Small-scale combined wheat washing equipment and small-scale combined wheat washing method

An equipment and wheat washing technology, applied in application, grain processing, grain milling, etc., can solve the problem of large water consumption for wheat washing, and achieve the effects of high washing rate, reasonable structure design and less increase in equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

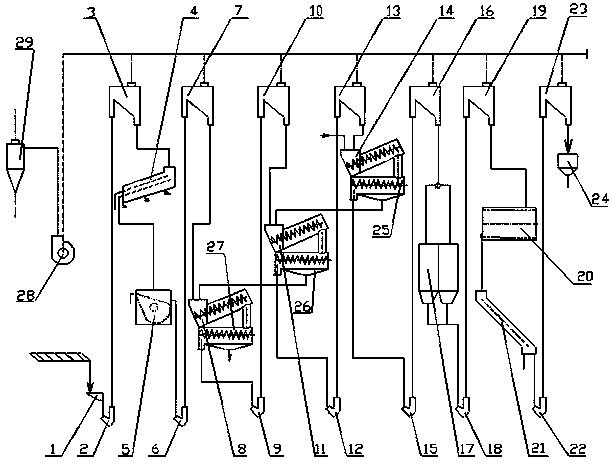

[0024] A small combined wheat washing equipment, which includes: a grain lowering hopper (1), a first feeder (2) connected to the grain lowering hopper (1), a first discharger connected to the first feeder (2) The feeder (3), the plane rotary screen (4) connected with the first unloader (3), the stone remover (5) connected with the plane rotary screen (4), the stone remover (5) connected in sequence The second material receiver (6), the second material unloader (7) and the rough washing and washing equipment (8), the third material receiving device (9) connected to the rough washing and washing equipment (8) in sequence, the third The unloader (10) and the second wheat washing equipment (11), the fourth material receiver (12) connected in sequence with the second washing wheat washing equipment (11), the fourth unloader (13) and the final washing wheat washing equipment Equipment (14), the fifth feeder (15) connected successively with the final washing and wheat washing equipm...

Embodiment 2

[0029] A small-scale combined wheat washing method, which includes the steps of plane rotary sieving, stone removal, rough washing, secondary washing, final washing, tempering and rubbing;

[0030]Specific steps are as follows:

[0031] First put the raw grain into the grain hopper (1), transport it to the first material receiver (2) through the grain hopper (1), and then transport it to the flat rotary screen (4) through the first unloader (3) After removing the large and small impurities in the raw grain through the plane rotary screen (4), the material is transported to the stone remover (5) to remove the sand and gravel; and then the material after the sand and gravel removal is transported to the second feeder (6), then after passing through the second unloader (7), it is transported to the rough cleaning and wheat washing equipment (8) for rough washing, and after rough washing, the material passes through the third feeder (9) and the third The unloader (10) is transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com