Technical method for controlling water in kilometer-level internal shaft in metal mine

A blind shaft, water prevention technology, applied in shaft equipment, drainage, mining equipment and other directions, can solve problems such as flooding and large water inflow, and achieve the effect of improving stability and reducing bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

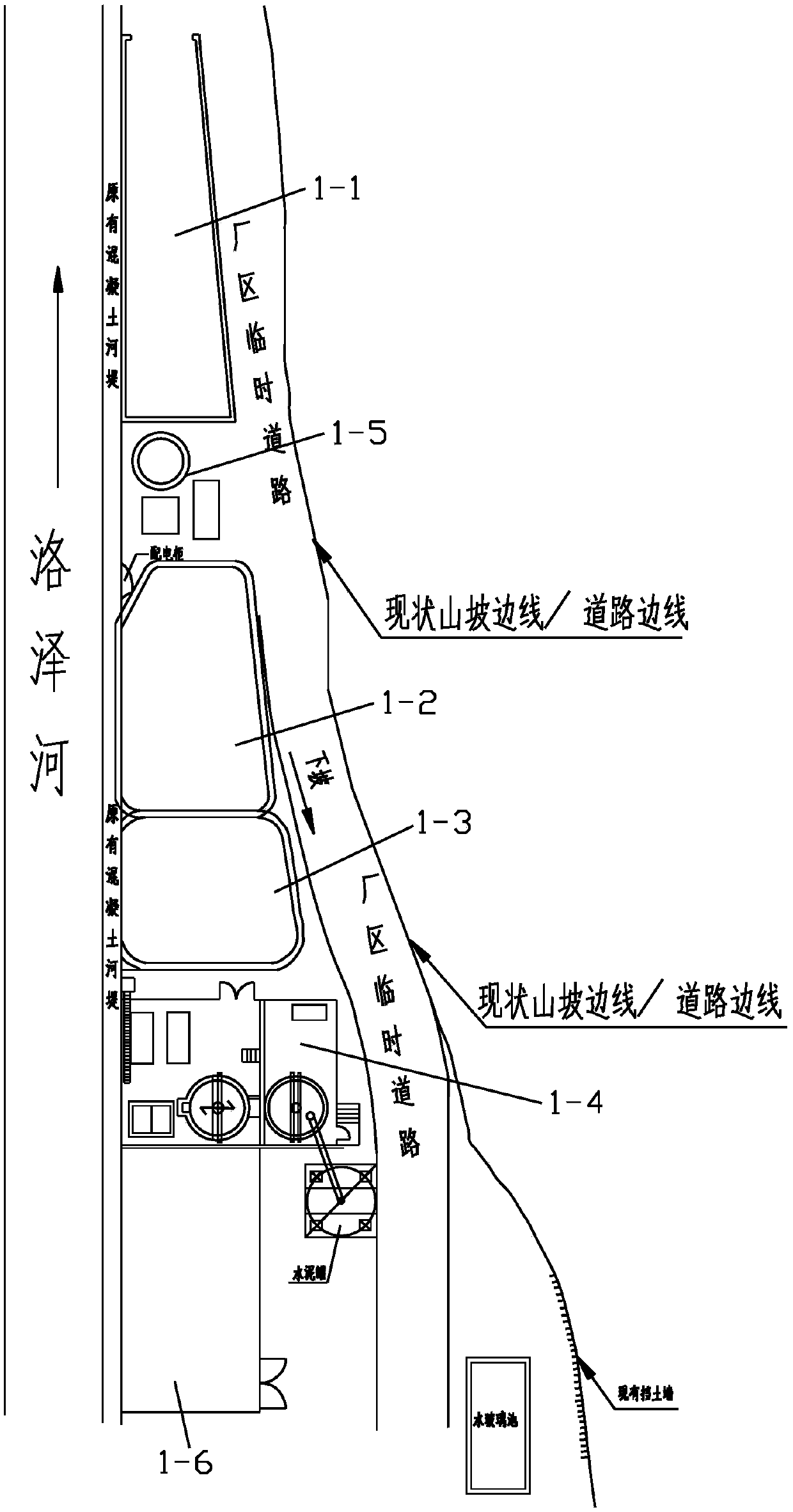

[0013] Yiliang Chihong Mining Co., Ltd. Maoping Lead-Zinc Mining Co., Ltd. has the lowest elevation of underground mineral mining in the middle section of 610 meters. At present, it has been proven that there are still abundant mineral deposits below the middle section of 610 meters. It is a continuous replacement project for deep resources aimed at developing deep mineral deposits. It is the focus of the company's strategic development plan, and the 112-line blind shaft shaft of the supporting construction of the deep resource replacement project is the top priority of the project.

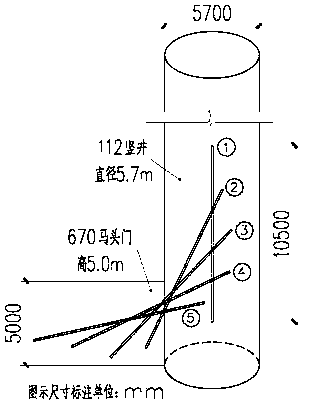

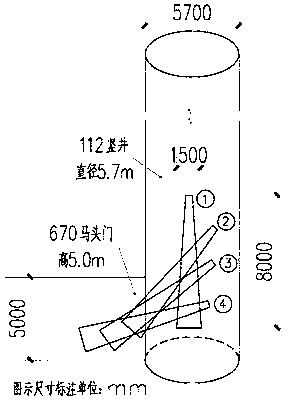

[0014] Yiliang Chihong Mining Co., Ltd. Maoping Lead-Zinc Mine plans to build the 112-line vertical shaft using a circular blind mixed shaft with a shaft diameter of 5.7m and an excavation diameter of 6.5m. The wellhead is located in the existing 910m horizontal roadway, the designed wellbore depth is 960m, and the elevation is from 910m to -50m. The shaft will serve as the main channel for the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com