Drilling mud

A mud and base mud technology, applied in the field of drilling mud, can solve the problems of accurate control, difficult to achieve composition and performance indicators, etc., and achieve the effects of accurate control, reducing sand content and improving performance indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

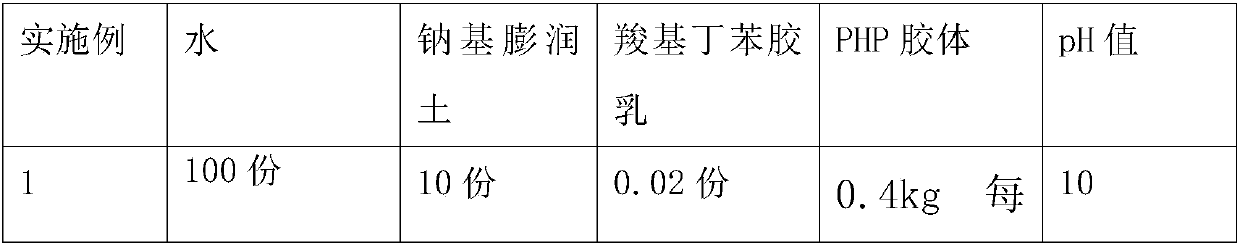

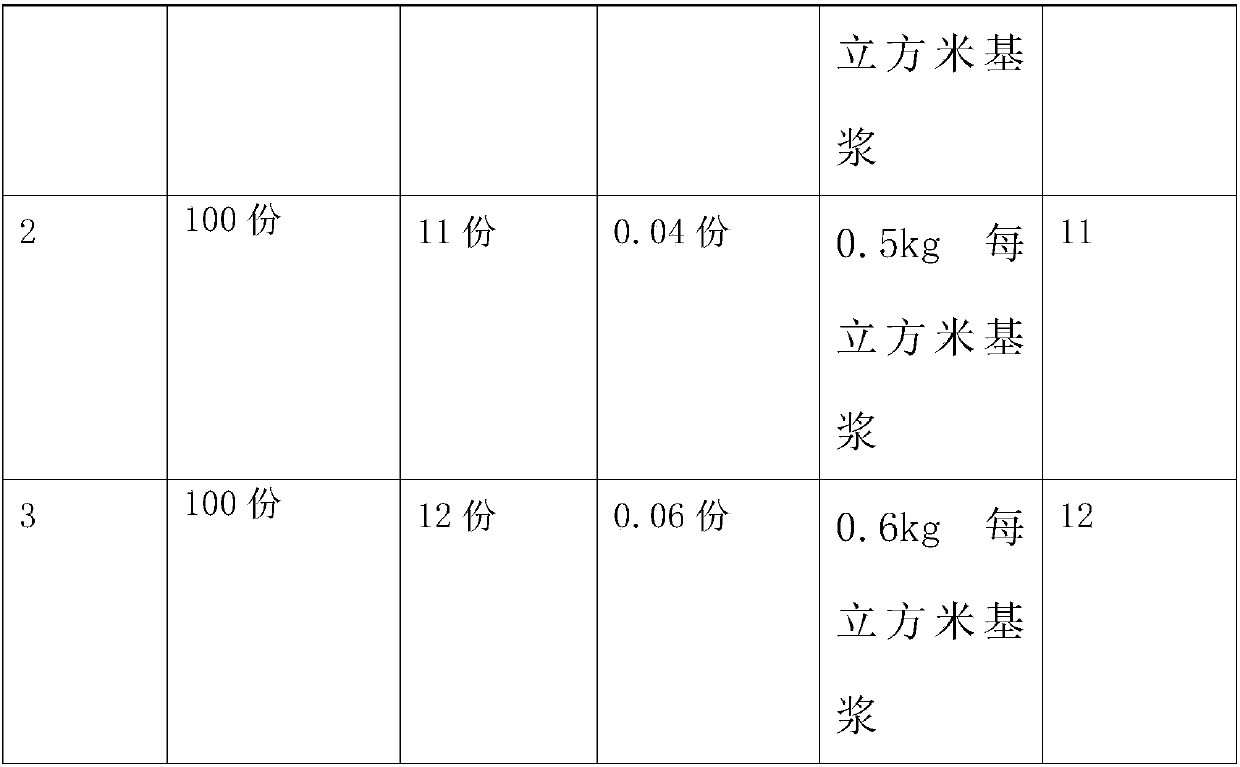

[0027] Embodiments 1-3 provide a kind of mud for drilling respectively, and the base slurry includes the following components:

[0028] Sodium bentonite, parts by weight as described in table 1;

[0029] Water, parts by weight as described in Table 1;

[0030] Soda ash, used to adjust the pH value, appropriate amount;

[0031] Viscosity: 20~22; specific gravity: 3 ;Sand content rate98%;Water loss rate:<20%;Shear force: 2~4N;

[0032] In the base slurry, add the carboxylated styrene-butadiene latex of the weight portion as described in table 1, the PHP colloid of the base slurry of the amount as described in table 1 and an appropriate amount of soda ash to make drilling mud;

[0033]

[0034]

[0035] The pH is obtained by adjusting the pH with an appropriate amount of NaOH;

[0036] Viscosity: 26~35; specific gravity: 3 ; Sand content rate 100%; water loss rate: <20%; shear force: 4~6N.

Embodiment 4

[0038] This embodiment provides a preparation method of drilling mud,

[0039] S1: Configure the base slurry without PHP. The base slurry is made by mixing bentonite, soda ash and water. The fineness of sodium-based bentonite is less than 200 mesh, accounting for more than 98%. In the preparation process, water and bentonite are mixed first. Bentonite and water cannot be mixed into mud in the natural state, and must be stirred at a high speed to form a mud colloid. That is, a high-pressure water pump is installed in the slurry tank, and a homogeneous slurry is formed through multiple cycles of self-priming and back-spraying. It is also possible to add a certain amount of water to the pulper first, then add bentonite in proportion, and use the mechanical function of the pulper to perform high-speed rotation (1200-1500r / min) and stir for 10 minutes. After the bentonite particles are fully dispersed in water, add soda ash to the solution to adjust the specific gravity, viscosity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| colloid rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com