Construction process of underwater churning-driven cast-in-place bored pile by adopting chemical slurry powder to make slurry and protect wall

A technology of bored piles and construction technology, which is applied in excavation, sheet pile wall, infrastructure engineering and other directions, can solve the problems of unprotected wall protection effect, poor wall protection effect, borehole collapse, etc., and achieves convenient and fast pulping. , The effect of fast hole cleaning and speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

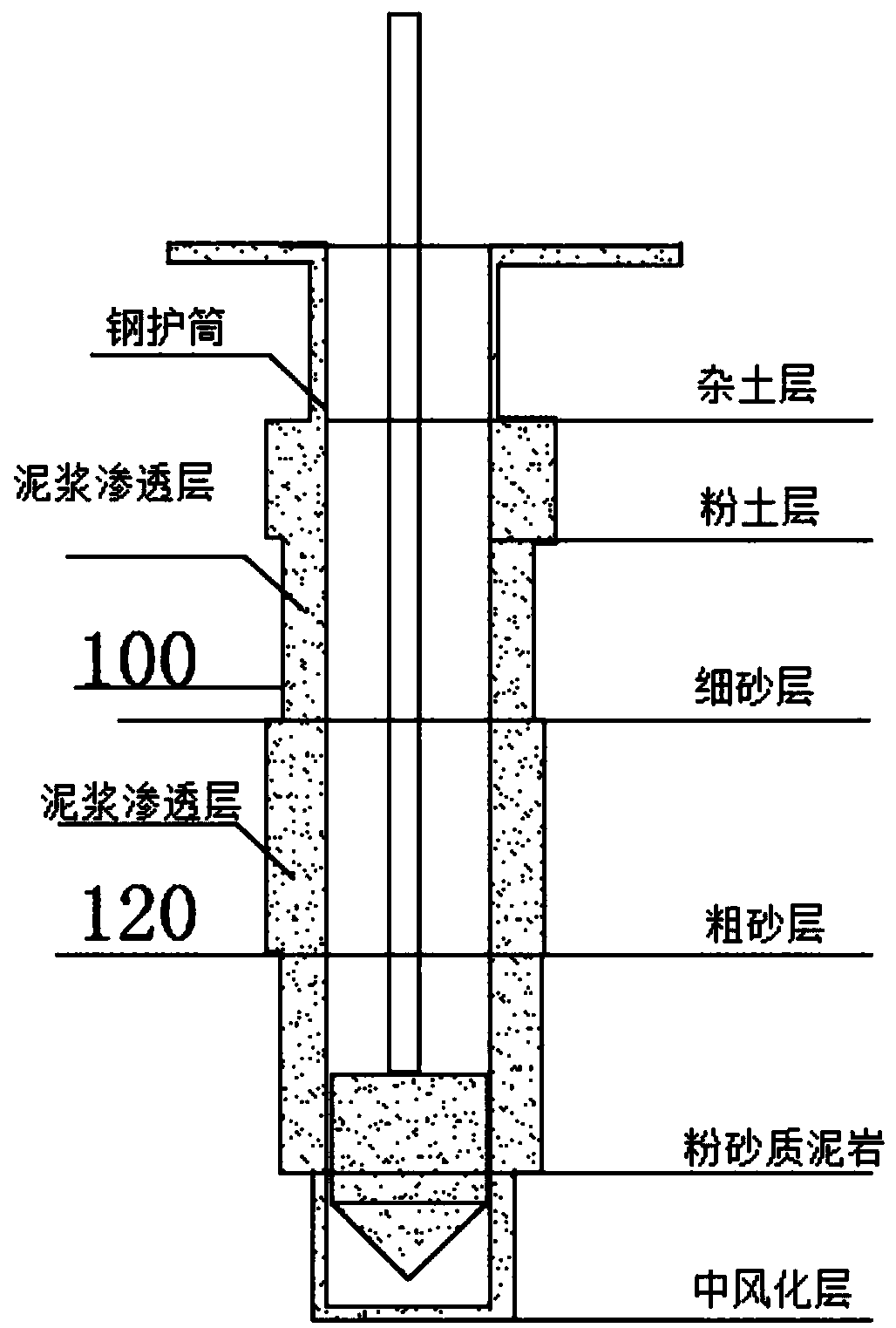

[0027] according to figure 1 The shown one kind of underwater rotary excavation bored cast-in-place pile adopts the construction technology of chemical mud powder to slurry the retaining wall, and the specific operation steps are as follows:

[0028] Step 1: Construction preparation, fully prepare the equipment, tools and objects needed for construction, level and compact the construction site and clean up debris, replace the soft soil, measure the center of the pile position and bury the casing;

[0029] Step 2: Put the drilling rig in place, move the drilling rig to the casing, and install and adjust it so that the drill bit is aligned with the center of the pile, check the drilling rig as a whole, and troubleshoot in time;

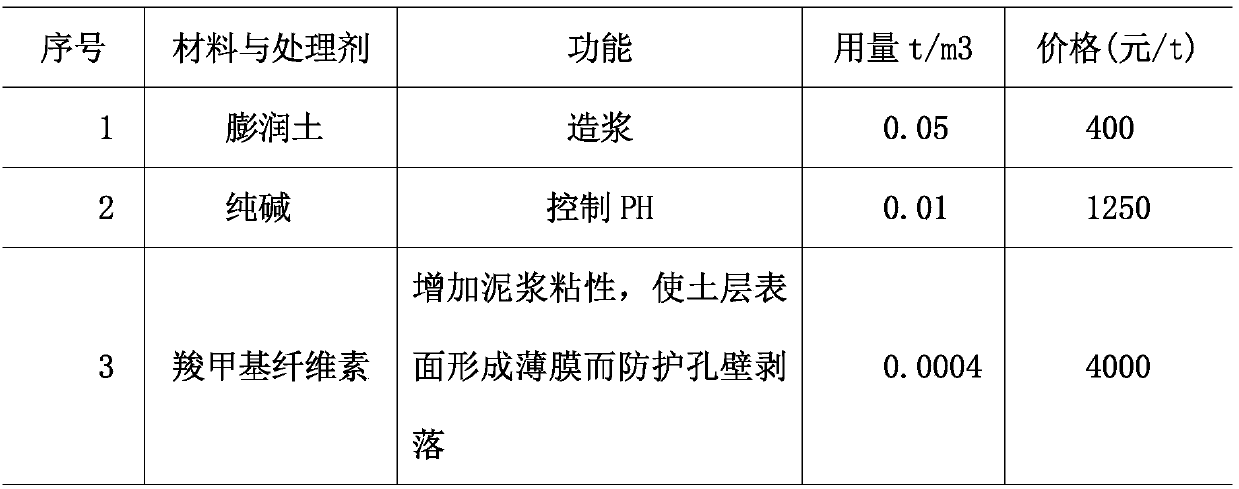

[0030] Step 3: Mud retaining wall, arrange a mud pool on the construction site, the size of the mud pool: length × width × depth = 4m × 2m × 1.5m, add water and chemical mud powder to prepare 0.01% chemical mud liquid in proportion, the slurry surface c...

Embodiment 2

[0038] according to figure 1 The shown one kind of underwater rotary excavation bored cast-in-place pile adopts the construction technology of chemical mud powder to slurry the retaining wall, and the specific operation steps are as follows:

[0039] Step 1: Construction preparation, fully prepare the equipment, tools and objects needed for construction, level and compact the construction site and clean up debris, replace the soft soil, measure the center of the pile position and bury the casing;

[0040] Step 2: Put the drilling rig in place, move the drilling rig to the casing, and install and adjust it so that the drill bit is aligned with the center of the pile, check the drilling rig as a whole, and troubleshoot in time;

[0041] Step 3: mud retaining wall, arrange mud pool on the construction site, size of mud pool: length x width x depth = 4m x 2m x 1.5m, add water and chemical mud powder to prepare 0.05% chemical mud liquid in proportion, the slurry surface can never b...

Embodiment 3

[0049] according to figure 1 The shown one kind of underwater rotary excavation bored cast-in-place pile adopts the construction technology of chemical mud powder to slurry the retaining wall, and the specific operation steps are as follows:

[0050] Step 1: Construction preparation, fully prepare the equipment, tools and objects needed for construction, level and compact the construction site and clean up debris, replace the soft soil, measure the center of the pile position and bury the casing;

[0051] Step 2: Put the drilling rig in place, move the drilling rig to the casing, and install and adjust it so that the drill bit is aligned with the center of the pile, check the drilling rig as a whole, and troubleshoot in time;

[0052] Step 3: mud retaining wall, arrange mud pool on the construction site, size of mud pool: length x width x depth = 4m x 2m x 1.5m, add clean water and chemical mud powder to prepare 0.1% chemical mud liquid in proportion, the slurry surface can ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com