Patents

Literature

102results about How to "Guarantee the quality of hole formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beneath-soil through-tunnel superlarge diameter pipe curtain construction method

ActiveCN101737060AAvoid disturbanceGuaranteed drilling accuracyUnderground chambersDirectional drillingSoil massLevel crossing

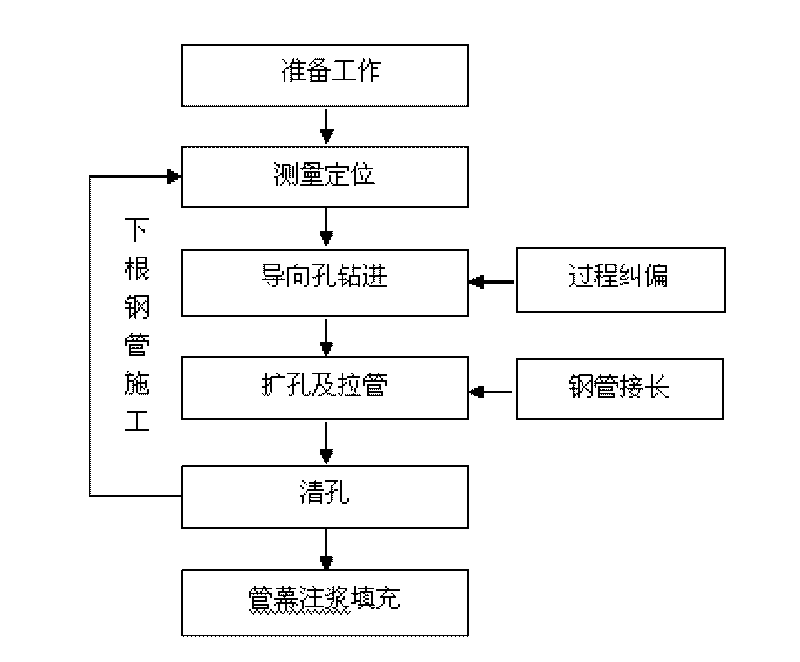

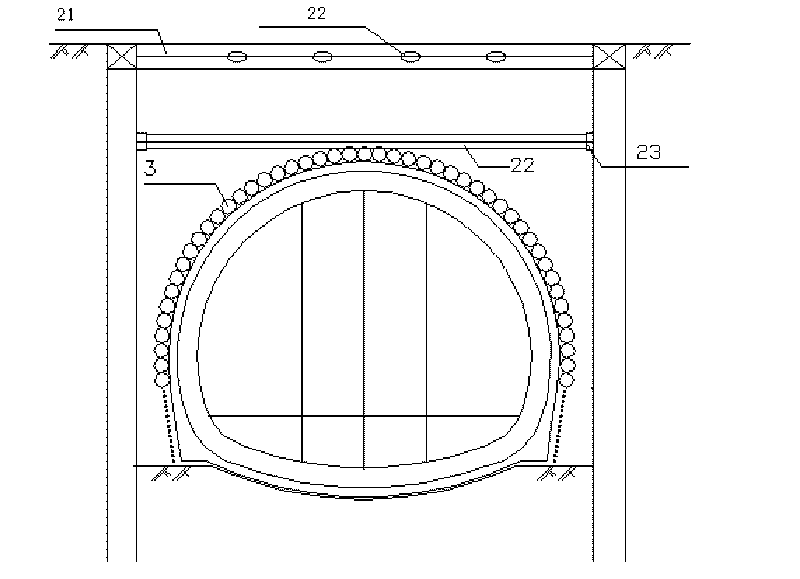

The invention discloses a beneath-soil through-tunnel superlarge diameter pipe curtain construction method. The method comprises the following construction steps of: preparation, measurement and positioning, guide hole drilling, process correction, reaming and pipe drawing, hole cleaning and pipe curtain grouting. In the method, the guide hole is constructed in a soil layer first, and a steel tube in superlarge diameter is drawn in the guide hole in a mode of reaming and drawing the tube at the same time, so that the disturbance on the soil layer in construction is effectively avoided; and a wedge-shaped drill bit provided with a guide plate is used for the process correction in the construction of the guide hole, so that the drilling precision and the hole forming quality are highly guaranteed. In the construction, the sedimentation of the soil mass on the middle-upper part meets the safety requirements of the existing line. After excavation, the steel pipes are nearly flat and straight, no phenomenon of level-crossing and interchanging occurs and the construction method of the invention creates conditions for water resistance and lining construction of the tunnel.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

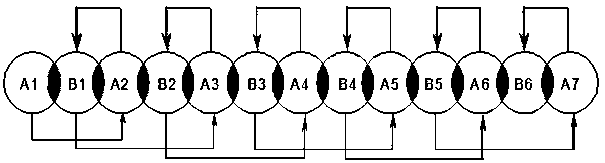

Construction method for subway contact passage

The invention provides a construction method for a subway contact passage suitable for a very thick Cenozoic stratum region with low heat conductivity and strong heat insulation effect. The method comprises five stages, namely construction preparation, construction of freezing holes, freezing, digging and supporting of the passage and a water collecting well and slurry filling in the back of a wall. The method specifically comprises the following steps of: performing the construction preparation, then forming the freezing holes under the condition that the thickness of a frozen soil curtain is ensured, adding short-range freezing holes on the upper parts of the bell mouths of the freezing holes, and detaching reserved steel pipe sheets at the opening of the passage by adopting a secondary hole forming technology; performing positive freezing after a freezing system runs normally, and making the freezing system perform maintenance freezing after the frozen soil curtain meets the design requirement; after the procedures are finished, performing the digging and supporting stage of the passage and the water collecting well; and pre-burying slurry pipes and filling slurry. By the construction method, the construction difficulty is reduced, the safety and the reliability of engineering are improved, the construction period is shortened, the construction efficiency is improved, and the quality of the engineering is ensured.

Owner:TIANJIN URBAN CONSTR TUNNEL

Cast-in-situ bored pile technique

The invention relates to the technical field of foundation treatment and in particular relates to a cast-in-situ bored pile technique. The cast-in-situ bored pile technique comprises the following steps of: firstly, releasing a point at a pile position; secondly, placing a drilling machine in position; thirdly, repairing the point at the pile position; fourthly, mounting a pile casing and making holes; fifthly, cleaning the holes for the first time; sixthly, placing a reinforcement cage and a concrete guide pipe; seventhly, cleaning the holes for the second time; eighthly, casting and compacting concrete; ninthly, removing the guide pipe; tenthly, teeming concrete; and eleventhly, protecting a pile top. The cast-in-situ bored pile technique provided by the invention can carry out the foundation treatment in a limited space below a loading shed, pile body concrete quality and bearing capacity requirements of a bored pile can be met, and stability and safety of the ground below the loading shed are guaranteed. The cast-in-situ bored pile technique provided by the invention overcomes the defect that the existing foundation treatment method is difficult to realize a foundation treatment target in the limited space below the loading shed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

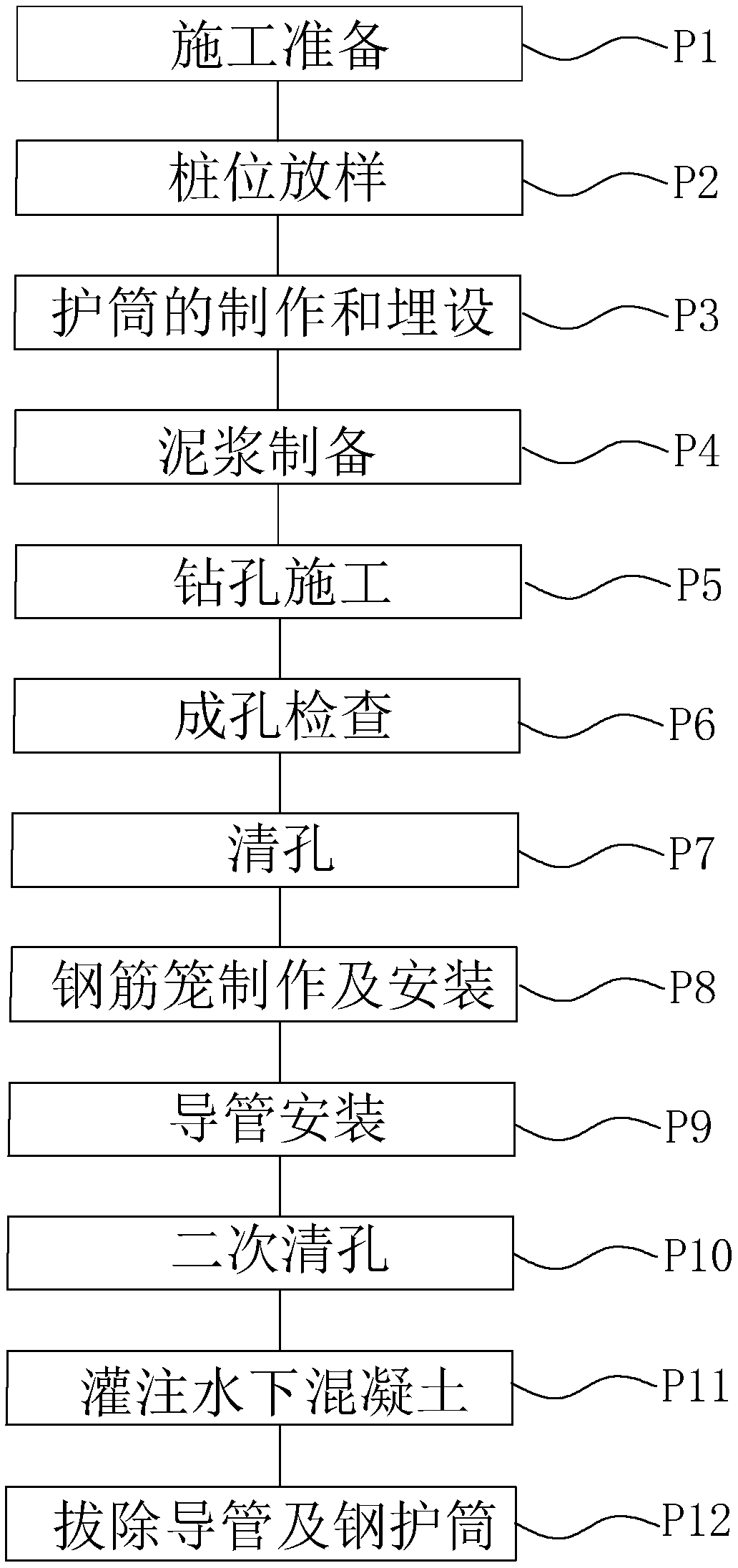

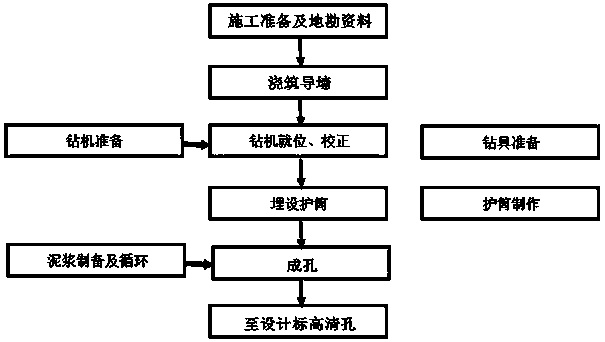

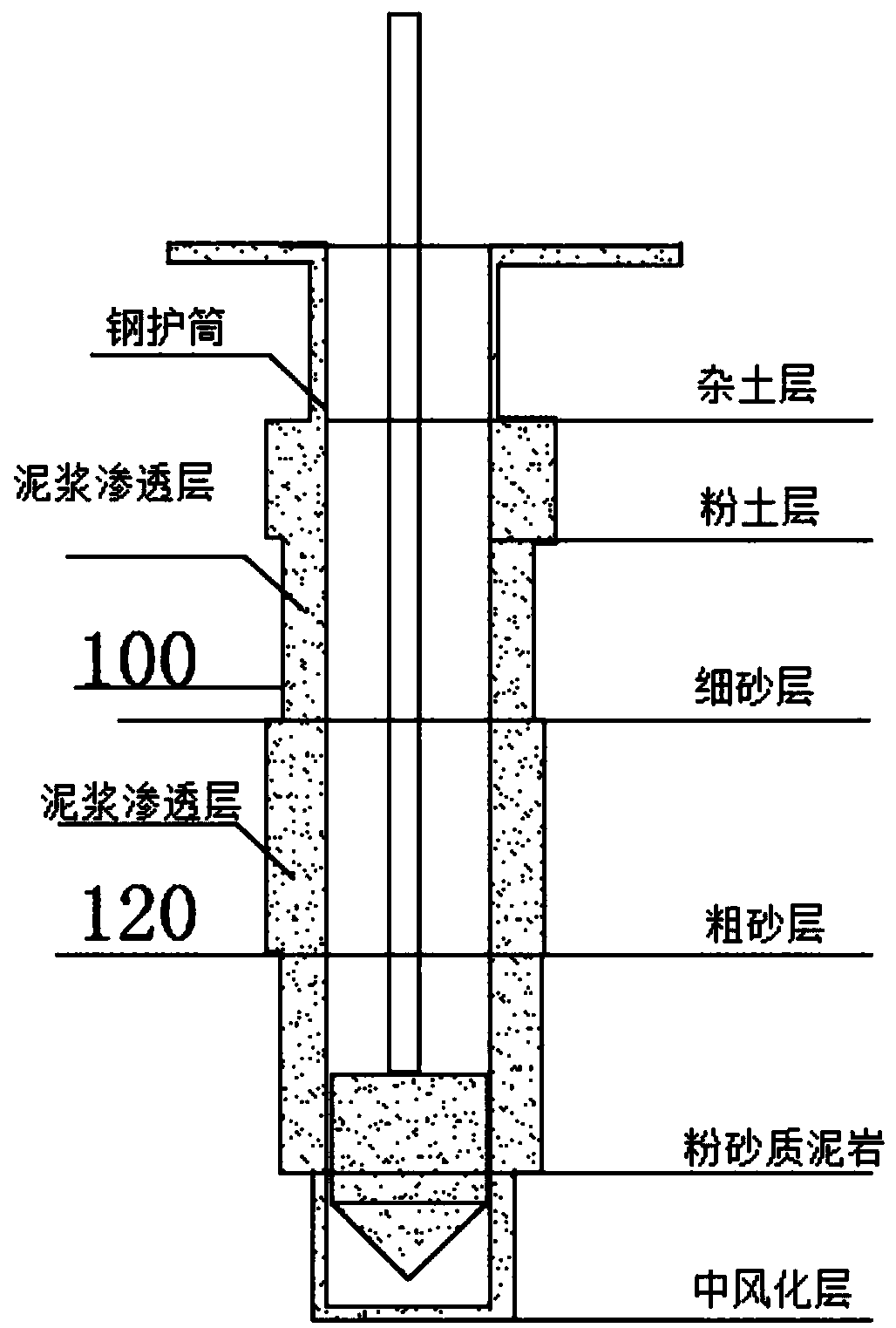

Method of pile foundation construction in miscellaneous fill region and sludge region

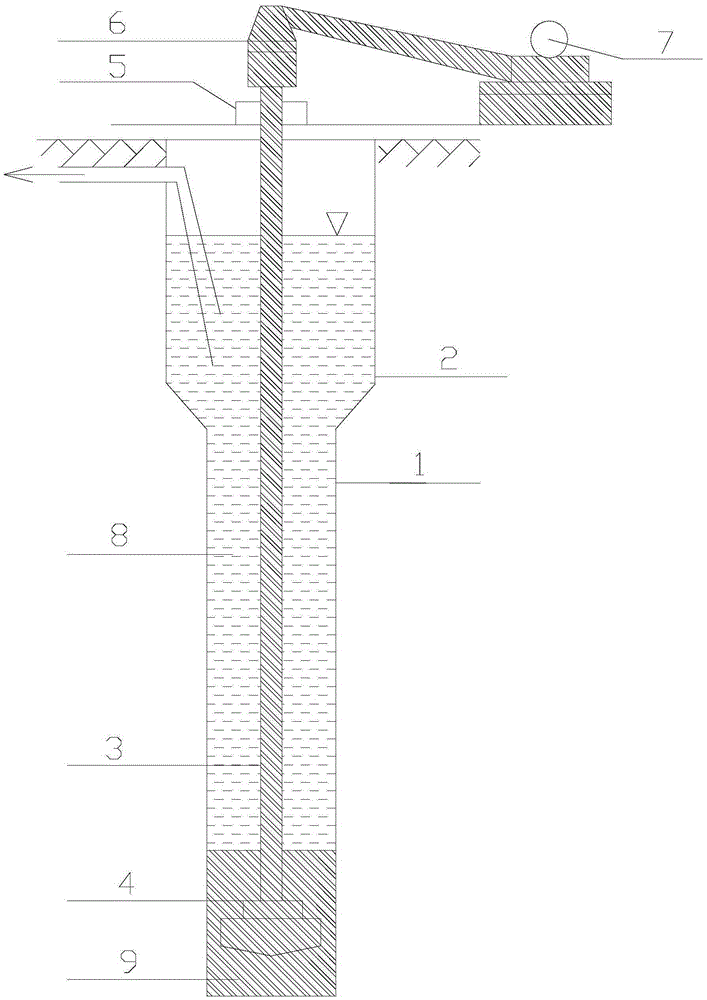

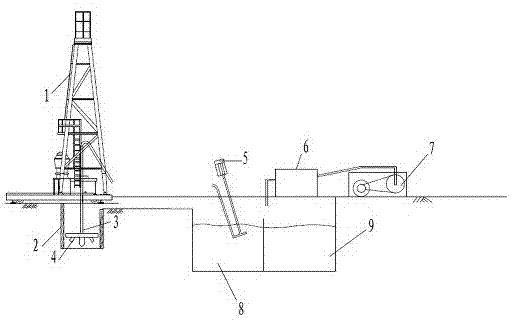

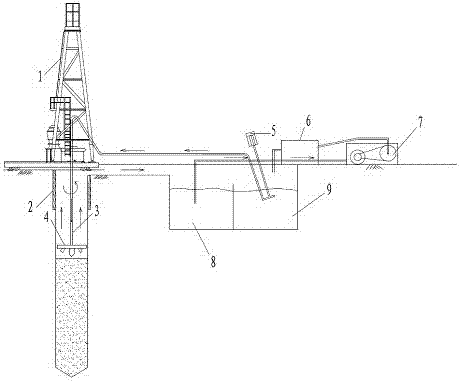

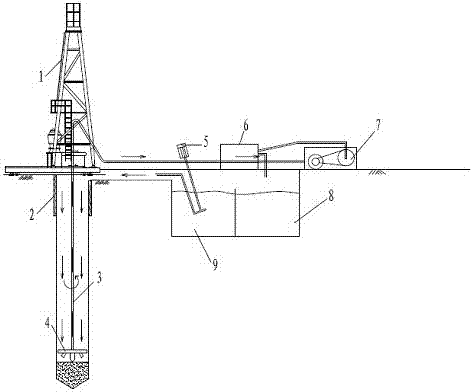

InactiveCN109469052APrevent drilling deflectionGuarantee the quality of hole formationBulkheads/pilesDrill holeEngineering

The invention provides a method of pile foundation construction in a miscellaneous fill region and a sludge region, and relates to the technical field of pile foundation construction. The common problem that due to the fact that a drilled hole is prone to collapsing in the process that pile foundation construction is conducted in the shallow sea sludge region and the miscellaneous soil backfillingregion, an abandoned hole or an abandoned pile is caused is solved. According to the technical scheme, the method is characterized by comprising the steps of construction preparation, pile position lofting, fabrication and embedment of a pile casing, slurry preparation, drilling construction, inspection of a formed hole, hole cleaning, fabrication and installation of a steel reinforcement cage, installation of a guide pipe, hole cleaning for the second time, pouring of underwater concrete and removal of the guide pipe and the steel pile casing. The method of pile foundation construction in the miscellaneous fill region and the sludge region is suitable for pile foundation construction in the miscellaneous fill region and the sludge region and achieves the purposes that the pile foundationconstruction quality is ensured, and the construction efficiency is improved.

Owner:深圳市蛇口招商港湾工程有限公司

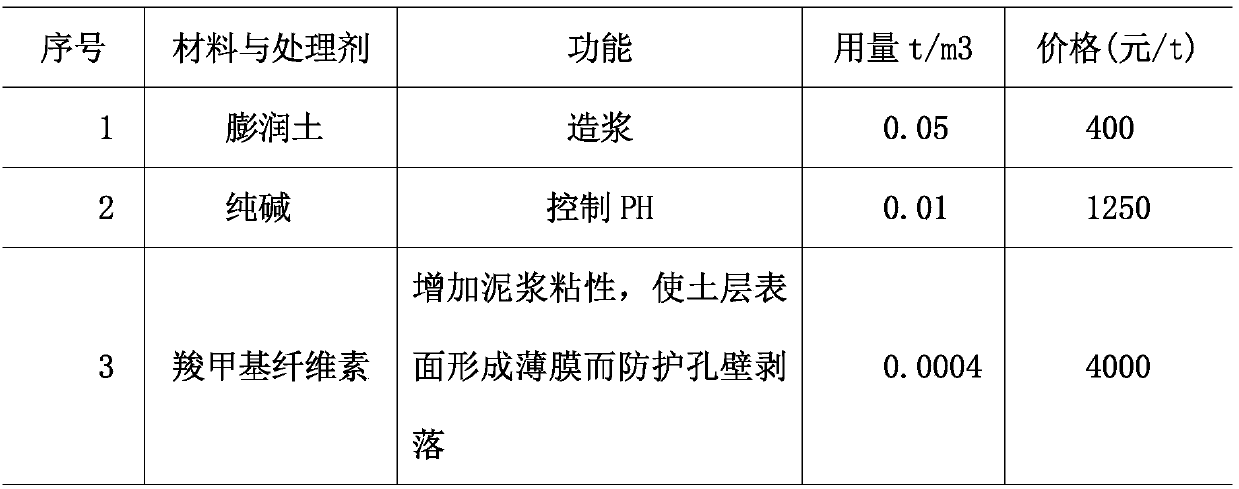

PHP mud manufacturing method and applications of PHP mud

InactiveCN105236832APrevent sinkingReduce resistanceFlushingBulkheads/pilesMaterials preparationSodium Bentonite

The invention discloses a PHP mud manufacturing method and applications of PHP mud, and belongs to the reconstruction technology field of cast-in-situ bored pile manufacturing method and applications thereof. According to the PHP mud manufacturing method, bentonite, sodium carbonate, hydroxymethyl cellulose, and polyacrylamide are taken as main raw materials, barite powder is taken as an additive. The PHP mud manufacturing method comprises following steps: a, material preparation; b, stirring of a base slurry; c, material adjusting; and d, additive adding. The invention also discloses applications of PHP mud, and PHP mud can be applied to construction of cast-in-situ bored piles. Beneficial effects are that: thixotropy is excellent; specific gravity is low, and solid phase content is low; viscosity is high; mud cover is thin; water loss is low; dispersion is not caused; and environmental protection performance is excellent.

Owner:JSTI GRP CO LTD

Positive and negative circulation construction technology of ultra-deep bored piles

ActiveCN102787815AGuarantee the quality of hole formationImprove construction efficiencyFlushingEngineeringSoil horizon

The invention relates to a positive and negative circulation construction technology of ultra-deep bored piles. The positive and negative circulation construction technology specifically comprises the following steps of: (1) carrying out site layout preparation; (2) carrying out boring of upper viscous soil layer positive circulation process; (3) carrying out boring of lower viscous soil layer positive circulation process; (4) carrying out reverse circulating cleaning after pore-forming. The invention has the beneficial effects that: the construction technology is suitable for complicated geological conditions, construction efficiency is greatly increased, and pile bore quality is effectively ensured.

Owner:SHANGHAI FOUND ENG GRP

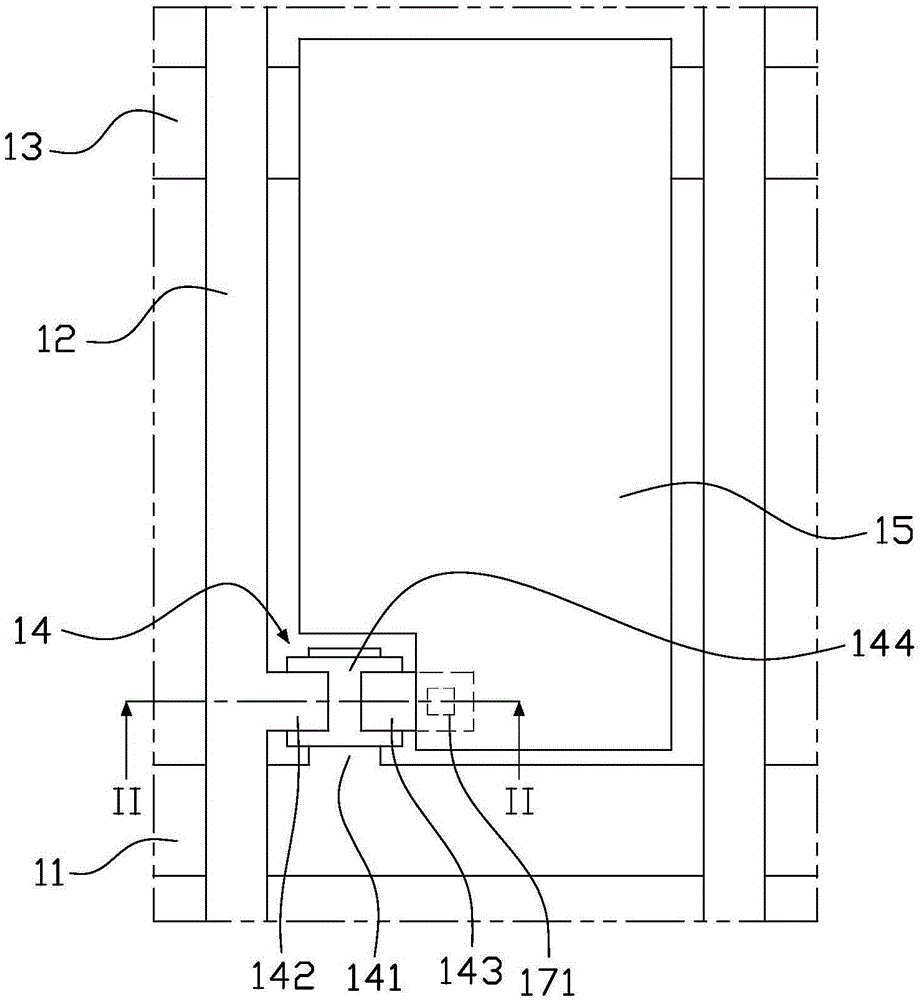

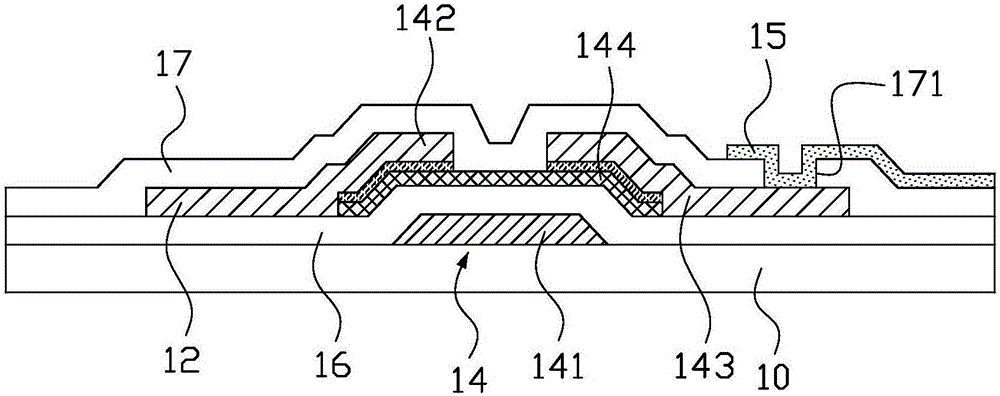

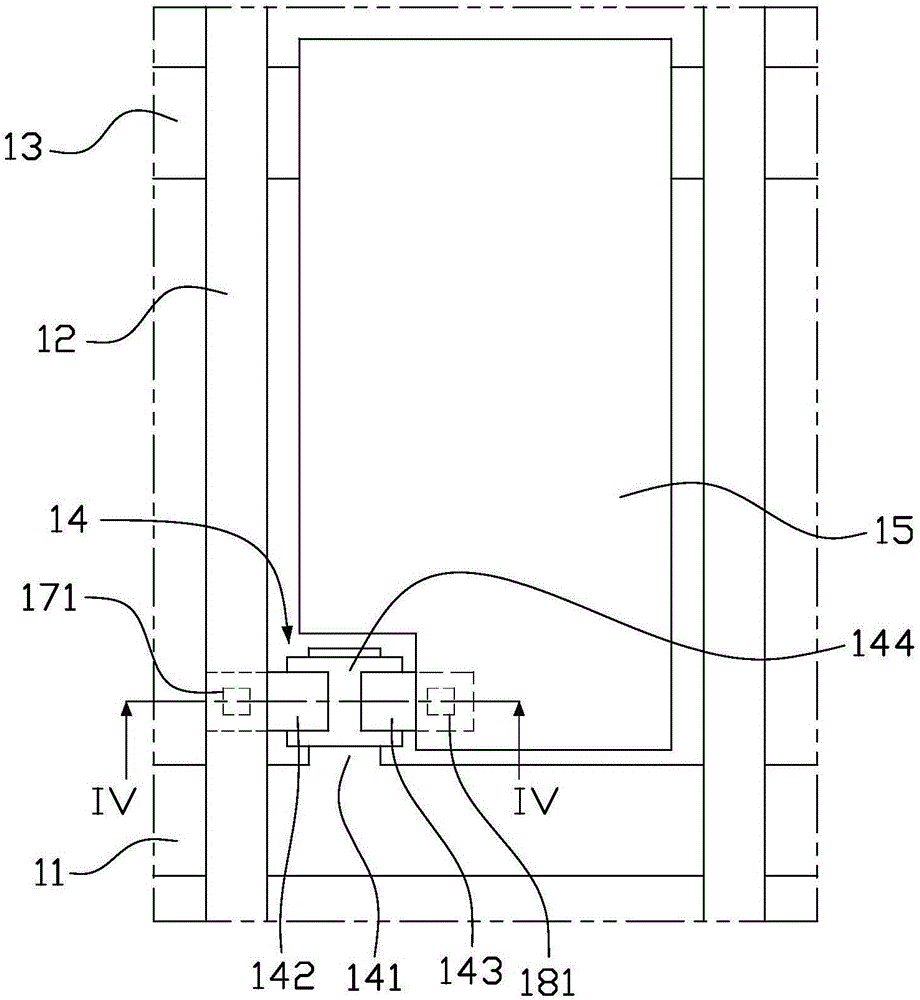

Thin film transistor array substrate, manufacturing method and liquid crystal display panel

ActiveCN106483726AIncreasing the thicknessImprove alignment accuracySolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayInsulation layer

Provided are a thin film transistor array substrate, a manufacturing method and a liquid crystal display panel. The thin film transistor array substrate comprises a substrate, a first metal layer, a first insulation layer, an active layer, a second metal layer, a second insulation layer, a third metal layer, a third insulation layer and a pixel electrode. The first metal layer is formed on the substrate and comprises a scanning line and a grid. The first metal layer is covered with the first insulation layer, and the active layer is formed on the first insulation layer. The second metal layer is formed on the first insulation layer and comprises a source electrode and a drain electrode. The second metal layer is covered with the second insulation layer, and a first contact hole and a second contact hole are formed in the second insulation layer. The third metal layer is formed on the second insulation layer and comprises a data line and a conductive block, the data line is connected with the source electrode through the first contact hole, and the conductive block is connected with the drain electrode through the second contact hole. The third metal layer is covered with the third insulation layer, and a third contact hole is formed in the third insulation layer. The pixel electrode is formed on the third insulation layer, and the pixel electrode is connected with the conductive block through the third contact hole.

Owner:KUSN INFOVISION OPTOELECTRONICS

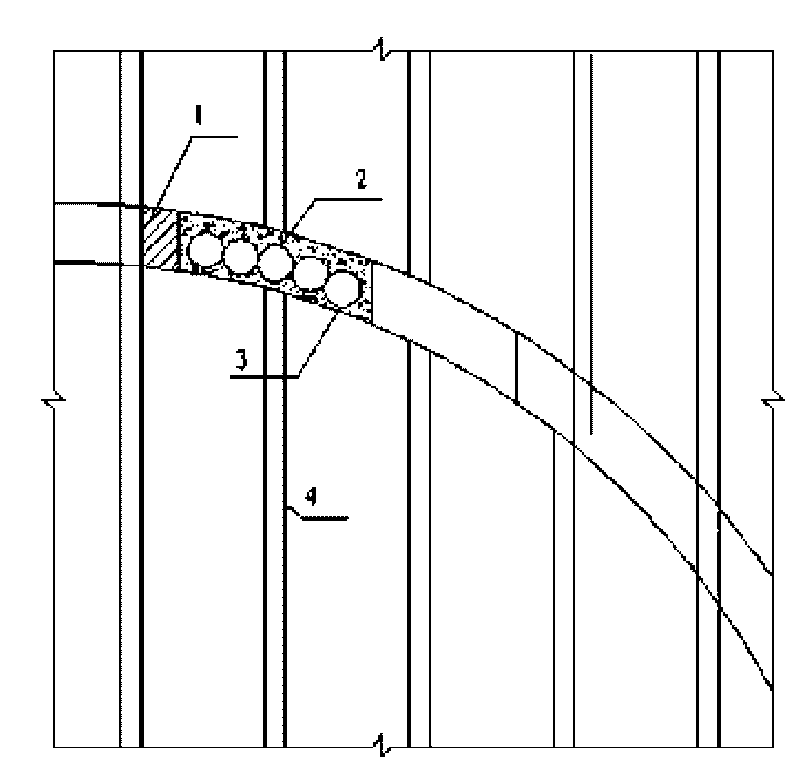

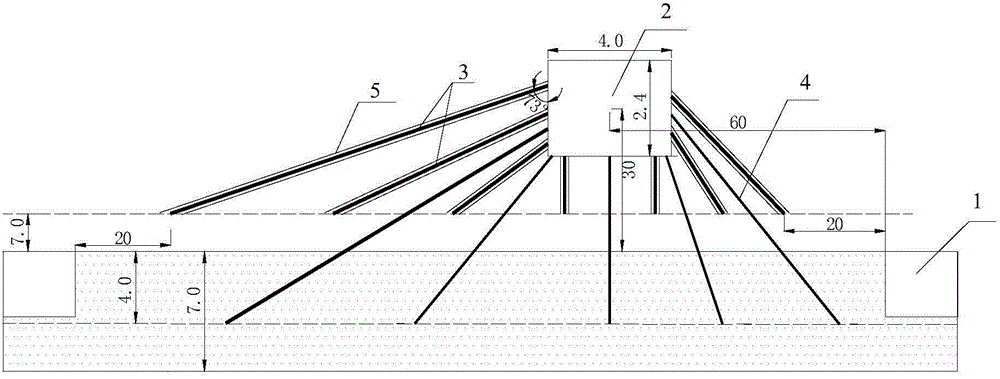

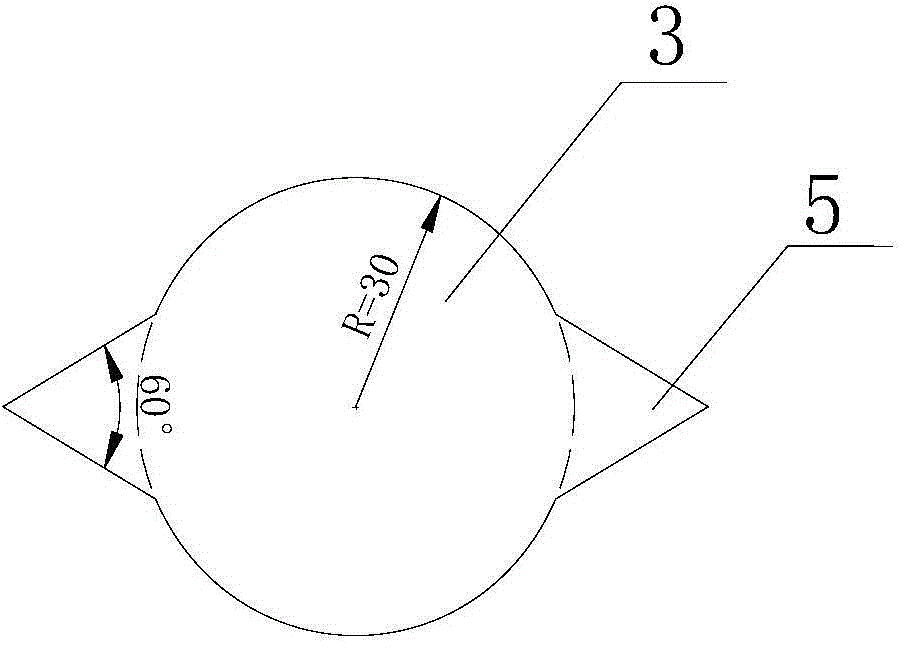

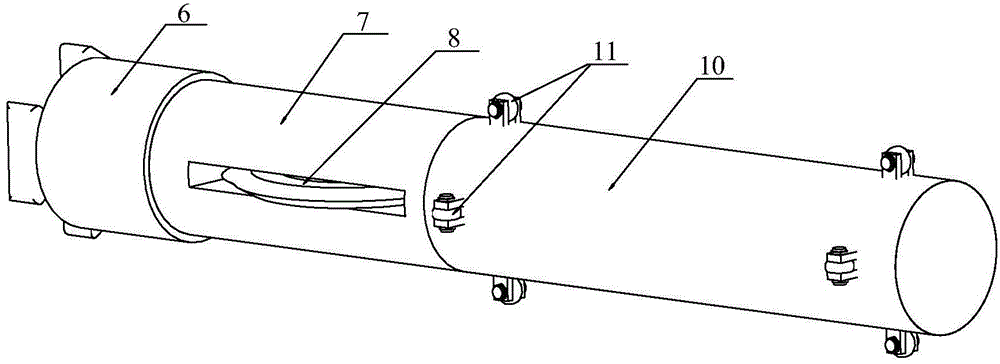

Huge thick hard roof high gas thick coal seam roof control and gas drainage efficiency improvement method and drilling machine

The invention discloses a huge thick hard roof high gas thick coal seam roof control and gas drainage efficiency improvement method and a drilling machine. The method includes: firstly constructing two crossheadings (1) along the roof in the mining coal seam, and constructing a gas high drainage roadway (2) at certain distance away from the mining coal seam top; constructing angular groove blastholes (3) and round holes (4) on two sides of the gas high drainage roadway (2) and a base plate, with the angular groove blasthole (3) comprising a round blasthole, and two ends of the round blasthole diameter being equipped with two angular groove (5); filling the angular groove blastholes (3) with explosive, and filling the bottom of the round holes (4) with 2-3 length explosive, thus finishing deep hole block blasting operation. The invention adopts the deep hole block blasting method to integrate hard roof control and coal seam permeability increase, and gas drainage efficiency improvement, and the while caving pace of the roof is effectively controlled, the coal seam air permeability is enhanced, the crack channel between the coal seam and the gas high drainage roadway is increased, and the gas drainage efficiency of the high drainage roadway is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for forming holes in long and large anchor cables in karst region

InactiveCN107503681AHole forming efficiency guaranteeGuarantee the quality of hole formationDirectional drillingBulkheads/pilesWork periodKarst

The invention provides a method for forming holes in long and large anchor cables in a karst region, and relates to the field of construction of drilling. The method for forming holes in long and large anchor cables in the karst region comprises the following steps: step one, placing a drilling machine at a suitable position; step two, carrying out exposed drilling for the first time; step three, carrying out primary pipe-following construction; and step four, carrying out secondary exposed drilling. By the method for forming holes in long and large anchor cables in the karst region, the technical problem that existing anchor cable hole forming construction is low in hole forming efficiency, high in cost and long in working period is solved.

Owner:CCFEB CIVIL ENG

Construction method for drilling of rotary drilling rig in complicated geological formation

PendingCN109025807AAdvantages of working condition quality requirementsCost advantageBulkheads/pilesDrilling machines and methodsRock coreHardness

The invention discloses a construction method for drilling of a rotary drilling rig in a complicated geological formation. The method includes steps: wedge-shaped angle steel is welded on inner wallsof a cylindrical drill and a roller bit by employing an improved cone cylindrical drill or a pick cylindrical drill to enable the periphery of rocks to perform crushing cutting, after the top is clamped with a rock core, the rock core is twisted off back and forth through forward and reverse rotation to directly bring out a rock sample, the problems of difficult hole forming in the hard rock formation and hole shift and hole deviation caused by uneven pile heads of two sides of an engagement pile are solved, the influence of drilling on pile forming is effectively reduced, the construction efficiency and the construction quality are improved, and the construction cost is reduced. According to the construction method, compared with a percussion drilling construction method, the footage speed is fast, the footage of a percussion drilling at each time is usually 0.5-0.8 m, the rotary drilling rig can achieve the footage of 5-10 meters in cooperation with a drilling tool at each time, thedrilling machine can be sensed in time during change of the hardness of the formation, the rotating speed of the drilling machine and the pressure are adjusted to control the verticality of holes, andthe hole-forming quality is guaranteed.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

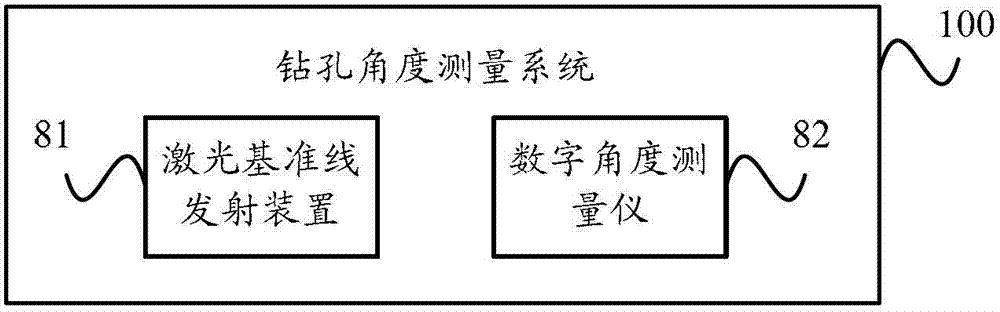

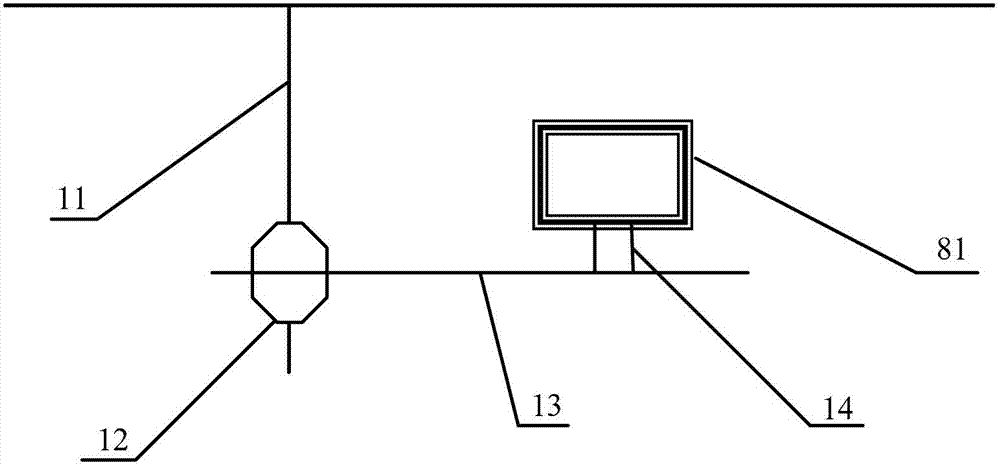

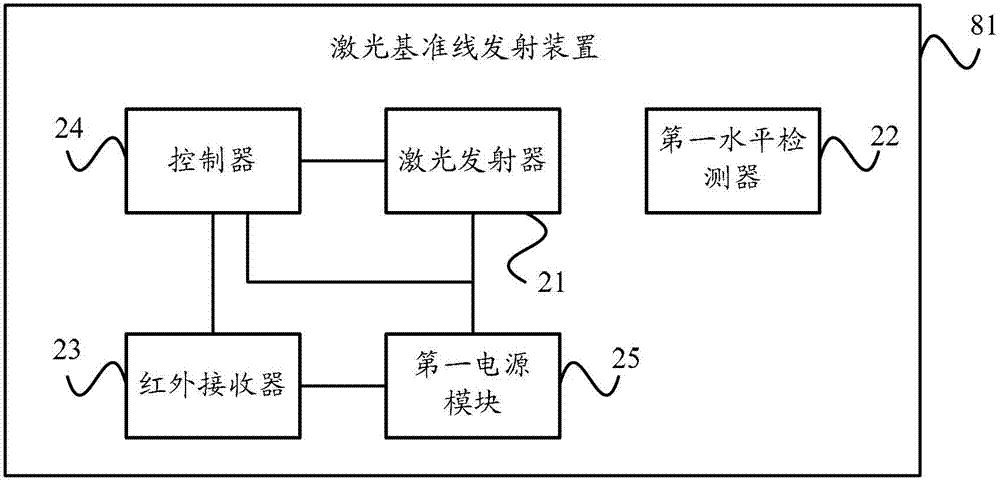

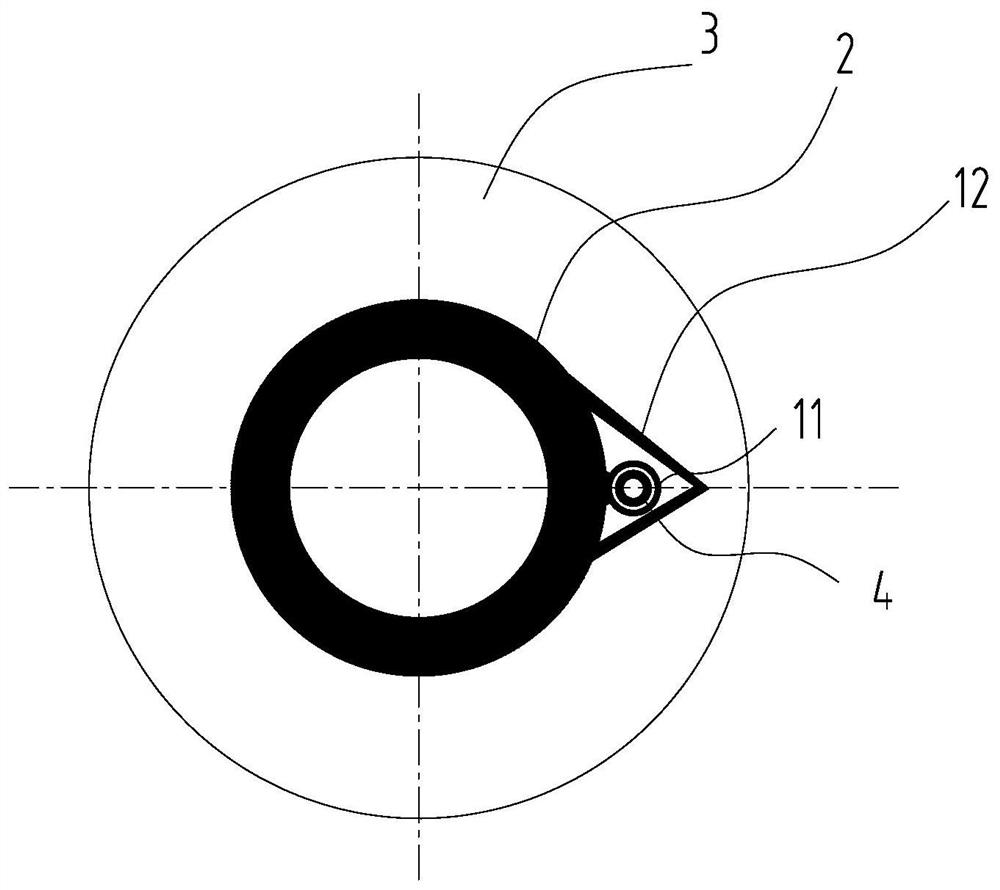

Coal mine drilling angle measuring system and method

ActiveCN102889075AGuarantee the quality of hole formationAvoid the defect of large measurement errorSurveyOptoelectronicsCoal mine methane

The invention provides a coal mine drilling angle measuring system and method; the coal mine drilling angle measuring system comprises a laser reference line transmitting device and a digital angle measuring device, wherein the laser reference line transmitting device is used for generating a first laser plane and a second laser plane, which are vertical to each other; the first laser plane is coincided with an intersecting line of inner walls of a roadway and a midline of the roadway; the second laser plane is intersected with a drill pipe to be measured; the digital angle measuring device is used for measuring the angle of the drill pipe according to the second laser plane; and the digital angle measuring device is arranged on the drill pipe intersected with the second laser plane. Through the adoption of the coal mine drilling angle measuring system and method provided by the invention, the accuracy of drilling angle measuring parameters is enhanced, the construction quality of coal mine gas treatment drill hole is guaranteed, and a gas treatment effect is enhanced.

Owner:HUAINAN MINING IND GRP

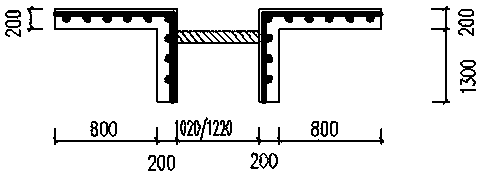

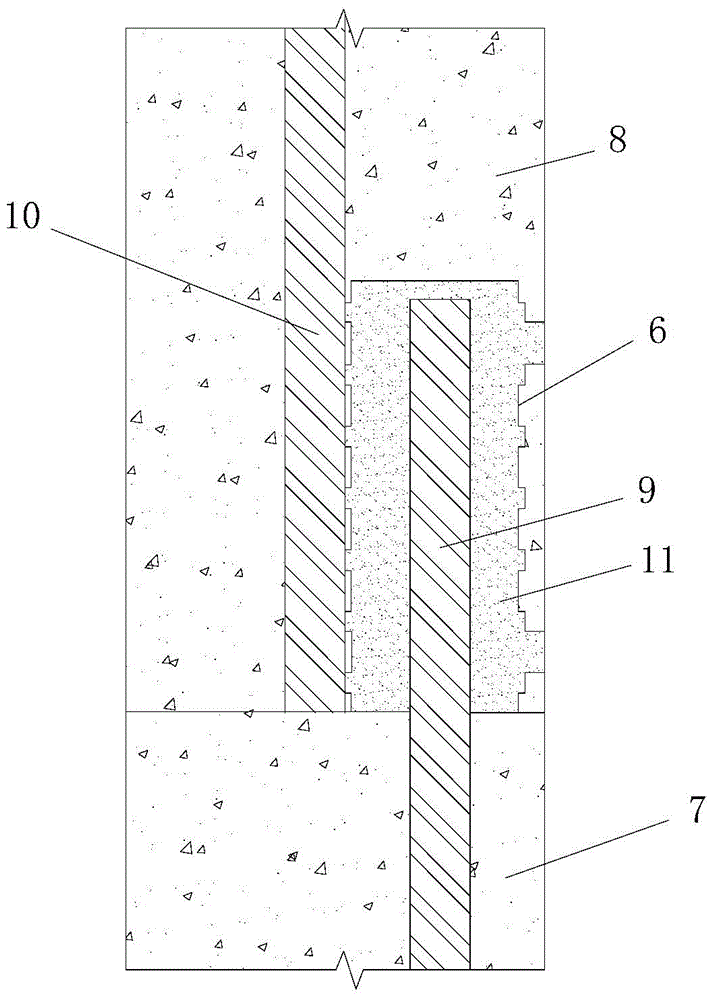

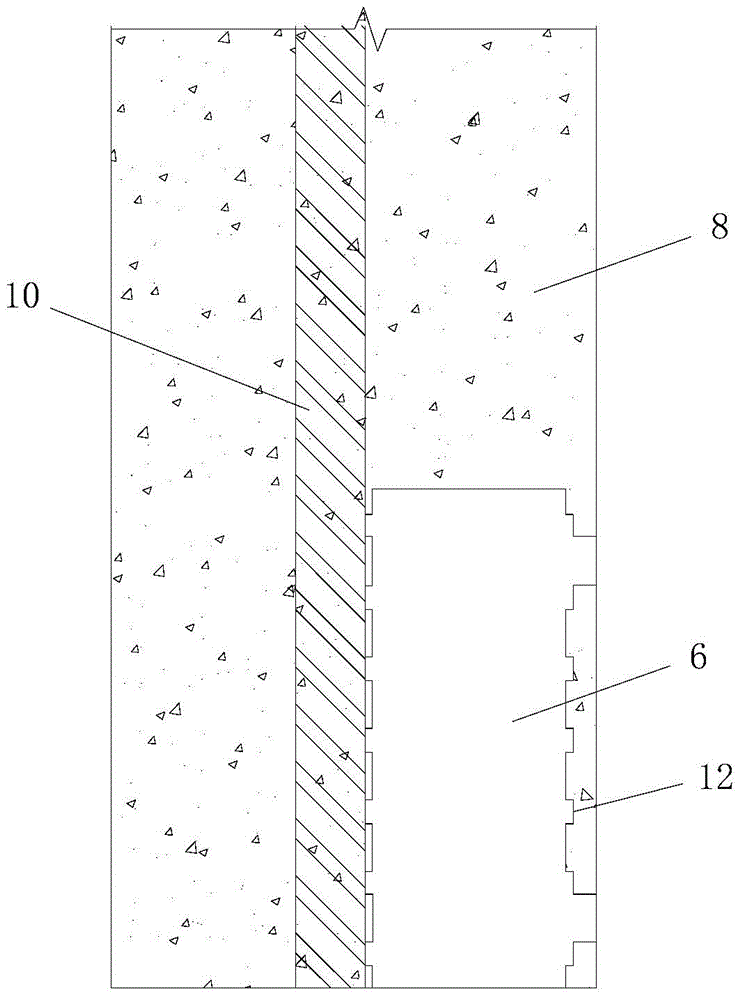

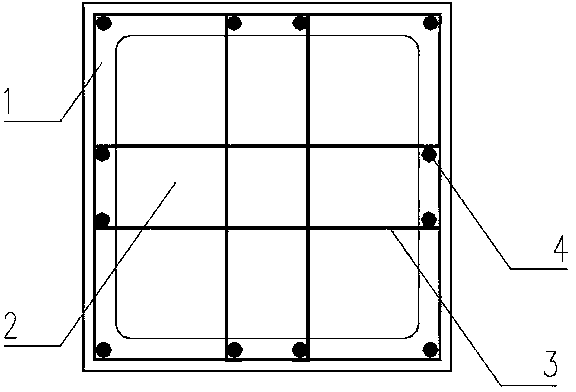

Steel bar anchoring connection structure and connection method for precast fabricated concrete components

InactiveCN105019558ASimple connection structureReasonable designMouldsBuilding reinforcementsRebarPre embedding

The invention discloses a steel bar anchoring connection structure and connection method for precast fabricated concrete components. The steel bar anchoring connection structure comprises the first precast concrete component and the second precast concrete component located above the first precast concrete component, and the bottom of the second precast concrete component is provided with a steel bar anchoring preserved hole used for anchoring of a first steel bar pre-embedded in the first precast concrete component; a grouting structure is arranged in a cavity between the steel bar anchoring preserved hole and the first steel bar; the steel bar anchoring preserved hole is located on the outer side of the lower portion of a second steel bar laid out in the second precast concrete component, and multiple grooves are formed in the inner side wall of the steel bar anchoring preserved hole. The steel bar anchoring connection method comprises the first step of precasting of the second precast concrete component, the second step of hoisting of the second precast concrete component and inserting mounting of the first steel bar, the third step of grouting and the fourth step of maintenance. The steel bar anchoring connection structure and connection method for the precast fabricated concrete components are reasonable in design, convenient to achieve, good in use effect, capable of completing the steel bar connection process easily, conveniently and rapidly and reliable in connection.

Owner:CHANGAN UNIV

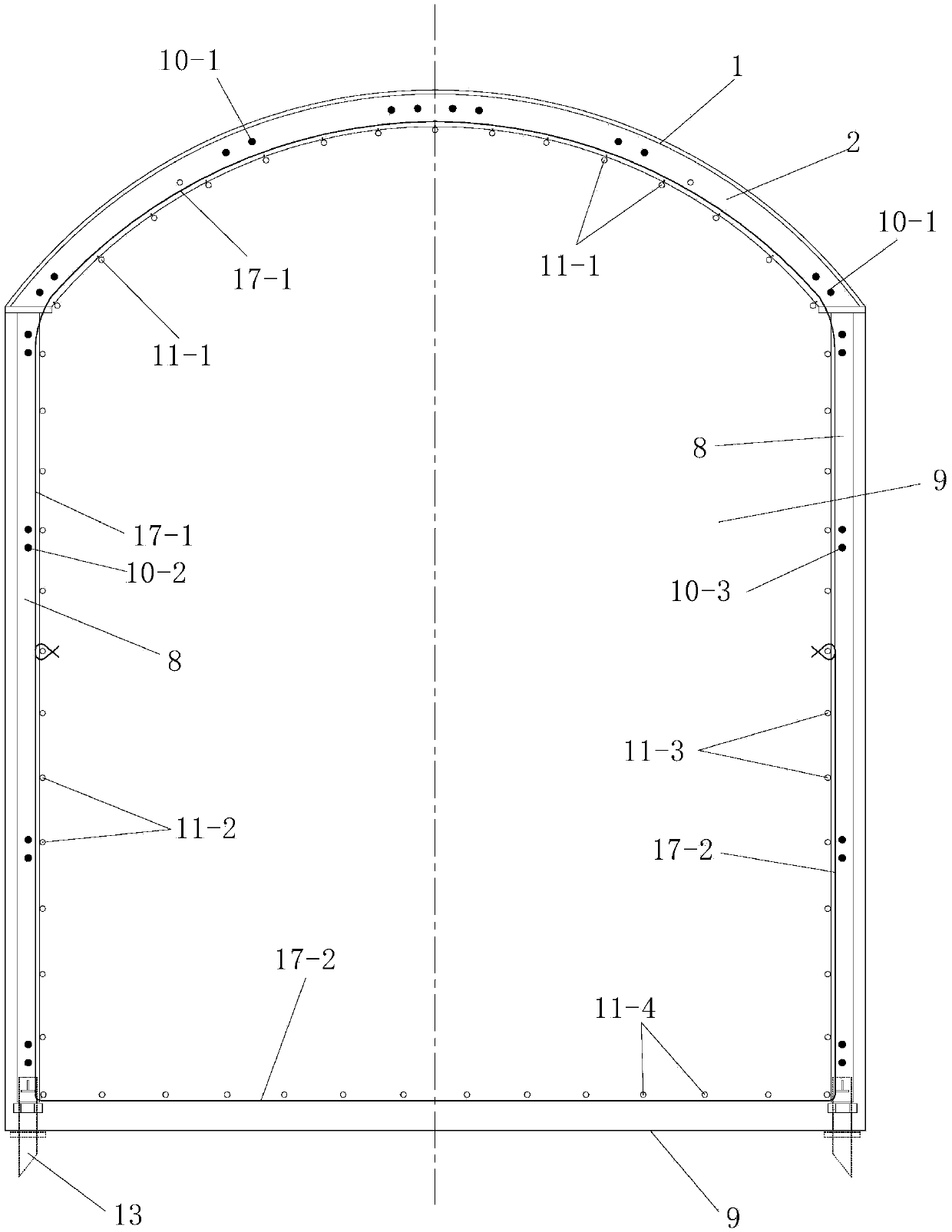

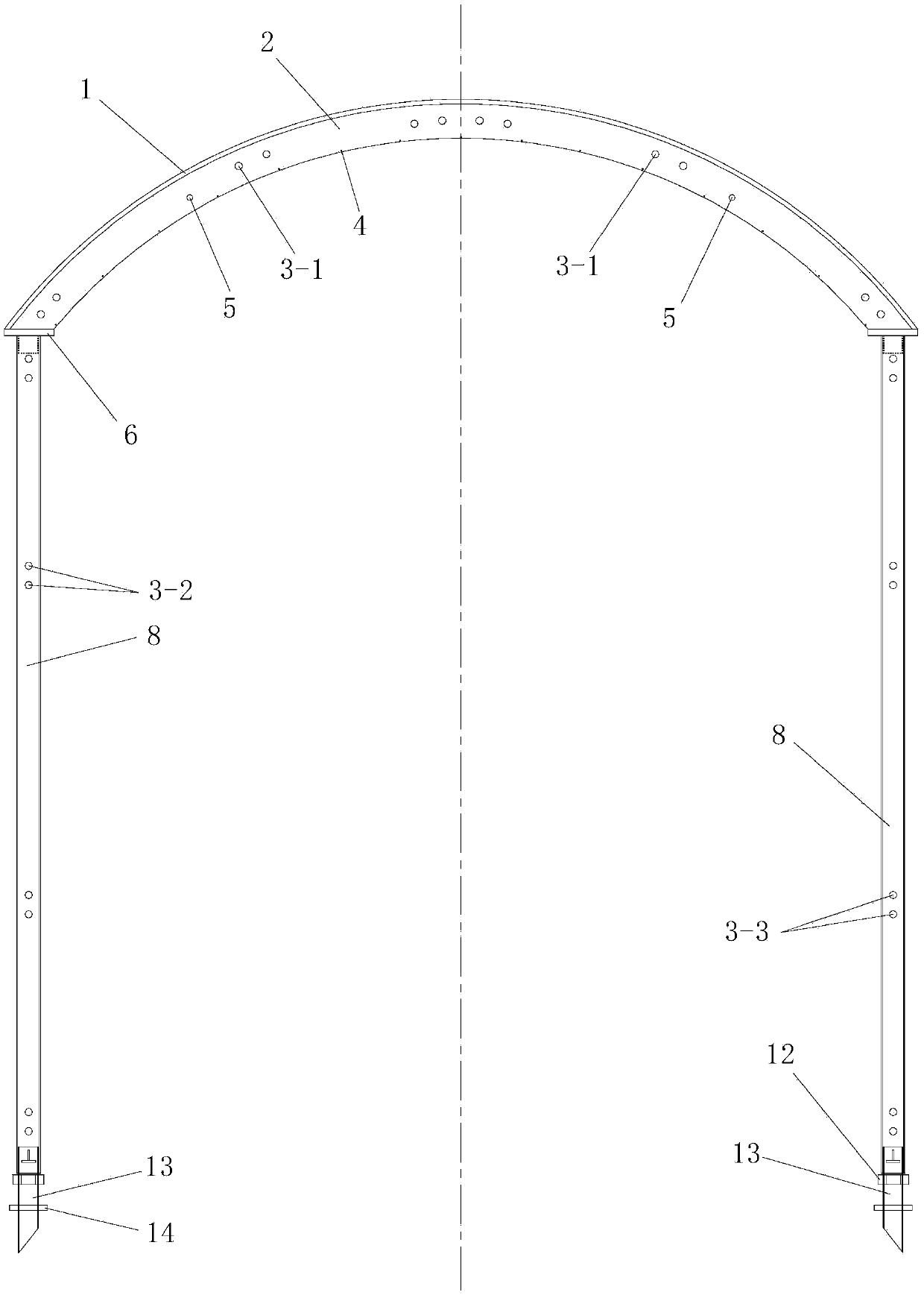

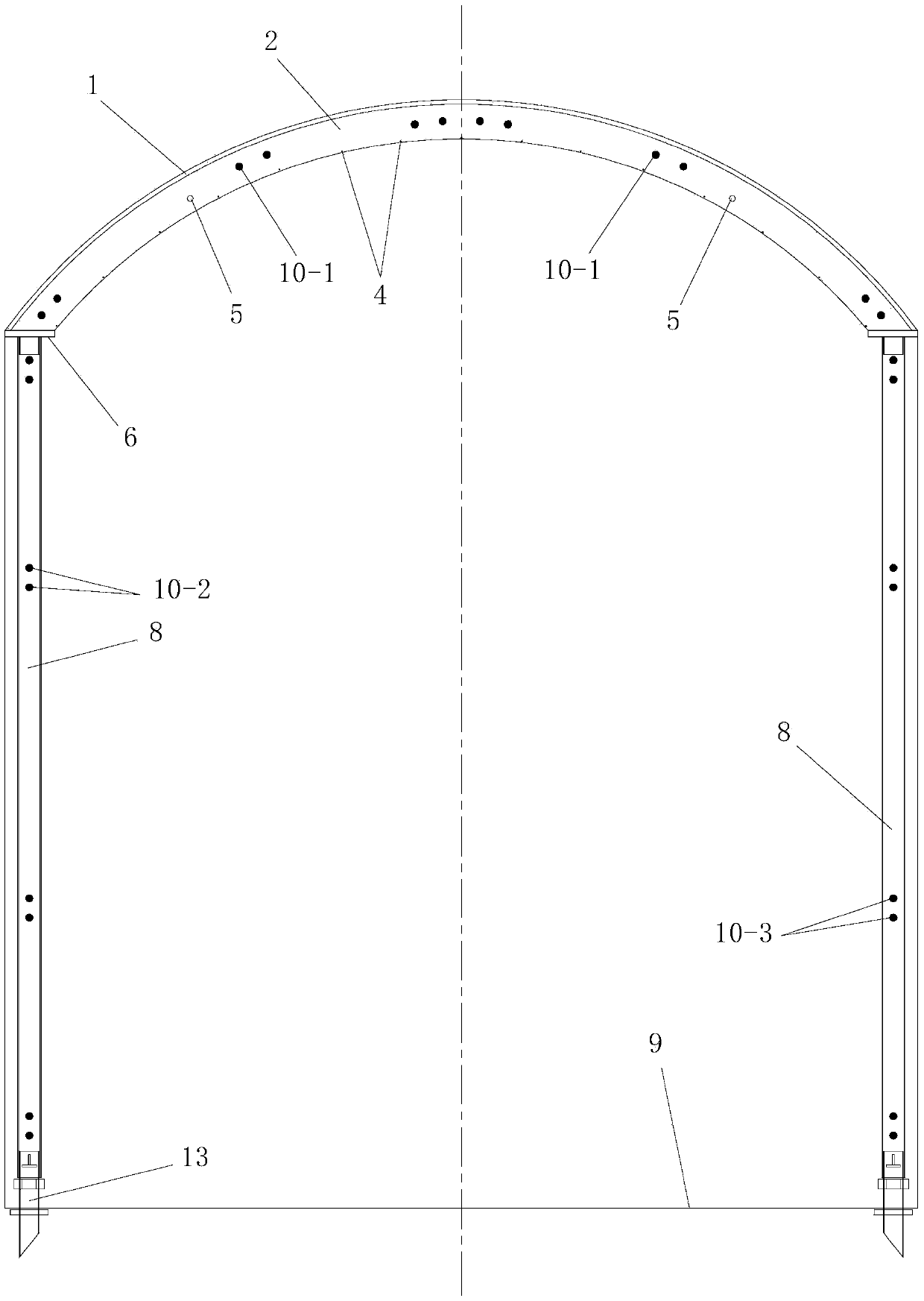

Supporting and bar-arranging structure for arch bridge raking pile hole forming construction

ActiveCN105369802ASimple structureReasonable designArch-type bridgeBulkheads/pilesArch bridgeContour line

The invention discloses a support and reinforcement structure for arch bridge raking pile hole forming construction. The support and reinforcement structure comprises a plurality of support frames, a plurality of first longitudinal connecting ribs, a plurality of second longitudinal connecting ribs, a plurality of third longitudinal connecting ribs and a plurality of fourth longitudinal connecting ribs, wherein the support frames are supported in a raking pile hole, and the first longitudinal connecting ribs, the second longitudinal connecting ribs, the third longitudinal connecting ribs and the fourth longitudinal connecting ribs are laid along the excavation contour line of the raking pile hole; the support frames are laid on the length direction of the raking pile hole from front to back, are laid in parallel and are perpendicular to the raking pile hole, and the distance between every two adjacent support frames is 50-100cm; each support frame comprises an arc-shaped support and two side supports, the two side supports are respectively a left side support and a right side support symmetrically supported under the left side and the right side of the arc-shaped support. The support and bar-arranging structure has the advantages of being simple in structure, reasonable in design, convenient to construct and good in using effect. The excavated raking pile hole is effectively supported, and the ribs are arranged in the raking pile hole, so that the hole forming quality of the raking pile hole can be effectively ensured.

Owner:ZHONGJIAO TONGLI CONSTR

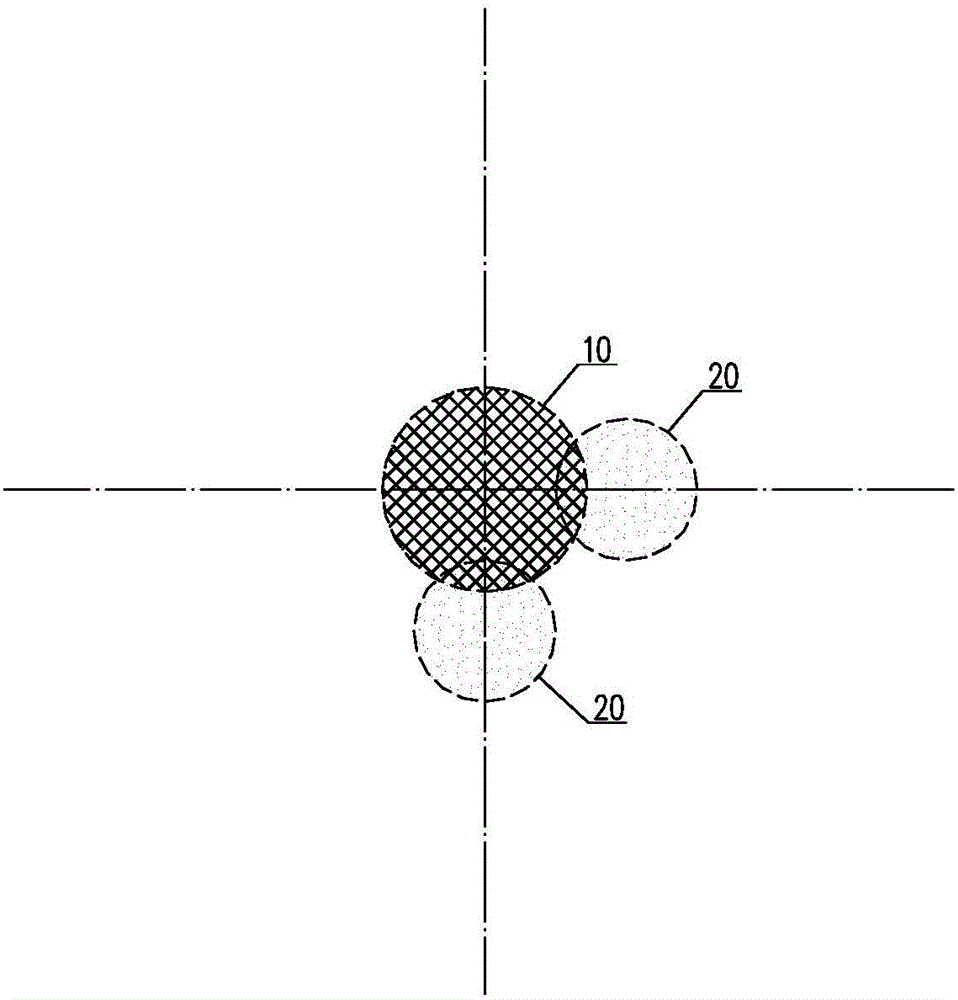

Semi-mechanical hole-forming method for super-large diameter hard rock cast-in-place pile

ActiveCN106759282AReduce construction difficultyImprove construction efficiencyBulkheads/pilesEngineeringDeep excavation

The invention relates to a semi-mechanical hole-forming method for a super-large diameter hard rock cast-in-place pile. The semi-mechanical hole-forming method comprises the following steps that firstly a pile position is positioned and measured, specifically, at first, a central pile hole is drilled through mechanical hole drilling, the hole center of the central pile hole coincides with the center of the pile position, and the hole diameter of the central pile hole is 45-50% of the diameter of a pile body of the cast-in-place pile; then a plurality of peripheral side pile holes evenly distributed along the periphery of the central pile hole are drilled in the periphery of the central pile hole through mechanical hole drilling, and the hole diameter of each peripheral side pile hole is 30-35% of the diameter of the pile body of the cast-in-place pile; and finally, hole broadening operation is conducted at the bottom of the pile holes, the pile bottom diameter after the pile is broadened is 1.5-2 times the diameter of the pile body of the cast-in-place pile. According to the semi-mechanical hole-forming method for the super-large diameter hard rock cast-in-place pile, the construction schedule of a pile foundation can be ensured, and the difficulty that the cost of mechanical pile bottom broadening is high is solved; compared with a procedure, downward excavation from the ground, of a traditional man-dug pile, the man-dug pile is constructed after large excavation, large and deep excavation is not needed, so that construction safety is ensured, and cost is saved; and in addition, the hole-forming quality can be ensured through manual hole broadening and building.

Owner:ANHUI INST OF BUILDING RES & DESIGN

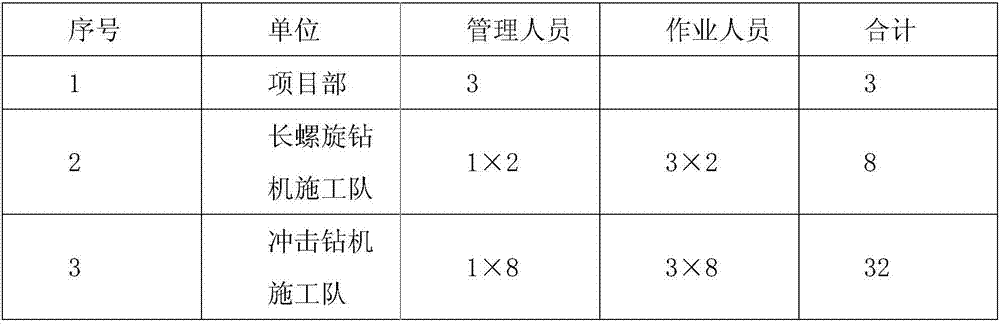

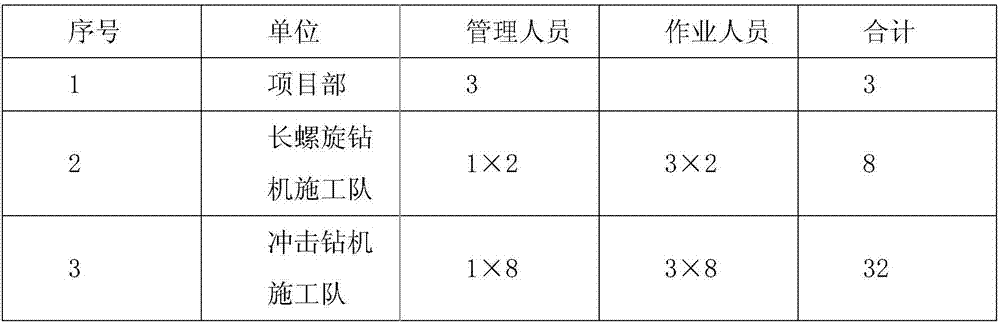

Long spiral drilling and percussion drilling dual-machine composite pore-forming grouting pile construction method

ActiveCN107130592ALow costImprove hole qualityBulkheads/pilesComposite constructionEnvironmental resistance

The invention discloses a long spiral drilling and percussion drilling dual-machine composite pore-forming grouting pile construction method. The method comprises the following steps of (1) construction preparation, (2) long spiral drilling primary pore forming, (3) percussion drilling machine secondary chambering and rock entering, (4) the from-inside-to-outside one-spiral multi-percussion dual-machine joint construction technology, and (5) reinforcement cage placement and concrete pouring. According to the method, under the condition of guaranteeing the pore-forming quality, the pore-forming efficiency and rock-entering depth are greatly improved through the construction technology, and the construction efficiency is greatly improved; spiral and percussion composite construction is achieved, the noise and vibration duration is short, and the phenomena of pile breaking, virtual piles, necking down, hole collapse and repeated construction are avoided; and several devices carry out construction at the same time, the foundation treatment speed is increased, a user can use a foundation in advance, and social and environment protection benefits are remarkable.

Owner:荣泰建设集团有限公司

Construction method of medium-hole vibrating casing wall protection type long spiral cast-in-situ bored pile

The invention relates to a construction method of a medium-hole vibrating casing wall protection type long spiral cast-in-situ bored pile. The construction method comprises the steps that surveying and setting-out are conducted for determining a pile position, and a long spiral drilling machine is made to be aligned to the pile position; the long spiral drilling machine is started, and a spiral drill rod and a drill bit are driven to conduct rotary drilling vertically downwards; a medium-hole vibrating hammer is started at the same time to drive a pile casing to follow up vertically downwards to a preset pile end depth; the spiral drill rod idles, so that residue soil at the bottom is discharged; the drill rod is lifted, concrete is poured into a pile hole while the spiral drill rod is lifted, and concrete pouring is stopped after the spiral drill rod is lifted to a preset height; after concrete pouring is completed, the pile casing is left in the pile, the long spiral drilling machine is removed out of the pile hole, and a steel bar insertion device and a steel reinforcement cage are inserted into the poured concrete together by means of a crane while being vibrated; and after the steel reinforcement cage is inserted to a preset depth, the steel rib insertion device is pulled out, the pile casing is completely pulled out, and the cast-in-situ pile is solidified and formed. The construction method of the medium-hole vibrating casing wall protection type long spiral cast-in-situ bored pile has the advantages that the quality of the cast-in-site pile is high, construction is safe, the cost is low, the speed is high, environmental friendliness is achieved, and results are practical.

Owner:HENAN JINYUAN FOUND ENG CO LTD

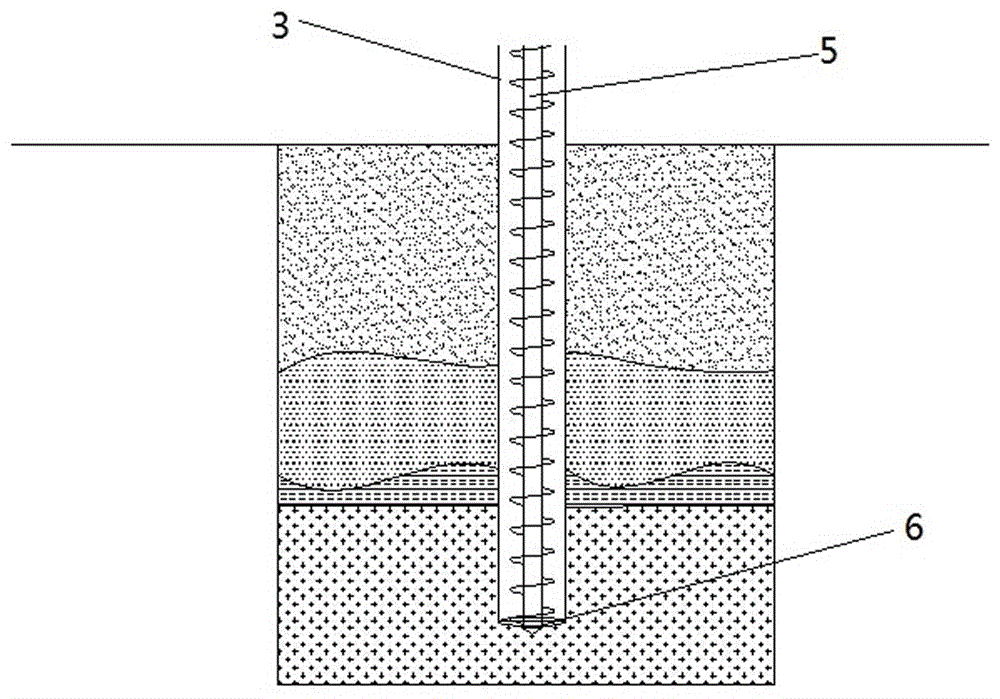

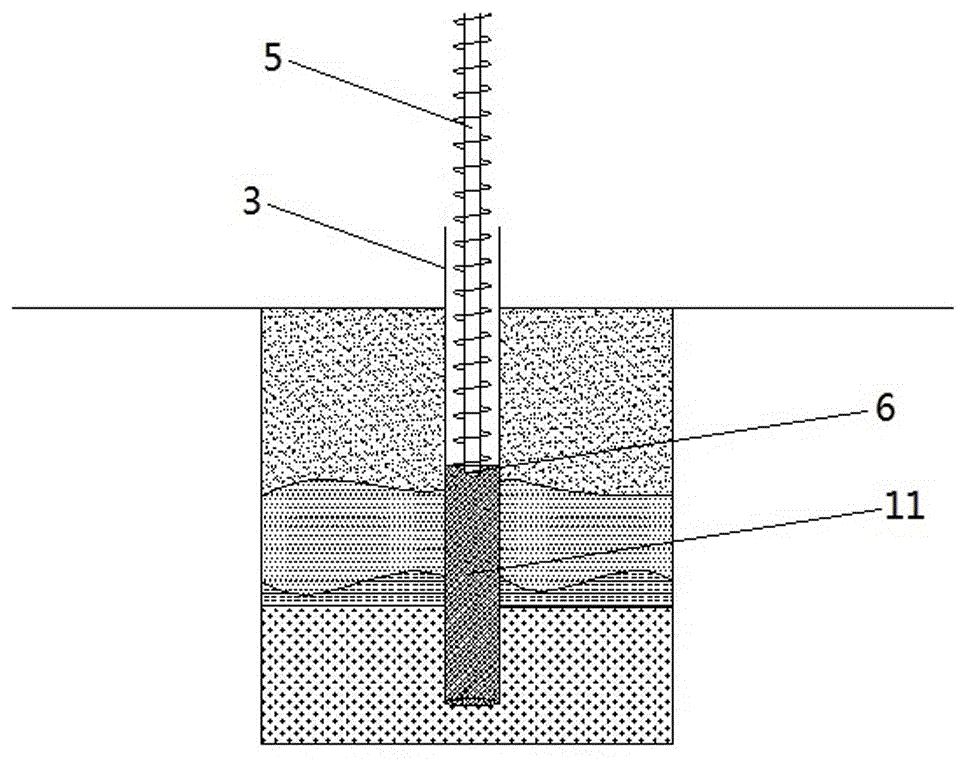

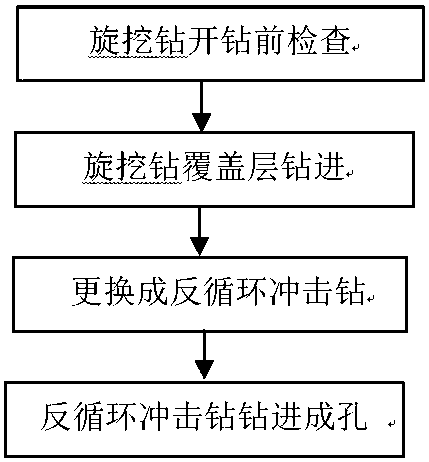

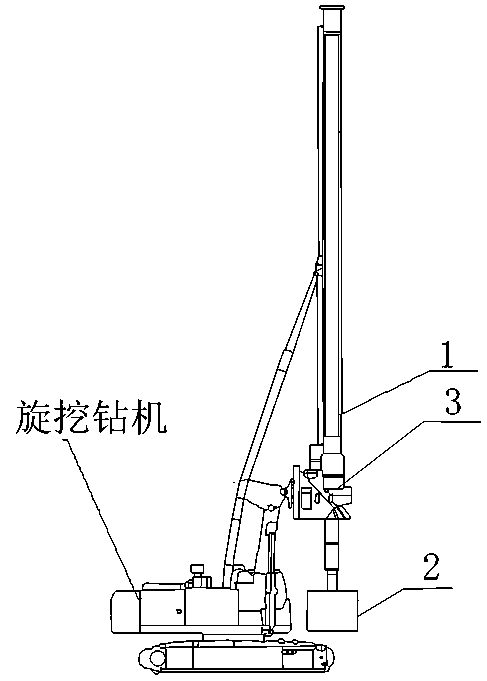

Rapid hole-forming construction method of large-diameter deep hole pile foundation under karst geology

InactiveCN111594041AEasy to moveAvoid drilling difficulties, low efficiency and other problemsDrilling drivesFlushingKarstEconomic benefits

The invention discloses a rapid hole-forming construction method for a large-diameter deep hole pile foundation under karst geology. 'Rotary drill and reverse circulation impact drill' combined relaydrilling is performed, a rotary drill rapidly performs drilling construction of a covering layer, and a reverse circulation impact drill is used for relay construction when a karst geological layer isdrilled. The combined construction process gives full play to the advantages of the two kinds of drills under the situations of different geological conditions and hole depths, the advantages are complemented with each other, and the construction efficiency and economic benefits of the large-diameter deep hole pile foundation under the karst geology are improved. Drilling of single drilling equipment is converted into combined drilling of the two different kinds of drilling equipment, the construction progress of the pile foundation is greatly accelerated under the condition of ensuring the hole-forming quality of the pile foundation, meanwhile, environmental friendliness is better achieved, civilized construction is facilitated, input of personnel and mechanical equipment is reduced, andthe good economic benefits are generated.

Owner:THE 5TH ENG MBEC

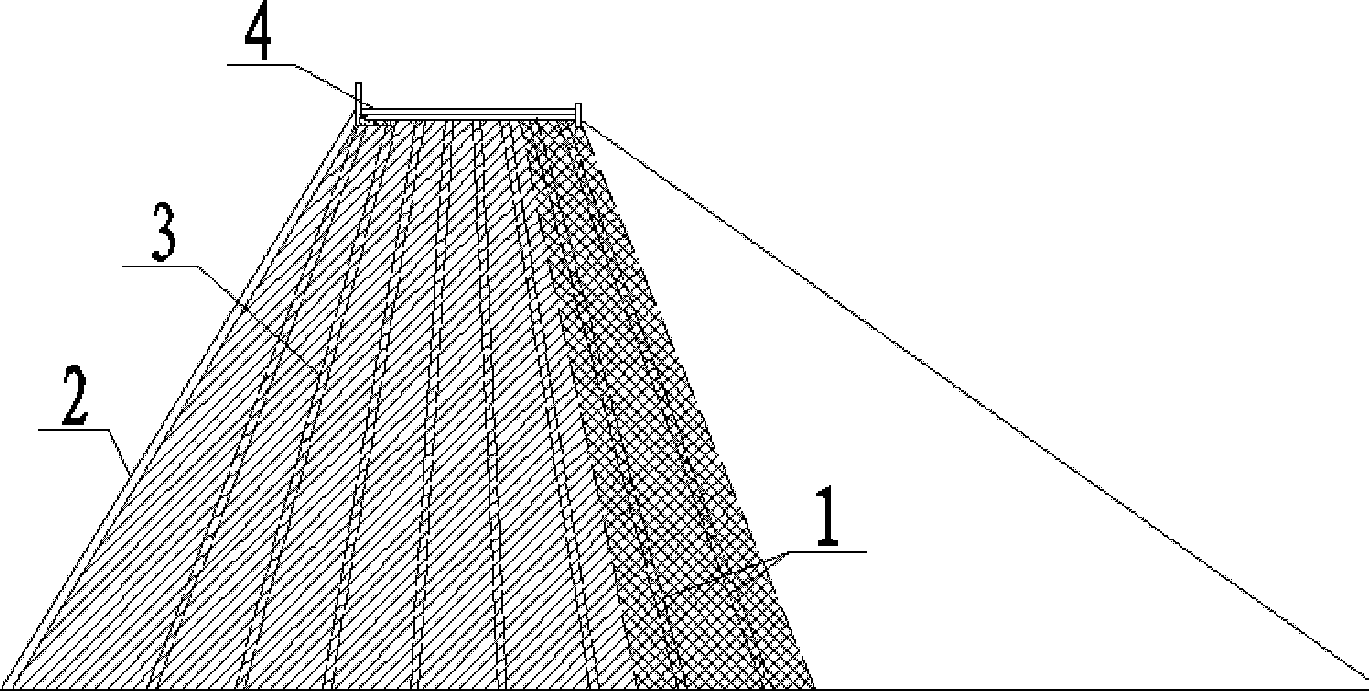

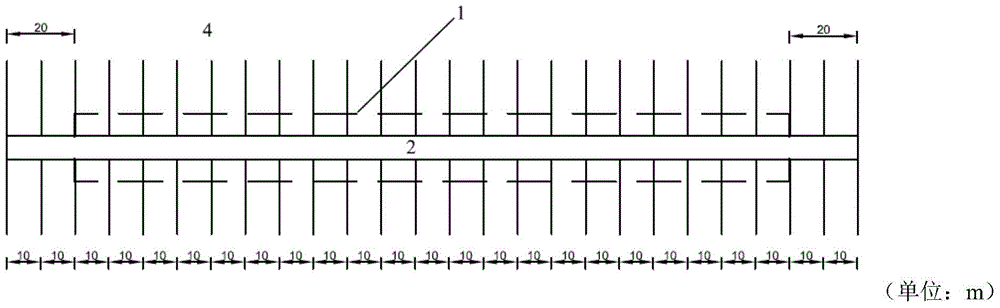

Rock-fill dam deformation control technology

InactiveCN102493403APotableControllableFoundation engineeringEarth-fill damsSlurryDeformation control

The invention belongs to the technical field of hydraulic and hydro-power engineering, and discloses a rock-fill dam deformation control technology which can be applied to diseased rock-fill dams or rockfill deformation control in the hydraulic and hydro-power engineering. The rock-fill dam deformation control technology comprises the following steps of: 1, preparing a pasty stable grouting liquid and cement mortar; 2, drilling holes in the dam body of the rock-fill dam, wherein the holes comprise stable grouting liquid grouting holes for sealing, and filling grouting holes; and 3, grouting: injecting the pasty stable grouting liquid into two rows of holes around a filling grouting area to make the pasty stable grouting liquid and a concrete panel on the upstream side of the rock-fill dam form an enclosed area, injecting the cement mortar into holes in the grouting area in an orifice filling mode after the pasty stable grouting liquid has been injected for 14 days, and controlling the rock-fill dam deformation after the grouting area has been grouted for 28 days. By the rock-fill dam deformation control technology, the deformation resistance of the rock-fill dam can be improved, the deformation of the dam body can be controlled, the grouting quality can be guaranteed, and the rock-fill dam deformation control technology has the advantages of short construction period, high work efficiency and the like.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

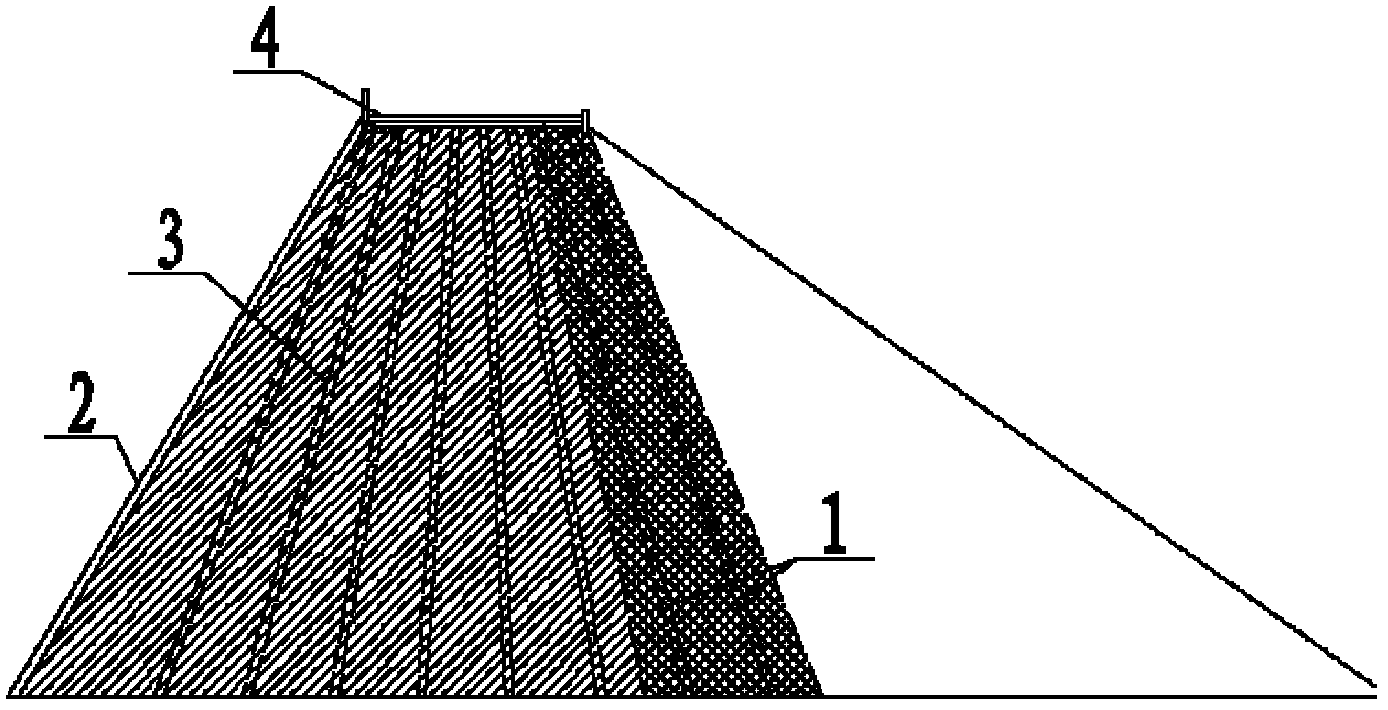

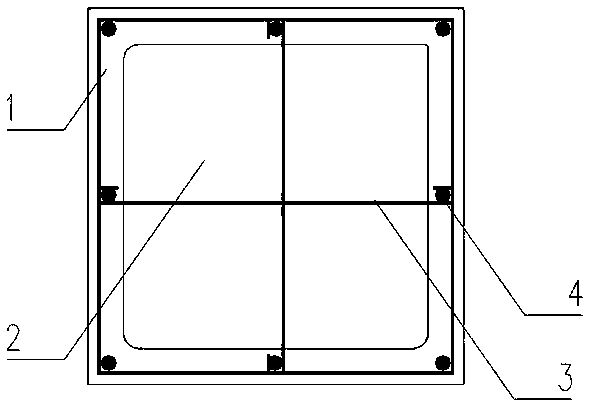

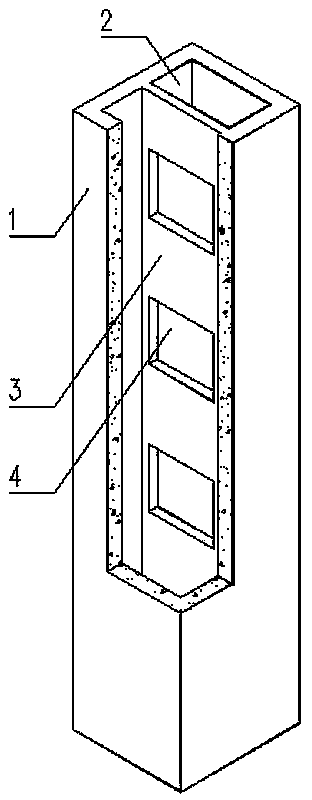

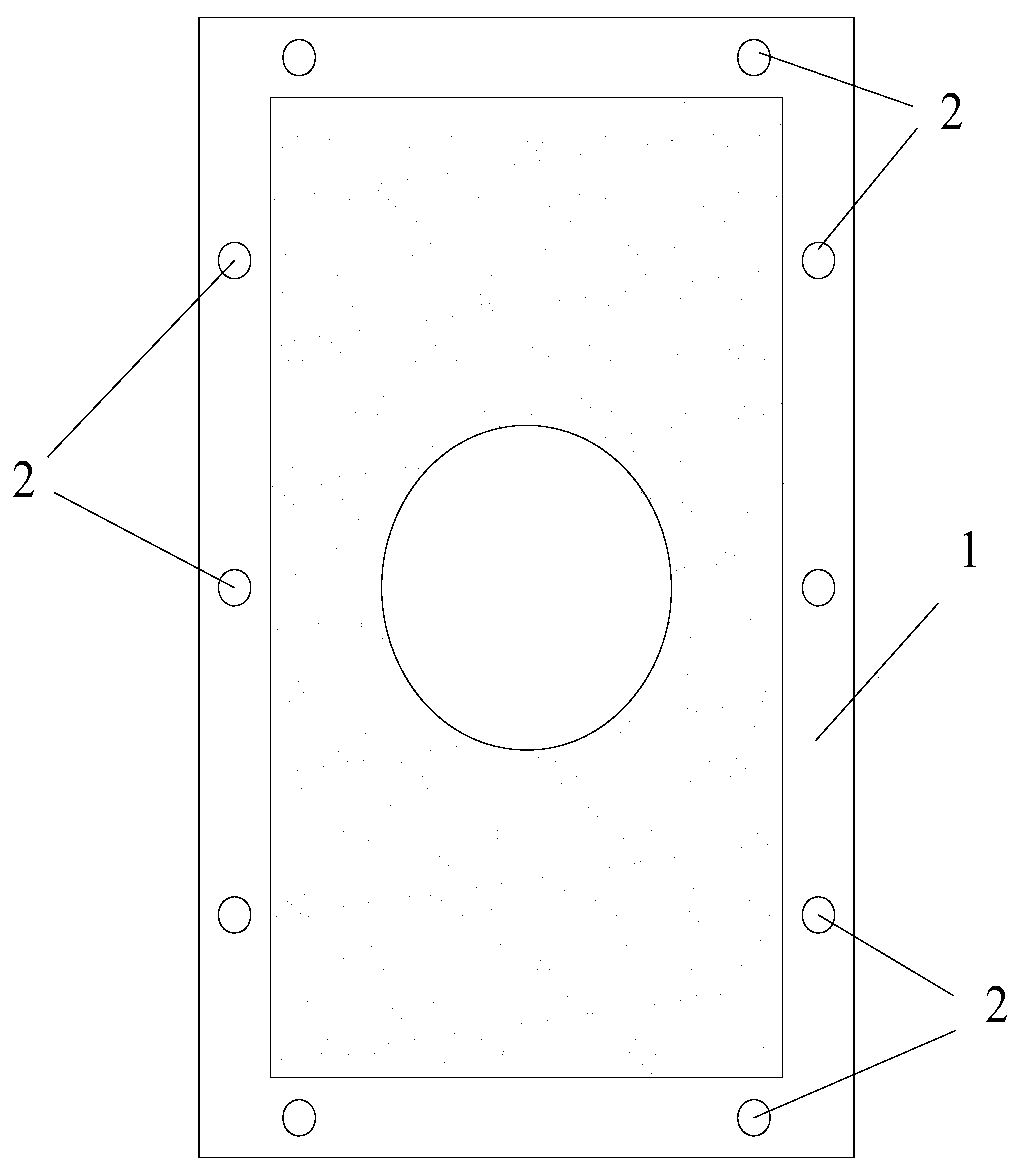

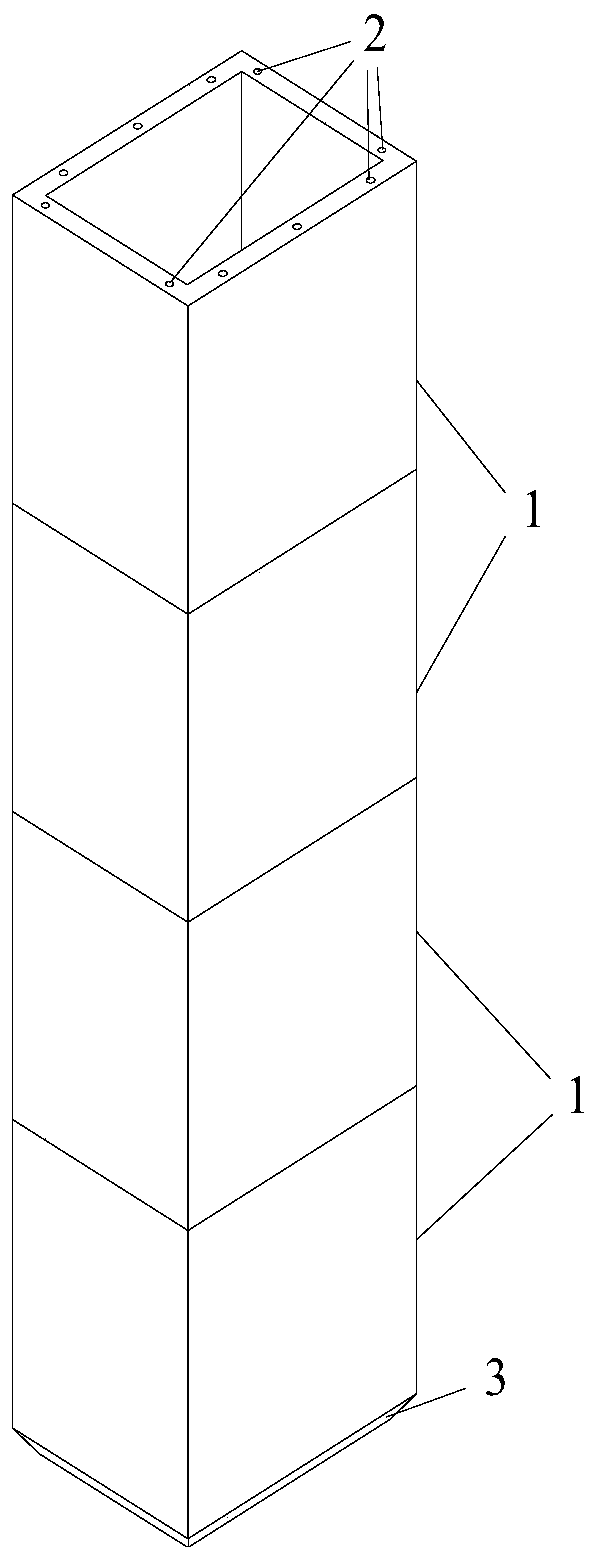

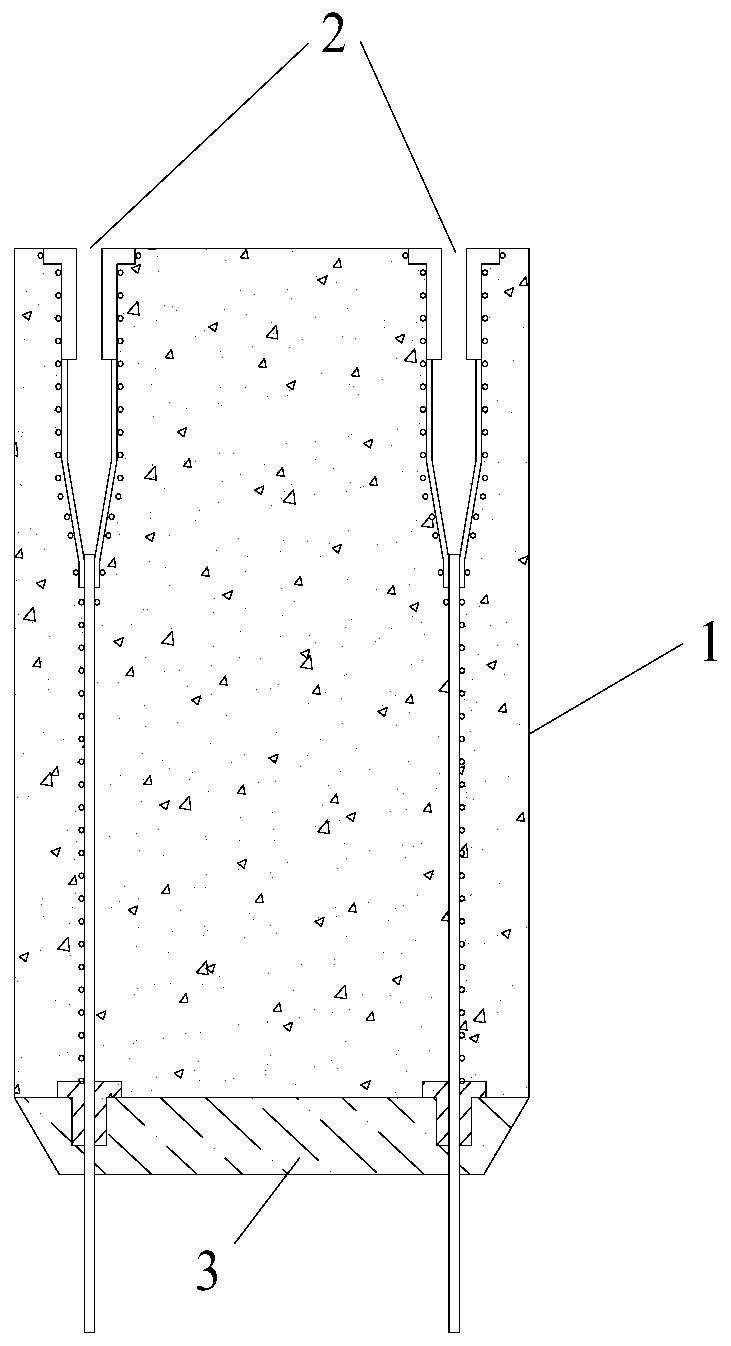

Prefabricated reinforced concrete hollow column template and making method thereof

ActiveCN103737718AMature technologyImprove the level of industrializationMouldsReinforced concrete columnEngineering

The invention provides a prefabricated reinforced concrete hollow column template. A plurality of stirrups are arranged on the column template, a longitudinally penetrating hollow duct is arranged in the column template, and part of the stirrups penetrate through the hollow duct. The invention further provides a making method for the prefabricated reinforced concrete hollow column template. The prefabricated column template provided by the invention can be used for manufacturing various reinforced concrete columns and can be widely used for various engineering structures.

Owner:初明进

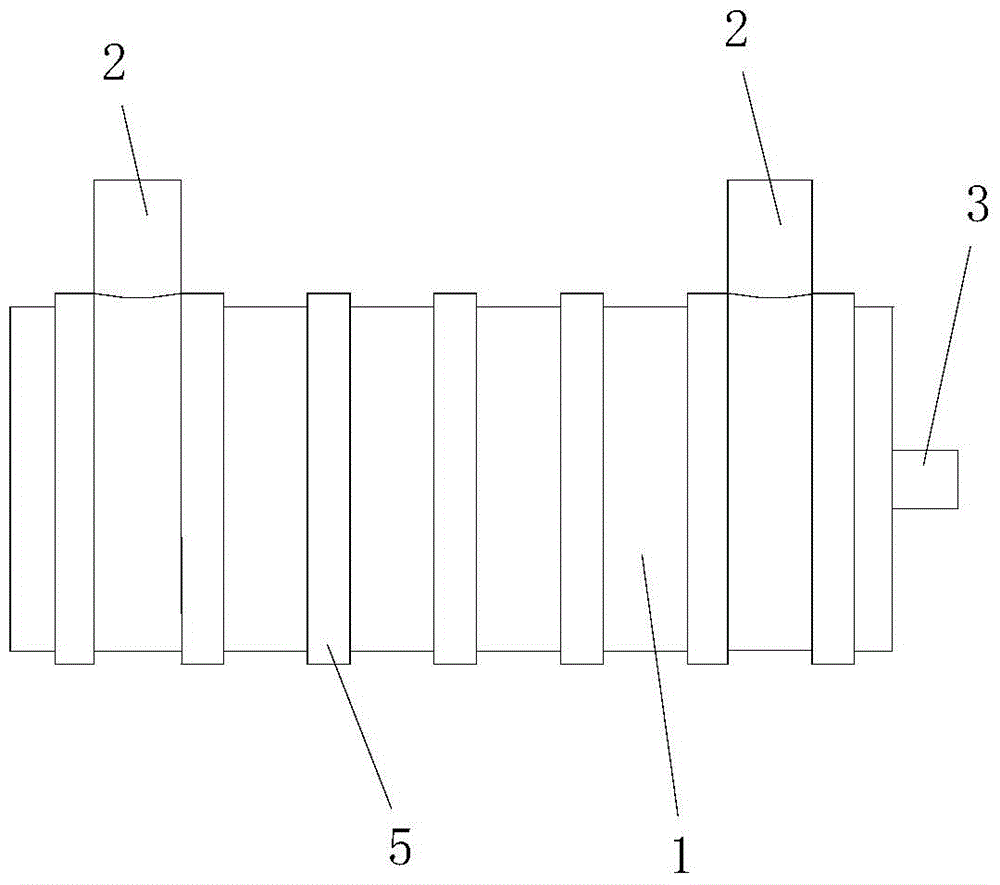

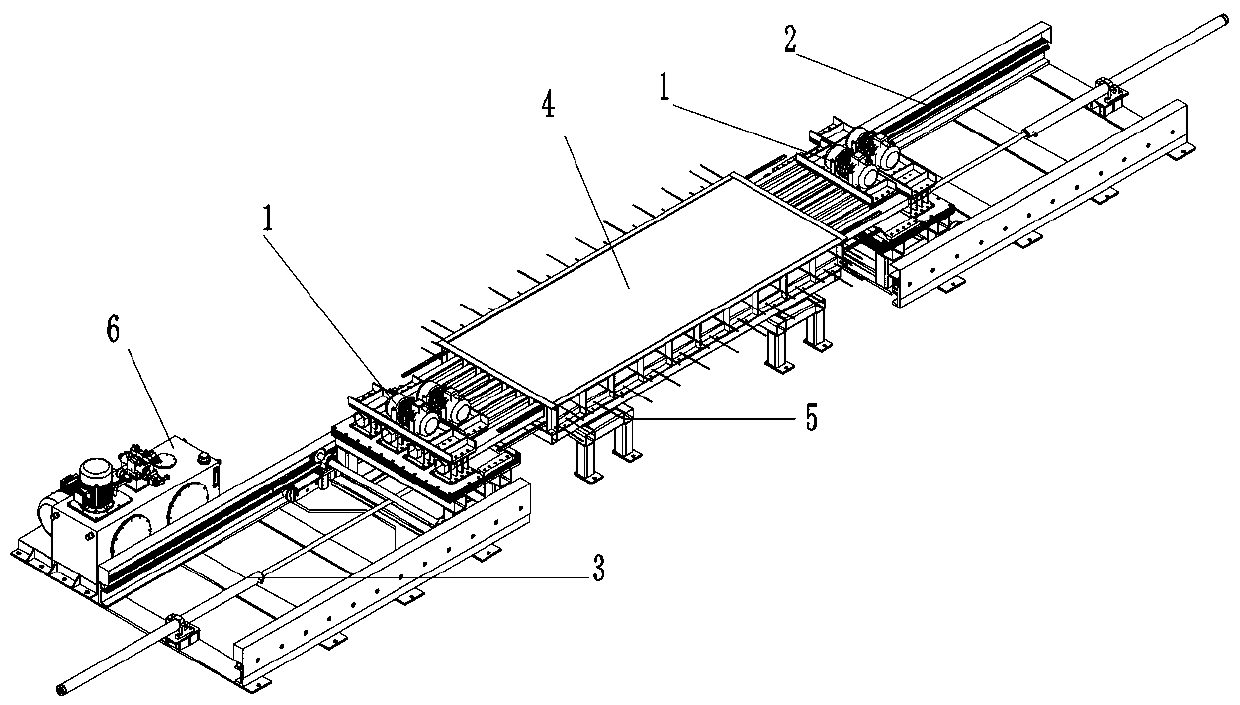

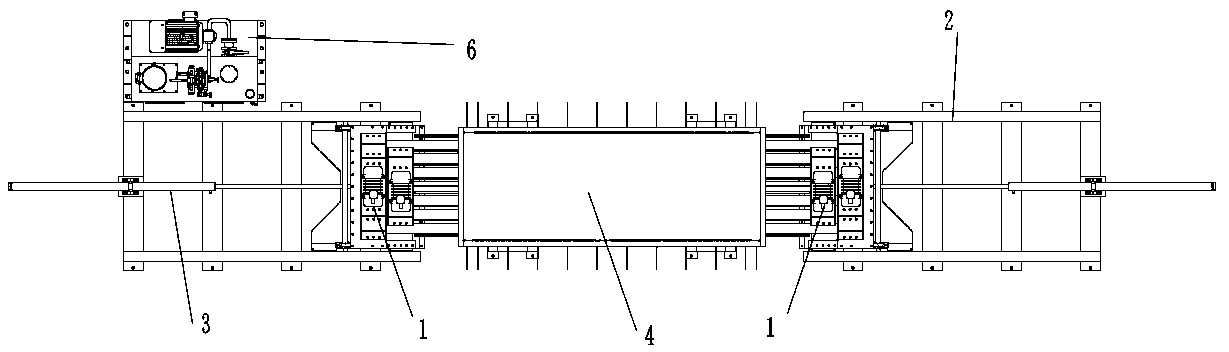

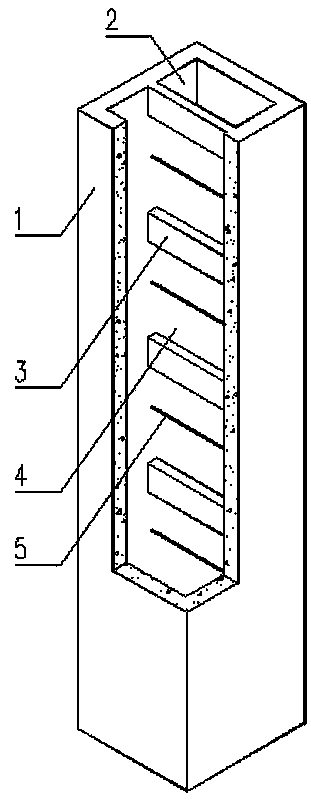

Production device and construction method for two-way core drawing prefabricated hollow seismic wall panel

PendingCN110385774AImprove mechanizationHigh degree of automationFeeding arrangmentsCeramic shaping mandrelsAdhesion forceMoving frame

The invention discloses a production device and a construction method for a two-way core drawing prefabricated hollow seismic wall panel. The production device and the construction method are used forproducing the prefabricated seismic hollow wall panel; and core pipe platforms, a mold platform and an auxiliary device are included; the mold platform comprises a molding mold and a work table, thecore pipe platforms are symmetrically arranged on the two sides of the mold platform, and each core pipe platform includes a core pipe frame, a core pipe rail and a core drawing oil cylinder, whereinthe core drawing oil cylinder pulls the core pipe frame to move on the core pipe rail, the core pipe frame comprises a fixed core pipe set, a movable core pipe set and a moving frame, the fixed core pipe set is fixedly connected to the moving frame, and the movable core pipe set is movably connected to the moving frame. A two-way core pulling process is adopted, the core drawing stroke is reduced,the concrete adhesion force during core drawing is reduced, and the hole forming quality of a hollow hole is ensured; the relative movement of the fixed core pipe set and the movable core pipe set during core drawing ensures the hole forming quality, and hole wall collapses during wire drawing are prevented; and the production device and the construction method have the advantages of mechanization, the high automation degree and high production efficiency.

Owner:山东兴玉机械科技有限公司 +1

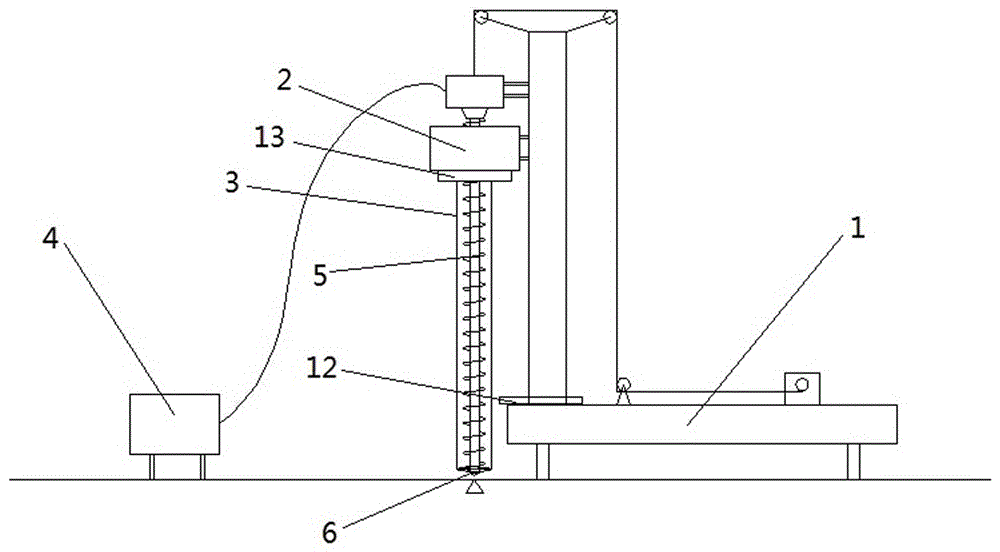

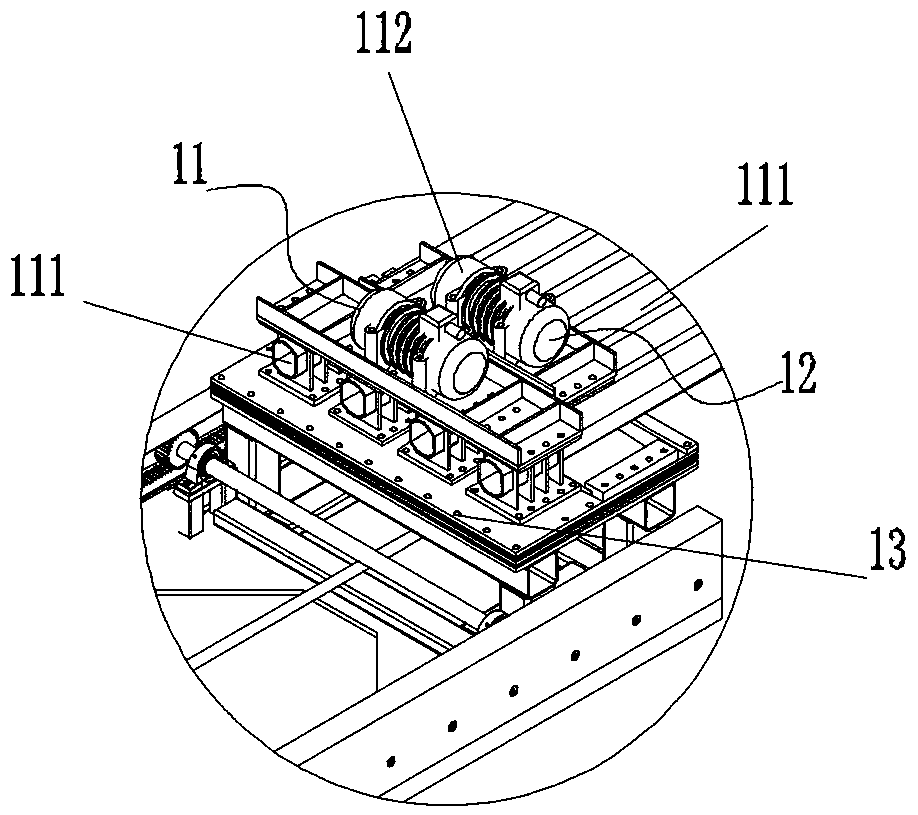

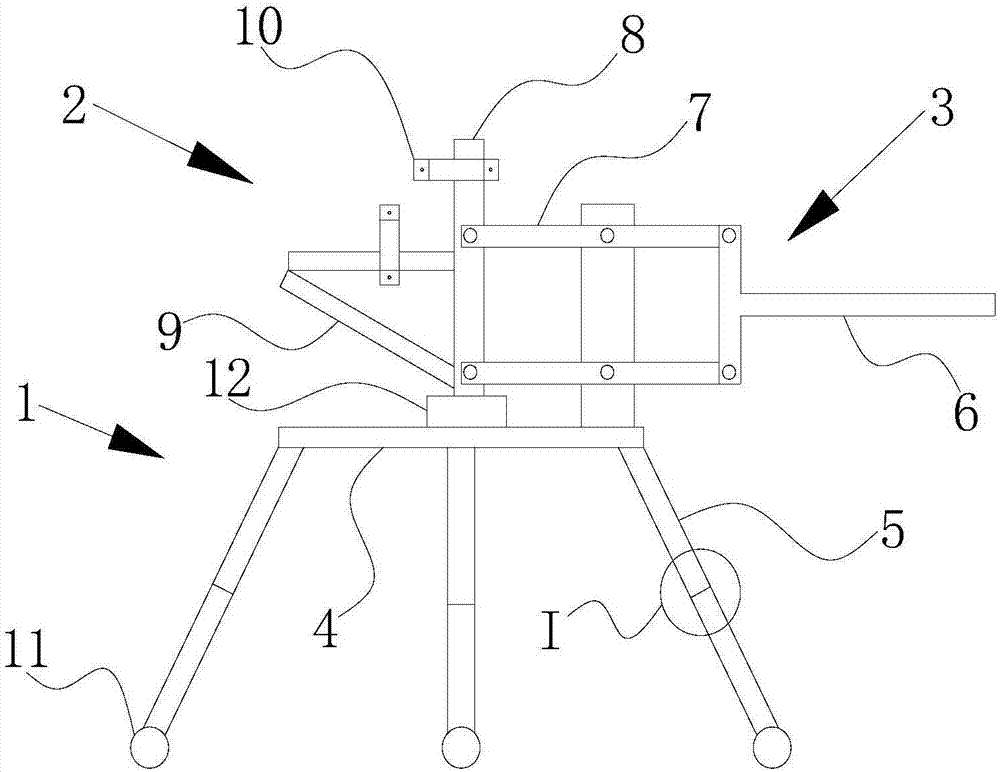

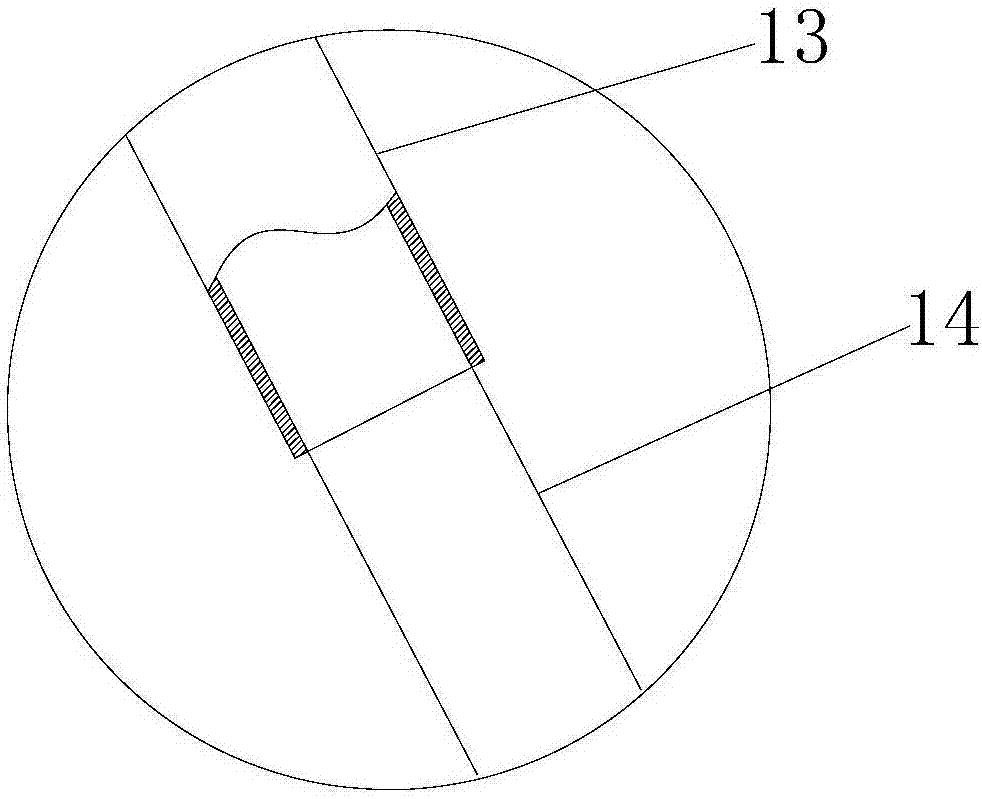

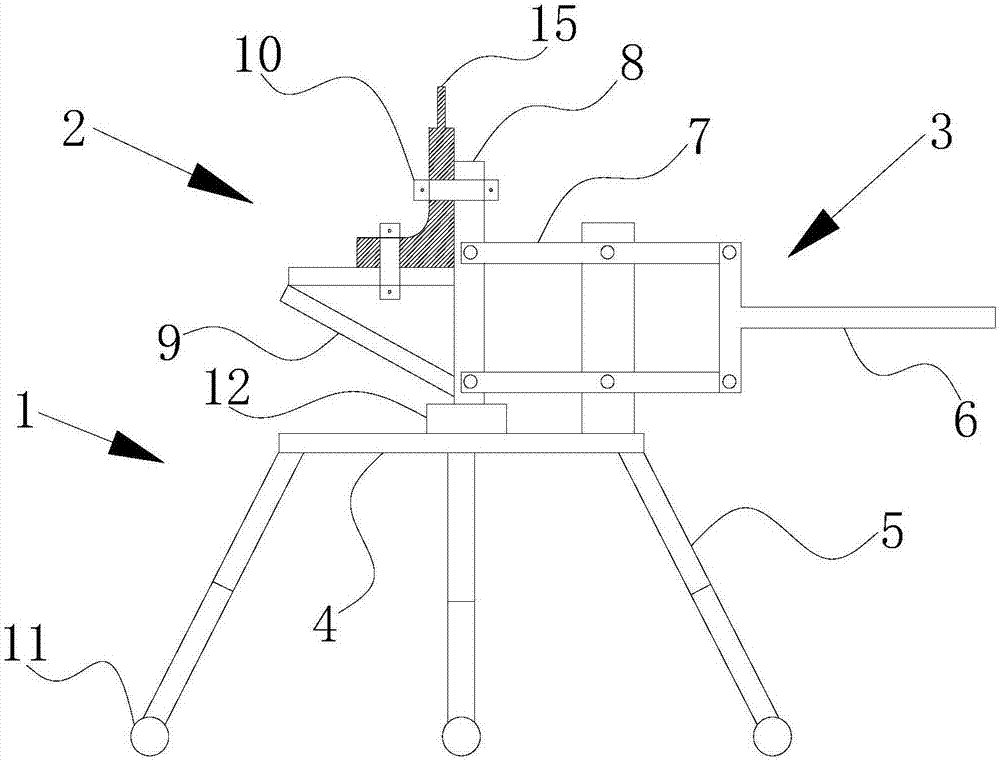

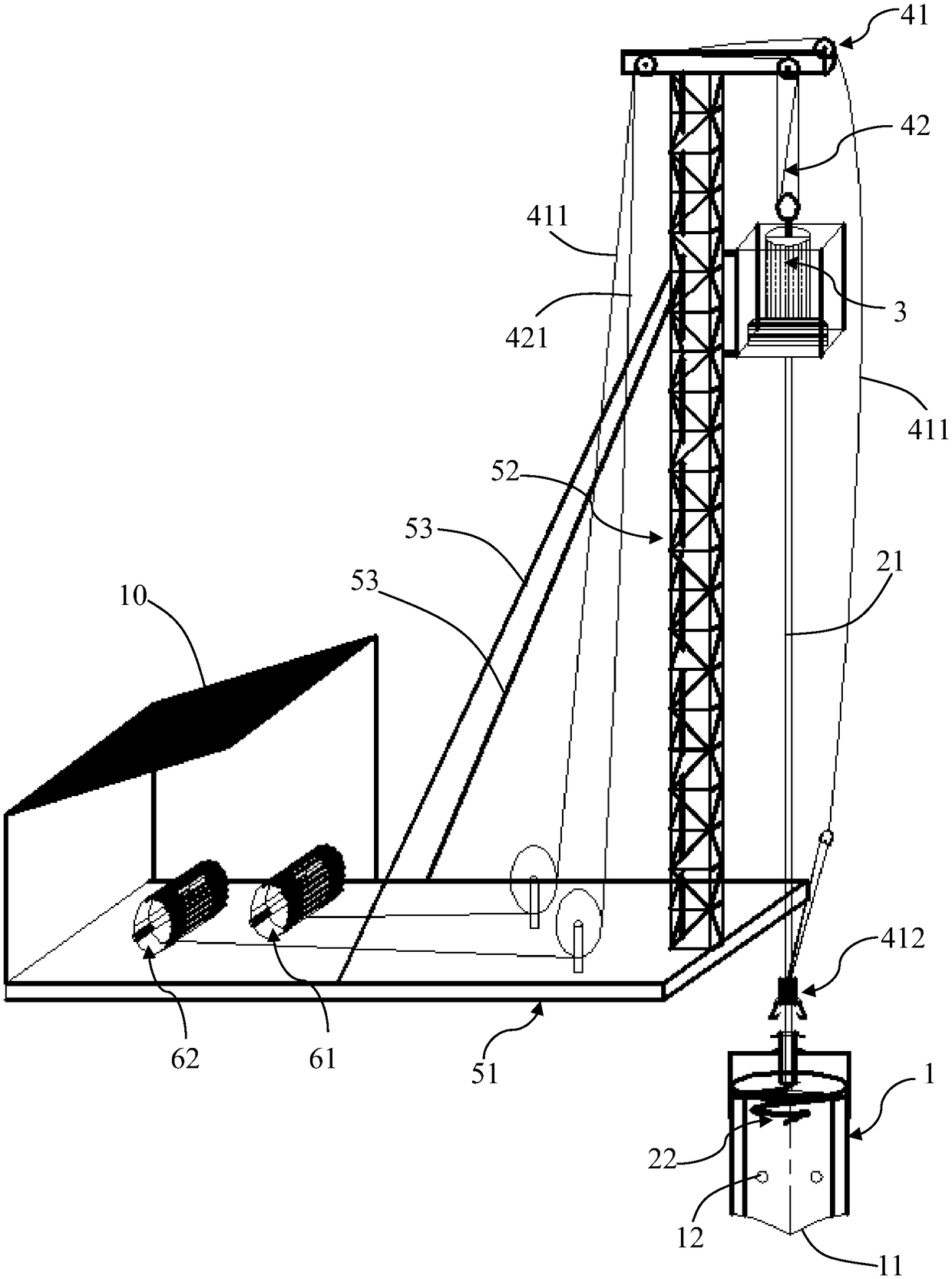

Precise lifting control device and drilling device

PendingCN107570757AImprove construction accuracyAccurate lift positioningLifting devicesPortable drilling machinesEngineeringMechanical engineering

The invention provides a precise lifting control device, and relates to the technical field of engineering construction equipment. The precise lifting control device comprises a base frame, a liftingseat and a swinging moment arm; the base frame comprises a base platform and a plurality of supporting legs for supporting the base platform, and the multiple supporting legs are telescopic; the lifting seat is arranged on the base platform through the swinging moment arm; and when the swinging moment arm rotates, the lifting seat can horizontally move up and down relative to the base platform. According to the precise lifting control device, the base platform and the multiple supporting legs are arranged on the base frame, the base platform can ascend and descend through the multiple telescopic supporting legs, and the lifting seat can horizontally move up and down relative to the base platform, and therefore precise lifting positioning of the lifting seat can be realized by adjusting thebase platform and the lifting seat. On the basis, the invention further provides a drilling device.

Owner:CCCC FOURTH HIGHWAY ENG

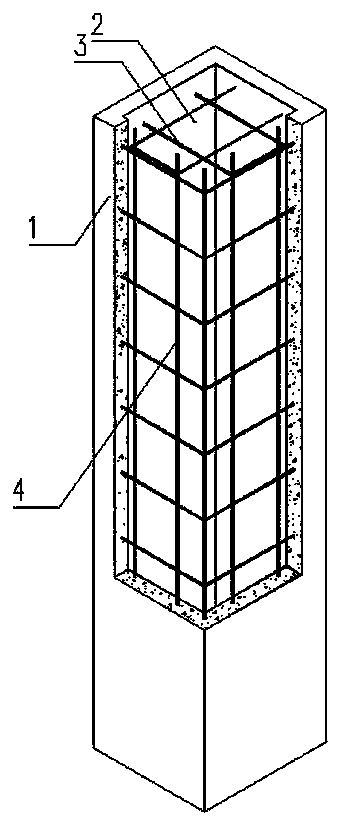

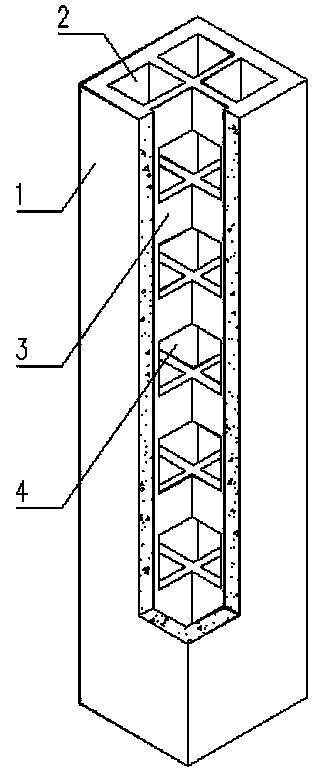

Prefabricated reinforced concrete column template and making method thereof

ActiveCN103741883AImprove the level of industrializationIncrease productivityStrutsCeramic shaping apparatusReinforced concrete columnEngineering structures

The invention provides a prefabricated reinforced concrete column template. The prefabricated reinforced concrete column template comprises a cylindrical outer wall and a longitudinal inner partition board, wherein the interior of the prefabricated reinforced concrete column template is separated into at least two longitudinally through hollow ducts by the inner partition board, and at least one lateral hole for communicating the hollow ducts on the two sides of the inner partition board is formed in the inner partition board. The invention further provides a making method of the prefabricated reinforced concrete column template. The prefabricated column template provided by the invention can be used for making various reinforced concrete columns and can be widely used for various engineering structures.

Owner:初明进

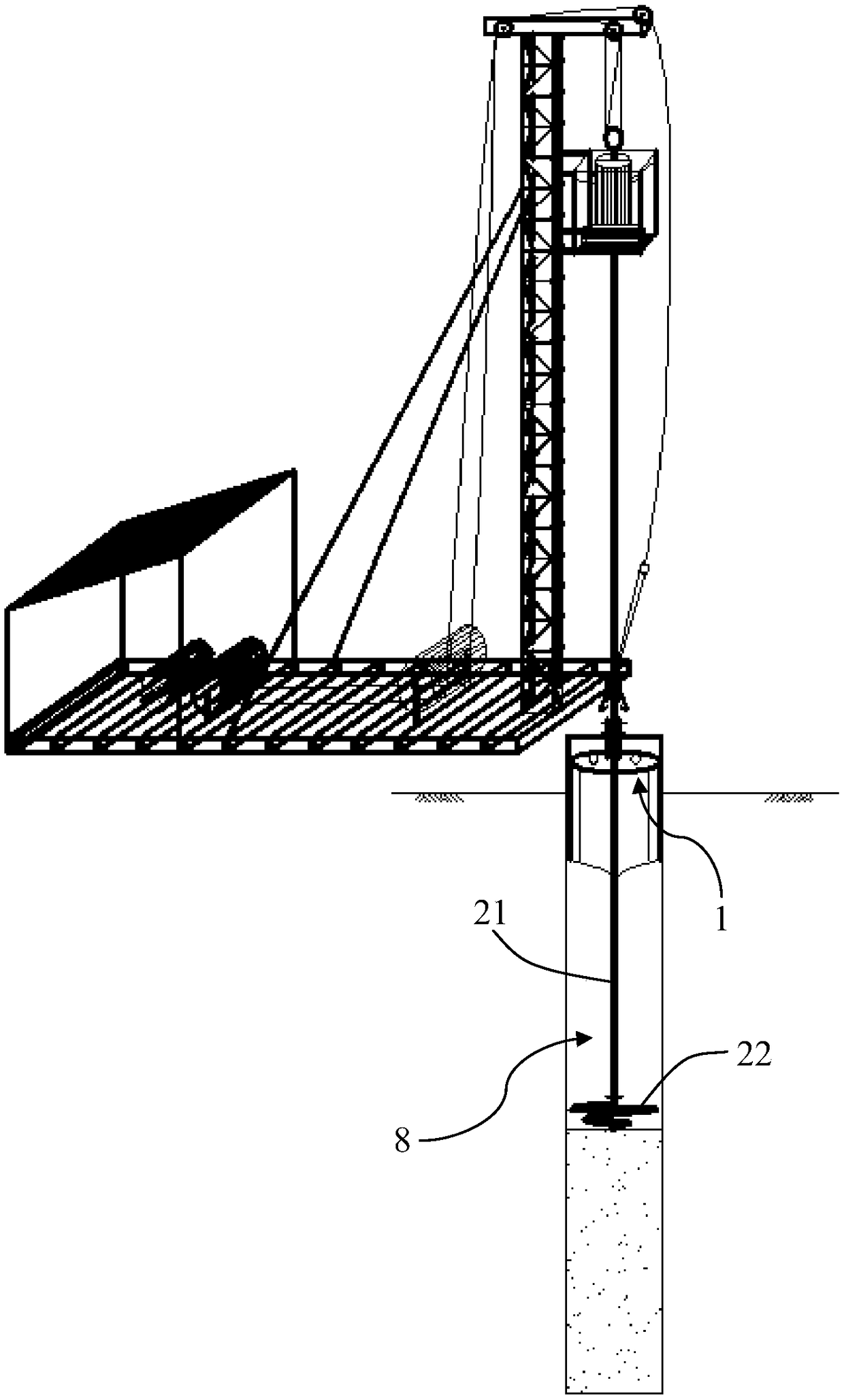

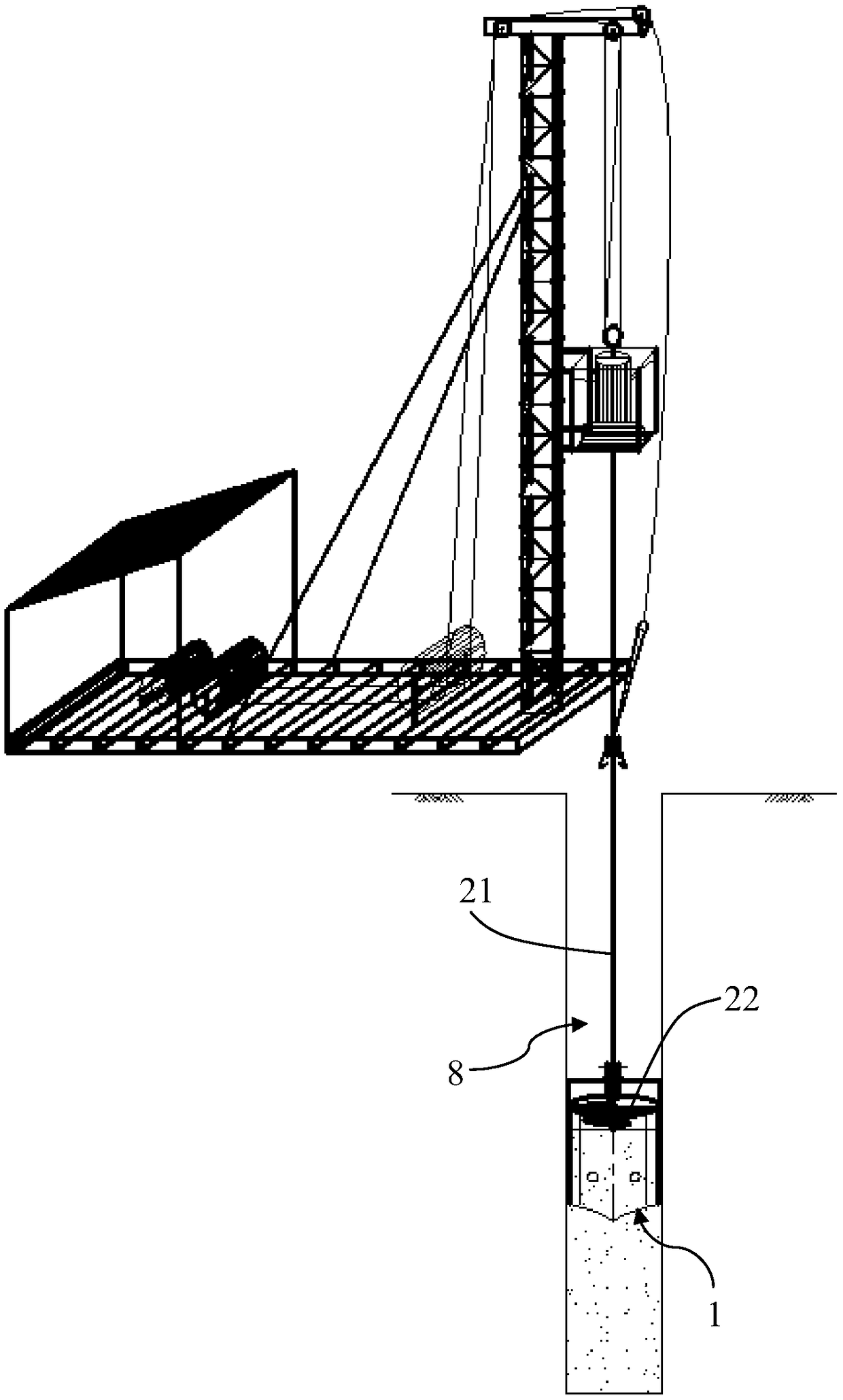

Construction process of underwater churning-driven cast-in-place bored pile by adopting chemical slurry powder to make slurry and protect wall

The invention discloses a construction process for an underwater churning-driven cast-in-place bored pile by adopting a chemical slurry powder to make slurry and protect a wall, comprising the following specific operation steps of: 1, making construction preparation, specifically, fully preparing equipment, tools and objects required by construction, flattening and compacting a construction site,cleaning impurities, removing soft soil, measuring and labeling the center of a pile position, and embedding a pile casing; 2, putting a drilling machine in place, moving the drilling machine to the pile casing, conducting installation and adjusting on the drilling machine, making a drill bit to be aligned with the center of the pile position, integrally checking the drilling machine, and removingfaults in time; and 3, conducting wall protection by slurry, specifically, arranging a slurry pool in a construction site. A double-bottom sand bailing drill is used for bailing slag, and through combination with a pump suction reverse circulation hole-cleaning construction process, the hole cleaning speed is high, hole bottom sediment can be effectively controlled, chemical slurry is prepared according to a proportion determined based on the construction site geology and actual conditions, complex geological conditions in water are considered, the wall protecting capacity of the slurry is improved, the hole forming quality is guaranteed, and the construction progress is accelerated.

Owner:CCCC TIANJIN DREDGING

Bore forming device of soft soil stratum cast-in-situ bored pile and construction method thereof

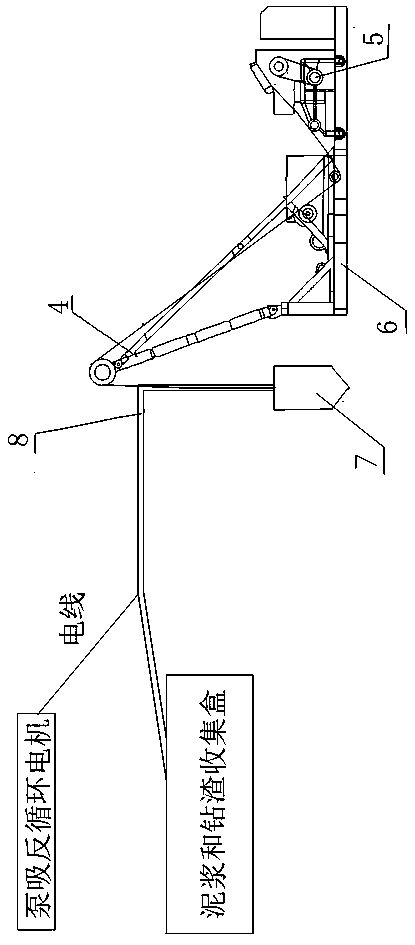

ActiveCN108661576AAchieve vertical separationReduce disturbanceDrill bitsDrilling rodsSlagDrive motor

The invention provides a bore forming device of a soft soil stratum cast-in-situ bored pile and a construction method thereof. The bore forming device comprises a slag barrel, a drill pipe which is inserted in the slag barrel and can move in the axial direction of the slag barrel, and a driving motor used for driving the drill pipe to rotate in the circumferential direction of the drill pipe. A cutting part used for being cut into a bore to-be-formed position in a soft soil stratum is arranged at the bottom of the slag barrel, and the drill pipe and the slag barrel are coaxially arranged. A spiral bit is coaxially connected to the bottom end of the drill pipe, the outer diameter of the spiral bit is matched with the inner diameter of the slag barrel, the spiral bit rotates in the circumferential direction under driving of the drill pipe. According to the bore forming device, bore forming construction of the soft soil stratum cast-in-situ can be quickly achieved, meanwhile, the disturbance to a bore wall soil layer is small, and the phenomena of bore collapse and chambering are effectively avoided.

Owner:中建八局轨道交通建设有限公司

Prefabricated retaining wall and pile hole excavation method

PendingCN110438988ATo meet the needs of hole formationThe settlement process is easyExcavationsBulkheads/pilesLarge sizeInternal stress

The invention discloses a prefabricated retaining wall and a pile hole excavation method. The excavation method comprises the steps that first, guide-hole construction is carried out by using a machinery in an excavation area of a rectangular hole, after the internal opening is carried out, a soil body at the edges and corners of the rectangular hole is disturbed, internal stress is released, thedifficulty of subsequent excavation is greatly reduced, moreover, with the continuous increase of gravity of the prefabricated retaining wall, the settlement process of the prefabricated retaining wall is easier, and construction efficiency is conducive to be improved; and according to the excavation method, excavation of the rectangular hole can be carried out effectively, construction safety isimproved, construction difficulty is reduced, the requirement for forming a large-size rectangular hole is met, at the same time, prefabricated retaining wall structure is effectively installed to avoid the risk of hole collapse, hole digging and the retaining wall can be completed simultaneously, the construction period is conducive to be shortened, energy saving and environment production are achieved, the quality hidden danger of the retaining wall can be avoided effectively, and the excavation method is especially suitable for construction of an anti-slide pile in cold and high altitude areas such as the sichuan-tibet line.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

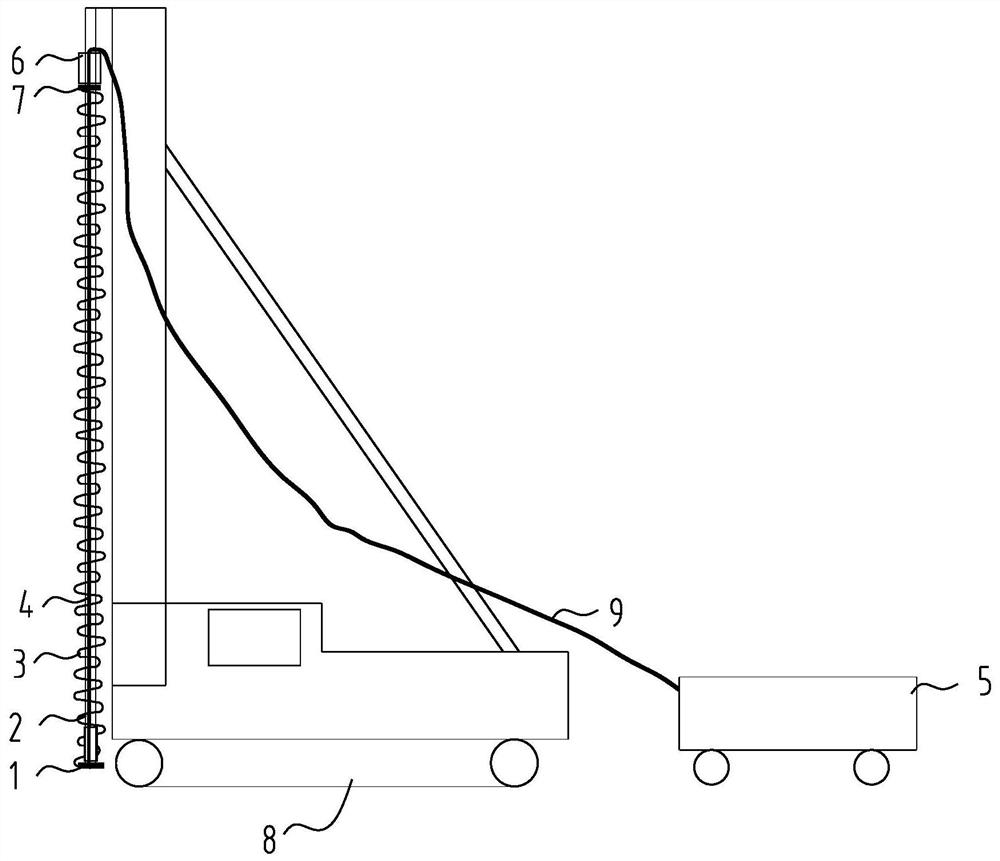

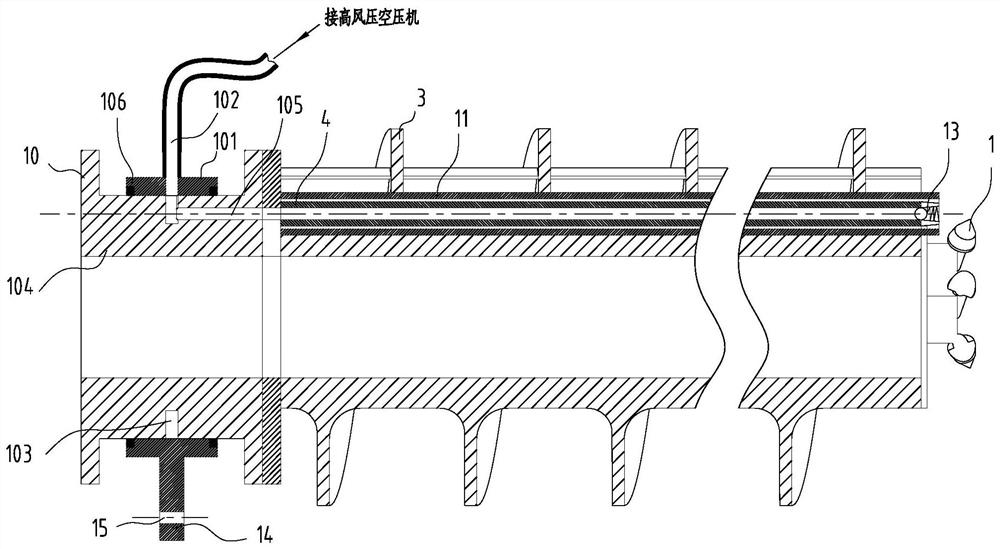

Efficient and environment-friendly long spiral rock-socketed pile machine

InactiveCN112523688AIncrease stiffnessHigh strengthDrilling rodsConstructionsSpiral bladeRock cutting

The invention belongs to the technical field of geotechnical engineering, and particularly relates to an efficient and environment-friendly long spiral rock-socketed pile machine. The efficient and environment-friendly long spiral rock-socketed pile machine comprises a high-power power head arranged at the top of a drilling machine and a long spiral drilling machine drill rod; the long spiral drilling machine drill rod is provided with spiral blades; an air supply outer pipe is arranged outside the long spiral drilling machine drill rod; the air supply outer pipe penetrates through the spiralblades along the outer wall of the long spiral drilling machine drill rod; and the drill bit is arranged at the end of the long spiral drilling machine drill rod. The efficient and environment-friendly long spiral rock-socketed pile machine has the advantages that by improving the structure of the long spiral drilling machine drill rod, the drilling efficiency during rock drilling can be 5-10 times that of a traditional long spiral drilling machine, and the single-pile bearing capacity of a cast-in-place pile formed through the process can be improved by 15% or above; and high-wind-pressure compressed air blows rock debris and rock powder at the bottom of a hole generated during drilling away from the contact surface of the drill bit and primary rock, so that the rock cutting and crushingcapacity of drill teeth is improved, the rock drilling efficiency is improved, and when the high-pressure air is pressed into the hole bottom to move upwards, the temperature of the drill bit and thedrill rod can be effectively reduced.

Owner:OCEAN UNIV OF CHINA +2

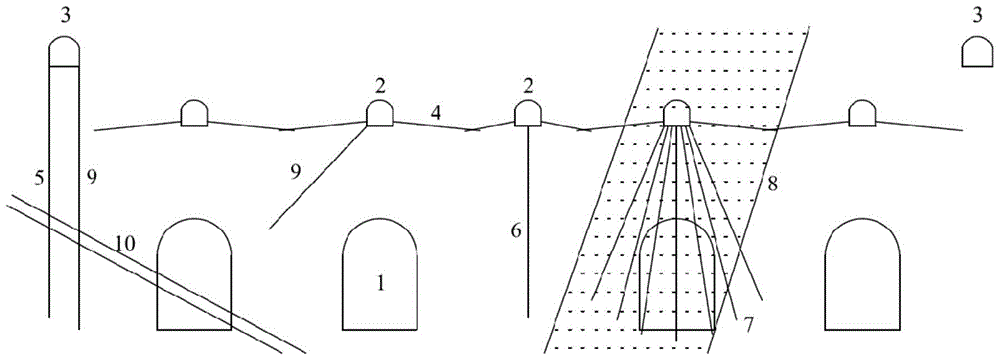

Design method of water curtain system for underground water-sealed cavern

The invention relates to the technical field of an underground water seal cave depot, in particular to a design method for a water curtain system of an underground water seal cave depot. The method comprises the steps: designing a water curtain roadway after the completion of the design of a main chamber and the design of a traffic roadway; designing a horizontal water direction curtain hole and a vertical direction water curtain hole; carrying out construction reconnaissance on the development condition of a fault fracture zone; after the excavation forming of the water curtain roadway, designing a preprocessing scheme to weak rock mass in the main chamber; carrying out a backup flooding test to all water curtain holes of the roadway after the completion of all water curtain holes of some water curtain roadway; and designing a blocking scheme to seepage channels discovered. According to the design method provided by the invention, the depth of the horizontal direction water curtain hole can be greatly reduced, and the pore-forming construction difficulty is low; furthermore, the preliminary grouting is injected to the weak rock mass in the main chamber through the water curtain roadway, so as to be beneficial for ensuring the construction progress and reducing the construction risk; furthermore, the grouting can be injected to the seepage channels for blocking, and the loss of underground water can be prevented or reduced when the main chamber is excavated, so as to ensure the water seal environment all around the main chamber.

Owner:TSINGHUA UNIV

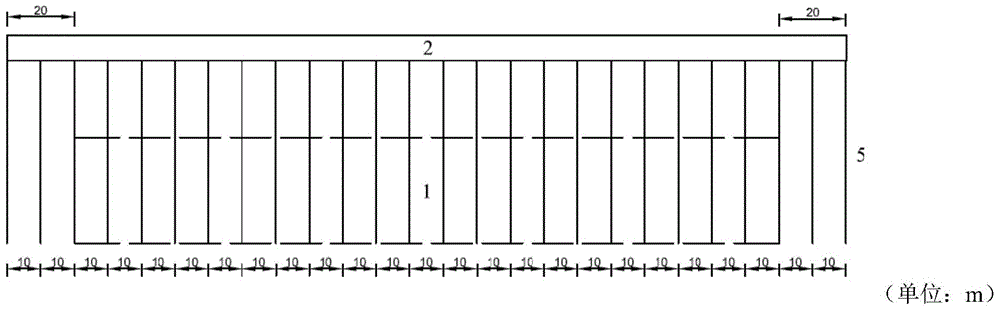

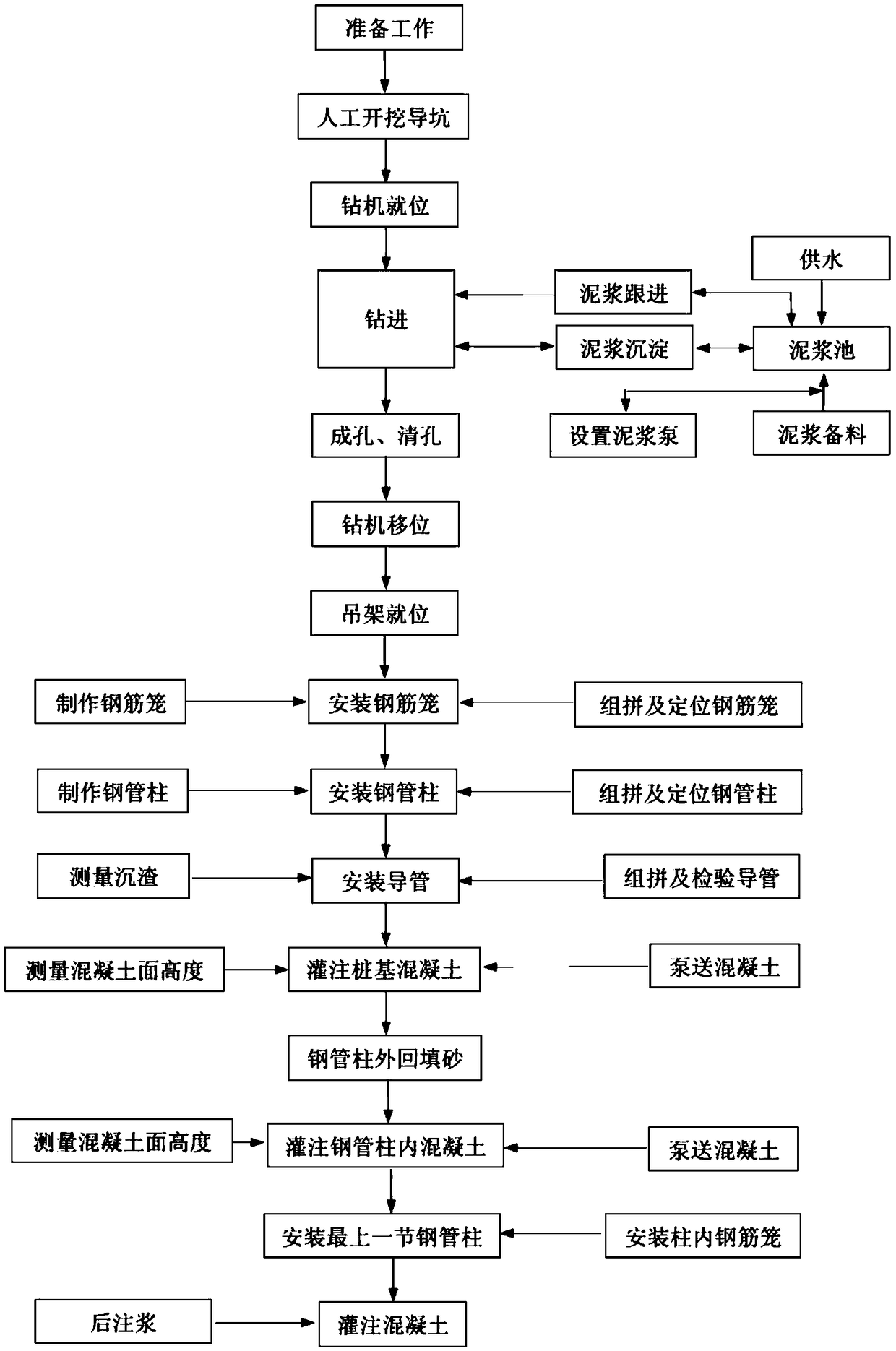

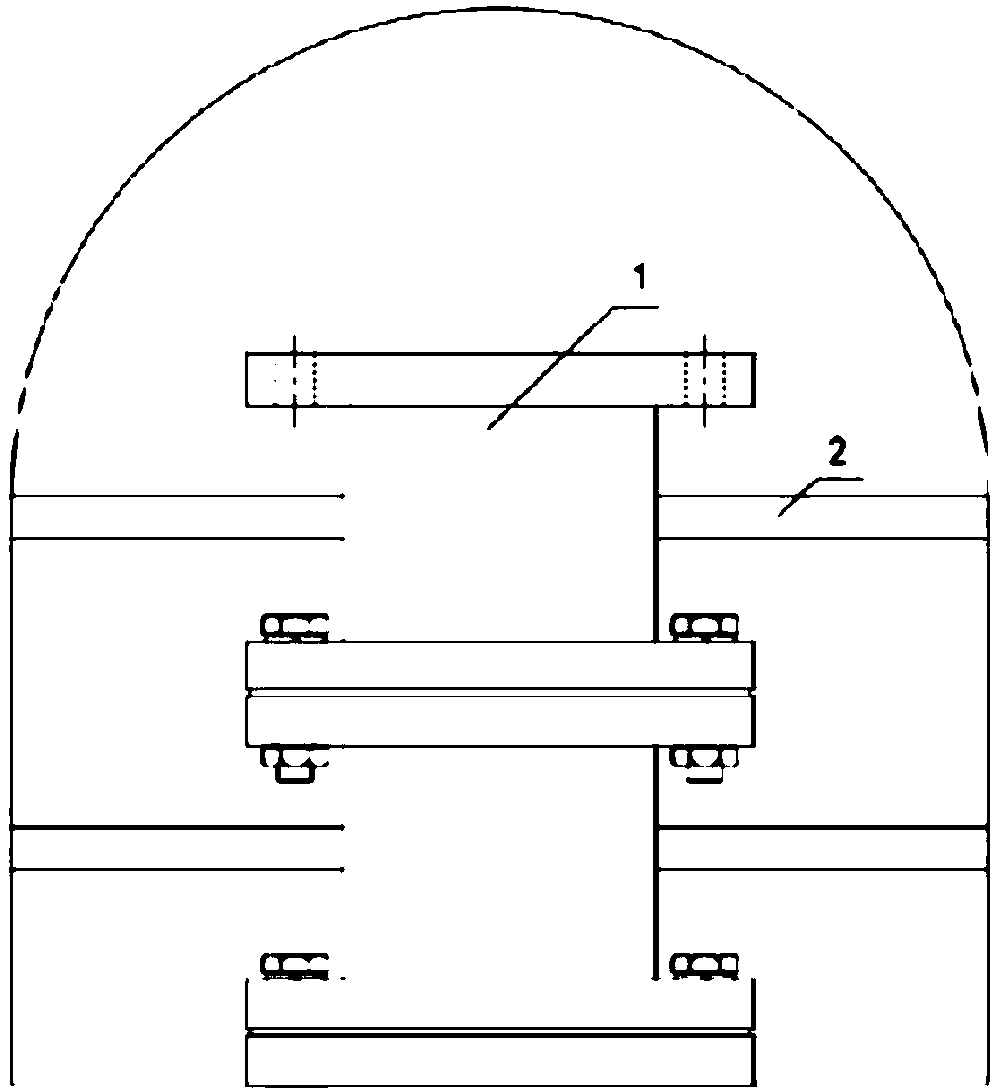

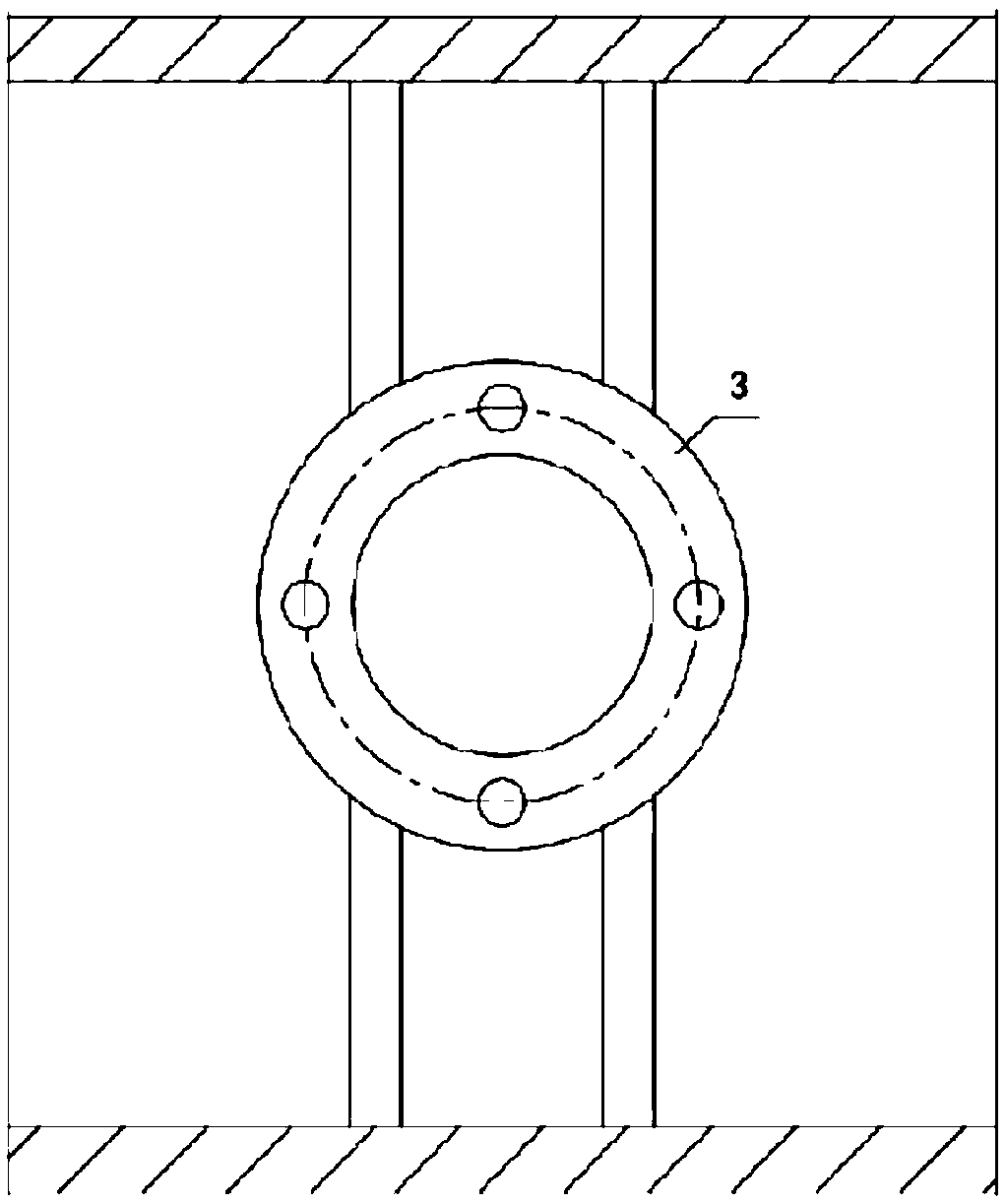

Subway station middle pile and steel pipe column construction method

InactiveCN109056808AGuarantee the quality of hole formationOptimize the construction processArtificial islandsUnderwater structuresSlagSubway station

The invention discloses a subway station middle pile and steel pipe column construction method. The method is characterized in that a guide hole inverted arch is broken before construction, a guide pit reinforcing ring beam is manufactured, and manual hole digging is carried out, a vertical shaft is used as a mud pit, the slag outlet and the slurry inlet are conveyed into the vertical shaft through a pipeline, a sedimentation zone and a mud zone are arranged in the vertical shaft, and a buffer mud pit is arranged in a small guide hole. When a reverse circulation drilling machine is used for forming a hole, the periphery of the drilling machine is supported by trusses and the drilling machine is fixed on the wall of the guide hole so as to ensure the perpendicularity of the drilling hole, and the situation of slag removal of a footage and a gravel pump is observed carefully during drilling. A pile foundation reinforcement cage is put down after mechanical hole forming, and then the steel pipe column is lowered in a section mode. The top section steel pipe column is finally subjected to unified construction, a steel pipe column top section tool joint is firstly installed, the top section tool joint is in the same model with the steel pipe column, and the top section tool joint is connected to the steel pipe column through a flange and is fixed on the side wall of the small guidehole through the supporting trusses. According to the method, the mud circulation is reasonably designed, the hole forming quality is guaranteed through the reverse circulation drilling machine, the construction process is optimized, the perpendicularity of the steel pipe column is guaranteed by the aid of the tool joint and a vertical adjusting machine, so that the construction safety and the construction efficiency are improved.

Owner:CHINA RAILWAY FIRST GRP SECOND ENG CO LTD +1

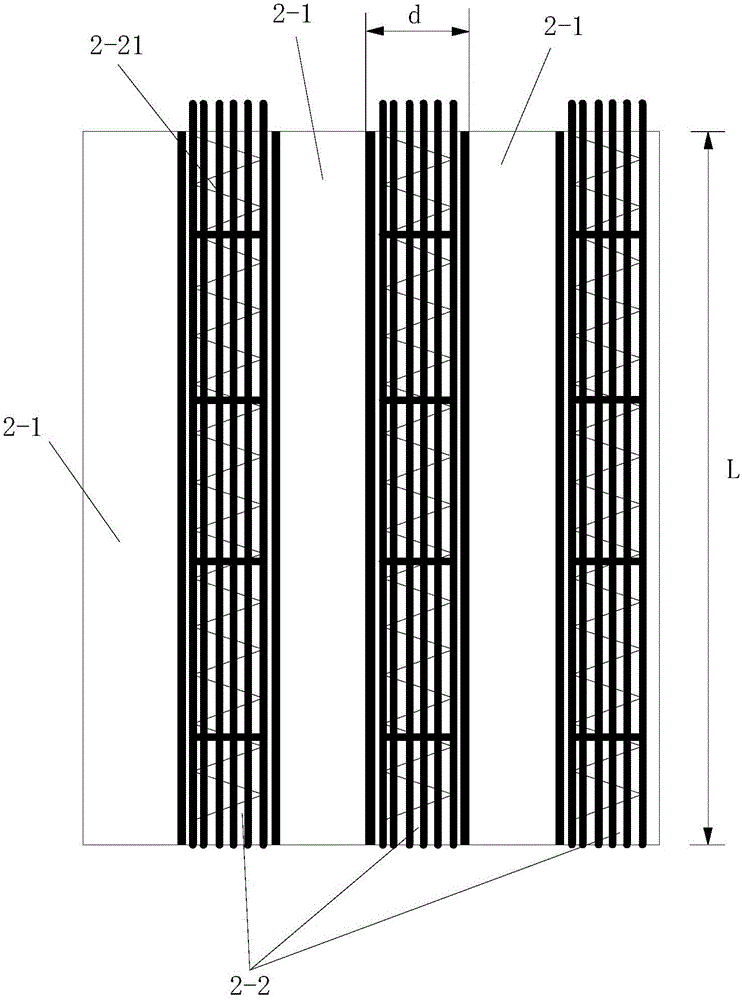

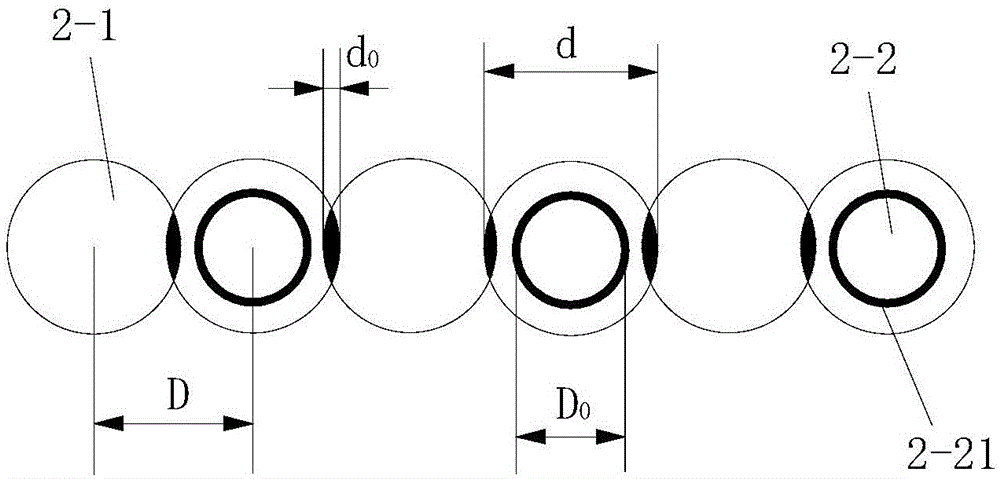

Engaged retaining pile and construction method and application thereof

The invention discloses an engaged retaining pile. The engaged retaining pile comprises a plurality of plain concrete piles laid from front to back and a plurality of reinforced concrete piles laid from front to back. The plain concrete piles and the reinforced concrete piles are laid in a staggered mode. A pile body of each reinforced concrete pile is engaged with pile bodies of two plain concrete piles located front and back, so that the retaining effect is good. The invention further discloses a construction method of the engaged retaining pile. The construction method comprises the steps that firstly, construction of the plain concrete piles is conducted, and the multiple plain concrete piles are constructed from front to back; and secondly, construction of the reinforced concrete piles is conducted, the multiple reinforced concrete piles are constructed from front to back in the construction process of the multiple plain concrete piles, drilled hole-forming construction processes of any one of the reinforced concrete piles are conducted after the construction of the two adjacent plain concrete piles front and back is completed. The construction method is simple; the design is reasonable and the construction is simple and convenient; the construction efficiency is high and the construction effect is good. In addition, the invention discloses an application of the engaged retaining piles, namely a foundation pit retaining structure is formed by fixedly connecting the multiple engaged retaining piles tightly.

Owner:SHAANXI ZHUANGXIN CONSTR ENG +1

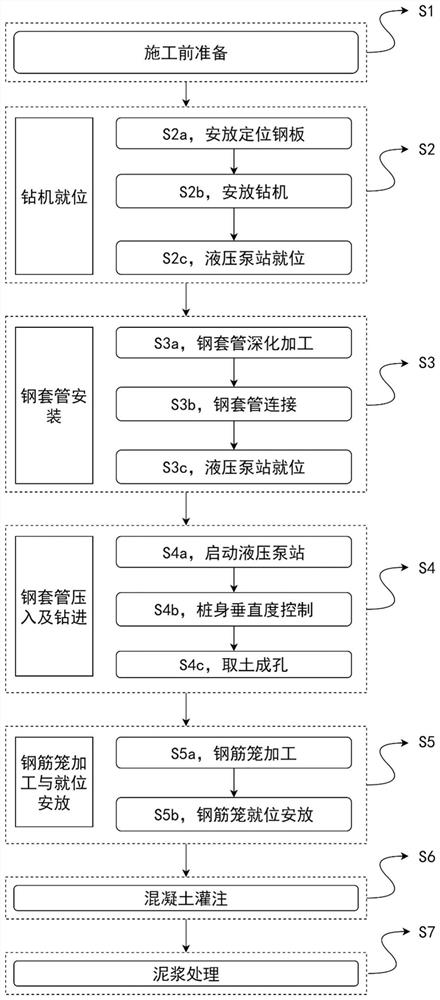

Micro-disturbance construction method for full-casing cast-in-situ bored pile adjacent to subway

The invention provides a micro-disturbance construction method for a full-casing cast-in-situ bored pile adjacent to a subway, and belongs to the technical field of foundation engineering. The micro-disturbance construction method adopts a 360-degree full-rotation drilling machine to rotate a customized steel casing into soil firstly, so that the steel casing penetrates through (3)-4b silty clay powder mixed lump silty-fine sand layer and (3)-4c silty-fine sand layer to enter a supporting layer by 100 mm; then, a rotary drilling rig is adopted for taking soil in a cylinder, a reinforcement cage is lowered, concrete is poured, slight disturbance to an adjacent subway is achieved in the whole construction process, a customized steel sleeve with a plate tooth tool bit is used for drilling, through reasonable segmentation of the steel sleeve, optimization of the connection mode between segments and the like, the steel sleeve can smoothly penetrate through a silty-fine sand layer with the thickness of 17 m without deformation, and the hole forming quality is guaranteed; and due to the fact that a steel sleeve protecting wall is adopted in the hole forming process, the phenomena of sandflowing, sand gushing and hole collapsing in a hole are effectively prevented, the pile forming quality of concrete in the sleeve is improved, a soil body is basically free of deformation in the construction process, and the influence on the surrounding environment is effectively controlled.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com