Micro-disturbance construction method for full-casing cast-in-situ bored pile adjacent to subway

A technology of bored piles and construction methods, which can be applied to sheet pile walls, earthwork drilling, foundation structure engineering, etc., and can solve problems such as hole wall collapse or shrinkage, displacement and deformation of subway tunnels, and improve overall safety , Improving the quality of pile formation and ensuring the quality of hole formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

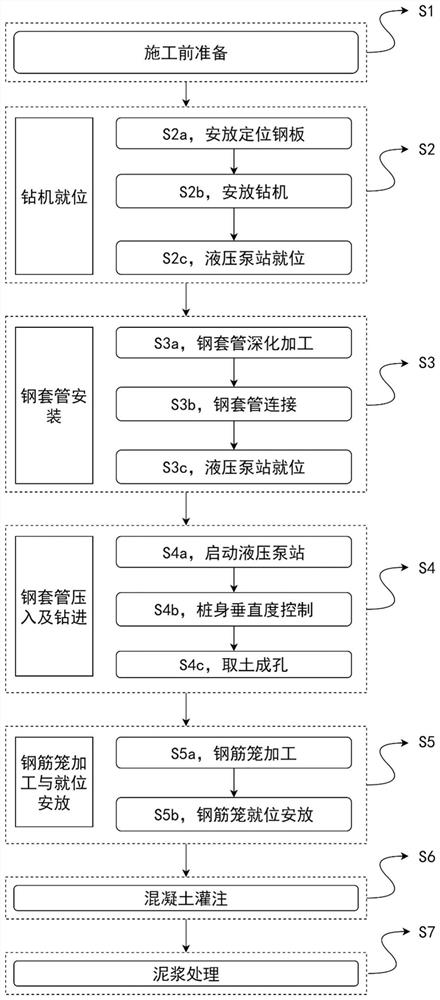

[0041] Refer to attached figure 1 As shown, the present invention provides a technical solution: a micro-disturbance construction method for a full casing bored pile adjacent to a subway, comprising the following steps:

[0042] S1, preparation before construction, flatten and compact the required hole-forming pile positions and the ground of the main equipment operation parts, and then the surveyors accurately set out the specific positions of the pile positions and mark them;

[0043] S2, the drilling rig is in place, according to the marks made in advance, the positioning steel plate is installed in the center of the hole, and then the motor is installed, and finally the hydraulic pump station of the supporting power system of the drilling rig is in place;

[0044] In this embodiment, each working procedure is:

[0045] Among them, S2a, place the positioning steel plate, the positioning steel plate must be placed flat, and the center of the hole position coincides with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com