Engaged retaining pile and construction method and application thereof

A construction method and wall-retaining pile technology are applied in excavation, sheet pile wall, foundation structure engineering, etc., which can solve the problems of low construction labor, cumbersome operation, limited application scope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

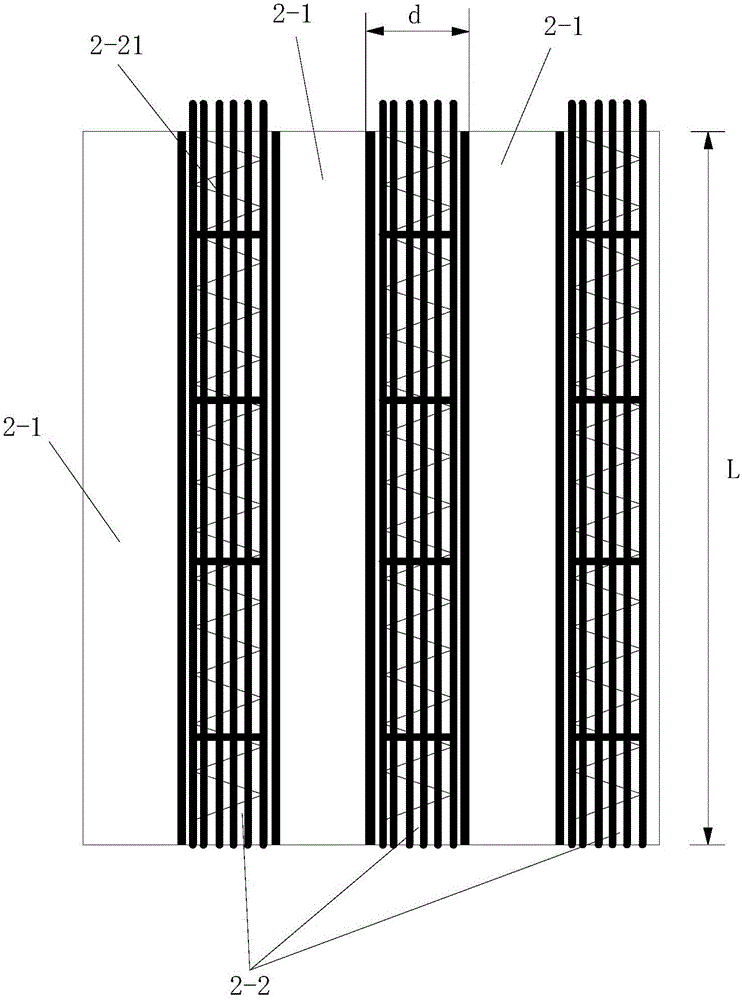

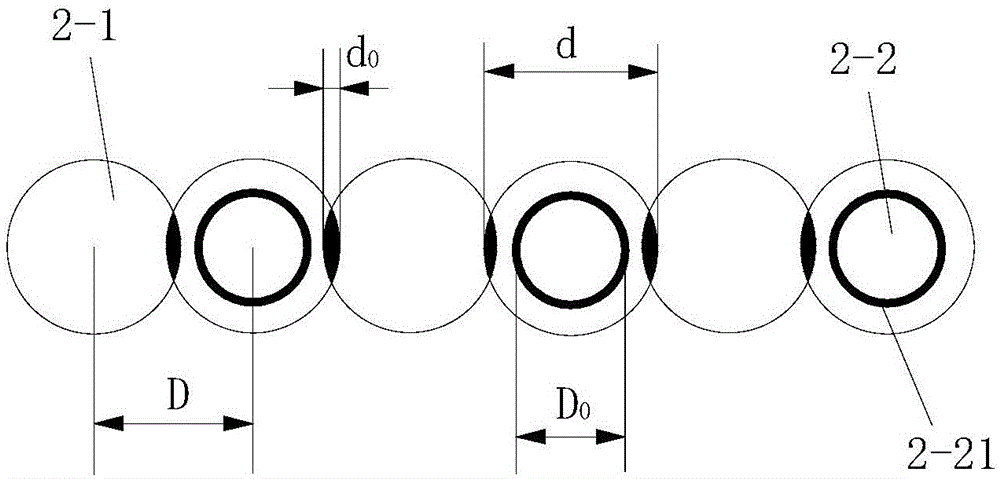

[0092] like Picture 1-1 , Figure 1-2 The occlusal retaining pile shown includes a plurality of plain concrete piles 2-1 arranged from front to back and a plurality of reinforced concrete piles 2-2 arranged from front to back, and a plurality of plain concrete piles 2-1 and a plurality of the reinforced concrete piles 2-2 are arranged vertically and are arranged on the same vertical plane, and a plurality of the plain concrete piles 2-1 and a plurality of the reinforced concrete piles 2-2 are arranged vertically. It is a cylindrical pile with the same pile length and pile diameter. combine Figure 1-4 A plurality of reinforced concrete piles 2-2 have the same structure and their piles are reinforced concrete piles, and the reinforced concrete piles are composed of concrete piles and reinforcement cages 2-21 arranged in the concrete piles. composition. combine Figure 1-3 The structures of the plurality of plain concrete piles 2-1 are the same and the pile bodies are all p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com