Patents

Literature

47results about How to "Wall protection effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature resistant circulating micro-foam drilling fluid or completion fluid

ActiveCN101148579AImprove stabilityHigh temperature resistanceDrilling compositionFoaming agentWell drilling

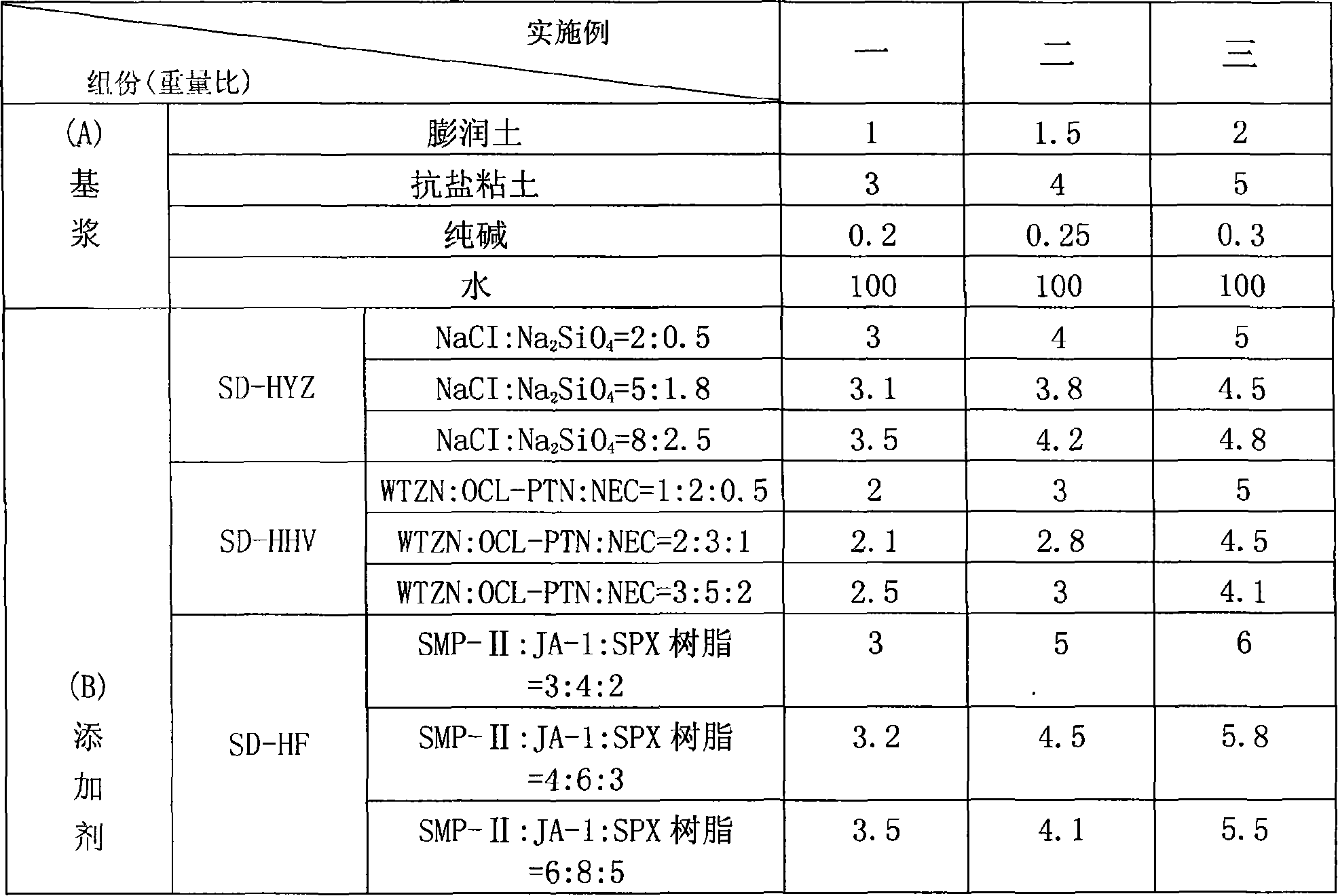

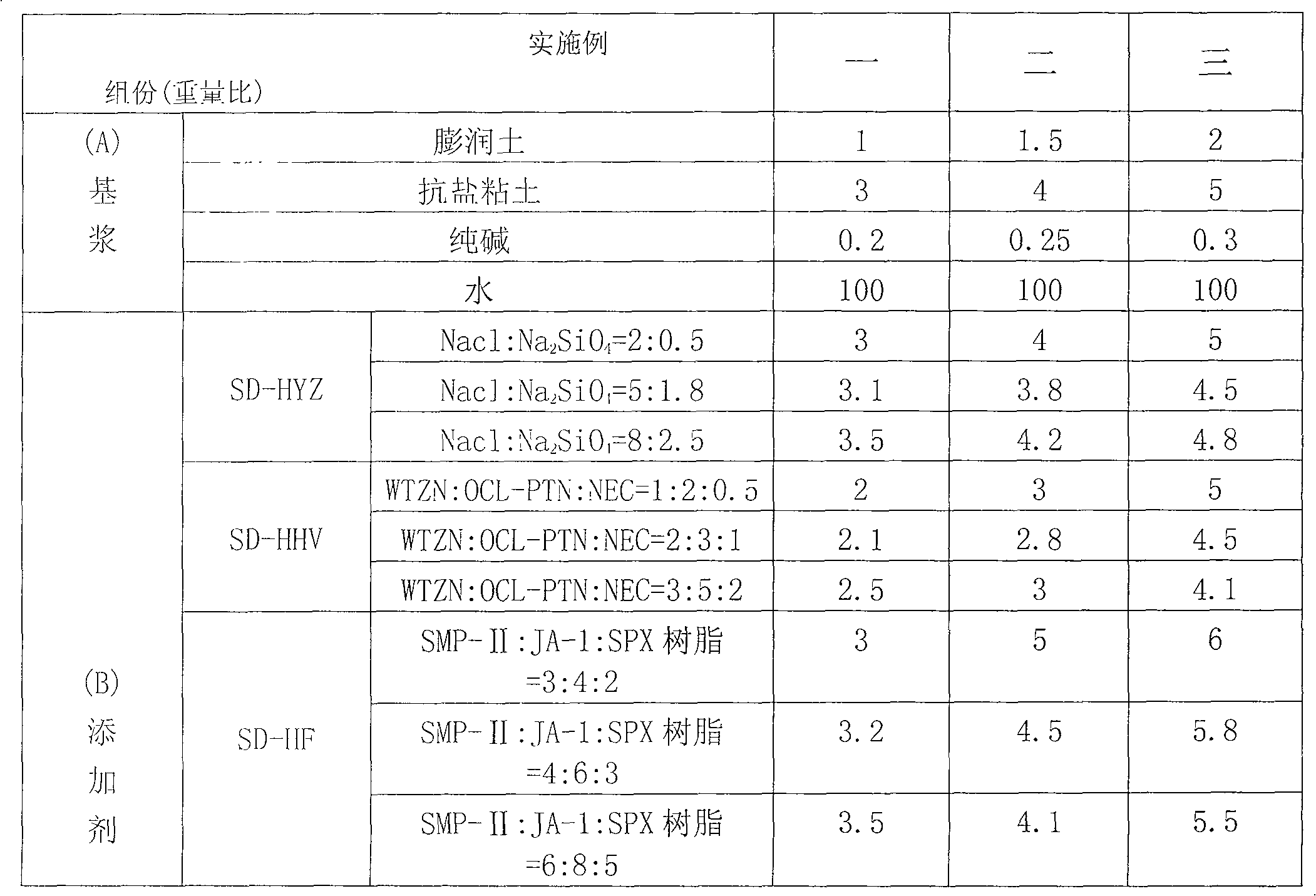

The present invention discloses one kind of high temperature recyclable microbubble drilling and completing fluid, which includes basic slurry comprising bentonite 1-2 (in weight portions, the same below), salt tolerant clay 3-5, sodium carbonate 0.2-0.3 and water 100; and additives comprising high temperature inhibitor 3-5, high temperature tackifier 2-5, high temperature filter loss reducing agent 3-6, high temperature salt resisting filter loss reducing tackifier 1-3, flow form regulator 1-3, high temperature foaming agent 2-5 and high temperature foam stabilizer 1-2.5. The high temperature recyclable microbubble drilling and completing fluid has excellent high temperature performance, high carrying, suspending capacity in low pressure deep well, and functions of inhibiting the hydrating expansion of mudstone and protecting oil and gas reservoir, is suitable for different types of high temperature stratum. It is applied in well drilling and well completing construction for low pressure and low permeation stratum.

Owner:DONGYING TAIER GASOLINE TECH

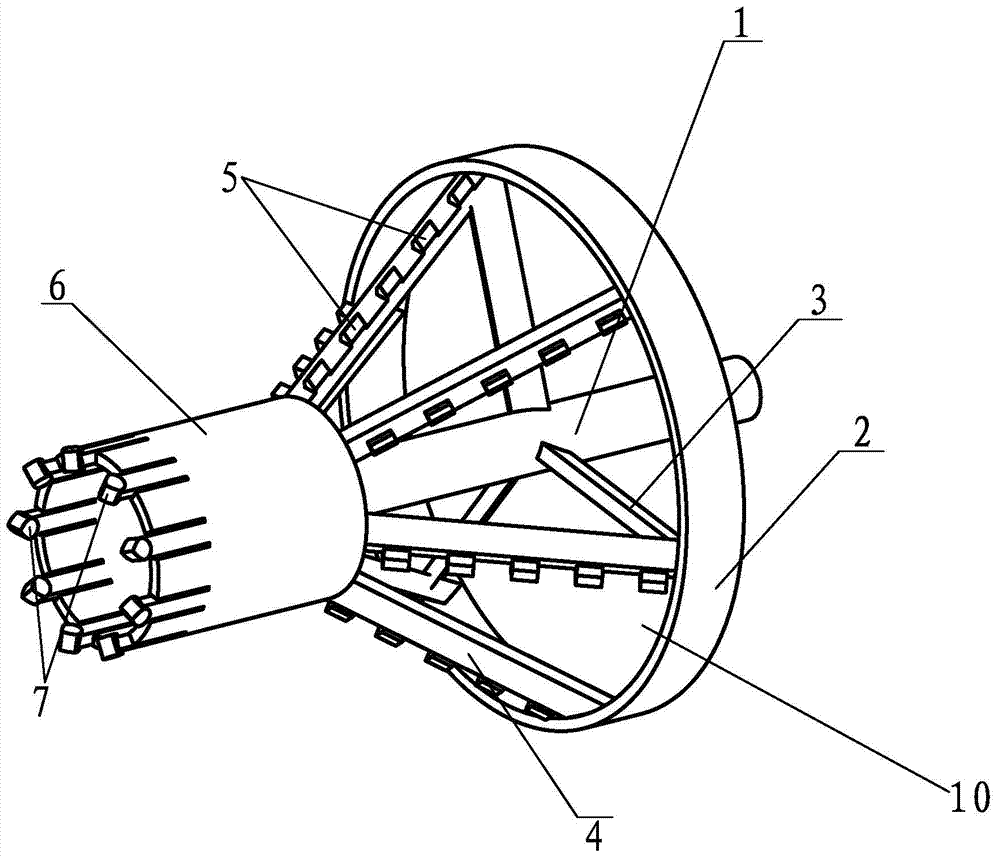

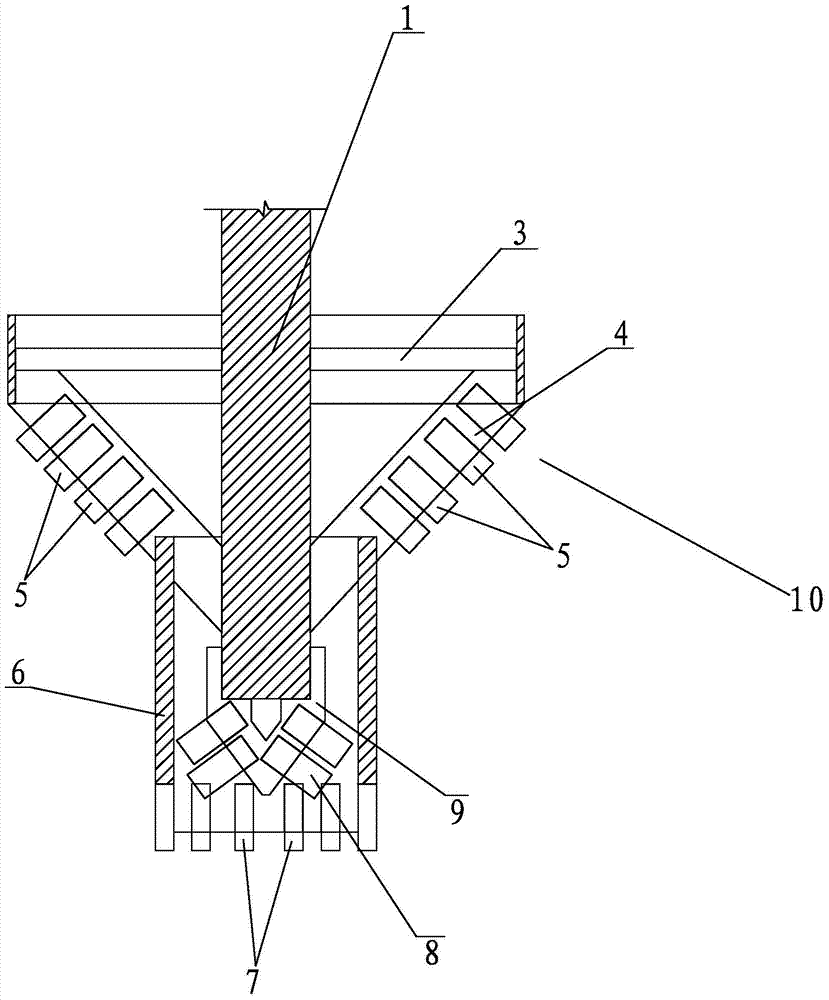

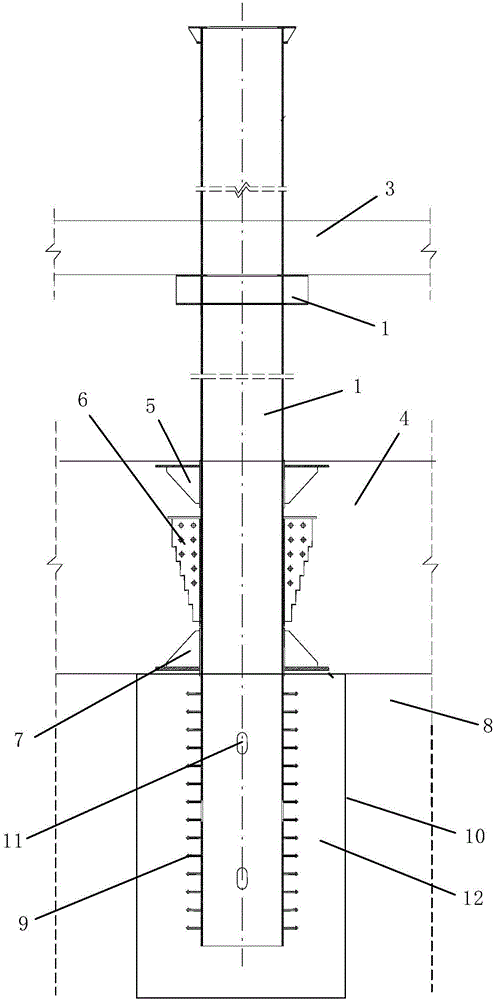

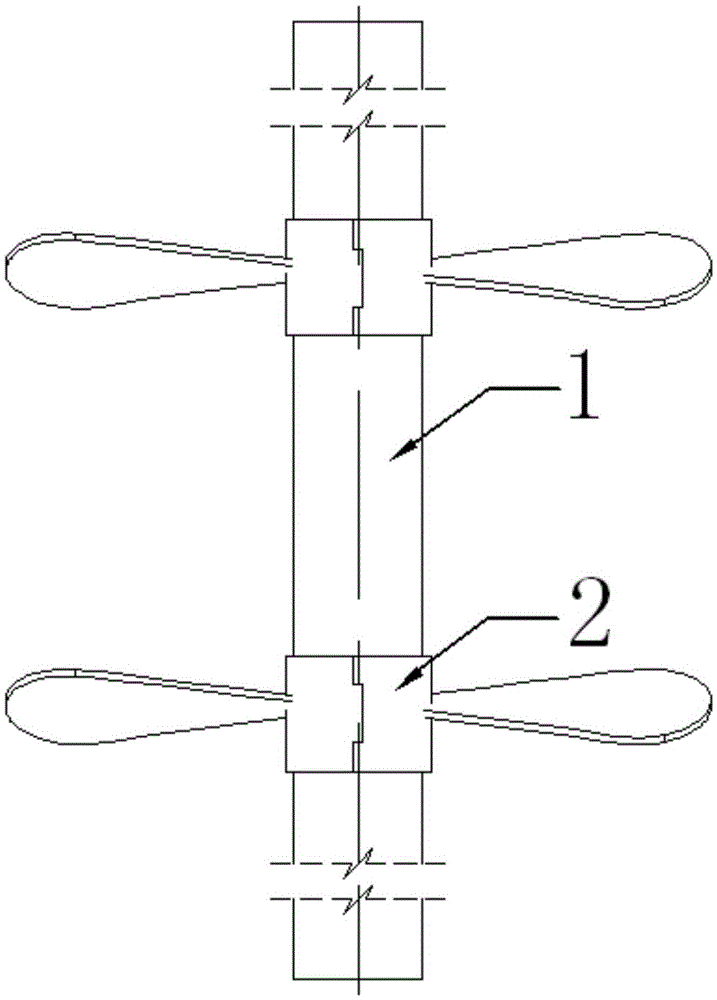

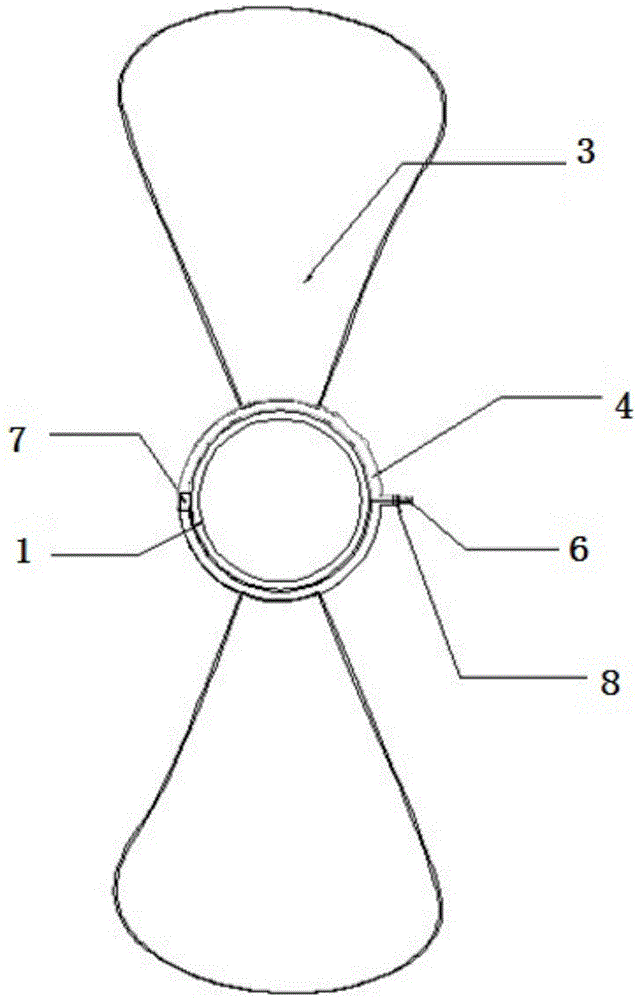

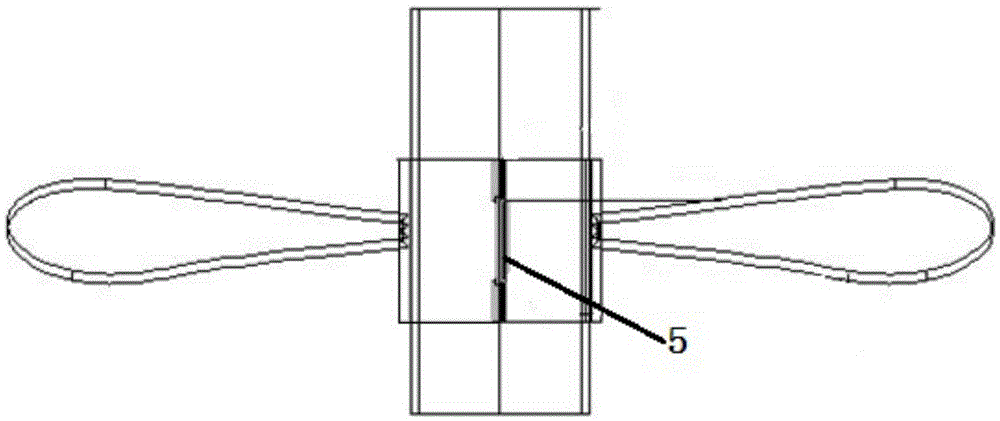

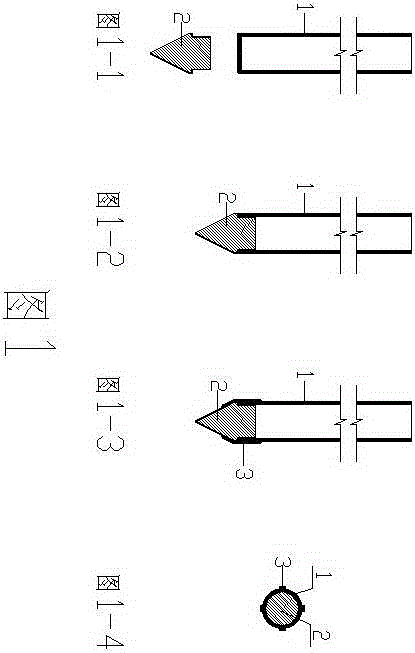

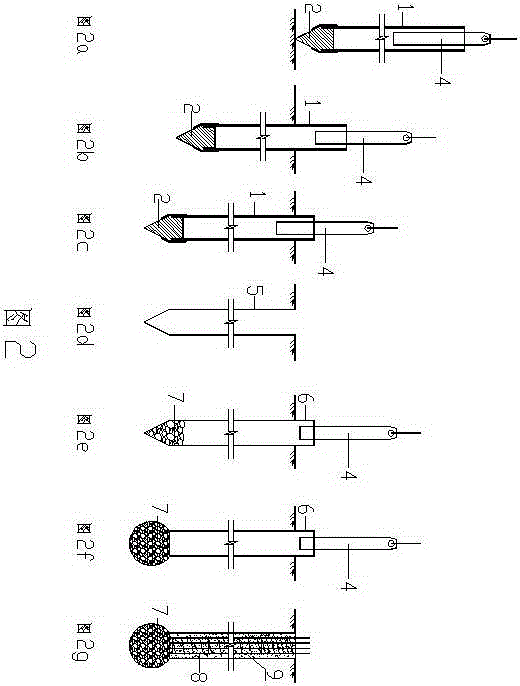

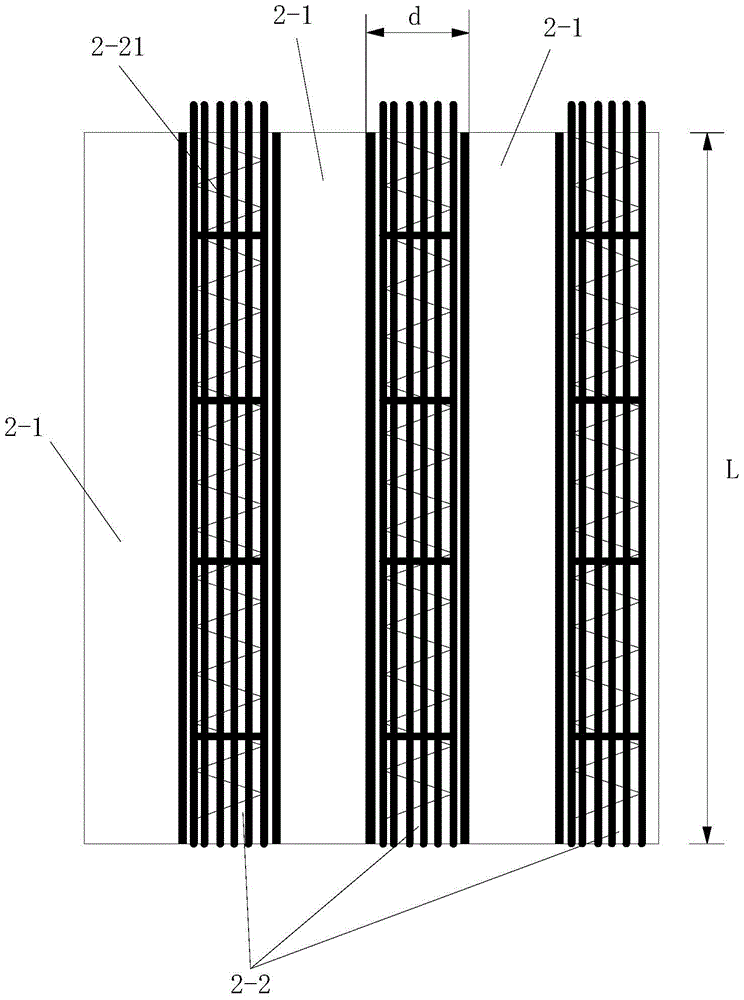

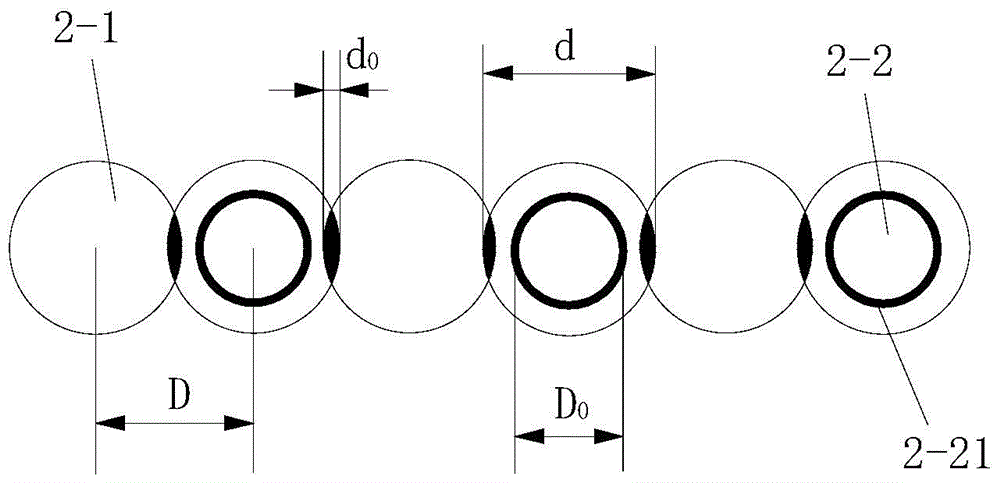

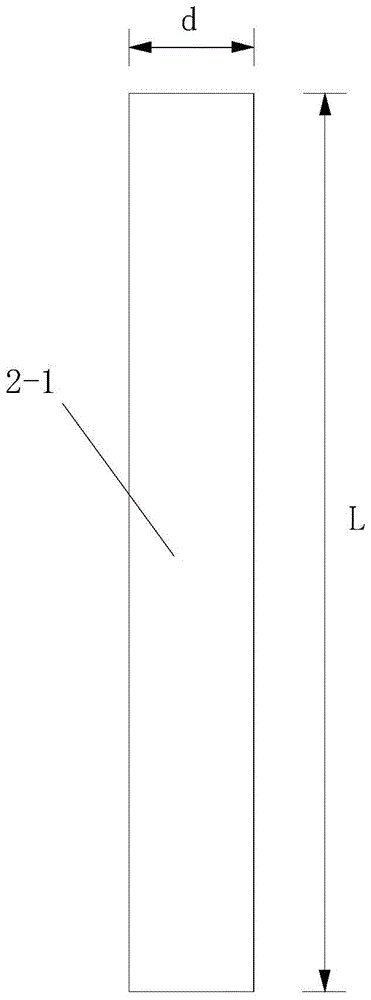

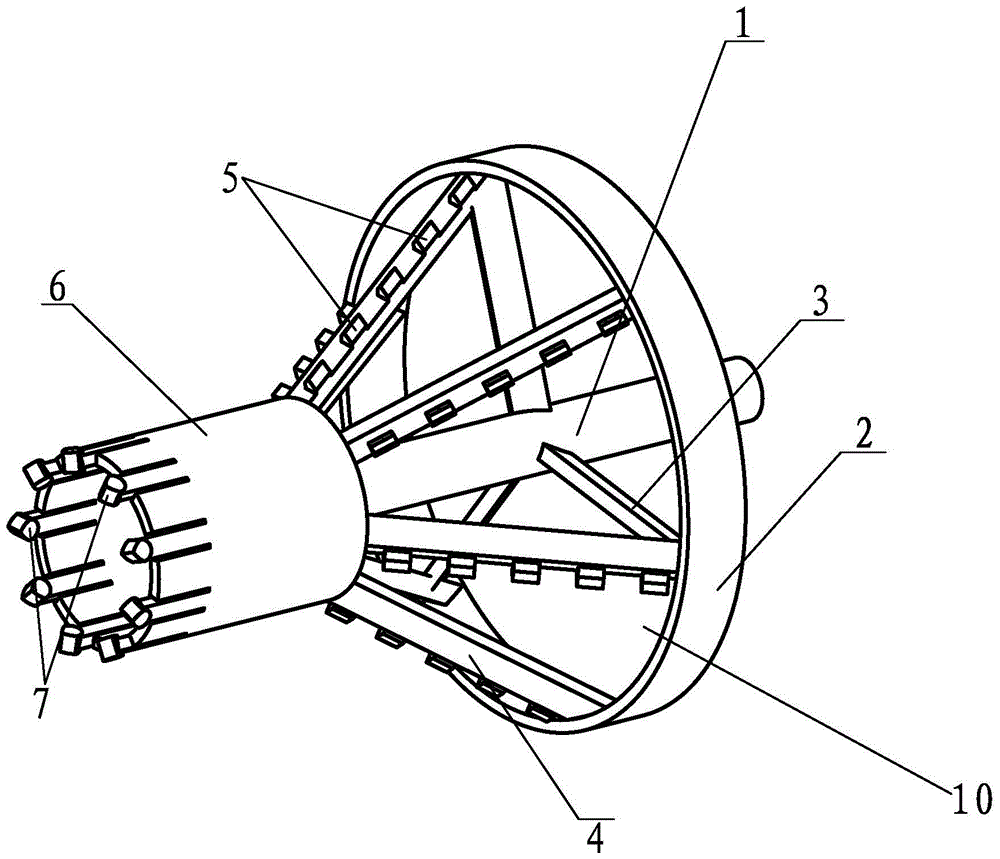

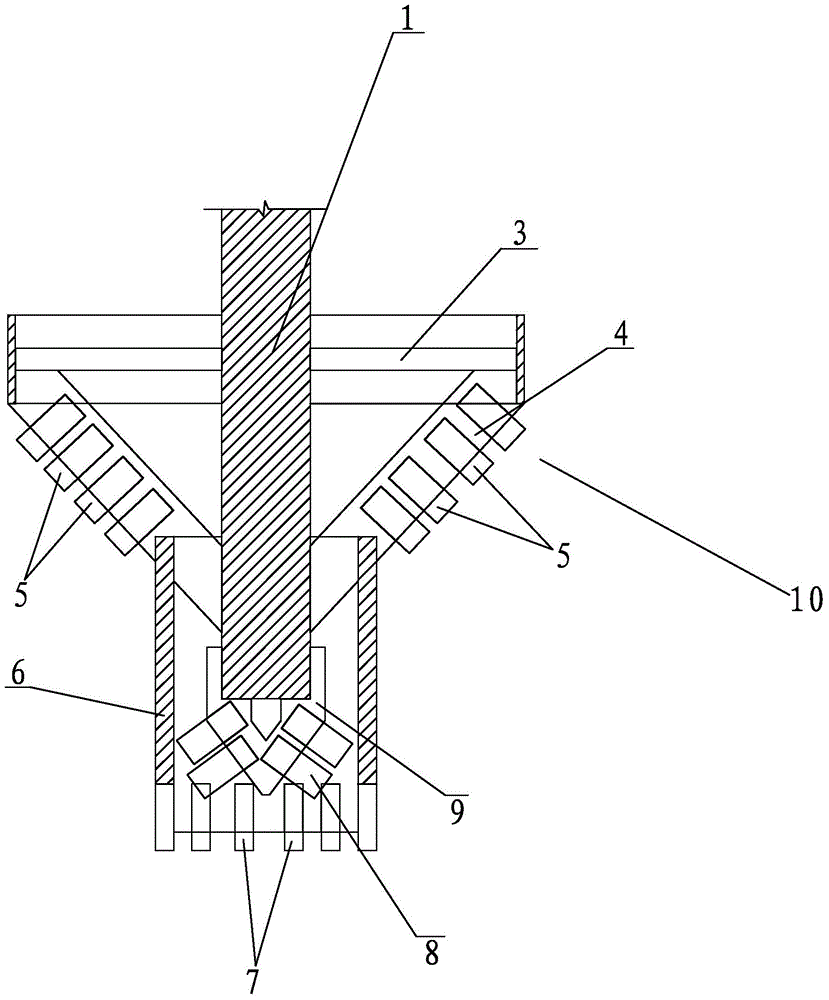

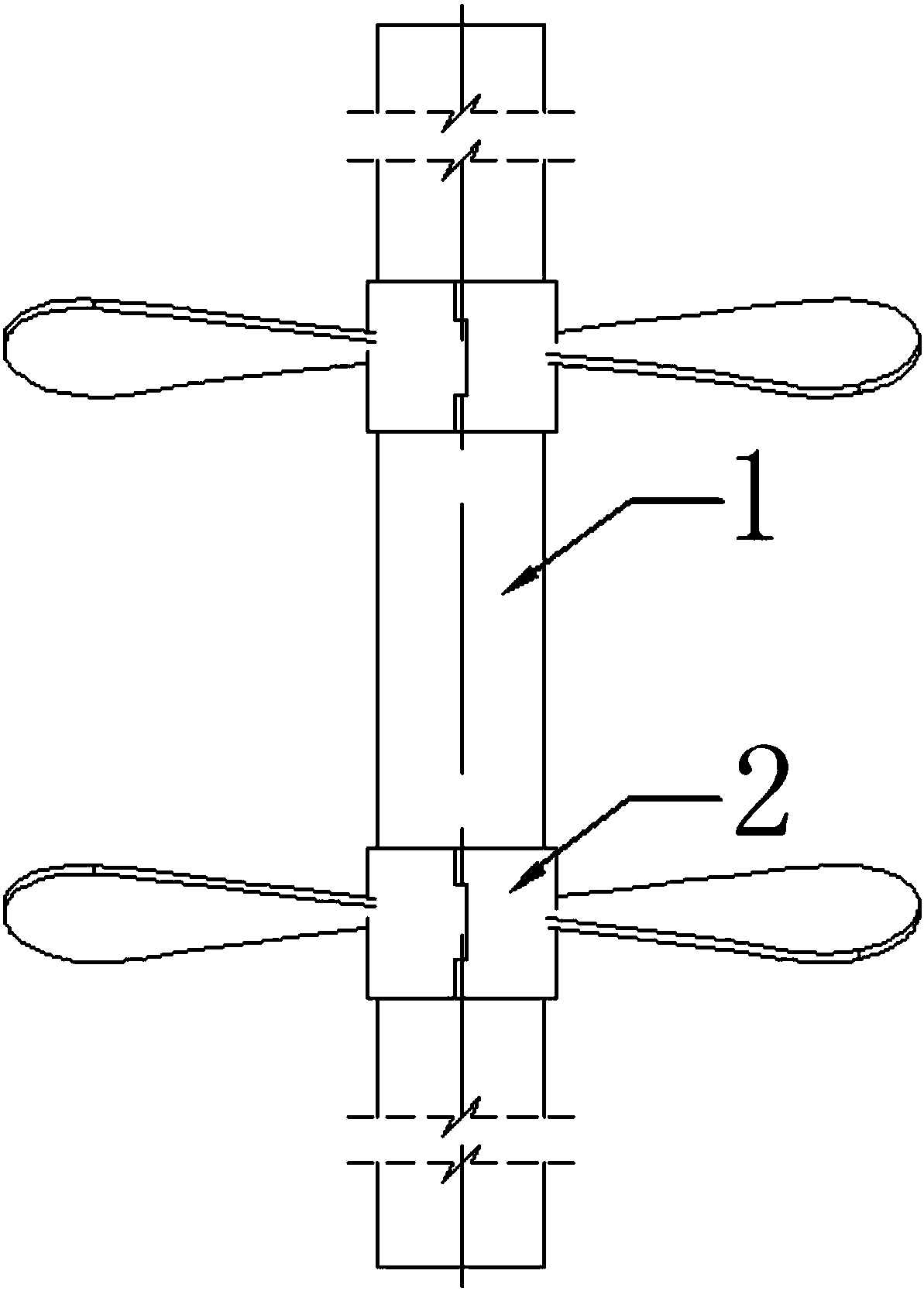

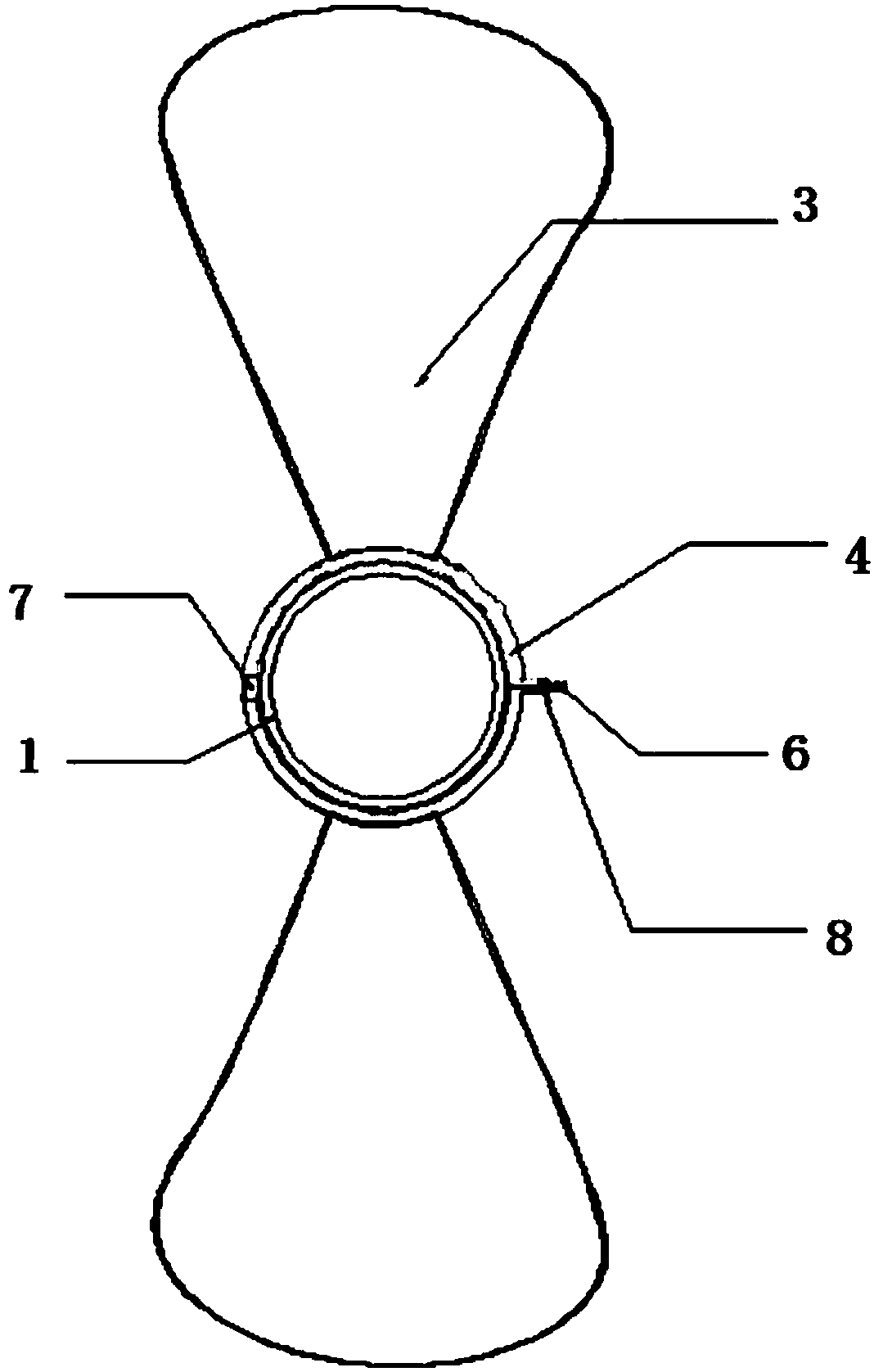

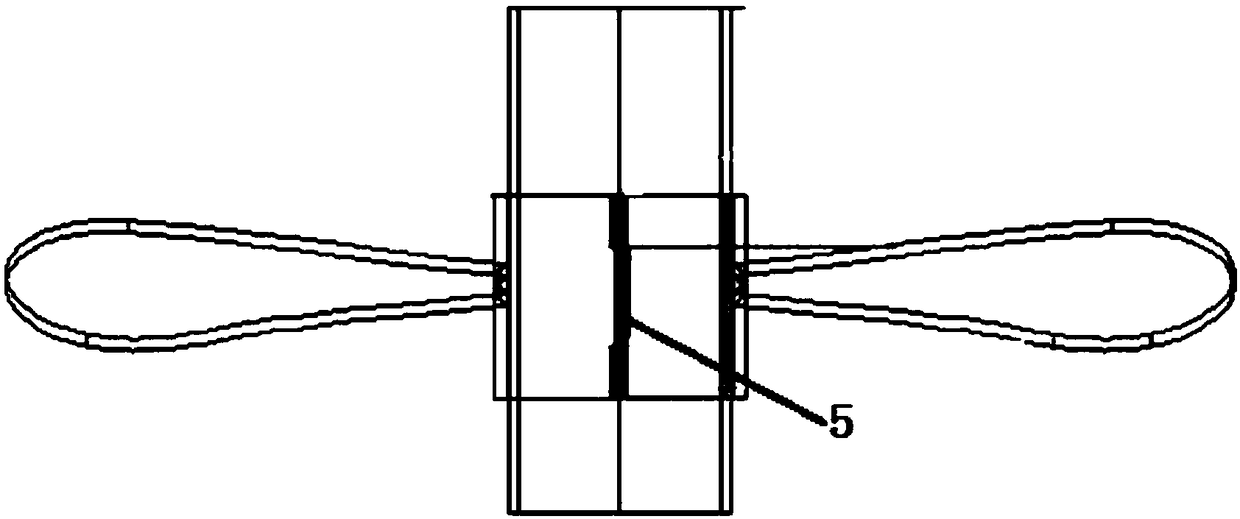

Single-waist multi-leaf hose bit for bored pile and drilling construction method thereof

ActiveCN104747088AGuaranteed verticalityOvercome direction uncertaintyDrill bitsBulkheads/pilesEngineeringDirectivity

The invention belongs to the field of building construction and particularly relates to a single-waist multi-leaf hose bit for a bored pile and a drilling construction method thereof. The technological process comprises the steps of positioning and sampling, centering in position, forming a hole, clearing the hole for the first time, descending a reinforcement cage, descending a guide pipe, clearing the hole for the second time and pouring concrete. The single-waist multi-leaf hose bit for the bored pile comprises a single-waist multi-leaf taper bit body. A positioning and guiding cylinder is fixedly welded to the end of the single-waist multi-leaf taper bit body. A plurality of positioning and guiding cylinder tungsten steel heads are distributed on a circumferential edge opening of one end of the positioning and guiding cylinder. The single-waist multi-leaf hose bit of the bored pile and the drilling construction method thereof have the advantages that the directivity is good, the hole forming perpendicularity is high, the wall protecting effect is good, deslagging is convenient, the hole forming speed is high, and the rock breaking speed is high.

Owner:ZHEJIANG YUJIAN CONSTR GRP CO LTD

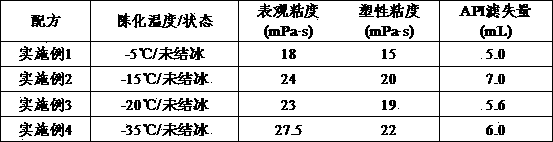

Ultra-low temperature resistant calcium-based low-solid drilling fluid for drilling in permafrost or severe cold areas

InactiveCN103834371AImprove rheologyWall protection effect is goodDrilling compositionPermafrostEngineering

The invention relates to ultra-low temperature resistant calcium-based low-solid drilling fluid for drilling in permafrost or severe cold areas. The ultra-low temperature resistant calcium-based low-solid drilling fluid is composed of 100 parts of water, 10-30 parts of calcium chloride, 1-10 parts of multifunctional complexing agent, 0.5-2.0 parts of viscosity reducer, 0.1-1.0 parts of filtrate reducer, 1-5 parts of lubricant and 1-3 parts of antifoaming agent. The drilling fluid provided by the invention has good rheological property in an ultra-low temperature environment and quite good wall protection capability and carrying ability, thereby providing a technical support for drilling constructions in permafrost and severe cold areas in winter of our country.

Owner:BEIJING INST OF EXPLORATION ENG +1

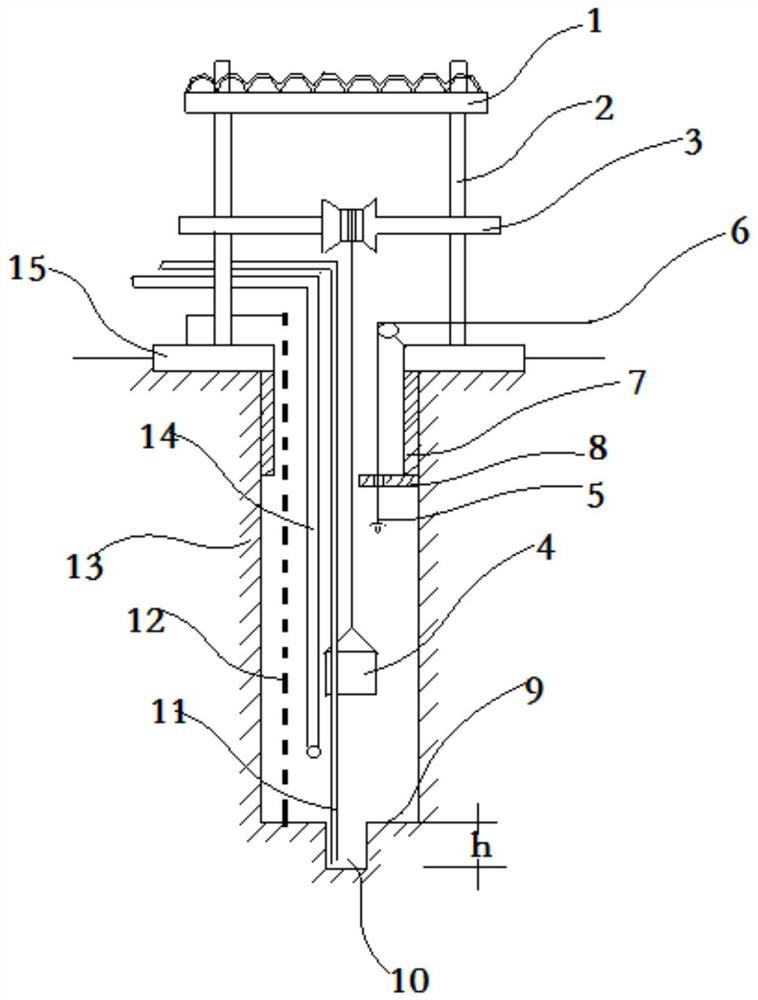

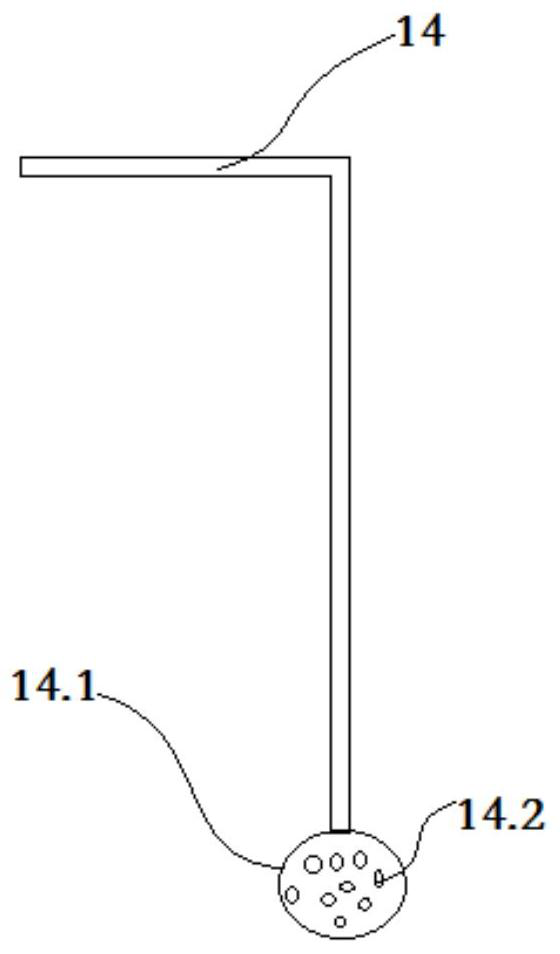

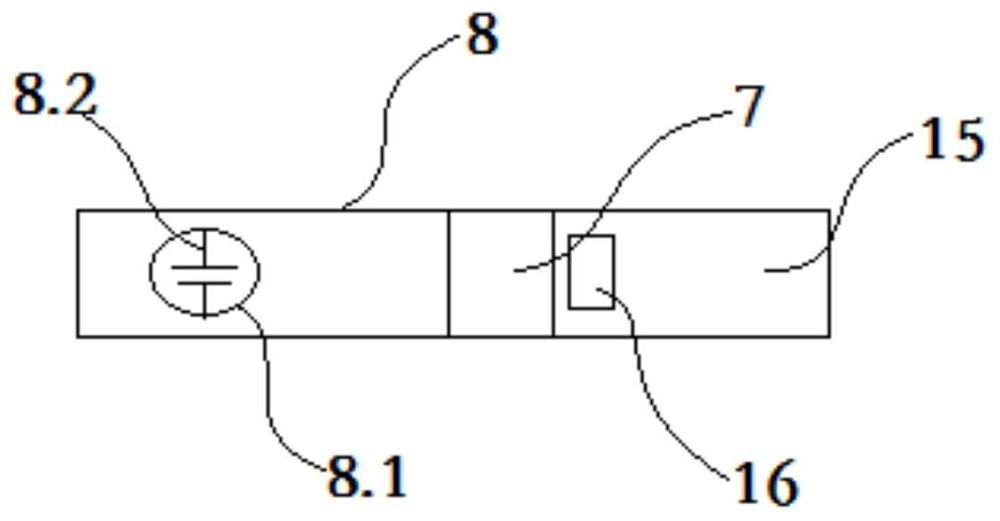

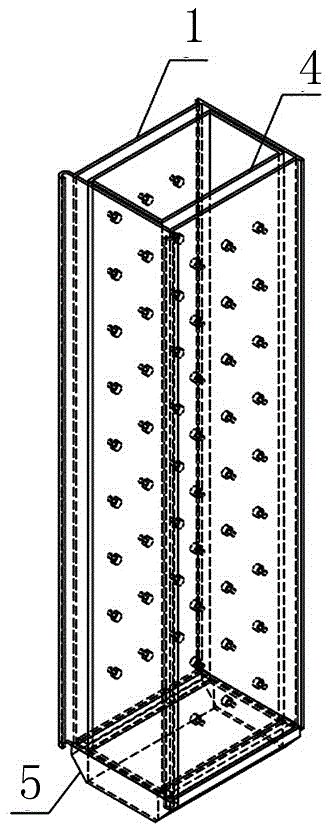

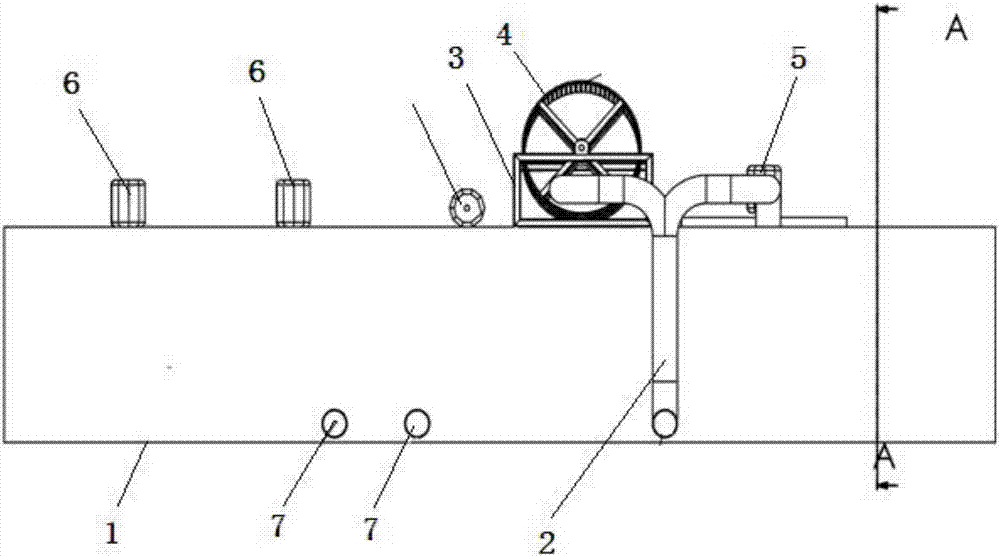

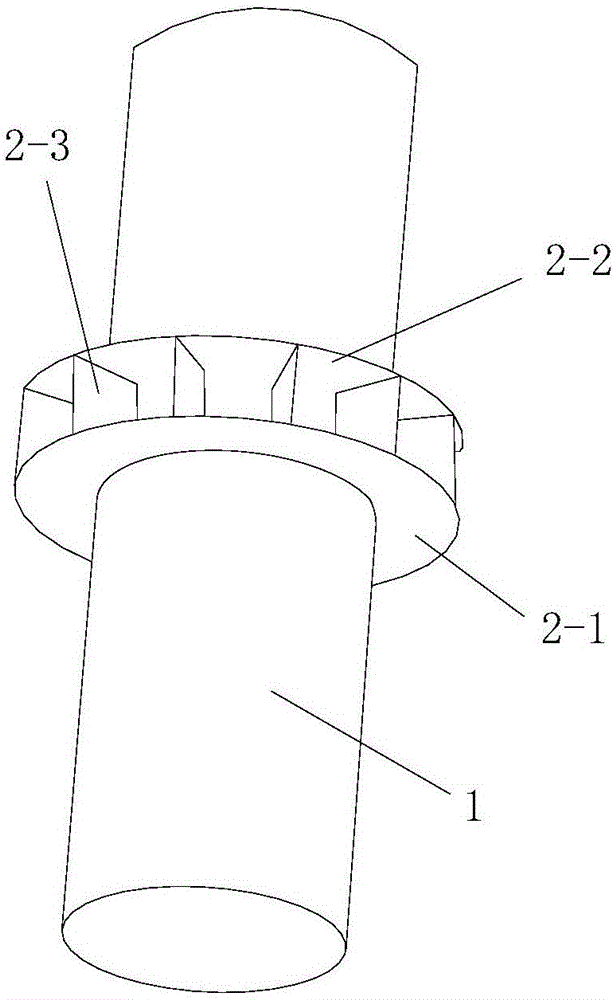

Manual hole digging pile hole mechanical high-pressure grouting construction protection device and manual hole digging pile hole construction method

InactiveCN111749239APrevent fallingEnsure safetyBulkheads/pilesArchitectural engineeringDrainage tubes

The invention relates to the technical field of pile foundation hole digging, in particular to a manual hole digging pile hole mechanical high-pressure grouting construction protection device and a manual hole digging pile hole construction method. By combing selection and installation of a to-be-dug pile foundation site of the manual hole digging pile, and by combining the arrangement of the connecting relation among stand columns, a protective shed, a winch, a soil container, a telescopic retaining wall, a protective end plate, a well bottom, a water collecting pit, a drainage pipe, a crawling ladder, an air supply pipe, the front end of a retaining wall and other components, rainwater and falling objects can be effectively prevented from falling into a manual hole digging pile hole in the construction process of the manual hole digging pile, the safety of constructors is ensured, meanwhile, the device is simple in structure and good in wall protection effect, the excavated well wallis protected through fixed connection between the front end of the protection wall and the telescopic protection wall and telescopic protection wall operation of the telescopic protection wall, the defects that in the traditional concrete pouring process, the difficulty is large, and the pouring protection period is long are overcome, and the protective security is improved.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP SAIDE CONSTR CO LTD

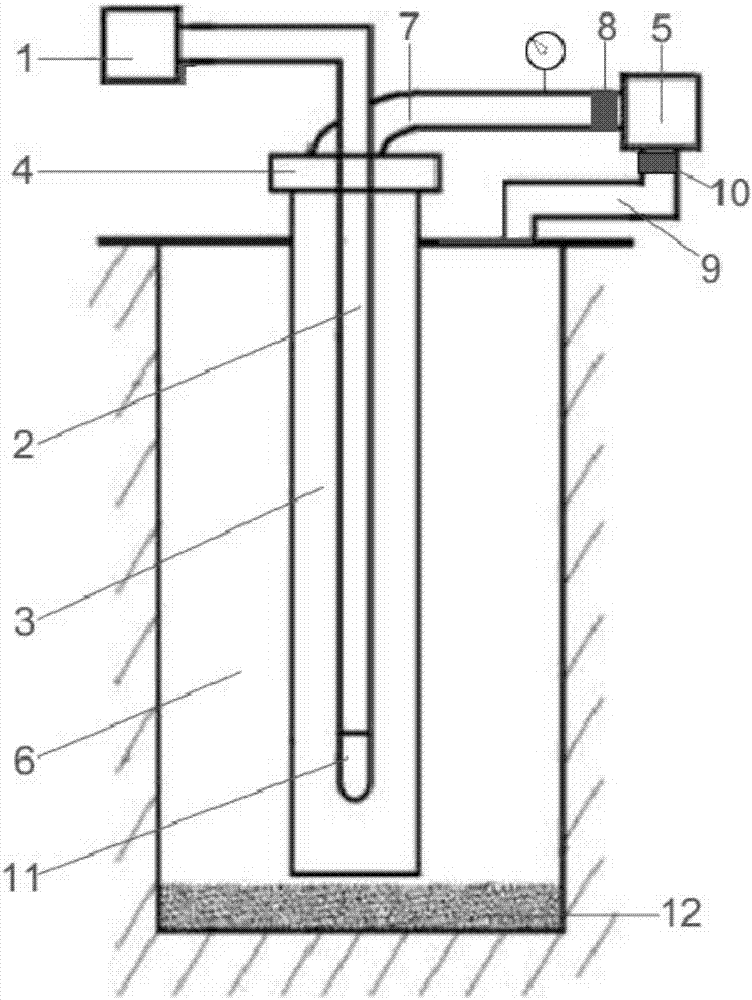

Pile foundation hole cleaning device and technology

The invention discloses a pile foundation hole cleaning device, which includes an air compressor, an air supply pipe, a conduit, an air lift reverse circulation guide cover and a sedimentation tank. One end of the air supply pipe is connected to the input port of the air compressor, and the other end is inserted into the conduit , the conduit is set in the pile hole to be cleaned, the pile hole is provided with chemical slurry, the upper port of the conduit is connected to the sedimentation tank through the slag discharge pipe, the outlet of the slag discharge pipe is provided with a pressure gauge, and the slag discharge pipe and the sedimentation tank are provided with a The first filter screen, the sedimentation tank is connected to the pile hole through the grout filling pipe, the second filter screen is set between the sedimentation tank and the grout filling pipe, the upper port of the conduit is connected to the gas lift reverse circulation guide cover, the air supply pipe and the slag discharge pipe are both It is installed in the hole of the gas lift reverse circulation shroud, wherein the internal sectional area of the conduit is smaller than the annular sectional area between the external wall of the conduit and the pile wall. The invention has simple structure and process, low cost, high hole cleaning efficiency and good hole cleaning effect.

Owner:广州公路工程集团有限公司

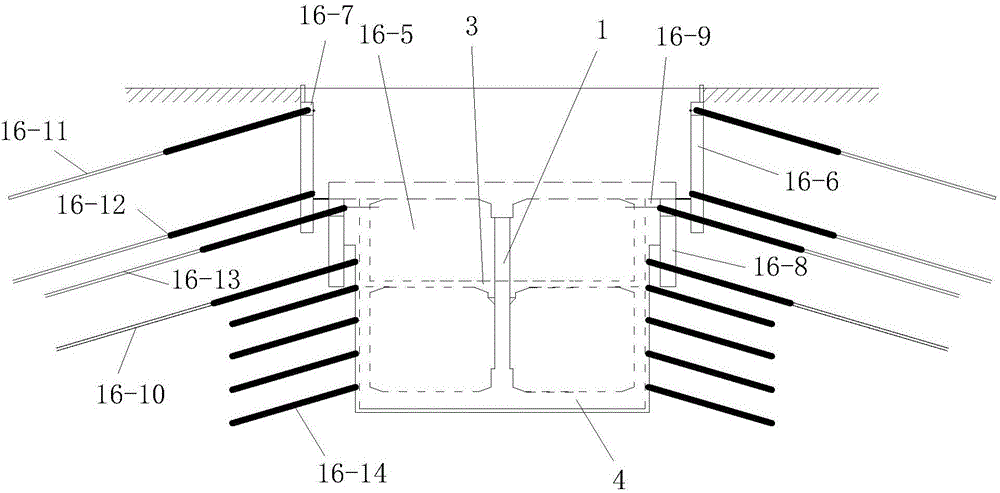

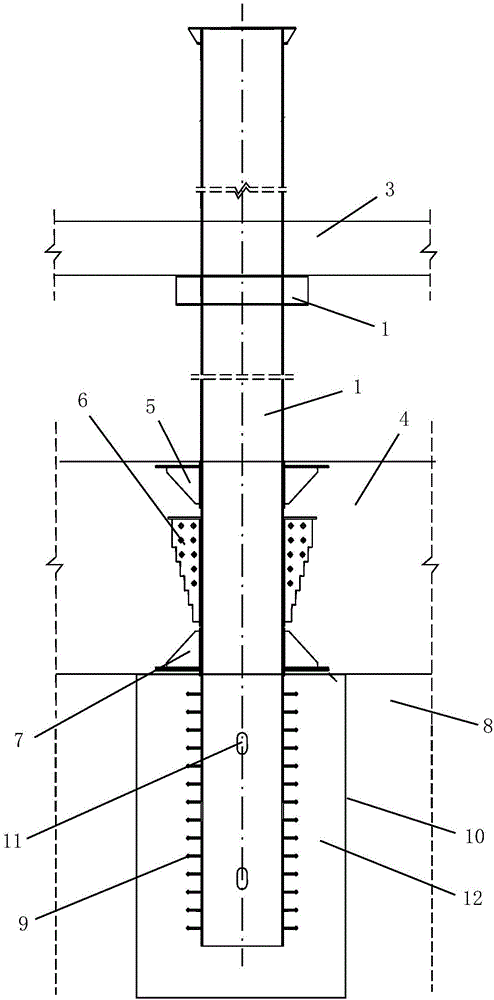

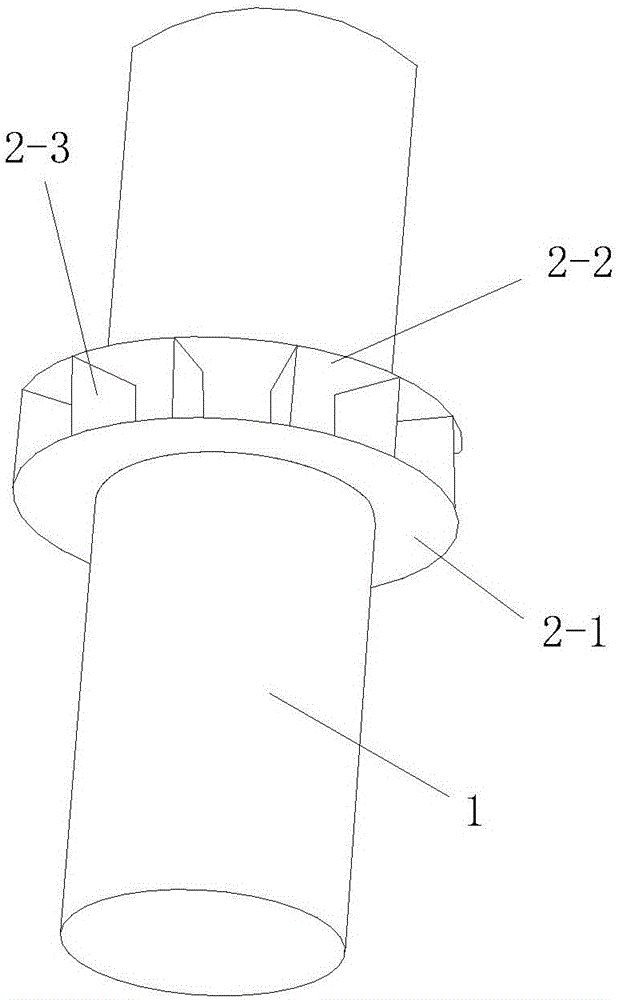

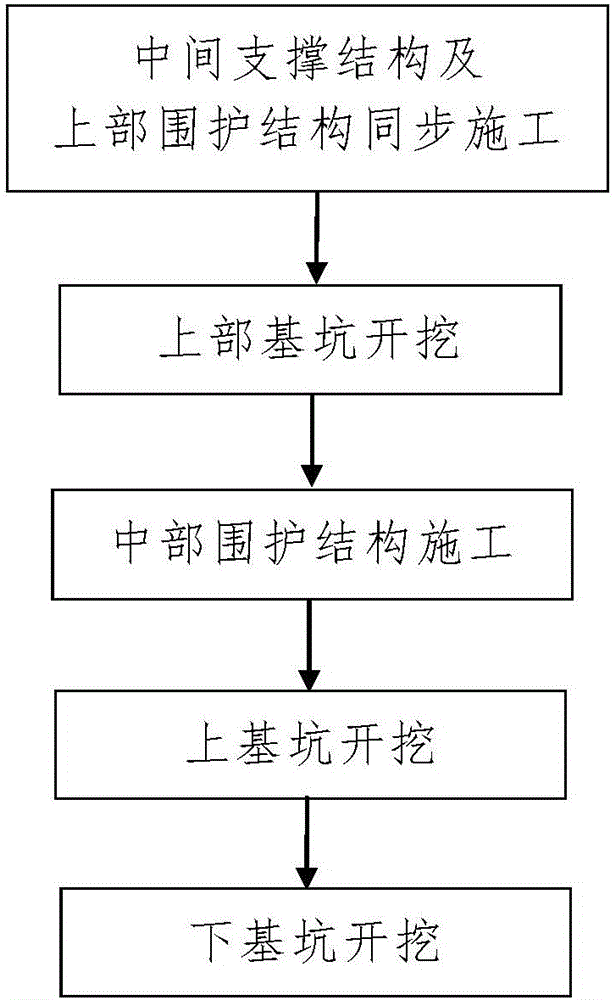

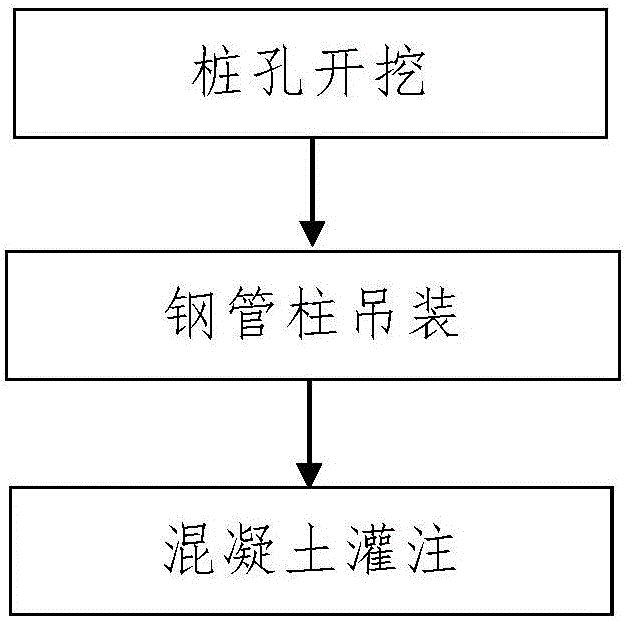

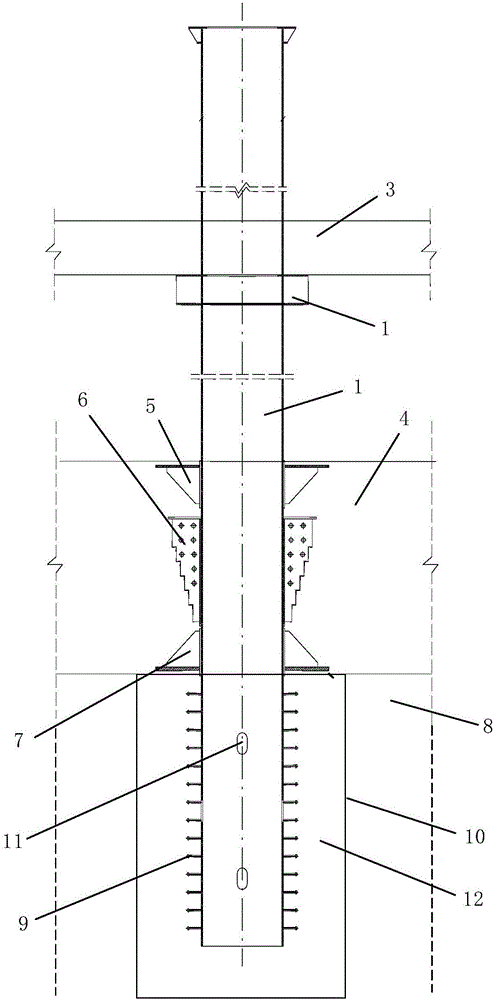

Upper-soft lower-hard ground subway station foundation pit support system and construction method thereof

The invention discloses an upper-soft lower-hard ground subway station foundation pit support system and a construction method thereof. The support system comprises a building envelope distributed on the outer side of a constructed subway station foundation pit and a middle supporting structure distributed in the middle of the inner side of the subway station foundation pit. The middle supporting structure comprises a plurality of digging piles distributed from front to back. The digging piles are steel pipe concrete piles, and each steel pipe concrete pile comprises a steel pipe supporting column, a middle joint structure and a lower joint structure. The construction method comprises the steps that the building envelope and the middle supporting structure are constructed correspondingly; and when the middle supporting structure is constructed, the multiple digging piles in the middle supporting structure are constructed from front to back correspondingly, and when the drilled piles are constructed, the process comprises the following steps of firstly, pile hole excavation, secondly, steel pipe column hoisting and thirdly, concrete pouring. According to the upper-soft lower-hard ground subway station foundation pit support system and the construction method, design is reasonable, construction is easy and convenient, and the use effect is good; the upper-soft lower-hard ground subway station foundation pit can be effectively supported; and stability in the foundation fit excavation process and stability generated after foundation fit excavation is completed are ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

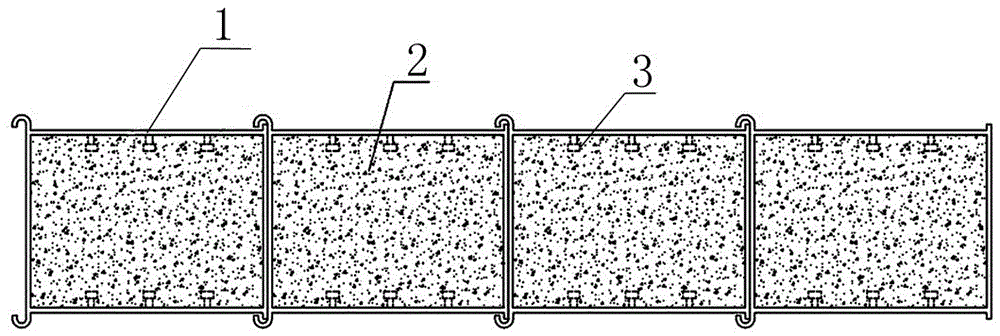

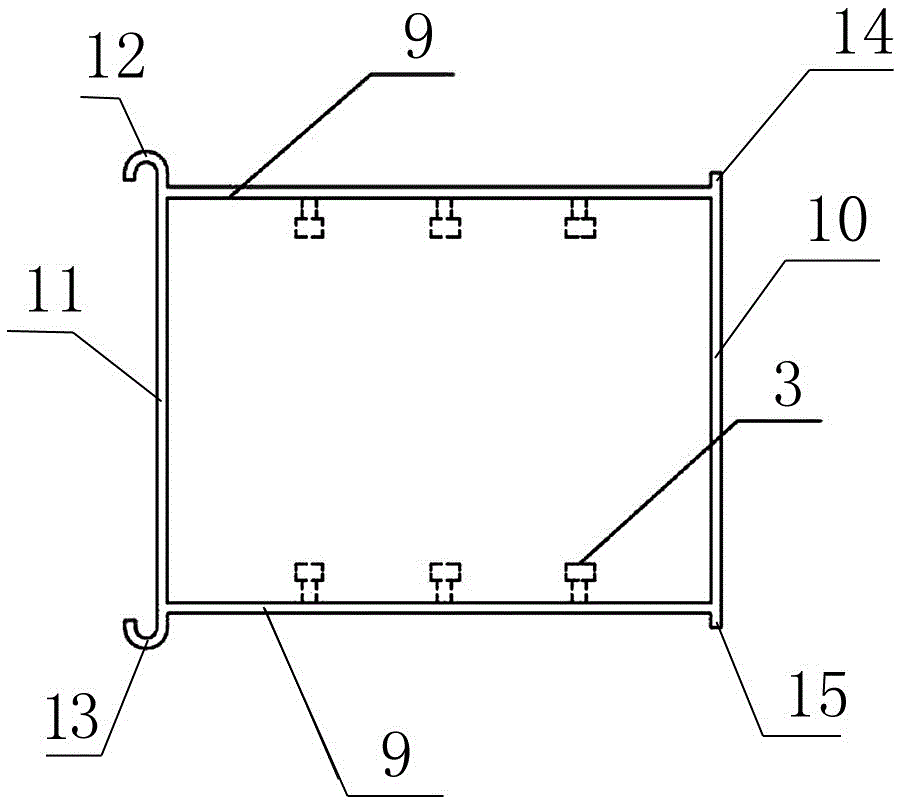

Steel plate and concrete diaphragm wall and construction method thereof

InactiveCN105625438AOvercome the defects of low rigidity and low bearing capacitySolve the technical problems of thick walls and large space occupationExcavationsBulkheads/pilesEngineeringBuilding construction

The invention discloses a steel plate and concrete diaphragm wall and a construction method thereof. The steel plate and concrete diaphragm wall is formed by buckling a plurality of steel plate and concrete diaphragm wall units end to end. Each steel plate and concrete diaphragm wall unit comprises an externally-wrapping steel plate barrel, concrete poured inside the corresponding externally-wrapping steel plate barrel, and shearing-resistant pins arranged on the inner side of a main steel plate body of the corresponding externally-wrapping steel plate barrel. Each externally-wrapping steel plate barrel is a cuboid sleeve which is composed of two main steel plate bodies, a straight steel plate body and a steel plate body with the two ends being provided with hooks. According to the steel plate and concrete diaphragm wall and the construction method thereof, construction cost is lowered, pollution is avoided, and there is no need to assemble reinforcement cages on the site, so that time and labor are saved; moreover, the concrete is poured inside each sleeve, and thus the pouring quality can be guaranteed easily.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

High temperature resistant circulating micro-foam drilling fluid or completion fluid

ActiveCN100516163CImprove stabilityHigh temperature resistanceDrilling compositionFoaming agentWell drilling

The invention discloses a high-temperature-resistant recyclable micro-foam drilling fluid or well-completion fluid, which is composed of: (A) base slurry: 1-2 bentonite, 3-5 salt-resistant clay, 0.2-0.3 soda ash, and 100 parts by weight ;(B) Additives: ①High temperature inhibitor 3-5, ②High temperature viscosifier 2-5, ③High temperature fluid loss reducer 3-6, ④High temperature salt resistance, viscosity raising fluid loss reducer 1-3, ⑤Flow type Regulator 1-3, ⑥ high temperature foaming agent 2-5, ⑦ high temperature foam stabilizer 1-2.5. The invention has high temperature resistance, good carrying and suspension ability in low pressure deep wells, can be used for deep well exploration and development, has strong adaptability, can be used as drilling fluid and well completion fluid, and can be used in high temperature deep wells and low pressure Carbonate formations can also be used in high-temperature, low-pressure, low-permeability mudstone formations, mudstone shale reservoirs and salt-bearing formations. They have the ability to inhibit hydration expansion of mudstone and have a good effect of protecting oil and gas layers. They are mainly used in low-pressure, low-permeability Formation drilling and well completion construction process.

Owner:DONGYING TAIER GASOLINE TECH

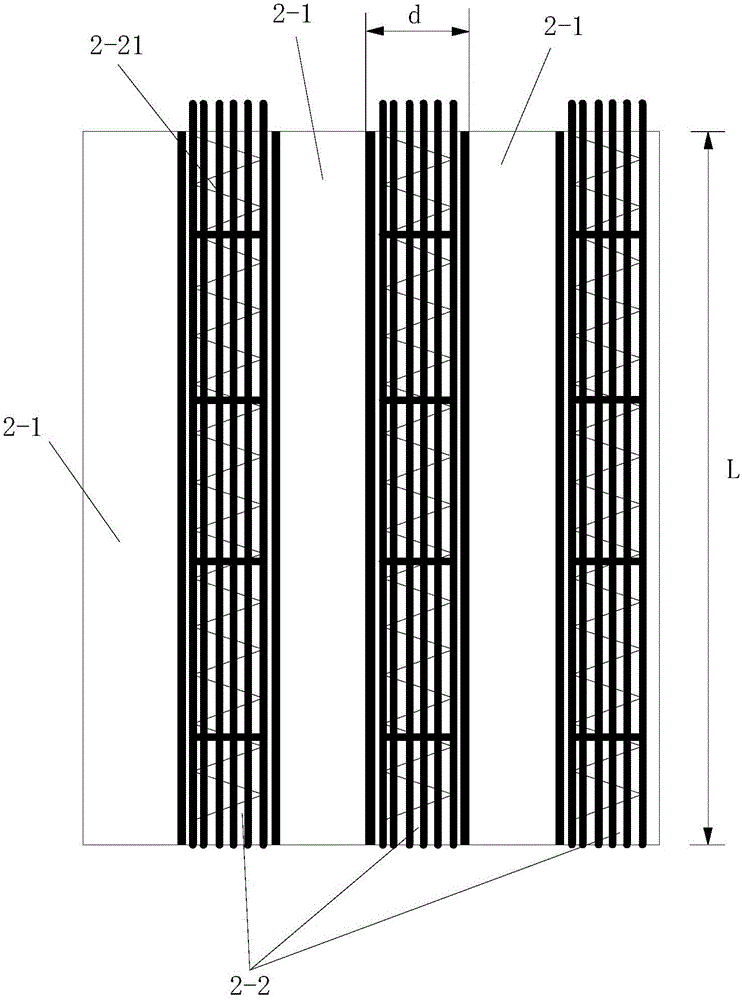

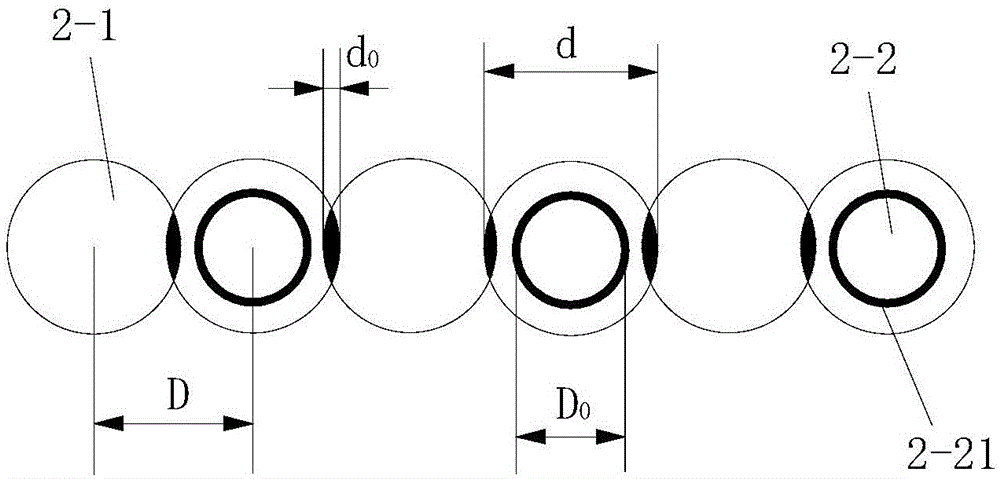

Engaged retaining pile and construction method and application thereof

The invention discloses an engaged retaining pile. The engaged retaining pile comprises a plurality of plain concrete piles laid from front to back and a plurality of reinforced concrete piles laid from front to back. The plain concrete piles and the reinforced concrete piles are laid in a staggered mode. A pile body of each reinforced concrete pile is engaged with pile bodies of two plain concrete piles located front and back, so that the retaining effect is good. The invention further discloses a construction method of the engaged retaining pile. The construction method comprises the steps that firstly, construction of the plain concrete piles is conducted, and the multiple plain concrete piles are constructed from front to back; and secondly, construction of the reinforced concrete piles is conducted, the multiple reinforced concrete piles are constructed from front to back in the construction process of the multiple plain concrete piles, drilled hole-forming construction processes of any one of the reinforced concrete piles are conducted after the construction of the two adjacent plain concrete piles front and back is completed. The construction method is simple; the design is reasonable and the construction is simple and convenient; the construction efficiency is high and the construction effect is good. In addition, the invention discloses an application of the engaged retaining piles, namely a foundation pit retaining structure is formed by fixedly connecting the multiple engaged retaining piles tightly.

Owner:SHAANXI ZHUANGXIN CONSTR ENG +1

Rotary excavating and drilling half-hole mud wet-method hole formation process of collapsible loess super-length large-diameter pile foundation

The invention provides a rotary excavating and drilling half-hole mud wet-method hole formation process of a collapsible loess super-length large-diameter pile foundation and belongs to the technicalfield of pile foundation rotary excavating and drilling hole formation. The process comprises the following steps: confirming pile foundation rotary excavating and drilling half-hole mud wet-method hole formation conditions, flattening a field, burying protection barrels, making mud, drilling holes, cleaning the holes, manufacturing reinforcement cages, mounting the reinforcement cages, mounting guide tubes, and grouting concrete. According to the half-hole mud wet-method hole formation process provided by the invention, dry-method mud-free hole formation is implemented in an upper crack sinkhole development section, a rapid speed can be achieved, a hole wall can be extruded by a drilling hopper, and the hole wall stability can be improved; mud wall protection wet-method hole formation isimplemented in a lower part, hole collapse can be effectively prevented, and a hole formation speed can be ensured; a good mud wall protection effect can be achieved, remarkable effects in reducing hole collapse and the like can be achieved, and the security can be easily ensured; holes can be cleaned through bottom blowing and slag turnover and positive circulation of high pressure water, or bydoping mud or clean of a low density at the hole bottoms to directly dilute the mud, slag settled at the hole bottoms can be completely cleaned off, the possibility that the settled slag is mixed withthe mud in pile foundation concrete can be reduced, and the quality can be easily ensured.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

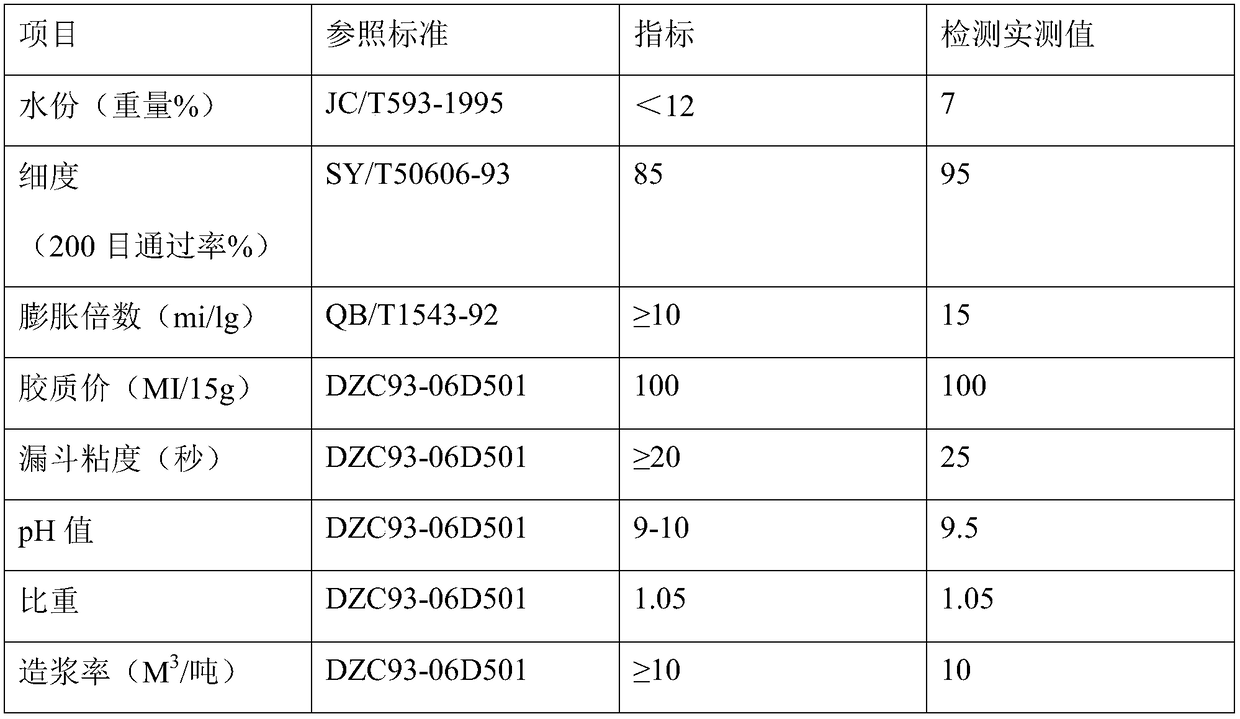

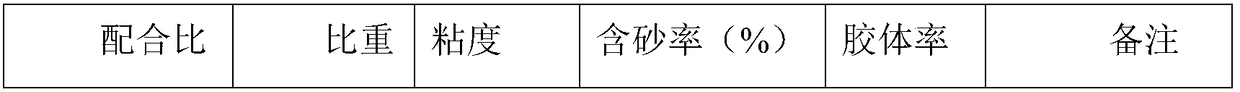

Slurry for hole drilling and wall protection as well as preparation technology and on-site construction technology thereof

InactiveCN109181660AConsistent viscosity ratioLong effective timeFlushingDrilling compositionAluminium chlorohydrateMass ratio

The invention discloses slurry for hole drilling and wall protection. The slurry is prepared from the following components: water, bentonite and an admixture according to the mass ratio of (8 to 14) to (0.8 to 1.2) to 0.01, wherein the admixture is prepared by mixing water, sodium bentonite, polyaluminum chloride and sodium carbonate according to the ratio of (600 to 800ml) to (60 to 80g) to (1.4to 1.65g) to 1.54g. The slurry disclosed by the invention has a good wall protection effect; the slurry is uniform and the viscosity ratios of upper and lower layers are the same; the inner part of asand layer is drilled in a rotary manner and hole collapse is not caused; and the slurry has suitable viscosity and does not cause a drill pasting phenomenon.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 2ND ENG

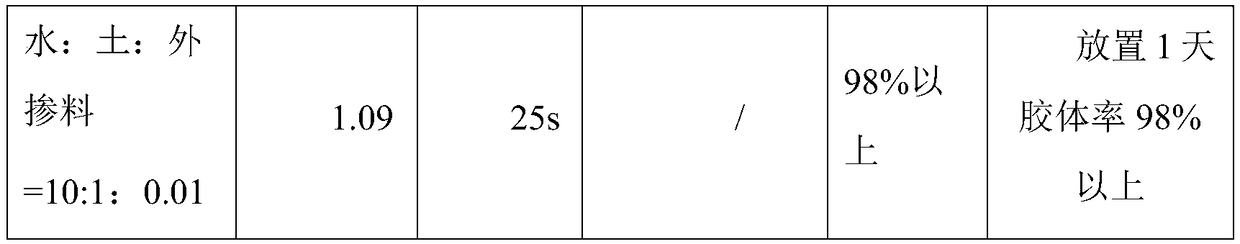

Excavation construction technology for subway station foundation pit in upper-soft lower-hard ground

ActiveCN106381874AThe process steps are simpleReasonable designArtificial islandsExcavationsSubway stationPipe support

The invention discloses an excavation construction technology for a subway station foundation pit in upper-soft lower-hard ground. The excavation construction technology is characterized in that a middle support structure is arranged in the middle of the constructed subway station foundation pit; a retaining structure of the constructed subway station foundation pit comprises an upper-part retaining structure, a middle-part retaining structure and a lower-part retaining structure; a lower-part foundation pit is divided into an upper foundation pit and a lower foundation pit; the middle support structure comprises a plurality of dug piles; the dug piles are concrete-filled steel pipe piles; and each concrete-filled steel pipe pile comprises a steel pipe support pillar, a middle joint structure and a lower joint structure. The excavation construction of the subway station foundation pit comprises the following steps: A, synchronous construction of the middle support structure and the upper-part retaining structure; B, excavation of an upper-part foundation pit; C, construction of the middle-part retaining structure; D, excavation of the upper foundation pit; and E, excavation of the lower foundation pit. The excavation construction technology is simple in step, reasonable in design, simple and convenient in construction and good in using effect, and ensures that the excavation construction process of the subway station foundation pit in the upper-soft lower-hard ground can be simply, conveniently and quickly completed and is safe and reliable.

Owner:CHINA RAILWAY 20 BUREAU GRP

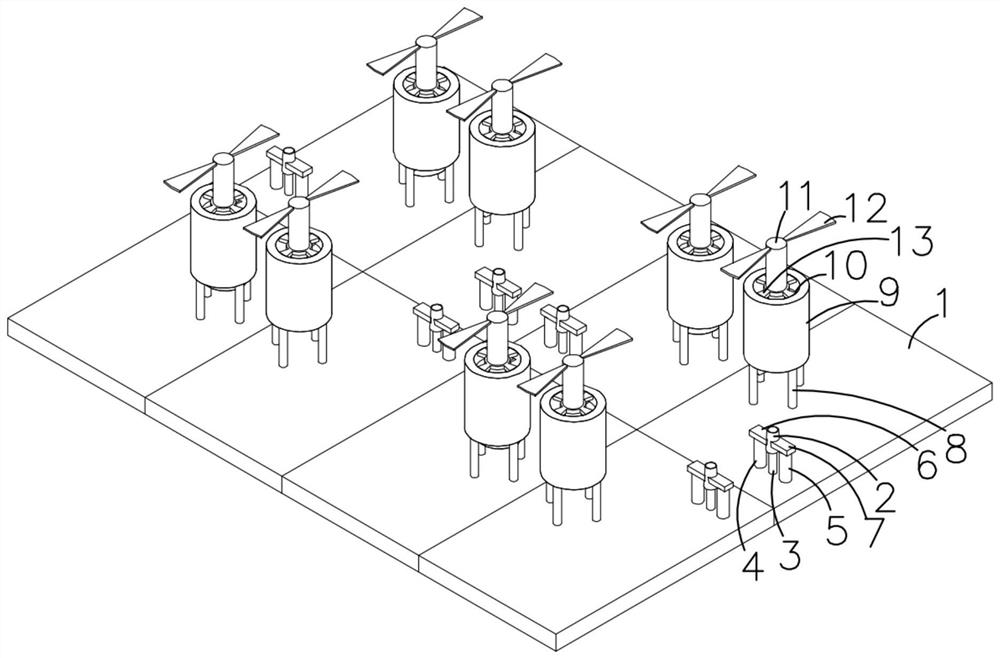

Hole cleaning device for cast-in-situ bored pile

InactiveCN105649085ASimple structureEasy to assemble and disassembleBulkheads/pilesSludgeEconomic benefits

The invention discloses a hole cleaning device for a cast-in-situ bored pile. The hole cleaning device comprises a drill pipe. At least one stirring paddle is installed on the drill pipe and composed of blades and a paddle hub, wherein the paddle hub surrounds the drill pipe in a hooped mode, the number of the blades is at least two, and the blades are fixed to the paddle hub with the blade surfaces facing upwards. During primary hole cleaning of positive circulating rotation, the drill pipe drives the stirring paddles fixed to the drill pipe to rotate, and in combination with the idling of a drill bit, dregs arising from the pile bottom are effectively and gradually pushed upwards, so that the carrying efficiency of the dregs is improved, the thickness of the dregs is lowered, and the hole cleaning efficiency and the bearing capacity of a pile foundation are improved. Meanwhile, the concentration of sludge at the pile bottom is high, the sludge pushed upwards by the blades has a painting function on a hole wall, the circulation speed of the sludge is increased due to the lifting function of the blades, formation of a sludge cover is accelerated, and occurrence of a hole collapse phenomenon is reduced. The hole cleaning device for the cast-in-situ bored pile is simple in structure, convenient to operate, high in dreg cleaning efficiency, high in dreg cleaning depth, good in economic benefit, and obvious in effect during hole cleaning for the ultra-deep cast-in-situ bored pile.

Owner:SUZHOU UNIV

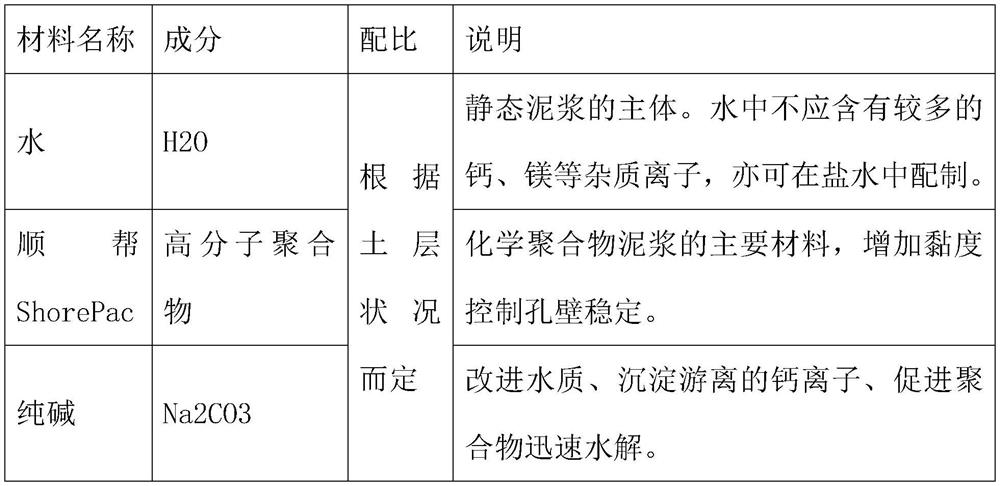

Construction method of bored pile in sand seam geology, application of chemical sludge dado to same, and pile foundation

InactiveCN107254874AWall protection effect is goodPrevent precipitationBulkheads/pilesSocial benefitsSludge

The invention discloses a construction method of a bored pile in sand seam geology, application of chemical sludge dado to the same, and a pile foundation, and relates to the technical filed of building operations so that the problems that collapsing holes, broken drill points or drill stems are likely to happen in the existing bored pile in sand seam geology construction process can be improved. The construction method of the bored pile in sand seam geology can guarantee that the chemical sludge dado has fine effect protective shelter, prevent the collapsing holes, effectively cool drill bits and lubricate drilling tools, and reduce the problems of broken drill points or drill stems so that it is guaranteed that drilling work can go on smoothly. The application of the chemical sludge dado in the construction method of the bored pile in sand seam geology are also provided, so that construction progresses and construction quality are effectively ensured, construction risks are reduced, economic benefits and social benefits are significantly increased, and accordingly the chemical sludge dado is suitable for popularization and application. A pile foundation obtained through the method is also provided. The integrity of the foundation pile is tested by ultrasonic testing, which shows that the foundation pile is I-grade pile and has good construction quality.

Owner:江苏燕宁工程科技集团有限公司

A kind of protective tube device for forming holes in building foundation and construction method thereof

The invention aims to provide a pile casing device for hole formation in building foundation and a construction method of the building foundation by adopting the pile casing device. The pile casing device for hole formation in the building foundation comprises a pile casing body formed by a round steel pipe, and is characterized in that an impact cone is arranged at the bottom end of a pile casing, the lower half part of the impact cone adopts a cone whose diameter is larger than or equal to the outer diameter of the pile casing, the sharp corner of the cone faces downwards, the upper half part adopts a cylinder whose diameter is smaller than the inner diameter of the pile casing, and the upper half part of the impact cone is inserted into the casing body from the bottom end of the pile casing and fixed into a whole in the joint position through welding or casting or bolts. The construction method of the building foundation by adopting the pile casing device comprises construction steps as follows: 1), the pile casing device is used for construction of a pile hole; (2), the pile casing is lifted up to form the pile hole; (3), pile end treatment is performed according to soil property and upper load requirements; and (4) construction of a pile body is performed.

Owner:北京波森特岩土工程有限公司

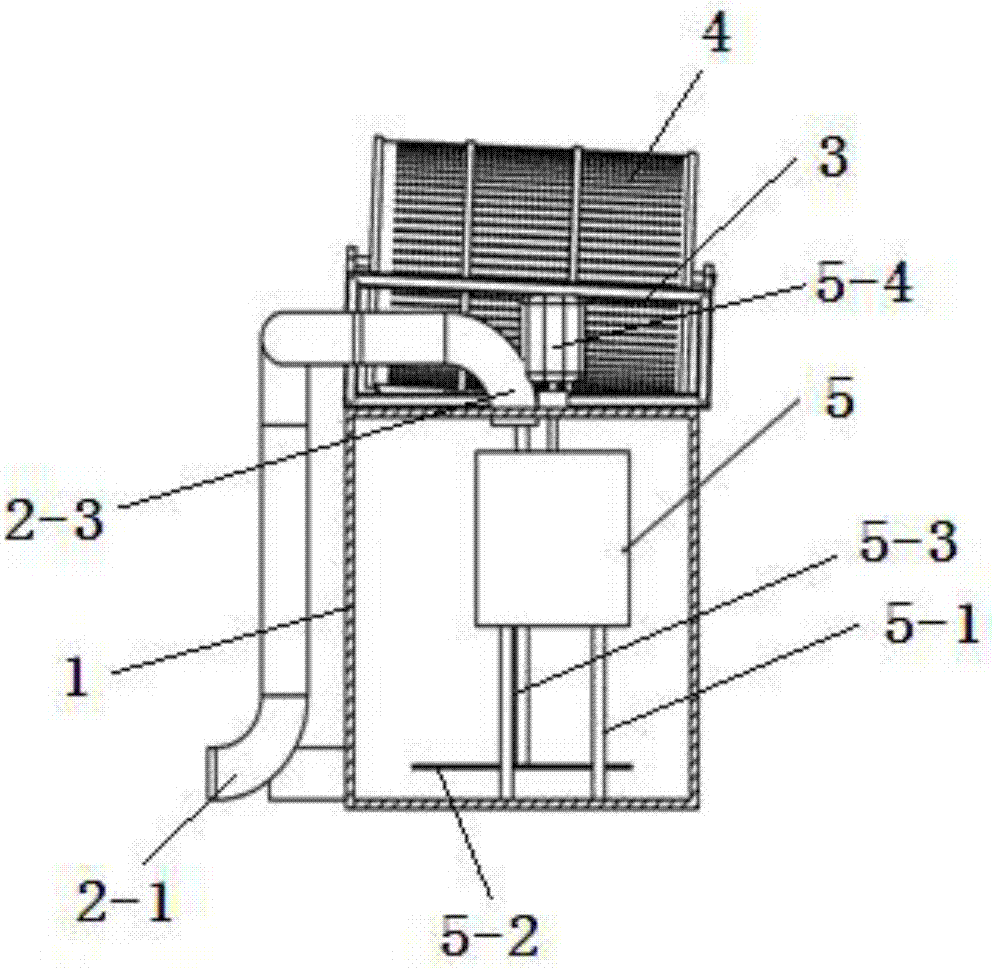

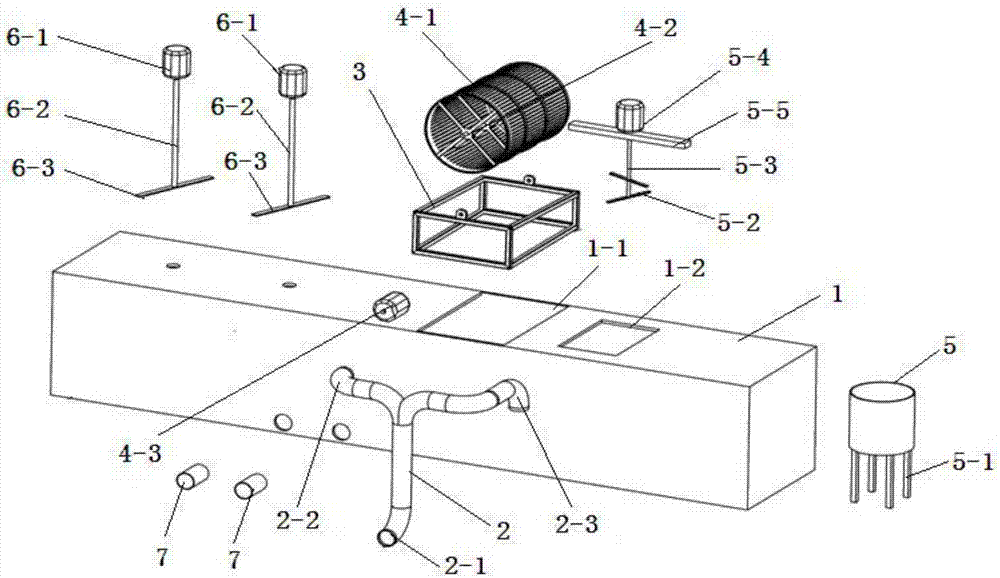

Mud circular disposing device and using method thereof

PendingCN106978983AKeep it clean and aesthetically pleasingImprove the image of construction managementFlushingWater savingMechanical engineering

The invention discloses a mud circular disposing device and a using method thereof. The mud circular disposing device comprises a mud storage case and a three-way mud inlet pipeline, a roller type filter sieve opening and a clay stirring barrel opening are formed in the mud storage case, a roller type filter sieve is mounted at the roller type filter sieve opening, a clay stirring barrel is arranged below the clay stirring barrel opening in the mud storage case, and a mud stirrer is further mounted on the mud storage case; and the three-way mud inlet pipeline comprises a pipeline inlet, a first pipeline outlet and a second pipeline outlet, a three-way valve is mounted on the three-way mud inlet pipeline to control the pipeline inlet to communicates with the first pipeline outlet or the second pipeline outlet. The mud circular disposing device is assembled in a prefabricated mode, is used circularly and good in maneuvering performance, and simple in using method and can dispose the mud containing large granule gravel-cobbles and the mud containing clay chunks, the mud is almost free of wasting in the circular disposing process, mud consistency can also be adjusted to enable the mud to be used for a dado, a mud channel is isolated from the ground, seepage loss of mud water in the reflowing process is avoided, and water saving and environmental friendly effects are achieved.

Owner:浙江坤德创新岩土工程有限公司

Construction method of large-diameter digging pile in subway station on upper-soft and lower-hard stratum

Disclosed is a construction method of a large-diameter digging pile in a subway station on an upper-soft and lower-hard stratum. The constructed digging pile is a concrete-filled steel tube pile which is located in the constructed subway station, and the concrete-filled steel tube pile comprises a steel tube supporting column, a middle joint structure and a lower joint structure. When the digging pile is constructed, the method comprises the steps that firstly, a pile hole is dug, wherein the pile hole of the constructed digging pile is dug from top to bottom and comprises an upper pile hole and a lower pile hole, the upper pile hole is located in an upper soil layer, and the lower pile hole is located in a lower bedrock layer; when the pile hole is dug, the process comprises the following steps that 101, the upper pile hole is dug, wherein hole opening digging and locking opening structure construction are conducted, and follow-up digging of the upper pile hole is conducted; secondly, the steel tube supporting column is hoisted; and thirdly, concrete pouring is conducted. The method is simple in step, reasonable in design and good in using effect, construction is easy and convenient, the construction process of the large-diameter digging pile in the upper-soft and lower-hard stratum can be easily, conveniently and rapidly accomplished, the construction quality is easy to guarantee, and the construction process is safe and reliable.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

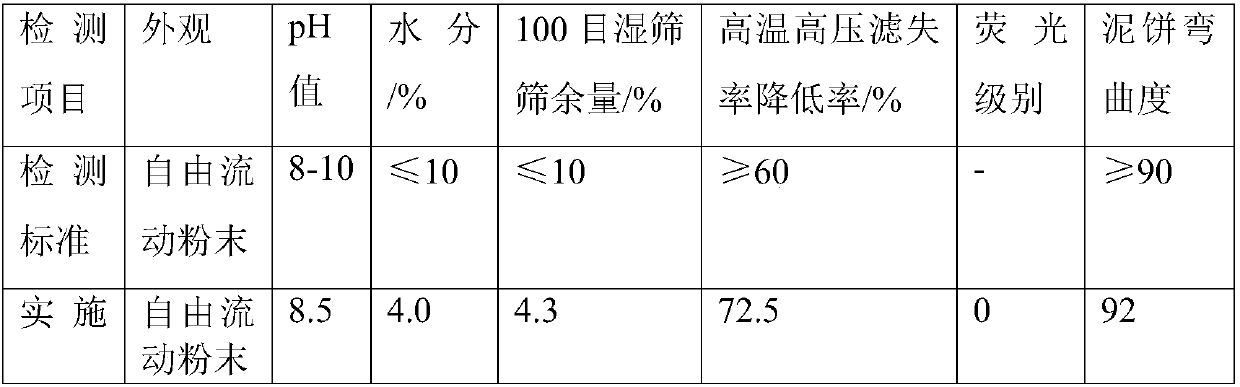

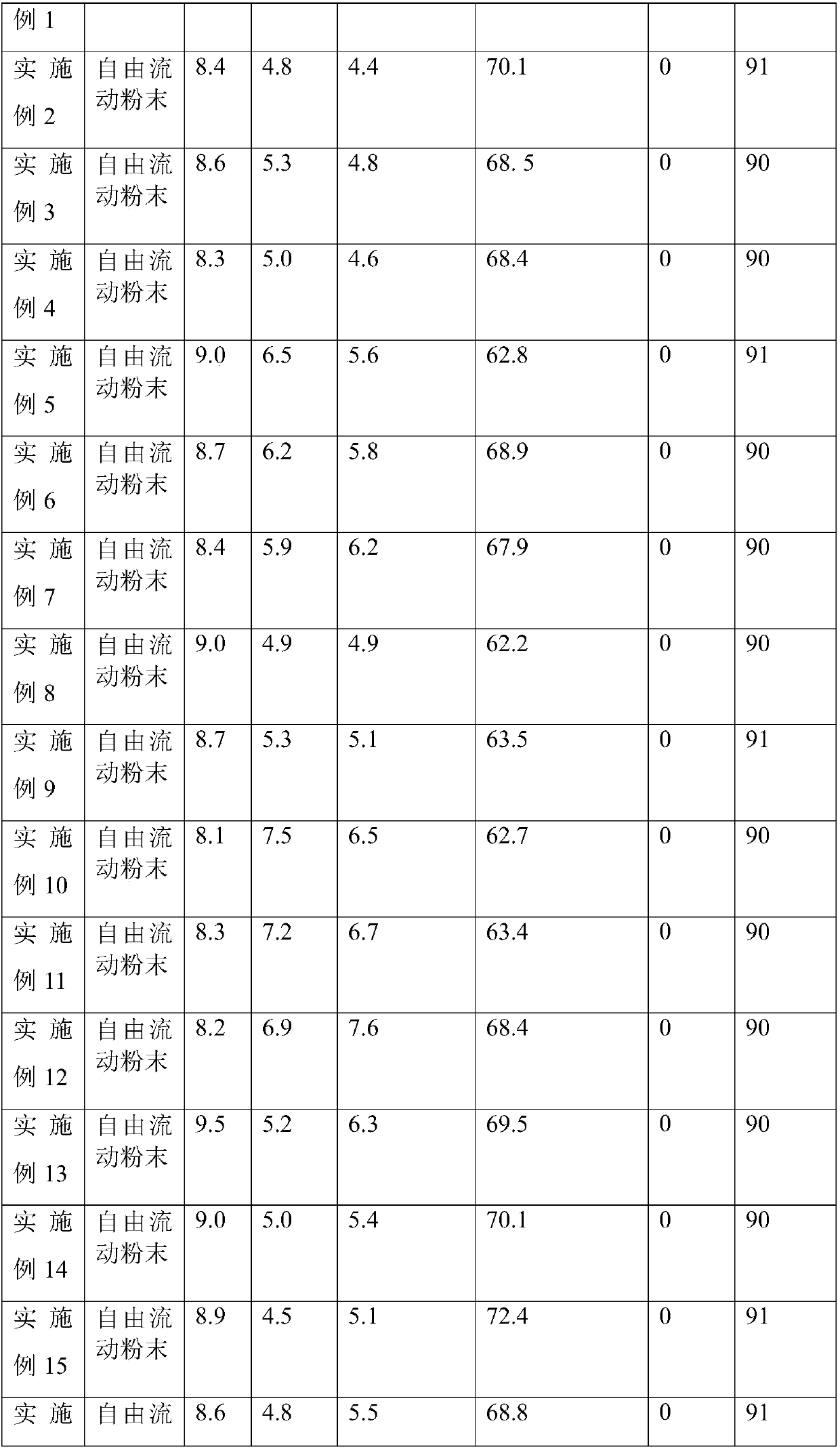

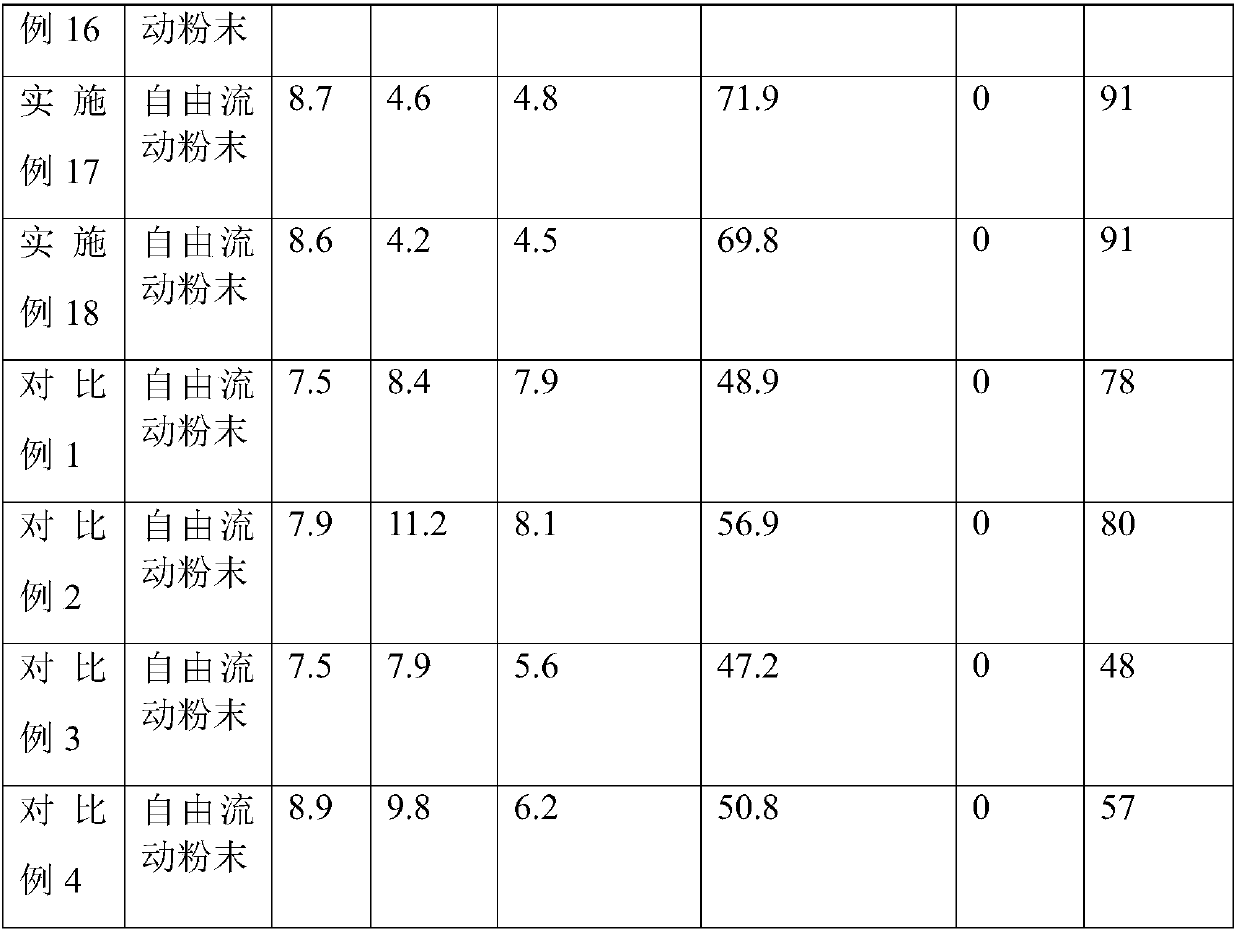

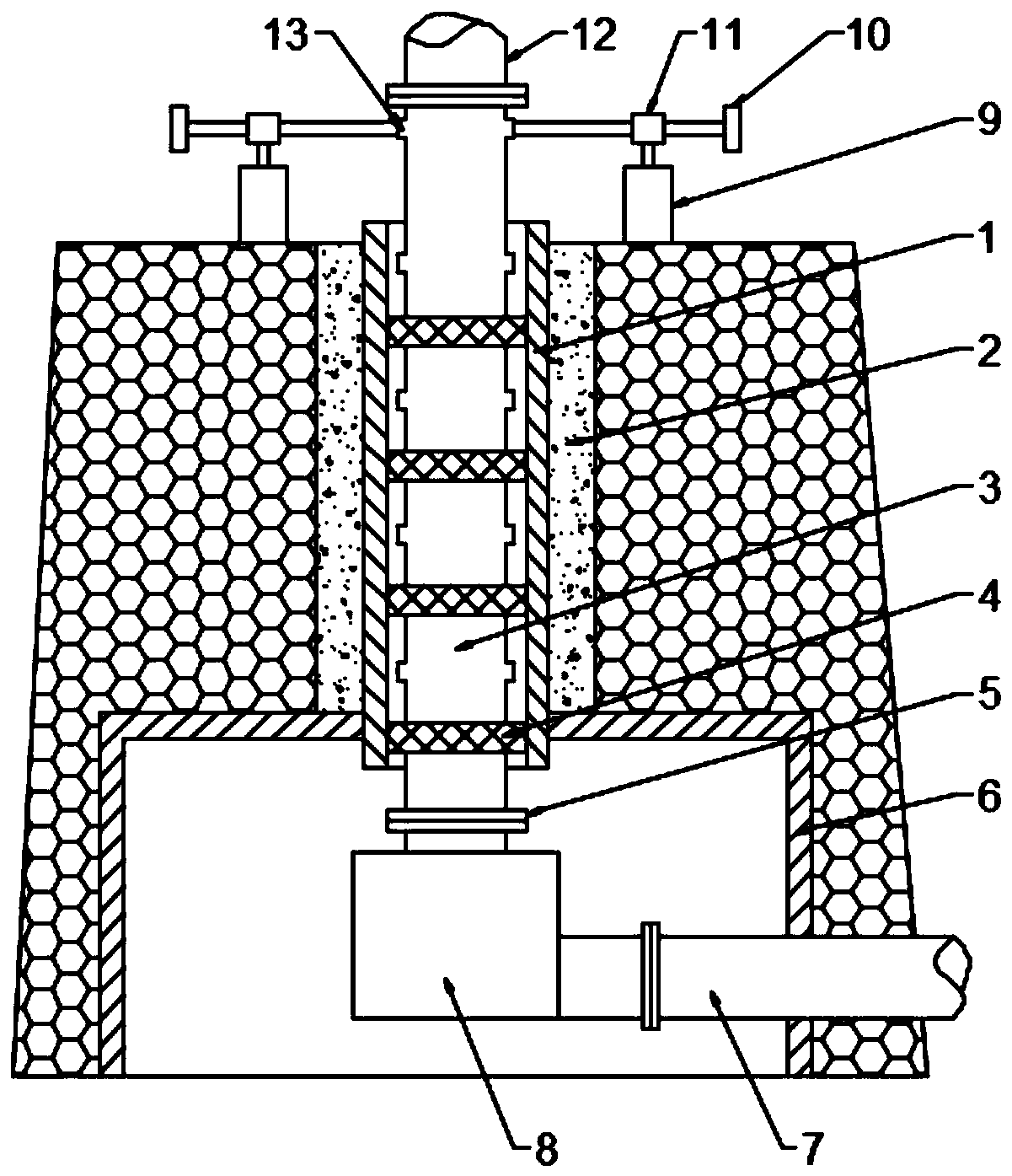

Mud cake toughening improver for drilling fluid and preparation method of mud cake toughening improver

ActiveCN109652032AImprove toughnessExcellent retaining performanceDrilling compositionMineralogyCellulose

The invention discloses a mud cake toughening improver for a drilling fluid. The mud cake toughening improver is prepared from, by weight, 60-80 parts of modified starch, 20-45 parts of cellulose, 35-50 parts of synthetic resin, 5-20 parts of a toughening additive and 15-30 parts of lignin. The invention also discloses a preparation method of the mud cake toughening improver for the drilling fluid. The method comprises the following steps that the cellulose and 1 / 3 modified starch are stirred and mixed uniformly, then the synthetic resin is added, stirring is performed for 40-60 min at 85-120DEG C, the rotation speed is 4500-6000 r / min, the lignin and the remaining 2 / 3 modified starch are added, stirring is performed for 1.5-2 h, the rotation speed is 3000-4000 r / min, then the temperatureis adjusted to 70-110 DEG C, the toughening additive is added, stirring is performed for 4-5 h, drying is performed, and the mud cake toughening improver is obtained. The mud cake toughening improverhas the advantages that when the prepared mud cake toughening improver is applied to the drilling fluid and then acts, a formed mud cake is thinner and more tough, and the wall protection performanceis more excellent.

Owner:北京宏勤石油助剂有限公司

Sleeving type underground conveying device for tailing paste filling

The invention discloses a sleeving type underground conveying device for tailing paste filling. The sleeving type underground conveying device comprises a drilling sleeve fixedly sleeved with a drilled hole and a slurry filling pipe sleeved with the drilling sleeve. The top of the slurry filling pipe is lifted by a lifting mechanism. An underground chamber is constructed at the lower portion of the drilled hole and internally provided with a slurry buffering cavity. The slurry buffering cavity communicates with the bottom of the slurry filling pipe through a flange. One side of the slurry buffering cavity is connected with a downhole filling pipe through a flange. By means of the sleeving type underground conveying device for tailing paste filling, due to the sleeving structural form of the drilling sleeve and the slurry filling pipe, the slurry filling pipe does not make direct contact with the drilled hole, when the slurry filling pipe is abraded to leak, the slurry filling pipe canbe replaced without damaging the drilled hole, the permanent use of the drilled hole is ensured, and filling cost is effectively saved.

Owner:HUNAN CHENZHOU MINING CO LTD

Composition for tunnel backwall filling, consolidation fluid and preparation method

InactiveCN109704654APlay the role of wallImprove work performanceCarboxymethyl celluloseSodium Bentonite

The invention belongs to the technical field of filling slurry materials, the invention discloses a composition for tunnel backwall filling, a consolidation fluid and a preparation method; the composition is mainly prepared from the following raw materials in parts by weight: 70-80 parts of bentonite; 1-2 parts of a carboxymethyl cellulose soluble salt; 0.1-1 part of a carbonic acid soluble salt and 0.1-0.6 part of polyacrylamide; wherein the consolidation fluid is formed by mixing cement slurry and inert drag-reducing bentonite slurry; wherein the cement slurry is prepared by mixing water andcement according to the weight ratio of 1: 0.8-1.3; and the compressive strength of the consolidation fluid is more than 1 mpa during solidification. The preparation method comprises the following steps: dissolving the bentonite, the carboxymethyl cellulose soluble salt, the carbonic acid soluble salt and the polyacrylamide are uniformly mixed with water, and after hydration, the inert drag-reducing bentonite slurry is obtained. The composition has the characteristics of high curing strength and good wall protection effect.

Owner:SANCHU OF CHINA RAILWAY TUNNEL GROUP

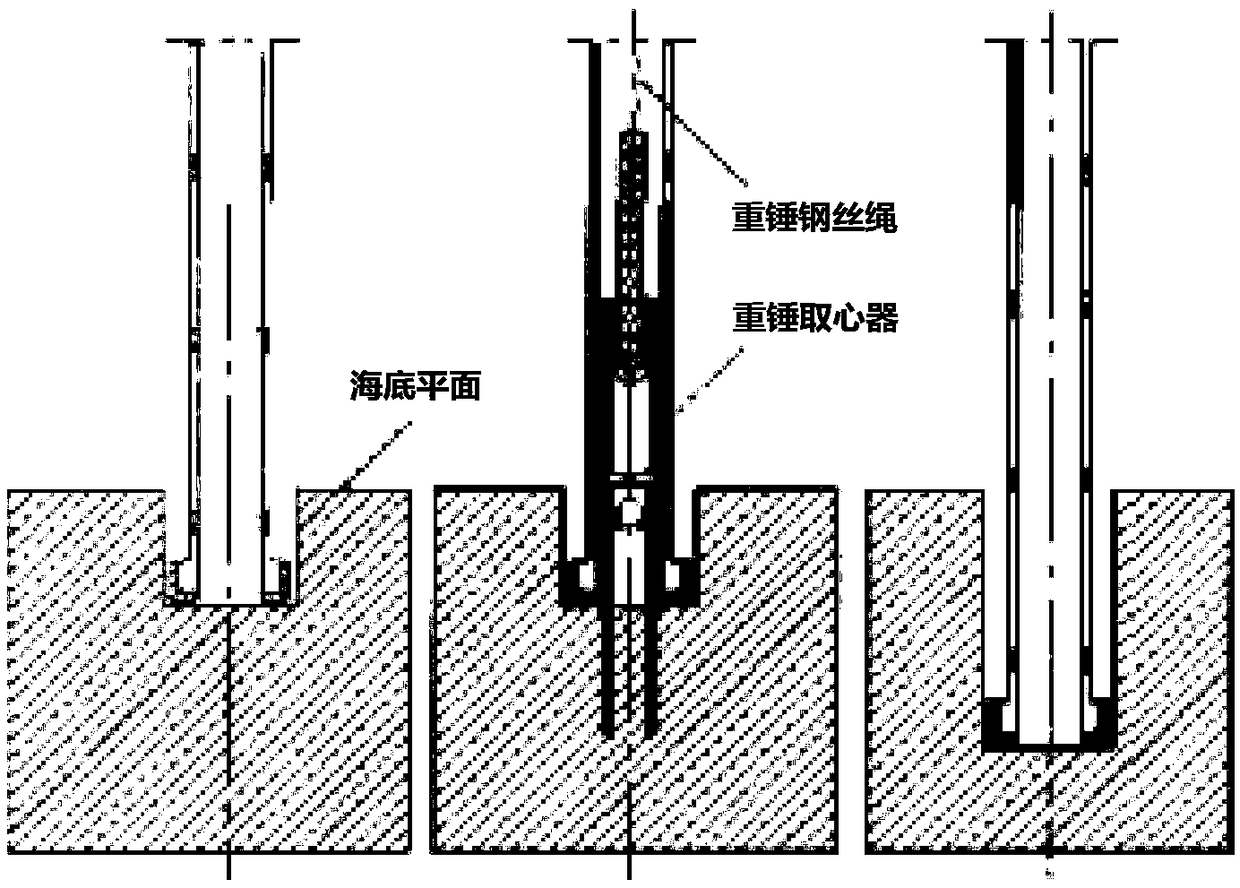

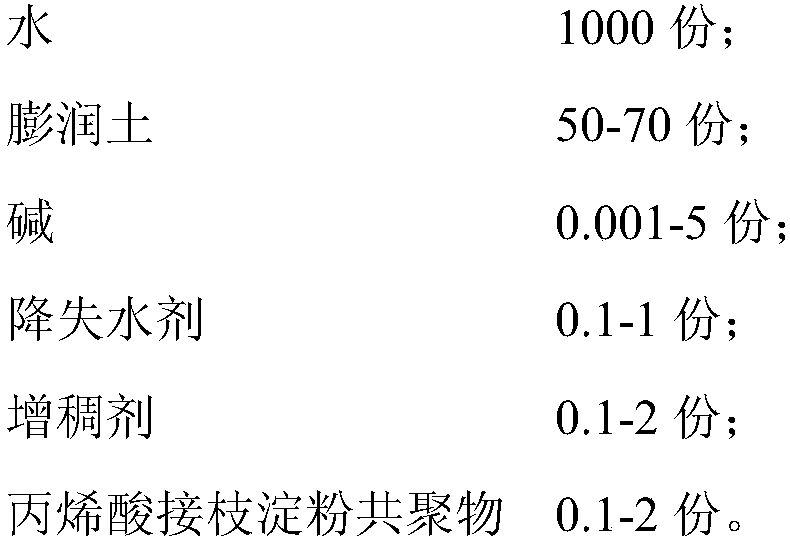

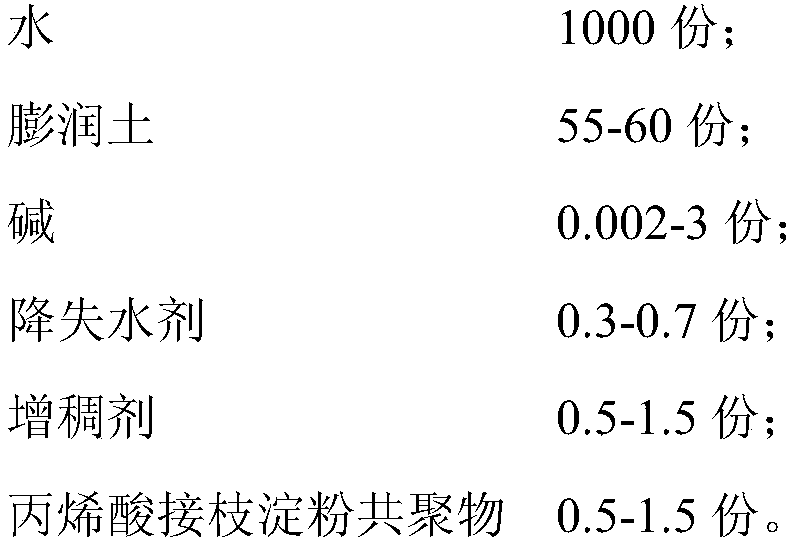

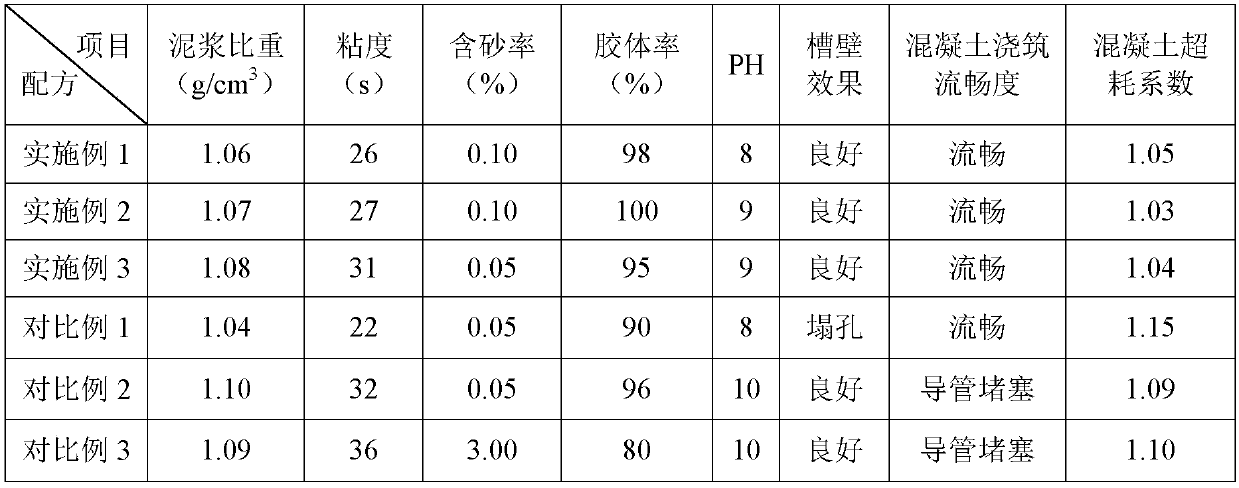

Marine quaternary formation drilling fluid

InactiveCN108611079AWall protection effect is goodEffective suspensionDrilling compositionCopolymerOpen hole

The invention belongs to the technical field of drilling, and provides marine quaternary formation drilling fluid. The fluid is prepared from, by weight, 1000 parts of water, 50-70 parts of bentonite,1-5 parts of alkali, 0.1-1 part of fluid loss additive, 0.1-2 parts of thickener and 0.1-2 parts of acrylic grafted starch copolymer. The invention further provides a method for preparing the marinequaternary formation drilling fluid and application thereof in the drilling and core removal process of the marine quaternary formation. The marine quaternary formation drilling fluid has excellent wall protection performance, and in the process of open hole core removal of the marine quaternary loose formation, the problems that hole walls of sand formation easily collapse, sand gushing and drillbit burying occur, hole walls of water-sensitive muddy formation are reduced in diameter, the bottoms of holes are not clean and the like are better solved.

Owner:中石化石油工程技术服务有限公司 +1

Mud applicable to underground continuous wall construction

ActiveCN109574554AGuaranteed stabilityGuaranteed specific gravityExcavationsSlurry wallCarboxymethyl cellulose

The invention discloses mud applicable to underground continuous wall construction. Preparation raw materials for the mud include, by weight, 9%-11% of sodium bentonite, 2%-5% of sodium carbonate, 0.01%-0.04% of sodium carboxymethyl celluloses and the balance water. The mud has the advantages that the mud is low in cost, and good wall protection effects can be realized by the mud.

Owner:SINOHYDRO BUREAU 8 CO LTD

Bore cleaning device for cast-in-place bored piles

ActiveCN102605768BSimple and fast operationImprove cleaning efficiencyFlushingBulkheads/pilesSocial benefitsImpeller

The invention provides a bore cleaning device for cast-in-place bored piles, which comprises a drill stem and an externally hung steel wire rope disposed on the same. The bore cleaning device enables the steel wire rope on the drill stem to rotate with the drill stem, such as an impeller to rotate, so that firstly, large mud pies in a cast-in-place bored pile can be broken to facilitate sludge settling and bore cleaning, and the efficiency of hole cleaning can be improved greatly; and secondly, under rotation of the impeller, such as the steel wire rope, the mud is mixed fully and generates impact to sweep the wall of a bore, the effect of mud wall protection is improved greatly, and bore forming quality and pile forming quality are improved. The bore cleaning device is simple to operate and saves construction period, so that the pile forming quality can be improved, and considerable economic benefit and social benefit are created for engineering.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

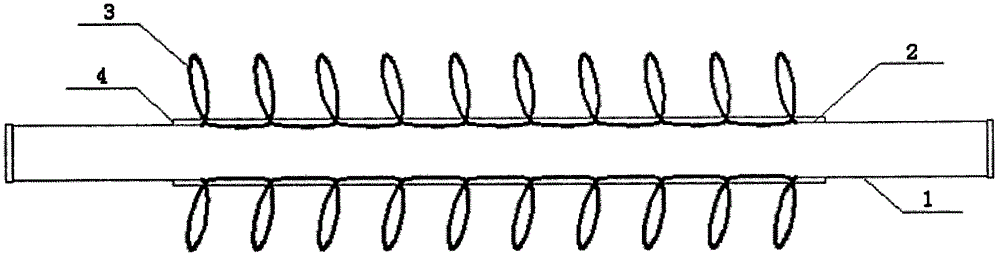

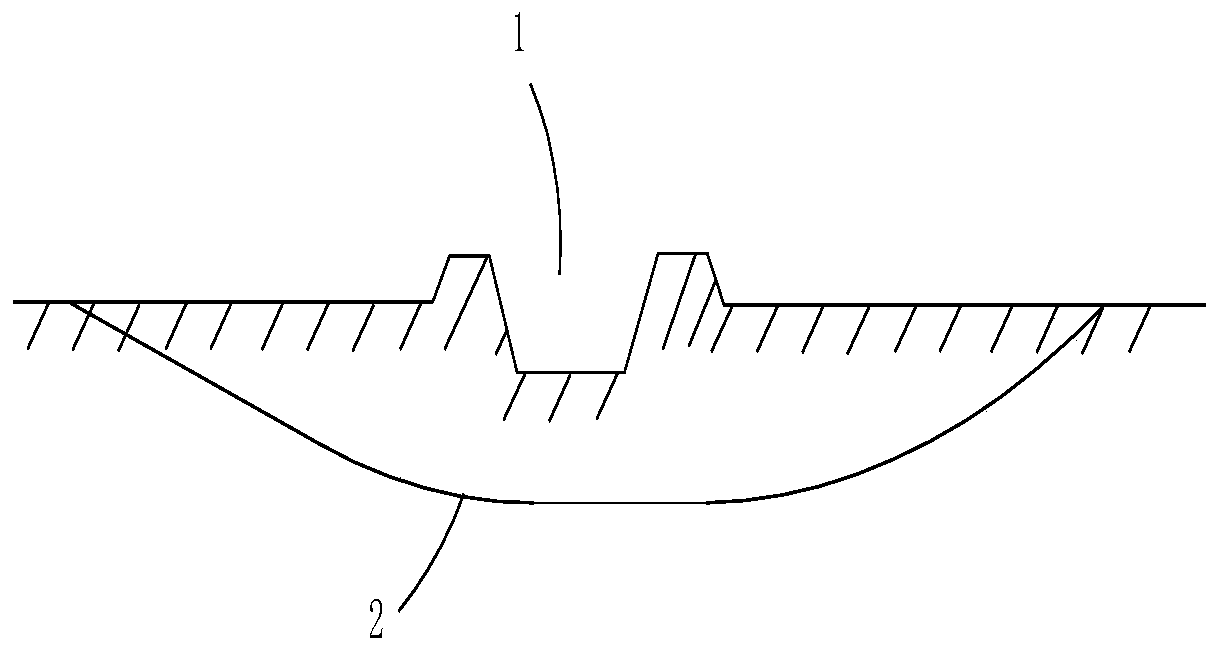

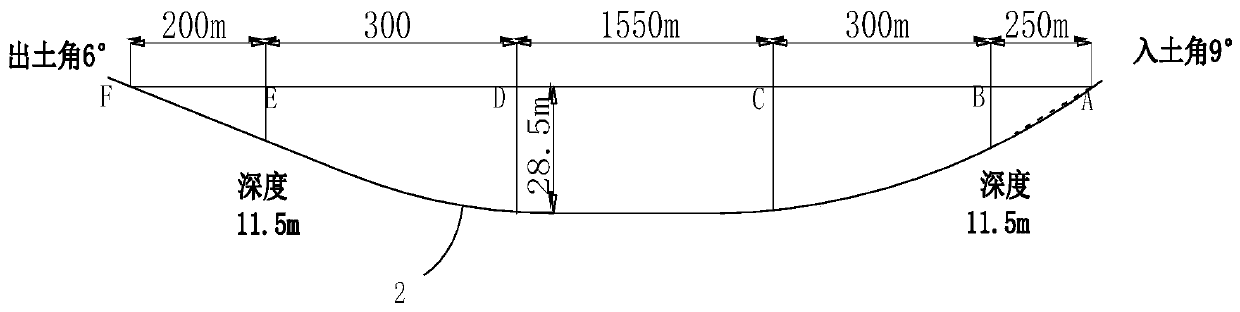

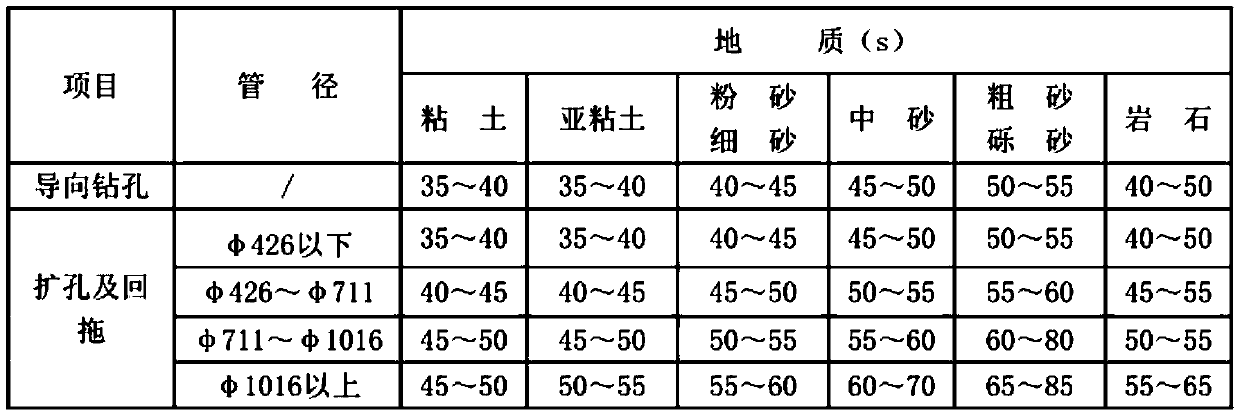

The method of using mud in the construction of directional drilling crossing the river

ActiveCN108086908BGood suspensionImprove liquidityDirectional drillingDrilling compositionSoil scienceRiver routing

The invention discloses a using method of slurry in crossing-with-directional-drilling of river construction. The method comprises the steps that the slurry is prepared according to formation conditions and diameter and length of crossing pipelines, and suitable slurry materials are selected; in a pipeline crossing process, time needed by the slurry and a drilling bit to reach different soil layers is calculated according advance speed of directional drilling, reaming, hold flushing and pipeline back-dragging in different soil layers and flow rate of the slurry, the slurry required by different soil layers is injected into a drill hole at preset times, the slurry returned from the drill hole is injected into a slurry circulation tank, and the slurry is returned to the drill hole and used after the slurry is processed. According to the method, effects of suspending, carrying, lubricating, hole fixing, leakage plugging and the like of the slurry are improved, and occurrences of phenomenons of hole collapse, formation leakage and the like are effectively avoided.

Owner:CHINA MCC 2 GRP CO LTD

A kind of mud suitable for underground diaphragm wall construction

ActiveCN109574554BGuaranteed stabilityGuaranteed specific gravityExcavationsCarboxymethyl celluloseCellulose

Owner:SINOHYDRO BUREAU 8 CO LTD

Occlusion retaining wall pile and its construction method and application

ActiveCN105089062BSimple structureReasonable designExcavationsBulkheads/pilesReinforced concreteEngineering

The invention discloses an engaged retaining pile. The engaged retaining pile comprises a plurality of plain concrete piles laid from front to back and a plurality of reinforced concrete piles laid from front to back. The plain concrete piles and the reinforced concrete piles are laid in a staggered mode. A pile body of each reinforced concrete pile is engaged with pile bodies of two plain concrete piles located front and back, so that the retaining effect is good. The invention further discloses a construction method of the engaged retaining pile. The construction method comprises the steps that firstly, construction of the plain concrete piles is conducted, and the multiple plain concrete piles are constructed from front to back; and secondly, construction of the reinforced concrete piles is conducted, the multiple reinforced concrete piles are constructed from front to back in the construction process of the multiple plain concrete piles, drilled hole-forming construction processes of any one of the reinforced concrete piles are conducted after the construction of the two adjacent plain concrete piles front and back is completed. The construction method is simple; the design is reasonable and the construction is simple and convenient; the construction efficiency is high and the construction effect is good. In addition, the invention discloses an application of the engaged retaining piles, namely a foundation pit retaining structure is formed by fixedly connecting the multiple engaged retaining piles tightly.

Owner:SHAANXI ZHUANGXIN CONSTR ENG +1

A single-waisted multi-leaf cylinder drill bit and a hole-forming construction method for bored piles

ActiveCN104747088BGuaranteed verticalityOvercome direction uncertaintyDrill bitsBulkheads/pilesDirectivityDrill bit

Owner:ZHEJIANG YUJIAN CONSTR GRP CO LTD

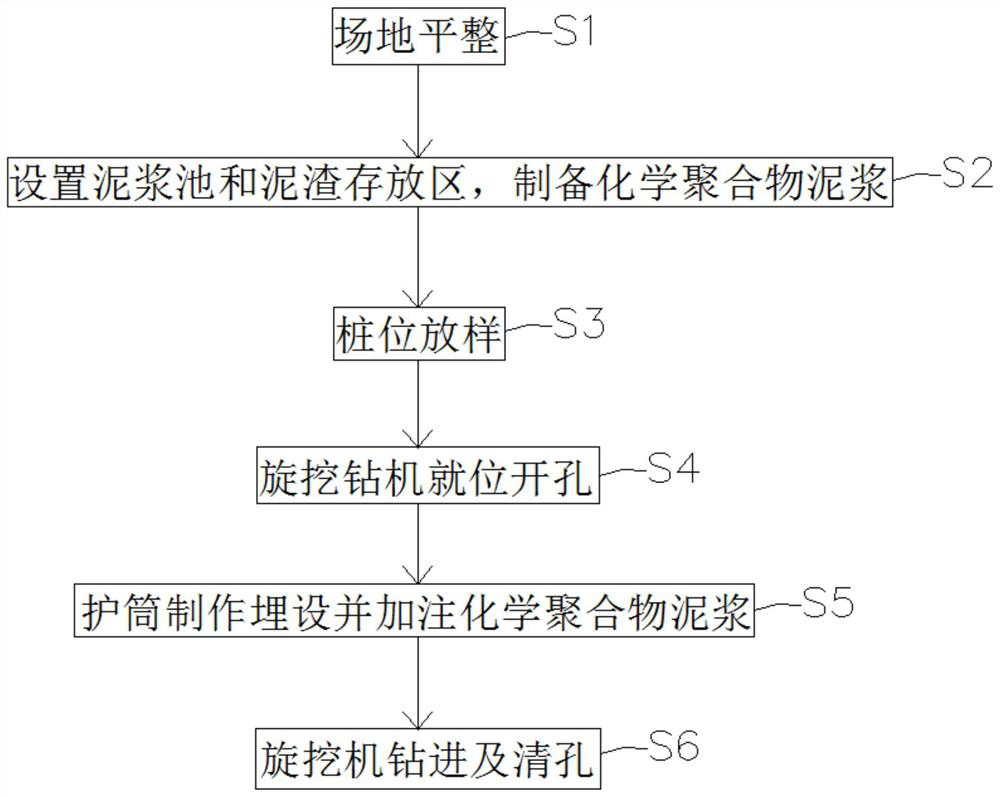

A construction method for drilling holes with a rotary drilling rig using chemical polymer mud retaining walls

ActiveCN111594175BNo pollution in the processShort mud preparation timeShaft sinkingBulkheads/pilesMechanical engineeringPolymer

The invention discloses a drilling construction method of a rotary drilling rig using a chemical polymer mud wall protection, comprising the following steps: S1: leveling the site; S2: setting a mud pool and a mud storage area, and preparing the chemical polymer mud; S3: piles Stake-out; S4: Drilling in place with rotary drilling rig; S5: Fabrication and embedding of casing and filling with chemical polymer mud; S6: Drilling and hole cleaning with rotary drilling machine. Compared with the prior art, the present invention provides a drilling construction method using a rotary drilling rig using chemical polymer mud to protect the wall, which has a short time for preparing mud and is convenient to use; It can reduce the amount of rotary excavation and concrete pouring, saving materials and mechanical shift costs; the slurry of the mud has a low sand content, can be cleaned by itself, and can be separated from the concrete by itself; the mud is non-polluting, does not produce waste mud, and can be recycled .

Owner:湖南交通国际经济工程合作有限公司

Bored pile cleaning device

InactiveCN105649085BSimple structureEasy to assemble and disassembleEarth drilling toolsBulkheads/pilesSludgeEconomic benefits

The invention discloses a hole cleaning device for a cast-in-situ bored pile. The hole cleaning device comprises a drill pipe. At least one stirring paddle is installed on the drill pipe and composed of blades and a paddle hub, wherein the paddle hub surrounds the drill pipe in a hooped mode, the number of the blades is at least two, and the blades are fixed to the paddle hub with the blade surfaces facing upwards. During primary hole cleaning of positive circulating rotation, the drill pipe drives the stirring paddles fixed to the drill pipe to rotate, and in combination with the idling of a drill bit, dregs arising from the pile bottom are effectively and gradually pushed upwards, so that the carrying efficiency of the dregs is improved, the thickness of the dregs is lowered, and the hole cleaning efficiency and the bearing capacity of a pile foundation are improved. Meanwhile, the concentration of sludge at the pile bottom is high, the sludge pushed upwards by the blades has a painting function on a hole wall, the circulation speed of the sludge is increased due to the lifting function of the blades, formation of a sludge cover is accelerated, and occurrence of a hole collapse phenomenon is reduced. The hole cleaning device for the cast-in-situ bored pile is simple in structure, convenient to operate, high in dreg cleaning efficiency, high in dreg cleaning depth, good in economic benefit, and obvious in effect during hole cleaning for the ultra-deep cast-in-situ bored pile.

Owner:SUZHOU UNIV

Method for laying ore pulp pipelines in quicksand bed section

The invention relates to laying of large-calibre long-distance transportation pipelines for pulp and provides a method for laying ore pulp pipelines in a quicksand bed section. Pipe ditches are excavated by sections. The method comprises the following steps of: (1) arranging sealing structures to block excavated pipe ditches and pipe ditches to be excavated; (2) excavating the pipe ditches to be excavated, injecting water into the excavated ditches at the same time until completion; (3) sealing both ends of each pipeline, and moving the pipelines to the pipe ditches so that the pipelines float on water surface; (4) injecting water into the pipelines or pressing the pipelines to the bottom of the ditches through a counterweight; and (5) backfilling the ditches. Quick sands are prevented from flowing into the ditches by using the osmotic pressure of water, the surrounding sand bed is extruded and compacted through osmotic pressure to avoid the collapse of ditch walls and the land subsidence of pipeline ditch edges, and the pipeline ditches are convenient to form. After backfilling, most of injected water penetrates into ground, and the rest of injected water is extruded back to ground surface due to backfilling. Therefore, construction is convenient and quick, and the construction cost is low. The method provided by the invention is applicable to the laying of ore pulp pipelinesin the quick sand bed section.

Owner:CHINA 19TH METALLURGICAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com