High temperature resistant circulating micro-foam drilling fluid or completion fluid

A drilling fluid and high temperature resistance technology, which is applied in the field of drilling and completion fluids, can solve the problems of poor high temperature stability of foam technology, poor high temperature stability of foam, and poor foam stability, etc., to reduce complex downhole accidents, good wall protection performance, and high temperature resistance powerful effect

Active Publication Date: 2008-03-26

DONGYING TAIER GASOLINE TECH

View PDF2 Cites 61 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The existing microfoam drilling fluid technology used in oil drilling has (1) Chinese Patent No. 200410021014.8 titled "A Microfoam Foaming Agent and its Drilling Fluid System Formula", and its formula is: 5% base slurry+0.3% MF+0.03%SF+2%SMP-II+0.05%80A-51+0.2%XC+1%SPNH, its shortcoming or deficiency is that it can only be used in shallow wells and hard formations, and the foam has poor high temperature stability and cannot be used at high temperatures; (2 ) Chinese Patent No. 20041001323.7 titled "Application and Preparation Method of Surplus Activated Sludge Protein as Foam Drilling Fluid", its formula is parts by weight: bentonite 5, tackifier 0.1, stabilizer 0.2, foaming agent 0.5; The agent is hydroxymethyl cellulose; the stabilizer is polyacrylamide; the above-mentioned foam technology has poor high-temperature stability and can only be used in low-temperature shallow wells, and can only be adapted to drilling in limestone formations. The effect is poor, and the use cost is high. During construction, the foam stability is poor, and the density cannot be reduced. When applied in high-temperature deep well reservoirs, it will cause serious pollution to the reservoir

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

[0050]

[0051] SJ1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

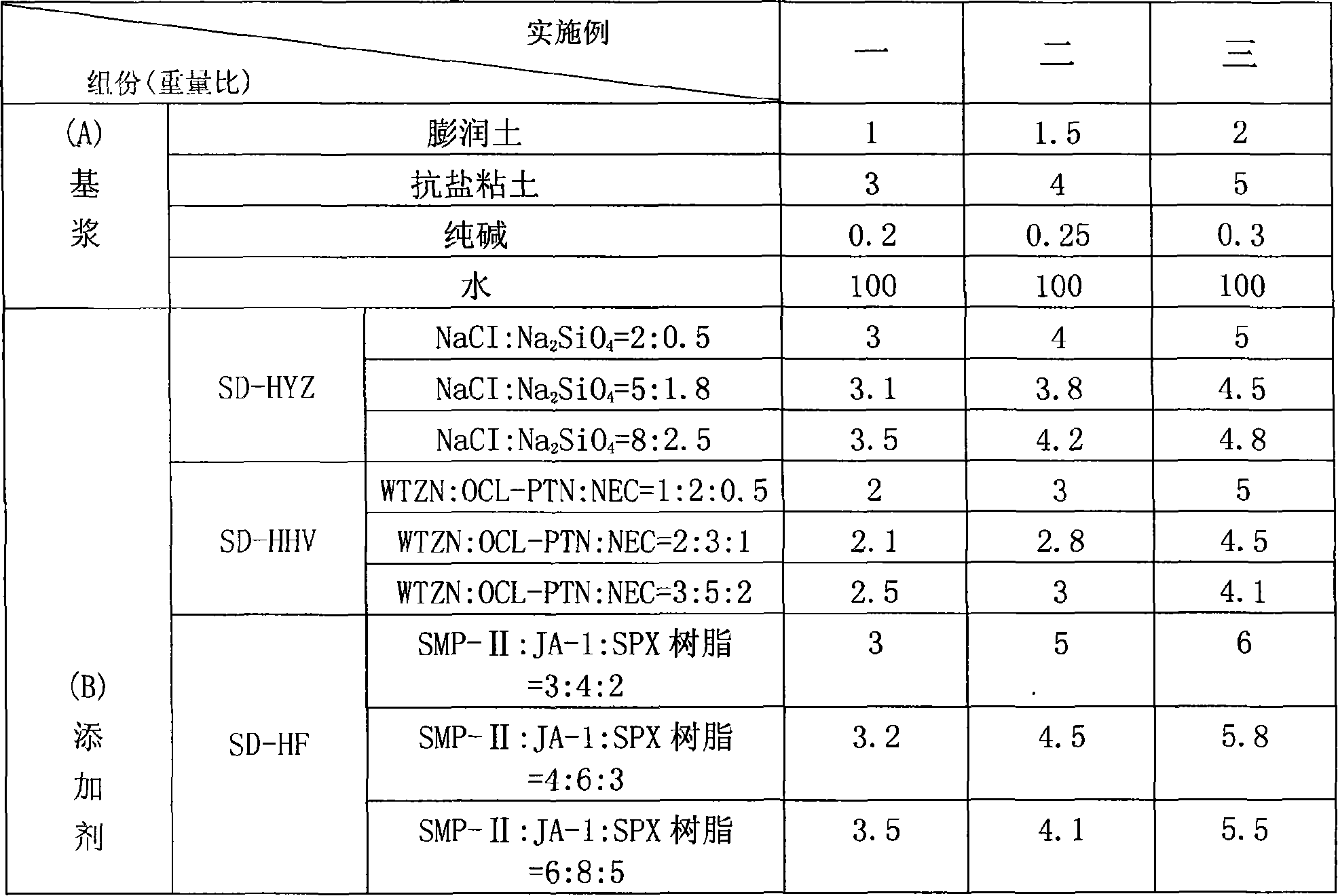

The present invention discloses one kind of high temperature recyclable microbubble drilling and completing fluid, which includes basic slurry comprising bentonite 1-2 (in weight portions, the same below), salt tolerant clay 3-5, sodium carbonate 0.2-0.3 and water 100; and additives comprising high temperature inhibitor 3-5, high temperature tackifier 2-5, high temperature filter loss reducing agent 3-6, high temperature salt resisting filter loss reducing tackifier 1-3, flow form regulator 1-3, high temperature foaming agent 2-5 and high temperature foam stabilizer 1-2.5. The high temperature recyclable microbubble drilling and completing fluid has excellent high temperature performance, high carrying, suspending capacity in low pressure deep well, and functions of inhibiting the hydrating expansion of mudstone and protecting oil and gas reservoir, is suitable for different types of high temperature stratum. It is applied in well drilling and well completing construction for low pressure and low permeation stratum.

Description

1. Technical field [0001] The invention relates to drilling and well completion fluids, in particular to a high-temperature-resistant circulating microfoam drilling fluid or well completion fluid. 2. Background technology [0002] The existing microfoam drilling fluid technology used in oil drilling has (1) Chinese Patent No. 200410021014.8 titled "A Microfoam Foaming Agent and its Drilling Fluid System Formula", and its formula is: 5% base slurry+0.3% MF+0.03%SF+2%SMP-II+0.05%80A-51+0.2%XC+1%SPNH, its shortcoming or deficiency is that it can only be used in shallow wells and hard formations, and the foam has poor high temperature stability and cannot be used at high temperatures; (2 ) Chinese Patent No. 20041001323.7 titled "Application and Preparation Method of Surplus Activated Sludge Protein as Foam Drilling Fluid", its formula is parts by weight: bentonite 5, tackifier 0.1, stabilizer 0.2, foaming agent 0.5; The agent is hydroxymethyl cellulose; the stabilizer is polya...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K8/38

Inventor 隋跃华关芳秦涛崔亘玉成效华隋彩云苏振宝关山

Owner DONGYING TAIER GASOLINE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com