Bore cleaning device for cast-in-place bored piles

A hole cleaning device and bored pile technology, which is applied in the direction of sheet pile wall, earthwork drilling, wellbore/well parts, etc., can solve the problem of relative density of mud that takes a long time, long time spent cleaning holes, and difficult Clear and other problems, achieve considerable economic and social benefits, improve the efficiency of hole cleaning, easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The exemplary preparation process of the bored pile cleaning device of the present invention is as follows:

[0024] The steel wire rope is set on the drill pipe of the bored pile such as GPS-15 pile driver by welding, or the steel wire rope is set on the drill pipe of the bored pile machine by the following methods:

[0025] On the bored pile such as the drill pipe of the GPS-15 pile driver, a 2-meter-long Φ18 steel bar is welded, and 20 holes are evenly reserved in the middle, and then a steel wire rope with a diameter of Φ16 passes through these holes in sequence, thereby An external steel wire rope is formed on the drill pipe.

[0026] When clearing the hole, the bottom two drill pipes of the bored pile machine are set as the hole clearing device of the present invention, and the hole clearing device of the present invention and the drill bit carried by the bored pile machine can form an approx. 7 meters of swivel length.

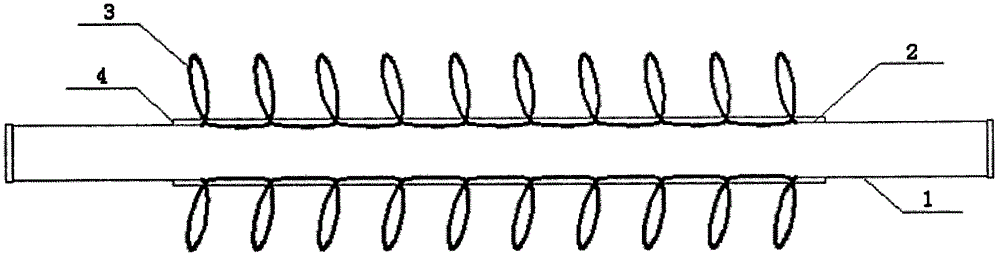

[0027] see figure 1 , each component sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com