Steel plate and concrete diaphragm wall and construction method thereof

A steel plate concrete and construction method technology, applied in the direction of sheet pile wall, excavation, foundation structure engineering, etc., can solve the problems of high cost of underground diaphragm wall, difficulty in guaranteeing construction quality, complicated construction process, etc. Good effect and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

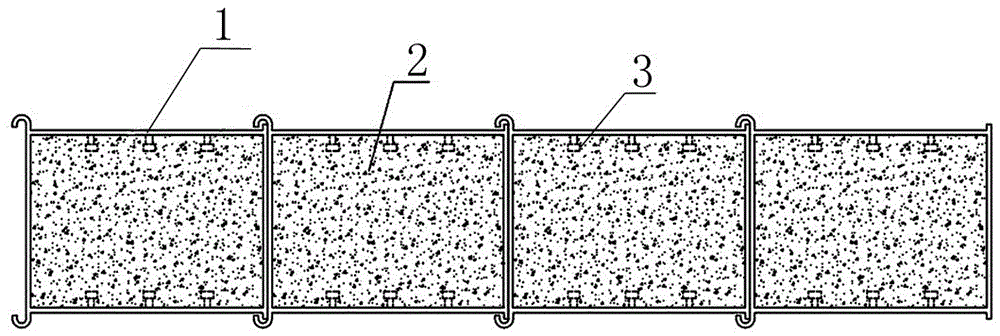

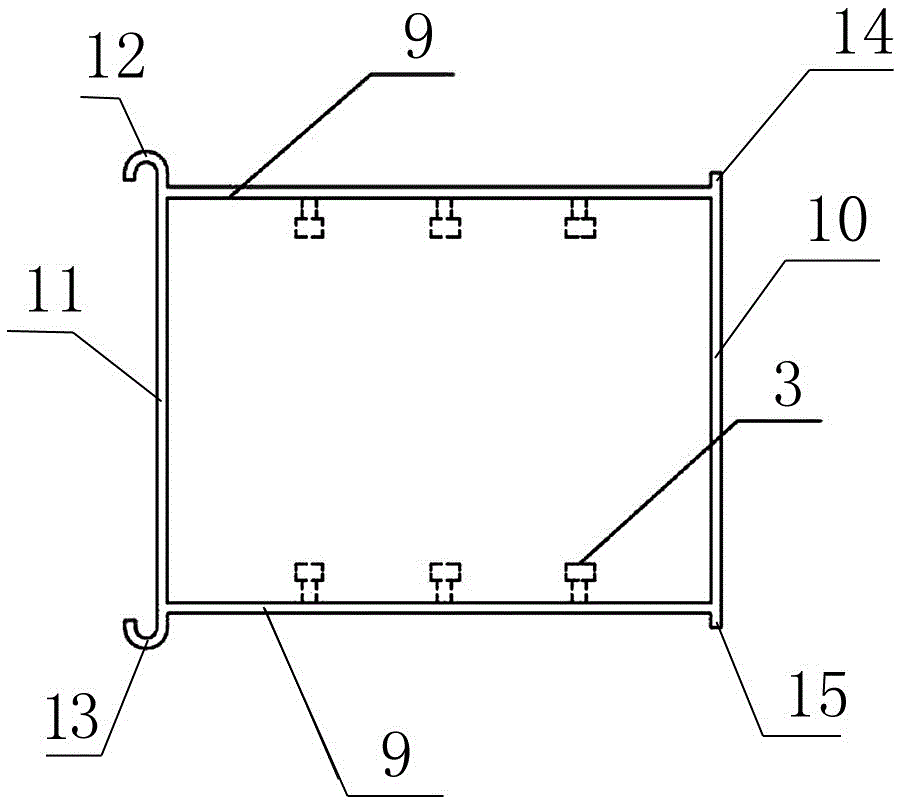

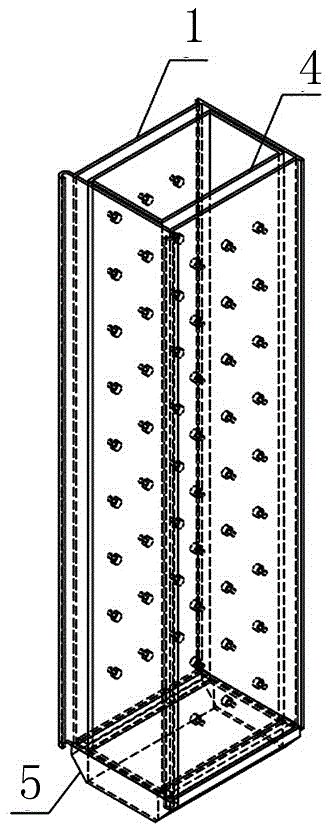

[0043] Example Figure 1-4 As shown, this steel plate concrete ground connection wall is composed of several steel plate concrete ground connection wall units buckled end to end.

[0044] The steel plate concrete floor connecting wall unit includes an outsourcing steel plate cylinder 1 and concrete 2 poured in the outsourcing steel plate cylinder 1; the outsourcing steel plate cylinder 1 is composed of two main steel plates 9, one straight steel plate 10 and one with bent ends at both ends. A rectangular steel tube made of hooked steel plates 11; the steel plate 11 with hooks at both ends is arranged on the opposite side of the straight steel plate 10; the steel plate 11 with hooks at both ends is provided with a hook a12 at one end and There is a hook b13; one end of the straight steel plate 10 is provided with a protruding rib a14 for interlocking with the hook a12 on the adjacent steel plate concrete ground connection wall unit, and the other end is provided with an adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com