Slurry for hole drilling and wall protection as well as preparation technology and on-site construction technology thereof

A kind of mud and process technology, which is applied in the field of drilling mud and its preparation process for wall protection, and on-site construction technology. It can solve the problems of poor hole forming effect and poor uniformity, and achieve long effective time, increased interlayer distance and reduced cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-A

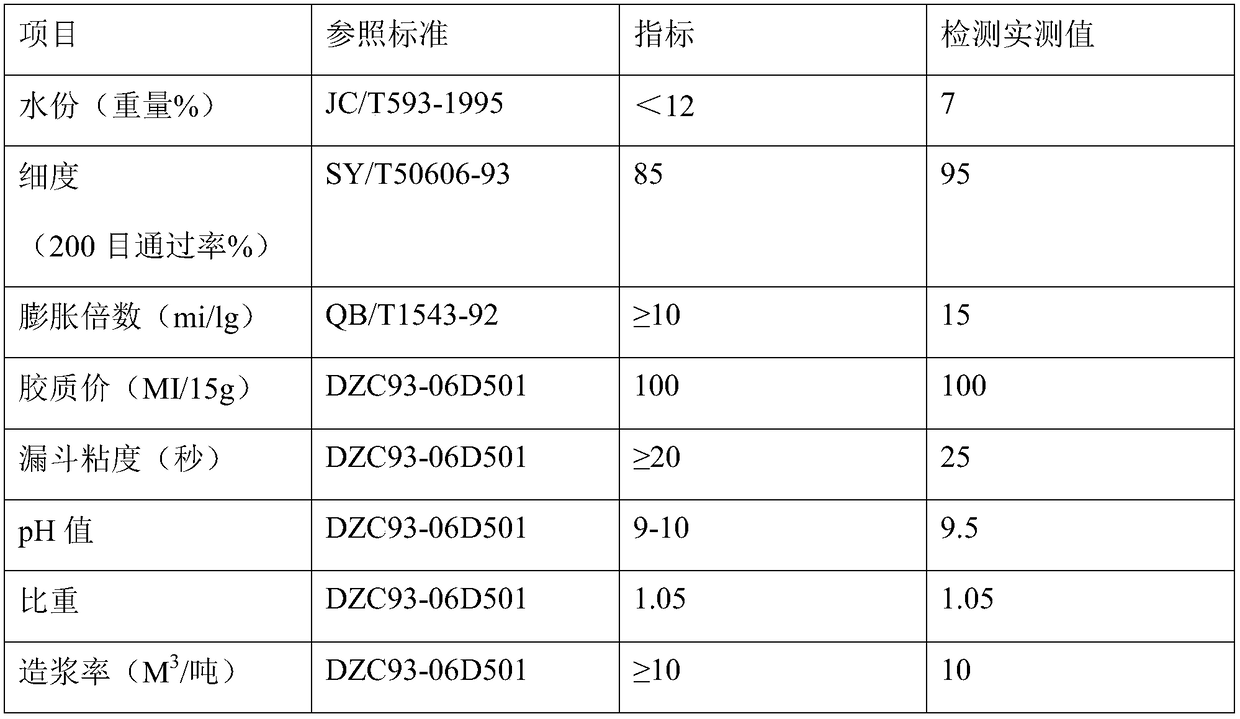

[0030] A kind of mud for drilling wall protection, the raw materials adopted include the following components:

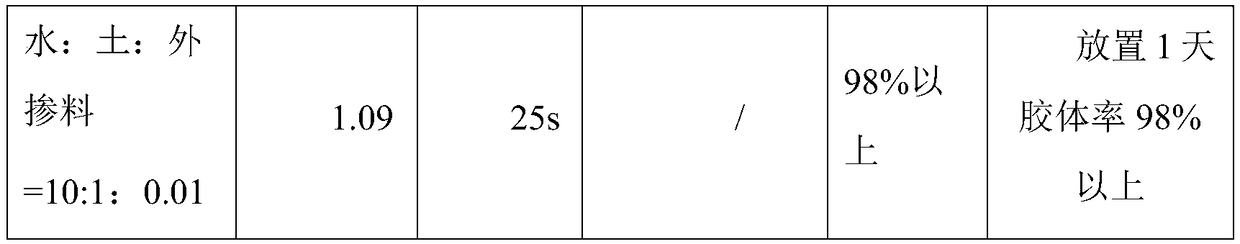

[0031] Water, bentonite and external admixtures with a mass ratio of 8:0.8:0.01;

[0032] The external admixture is mixed in the proportion of water: sodium bentonite: polyaluminum chloride and sodium carbonate = 600ml: 60g: 1.4g: 1.54g.

Embodiment 1-B

[0034] A preparation process of mud for drilling wall protection, the following steps are adopted:

[0035] Step 1), take water, soil and external admixture according to the above ratio, stir and mix, and let stand until the raw materials are fully fused and dissolved to obtain the initial body of mud.

Embodiment 2-A

[0037] A kind of mud for drilling wall protection, the raw materials adopted include the following components:

[0038] Water, bentonite and external admixtures with a mass ratio of 12:1.0:0.01;

[0039] The external admixture is mixed in proportions of water: sodium bentonite: polyaluminum chloride and sodium carbonate = 600-800ml: 60-80g: 1.4-1.65g: 1.54g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com