Hole cleaning device for cast-in-situ bored pile

A technology of bored piles and hole cleaning devices, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc., and can solve problems such as long cleaning time, incomplete hole cleaning, and difficulty in ensuring the quality of piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

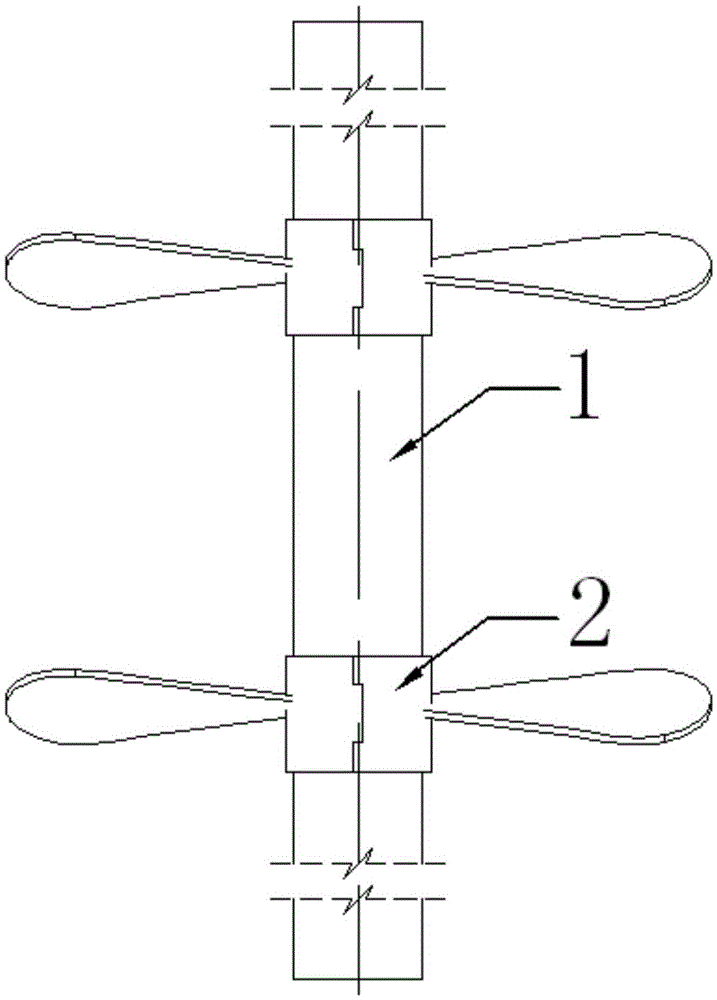

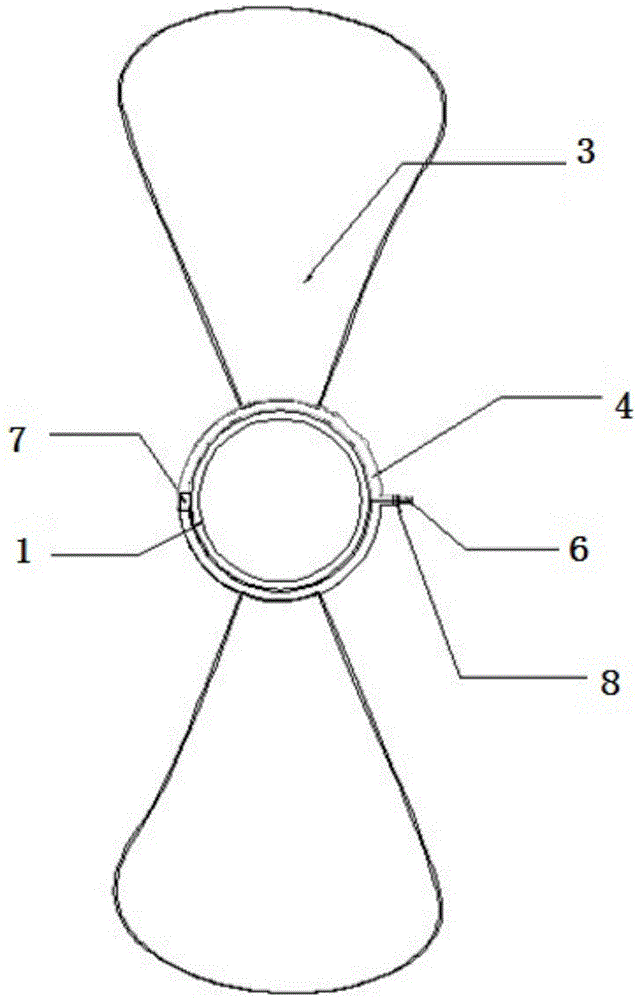

[0017] Embodiment: A device for clearing bored cast-in-situ piles, comprising a drill pipe 1, on which at least one stirring paddle 2 is installed, the stirring paddle is composed of a paddle 3 and a paddle hub 4, and the circumference of the paddle hub is Hooped on the drill pipe, the paddle has at least two blades and is fixed on the paddle hub with the blade facing upward.

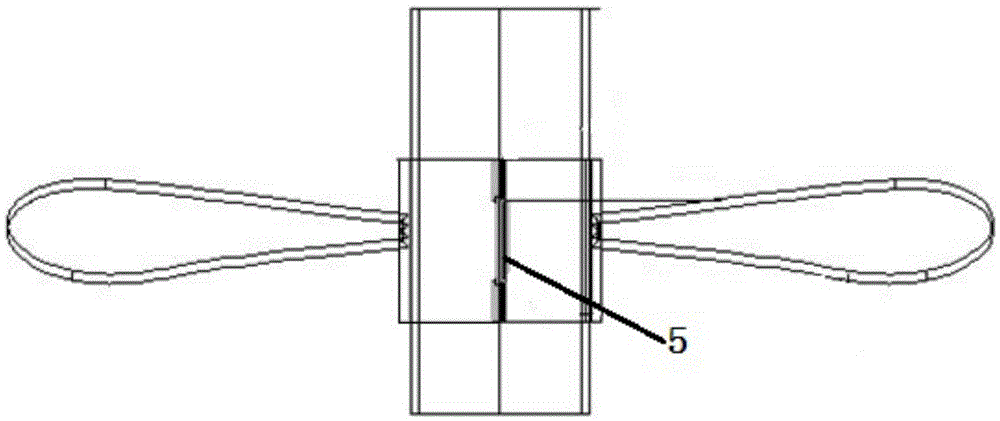

[0018] The propeller hub is composed of two petals. One end of the two-petal propeller hub is a concave-convex groove 5, and the other end is a butt joint 6 folded along the axial direction. The radians of the two-petal propeller hubs are equal and less than 180 degrees.

[0019] The stirring paddle is fixed on the drill pipe through the hoop function of the two paddle hubs. After the drill pipe is connected, insert the stirring paddle into the drill pipe. There can be multiple stirring paddles, which are arranged on the drill pipe at a certain interval according to the construction requirements, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com