Construction method of large-diameter digging pile in subway station on upper-soft and lower-hard stratum

A technology for subway stations and construction methods, applied to sheet pile walls, foundation structure engineering, buildings, etc., can solve the problems of poor use effect of hole-digging piles, complex geological conditions, and random construction operations, so as to avoid hidden dangers in quality and reduce investment Low construction cost, easy processing and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

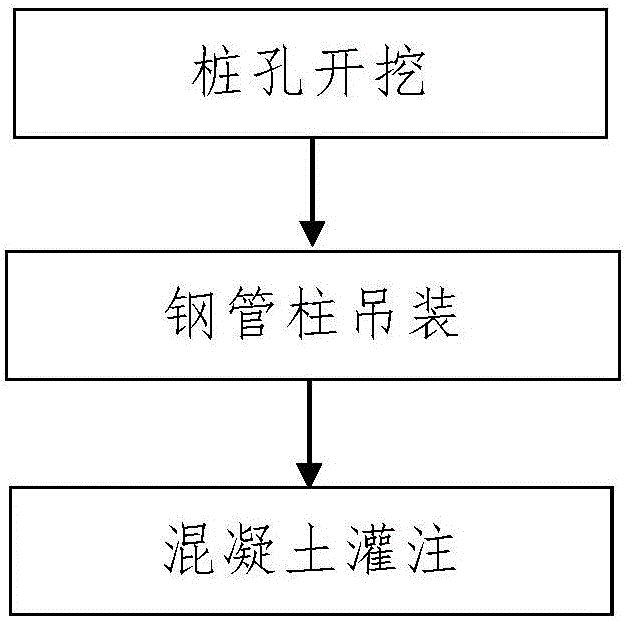

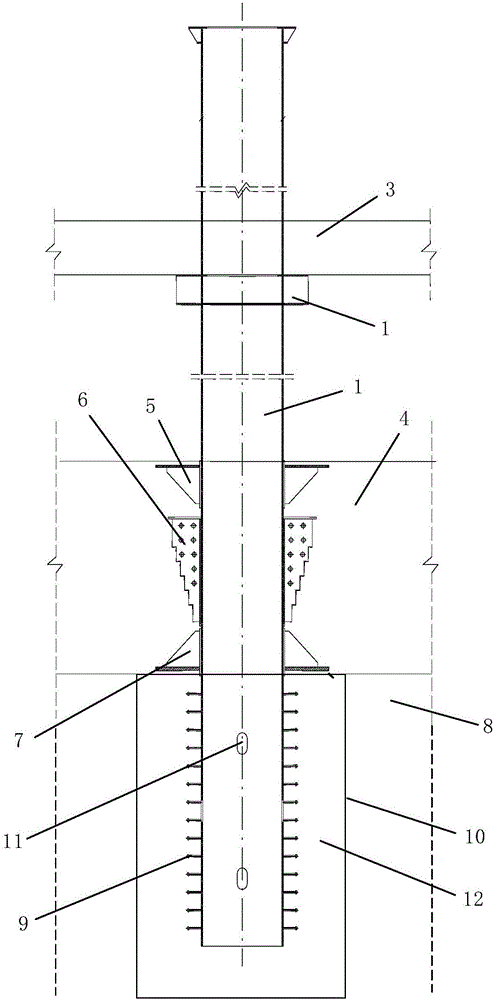

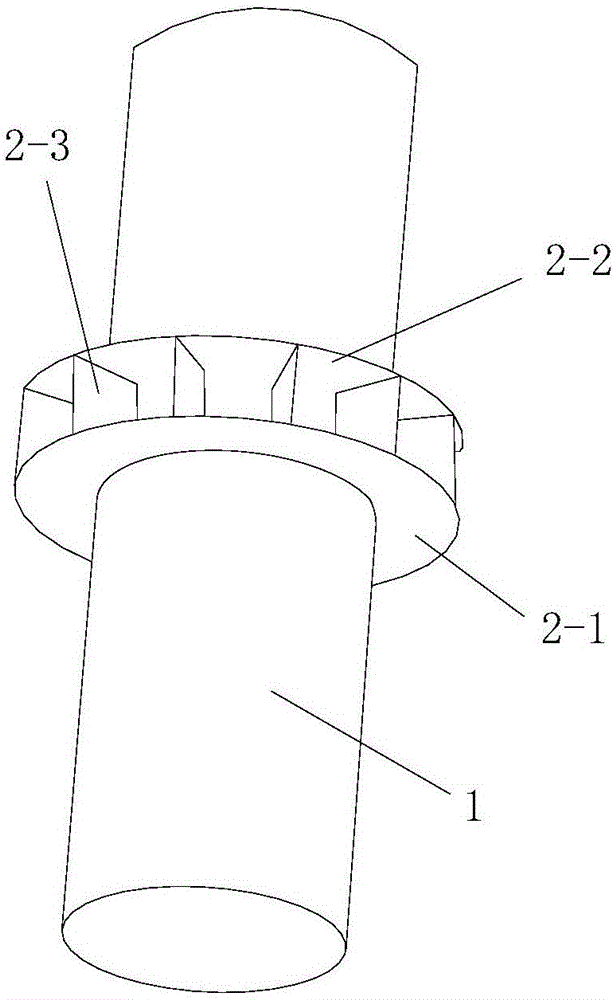

[0056] Such as figure 1 Shown is a construction method for large-diameter hole-digging piles in subway stations on upper-soft and lower-hard strata. The hole-digging piles constructed are steel pipe concrete piles located in the subway station under construction. The diameter of the steel pipe concrete piles is Φ550mm~Φ650mm; figure 2 , the steel pipe concrete pile includes a steel pipe support column 1 located in the constructed subway station, a middle node structure arranged in the middle of the steel pipe support column 1 and a lower node structure arranged at the lower part of the steel pipe support column 1, and the steel pipe support column 1 is in the form of Layout vertically; the main structure of the subway station under construction includes a bottom plate 4, two side walls respectively arranged above the left and right sides of the bottom plate 4, a top plate located directly above the bottom plate 4, and a top plate arranged between the top plate and the bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com