Sleeving type underground conveying device for tailing paste filling

A technology of paste filling and underground transportation, which is applied to fillings, safety devices, mining equipment, etc. It can solve the problems of pipeline wear and leakage, mine loss, high construction costs, etc., and achieves avoiding rigid friction, long service life, and good wall protection The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

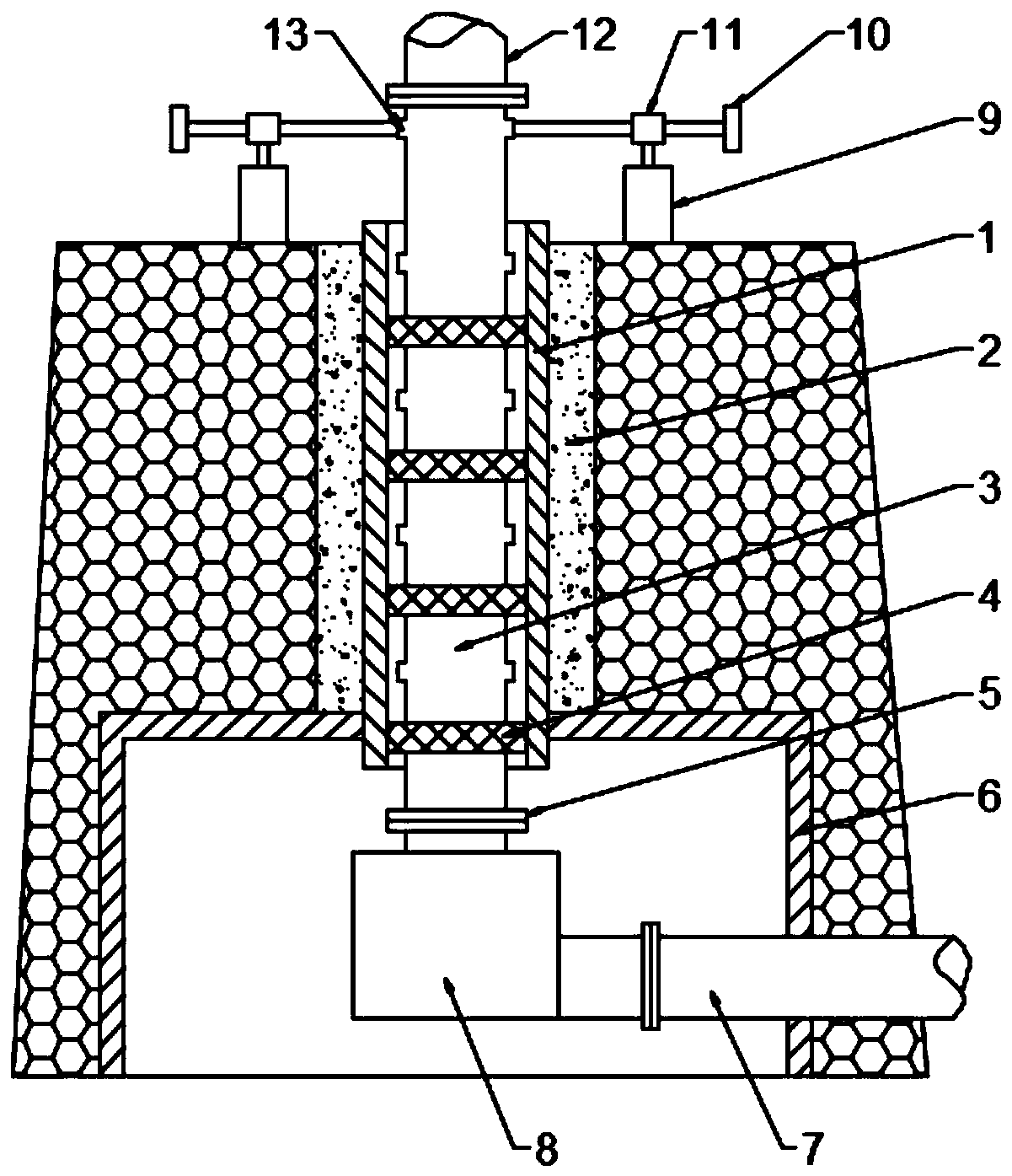

[0019] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 Shown: a socketed underground conveying device for tailings paste filling, including a borehole casing 1 fixedly socketed with the borehole and a slurry filling pipe 3 socketed with the borehole casing 1, the The cement layer 2 is filled between the inner wall of the borehole and the outer wall of the borehole casing. The cement layer 2 can not only reliably fix the borehole casing 1, but also play a good role in protecting the borehole and prevent the inside of the borehole from Collapse occurs. A damping ring 4 is arranged between the drilling casing 1 and the slurry filling pipe 3. The vibration damping ring is a wear-resistant rubber damping ring. The vibration damping ring 4 is sleeved on the slurry filling pipe 3 to reduce the The vibrating ring avoids the rigid friction caused by vibration between the drilling casing and the slurry filling pipe.

[0020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com